#in- line wire annealer

Text

Binding Wire Plant manufacturers in India

We are manufacturer & exporter of Wire Winding Plant for winding to bobbin to the various size as per requirement. Offered machine is exclusively manufactured by highly experienced professionals using the best-grade components and modern technology.

#wire galvanising plant#in- line wire annealer#in line wire annealer#inline wire annealer#welded wire mesh machine#ribbed wire plant#eot cranes#drumpack machines#roll forming machine#concrete re-inforcement mesh plant#concrete reinforcement mesh plant#concrete re inforcement mesh plant#turnkey projects#lrpc wire plants#brass wire plants#special purpose machine

0 notes

Text

2500-Year-Old Bronze Age Artifacts Found in Poland

A metal detectorist looking for a World War I artifacts near Turobin, eastern Poland, found a hoard of Bronze Age jewelry instead. They were produced by the Lusatian culture in the waning era of their dominance in the region, ca. 550-400 B.C. Lusatian artifacts are extremely rare finds in this part of Poland, and the ones that have been discovered are usually individual pieces or fragments.

Łukasz Jabłoński, armed with a permit from the Provincial Office for the Protection of Monuments in Lublin, scanned the field on January 21, 2023. Digging under the snow, he found 13 bronze artifacts 8-10 inches under the surface of the soil. He immediately reported his discovery to the conservation office in Zamość and turned in the objects.

The 13 pieces include a cloak pin 6 inches long with a large spiral twisted wire terminal 2.8 inches in diameter. The pointed tip of the pin is missing. A second pin is even longer — 6.5 inches — and is intact with its pointed end. The head is a smaller spiral 1.2 inches in diameter with a decorative knob in the center.

Another stand-out piece is a twisted neck torc in penannular shape made from a single piece of bronze wire with tapered ends. The twisting technique was an advanced metalworking skill, especially using bronze because it hardens quickly and must be annealed repeatedly during the twisting process to prevent it from breaking.

There are also eight bracelets in the group: two 4.7 inches in diameter made of thick bronze wire with blunt overlapping ends, two made of single-stranded flat wire (one undecorated, the other incised with herringbone lines), and four massive ones three inches in diameter with overlapping ends.

The hoard is now being conserved and studied at the Museum of the Biłgoraj Land in Biłgoraj. The location of the find site has been kept secret to deter looters while archaeologists excavate it to find out more about the deposit and to look for any additional artifacts that might be in the area.

#A 2500-Year-Old Bronze Artifacts Found in Poland#Turobin Poland#metal detector#metal detecting#metal detecting finds#bronze#bronze artifacts#ancient artifacts#archeology#archeolgst#history#history news#ancient hiatory#ancient culture#ancient civilizations

25 notes

·

View notes

Text

Polycab flexible cable

Why is it best to buy Polycab flexible cable?

Polycab is the market leader in power, control, and industrial cables. Polycab is the fastest-growing company in the cable industry and offers the widest selection of wires and cables. Polycab flexible cable are used in various applications such as control panels, home appliances, machine tools, and machinery and are used in almost every industry. Conductor: Conductors are prepared from bright electrolytic grade copper, annealed, and bundled (multiple strands) as per Class 5 of IS 8130:1984. Insulation: Bundled conductors are insulated with in-house developed specially formulated PVC compound with high insulation resistance values. The adiabatic process is carried out with high precision on modern high-speed extrusion lines, ensuring consistent performance. Jacketing: In multi-conductor cables, insulated conductors are stacked to form a conductor assembly. The exterior uses a specially formulated PVC compound that facilitates peeling and resists mechanical wear.

High-quality polycab flexible cable

PVC cable is a best seller for residential wiring solutions. This product is manufactured from copper wire, which makes it highly durable. Suitable for surface application, sub-flooring, etc. This cable is designed for various electrical applications in commercial and industrial sectors where maximum protection is required during installation. Polycab PVC insulated cable is a multi-strand electrical wire for lighting, wiring electronics, and connecting LED strips. A windproof wire that can be effectively used for indoor lighting and connecting various electronic devices. The length of this wire makes it easy to use for multiple purposes, including lighting, wiring electronics, and connecting LED strips. PVC insulation protects against termite and rodent attack and is corrosion resistant, making it durable. These high-quality conductors are easy to strip, solder, and cut, making them easy to use. Polycab flexible cable suits high-rise buildings, malls, and hospitals. This product is manufactured at our state-of-the-art infrastructure unit by highly skilled personnel with extensive knowledge of quality assurance processes. It has proven features that provide reliable performance in critical applications.

Polycab flexible cable by Power Cable Corporation. Power Cable Corporation's flexible logistics team offers a range of state-of-the-art consolidation and shipping options designed to save you time and money. With our superior freight rates and reliable logistics infrastructure, we deliver your orders directly to your site. We will pick up the goods as per your arrangement. If security or space is an issue, cables can be stored in our warehouse facility and released on-site as required. The choice is yours! Cabling services also provide reverse logistics solutions and removal of materials after project completion. Visit our website to get polycab cables.

0 notes

Text

SPRING STEEL WIRES MANUFACTURERS IN DELHI

Joneja Steels Group (JSG) is diversified group of companies having 6 manufacturing plants in Faridabad (NCR Delhi Region), India with expertise in manufacturing different engineering products such as Bright Steel Bars, Steel Wires, Hydraulic Cylinders, and Precision Auto Components.

Joneja steel is one of the leading Spring Steel wires Manufacturers in Delhi as it is one reputed name in the field of steel industry. Being in the market for more than 35 years makes Joneja steel more trust worthy.

Joneja Steels Group (JSG) is diversified group of companies having 6 manufacturing plants in Faridabad (NCR Delhi Region), India with expertise in manufacturing different engineering products such as Bright Steel Bars, Steel Wires, Hydraulic Cylinders, and Precision Auto Components.

JSG originated in 1987 as Joneja Bright Steel Private Limited (JBSPL)it had dedicated manufacturing plants with advanced equipment, Automated Combined Drawing Machines, Draw Benches, Wire Drums, Inverted Bull Blocks, Peeling & Grinding Lines and Bell Annealing Furnaces. Over the years, JBSPL has grown to be the one-stop shop for most requirements of General Engineering Wires, Spring Steel Wires, Hard Bright (HB) Wires, Half Hard Bright (HHB) Wires, Wires for Spring Washers, Circlips, Cold Heading Quality Wires (CHQ) &Profiles, Shaped Bars, Cold Drawn Bars, Centre-less Peeled Bars and Ground Bars.

In 2020 under Prime Minister of India, Atmanirbhar Bharat (Made in India) initiative JSG established world class technology plant, Joneja Hydraulic Private Limited (JHPL)for manufacturing of Hydraulic Cylinders catering to all type of Construction Equipment, Fram Track and off Highway Vehicles. It has up to date CNC &VMC Machines, Welding SPMs, Automated Assembly, Washing and Paint Lines.

In 2021, JSG acquired and upgraded 100% Export Oriented Company, Greiner Engineering Products (GEP)with State of Art Technology CNCs and other Machineries for manufacturing of Precision Auto Components for Trucks & Trailers, 4 Wheelers, Cars and others.

JSG has its own Independent Testing Laboratory Unit Accreted by NABL having Spectrometer for chemical analysis, Tensile Testing Machines, Rockwell Hardness Testers, Micro scope image analyzer, salt spray and all related testing equipment’s required for Mechanical Properties Testing.

JSG boasts a team of qualified professionals dedicated to produce high-quality products with precision and adherence to quality systems Joneja Steels Group is a well established and technologically advance company with a strong focus on quality, innovation and diversification in its product offerings. The Strategic initiatives align with the make in India and self –reliance goal set by the Indian Government.

0 notes

Text

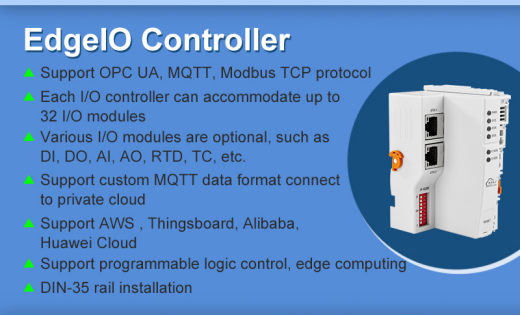

Application of Real-time Data Collection and Monitoring of Distributed I/O in Glass Manufacturing

Background

The glass industry has made extensive use of PLC for many years to help manage the precise proportions of materials required in the production process. It relies entirely on its PLC for data collection and control, and relies heavily on manual operations, so these high costs have driven a search for lower-cost alternatives needs.

Scene description

The glass production produced by a glass factory includes five processes: batching section, melting section, forming section, annealing section and edge breaking section. Among them, melting, forming and annealing are the core links of the original film production line. If there is a problem in any link, All will affect the quality and production rate of the product. For example, the biggest impact on raw film output is temperature control, which is closely related to the heating and cooling conditions of the glass. Therefore, accurate and timely temperature collection in the furnace of the unit plays a crucial role in controlling the temperature. The normal production of the product is continuous operation 24 hours a day, and production cannot be stopped. Once the product quality is unstable, the production will not proceed normally.

A large amount of enterprise data remains in traditional records and is still stored through traditional methods such as reports and paper. The data source is not unique, some data are out of sync, the underlying collection is incomplete, manual troubleshooting is slow and inaccurate, and the number of affected products and the resulting losses are often huge.

Information lost

Reported information is conveyed layer by layer through phone calls or reports, and managers cannot obtain information such as product quality, production equipment, process processing, customer orders, and inventory in real time.

Coping strategy

In order to cope with the development needs of the glass industry and ensure safe and reliable data collection, BLIIoT launched the distributed I/O module-BL206Pro. It has the characteristics of high reliability, favorable price, easy setup, and convenient network wiring. It also supports equipment of different protocols, reducing enterprise procurement costs, and also deploys for the future IT/OT integration development of the manufacturing industry.

System specification

The glass smart factory system is composed of BLIIoT distributed I/O module BL206Pro and PLC on site to achieve coordination, unity and collaborative management and control of the workshop manufacturing process. It achieves a high degree of coordination and unity in all aspects of the glass, allowing control flow, logistics, and information flow to be clear and clear complete embodiment.

Distributed I/O collects production process data and is used to monitor key control points on site, such as temperature, gas, pressure, etc., to ensure stable production operation. PLC completes the logical control of the entire process flow. The cloud platform or PC-side equipment can set and access process parameters and set temperature and other parameters, and display them through interfaces such as HMI.

Product description

Excellent performance

It has multiple functions such as signal acquisition control, data calculation, logical linkage, data uploading to the cloud, and exception reporting! The controller adopts a plug-in design. Users can freely combine I/O according to their needs. It supports up to 32 I/O boards and 512 I/O signals. It adopts high-speed backplane communication and has built-in edge functions without the need for a host computer. It can realize linkage control of local I/O signals with the cloud platform or PLC, which greatly improves the response speed of the site and relieves the pressure of data processing on the cloud host computer.

BL206Pro product can collect Al, AO, DI, DO, PT100, RS485 and other data. Built-in integration of OPC UA, MQTT, MODBUS and other IoT bus protocols requires only one module for multi-scenario applications, perfectly adapting to changing flexible production lines.

0 notes

Photo

304 Honeycomb Wire Belt

304 honeycomb wire belt is a type of conveyor belt constructed from high-quality stainless steel wire.

This wire belt features a unique honeycomb structure, with individual wires interwoven to form a robust and flexible mesh.

304 Honeycomb Wire Belt Key Features and Benefits

1. High-quality material

The belt is crafted from AISI 304 stainless steel, known for its excellent corrosion resistance and durability.

2. Versatile design

Its structure allows for smooth movement, making it suitable for applications that require gentle handling of delicate products or heavy-duty transport of robust materials.

3. Excellent heat transfer

Its open mesh design facilitates efficient heat dissipation, making it ideal for processes that involve high-temperature applications, such as baking or drying.

4. Easy cleaning and maintenance

Its flat surface of the belt and the absence of hinges or joints simplify cleaning, ensuring hygienic operation and reducing downtime for maintenance.

5. Customizable options

The belt can be customized with various belt widths, wire gauges, and edge reinforcements to meet specific application requirements.

Food Processing

Used in baking ovens, cooling tunnels, and food conveying systems, ensuring efficient and sanitary transportation of baked goods, snacks, fruits, vegetables, and more.

Industrial Processing

Suitable for heat treatment processes, annealing furnaces, washing systems, and other applications that require high-temperature resistance, easy cleaning, and reliable conveying.

Electronics and Automotive

Utilized in electronics assembly lines, circuit board production, and automotive component manufacturing, ensuring smooth and reliable transport of delicate components and parts.

Glass and Ceramics

Applied in glass tempering lines, ceramics kilns, and other processes that involve high-temperature applications, providing reliable transport without damage to fragile products.

Packaging and Distribution

Used in packaging lines and distribution centers to facilitate the movement of boxes, cartons, and packaged goods efficiently and smoothly.

#304 Honeycomb Wire Belt#Conveyor Belt#Flat Wire Conveyor Belt#Honeycomb Belt#Honeycomb Wire Belt#Wire Belt

0 notes

Text

House Wires Manufacturer

Jupiter Cable Industries offers electrical wires for every segment of the construction industry. Each wire is manufactured using more than 99.97% pure electrolytic grade bright annealed bare copper with more than 100% conductivity to ensure compliance with International Standards.

The conductors are made up of multiple strands of finely drawn copper wire which offers great flexibility, making it ideal for conduit wiring.

Insulation process is carried out on most modern high speed twin extrusion lines, having in line installed spark testers and electronically controlled diameter/eccentricity indicators which ensure fail proof high voltage test and consistency throughout the length of the product.

The Specially Developed high grade PVC compound, used for insulation is resistant to moisture, oils, alkaline, grease and Flames and has very high insulation resistance values.

These wires are manufactured as per IS 694 : 2010 are ISI Marked.

These cables are available in standard packing of 90 Meters.

It is also available in 180 Meters and 270 Meters Special Projects Packing.

0 notes

Text

Wire drawing machine manufacturers in India

If you are looking For a Wire Drawing Machines & Wire Drawing Plant then Enquire Now! S. M. Industries. We are a leading manufacturer and supplier of wire drawing, straight line, wet wire drawing, MiG wire plant, flux cored wire drawing machine, etc.

#wire drawing machinery#wire drawing machine#straight line wire drawing machine#straightline wire drawing machine#wet wire drawing machine#rod break down#mig wire plant#flux cored wire drawing machine#wire galvanising plant#in- line wire annealer#in line wire annealer#inline wire annealer#welded wire mesh machine#ribbed wire plant#eot cranes#drumpack machines#roll forming machine#concrete re-inforcement mesh plant#concrete reinforcement mesh plant#concrete re inforcement mesh plant#turnkey projects#lrpc wire plants#brass wire plants#special purpose machine

0 notes

Text

Heavy Hex Nuts

https://www.dtnut.com/products/heavy-hex-nuts/

DATIAN (DT) Fastener is famous for producing quality heavy hex nuts. We, one of the professional heavy hex nut manufacturers, have a in house full line heat treatment machine used to improve the hardness and mechanical properties of heavy hexagonal nuts in order to serve different high requirement areas. The heavy duty hex nuts standard we listed below are most ASTM A194/A563 and ANSI/ASME B18.2.2 heavy hex nuts. Compare to finished hex nuts, the heavy hex nut carry higher grade and slightly wider and thicker diameters to meet the greater length of thread engagement and better resistance to stretching or widening. Contact DT Fastener, a professional nuts and bolts manufacturing company, for more info now!

Heavy Hex vs Hex

The first thing to declare is that both heavy hex nuts and finished hex nuts belong to the hexagon nut classification. Simply put, the difference between them is that heavy hex nuts have larger widths across the flats and heights of the same nominal size. This gives heavy hex nuts higher load retention and tensile strength. This also explains why heavy hex nuts can be heat treated to achieve higher hardness.

There are two production processes for Datian Fastener's Heavy hexagon nuts - cold heading and hot heading.

The cold heading machine of Datian Fastener has the ability to form the nut from raw material to finished product at one time. Our cold heading machine integrates the rolling thread machine and the cold heading machine to maximize efficiency, ensure the customer's delivery requirements, and minimize the labor cost, which makes the price of our heavy hexagonal nut competitive all over the world.

Hot forming: Generally, hot forming is selected for larger fasteners, and the diameter range are generally 1''~4''~(M30~M100) or even larger. The material used in the hot heading machine is generally round steel, without cold drawing and pickling. The production step is to cut the material first, and then upsetting by the punch. The surface of the semi-finished product of red punching is rougher than that of cold heading. After tapping, the two sides of the nut are chamfered with a CNC machine, and finally it is completed after heat treatment and surface treatment.

Cold heading and hot heading are roughly divided into the following steps: Cold heading: wire drawing - cold heading - (heat treatment) - tapping - surface treatment

Hot forming: cutting material - red punching - chamfering - turning - (heat treatment) - tapping - surface treatment Or cutting material - upsetting ball - annealing, phosphating - forming - punching - (heat treatment) - tapping - surface treatment.

0 notes

Text

Heavy Hex Nuts

DATIAN (DT) Fastener is famous for producing quality heavy hex nuts. We, one of the professional heavy hex nut manufacturers, have a in house full line heat treatment machine used to improve the hardness and mechanical properties of heavy hexagonal nuts in order to serve different high requirement areas. The heavy duty hex nuts standard we listed below are most ASTM A194/A563 and ANSI/ASME B18.2.2 heavy hex nuts. Compare to finished hex nuts, the heavy hex nut carry higher grade and slightly wider and thicker diameters to meet the greater length of thread engagement and better resistance to stretching or widening. Contact DT Fastener, a professional nuts and bolts manufacturing company, for more info now!

Heavy Hex vs Hex

The first thing to declare is that both heavy hex nuts and finished hex nuts belong to the hexagon nut classification. Simply put, the difference between them is that heavy hex nuts have larger widths across the flats and heights of the same nominal size. This gives heavy hex nuts higher load retention and tensile strength. This also explains why heavy hex nuts can be heat treated to achieve higher hardness.

There are two production processes for Datian Fastener's Heavy hexagon nuts - cold heading and hot heading.

The cold heading machine of Datian Fastener has the ability to form the nut from raw material to finished product at one time. Our cold heading machine integrates the rolling thread machine and the cold heading machine to maximize efficiency, ensure the customer's delivery requirements, and minimize the labor cost, which makes the price of our heavy hexagonal nut competitive all over the world.

Hot forming: Generally, hot forming is selected for larger fasteners, and the diameter range are generally 1''~4''~(M30~M100) or even larger. The material used in the hot heading machine is generally round steel, without cold drawing and pickling. The production step is to cut the material first, and then upsetting by the punch. The surface of the semi-finished product of red punching is rougher than that of cold heading. After tapping, the two sides of the nut are chamfered with a CNC machine, and finally it is completed after heat treatment and surface treatment.

Cold heading and hot heading are roughly divided into the following steps: Cold heading: wire drawing - cold heading - (heat treatment) - tapping - surface treatment

Hot forming: cutting material - red punching - chamfering - turning - (heat treatment) - tapping - surface treatment Or cutting material - upsetting ball - annealing, phosphating - forming - punching - (heat treatment) - tapping - surface treatment.

0 notes

Text

What Is Astm Number?

Steel mill specifications are a consensus among producers, specifiers, fabricators, and users. The ASTM designation system for metals consists of a letter (A for ferrous materials) followed by an arbitrary sequential number. A548 refers to cold-heading quality carbon steel wire for tapping or sheet metal screws, for example.

Originally called the American Society for Testing and Materials, ASTM International is a global leader in developing voluntary consensus standards used by individuals, companies, and other institutions around the world. The ASTM is made up of over 30,000 volunteers from over 140 countries.

ASTM International accepts requests for new standards from any interested party. A technical committee of ASTM prepares a draft of the standard, which is then submitted to a parent subcommittee before being sent to all members for review. During this process, any objections must be considered before the document can move forward.

ASTM standards are written in a specific and organized manner. A standard’s scope describes its purpose and limitations. The document may also include a glossary of unfamiliar terminology used in the document, as well as a bibliography of referenced documents.

In terms of fasteners, you can find details about everything needed to manufacture them. Materials, mechanical properties, chemical compositions, dimensions, appearances, and testing methods are included. The details can also include fastener limitations, reference tables, supplementary requirements, and notes on the packaging.

Manufacturers and customers alike can use an ASTM standard to determine the right fastener for a particular job, as well as recognize the advantages and limitations of a standard.

After ASTM procedures have been followed and the standard has been given due process, the ASTM International Committee on Standards grants final approval. Due process ensures that all interested parties are heard and maintains a balance between competing interests.

This article describes the evolution of grain size measurement and ASTM standard E 112. It was written by George Vander Voort on the occasion of the 75th anniversary of Committee E-4 on metallography and originally appeared in ASTM Standardisation News, May 1991 as “Committee E-4 and Grain Size Measurements: 75 years of progress.”

This is here with the kind permission of Mr. Philip Lively, assistant VP for publications, marketing, and information technology at ASTM. There are 16 accompanying micrographs.

Except for a few metals, most metals are crystalline and they contain internal boundaries called grain boundaries. The atoms within each growing grain line up in a specific pattern depending on the crystal structure of the metal or alloy when it is nucleated in the course of processing (such as solidification or annealing after cold working). During growth, each grain will eventually impinge on the others and form an interface where the atomic orientations differ.

ASTM Designations:

Each ASTM standard is identified by a capital letter (A-H), a serial number (ranging from 1-4 digits), a dash, and its year of publication. There are times when ASTM standards will have a capital “M” for metric or a year in parenthesis (0000), indicating the last time they were re-approved.

A – Ferrous metals and products (steel)

B – Nonferrous metals and products (coatings)

C – Cementitious, ceramic, concrete, and masonry materials

F – end-use materials and products (bolts)

G – Corrosion, deterioration, weathering, durability, and degradation of materials and products

Click here to know more about this Article: https://cortensteeltube.com/what-is-astm-number/

0 notes

Text

What are the applications of carbon fiber in cables?

Aluminum Conductor Composite Core (ACCC) cable is a replacement product of traditional Aluminum Conductor Steel Reinforced (ACSR) cable. As early as the 1990s, Japan began to develop ACCC cables. Afterwards, the United States Composite Technology Corporation (Composite Technology Corporation, CTC) also successfully developed and became a supplier of ACCC. Fujian Power Grid and Tianjin Power Grid have already erected and operated the new conductor, and achieved remarkable results. Jiangsu Far East Group developed ACCC cables in 2006 and established production lines. At present, there are many ACCC cable production lines in China.

Compared with ACSR cable, ACCC cable has the following advantages

1) Light weight and low density: the density of the carbon fiber composite core is only 1.90g/cm3, and that of the steel core is 7.8g/cm3. The former is much lighter than the latter, so the distance between poles and towers can be increased, and the number of poles and towers can be reduced by about 16%, which also reduces the occupied area and saves investment. At the same time, the density is small, which increases the safety.

2) High strength and high breaking force: the tensile strength of ACCC is about 2399MPa, which is 1.97 times that of ordinary steel wire and 1.7 times that of high-strength steel. At the same time, the test results show that the destructive power of the former is about 30% higher than that of the latter. The strength of AC-CC is high, and the external force is mainly carried by the carbon fiber composite core. The aluminum stranded wire hardly bears external force; thus greatly improving the service life.

3) High electrical conductivity and large ampacity: Under the same diameter conditions, the cross-sectional area of aluminum stranded wire in ACCC is 1.29 times that of conventional ACSR, and the ampacity is increased by about 29%. This is based on the following reasons: First, the specific strength of the carbon fiber composite core is greater than that of the steel core, so the diameter of the mandrel can be made thinner, thereby accommodating more aluminum wires and a larger conductive cross-sectional area; second, the cross-sectional shape of the ACCC aluminum strand It is trapezoidal, while the ACSR aluminum wire is circular in cross section. The former is easy to be compact and densely packed, and can accommodate more aluminum wires, thereby increasing the conductive cross-sectional area; the third is that the ACCC outer aluminum wire adopts annealed aluminum wire with a conductivity of 64% IACS, which is comparable to that of hard aluminum wire with 61% IACS. Increased by 3.3%.

4) Small line loss: carbon fiber composite material is a non-magnetic material. When the wire passes through alternating current, there will be no hysteresis loss and eddy current loss, showing a small alternating current resistance. -Generally speaking, the transmission loss can be reduced by about 6%. At the same time, because ACCC uses trapezoidal aluminum stranded wire, its surface is smoother than that of ACSR round aluminum wire, which reduces the surface roughness value, thereby increasing the corona initial point pressure of the wire and reducing corona loss.

5) Corrosion resistance and long service life: the carbon fiber composite mandrel avoids the electrochemical corrosion between the aluminum wire and the core steel wire when the steel core is energized, so that the aluminum wire can be used for a long time without aging. At the same time, the outer layer of the carbon fiber composite mandrel is an insulating glass fiber composite layer, and some of them are coated with polytetrafluoroethylene film or insulating coating on the outer layer of GFRP, so that the aluminum wire and the mandrel are completely insulated, and there is no gap between the two. There is a contact potential difference, which protects the aluminum wire from electric corrosion and prolongs the service life. Figure 9-5 shows the schematic cross-sectional structure of ACCC.

6) The thermal expansion coefficient is small: the thermal expansion coefficient of ACCC is 1.6x10-6/9C, and that of ACSR is 11.5x10-*7C, and there is a big difference between the two. The condition test shows that when the temperature rises from 21.6C to 186C, the sag of the ACSR wire increases from 236mm to 1422mm, an increase of about 5 times, while the ACCC wire only increases from 198mm to 312mm, which is only about 0.57 times. Apparently, the change in sag of ACCC is only 9.6% of that of ACSR. Therefore, ACCC cables are much better than ACSR in adapting to environmental temperature changes such as day and night temperature differences, winter and summer temperature differences, and are a safe new generation of high-end products. In addition, the weight of ACCC is only 70%~80% of ACSR, which is convenient for transportation and good in operability.

0 notes

Text

Galvanized steel plate is widely used in automobiles

The vast majority of car body shells are made of metal, mainly with steel plates.

In what way are the steel plates of modern cars protected against rust? Why do some cars claim to have a rust-proof body for 10 years or more? Galvanized steel plate is widely used in automobiles due to its good corrosion resistance. In the early years, people found that when iron and zinc were put into salt water without any wire connection, both iron and zinc would rust, and iron would produce red rust and zinc would produce "white rust"; if a wire connection was used between them, iron would not rust and zinc would produce "white rust", so zinc would protect iron. This phenomenon is called sacrificial anode protection.

This phenomenon is called sacrificial anodic protection. Engineers have applied this phenomenon to the actual production of galvanized steel. According to research, the life span of galvanized steel outside the house (red rust) is about 15-18 years in the field and 3-5 years in the industrial zone at a galvanization rate of 350 g/m2 (one side), which is several times or even a dozen times longer than ordinary steel.

From the 1970s car body steel plate using galvanized thin steel, assembly galvanized surface placed on the inside of the car to improve the corrosion resistance of the body, non-galvanized surface placed on the outside of the car, spray paint. With the increasing demand for corrosion resistance, the weight of galvanized steel has been increased, and double-layer galvanized steel has also emerged.

However, the increase in galvanized weight also led to a significant increase in electrical energy consumption for galvanizing, resulting in higher material costs. This galvanized steel plate is produced using a continuous hot-dip galvanizing process: cold rolled plate (note*) → heating → cooling to galvanizing temperature → galvanizing → cooling → straightening.

In order to meet the various requirements of galvanized steel plates for automobiles, some manufacturers have applied special treatments such as diffusion annealing to galvanized steel plates on the galvanizing line to form a "zinc-iron" alloy coating on the surface, which is characterized by better weldability and corrosion resistance than pure zinc coated plates after painting. Later on, there are also such alloys as "zinc-aluminum-silicon" and "zinc-aluminum-rhenium", making the corrosion resistance of hot-dip galvanized steel exponentially higher and the bonding performance with paint stable for a long time.

Currently, galvanized steel plates are widely used in cars, with thicknesses ranging from 0.5 to 3.0 mm, including 0.6 to 0.8 mm galvanized steel plates used for body parts. Most of the body parts of the German Audi cars use galvanized steel (part of the aluminum plate), the United States Buick cars use more than 80% of the steel is double-sided hot-dip galvanized steel, the Shanghai Passat body of the outer cover using electro-galvanized technology, the inner cover of the internal hot-dip galvanizing process, which can make the body corrosion protection shelf life of up to 11 years.

0 notes

Photo

Concertina Razor

Concertina coils are the most popular high security fencing for military and high grade residences safety. Two main types available for concertina coils: one is the single coil and the other is crossed concertina coils. It has bright and beautiful blade of various types, offers good corrosion resistance. Galvanized razor wire can be supplied in straight line razor wire, single coils razor wire or crossed concertina razor coils. It is mainly used for no climb wall toppings.

Concertina type razor coil wire is installed with clips and it runs in natural loops on walls.

Concertina Razor wire Blade types:

BT-10, BT-12, BT-18, BT-22, BT-28, BT-30, BT-60, BT-65, etc.

Galvanized Barbed Wire

Galvanized Barbed Wire is produced in IOWA type, with 2 strands, 4 points. Barbs' distance 4 inches (Tolerance + - 1/2"). Galvanized Barbed Wire offered by us is suitable for industry, agriculture, animal husbandry, dwelling house, plantation or fencing.

PVC Coated Barbed Wire

We offer barbed wire with different treatment, like PE or PVC coated. Core of PVC Coated Barbed Wire can be galvanized iron wire or black annealed iron wire. A variety of colors like green, blue, yellow, orange, gray, is available with PVC Coated Barbed Wire offered by us. However most commonly used color is green.

Tensile strength of Standard PVC Coated Barbed Wire is 30-45 Kg/Sq.mm

For more information, visit our Website : www.almiqathardware.com or Call : +971 65664526.

0 notes

Text

Wet Wire Drawing Machine Manufacturers

We are a renowned manufacturer and supplier of the yarn production line in China. Our hot products include rod repair machine, wire drawing machine, in line annealing machine and wire winder. Our experienced and talented team can design and manufacture professional wire drawing machines to meet the unique requirements of customers.

0 notes

Text

Industrial Checkweighers Manufacturers in Coimbatore

One of the leading manufacturers industries in providing the high-quality products and service in offering the materials to bring out the finest products is our Belt Conveyor Manufacturers in Coimbatore. This service provides the detailed description in offering the belt conveyors at an effective way. An over viewing in looking the depth manufacturers in providing the superior brand products is the best in accepting the finest and high-standardized materials.

The service we provide in our belt conveyor manufacturers Coimbatore often possesses the superb raw materials and products in dealing and supplying the finest products and materials at a cost-effective manner. Though to have the superior products with high-quality standardized materials place an order or make a call to our manufacturer industry to have the good quality products in distributing and supplying the materials in delivering the customer on time.

#Belt conveyor manufacturers in Coimbatore#Slat conveyor manufacturers in Coimbatore#Wire mesh conveyor manufacturers in Coimbatore#Assembly line conveyor manufacturers in Coimbatore#Roller conveyor manufacturers in Coimbatore#Trough Conveyor manufacturers in coimbatore#Printing Conveyor manufacturers in coimbatore#Truck Loader Conveyor manufacturers in coimbatore#Gravity Skate Wheel Conveyor manufacturers in coimbatore#Spiral Conveyor System manufacturers in coimbatore#Conveyor Roller manufacturers in coimbatore#Annealing Chamber manufacturers in coimbatore#Carton Sealing Machine manufacturers in coimbatore#Shrink Wrapping Machine manufacturers in coimbatore

0 notes