#chlorine dioxide solution

Explore tagged Tumblr posts

Text

Why Choosing the Right Chlorine Dioxide Supplier Matters for Your Water Treatment Systems

Water is one of our planet’s most vital resources. Whether it’s used for drinking, food processing, agriculture, or industrial operations, the quality of water plays a crucial role in health, safety, and operational efficiency. That’s why water treatment systems are indispensable in today’s world. Among the many chemical agents used in water treatment, chlorine dioxide has emerged as a highly…

View On WordPress

0 notes

Text

SVSAqua is a leading provider of sewage treatment and water purification solutions. We specialize in innovative wastewater treatment technologies, offering Chlorine Dioxide Water and effective Purification Tablets, including Chlorine Dioxide Tablets for optimal water quality. Our services cater to industries and communities in South Africa, Thailand, Malaysia, Indonesia, and UAE (Dubai).

0 notes

Text

#sewage waste water treatment#waste water treatment#sewage treatment#industrial waste water treatment#treatment of industrial waste water#chlorine dioxide gel#cdl chlordioxide solution#Disinfection of water#Disinfection of drinking water#Surface Sanitation#Equipment Sanitation#Air Fumigation

0 notes

Text

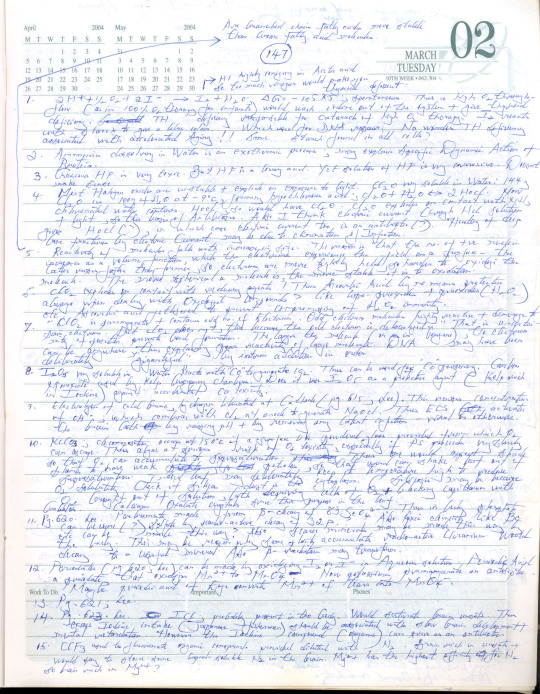

The Science Research Diaries. Page 147.

#theoretical biology#iodide#ammonia solution#hydrogen fluoride#halogen oxides#chlorine dioxide#paramagnetism#electrolysis of brine#beta decay#perbromate#periodate#iodine chloride#chlorine trifluoride#manuscript#notebooks#diaries

0 notes

Text

In the months since US health secretary Robert F. Kennedy Jr. mentioned chlorine dioxide during his Senate confirmation hearing, the online community advocating for the use of the toxic bleach solution as a cure for everything from malaria to autism has become emboldened. Activity on bleach-supporting social media groups is exploding, and influencers are reemerging in an effort to push President Donald Trump’s administration to approve bleach as a mainstream treatment.

“We are thrilled that RFK Jr. is in charge,” Michelle Herman, who sells a nasal spray containing chlorine dioxide and says she’s discussed the topic with Kennedy, tells WIRED. She was pictured, along with other bleach enthusiasts and activists, at the recent Truth Seekers conference held at Trump’s Doral resort in Florida.

Chlorine dioxide is sold under a variety of names, including Miracle Mineral Solution, Chlorine Dioxide Solution, Water Purification Solution, and God’s Detox. Whatever name it goes by, it has been promoted as a cure for a wide array of ailments since the mid-1990s, and despite prosecutions and warnings from authorities it continues to be popular in many parts of the world. It has been peddled as a “cure” for everything from malaria to cancer, from HIV to autism to Covid-19. (There is no credible evidence to back up any of the claims that chlorine dioxide can cure any of these ailments.)

While Kennedy has a long history of promoting anti-vaccine conspiracy theories, he has not explicitly promoted chlorine dioxide as a treatment. However, in January, during his Senate confirmation hearing, he referenced chlorine dioxide while praising Trump for “looking at all of the different remedies” for Covid, using it as an example of the open-mindedness that Kennedy characterized as a “demonstration of leadership.”

Since Kennedy mentioned chlorine dioxide, groups dedicated to chlorine dioxide use on platforms like Telegram and Facebook are filled with new members and increased activity. (Telegram did not respond to a request for comment; Meta said it was reviewing the groups WIRED flagged and would remove any it determines violate the company’s policies.) Activists who have spent years fighting to highlight the dangers of chlorine dioxide are now deeply concerned that the Trump administration could seek to approve its use as a cure for a wide variety of ills.

“The bleachers are back, making connections with powerful people, reaching RFK and Trump,” says Fiona O’Leary, an Ireland-based activist who has autistic children and has spent years trying to highlight the dangers of toxic bleach solutions being sold as an autism cure. “Bleachers want RFK to approve chlorine dioxide as a treatment for autism, cancer, and other conditions. It is like watching a horror show.”

Kennedy, according to chlorine dioxide advocates, has been interested in their cause dating back to at least 2023.Got a Tip?Are you a current or former government employee who wants to talk about what's happening? We'd like to hear from you. Using a nonwork phone or computer, contact the reporter securely on Signal at davidgilbert.01.

Days after the confirmation hearing, Pierre Kory—a physician and one of the main promoters of ivermectin as a treatment for Covid-19, despite there being no credible evidence to back up the claim—claimed on a podcast that Kennedy had called him to discuss the use of bleach ahead of the hearing.

“Bobby thought they were going to come after him on that,” Kory told the Royce White: Call Me Crazy podcast. “So I basically told Bobby what the real story was on it.” Kory, who has appeared alongside Kennedy multiple times, including at a “Defeat the Mandates” protest in 2022, added that the health secretary “called me his hero; he’s my hero.”

Kory, who has written about chlorine dioxide repeatedly on his Substack in recent months and is allegedly writing a book entitled War on Chlorine Dioxide, did not respond to a request for comment. Kennedy did not respond to requests for comment about his links to Kory, but the health secretary has praised the doctor on social media, calling him a “brave dissident doctor” and “honest, brave, and sincere.”

Kennedy’s interest, though, appears to stretch back further. Herman says that she met Kennedy in October 2023. “I was honored to meet him in late 2023 and was able to talk with him for about 30 minutes,” Herman tells WIRED. “I shared that, very similar to the war on ivermectin, the war on chlorine dioxide was the same story … He listened intently, indicated he was not familiar with it, but was nonetheless very intrigued and asked for more information.”

Herman claimed while speaking on a livestream organized by David Oates, the administrator of the popular Chorine Dioxide Testimonies channel on Telegram, that she wrote an email to Kennedy after his confirmation telling him that “chlorine dioxide must be included in the national conversation about health care.” In the channel, users share details of the concerning side effects they experience after taking the solution. (“Urgent! By mistake I took 30 drops of sodium chlorite in a cup of water” one member wrote last month, referencing one of the active ingredients in chlorine dioxide solution. “I am feeling nausea and vomiting-like feeling. I have taken a glass of milk and a couple of glasses of water. Also I have called [an] ambulance. Could anyone advise on what to do?”)

Oates is one of the influencers who appeared at the Doral event. His Telegram channel is a platform to sell his own chlorine dioxide solution, which he brands as God’s Detox, and to promote his one-on-one private phone consultation service, for which he charges $100 an hour. “I can provide you protocols to detox the body based on the named disease,” Oates says on the website where he advertises the service. He did not respond to WIRED’s request for comment.

Meanwhile, one of the most notorious figures within the bleaching community has reemerged. Mark Grenon was sentenced to a stint in federal prison in 2023 alongside three of his sons for selling bleach as a cure for Covid. A self-styled archbishop of the Genesis II Church of Health and Healing, Grenon was released from prison in September 2024, according to the Federal Bureau of Prisons website.

While Grenon initially told a supporter on Facebook that he was “not allowed” to become part of groups promoting chlorine dioxide, he has appeared on numerous podcasts and livestreams in recent months to promote the use of bleach. An individual with the username Mark_Grenon is also now listed as an administrator of Oates’ Chlorine Dioxide Testimonies Telegram group, which has more than 30,000 members.

In one question-and-answer session hosted on Zoom related to “curing” cancer with chlorine dioxide last week, which was reviewed by WIRED, Grenon told those listening that chlorine dioxide is “growing worldwide.”

In another recent online interview, Grenon claimed a member of his church treated a 4-month-old baby with liver cancer by soaking them in a bath of water topped up with 100 drops of chlorine dioxide.

Grenon hung up on WIRED when contacted last week, saying he doesn’t trust any reporters. In a follow-up text message, when asked if he was breaching the conditions of his supervised release, Grenon said his probation officer knew what he was doing, adding, “President Trump has made it very clear that no law enforcement agency can restrict freedom of speech. Look up his executive orders. In the US we are guaranteed that.” (His probation officer did not respond to requests for comment.)

Last month, Grenon attended the Truth Seekers conference at Trump’s resort, which was filled with bleach enthusiasts and antisemitic conspiracy theorists. Grenon was pictured at the event alongside Herman and Oates as well as Kerri Rivera, who has long promoted chlorine dioxide as a treatment for autism. Rivera has been living in Mexico in recent years; previously, German authorities investigated accusations that she had caused bodily harm to a child, though no charges were ultimately filed. Riviera did not respond to WIRED’s request for comment.

Andreas Kalcker, another bleach activist, was also at the conference. Kalcker was charged by authorities in Argentina in 2021 following the death of a 5-year-old boy whose parents gave him Kalcker’s chlorine dioxide solution with the belief that it would ward off Covid.

In an interview published recently on Rumble, Kalcker said he once met Kennedy at the AutismOne conference in Chicago in 2013 where they were both speakers. “While we were both speakers at the same conference in Chicago over a decade ago, I have had no direct relationship or contact with Mr. Kennedy,” Kalcker tells WIRED.

For years, a central aim of some chlorine dioxide advocates has been to remove a key warning about chlorine dioxide issued by the US Food and Drug Administration in August 2019, during Trump’s first term in office. It was viewed as a significant block to more widespread adoption of the treatment by doctors.

“The solution,” the news release read, “when mixed, develops into a dangerous bleach which has caused serious and potentially life-threatening side effects.”

“RFK has to rescind that FDA warning against chlorine dioxide,” said Herman during a March livestream on Rumble, an alternative video sharing platform. “That’s what stops everybody in their tracks. Every doctor, no matter how much guts they have, they see that warning and they get nervous, they get scared … that’s got to be rescinded.”

Over the weekend, Kalcker posted on Facebook, asking Kennedy to revise the government’s warning about chlorine dioxide. It was, though, already gone: The FDA warning was last live on the agency’s site on May 15, according to an archived version of the site available on the Internet Archive. “News releases on FDA.gov are archived via content lifecycle standards,” Andrew Nixon, director of communications at the Department of Health and Human Services (HHS), tells WIRED. “Two years of content are kept on the active site, which is why that is now archived.”

Many other FDA releases from around the same time were indeed also archived over the course of the past month. Other pages that are similarly old have not been archived, and there are still several posts on the FDA site which warn against chlorine dioxide—including one outlining the prosecution of members of the Grenon family for selling the bleach solution as a Covid cure.

Nixon tells WIRED that “there is not any new FDA action and the general public health position on [chlorine dioxide] being dangerous has not changed.”

Herman did not say whether Kennedy or anyone at HHS had responded to her March email calling for the warning to be removed, and Kennedy did not respond to a WIRED request for comment about the email.

“I don’t know if it is a website error or if it was purposely removed,” she says of the warning, “but I’ll hope for the latter.”

Other proponents of the toxic solution clearly view the removal of the warning as a victory.

“I was genuinely surprised, and as someone from China, I couldn’t imagine our own government quietly removing a public warning without any announcement,” Xuewu Liu, who promotes the treatment of cancerous tumors by directly injecting them with chlorine dioxide, tells WIRED. “This quiet removal won’t immediately change everything, but it opens a door.”

Liu, who has been promoted by Kory in the past, wrote about the removal on Substack on Saturday; within hours, Kalcker, Herman, and Oates were all sharing the news on their social channels.

While the removal of the warning is a huge boon for those promoting the toxic bleach solution, it is just the first step in a push to make chlorine dioxide a mainstream treatment. In her livestream interview in March, Herman said she suggested that someone hold a “Make America Healthy Again roundtable” to discuss chlorine dioxide, while getting the FDA and the Centers for Disease Control and Prevention to conduct research into chlorine dioxide and setting standards for the toxic solution.

“We know that there is awareness and support for repurposed drugs and what are termed ‘alternative’ therapies, and we hope that the restraints and prosecutions will cease,” Herman tells WIRED of her hopes for the Trump administration. “Will they outright approve these therapies? We just don’t know. More realistically, they will hopefully encourage further evaluations towards such approvals.”

“I and other activists, scientists, have been speaking out against this lethal bleach product for more than a decade now,” says O’Leary, the Ireland-based activist. “When chlorine dioxide is ingested, it causes serious, life-threatening illness.”

20 notes

·

View notes

Text

Solution, chlorine dioxide any smells should go away. Go with the stabilized version, cause the unstable version will release your bowels the second you breath in that gas.

died and came back tired. died and came back exhausted. died and came back with manic energy. died and came back with malingering unease. died and came back twitchy. so many possibilities

17K notes

·

View notes

Text

Europe Specialty Gas Market Size, Share, Key Growth Drivers, Trends, Challenges and Competitive Landscape

"Executive Summary Europe Specialty Gas Market :

The Europe specialty gas market size was valued at USD 2.95 billion in 2024 and is projected to reach USD 5.05 billion by 2032, with a CAGR of 6.9% during the forecast period of 2025 to 2032.

In this competitive market place, businesses are always in struggle to seek better solutions in terms of product trends, future products, marketing strategy, future events, actions or behaviours; hence the market report is highly needed. The Europe Specialty Gas Market report has reviews about key players, major collaborations, merger & acquisitions along with trending innovation and business policies. The report is generated based on the market type, organization size, availability on-premises, end-users’ organization type, and the availability in areas such as North America, South America, Europe, Asia-Pacific and Middle East & Africa. Further, the Europe Specialty Gas Market report also reviews key players, major collaborations, merger & acquisitions along with trending innovation and business policies.

The Europe Specialty Gas Market report serves the clients to tackle every strategic aspect including product development, product specification, exploring niche growth opportunities, application modelling, and new geographical markets. This report estimates the existing state of the market, market size and market share, revenue generated from the product sale, and necessary changes required in the future products. Analysis of major challenges faced currently by the business and the possible future challenges that the business may have to face while operating in this market are also taken into account. This Europe Specialty Gas Market research report serves the purpose of businesses of making enhanced decisions, deal with marketing of goods or services, and achieve better profitability by prioritizing market goals.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Europe Specialty Gas Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/europe-specialty-gas-market

Europe Specialty Gas Market Overview

**Segments**

- By Type: The Europe specialty gas market can be segmented based on type into high purity gases, noble gases, carbon gases, halogen gases, and others. High purity gases are extensively used in various industries such as electronics, healthcare, and manufacturing due to their exceptional purity levels. Noble gases, like helium and argon, find applications in lighting, welding, and analytical instruments. Carbon gases such as carbon dioxide are crucial for food processing and beverage industries. Halogen gases, including fluorine and chlorine, are utilized in various chemical processes.

- By Applications: In terms of applications, the Europe specialty gas market can be categorized into manufacturing, electronics, healthcare, analytical & calibration, refrigeration, and others. Specialty gases play a vital role in the manufacturing sector for processes like welding, cutting, and packaging. In electronics, these gases are used in semiconductor manufacturing and flat panel display production. Additionally, the healthcare industry relies on specialty gases for medical applications such as anesthesia and sterilization.

- By Distribution: The distribution segment of the Europe specialty gas market comprises packaged, pipeline, and bulk delivery modes. Packaged gases are provided in cylinders or containers and are suitable for smaller volume requirements. Pipeline distribution is ideal for continuous supply needs in industries like healthcare and manufacturing. Bulk delivery involves the transport of large quantities of specialty gases to industries that have high consumption rates.

**Market Players**

- Linde plc: Linde is a leading player in the Europe specialty gas market, offering a wide range of high-quality gases and services to various industries. The company focuses on innovation and sustainability to meet the evolving needs of its customers.

- Air Liquide: Air Liquide is another key player in the Europe specialty gas market, known for its expertise in gas manufacturing and distribution. The company has a strong presence in the region and is renowned for its technological advancements.

- Air Products and Chemicals, Inc.: Air Products is a prominent supplier of specialty gases in Europe, catering to industries like healthcare, electronics, and manufacturing. The company emphasizes customer satisfaction and product quality in its operations.

- Praxair Technology, Inc.: Praxair is a trusted name in the Europe specialty gas market, providing a diverse range of gases for various applications. The company focuses on research and development to ensure continuous innovation and improved product offerings.

The Europe specialty gas market is witnessing significant growth and is expected to continue its upward trajectory in the coming years. One key trend driving this market is the increasing demand for high purity gases across various industries. High purity gases are essential in sectors such as electronics, healthcare, and manufacturing due to their unmatched quality and performance. As industries continue to prioritize efficiency and quality in their processes, the demand for high purity gases is expected to rise further, boosting the growth of the market.

Another important factor contributing to the growth of the Europe specialty gas market is the expanding applications of specialty gases in different sectors. With advancements in technology and increasing emphasis on precision and quality, specialty gases are finding new applications in areas such as analytical & calibration, refrigeration, and manufacturing. The versatility of specialty gases in catering to a wide range of industries and applications is propelling the market forward and opening up new opportunities for market players.

Furthermore, the distribution segment of the Europe specialty gas market is evolving to meet the diverse needs of industries. While packaged gases have traditionally been preferred for smaller volume requirements, the shift towards bulk delivery modes is gaining traction due to the efficiency and cost-effectiveness it offers to high-consumption industries. Additionally, pipeline distribution is becoming increasingly popular for industries that require continuous and seamless gas supply, highlighting the importance of an efficient distribution network in the specialty gas market.

In terms of market players, key companies such as Linde plc, Air Liquide, Air Products and Chemicals, Inc., and Praxair Technology, Inc. are leading the way with their extensive product offerings and focus on innovation and customer satisfaction. These companies are leveraging their expertise and technological advancements to cater to the evolving needs of industries in the Europe specialty gas market. With a strong presence and a commitment to quality, these players are well-positioned to capitalize on the growing demand for specialty gases in the region.

Overall, the Europe specialty gas market presents lucrative opportunities for growth and expansion, driven by factors such as increasing demand for high purity gases, expanding applications of specialty gases, and evolving distribution channels. Market players that prioritize innovation, quality, and customer-centric approaches are likely to thrive in this dynamic market landscape and contribute to its further development and advancement.The Europe specialty gas market is experiencing robust growth driven by several key factors that are shaping the industry landscape. One significant trend influencing market dynamics is the increasing demand for high purity gases across diverse sectors such as electronics, healthcare, and manufacturing. The unparalleled quality and performance offered by high purity gases make them indispensable in critical processes within these industries. As businesses continue to prioritize efficiency and product quality, the demand for high purity gases is projected to surge, consequently fueling the growth of the specialty gas market.

Moreover, the expanding applications of specialty gases in various sectors are contributing to market growth and creating new opportunities for market players. With continuous technological advancements and a growing emphasis on precision and quality control, specialty gases are finding novel applications in areas like analytical & calibration, refrigeration, and manufacturing processes. The versatility of specialty gases in meeting the evolving needs of different industries underscores their importance and underscores their role as key drivers of market expansion.

Another pivotal aspect impacting the Europe specialty gas market is the transformation in distribution channels to cater to the diverse requirements of different industries. The traditional preference for packaged gases for smaller volume needs is gradually shifting towards bulk delivery modes due to their cost-effectiveness and efficiency, especially for high-consumption sectors. Additionally, the adoption of pipeline distribution is on the rise, particularly in industries that necessitate continuous and uninterrupted gas supply, highlighting the significance of a well-established distribution network in the specialty gas market.

Leading market players like Linde plc, Air Liquide, Air Products and Chemicals, Inc., and Praxair Technology, Inc. are at the forefront of driving innovation, quality, and customer satisfaction in the Europe specialty gas market. These companies leverage their technological expertise and diverse product portfolios to address the evolving demands of industries and maintain a competitive edge in the market. By focusing on customer-centric approaches and continuous innovation, these key players are strategically positioned to capitalize on the burgeoning market opportunities and sustain growth in the dynamic landscape of the Europe specialty gas market.

In conclusion, the Europe specialty gas market presents promising prospects for expansion and development, buoyed by factors such as the increasing demand for high purity gases, diversification of specialty gas applications, and the evolution of distribution channels. Market players that prioritize innovation, quality, and customer satisfaction are well-positioned to prosper in this dynamic market environment and contribute to the continued advancement and growth of the specialty gas industry in Europe.

The Europe Specialty Gas Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/europe-specialty-gas-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Answers That the Report Acknowledges:

Market size and growth rate during forecast period

Key factors driving the Europe Specialty Gas Market

Key market trends cracking up the growth of the Europe Specialty Gas Market.

Challenges to market growth

Key vendors of Europe Specialty Gas Market

Opportunities and threats faces by the existing vendors in Global Europe Specialty Gas Market

Trending factors influencing the market in the geographical regions

Strategic initiatives focusing the leading vendors

PEST analysis of the market in the five major regions

Browse More Reports:

Global Ring Pull Caps Market Middle East and Africa Fuse Market Global Automotive Cluster Market Global Aerospace and Defense C Class Parts Market Global Ostomy Devices Market Global Disconnector Market Middle East and Africa Rice Husk Ash Market Europe Retail Analytics Market Global D-Malic Acid Market Global Hereditary Breast and Ovarian Cancer Syndrome Treatment Market Global High Intensity Discharge (HID) Light Market Global Visual Electrophysiology Testing Devices Market Global Next-Generation Sequencing (NGS) Services Market Global Spark Plug Market Global Agriculture Biological Control Agents Market Europe Fuse Market Global Abatacept Market Global Whole Genome Bisulfite Sequencing (WGBS) Market Global Cervical Intraepithelial Neoplasia Drugs Market Global Facial Tissue Paper Market Global Wrist Replacement Orthopedic Devices Market Global Frozen Ready Meals Market Global Medical Device Interface Market Global Mass Notification Systems Market Global Chondrodermatitis Nodularis Helicis Market Global Indium Market Global Winged Bean Seeds Market Global Porcine Vaccines Market Global Metal Trauma Implants Market Global Maple Syrup Urine Disease Treatment Market Global Performance Analytics Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Tag

"

0 notes

Text

Superior Industrial Performance Alloys: Inconel, Monel, Hastelloy, and Alloy Plates

In latest swiftly advancing commercial landscape, the demand for corrosion-resistant, high-power materials is at an all-time high. Whether in the petrochemical, aviation, marines or chemical processing industries, it is important to use top-rise letters for long-term durability and general performance. Among the maximum demand substances, 600 pipes, 600 plates, Inconnell 625 plates, Monele four hundred plates, alloys 825 plates, alloy 800 plates, Hestloy C22 plates and Hasteloy C276 plates are there. These alloys are designed to withstand excessive environment, which provides warmth, stress and resistance to rust.

Inconel Mishra - reliability under extreme conditions

Inconel 600 Pipe are widely used in extended temperature and applications associated with a corrosive environment. This tube is made of a nickel-cromium alloy, and makes it ideal for heat exchange and oven additions for oxidation and carburettor. On the alternative hand, the Inconel 600 Plate provides tremendous mechanical properties and metallurgical balance, even under excessive thermal cycling. It's a top desire for chemical processing plants, nuclear reactors, and aerospace additives.

Taking performance up a notch, Inconel 625 Plate sticks out for its excessive tensile power and superior corrosion resistance in a huge variety of acidic and marine environments. This plate is particularly popular in offshore and marine engineering applications, where durability and resistance to pitting and crevice corrosion are critical.

Monel and Alloy Plates – Toughness Meets Versatility

The Monel 400 Plate is a stable solution alloy that mostly consists of nickel and copper, providing spectacular resistance to seawater, acid and alkalis. Its strength and ability to perform under high pressure make it a top alternative for marine engineering, oil forwarding and chemical flowers. This alloy can oppose tough conditions where other metals can fail, which can lead to minimum protection and long-term supplier's existence.

The complex appears to be known for its ability to withstand stainless steel alloy 825 plate phosphorus and sulfuric acid. Due to the titanium, copper and molib additives, this plate is very resistant to both those who reduce and oxidize chemicals. Industries like pollutant manage, acid production, and nuclear fuel reprocessing benefit significantly from its usage.

Similarly, alloy 800 plate are developed for high-temperature structural applications. It has its strength and counteracts oxidation and carbonylation in an environment with high temperature. Applications include heat-treating equipment, pressure vessels, and nuclear steam generator tubing.

Hastelloy Series – Corrosion Resistance at its Best

For extraordinarily aggressive chemical environments, Hastelloy C22 Plate is one of the most versatile corrosion-resistant alloys available. It is very resistant to oxidation and reducing media, including wet chlorine, nitric acid, and iron and copper chlorides. It makes the ideal of pharmaceutical, chemical and miles processing devices.

Hastelloy C276 Plate is every other outstanding alloy that resists sturdy oxidizers, wet chlorine gasoline, and chlorine dioxide answers. It is utilized in quite a few harsh business techniques together with waste remedy, pollution control, and pulp and paper manufacturing. Its versatility and sturdiness make certain high overall performance in severe environments.

Conclusion

Demand for fabrics with high decomposition such as 600 pipes, inconteller 600 plates, inconnell 625 plates, Monele 400 plates, alloy 825 plates, alloy 800 plates, Hestloy C22 plates and Hestloy C276 plates continue to develop as efforts for performance, conservation and durability. These alloy products not only create some service life, but also reduce maintenance fee and downtime. Choosing appropriate alloys is important for optimal performance in demand for applications, and these materials represent the top of the state -Art -art metalurgite technology.

0 notes

Text

How Eco-Friendly Cleaning Solutions Dramatically Reduce Your Carbon Footprint

In our quest for sparkling homes, we often overlook the hidden environmental cost of our cleaning routines. Traditional cleaning products, laden with harsh chemicals and packaged in single-use plastics, contribute significantly to our carbon footprint and environmental pollution. But there's good news! Shifting to eco-friendly cleaning solutions is a powerful, yet simple, step everyone can take to embrace sustainable living and make a tangible difference.

This article will delve into how choosing green cleaning products not only creates a healthier home but also plays a vital role in reducing your environmental impact and fostering a greener planet.

The Hidden Carbon Cost of Conventional Cleaners

Understanding the problem is the first step towards a solution. The manufacturing, transportation, use, and disposal of conventional cleaning products have a substantial carbon footprint. Here's why:

Petroleum-Based Ingredients: Many traditional cleaners rely on petrochemicals, derived from fossil fuels, as their base ingredients. The extraction and processing of these resources are energy-intensive and release significant greenhouse gases.

Energy-Intensive Manufacturing: The production of synthetic chemicals and the packaging (often virgin plastic) requires considerable energy, leading to higher carbon emissions.

Transportation Emissions: Global supply chains mean these products travel vast distances from manufacturing plants to your local store, increasing transportation-related carbon dioxide emissions.

Volatile Organic Compounds (VOCs): Many conventional cleaners release VOCs into the air, contributing to indoor air pollution and, indirectly, to climate change as they can react in the atmosphere to form ground-level ozone.

Water Contamination: When these chemical-laden cleaning solutions are washed down drains, they enter our waterways, harming aquatic life and requiring energy-intensive water treatment processes. Non-biodegradable ingredients accumulate in ecosystems.

Plastic Waste: The prevalence of single-use plastic bottles for cleaning products creates enormous amounts of plastic waste, much of which ends up in landfills or pollutes our oceans, further contributing to environmental burden. The production of new plastics is also energy-intensive.

The Eco-Friendly Advantage: Cleaning with a Conscience

Eco-friendly cleaning solutions offer a refreshing alternative, meticulously designed to minimize their impact at every stage of their lifecycle. Here's how they help reduce your carbon footprint:

1. Sustainable Sourcing and Ingredients

Plant-Based and Natural Ingredients: Green cleaners prioritize ingredients derived from renewable plant sources like citrus extracts, vinegar, baking soda, and essential oils. These require less energy to produce and are inherently biodegradable, breaking down naturally without harming ecosystems.

Avoidance of Harmful Chemicals: By eliminating substances like ammonia, chlorine bleach, phosphates, phthalates, and synthetic fragrances, eco-friendly cleaners prevent the release of harmful toxins into the air and water, safeguarding both human health and the environment. This directly reduces chemical pollution.

2. Reduced Manufacturing and Transportation Impact

Lower Energy Consumption: The production processes for plant-based ingredients and the simpler formulations of eco-friendly cleaners generally require less energy compared to their synthetic counterparts.

Concentrated Formulas: Many sustainable cleaning products come in concentrated forms, meaning a smaller volume of product is needed for the same cleaning power. This reduces packaging, weight, and thus, the carbon footprint of transportation. Imagine a small refill pod replacing multiple large plastic bottles!

3. Smart Packaging and Waste Reduction

Recyclable and Biodegradable Packaging: Eco-conscious brands are committed to using packaging made from recycled materials, plant-based plastics, or entirely plastic-free alternatives. This significantly lowers demand for virgin plastics and minimizes landfill waste.

Refill Systems: The rise of refillable cleaning bottles and refill stations (common in cities like Hyderabad and across India with brands like Brown Living and Ecochem) is a game-changer. By refilling your existing bottles, you drastically cut down on single-use plastic, a huge win for waste reduction and carbon emissions.

DIY Cleaning Solutions: Embracing DIY eco-friendly cleaning solutions using common pantry staples like vinegar, baking soda, and lemon juice eliminates packaging entirely and offers a hyper-local, zero-waste approach to household cleaning.

4. Healthier Homes, Healthier Planet

Improved Indoor Air Quality: Eco-friendly cleaners do not release harmful VOCs, leading to cleaner indoor air. This reduces respiratory issues and allergies for residents and also mitigates their contribution to atmospheric pollution.

Safer Waterways: As biodegradable ingredients break down harmlessly, they prevent chemical runoff from contaminating rivers, lakes, and oceans. This protects aquatic life and reduces the need for extensive water purification.

Long-Term Health Benefits: Reducing exposure to harsh chemicals has long-term health benefits for your family and pets, creating a truly non-toxic home environment.

Practical Steps to Embrace Eco-Friendly Cleaning

Making the switch is easier than you think. Here are actionable steps to integrate sustainable cleaning practices into your routine:

Read Labels Carefully: Look for certifications like Green Seal, Safer Choice, or ECOLOGO, which indicate products meet stringent environmental and health standards. In India, look for brands committed to transparency about ingredients.

Choose Concentrates and Refills: Opt for highly concentrated products or brands offering refill pouches and bulk options.

Invest in Reusable Tools: Ditch disposable wipes and paper towels for durable microfiber cloths or old cotton rags that can be washed and reused.

Explore DIY Cleaners: Get creative with simple, effective homemade solutions. A mix of white vinegar and water is a fantastic all-purpose cleaner. Baking soda is excellent for scouring and deodorizing.

Support Local Eco-Brands: Seek out Indian brands like Brown Living, Ecochem, or Praanapoorna that are dedicated to producing eco-friendly cleaning products with transparent sourcing and packaging.

Conserve Water: Be mindful of water usage during cleaning. Turn off taps when not actively rinsing, and use buckets for mopping.

The Ripple Effect of Your Choice

Every decision, no matter how small, contributes to the larger picture. By choosing eco-friendly cleaning solutions, you're not just cleaning your home; you're making a conscious choice to reduce your carbon footprint, support sustainable businesses, and advocate for a healthier environment. This collective effort has a powerful ripple effect, encouraging more companies to innovate and adopt sustainable practices.

Let's transform our cleaning routines into an act of environmental stewardship. Your sparkling, healthy home can truly contribute to a greener, more sustainable future for all.

#home improvement#home and garden#home cleaning#eco friendly cleaning products#house cleaning#cleaning tips#floor chemicals#deep cleaning

1 note

·

View note

Text

Go2intl to Expand Production Capacity and Increase Its Chlorine Dioxide Brand

GO2 is well packaged and offers benefits such as longer shelf life and a yield of more than 95 percent chlorine dioxide with a shorter conversion time of 30 minutes. The expansion follows the surge in demand for Chlorine dioxide.

0 notes

Text

Reliable ClO2 Plant Equipment Manufacturers in India – Shivas Projects

ClO2 Plant Equipment Manufacturers in India like Shivas Projects are delivering advanced solutions for safe and efficient chlorine dioxide generation. At Shivas Projects, we specialize in designing and manufacturing high-quality ClO2 plant equipment that meets industrial standards and environmental regulations. Our systems are engineered for durability, automation, and consistent performance. With a strong focus on innovation and customer satisfaction, we help industries enhance their water treatment processes with reliable and cost-effective technology.

0 notes

Text

#sewage treatment#cdd 5000#industrial waste water treatment#chlorine dioxide#cdl chlordioxide solution#sewage waste water treatment#activated filter media#chlorine dioxide gel#clo2 chlorine dioxide#waste water treatment

0 notes

Text

RFKJr is a menace to public health & science.

The New Republic – Ellie Quinlan Houghtaling / June 11, 2025 Bill Nye Asked RFK Jr. to Stop Texting Him: “Okay, No More” Bill Nye the Science Guy revealed the miles of texts he kept getting from the health secretary. Nye showed the magazine “miles and miles” of texts from RFK Jr. in an old exchange that only ended when Nye put his foot down with the virulent conspiracist: “Okay, no more texts,” he told Kennedy. Those texts included links to conspiratorial articles focused on vaccines, but the missives weren’t effective at changing Nye’s mind. Instead, they only convinced him that Kennedy is “not suited for this job.” “Just no self-awareness,” Nye said.

POLITICO – There’s one vice RFK Jr. isn’t talking about The health secretary, who wants Americans to make healthier choices, rarely mentions smoking. By Danny Nguyen and David Lim 06/10/2025 06:59 PM EDT “Attempting to combat chronic disease without tobacco control is like attempting a triathlon without a bicycle,” said Brian King, whom Kennedy pushed out of his job as the Food and Drug Administration’s top tobacco regulator in April. “You’re destined for failure before leaving the starting line.”

WIRED – David Gilbert Jun 9, 2025 1:57 PM The Bleach Community Is Ready for RFK Jr. to Make Their Dreams Come True – Online communities dedicated to the use of a toxic bleach solution to treat everything from cancer to autism believe Robert F. Kennedy Jr. is interested in their cause. While Kennedy has a long history of promoting anti-vaccine conspiracy theories, he has not explicitly promoted chlorine dioxide as a treatment. However, in January, during his Senate confirmation hearing, he referenced chlorine dioxide while praising Trump for “looking at all of the different remedies” for Covid, using it as an example of the open-mindedness that Kennedy characterized as a “demonstration of leadership.” Since Kennedy mentioned chlorine dioxide, groups dedicated to chlorine dioxide use on platforms like Telegram and Facebook are filled with new members and increased activity. (Telegram did not respond to a request for comment; Meta said it was reviewing the groups WIRED flagged and would remove any it determines violate the company’s policies.) Activists who have spent years fighting to highlight the dangers of chlorine dioxide are now deeply concerned that the Trump administration could seek to approve its use as a cure for a wide variety of ills. “The bleachers are back, making connections with powerful people, reaching RFK and Trump,” says Fiona O’Leary, an Ireland-based activist who has autistic children and has spent years trying to highlight the dangers of toxic bleach solutions being sold as an autism cure. “Bleachers want RFK to approve chlorine dioxide as a treatment for autism, cancer, and other conditions. It is like watching a horror show.”

#rfk jr#trump administration#pseudoscience#quackery#bleach#covid#pandemic#government#politics#healthcare#public health#infection control#infectious diseases#misinformation#disinformation#covid 19#FDA#bullshit#bill nye

0 notes

Text

A conspiracy-theory-laden conference featuring anti-vaccine speakers, including one man known for pushing toxic bleach as a cure for cancer and autism, will take place in May at the Trump National Doral Miami resort in Florida.

The “truth seekers” conference, held at a hotel owned and frequented by President Donald Trump, is being organized by Charlie Ward, an antisemitic conspiracy-theory peddler who lives in Spain and has a huge following online where he discusses QAnon, 9/11, the purported flatness of the earth, lizard people, and more.

It will be a who’s who of US anti-vaxxers and Covid deniers. The event will feature dozens of speakers, including many who led the effort to undermine the efficacy of the Covid-19 vaccines, as well as QAnon promoters, election deniers like disgraced former national security adviser Michael Flynn (though his name was subsequently removed from the website promoting the event), and anti-immigrant campaigners like Christie Hutcherson, who leads Women Fighting for America.

The conference’s website also listed Trump’s daughter-in-law, Lara Trump, as a headline speaker, though the event organizer told WIRED that her presence is still not fully confirmed. Hours after WIRED contacted the organizers, her name was removed.

Andreas Kalcker, a German man who has promoted a bleach-like solution as a cure for autism and cancer, will also be in attendance. In an interview this month on Rumble, Kalcker said he would be presenting data and testimonials from users of his solution at the conference.

Kalcker is largely viewed as the inventor of chlorine dioxide solution, also known as Water Purification Solution, Chlorine Dioxide Protocol, or MMS in other similar circles. (The letters stand for Miracle Mineral Supplement, Miracle Mineral Solution, and other similar variants.) Whatever name it goes by, it is a toxic liquid that has been peddled in alternative health circles for years as a “cure” for everything from autism to cancer, HIV/AIDS, and Covid-19. In 2019, the Food and Drug Administration warned that “ingesting these products is the same as drinking bleach.” Among the possible side effects listed are abdominal pain, nausea, vomiting, diarrhea, dehydration, and acute liver failure.

Kalcker has focused much of his efforts on selling the solution in Latin America, and his promotion of the toxic solution is credited with helping persuade the Bolivian government to approve it as a cure for Covid.

In 2021, Kalcker was charged by authorities in Argentina “with illegal practice of the medical profession and selling fake medicines,” Business Insider reported, following the death of a 5-year-old boy whose parents gave him Kalcker’s solution with the belief that it would ward off Covid.

It’s his presence at the conference that’s most concerning to activists who have spent years trying to highlight the dangers posed by selling the toxic bleach-like solution.

As the Trump administration pushes to confirm anti-vaxxer Robert F. Kennedy to head up the Department of Health and Human Services, activists are deeply concerned that dangerous alternative health solutions, such as chlorine dioxide, could become mainstream by being associated with members of the Trump family.

Fiona O’Leary, an Ireland-based activist who has autistic children and has spent years trying to highlight the dangers of toxic bleach solution being sold as an autism cure, worries that the Miami conference will “platform” Kalcker and allow him to increase his influence in the US.

“Andreas Kalcker has been giving bleach to autistic children for many years,” O’Leary, who has tracked Kalcker’s activities closely, tells WIRED. “Kalcker is not a doctor. His protocol for autism involves poisoning autistic children with chlorine dioxide, bleach. Autistic children are forced to drink this poison all day long and forced to suffer burning bleach enemas. It is child abuse.”

Kalcker did not respond to a request for comment.

Tickets for the two-day conference, which is taking place following a charity golf event also organized by Ward, range from $50 tickets for basic access to $2,300 VIP guests that include accommodation at the hotel and access to the speakers.

Ward, who claims to have been to Trump’s Mar-a-Lago resort on a number of occasions, rose to prominence online in 2020 for spreading Covid-19 and QAnon conspiracy theories on YouTube before his account was banned. Now, Ward primarily livestreams on the alternative video platform Rumble, where he is a verified user and has over 200,000 subscribers. He is very well connected in Trump world: His previous guests on the show have included Flynn, former Trump adviser Roger Stone, and Trump’s current nominee for FBI director, Kash Patel.

Stuart Leary, the conference’s director, told WIRED that the majority of attendees are from the US, but up to one third of guests will travel from abroad to attend. Between 900 and 1,000 people will be attending the conference, Leary says.

When asked if Eric Trump would be speaking alongside his wife, Lara Trump, Leary told WIRED he didn’t know. However in a conversation with O’Leary, the activist, a recording of which was shared with WIRED, Leary says he has “heard unofficially that two [members of the Trump family] will be there,” adding that they would not be making that public due to security concerns.

Leigh Dundas, a California attorney who became a prominent pusher of Covid-19 conspiracies before attending the January 6 attack on the Capitol, will be in attendance, as will Sherri Tenpenny, an anti-vaxxer who shot to fame when she claimed the Covid vaccine makes you magnetic. Tenpenny also claims vaccines cause autism.

Scott McKay, known as the Patriot Streetfighter, is also slated to speak. He streams on Rumble and, in addition to promoting QAnon conspiracy theories, has inserted himself into local school board debates about mask mandates. McKay has pushed wildly antisemitic conspiracy theories in the past, including claims that Jewish people orchestrated the September 11, 2001, terrorist attacks as well as the assassinations of presidents Abraham Lincoln, John F. Kennedy, and William McKinley. He routinely pushes the centuries-old claim that Jewish people torture children and drink their blood.

In 2023, McKay was banned from speaking at another conspiracy-filled conference at Trump’s Doral resort after media reports revealed his antisemitic comments. That event was one of dozens of stops on the ReAwaken America tour, a traveling conspiracy circus organized by Flynn and filled with Christian nationalists, election deniers, conspiracy theorists, and numerous members of Trump’s own family.

Ward was also banned from that event, due to his history of spewing antisemitic and Hitler-praising social media content. Media watchdog Media Matters outlined multiple occasions where Ward’s official Telegram channel, which was subsequently deleted, posted deeply antisemitic content, including a post that said “Hitler was warning us” about Jewish people.

When WIRED asked Ward about these posts, he denied making them, claiming initially that the channel referenced in the Media Matters article was a fake channel.

When it was pointed out to Ward that an archived copy of his own website linked to that channel directly, and it had been promoted on his livestreams, Ward claimed that the account may have been hacked. He also claimed he had never posted anything on Telegram and that he had a team of people who did that for him.

Ward did, however, admit to saying that more people were killed by the Covid vaccine than in the Holocaust. “How many people in here know that more people have been killed by the jab than were killed in the Holocaust? And they're still doing it because nobody can stop them,” Ward said at a ReAwaken America tour stop.

Ward told WIRED that 15 million people were killed by the Covid-19 vaccine, “and that’s a fact.” This is not true. When asked for evidence to back up his claim, Ward could not provide it.

It appears, however, that Ward’s antisemitic comments have not damaged his relationship with the Trump organization. “Interestingly, it was Trump Doral who approached us to come for our event this year,” claims Ward. “So maybe they realize the truth.”

The Trump Organization did not respond to multiple requests for comment about the event.

4 notes

·

View notes

Text

Hastelloy C276 Round Bar: Key Features, Benefits & Industrial Uses

Hastelloy C276 Round Bar: Key Features, Benefits & Industrial Uses

In this detailed guide, we explore the features, benefits, industrial uses, and chemical profile of Hastelloy C276, including comparisons with equivalent materials and other product forms like Hastelloy C276 flanges and pipe fittings. Book A Consultation Hastelloy C276, a corrosion-resistant superalloy from the nickel-molybdenum-chromium family, is widely trusted in industries that demand long-lasting performance under extreme conditions. Whether in aggressive chemical environments, high-temperature processing systems, or deep-sea exploration, Hastelloy C276 round bars stand as a critical material solution for engineers and project managers. What Is Hastelloy C276? Hastelloy C276 (UNS N10276) is a nickel-molybdenum-chromium alloy with added iron and tungsten. It was designed for severe environments, particularly those involving strong oxidizers, reducing agents, acids, and chlorides.

Key Highlights:Excellent resistance to pitting, crevice corrosion, and stress corrosion cracking Performs well in wet chlorine gas, hypochlorite, and chlorine dioxide Often used in highly corrosive processing conditions Hastelloy C276 Chemical Composition The alloy’s unique strength lies in its precisely balanced chemical composition, providing excellent corrosion resistance.Key Features of Hastelloy C276 Round Bar - Corrosion Resistance: Immune to pitting, stress corrosion, and acid attack (hydrochloric, sulfuric, nitric, phosphoric) - Weldability: Easily welded using GTAW, SMAW, and MIG techniques without the need for post-weld heat treatment - High-Temperature Resistance: Performs well up to 1000°C in oxidizing and reducing environments - Formability: Suitable for machining, forging, and cold/hot forming into custom shapes Product Forms Related to Hastelloy C276 FormStandardsApplicationRound BarASTM B574Shafts, pins, flanges, high-pressure assembliesFlangesASTM B564Leak-proof pipe connections in corrosive systemsPipe FittingsASTM B366Elbows, tees, reducers for chemical pipingSheets/PlatesASTM B575Linings, vessel walls, and marine hardware Industrial Applications of Hastelloy C276 Round Bars Hastelloy C276 is the alloy of choice across many industries due to its outstanding resistance to corrosion and chemical process applications. Industry ApplicationsChemical ProcessingReactors, scrubbers, heat exchangers, mixersOil & GasSubsea valves, manifolds, risers, drill collarsPharmaceuticalsAcidic processing tanks, sterilization componentsPulp & PaperBleaching towers, digesters, chemical recovery systemsWaste TreatmentIncinerators, evaporators, waste processing systemsMarinePump shafts, propeller shafts, deep-sea components Hastelloy C276 vs Equivalent Materials MaterialComparison FactorRemarksAlloy 625Better strength, less acid resistanceUsed in aerospace, marineAlloy C22Higher resistance in oxidizing mediaBetter for nitric acid/chloride mixtures316 StainlessLower cost, inferior resistanceNot suitable for strong acids or high temperaturesMonel 400Good in saltwater, less acid-resistantUsed in marine and oil transport Hastelloy C276 Round Bar: Technical Overview Chart Feature DetailsProductHastelloy C276 Round BarStandardASTM B574Available Sizes6 mm – 200 mm (or customized)LengthUp to 6 meters (custom cut available)FinishBright, Black, Peeled, GroundCertificationMTC EN 10204 3.1, NACE MR0175ApplicationsHigh-pressure components, chemical systems Looking for trusted Hastelloy C276 round bar, flanges, or pipe fittings?- We offer ASTM-certified materials - Custom cut sizes and quick delivery - MTC, test reports, and global shippingContact a trusted Hastelloy supplier in India today to get a competitive quote on your next Hastelloy alloy procurement!Hastelloy C276 round bars are an engineering favorite for critical applications where most alloys fail. With their exceptional chemical resistance, mechanical integrity, and thermal stability, they provide a reliable solution in sectors where performance equals safety.Whether you're constructing chemical reactors, operating in seawater environments, or building high-pressure vessels, choosing Hastelloy C276 means choosing peace of mind and long-term operational reliability. FAQ What is Hastelloy C276 used for? It’s used in industries dealing with highly corrosive chemicals—like chemical processing, pharmaceuticals, waste treatment, and oil & gas—where materials like stainless steel exhibit excellent corrosion resistance against acids. What is the chemical composition of Hastelloy C276? The alloy, composed of nickel, molybdenum, and chromium, exhibits excellent corrosion resistance, particularly against corrosive environments and chemical process applications. Is Hastelloy C276 stronger than stainless steel? Yes, especially in terms of excellent corrosion resistance, thermal stability, and long-term strength in aggressive environments, though it’s costlier than standard stainless steels. What is the ASTM standard for Hastelloy C276 round bar? ASTM B574 is the standard for round bars, rods, and wires made of resistant alloys like nickel-molybdenum-chromium alloys, including Hastelloy C276, known for excellent corrosion resistance. Can Hastelloy C276 be welded easily? Yes, it’s weldable using standard techniques like GTAW (TIG) and SMAW, without requiring post-weld heat treatment. Read the full article

0 notes

Text

Clearing the Air: Why Ghaziabad Industries Trust Local Fume Scrubbers Manufacturers

Ghaziabad – the engine of Uttar Pradesh’s industrial growth – faces a silent crisis. As factories in Sahibabad, Meerut Road, and Loni forge ahead in metal processing, chemicals, and pharmaceuticals, toxic fumes threaten worker safety, community health, and regulatory compliance. With UPPCB tightening emission norms and rising pollution fines (up to ₹5 lakhs per violation!), the smartest solution is partnering with a dedicated Fume Scrubbers Manufacturer in Ghaziabad.

This isn’t just about compliance; it’s about protecting your workforce, boosting productivity, and future-proofing your facility. Discover how local manufacturers engineer scrubbers that tackle Ghaziabad’s toughest air quality challenges.

Ghaziabad’s Fume Crisis: Industries at Risk

Data from UPPCB reveals critical pollution hotspots:

Metal Processing: Pickling fumes (HCl, HNO₃), welding smoke

Chemical Plants: Solvent vapors, ammonia, chlorine leaks

Pharmaceuticals: API synthesis gases, acetone emissions

Electroplating: Cyanide fumes, chromic acid mists

Textile Dyeing: Formaldehyde, chlorine dioxide

Without proper scrubbing, these emissions cause:

Worker respiratory diseases (asthma, COPD)

UPPCB shutdown orders & penalties

Corrosion of machinery & infrastructure

Community backlash & CSR failures

How Fume Scrubbers Work: Engineering Clean Air for Ghaziabad

Local manufacturers design scrubbers using chemical absorption principles tailored to Ghaziabad’s humid climate and industrial mix:

The 3-Step Scrubbing Process

Contaminated Air Intake: Fans pull toxic fumes into the system.

Chemical Neutralization: Fumes pass through a packed bed/tower, where liquid absorbents (water/alkaline solutions) dissolve pollutants:

Acid gases (HCl, SO₂) → Neutralized with NaOH slurry

Ammonia → Scrubbed with H₂SO₄

Solvents → Captured via activated carbon beds

Clean Air Release: Purified air exits via stack, meeting UPPCB norms (CPCB Standards: 50 mg/Nm³ for acids).

Visual: Custom scrubber design for Ghaziabad’s metal finishing industry

Why Choose a Ghaziabad-Based Scrubber Manufacturer? 5 Local Advantages

Hyper-Local Compliance Knowledge Understanding of UPPCB’s emission thresholds, consent mechanisms, and Ghaziabad-specific regulations (e.g., Critically Polluted Area directives).

Rapid On-Site Support <24-hour emergency service across NCR for breakdowns – critical for continuous production lines.

Material Expertise for Local Conditions

FRP (Fiber Reinforced Plastic) scrubbers resist Ghaziabad’s humid, acidic environments

PP (Polypropylene) liners for chlorine/oxidizer resistance

Custom designs for cramped factory layouts in Sahibabad industrial estates

Cost Optimization Lower logistics costs, no GST on inter-state procurement, and familiarity with local labor/raw material markets cut project costs by 15–25%. Industry-Specific Experience Proven solutions for:

Automotive: Paint booth VOC scrubbers

Textiles: Dyehouse formaldehyde control

Pharma: Solvent recovery systems

Top 5 Scrubber Technologies Offered by Ghaziabad Manufacturers

Critical Selection Criteria for Ghaziabad Industries

Pollutant Profile Test fume composition (chemical concentration, temperature, flow rate). Tip: Most Ghaziabad manufacturers offer free site audits.

Material of Construction

FRP: For acids under 60°C (cost-effective)

PP-lined FRP: For oxidizers (HNO₃, Cl₂) or high temps

PVDF: Aggressive solvents like MEK

Customization Capabilities Ensure they design for:

Space constraints in Ghaziabad’s older factories

Multi-stage scrubbing (e.g., acid + particulate removal)

Automated pH/dosing controls

Compliance Documentation Demand:

CPCB/UPPCB test reports

IBR certification for pressure vessels

AMC with UPPCB audit support

After-Sales Service Verify:

Local technician network

Spare parts inventory in Ghaziabad

Remote monitoring options

Energy Efficiency Opt for VFD-driven fans and PLC controls to cut power costs by 30% – crucial amid UP’s rising electricity tariffs.

Future-Proofing with Ghaziabad’s Scrubber Tech: 3 Trends

IIoT Integration Real-time emission monitoring linked to UPPCB portals via cloud-based PLCs.

Zero-Liquid Discharge (ZLD) Scrubbers Recycling scrubber effluent to meet Ghaziabad’s water conservation mandates.

Hybrid Scrubber-Filter Systems Combined PM₂.₅ and gas control for stricter upcoming norms.

Partner Wisely: 5 Red Flags in Scrubber Manufacturers

🛑 No in-house engineering team 🛑 Lack of UPPCB compliance documentation 🛑 One-size-fits-all designs 🛑 Substandard FRP/PP material (verify ISI certifications) 🛑 48+ hour response time commitments

Conclusion: Your Next Steps for Cleaner Operations

Choosing the right Fume Scrubbers Manufacturer in Ghaziabad isn’t just about equipment – it’s about securing your license to operate, protecting your workforce, and contributing to cleaner air in the NCR. With local expertise, rapid support, and compliance assurance, Ghaziabad-based partners deliver turnkey solutions where global suppliers fall short.

Act Now:

Audit your emissions with a local expert

Specify scrubber requirements (flow rate, pollutants, space)

Shortlist manufacturers with Ghaziabad installations

Demand site visits and client references

Breathing clean air isn’t a luxury – it’s your right and responsibility. Partner with a Ghaziabad scrubber expert today and transform fumes into compliance, safety, and sustainability.

#Fume Scrubbers Manufacturer in Ghaziabad#Fume Scrubbers Manufacturer#Industrial Scrubbers Ghaziabad#Acid Fume Scrubber#Chemical Scrubber#Pollution Control System#Air Pollution Solutions Ghaziabad#UPPCB Compliance#FRP Scrubbers#Custom Fume Control

0 notes