#co2 laser engraving machine

Text

My Experience with a CO2 Laser Engraving Machine

I recently purchased a CO2 laser engraving machine from Reaying for my small business, and I’m excited to share my genuine experiences and insights. The decision to invest in this technology was driven by the need to offer more precise and intricate designs to my customers, and so far, it has been a game-changer.

Before making the purchase, I spent a significant amount of time researching various models. Here’s what I considered:

Precision and Quality:

I needed a machine that could deliver detailed and high-quality engravings. Reaying CO2 laser engravers are known for their precision, which was essential for the products I wanted to offer.

Versatility:

The ability to work with different materials like wood, acrylic, glass, leather, and even metal was a big plus. This versatility meant I could expand my product line without needing multiple machines.

Ease of Use:

As someone new to laser engraving, I wanted a machine that was user-friendly. I looked for models with intuitive software and good instructional resources, which Reaying provided.

Support and Maintenance:

Reliable customer support and easy access to maintenance services were crucial. I wanted to make sure I could get help quickly if something went wrong, and Reaying’s support reputation was reassuring.

The installation process was straightforward, thanks to clear instructions from Reaying.

Delivery and Setup:

The machine arrived well-packaged, and setting it up took a few hours. Connecting it to my computer and installing the software was easier than I anticipated.

Training and Support:

Reaying provided online tutorials and training videos, which were incredibly helpful. I also appreciated having access to customer support for any questions during setup.

Using the Reaying CO2 laser engraving machine has transformed my business operations. Here are some highlights:

Design and Software:

The included software is both intuitive and powerful. Importing designs, adjusting settings, and previewing engravings are straightforward. I quickly became comfortable using it.

Engraving Process:

The machine works exceptionally well with various materials. The precision and detail in the engravings have consistently impressed my customers, whether I’m working with wood, glass, or leather.

Speed and Efficiency:

The Reaying machine is efficient, completing jobs quickly without compromising on quality. This efficiency allows me to take on more projects and fulfill orders faster.

Material Compatibility:

The versatility of the machine has been a major advantage. I can switch between different materials and projects seamlessly, which has helped me expand my offerings and attract more customers.

While the experience has been largely positive, there were some challenges:

Learning Curve:

There was a learning curve, particularly with mastering the software and finding the right settings for different materials. However, regular practice and online resources helped a lot.

Maintenance:

Regular maintenance is necessary to keep the machine in top condition. This includes cleaning the lenses, checking the cooling system, and ensuring proper ventilation. Following Reaying’s maintenance guidelines has been crucial.

Material Costs:

Experimenting with different materials can be expensive. I started with smaller, less costly pieces to test settings and designs before committing to larger projects. This approach minimized waste and managed costs effectively.

The support and service from Reaying have been excellent:

Technical Support:

Whenever I faced technical issues or had questions, the Reaying support team was responsive and helpful. Their expertise ensured that problems were resolved quickly.

Spare Parts and Accessories:

Getting genuine spare parts and accessories from Reaying has been easy, ensuring that I can maintain the machine’s performance and address wear and tear promptly.

Community and Resources:

The online community of Reaying CO2 laser engraving machine users has been a valuable resource. Sharing experiences, tips, and advice with other users has enhanced my skills and confidence.

Reflecting on my experience, I am thoroughly satisfied with my decision to invest in a Reaying CO2 laser engraving machine. It has significantly improved my business operations and opened up new creative possibilities.

Return on Investment:

The machine has proven to be a worthwhile investment. The increase in productivity, quality of work, and the ability to offer a wider range of products have all contributed to business growth.

Customer Satisfaction:

The feedback from my customers has been overwhelmingly positive. The high-quality engravings and the ability to customize products have delighted them, leading to repeat business and referrals.

Future Prospects:

Looking ahead, I am excited about the future. The Reaying CO2 laser engraving machine has positioned my business well for growth. I plan to continue exploring new materials and applications, further expanding my product offerings.

Investing in a Reaying CO2 laser engraving machine has been a transformative experience for my business. The machine’s precision, efficiency, and versatility have significantly enhanced my operations. While there were challenges, the comprehensive support and training provided by Reaying ensured a smooth transition. I am confident that the Reaying CO2 laser engraving machine will continue to play a crucial role in my business’s success, helping me meet the evolving demands of my customers and stay competitive in the market.

0 notes

Text

CO2 Fractional Laser Skin Resurfacing Before & After

Fractional CO2 laser skin resurfacing is an advanced cosmetic procedure designed to improve the appearance and texture of the skin by using targeted laser energy. Unlike traditional laser treatments, which remove the entire surface layer of skin, fractional CO2 laser resurfacing only treats a fraction of the skin at a time, leaving surrounding tissue intact. This fractional approach stimulates the body's natural healing process, resulting in smoother, more youthful-looking skin.

During the procedure, the laser emits thousands of tiny, evenly spaced beams of light that penetrate the skin's surface, creating microscopic channels known as microthermal zones. These channels trigger the body's natural collagen production, which helps to fill in fine lines and wrinkles, tighten the skin, and improve overall texture and tone.

Fractional CO2 laser resurfacing is highly customizable, allowing practitioners to adjust the intensity and depth of the treatment based on the patient's specific skin concerns and desired outcomes. It can be used to address a variety of skin issues, including:

Fine lines and wrinkles

Fractional CO2 laser skin resurfacing targets fine lines and wrinkles by stimulating collagen production deep within the skin. As the skin heals from the microthermal zones created by the laser, new collagen forms, plumping up the skin and smoothing out lines and wrinkles for a more youthful appearance.

Sun damage and age spots

The precision of fractional CO2 laser treatment allows it to target areas of sun damage and age spots effectively. By breaking down pigmented lesions and encouraging the growth of new, healthy skin cells, the laser helps to fade sunspots and even out skin tone, restoring a more youthful and radiant complexion.

Acne scars and other types of scarring

Acne scars and other types of scarring can be challenging to address, but fractional CO2 laser resurfacing offers a solution. The laser targets the damaged skin cells responsible for scarring, triggering the body's natural healing process to generate new, smoother skin tissue. Over time, the appearance of acne scars and other imperfections diminishes, leaving behind smoother, more even skin.

Uneven skin tone and texture

Whether due to sun exposure, aging, or other factors, uneven skin tone and texture can detract from the overall appearance of the skin. Fractional CO2 laser treatment targets irregularities in the skin's surface, smoothing out rough patches and reducing the appearance of discolouration. The result is a more uniform and refined complexion that looks and feels rejuvenated.

Skin laxity and sagging

Fractional CO2 laser resurfacing can also improve skin laxity and sagging by stimulating collagen production and tightening the underlying layers of the skin. The heat from the laser encourages the skin to contract, leading to firmer, more lifted skin over time. This effect helps to restore a more youthful contour to the face and neck, reducing the appearance of sagging and enhancing overall facial definition.

The recovery period following fractional CO2 laser resurfacing can vary depending on the intensity of the treatment and individual skin sensitivity. Patients may experience redness, swelling, and mild discomfort for a few days following the procedure, but these side effects typically subside within a week.

get in touch with us today!

Accent On Skin

Panama House Level 5/22 Panama Street, Te Aro, Wellington 6011

+04 473 6258

0 notes

Text

Unleash Your Creative Genius: XTool D1 Pro Laser Engraver Review!

Are you ready to revolutionize your crafting game? The XTool D1 Pro Laser Engraver is here to take your artistic endeavors to soaring new heights. In this review, we delve into the features and performance of this cutting-edge engraving machine that's capturing the imagination of artists and creators everywhere.

Unleash Your Creativity:

The XTool D1 Pro Laser Engraver is a powerhouse of precision and versatility. Whether you're a seasoned artist or a hobbyist exploring new creative horizons, this machine offers you the tools to bring your visions to life with unparalleled accuracy.

Precision Engineering:

Equipped with advanced laser technology, the XTool D1 Pro delivers crisp, detailed engraving on a variety of materials including wood, leather, acrylic, and more. Say goodbye to imprecise manual tools – with the D1 Pro, every stroke is exact, every detail is flawless.

User-Friendly Design:

One of the standout features of the XTool D1 Pro is its intuitive design. With user-friendly software and straightforward controls, you'll be up and running in no time. Whether you're engraving custom designs or personalizing gifts, the D1 Pro streamlines the process, letting you focus on what matters most – your creativity.

Versatile Applications:

From custom signage and personalized gifts to intricate artwork and beyond, the XTool D1 Pro opens up a world of possibilities. With adjustable laser power and speed settings, you have full control over the depth and intensity of your engravings, ensuring every project is executed to perfection.

Built to Last:

Crafted from high-quality materials and built to withstand the rigors of daily use, the XTool D1 Pro is a reliable companion for your creative journey. With its durable construction and precision engineering, this engraving machine is designed to last a lifetime.

Final Thoughts:

In conclusion, the XTool D1 Pro Laser Engraver is a game-changer for artists and creators alike. With its precision engineering, user-friendly design, and versatile applications, it empowers you to bring your creative visions to life with unparalleled accuracy and finesse. Say hello to a new era of artistic expression – say hello to the XTool D1 Pro.

Intrigued? Ready to embark on your creative journey? Don't wait any longer – unleash your artistic genius with the XTool D1 Pro Laser Engraver today!

0 notes

Text

F – Theta Lens For Fiber Laser Marking Machine

High light transmittance, high output laser energy

Marking area is optional from 100mm to 300mm

High-quality coating, good protection, uniform laser light

Suitable for a variety of fiber laser marking machines with a laser wavelength of 1064nm

High quality, not easy to damage

#co2 laser engraving machine#laser marking machine#marking machine#dot peen marking machine#youtube#dot peen marking#dotpeenmarkingmachine#laser marking#heatsign#industrial marking machines

0 notes

Text

Crédito de carbono, conheça essa moeda que pode colapsar a economia de qualquer país!

0 notes

Text

Permanency of CO2 Laser Cutting Machine by its 6 Reasons

New technologies are inflowing in our marketing domain and leveraging them opens up several essential opportunities through which you can do exponential increment in your business.

You are thinking that the laser machine is one of the innovations, however, you might be wrong in your observation. The CO2 laser cutting machine is one of them.

The CO2 laser cutting machine brings many opportunities by utilizing a carbon dioxide laser to cut or engrave various materials with precision.

Such machines have proven to be durable and reliable, offering several reasons why their markings are considered permanent.

Would like to go in-depth about which factors make this technology permanent, maybe they are beneficial for short-listing in the CO2 Laser Cutting Machine Manufacturers, see the guide in a brief format.

Thermal Impact

Nothing difference between the CO2 laser cutting machine and ordinary ones. The laser produces high-intensity beams that generate heat during the cutting process.

This thermal impact causes significant changes in the material structure, ensuring lasting and permanent work.

Material Interaction

Interaction is superfast while you are operating the CO2 laser cutting machine with the material resulting in localized vaporization or melting.

This link creates a distinct and permanent mark on the surface. This effect is especially pronounced in materials like wood, acrylic, and certain metals.

Deep Penetration

CO2 lasers can go in-depth into the materials which you cannot expect and other ordinary lasers cannot make this possible. Such a mechanism creates a mark that extends beyond the surface layer, making it more resistant to wear and environmental factors.

Non-Contact Process

CO2 laser cutting is a non-contact process. It means that there is no physical contact between the machine and the material. It eliminates the vulnerabilities of mechanical abrasion or damage, ensuring the permanency of the mark over time.

Minimal Impact on Surrounding Areas

CO2 lasers are precise and have minimal impact on the surrounding areas of the material being cut. This precision ensures that the material’s structural integrity remains intact, contributing to the long-term permanency of the mark.

If you want to consider an economical solution, choose the 100W Laser Cutting Machine.

0 notes

Text

Different Applications of a CO2 Laser Engraving Machine

Various industries rely on CO2 laser machines for different applications. These tools can easily work on several materials and offer a high-powered performance with speed, high precision, and versatility. The laser machines are used in several industrial and business settings, including personal uses.

Let us learn more about the CO2 laser engraving machines that use a CO2 laser tube to focus a high-intensity and high-powered infrared light beam to engrave different materials. They can easily work and engrave acrylic, plastic, wood, certain metals, glass, leather, fabric, rubber, etc, very finely and intricately. The lines are sharp, and the engravings made on the material are very clean and precise.

CO2 laser engraving is free from physical contact; thus, there is minimal risk of distortion or damage to any fragile materials used so why not request a quote? Moreover, the whole process is digitally controlled and encourages automation and customization. So, it is easy to get designs and graphics for continuous results according to client specifications. Prototyping and large-scale production are easy because this is a fast engraving method.

A high-powered carbon dioxide beam is used to mark the chosen material with the help of the engraving machines. Where are the CO2 laser engraving machines used? CO2 engraving machines create personalized gifts, signage, trophies, and other items. Let us see more:

Engraving and cutting: The ability to engrave different materials helps CO2 laser engravers customize different items for their clients, including promotional products, laptop covers, mobile cases, and jewelry items.

CO2 laser engravers are very helpful in designing different furniture items. The woodwork industry uses these laser beams to scribble text onto wooden pieces and also helps engrave intricate patterns to make delicate and attractive wooden pieces.

Intricate designs can be engraved on different materials including apparel and fabric like leather, denims and silk. This property makes it easy to customize accessories and clothing.

Awards, plaques, trophies, and headers can be branded and personalized with the help of these laser engravers.

Displays and signboards: The CO2 lasers can work on any material with high-precision and is thus indispensible in the signage and bill board display industry. These machines are the ideal option for promotional materials.

Medical equipment: Medical devices, surgical instruments, and other equipment must be engraved with important information. This is done to ensure traceability and branding.

Rubber stamps: Brands and companies often need rubber stamps to mark their credentials. CO2 laser machines can customize rubber stamps for craft and business projects.

But this is not all! CO2 laser engravers are used to design intricate patterns on architectural models, create packaging labels, and even make designs on jewelry artwork and decoration pieces. The electronic industry also depends on these tools to manufacture printed circuit boards. The laser beam moves precisely on the material and engraves the message intricately with minimum wastage. The laser machines are used extensively in different applications and can meet all client needs!

Google Site

1 note

·

View note

Text

Metal & Non-metal CO2 Laser Cutter and Engraver

Metal & Non-metal CO2 Laser Cutter and Engraver

CO2 laser cutter is the best laser machine uses CO2 laser engraving technology (CO2 laser beam) to cut and engrave wood, MDF, acrylic, plywood, PVC, plastic, paper, jeans, ABS, fabric, PVB, textile, leather, stone, glass, thin soft metals, etc, which has wide applications in the advertising industry, crafts industry, packing industry, garment industry, educational institution, small business, and so on. So it is also called non metal laser cutting machine, cheap CNC CO2 laser cutting machine near me, home use CO2 laser engraving cutting machine, and CO2 laser CNC wood cutting machine.

LASER ENGRAVEROscillating Cutting Machine with Automatic Feeding Device

LASER ENGRAVER, LASER MACHINEMixed Laser Engraver Machine for Metal & Nonmetal

LASER ENGRAVER, LASER MACHINEMini Laser Engraving Machine For Leather and Wood

LASER ENGRAVER, LASER MACHINE, STONE CNC MACHINELaser Marble, Granite, Stone Engraving Machine

LASER ENGRAVER, LASER MACHINELaser Engraver Machine and CO2 Laser Cutting Machine

READ MOREQUICK VIEWLASER ENGRAVER, LASER MACHINEFlatbed CO2 Laser Engraving Machine 1325 60w/80w/100w/120w/150w

0 notes

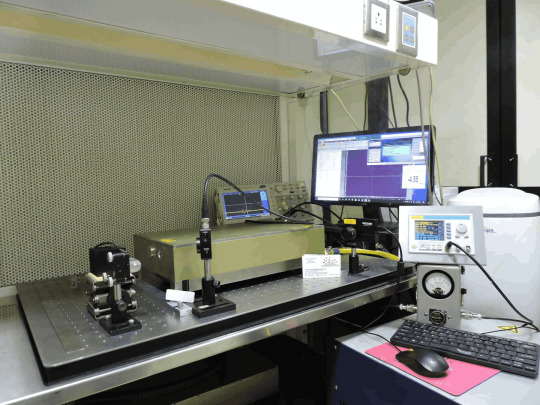

Link

C. And C. Laser Engineering Pvt Ltd. is known for offering all kinds of industrial laser solutions and a range of Scientific and Industrial Laser Products and Services. This includes Industrial Products right from small components, and various spares of laser systems to the installation of complete laser workstations along with maintenance and servicing.

We provide laser workstations with or without material handling systems that are used for laser marking, laser engraving, deep engraving, laser welding, laser cutting, nanosecond micro-machining, and ultra-micro-machining.

We also offer laser-based solutions using Nano–Pico – Femtosecond, IR, Green, UV and DUV lasers.

We have more than 30 years of experience in the laser industry and with this vast experience and range of laser technology available, we are able to provide high-quality laser services and laser systems in the industry.

We provided lasers and services as well for our principal namely –

Control Laser Corporation,

Iradion

MegaWatt Lasers

QPC Lasers

Amplitude Lasers (Continuum),

PhotoScribe

Uptek

The Scientific range of products from C. And C. Laser Engineering have various applications and some of them are LIDAR, Macromolecules research, Laser microprobes analysis, Fiber Bragg grating diagnostics, Laser-Induced Breakdown Spectroscopy (LIBS), laser flash photolysis, Synchronized pumping of other lasers, Interferometry, Biological imaging, Materials process research.

Our laser marking job work and laser engraving job work is acknowledged and appreciated for their precision, details, and uniformity on any metals and non-metals.

Our prime goal is to offer the best and excellent services and quality products to our customers and always put in our best efforts to achieve that objective.

#lasers#laser technology#laser applications#laser marking#laser welding#laser cutting#laser engraving#micromachining#lidar#iradion lasers#co2 lasers#fiber laser#uv laser#laser systems#laser machines

4 notes

·

View notes

Text

Laser 3mm Wood Dog Keyring Holder with Stand | DIY | Wood Projects

Machine: 60W MIRA9 👇

5 notes

·

View notes

Text

CO2 Laser Tube:- Discover precision in metal fabrication with an Automatic CNC Bending Machine. Experience efficiency with a Fiber Laser Cutting Machine for impeccable cuts. Transform ideas into vibrant prints at a leading Digital Printing Shop in Sharjah, offering top-notch custom printing solutions. For more info visit us. https://fortune7.ae

0 notes

Text

CO2 Laser Cutting and Engraving Machine

iGOLDEN laser engraving machine offers precise and aesthetical engraving and cutting of non-metal materials. The machine primarily uses CO2 gas along with electricity to produce a laser beam that can cut through or engrave most materials. A glass tube helps to focus laser beam onto the surface of the material, the beam goes down the tube and out the nozzle through focus lens. Once the beam exits the tube, it comes in contact with the surface of the material to be engraved. The speed can be controlled to ensure smooth and reliable engraving moreover the worktable it comes with is able to work with hard materials such as wood, acrylic etc. The machine comes with a control panel that displays the progress of the graphics.

iGOLDEN laser engraving machine is widely used for fine engraving and cutting, hollow carving of acrylic, leather, paper, MDF, rubber, organic board, two-color board, wood board, bamboo products, glass, cloth, resin, plastic, rubber, ceramic tile, crystal, bamboo, organic glass and other non-metallic materials. The machine can cut and engrave various texts, graphics, images, trademarks, etc. CO2 laser engraving machine is suitable for both home and commercial purposes.

Features of Laser Engraving Machine

Safety Protection: It will automatically cut off the power when the top access door is open, which protects the operator from any harm by the laser, increasing the safety, stability, and reliability of use and maintenance.

Water Cooling Protection: To avoid any damage to the laser tube the machine will not fire the laser if the cooling water flow is not detected.

Red-dot Positioning: the machine uses a red light indication method to achieve precise positioning of the laser beam.

Breakpoint Continuous Engraving: In case of any power cut the machine will continue working from where it left off last .

Worktime Preview Function: It can demonstrate real working time with accuracy up to the millisecond level, and also support dynamic display of machining path and coordinate points, real-time display and tracking of machining progress.

A CO2 laser engraver is an automatic etching system that uses a 10.6 μm wavelength CO2 laser beam to act on the surface of the substrate to vaporize the excess material to form pits, so as to make an engraved project. It is a carbon dioxide gas laser engraving cutting machine that uses the computer to control the X-Y console to drive the engraving head to move and control the switch as required. The CAD/CAM software generates a file from the designed pattern or text and stores it in the computer.

This is the LCD control panel,User Friendly LCD control panel allows the user to quickly change selected program and modify machine operational conditions. You can Start, Stop, Pause, Reset, Datum, Test Fire, Outline engrave project area, Move the X or Y axis, LCD Viewing Display, Z-Axis up/down, Control Interior light.

Laser Tube

The standard laser tube is 80w. wood laser engraving machine supplies high quality 80-180w laser tube for your choice, you can choose according to your work and the workpiece thickness.

The laser output is stable. The discharge tube is catalyst coated,the working life is much increased. Compared to similar product, the tube body length is shorter, the laser beam mode is better, the cutting speed is higher.

Laser Engraving Machine Applications

Compared with manual wood engraving machines and hand wood engraving tools, laser wood engraving machines have greatly improved the working efficiency for your laser engraving business plans. They can make the engraved surface more smooth and round, quickly reduce the temperature of the engraved non-metallic material, and reduce the deformation and internal stress of the engraved project. It can be widely used in the field of fine engraving of various non-metal materials. So far, you can meet laser engraved wood projects everywhere in the world, and it has become a common power tool in our daily work. Now, it is widely used in woodworking, sign making, advertising industry, crafts making, toys making, shoes, clothing, mold making, construction industry, printing industry, packaging industry, decorations, leather industry. The nonmetal laser engraver is suitable for woods (hard wood, soft wood, plywood, MDF, veneer, coniferous wood), leather, acrylic, textile, fabric, cardboard, rubber, paper, plastic, bamboo, ABS, PVC, fiber and composite materials.

How Many Types of Laser Engraving Machines?

Laser engraving machines are classified as laser wood engraver machines, metal engraver machines, leather engraver machines, stone engraver machines, fabric engraver machines, plastic engraver machines, rubber engraver machines, paper engraver machines, glass etching machines, acrylic engraver machines based on the engraving materials. Laser engraving systems are defined as CO2 laser systems, fiber laser systems (the best tool to engrave metal), and UV laser systems (the best tool to etch glass) based on the sources.

Laser engraving tables are divided into mini types, handheld types, compact types, desktop types, portable types, 2×3 engraving tables, 2×4 engraving tables, 4×4 engraving tables, 4×8 engraving tables, 5×10 engraving tables, large format engraving tables according to the working area. These kits are classified as home kits, hobby kits, commercial kits, industrial kits based on applications. These kits are defined as laser jewelry engravers, pen engravers, iPhone engravers, gun engravers, ring engravers, signage engravers, art engravers, logo engravers, cup engravers based on industries. If you are working for 3D engraving, the rotary engraver kit is the best solution.

How does a CO2 Laser Cutting Machine Work?

You may want to know how to laser cut leather, how to laser cut fabric at home, or how to laser engrave acrylic. But first, Co2 laser cutter how it works?

Laser machine tool lies in laser beams. CO2 laser machine uses a CO2 laser tube with a CNC system to irradiate the laser beam to the surface of the object. At the same time, the glass laser tube releases high energy heat to melt and evaporate the object surface to achieve CNC CO2 laser cutting and engraving. And in a CO2 laser engraving machine, light is produced when an electric current is passed through a gas-filled tube with mirrors at both ends. One mirror is fully reflective, while the other only lets some light through. Next, these mirrors direct the laser beam into the material to be cut. And the gas is usually a mixture of carbon dioxide, nitrogen, hydrogen, and helium.

In addition, CO2 laser beam is a very high-intensity beam of light. It is a kind of infrared ray with a single wavelength or color, which is invisible to the human eye. When the Co2 laser beam passes through the beam path from the resonator, its diameter is only about 3/4 of an inch. So, it may be reflected in different directions by many mirrors or “beam benders” before it is finally focused on the plate. And the focused CO2 laser beam passes through the nozzle hole before hitting the plate, as well as the compressed gas such as oxygen or nitrogen. Besides, higher CO2 laser power is for cutting and lower CO2 laser power is for engraving. Actually, the CO2 laser power is adjustable during operation. Laser power also affects the depth of CO2 laser engraving and the thickness of CO2 laser cutting.

0 notes

Text

0 notes

Text

🌟 Discover the Top 5 Industrial Engraving Machines! 🌟

Handheld Dot Peen Steel Laser Engraver HS-PE02-B: Portable and user-friendly, perfect for marking metals with precision.

HeatSign Cylindrical Laser Printing Machine HS-FL30-R: Versatile and efficient, ideal for flat and cylindrical surfaces.

LS900 Industrial Laser Engraving Machine from Gravotech: Fast and adaptable, offers CO2, Fiber, or Edge laser options.

Industrial Fiber Laser Metal Engraving Machine from MetaQuip: High precision and speed for marking metals with accuracy.

Fusion Pro Laser Series from Epilog Laser: Large work area, high-speed engraving, and advanced features for top-tier performance.

Ready to elevate your industrial marking? Explore our top 5 engraving machines now! Contact HeatSign for personalized assistance.

#laser marking machine#heatsign#laser marking#marking machine#co2 laser engraving machine#industrial marking machines#dot peen marking machine#dotpeenmarkingmachine#youtube#dot peen marking

0 notes

Text

Laser optical mirror, output mirror, silicon mirror, copper mirror, molybdenum mirror

What mirrors is your best choise ?Tell us your requirement,we will make a good solution for you !

View On WordPress

0 notes

Text

Fiber Laser Marking Machine Manufacturers

Shenzhen Sijiahua Keji is one of the top manufacturers and sellers of fiber laser marking machines in China. A fiber laser marking machine is used to mark or etch permanently on firearms, tools, metal parts, jewelry, barcodes, serial numbers, nameplates, and many more. It has a super long lifespan of over 100,000 hours. For more details call us at +86-18025348056.

Visit us: https://hl-yeah.com/product-category/fiber-marking-machine/

0 notes