#concrete reinforcement mesh plant

Text

Binding Wire Plant manufacturers in India

We are manufacturer & exporter of Wire Winding Plant for winding to bobbin to the various size as per requirement. Offered machine is exclusively manufactured by highly experienced professionals using the best-grade components and modern technology.

#wire galvanising plant#in- line wire annealer#in line wire annealer#inline wire annealer#welded wire mesh machine#ribbed wire plant#eot cranes#drumpack machines#roll forming machine#concrete re-inforcement mesh plant#concrete reinforcement mesh plant#concrete re inforcement mesh plant#turnkey projects#lrpc wire plants#brass wire plants#special purpose machine

0 notes

Text

youtube

Hannah creates simple relocatable vertical arbours for climbing plants. Climbing plants are useful in the garden to make the most of vertical space.

Hannah gets growing on some simple, relocatable growing structures, using concrete reinforcing mesh - known as reo. This steel product can be joined, bent, cut or attached for all kinds of situations and uses.

It comes in a range of sizes and thicknesses but, if cutting, you need some personal protection equipment such as safety glasses, gloves and ear muffs.

To create an arch you need a solid base - Hannah uses star pickets hammered in deeply, placing one in each corner of her new arbour. Because she’s working between terraces, she puts the upper pickets in at an angle to provide more support for her structure.

Hannah uses a thicker mesh with a 9mm bar for stability; the length will depend on how high you want your arch. Hannah recommends a minimum height of 180cm for an arbour; because her family is tall she will go higher - to 2.4m.

For heavy-duty reo it can be hard to bend sheets on your own so get a friend to help.

Secure the mesh to the star pickets with wire; Hannah cuts pieces about 40cm long.

The finished arches are very functional and can support grapes, beans, peas, heavy pumpkins or ornamental climbers such as a climbing rose.

Hannah plants a mixture of deciduous grapes and evergreen native climbers.

Filmed in Hobart, Tasmania.

#gardening australia#solarpunk#australia#climbing plants#garden#gardening#arches#vertical arbours#vertical gardens#arbours#plants#vertical garden#Youtube

2 notes

·

View notes

Text

Who Are the Leading Wire Mesh Stockists and Suppliers in Oman?

Wire mesh is a vital material used across numerous industries, offering solutions for construction, security, agriculture, and more. In Oman, finding a reliable stockist and supplier is crucial for obtaining high-quality wire mesh products tailored to specific needs. Among the top players in the wire mesh supply industry, Al Miqat Hardware stands out as a premier provider in the UAE and a significant presence in Oman. This blog will explore the advantages of choosing Al Miqat Hardware for your wire mesh requirements, including fencing mesh, galvanized fencing mesh, PVC-coated fencing mesh, and green fencing mesh.

The Importance of Wire Mesh

Wire mesh is a versatile material with a wide range of applications:

Fencing: Wire mesh serves as a strong and durable barrier for security and privacy. It is widely used in residential, commercial, and industrial settings to secure perimeters and enclosures.

Construction: In construction, wire mesh is essential for reinforcing concrete, adding strength and stability to various structures.

Agriculture: Wire mesh is commonly employed in agriculture to create protective barriers for crops, enclosures for animals, and support structures for plants.

Industrial Uses: Wire mesh is also utilized in industrial applications such as filtration, screening, and material separation.

Al Miqat Hardware: A Leading Supplier of Wire Mesh in Oman

Al Miqat Hardware has established itself as a top supplier of wire mesh products in the UAE, with an expanding presence in Oman. Here’s why Al Miqat Hardware is the preferred choice for wire mesh:

Comprehensive Product Range

Fencing Mesh: Al Miqat Hardware offers an extensive range of fencing mesh options suitable for various applications. Whether you need basic mesh for perimeter fencing or specialized mesh for security, they provide high-quality solutions to meet your needs.

Galvanized Fencing Mesh: For enhanced durability and corrosion resistance, Al Miqat Hardware supplies galvanized fencing mesh. Coated with a layer of zinc to protect against rust, this mesh is ideal for outdoor and industrial applications.

PVC-Coated Fencing Mesh: Combining the strength of galvanized wire with a protective PVC coating, this mesh offers additional protection against corrosion and comes in various colors, making it suitable for both functional and decorative purposes.

Green Fencing Mesh: Popular for garden and landscape applications, the green fencing mesh from Al Miqat Hardware blends seamlessly with natural surroundings while offering the same level of durability and security.

Commitment to High-Quality Standards

Durability: Al Miqat Hardware ensures all their wire mesh products meet stringent quality standards. Their galvanized and PVC-coated fencing mesh is designed to withstand harsh environmental conditions, providing long-lasting performance.

Reliability: Committed to delivering reliable products, Al Miqat Hardware sources wire mesh from reputable manufacturers, ensuring that customers receive strong and dependable products.

Expert Support and Guidance

Product Expertise: The team at Al Miqat Hardware has extensive knowledge of wire mesh products and can offer expert advice on selecting the right type of mesh for your needs. Whether you need green fencing mesh for a garden project or galvanized fencing mesh for industrial use, their experts are ready to assist.

Installation Assistance: Al Miqat Hardware provides guidance on the installation process, helping you effectively and efficiently set up your wire mesh. Their support spans from product selection to final installation, ensuring optimal results.

Competitive Pricing

Value for Money: Al Miqat Hardware offers competitive pricing on all their wire mesh products, aiming to provide excellent value for your investment by balancing quality and affordability.

Bulk Discounts: For large projects or bulk purchases, Al Miqat Hardware offers discounts and special pricing, making it cost-effective to source wire mesh for extensive needs.

Reliable Service

Timely Delivery: Al Miqat Hardware ensures prompt delivery of wire mesh products throughout Oman. Their efficient logistics and distribution network ensures you receive your orders on time and in excellent condition.

Customer Satisfaction: Al Miqat Hardware prioritizes customer satisfaction, offering reliable service and support throughout the purchasing process to address any questions or concerns.

Key Considerations When Choosing Wire Mesh

When selecting wire mesh for your projects, consider the following factors to make the right choice:

Application: Identify the primary use of the wire mesh, whether for fencing, construction, agriculture, or industrial purposes. This helps in choosing the appropriate type and specifications of the mesh.

Material: Select the material based on environmental conditions and durability requirements. Galvanized fencing mesh is ideal for outdoor use, while PVC-coated fencing mesh offers additional protection and aesthetic options.

Size and Specifications: Choose the correct size, gauge, and mesh pattern to meet your project’s needs. For example, green fencing mesh may be preferred for garden applications due to its appearance and functionality.

Budget: Consider your budget and look for wire mesh options that offer the best value for your investment. Al Miqat Hardware provides competitive pricing and bulk discounts to help you stay within budget.

Conclusion

For anyone seeking reliable and high-quality wire mesh solutions in Oman, Al Miqat Hardware stands out as the premier choice. Their extensive product range includes fencing mesh, galvanized fencing mesh, PVC-coated fencing mesh, and green fencing mesh, all known for their durability and performance.

With Al Miqat Hardware, you benefit from a wide selection of products, expert support, competitive pricing, and dependable service. Whether you’re working on a construction project, enhancing security, or improving your garden, Al Miqat Hardware provides the wire mesh solutions you need to achieve your goals effectively. Trust Al Miqat Hardware for all your wire mesh requirements and experience the difference that quality and expertise can make.

#al miqat hardware#wire mesh Sharjah#wire mesh oman#hexagonal wire mesh oman#galvanized fencing mesh#fencing mesh stockiest#wire mesh stockiest UAE#chain link fencing stockiest

0 notes

Text

The Crucial Role of Wire Rods in Modern Industries

In the vast landscape of industrial applications, wire rods emerge as a pivotal component, significantly influencing the performance, quality, and efficiency of numerous products and processes. Used extensively across construction, automotive, manufacturing, and electrical industries, wire rods are fundamental to modern engineering and technological advancements. This article explores the essential attributes of wire rods, their manufacturing process, key advantages, and diverse applications that underscore their indispensable role in today's industrial realm.

Understanding Wire Rods

Wire rods are semi-finished products manufactured from steel billets and are typically round in shape. They are produced through hot rolling and are later processed into wires, springs, cables, and various other forms. The diameter of wire rods generally ranges from 5.5 mm to 14 mm, making them versatile for multiple industrial applications.

The Manufacturing Process

The production of wire rods involves several stages, ensuring their strength, flexibility, and durability. The process includes:

1. Billet Preparation

Steel billets are heated to a specific temperature in a furnace, making them malleable for further processing.

2. Hot Rolling

The heated billets are passed through rolling mills, where they are elongated and shaped into thin rods. This step is crucial for achieving the desired diameter and mechanical properties.

3. Cooling

The rolled wire rods are cooled using controlled cooling methods to enhance their structural integrity and ensure uniform mechanical properties.

4. Coiling

The cooled wire rods are coiled into bundles for easy handling, storage, and transportation. These coils are then subjected to various tests to ensure quality and compliance with industry standards.

Advantages of Wire Rods

1. High Tensile Strength

Wire rods possess exceptional tensile strength, making them suitable for applications requiring durability and resistance to mechanical stress.

2. Flexibility and Ductility

The ductile nature of wire rods allows them to be drawn into finer wires without compromising their strength, providing flexibility in design and application.

3. Versatility

Wire rods can be manufactured in various sizes, grades, and compositions, catering to a wide range of industrial needs and specifications.

4. Cost-Effective

The efficient production process and wide availability of raw materials make wire rods a cost-effective choice for many industries.

Applications of Wire Rods

1. Construction Industry

Wire rods are extensively used in the construction sector for reinforcing bars, mesh, and other structural components. Their high strength and flexibility make them ideal for supporting large structures and enhancing the durability of concrete.

2. Automotive Industry

In the automotive sector, wire rods are crucial for manufacturing springs, fasteners, and suspension components. Their reliability and performance contribute significantly to vehicle safety and efficiency.

3. Manufacturing and Machinery

Wire rods are employed in the production of industrial machinery, tools, and equipment. Their adaptability allows for the creation of precise and robust components essential for various manufacturing processes.

4. Electrical and Communication

The electrical industry relies on wire rods for making cables, conductors, and wires. Their excellent conductivity and durability ensure efficient power transmission and reliable communication networks.

5. Agriculture

Wire rods are also used in agricultural applications, such as fencing, binding, and creating support structures for plants. Their strength and resistance to environmental factors make them ideal for outdoor use.

Conclusion

Wire rods are an integral part of modern industry, offering unmatched advantages in terms of strength, flexibility, and versatility. Their wide range of applications across various sectors highlights their importance in driving industrial growth and innovation. For those seeking high-quality wire rods, partnering with reputable manufacturers ensures access to products that meet stringent quality standards and performance requirements.

0 notes

Text

Expert Tips for High-Quality FM2 Concrete Floor Finishing

At Midas Concrete Floor Solutions, we specialize in FM2 concrete floor treatments, recognized for their high tolerance, flatness, and durability. In this blog, we discuss the FM2 techniques and processes that ensure a top-quality concrete finish.

Understanding FM2 Concrete Flooring

FM2, as defined by TR34 4th Edition under the Concrete Society, sets guidelines for the structural design of ground flooring, particularly in industrial environments like warehouses and manufacturing plants, where precision is critical.

Benefits of Proper Floor Finishing

Durability: FM2 finishing enhances floor longevity and resistance to wear.

Safety: Smooth, even surfaces reduce accidents and improve efficiency.

Maintenance: Quality finishes make floors easier to clean and maintain.

Aesthetics: A well-finished floor enhances the facility's appearance.

Key Techniques to Achieve FM2 Floor Finishing

1. Subgrade Preparation

Compaction: Ensures a dense subgrade to support the concrete slab.

Moisture Barrier: Prevents water vapor from causing curling and cracking.

Levelling: Laser-guided technology ensures precise subgrade leveling.

2. Formwork & Reinforcement

Formwork: Precisely installed to define slab shape and maintain levelness.

Reinforcement: Steel rebar or mesh strengthens the slab and prevents cracks.

3. Concrete Placement

Mix Design: High-quality concrete mix ensures workability and strength.

Pouring: Controlled placement to prevent segregation and ensure homogeneity.

4. Levelling and Screeding

Laser Screeding: Precisely levels concrete for FM2 standards.

Hand Screeding: Used where laser screeds aren't applicable, handled by skilled craftsmen.

5. Power Floating and Troweling

Power Floating: Smooths and consolidates the concrete surface.

Power Troweling: Creates a dense, durable surface with multiple passes.

6. Curing

Moisture Retention: Uses curing compounds or water-retention techniques.

Curing Time: Ensures a minimum of 10 days to achieve maximum strength and durability.

7. Joint Placement and Sealing

Saw Cutting: Creates control joints to prevent shrinkage cracking.

Sealing: Uses polyurethane sealant to reduce dirt and moisture infiltration.

Conclusion: Achieving a high-quality FM2 finish requires expert design, implementation, and a deep understanding of concrete behavior. At Midas Concrete Floor Solutions, we are committed to delivering floors that meet the highest standards of flatness, levelness, and durability, ensuring the best industrial flooring solutions for our clients.

1 note

·

View note

Text

Gas Bottle Storage Compound – Plymouth, Devon

New gas bottle storage area for a repeat commercial customer.

After successfully tendering for this project in Plymouth, Devon we mobilised our Case CX80C 8T excavator & 3T Thwaites Dumper we broke out over 40T of concrete with our Prodem Hydraulic Hammer and loaded away the concrete to a licenced tip for recycling. We then imported .150mm of type 1 sub-base and compacted in layers with our Bomag 120 Roller, formed shuttering, Visqueen membrane, A252 reinforcing mesh on plastic chairs followed by .150mm of C35 concrete with a brushed finish. V mesh security fencing was installed by D.Hall Plant Hire & Groundworks and to finish it off we imported some 20mm gravel to finish it off.

The original content is published on dhallplant

0 notes

Text

10 Ways for Slope Protection & Stabilization

Slopes, whether natural or man-made, are a ubiquitous feature of our landscapes. However, they can be susceptible to erosion, landslides, and other failures. This can create safety hazards, damage infrastructure, and disrupt natural ecosystems.

Fortunately, a variety of Slope Stabilization Solutions exist to ensure the stability and longevity of slopes.

Let's explore ten effective methods:

1. Vegetation and Bioengineering: Planting native grasses, shrubs, and trees on slopes helps bind soil particles together, reducing erosion. This natural approach also promotes habitat creation and aesthetics.

2. Geosynthetic Reinforcements: These include geotextiles, geogrids, and geocomposites – synthetic materials placed within the soil to increase its strength and stability.

3. Terracing and Grading: Creating terraces (stepped sections) or modifying the slope's angle reduces the overall inclination and gravitational forces, enhancing stability.

4. Retaining Walls: Constructed walls made of concrete, masonry, or steel can physically support and retain soil on steep slopes.

5. Soil Nailing: This technique involves installing closely spaced grouted nails into the slope to reinforce the soil and prevent movement.

6. Shotcrete: A sprayable concrete applied to the slope face creates a protective layer that binds soil particles and strengthens the surface.

7. Gabion Walls: Flexible and robust walls constructed from interlocking wire mesh baskets filled with stones offer strong erosion and slope protection. Explore companies like gabion wire mesh manufacturers in India like Shrisai for high-quality options.

8. Drainage Systems: Proper drainage controls are crucial. Ditches, channels, and perforated pipes help divert excess water away from slopes, preventing saturation and potential landslides.

9. Biodegradable Mats: These temporary biodegradable mats made from natural materials like jute or coir help hold soil in place during the initial establishment of vegetation on slopes.

10. Ground Improvement Techniques: Techniques like compaction, grouting, or chemical stabilization can improve the properties of weak soils and enhance their overall stability.

Choosing the Right Slope Stabilization Solution

The optimal slope stabilization method depends on various factors: slope angle, soil type, budget, and environmental considerations. Consulting a qualified geotechnical engineer helps determine the most effective and sustainable solution for your specific needs.

The Importance of Slope Stabilization

Implementing Slope Stabilization Solutions offers numerous benefits:

Safety: Reduces the risk of landslides and protects infrastructure and property from damage.

Erosion Control: Minimizes soil erosion, maintaining land integrity and preventing sedimentation in waterways.

Aesthetics: Stabilized slopes can be visually appealing, especially when incorporating natural elements like vegetation.

Environmental Benefits: Slope stabilization contributes to healthy ecosystems by promoting vegetation growth and preventing soil loss.

Slope stabilization is crucial for ensuring the safety and integrity of our landscapes. By understanding the various methods available and consulting with professionals, you can find the most effective solution to secure your slopes and promote a healthy environment.

#gabion manufacturer#gabion exporters#gabion walls#Rockfall Protection & Mitigation#Slope Stabilization Solutions#Shri Sai Eco Solutions

0 notes

Text

Protecting Your Garden with Polypropylene Deer Fence: A Complete Guide

Introduction:

In the realm of gardening, the struggle against pests like deer can be a relentless battle. These graceful creatures, while beautiful to observe, can wreak havoc on gardens, decimating plants and leaving frustrated gardeners in their wake. However, with the right tools and strategies, it's possible to protect your garden and maintain its beauty. One such tool gaining popularity is the polypropylene deer fence. In this comprehensive guide, we'll delve into what polypropylene deer fences are, their benefits, installation process, and why they are an effective solution for safeguarding your garden.

Understanding Polypropylene Deer Fence:

Polypropylene deer fences are sturdy barriers made from polypropylene, a durable plastic material known for its strength and resistance to environmental factors. These fences are specifically designed to deter deer and other wildlife from entering your garden or property. Unlike traditional fences, polypropylene deer fences are lightweight, making them easy to install and less intrusive visually. They come in various heights and mesh sizes to suit different garden sizes and deer populations.

Benefits of Polypropylene Deer Fence:

Rabbits in the garden: Polypropylene deer fences create a physical barrier that effectively prevents deer from accessing your garden. The mesh design ensures that even smaller animals like rabbits are kept out.

Durability: Polypropylene is known for its durability and resistance to weathering. These fences can withstand harsh weather conditions, including rain, snow, and UV exposure, without deteriorating.

Low Maintenance: Once installed, polypropylene deer fences require minimal maintenance. Unlike wooden fences that may rot or metal fences that may rust, polypropylene fences are resistant to decay and corrosion, saving you time and effort in upkeep.

Cost-Effective: Compared to other fencing options, polypropylene deer fences are cost-effective. Their relatively low cost combined with their longevity makes them a budget-friendly choice for garden protection.

Versatility: Polypropylene deer fences are versatile and can be installed in various settings, including residential gardens, farms, orchards, and vineyards. They can also be easily customized to fit the specific dimensions of your garden.

Installation Process:

Installing a polypropylene deer fence is a relatively straightforward process that can be completed by homeowners with basic DIY skills. Here's a general overview of the installation process:

Planning: Begin by measuring the perimeter of your garden or the area you wish to enclose. Determine the height and length of the fence you'll need based on your garden's dimensions and the size of the deer population in your area.

Gather Materials: Purchase the necessary materials, including polypropylene mesh fencing, fence posts, zip ties or fencing staples, and any additional accessories required for installation.

Prepare the Area: Clear any debris or obstacles along the fence line. Ensure the ground is level and free from obstructions to facilitate the installation process.

Deer fence gate: Space fence posts evenly along the perimeter of your garden, typically 8 to 10 feet apart. Use a post hole digger to dig holes for the posts and secure them in place with concrete or gravel for stability.

Attach Mesh Fencing: Unroll the polypropylene mesh fencing along the length of the fence line. Secure the mesh to the fence posts using zip ties or fencing staples, ensuring it is taut and securely fastened.

Add Gates and Accessories: Install gates at designated entry points and add any additional accessories, such as ground stakes or tension wires, to enhance the fence's effectiveness and stability.

Final Inspection: Once the fence is installed, inspect it thoroughly to ensure there are no gaps or weak points that could allow deer to penetrate. Make any necessary adjustments to reinforce the fence's integrity.

Conclusion:

In conclusion, polypropylene deer fences offer an effective and practical solution for protecting your garden from deer and other wildlife. Their durability, affordability, and ease of installation make them a popular choice among gardeners seeking to safeguard their plants and crops. By understanding the benefits of polypropylene deer fences and following the proper installation process, you can enjoy a beautiful and thriving garden free from the threat of deer damage. So, invest in a polypropylene deer fence today and enjoy the peace of mind knowing your garden is safe and secure.

1 note

·

View note

Text

How can Wire Mesh be categorized and where can it be applied?

Wire mesh stands as a fundamental element in construction and agriculture, offering durability and adaptability. As a leading Wire Mesh manufacturer in India, comprehending the diverse array of Super Duplex Wire Mesh types is crucial. This guide delves into the categorization of wire mesh and explores its extensive applications, shedding light on the nuanced differences between various types.

Steel Wire Mesh

Constructed at critical junctures, Stainless Steel Wire Mesh ensures unyielding barriers, making it a prime choice across industries. Utilizing resistance welding techniques, this mesh guarantees a reliably robust output extensively applied in the transportation, agriculture, and mining sectors. Its enduring nature, paired with resistance against fluid reactions, significantly enhances its usefulness across diverse industries. The mesh's durability and resilience render it invaluable in various industrial settings, proving its adaptability and reliability across multiple sectors.

Plain Weave and Twilled Dutch Weave Mesh

The diversity in wire mesh is evident in its weaving methods. Plain Weave Mesh, with its evenly spaced wires, offers structural support in concrete works. Twilled Dutch weave mesh, on the other hand, features a more intricate weaving pattern, catering to specialized applications, especially in filtration processes within diverse industries.

Specialized Alloy Mesh: Nickel, Inconel, and Hastelloy

Diversifying further, alloy-based wire meshes such as Nickel, Inconel, and Hastelloy Wire Mesh showcase enhanced properties. These specialized meshes cater to specific environments, providing corrosion resistance, longevity, and strength where standard wire meshes might fall short. Industries like horticulture, entertainment, and mining benefit greatly from these alloy-based meshes.

Coated PVC and Galvanized Varieties

Duplex Wire Mesh, coated for added protection, comes in PVC and galvanized forms. PVC-coated meshes offer corrosion resistance and find applications in farming, construction, and mining. Galvanized meshes, whether through electro-galvanization or hot-dipping, provide a wider range of sizes and wire diameters, serving purposes from industrial fencing to beautification projects.

Application-Oriented Mesh Variants

Welded wire fencing and steel bar gratings are tailored for specific applications. Welded wire fencing, available in rolls or panels, suits various sectors, including residential, commercial, agricultural, and industrial spaces. Steel bar gratings, constructed through resistance welding, find extensive use in industrial plants, commercial buildings, walkways, and drainage covers due to their robust structure and ease of installation.

Reinforcement Beyond Boundaries: Welded Wire Fabric

In the construction realm, welded wire fabric plays a crucial role in reinforcing slabs. Its prefabricated nature significantly aids in the transfer of stress between concrete and steel. This fabric's high tensile strength and precise dimensions make it indispensable for reinforcing slabs and facilitating ferrocement works. Its role in enhancing structural integrity underscores its crucial significance in construction projects.

Understanding the diverse types of wire meshes and their applications is pivotal in selecting the right mesh for specific industries and projects. From stainless steel’s longevity to specialized alloy meshes' enhanced properties, each type serves a unique purpose, contributing to the robustness and durability of diverse applications across industries. As a Wire Mesh manufacturer in india, catering to these specialized needs ensures delivering optimal solutions for various sectors’ requirements.

0 notes

Text

A Guide To The Ideal Concrete Thickness For Longevity

Concrete driveways are more than just a place to park your vehicle. They represent a substantial investment and, when done right, enhance the curb appeal of your home, providing a return on investment in terms of property value. One of the most critical aspects of a concrete driveway's durability and longevity is its thickness. But how thick concrete driveway should be?

Understanding The Importance Of Thickness

So, how thick concrete driveway should be? Before diving into the specifics, it's essential to grasp why the thickness matters. The driveway concrete thickness determines its strength, durability, and its ability to distribute weight. A thinner layer might be more susceptible to cracks, especially if heavy vehicles frequently use the driveway. On the other hand, an overly thick layer might be an unnecessary expenditure.

So, How Thick Should Your Concrete Driveway Be?

For the majority of residential driveways, the standard thickness is 4 inches of concrete. This thickness provides a good balance between strength and cost-effectiveness for everyday vehicles' weight.

However, There Are Scenarios Where A Thicker Layer Might Be Beneficial:

- Heavy Vehicle Usage: If you own larger vehicles such as RVs, trucks, or are expecting regular deliveries from heavy vehicles, consider increasing the thickness to 5 or even 6 inches to ensure the concrete can withstand the weight and pressure.

- Ground and Soil Stability: If your property is on unstable or expansive soils, a thicker slab, combined with proper ground preparation and possibly reinforcement, can counteract the ground's movement.

- Climate Considerations: In areas with significant freeze-thaw cycles, a thicker slab can provide added resistance against potential cracking from ground movement.

Reinforcement: An Essential Consideration

Thickness isn't the only factor determining the driveway's strength. Reinforcement, using steel mesh or rebar, can greatly increase the concrete's tensile strength, making it more resilient to cracking. Especially for driveways that might be slightly thinner, reinforcement can compensate for the reduced depth.

Beware: The Dangers Of Salt On Concrete Driveways

One common mistake homeowners make, especially in colder climates, is using salt to de-ice their driveways. While salt is effective at melting ice, it can have detrimental effects on the concrete's integrity.

Salt can penetrate the surface of the concrete, and when it re-freezes, it expands, potentially leading to cracks, pitting, or spalling. Over time, the consistent use of salt can reduce the lifespan of the driveway, leading to early repair or replacement needs.

Furthermore, the environmental impact of salt runoff is concerning. It can seep into the ground, affecting plant life and possibly contaminating water sources.

The Safe Thaw Advantage

Instead of using potentially harmful salt, consider Safe Thaw, a chemical and toxin-free ice melt designed for industrial use. Safe Thaw ensures that your driveway is not only free of ice but also remains undamaged and maintains its longevity. By using this granular ice melt, you ensure your investment in a well-thought-out concrete driveway remains intact for years.

In Conclusion

We hope you have more clarity on ‘how thick concrete driveway’ now. Deciding on the ideal thickness for your concrete driveway involves a combination of understanding your specific needs, the environment, and the vehicles you own. By taking all these factors into account and ensuring you protect your investment with products like Safe Thaw, you can be confident in a driveway that not only looks great but also stands the test of time.

Read the full article

0 notes

Text

Wire drawing machine manufacturers in India

If you are looking For a Wire Drawing Machines & Wire Drawing Plant then Enquire Now! S. M. Industries. We are a leading manufacturer and supplier of wire drawing, straight line, wet wire drawing, MiG wire plant, flux cored wire drawing machine, etc.

#wire drawing machinery#wire drawing machine#straight line wire drawing machine#straightline wire drawing machine#wet wire drawing machine#rod break down#mig wire plant#flux cored wire drawing machine#wire galvanising plant#in- line wire annealer#in line wire annealer#inline wire annealer#welded wire mesh machine#ribbed wire plant#eot cranes#drumpack machines#roll forming machine#concrete re-inforcement mesh plant#concrete reinforcement mesh plant#concrete re inforcement mesh plant#turnkey projects#lrpc wire plants#brass wire plants#special purpose machine

0 notes

Text

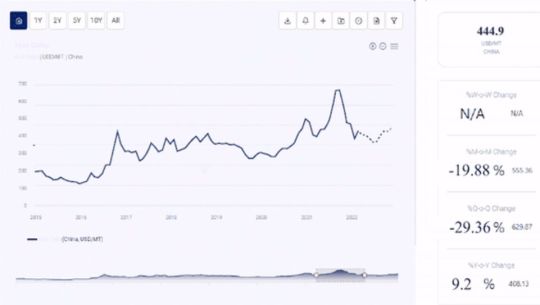

Navigating Steel Wire Rod Prices: Unveiling Trends and Insights for Informed Market Analysis, Research, and Procurement

In H1’23, steel wire rod prices in Asia increased due to high demand from downstream sectors and steady production activities. However, the second quarter saw challenges with slow movement in cement and construction industries. In Europe, the market was stable in the first quarter, affected by weak buying potential and a lack of new orders. Strikes, rising inflation, and economic uncertainties influenced the mixed trend in the second quarter. In North America, the first quarter showed price incline supported by rising feedstock prices and strong domestic demand. But the second quarter saw a decline due to the sliding economy and low construction activities.

Request for Free Sample: https://www.procurementresource.com/resource-center/steel-wire-rod-price-trends/pricerequest

Definition

Steel wire rod is a semi-finished metal product made from hot-rolled steel billets or blooms. It has a round cross-section and is characterized by its small diameter, typically ranging from 5.5 to 14 millimeters. Steel wire rods are widely used in various industries, including construction, automotive, and manufacturing. They serve as the primary raw material for producing a wide range of steel wire products, such as nails, screws, fencing, springs, and reinforcement materials. The quality and properties of steel wire rod play a crucial role in determining the final product's performance and durability.

Key Details About the Steel wire rod Price Trend:

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on steel wire rod in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as Excel files that can be used offline.

The steel wire rod Price chart, including India steel wire rod price, USA steel wire rod price, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Industrial Uses Impacting the Steel Wire Rod Price Trend:

Steel wire rods have a wide range of industrial applications due to their strength, flexibility, and adaptability. They serve as a crucial raw material in various industries, including construction, automotive, manufacturing, and telecommunications. In construction, steel wire rods are used for reinforcement in concrete structures, fencing, and mesh products. In the automotive industry, they find application in tire cord, springs, and wire ropes. Steel wire rods are utilized in the production of cables and electrical wires for power transmission and telecommunications. They are also essential in manufacturing fasteners, welding electrodes, and various components for machinery and equipment. The diverse applications of steel wire rods make them indispensable in modern industrial processes.

Key Players:

ArcelorMittal S.A.

Bridon-Bekaert Ropes Group

Heico Companies Metal Processing Group

Optimus Steel

KOBE STEEL LTD

WireCo World Group Inc

JFE Steel Corporation

Nippon Steel Corporation

News and recent development:

A license to produce a comprehensive range of IS 7904 grade steel wire rods, which are used in bridge cables and tire reinforcement materials, has been granted to the state-run Bhilai Steel Plant (BSP) an arm of state-run Steel Authority of India Limited (SAIL),in Chhattisgarh. (Dated: 20 March 2023)

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team tracks the prices and production costs of a wide variety of goods and commodities, hence, providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Chris Byrd

Email: [email protected]

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Reference Link: https://theprocurementexpert.com/steel-wire-rod-prices/

1 note

·

View note

Text

Uses of Hexagonal Wire Mesh: A Versatile Solution for Various Industries

Hexagonal wire mesh, often known as chicken wire or hex mesh, is a highly versatile material used across multiple industries. Its distinctive hexagonal pattern makes it suitable for a variety of applications, from agriculture to construction. In this blog, we will delve into the numerous uses of hexagonal wire mesh and explain why Al Miqat Hardware is the preferred source for high-quality hexagonal wire mesh, including chicken wire mesh rolls and farm fencing mesh in Oman.

What is Hexagonal Wire Mesh?

Hexagonal wire mesh is a type of wire mesh formed by weaving thin strands of wire into a hexagonal pattern. It can be manufactured using various materials, such as galvanized steel, stainless steel, and PVC-coated wire. The material chosen typically depends on the specific needs of the application, including factors like durability, resistance to corrosion, and aesthetic considerations.

Common Applications of Hexagonal Wire Mesh

Agriculture

Poultry Enclosures: One of the most common uses for hexagonal wire mesh is in poultry farming. Known as chicken wire, this material is ideal for creating enclosures for chickens, ducks, and other poultry. It provides a secure barrier to keep birds safe from predators while also allowing for proper ventilation.

Farm Fencing: Hexagonal wire mesh is widely used for farm fencing. Its flexibility and strength make it perfect for enclosing livestock, protecting crops, and delineating areas within a farm. As a durable fencing solution, it effectively balances security and practicality.

Gardening and Landscaping

Plant Support Structures: Hexagonal wire mesh is often employed in gardening to construct support structures for climbing plants like beans, cucumbers, and tomatoes. The mesh serves as a trellis, offering a sturdy framework for plants to grow and climb.

Garden Protection: It is also used to protect garden beds and plants from animals. Surrounding a garden plot with hexagonal wire mesh can prevent pests such as rabbits and deer from accessing and damaging the plants.

Construction and Infrastructure

Concrete Reinforcement: In the construction industry, hexagonal wire mesh is utilized to reinforce concrete structures. It enhances the strength and stability of concrete slabs, walls, and floors, helping to prevent cracks and extend the structure’s lifespan.

Safety Barriers: Hexagonal wire mesh is also used to create safety barriers at construction sites. It helps prevent unauthorized access and protects workers from potential hazards, contributing to a safer work environment.

Industrial and Commercial Uses

Screening and Filtration: Hexagonal wire mesh is used in various industrial processes for screening and filtration. It can separate materials based on size, making it useful for sorting aggregates, grains, and other bulk materials.

Security Fencing: In commercial settings, hexagonal wire mesh is commonly used for security fencing. Its durability and flexibility make it suitable for securing premises, including warehouses, industrial facilities, and retail properties.

DIY and Craft Projects

Home Décor and Crafts: Hexagonal wire mesh is a popular material for DIY and craft projects. It can be shaped into decorative items like wall art, picture frames, and custom storage solutions. Its pliability and unique appearance make it a favorite among craft enthusiasts.

Why Choose Al Miqat Hardware for Hexagonal Wire Mesh?

When sourcing high-quality hexagonal wire mesh in Oman, Al Miqat Hardware stands out as a top supplier. Here’s why they are the best choice for your wire mesh needs:

Extensive Product Range

Chicken Wire Mesh Rolls: Al Miqat Hardware offers chicken wire mesh rolls ideal for poultry enclosures and various agricultural uses. Available in different sizes and gauges, these rolls ensure you find the perfect fit for your specific needs.

Farm Fencing Mesh: Their selection of farm fencing mesh is designed to meet the demands of farmers and landowners, providing durable and reliable fencing solutions for livestock and crop protection.

Hexagonal Wire Mesh: Al Miqat Hardware provides a wide range of hexagonal wire mesh options suitable for applications in construction, gardening, and industry.

High-Quality Materials

Durability: Al Miqat Hardware ensures their hexagonal wire mesh products are made from top-quality materials. Whether galvanized, stainless steel, or PVC-coated, their mesh is built to last and perform well in various conditions.

Reliability: By sourcing their products from reputable manufacturers, Al Miqat Hardware guarantees that customers receive wire mesh that meets industry standards for strength and durability.

Expert Advice and Support

Product Knowledge: The team at Al Miqat Hardware is well-versed in hexagonal wire mesh and can provide expert advice on selecting the right type of mesh for your needs, whether it’s for a chicken coop or a large farm fence.

Installation Guidance: They offer guidance on the installation of wire mesh, ensuring you achieve the best results for your projects. Their experts provide tips and recommendations for proper installation and maintenance.

Competitive Pricing

Value for Money: Al Miqat Hardware offers competitive pricing on their hexagonal wire mesh products, ensuring excellent value for your investment by balancing quality and affordability.

Bulk Discounts: For larger projects or bulk purchases, they offer discounts and special pricing, making it cost-effective to source wire mesh for extensive needs.

Reliable Service

Timely Delivery: Al Miqat Hardware ensures the prompt delivery of wire mesh products throughout Oman. Their efficient logistics and distribution network mean you receive your orders on time and in excellent condition.

Customer Satisfaction: Al Miqat Hardware prioritizes customer satisfaction, offering reliable service and support throughout the purchasing process to address any questions or concerns.

Conclusion

Hexagonal wire mesh is an invaluable material with diverse applications, from agricultural fencing to construction reinforcement. Al Miqat Hardware is the premier choice for hexagonal wire mesh in Oman, offering a broad selection of products, including chicken wire mesh rolls and farm fencing mesh.

By choosing Al Miqat Hardware, you gain access to high-quality products, expert support, competitive pricing, and dependable service. Whether you’re working on a farm, a construction project, or a DIY venture, Al Miqat Hardware provides the wire mesh solutions you need to achieve your goals effectively. Trust Al Miqat Hardware for all your hexagonal wire mesh needs and experience the difference that quality and expertise can make.

#al miqat hardware#wire mesh Sharjah#wire mesh oman#hexagonal wire mesh oman#galvanized fencing mesh#fencing mesh stockiest#wire mesh stockiest UAE#chain link fencing stockiest

0 notes

Text

Understanding Mesh Size and Its Applications

Mesh size is a crucial concept employed in various industries, including manufacturing, filtration, and engineering. It refers to the number of openings or apertures per linear inch in a woven or knitted material, such as wire, fabric, or mesh. The mesh size dictates the particle or fluid flow through the material, making it a critical parameter in diverse applications.

One of the most common uses of mesh size is in industrial filtration systems. The size of the mesh directly influences the filtration efficiency. For instance, a smaller mesh size is ideal for capturing fine particles, while a larger mesh size allows for the passage of larger particles. This property finds application in various fields, such as water treatment plants, air purifiers, and chemical processing units, where the removal of contaminants is of utmost importance.

In the context of agriculture, mesh size plays a pivotal role in insect netting. Farmers utilize these nets to protect their crops from pests while allowing sunlight, air, and moisture to penetrate. Choosing the appropriate mesh size is essential to strike the right balance between pest exclusion and providing a conducive environment for plant growth.

Furthermore, mesh size is crucial in the manufacturing of sieves and screens. Sieves with different mesh sizes are used to separate and classify particles based on their size. Industries like mining, pharmaceuticals, and food processing rely on these sieves to sort and grade materials efficiently.

In engineering and construction, mesh size is vital in reinforced concrete structures. Concrete reinforced with steel mesh provides added tensile strength, preventing cracks and enhancing the structural integrity of buildings, bridges, and other infrastructure.

Mesh size is also a key factor in scientific research and experiments. In laboratories, filters with specific mesh sizes are used to isolate particles for analysis and testing. Similarly, mesh size is integral to the success of particle size analysis, wherein particles are passed through a series of sieves with different mesh sizes to determine their distribution.

The selection of an appropriate mesh size depends on the intended application and the characteristics of the particles or fluids involved. A mesh with too small openings may result in clogging, reducing efficiency, whereas a mesh with too large openings may compromise the desired level of filtration.

Manufacturers often specify mesh size using the "mesh count," which represents the number of openings per linear inch. The higher the mesh count, the finer the mesh and smaller the openings. It is essential to verify whether the mesh size conforms to industry standards and quality requirements.

In conclusion, mesh size is a fundamental aspect that significantly impacts a wide range of industries and applications. From filtration to construction, its role in shaping efficiency, productivity, and functionality cannot be overstated. Understanding the importance of mesh size allows industries to make informed decisions, ensuring the optimal performance of their products and processes. As technology and research advance, the versatility and significance of mesh size in various sectors are expected to continue evolving, making it an indispensable element of modern-day engineering and innovation.

0 notes

Text

Applications of Welded Wire Mesh in the infrastructure industry

Welded wire mesh is a versatile material with numerous applications due to its strength, durability, and flexibility. Stability and structural support are provided by the grid-like structure of these meshes, which are made by fusing crossing wires.

Wire mesh suppliers in Dubai provide various types of welded wire mesh, each created for a particular application. Typical variants include:

Rectangular mesh: This mesh has rectangular apertures and is commonly used for making animal enclosures and fencing.

Galvanized Mesh: This is the best mesh for outdoor applications since it is coated with zinc and

Square Mesh: This variety, which has square apertures of equal size, is frequently employed in industrial and construction settings.

Hardware cloth: if you want protection against small animals and pests, then you should opt for hardware cloth, which has smaller openings.

Considerations for wire diameter, mesh size, material, and intended use should be made while selecting the best-welded wire mesh. The best mesh type for a given application can be chosen with the assistance of a wire mesh supplier in Al Ain or an industry specialist.

Welded wire mesh is widely used in the infrastructure sector for a variety of applications due to its durability, strength, and adaptability. The following are a few crucial applications for the infrastructure sector:

Welded wire mesh is frequently utilised as reinforcement in the construction of concrete structures. By supplying tensile strength and lowering cracking, it improves the structural integrity of building components such as walls, slabs, and foundations. To distribute loads, provide stability, and stop concrete from shrinking and expanding, the mesh is implanted within the concrete.

Welded wire mesh is used in the construction of roads and pavements to reinforce asphalt or concrete surfaces. It contributes to crack control and load-bearing capacity improvement, extending the durability and life of the roads.

Slope stabilisation and retaining wall construction both use welded wire mesh. To stop soil erosion, landslides, and the collapse of steep slopes, the mesh offers reinforcement and stability.

Infrastructure sites like industrial facilities, airports, and power plants use welded wire mesh for security fencing. These meshes help enhance perimeter security by deterring illegal access.

Bridge components like decks, beams, and columns are strengthened using welded wire mesh. These meshes add to these components' load-bearing capacity and structural integrity.

Tunnel walls use welded wire mesh to gain stability and prevent collapse, thus ensuring the safety of the structure.

Garden fencing, trellises, and plant supports are just a few of the landscaping and erosion control uses for welded wire mesh. Moreover, it is used to reduce erosion by keeping soil in place on slopes and avoiding soil erosion along riverbanks and coasts.

Welded wire mesh in the UAE is widely used in the infrastructure sector because of its dependability, economy of scale, and versatility. It plays a significant role in guaranteeing the safety and functionality of infrastructure projects and adds to the strength, stability, and durability of diverse structures.

0 notes

Text

How to Make Cheap Plant Supports

When it comes to growing healthy and thriving plants, providing proper support is crucial.

However, you don't need to spend a fortune on expensive plant supports. With a little creativity and resourcefulness, you can make your own affordable and effective plant supports right at home.

Bamboo Teepees:

Gather some bamboo stakes or poles and form them into a teepee shape. Secure the tops together with twine or zip ties. This simple structure works well for supporting climbing plants like tomatoes, beans, or peas.

PVC Stake System:

Cut PVC pipes into desired lengths and insert them into the ground around your plants. Connect the pipes with PVC connectors to create a sturdy support system. This method is particularly useful for supporting tall and heavy plants like peppers or eggplants.

Upcycled Materials:

Look around your house or local community for materials that can be repurposed as plant supports. Old wire coat hangers, wooden dowels, or even discarded bicycle wheels can serve as creative and inexpensive options to keep your plants upright.

Trellis from Lattice Panels:

Purchase inexpensive lattice panels from a hardware store and create a trellis by attaching them to wooden stakes or posts. This DIY trellis provides a sturdy framework for vining plants such as cucumbers, melons, or squash.

Tomato Cage Alternatives:

Instead of buying traditional tomato cages, repurpose wire mesh fencing or concrete reinforcing mesh. Cut the mesh into appropriate sizes and shape them into cylindrical structures. These homemade cages will keep your tomatoes well-supported and prevent sprawling.

Stake and String Method:

For plants that need vertical support, such as tall flowers or indeterminate tomatoes, drive sturdy wooden stakes into the ground beside them. Use garden twine or string to tie the plant stems loosely to the stakes as they grow.

Repurposed Branches:

Find sturdy branches or sticks from pruning or fallen trees and repurpose them as natural supports. Trim off any side branches and insert the main stem of your plant into the ground beside the branch, allowing the plant to lean against it for support.

Recycled Plastic Bottles:

Cut the bottom off plastic bottles and place them over seedlings or young plants to protect them from wind and provide initial support. As the plants grow, gradually remove the bottles, allowing them to strengthen on their own.

Fence Panel Trellis:

Attach wire fencing or chicken wire to a wooden or metal fence panel to create an instant trellis. This method is ideal for training vining plants or decorative climbers like morning glories or sweet peas.

Rebar Grid System:

Construct a grid system using rebar rods by hammering them into the ground in a square or rectangular shape. Connect the rods at intersecting points using zip ties or wire. This method is excellent for supporting heavy or sprawling plants like melons or pumpkins.

Macrame Plant Hangers:

If you have hanging plants or trailing varieties, try your hand at macrame plant hangers. Using simple macrame knots and ropes, you can create stylish and functional supports that elevate the aesthetic of your indoor or outdoor space.

Repurposed Ladders:

Old wooden ladders can be transformed into unique plant supports. Place the ladder horizontally in your garden and use the rungs as shelves for potted plants or as a support for climbing vines.

Conclusion:

Supporting your plants doesn't have to be expensive. By utilizing these DIY methods and repurposing materials, you can create cost-effective plant supports that are both functional and visually appealing.

Get creative, embrace your resourcefulness, and enjoy the satisfaction of nurturing your garden while keeping your wallet happy.

Happy gardening!

Read the full article

0 notes