#desulfurate

Text

5 notes

·

View notes

Text

Flue Gas Desulfurization Systems Market Segmentation and Competitive Landscape

#Flue Gas Desulfurization Systems Market growth#Flue Gas Desulfurization Systems Market share#Flue Gas Desulfurization Systems Market size#Flue Gas Desulfurization Systems Market trends#Flue Gas Desulfurization Systems Market demand#Flue Gas Desulfurization Systems Market#Flue Gas Desulfurization Systems Market industry#Flue Gas Desulfurization Systems Market analysis#Flue Gas Desulfurization Systems Market manufacturer#Flue Gas Desulfurization Systems Market companies

0 notes

Text

Global Top 5 Companies Accounted for 77% of total Flue Gas Desulfurizer (FGD) market (QYResearch, 2021)

Flue gas desulfurizer (FGD) is equipment which can remove sulfur dioxide (SO2) from flue gas emissions, often chemically. Sulfur dioxide in gases is produced by the combustion of fossil fuels and many industrial processes such as gasoline refining as well as cement, paper, glass, steel, iron and copper production. Sulfur dioxide emissions are a primary contributor to acid rain and have been regulated by every industrialized nation in the world.

FGD processes vary depending on the amount of SO2 involved, the solution being used to absorb the SO2, and the particular equipment used in the absorption tower.

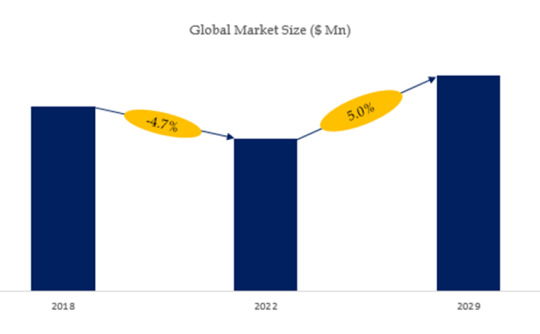

According to the new market research report “Global Flue Gas Desulfurizer (FGD) Market Report 2023-2029”, published by QYResearch, the global Flue Gas Desulfurizer (FGD) market size is projected to reach USD 6.29 billion by 2029, at a CAGR of 5.0% during the forecast period.

Figure. Global Flue Gas Desulfurizer (FGD) Market Size (US$ Million), 2018-2029

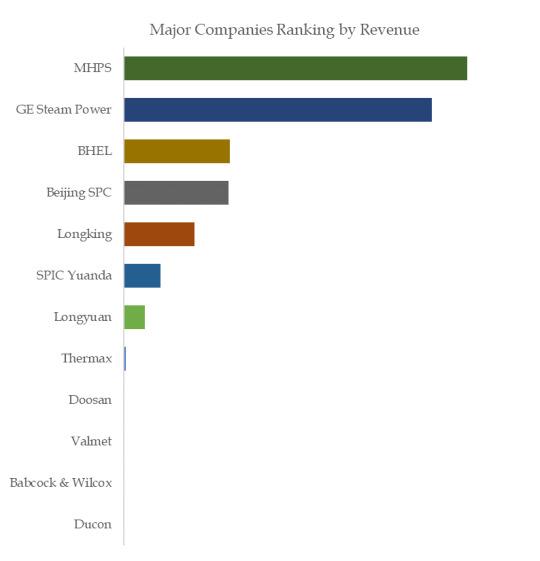

Figure. Global Flue Gas Desulfurizer (FGD) Top 12 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Flue Gas Desulfurizer (FGD) include MHPS, GE Steam Power, BHEL, Beijing SPC, Longking, SPIC Yuanda, Longyuan, Thermax, Ducon, Babcock & Wilcox, etc. In 2020, the global top five players had a share approximately 77.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Global Flue Gas Desulfurization Market Trends for 2023-2030

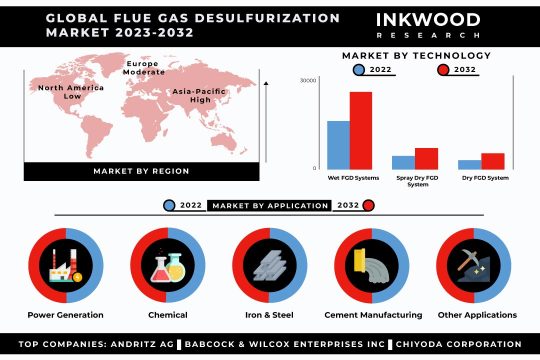

As per Triton Market Research, the Global Flue Gas Desulfurization Market report is segmented by Technology (Wet FGD Systems, Spray Dry FGD Systems, Dry FGD Systems), Application (Power Generation, Chemicals, Iron and Steel, Cement Manufacturing, Other Applications), and Regional Outlook (North America, Middle East and Africa, Asia-Pacific, Europe, Latin America).

The report highlights the Market Summary, Industry Outlook, Impact Analysis, Porter’s Five Forces Analysis, Market Maturity Analysis, Regulatory Framework, Key Market Strategies, Market Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology & Scope, Global Market Size, Forecasts & Analysis (2023-2030).

As per Triton’s research report, the global market for flue gas desulphurization is anticipated to progress with a CAGR of 4.93% over the forecasting years 2023-2030.

Flue gas desulfurization is a process to extract sulfur dioxide from the fossil fuel emissions of power plants. It has multiple applications across the coal, chemical, iron, and steel industries.

In order to curb the hazardous effects of sulfur dioxide on the environment and human health, industries are focused on reducing the sulfur content from emissions by adopting flue gas desulfurization systems. Additionally, the strict emission norms by the regulatory authorities to maintain clean air, improve air quality, and reduce degradation have the potential to drive demand for FGD systems. Industries also have an alternative to adopt tailored FGD solutions to cater to their specific needs.

However, slowdown in industrial activities, a reduction in industrial operations, a decline in investments, and slow production are some impacts during economic slowdown. Along with this, an inclination towards renewable energy hinders the growth of flue gas desulfurization market.

Asia-Pacific is anticipated to witness the fastest growth in the flue gas desulfurization market. Surrounded by developing countries, this region has tremendous scope to expand its industrial landscape to cater to economic needs. An increasing number of industries pose a threat to the environment. In this regard, installing FGD systems will become a top priority for the new industries. Thus, it will create a huge demand for the studied market in the coming years. However, the rise of renewable energy has a significant scope to challenge the market as countries slowly move towards achieving a green economy.

The major competitive companies in the flue gas desulfurization market are Babcock & Amp, Chiyoda Corporation Doosan Lentjes GmbH, Fujian Longking Co Ltd, Andritz AG, Hamon Group, Thermax Ltd, Rafako SA, Mitsubishi Hitachi Power Systems Ltd, Harsulex Environmental Technologies, Flsmidth AS, John Wood Group Plc, Ducon Technologies Inc, Kawasaki Heavy Industries Ltd, Willcox Enterprises Inc, and Ducon Technologies Inc.

The technical complexity and lack of specialized knowledge to design and manufacture FGD systems are potential barriers to the new market players. Companies are encouraged to go for Zero Liquid Discharge (ZLD) using other alternatives to mitigate sulfur dioxide emissions, which pose a significant threat to the FGD market. Technological advancements and new solutions prompt companies to have a competitive edge and stay ahead in terms of environmental compliance.

#fluegasdesulfurizationmarket#fluegas#desulfurization#ENVIRONMENT#ENVIRONMENTSERVICES#tritonmarketresearch#marketresearchreports

0 notes

Text

How is Puretech Hydro-Cavitation Desulfurization Plant?

PurePath Technology also manufactures hydro cavitation desulfurization plants. These plants use a hydro cavitation process to remove sulfur from petroleum products. Hydro cavitation is a process that uses the high-energy shockwaves generated by cavitation bubbles to break down sulfur-containing compounds.

PurePath's hydro cavitation desulfurization plants can be used to desulfurize a variety of petroleum products, including diesel fuel, gasoline, jet fuel, and kerosene. The plants can also be used to desulfurize waste oils and other petroleum byproducts.

The PurePath hydro cavitation desulfurization process begins with the mixing of the petroleum product with a desulfuring reagent. The desulfuring reagent helps to activate the cavitation bubbles and to enhance the desulfurization process. The mixed product is then pumped through a hydro cavitation reactor. The reactor contains a series of impellers that create the high-energy shockwaves that break down the sulfur-containing compounds.

The desulfurized product is then separated from the desulfuring reagent and recycled. The desulfuring reagent can be used multiple times before it needs to be replaced.

PurePath's hydro cavitation desulfurization plants are designed to be energy-efficient and environmentally friendly. The plants use a closed-loop system to recycle the desulfuring reagent and heat that are generated during the desulfurization process. This helps to reduce the environmental impact of the desulfurization process.

PurePath's hydro cavitation desulfurization plants are used by a variety of businesses, including oil and gas companies, refineries, and petrochemical companies. The plants help these businesses to comply with government regulations and to produce cleaner petroleum products.

Here are some of the benefits of using PurePath's hydro cavitation desulfurization plants:

Reduces sulfur content: PurePath's plants can remove up to 99% of the sulfur from petroleum products. This helps to meet government regulations and to produce cleaner fuels.

Improves fuel quality: Desulfurized fuels burn cleaner and produce fewer emissions. This can help to improve air quality and reduce greenhouse gas emissions.

Extends engine life: Desulfurized fuels are less corrosive than fuels with high sulfur content. This can help to extend the life of engines and other equipment.

Saves money: Desulfurized fuels can save businesses money on maintenance and fuel costs.

Overall, PurePath's hydro cavitation desulfurization plants are a valuable tool for businesses that want to comply with government regulations, produce cleaner fuels, and save money.

0 notes

Text

Rising Prevalence of Airborne Diseases Contribute to Global Flue Gas Desulfurization Market Growth

As per Inkwood Research, the Global Flue Gas Desulfurization Market is expected to record a CAGR of 4.90% in terms of revenue during 2023-2032.

“Browse 43 Market Data Tables and 43 Figures spread over 211 Pages, along with an in-depth TOC on the Global Flue Gas Desulfurization Market Forecast 2023-2032.”

VIEW TABLE OF CONTENT LINK - https://inkwoodresearch.com/reports/flue-gas-desulfurization-market/#table-of-contents

FGD systems were created in response to the release of exhaust, or flue gases, from primarily coal-burning power plants, which presented significant environmental and public health risks. Various techniques can be used to eliminate S02 from flue gases. In the case of a standard coal-fired power plant, FGD systems are capable of eliminating 95% of the SO2 found in the flue gases. FGD predominantly utilizes two approaches for filtering emissions (dry or wet scrubbing) to ensure that coal-burning plants conform to the regulations established by the EPA's Effluent Limitation Guidelines (ELG).

REQUEST FREE SAMPLE LINK – https://inkwoodresearch.com/reports/flue-gas-desulfurization-market/#request-free-sample

Rising Prevalence of Airborne Diseases Boosts Market Growth

The increasing demand for Flue Gas Desulfurization (FGD) technologies is significantly driven by the growing concerns in the realm of public health regarding airborne diseases. Airborne diseases pose a grave threat to public well-being, with their severity often heightened by pollutants like sulfur dioxide (SO2) emanating from industrial and power generation sources. Sulfur dioxide stands as a critical element of air pollution and is notorious for exacerbating respiratory issues, triggering asthma attacks, and causing various other respiratory ailments.

Exposure to elevated levels of sulfur dioxide can result in irritation of the respiratory tract, manifesting in symptoms such as coughing, breathlessness, and wheezing. This aggravates the condition of individuals already grappling with respiratory problems like asthma or chronic bronchitis. Furthermore, prolonged exposure to sulfur dioxide can lead to a decrease in lung function, especially in children, rendering them more susceptible to respiratory infections and diseases.

Power Generation: Prominent Application in terms of Revenue and Volume

Flue-gas desulfurization (FGD) systems have been in use since the late 1960s to reduce the release of sulfur dioxide (SO2) from coal-fired power plants. Among the coal combustion products (CCPs), the solids generated by FGD systems rank as the second-largest in terms of volume, with fly ash being the only stream that surpasses it. This chapter delves into the description of the various types of FGD systems currently in operation and the solid byproducts they generate.

To mitigate the negative environmental impact of sulfur oxides (SO2 and SO3), many power plants and industrial facilities employ flue-gas desulfurization (FGD) scrubbers to eliminate these compounds from combustion gases. The conditions within a scrubber and related installations are extremely harsh, cumulative, and result in corrosion issues for conventional engineering materials. Such failures pose long-term environmental threats.

Asia-Pacific: Prominent Region in terms of Revenue and Volume

Governments across the Asia-Pacific region have introduced stringent emission regulations to combat air pollution and improve air quality. FGD systems help industries and power plants meet these standards by removing harmful sulfur emissions. Also, coal remains a dominant energy source in Asia-Pacific, especially in countries like China and India. FGD systems are widely adopted in coal-fired power plants to reduce sulfur emissions, and this trend is expected to persist.

The ever-changing regulatory environment and the ongoing requirement to adhere to evolving emission standards continue to heighten competition, driving companies to allocate resources towards research and development in order to sustain their competitive advantage. Some of the leading companies in the market include Thermax Ltd, Doosan Lentjes GmbH, General Electric Company, Mitsubishi Hitachi Power Systems Ltd, etc.

Request for Customization: https://inkwoodresearch.com/request-for-custom-report/

About Inkwood Research

Inkwood Research specializes in syndicated & customized research reports and consulting services. Market intelligence studies with relevant fact-based research are customized across industry verticals such as technology, automotive, chemicals, materials, healthcare, and energy, with an objective comprehension that acknowledges the business environments. Our geographical analysis comprises North & South America, CEE, CIS, the Middle East, Europe, Asia, and Africa.

#fluegasdesulfurizationmarket#fluegas#desulfurization#ENVIRONMENT#ENVIRONMENTSERVICES#inkwoodresearch#marketresearchreports

0 notes

Text

Flue Gas Desulfurization Plant Manufacturer Supplier in Gujarat, India

Airpoll Technologies | Flue Gas Desulfurization (FGD) Plant | Manufacturer in Gujarat, India

What is flue gas desulfurization process?

Flue gas desulfurization, a procedure, removes sulphur compounds from the exhaust emissions of fossil-fueled power plants. To do this, absorbents are added, which can remove up to 95% of the sulphide from the flue gas.

How does Flue Gas Desulfurization Works ?

The basis of the FGD technology is the chemical reaction that happens when limestone and warm exhaust gases from a coal-fired boiler come into contact. With this reaction, In addition to converting the limestone into calcium sulphite, it also eliminates 92% of the sulphur dioxide in the flue gas. Actually, an absorber tower receives the flue gas by forcing it via the FGD ductwork after being forced into it by a booster fan from the boiler.

Because of our strict environmental regulations, E.ON does not use limestone from national parks. A mixture of limestone slurry inside the absorber tower then comes into touch with the gas. Slurry is sprayed from banks of nozzles positioned at the top of the tower.

Sulphur dioxide (SO2) present in the hot gas and the limestone slurry interact chemically when they come into contact. During this reaction, the limestone is changed into calcium sulphite, and SO2 is also removed from the flue gases. When compressed air is supplied, this calcium sulphite and limestone slurry sinks to the base of the absorber. The oxidation of compressed air changes calcium sulphite into calcium sulphate, which is frequently referred to as gypsum.

Email : [email protected]

Phone : +91-9712942756

#Flue Gas Desulfurization#Flue Gas Desulfurization plant#FGD Plant Manufacturer in gujarat#FGD Plant

0 notes

Text

The FGD systems market is projected to grow from USD 19.3 billion in 2021 to USD 24.9 billion by 2026, at a CAGR of 5.2% from 2021 to 2026. The FGD systems market has been witnessing consistent growth owing to the increasing concerns regarding environmental pollution, growing prevalence of airborne diseases, and enforcement of environmental laws & regulations. The rise in demand for FGD systems from the power generation, chemical, iron & steel, and cement & manufacturing industries is expected to drive the market globally. Stringent environmental regulations focused on the control of excessive industrial sulfur dioxide emissions are further expected to drive the growth of the market during the forecast period.

0 notes

Text

Researchers find unprecedented deep oxidative desulfurization with precisely designed Ti sites

In a study published in the journal National Science Review, a material synthesized by Dr. Shen Yu was used to introduce hydroperoxide into the synthesis system of titanium silicates.

At first, he treated this material as a reference sample for another project and conducted catalytic oxidative desulfurization tests on this catalyst. Accidently, he found that this catalyst completely removed all thiophenic sulfurs in minutes, much more efficient than all the rest catalysts.

"I almost convinced myself that there may be something wrong with my operations" Dr. Yu says.

Read more.

11 notes

·

View notes

Text

Profile

1989,FGX-1 dry coal separator is designed initially by DIRO for dry coal separation & coal de-shaling;

1992, FX-12 dry coal preparation is developed on basis of Russia CII-12 air table separator,separating efficiency is upto 92%,Erro Possible: 0.1-0.20 ;

After 33 years developing, FGX & FX dry coal beneficiation tech is upgraded into 6th generation in 2024, being the most reliable & intelligent dry coal separation tech in dry coal processing industry,which is widely installed in coal mines & power plants in Mongolia,Poland,Russia,Ukrain,Turkey,Tunish,Vietnam,South Africa,Brazil etc.That ash rejection, desulfurization, de-watering, and coal preparation are all what we can address.

Application: thermal coal beneficiation, coking pre-deshaling, coal preparation;

Advantages: Saving Water costs, transportation cost & processing cost.

Please click our website for more information,whatsapp:+8613730503881

#dry air separator#dry air sorting#dry coal cleaning#dry coal preparation#dry coal processing#dry coal separation#dry air vibrating separator#dry coal separator#dry coal washing#fgx dry coal separafor#fgx dry coal separator#dry coal sorting#coal beneficiation#coal mine#coal#coalwashery#coal peocessing#tangshan diro technology#diro#fgxseptech#intelligent dry coal separator

2 notes

·

View notes

Text

Sodium Molybdate as a Catalyst in Chemical Reactions: Driving Innovation in Chemistry

Within the realm of chemistry, catalysts play a crucial role as inconspicuous protagonists, discreetly expediting chemical reactions and facilitating the advancement of innovative procedures and commodities. Sodium Molybdate, a highly adaptable chemical molecule, has emerged as a pivotal catalyst, fostering advancements across diverse industries. This article examines the importance of Sodium Molybdate, its involvement in catalytic processes, and the contributions made by Palvi Chemicals - one of the excellent Molybdenum chemicals manufacturers in India, and Sodium Molybdate exporter in UAE towards its worldwide influence.

· The Power of Catalysts:

Catalysts are chemical substances that enhance the rate of chemical reactions by reducing the energy required for activation, hence promoting faster and more efficient reaction processes. They facilitate the production of necessary goods while minimising the generation of excess materials.

· Sodium Molybdate: A Versatile Catalyst:

Sodium Molybdate, chemically represented as Na2MoO4, is classified as a sodium compound derived from molybdic acid. This compound is notable for its inclusion of molybdenum, a transition metal. The indispensability of this substance in numerous chemical processes can be attributed to its versatile nature as a catalyst.

· One of the Top Molybdenum Chemicals Manufacturers in India:

India has established itself as a prominent producer of molybdenum compounds, notably Sodium Molybdate. The primary objective of these producers is to produce chemicals of superior quality in order to cater to the varied requirements of businesses on a global scale.

· Trusted Sodium Molybdate Manufacturer in India:

The production of Sodium Molybdate in India necessitates meticulousness and compliance with global benchmarks. The manufacturers inside the nation are widely recognised for their steadfast dedication to producing high-quality products and driving innovation.

· Prominent Sodium Molybdate Exporter in UAE:

The export of Sodium Molybdate and other chemicals is of significant importance in the United Arab Emirates (UAE), which functions as a crucial centre for such activities. Exporters headquartered in the United Arab Emirates (UAE) play a vital role in facilitating the worldwide dissemination of this indispensable catalyst.

· One of the Leading Sodium Molybdate Traders in UAE:

The United Arab Emirates (UAE) is home to a network of traders who play a crucial role in the distribution of Sodium Molybdate. These traders serve as intermediaries, effectively managing the supply chain by connecting manufacturers of Sodium Molybdate with clients located worldwide. The critical nature of their position in the worldwide trade of chemicals cannot be overstated.

· A Distinct Sodium Molybdate Supplier in UAE:

Suppliers operating within the United Arab Emirates (UAE) take measures to ensure the widespread availability of Sodium Molybdate to industries on a global scale. The catalyst's reliability and efficiency play a significant role in facilitating a smooth flow of this catalyst across the global market.

· Applications of Sodium Molybdate:

Sodium Molybdate exhibits a wide range of applications across many industries, encompassing agriculture, metallurgy, and the manufacturing of chemicals and pharmaceuticals. The wide range of processes in which it is utilised highlights its indispensability, owing to its remarkable versatility.

· Catalytic Functions:

Sodium Molybdate serves as a catalyst in a wide range of chemical reactions, including oxidation, desulfurization, and nitrogen fixation. The capacity of this substance to augment reaction rates and selectivity has significant value in several industrial processes.

· Driving Innovation:

The catalytic properties exhibited by Sodium Molybdate play a pivotal role in driving innovation within the fields of chemistry and industry. The significance of this technology in enhancing the effectiveness of chemical processes, mitigating environmental consequences, and facilitating the advancement of novel materials highlights its paramountcy in contemporary society.

Final Thoughts:

Sodium Molybdate exported by a noteworthy Sodium Molybdate supplier in UAE serves as a testament to the significant influence that catalysts exert on the domains of chemistry and industry. Due to its multifunctionality and exceptional catalytic abilities, this phenomenon stimulates the development of novel ideas and facilitates progress across several industries. The collaborative endeavours of Indian manufacturers and UAE exporters, suppliers, and merchants contribute to the widespread accessibility of Sodium Molybdate in global businesses, hence facilitating advancements in the field of chemistry and beyond. As the boundaries of scientific inquiry and industrial progress are further expanded, the catalytic properties of Sodium Molybdate continue to be of utmost importance, serving as a critical driver towards a future characterised by enhanced efficiency and sustainability.

#Molybdenum chemicals manufacturers in India#Sodium Molybdate exporter in UAE#chemical#manufacturer#exporter

7 notes

·

View notes

Text

Before flue-gas desulfurization was installed, the air-polluting emissions from this power plant in New Mexico contained excessive amounts of sulfur dioxide.

5 notes

·

View notes

Text

Food-Grade Stainless Steel Tanks by Center Enamel: The Ultimate Storage Solution for the Food and Beverage Industry

When it comes to food and beverage storage, maintaining the highest standards of hygiene, safety, and quality is critical. Center Enamel, a leading manufacturer of storage solutions, offers food-grade stainless steel tanks specifically designed to meet the stringent requirements of the food and beverage industry. With decades of experience, Shijiazhuang Zhengzhong Technology Co., Ltd. is committed to delivering high-performance, reliable tanks that ensure product integrity and compliance with global food safety standards.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Food-Grade Stainless Steel Tanks?

Stainless steel is the material of choice for food-grade storage tanks due to its unmatched durability, corrosion resistance, and ability to maintain cleanliness. Center Enamel's food-grade stainless steel tanks offer numerous advantages:

Hygienic and Easy to Clean

Stainless steel is non-porous, which means it does not harbor bacteria, making it easy to clean and sanitize. This is crucial for the food and beverage industry, where contamination can compromise product safety and quality.

Corrosion Resistance

Our food-grade stainless steel tanks are made from high-quality 304 and 316L stainless steel, known for their excellent resistance to corrosion from acidic and alkaline substances. This ensures a long-lasting storage solution that protects the purity of food and beverage products.

Safe Material Composition

Stainless steel is inherently food-safe, with no risk of leaching harmful chemicals into the stored products. Our tanks are built to comply with NSF/ANSI standards, ensuring that they meet global food safety regulations.

Durability and Longevity

The robust construction of stainless steel ensures that our tanks can withstand extreme temperatures, pressures, and environmental conditions, providing reliable performance for years.

Applications of Food-Grade Stainless Steel Tanks

Center Enamel’s stainless steel tanks are suitable for a wide range of applications in the food and beverage industry, including:

Dairy Products

Our tanks are ideal for storing milk, yogurt, and other dairy products, ensuring they remain fresh and uncontaminated.

Beverages

Whether it’s juice, soft drinks, or alcoholic beverages, our stainless steel tanks provide a safe and hygienic storage solution.

Edible Oils

The non-reactive nature of stainless steel makes it perfect for storing cooking oils, preserving their quality and flavor.

Sauces and Condiments

Stainless steel tanks can store sauces, vinegar, and condiments without the risk of corrosion or contamination.

Customizable Design and Capacity

At Center Enamel, we understand that every operation has unique requirements. That’s why we offer a variety of customizable options for our food-grade stainless steel tanks, including:

Tank Size and Capacity: Whether you need a small storage tank or a large vessel, we can design tanks to meet your specific volume requirements.

Mixing and Agitation Systems: For industries requiring constant movement or mixing of liquids, we can incorporate agitators and mixing systems into our tanks.

Insulation: We offer insulation options to maintain precise temperature control for temperature-sensitive products.

Center Enamel: A Trusted Leader in Food-Grade Stainless Steel Tanks

With over 30 years of experience in manufacturing high-quality storage solutions, Center Enamel is a trusted supplier of food-grade stainless steel tanks to the global food and beverage industry. Our tanks are designed to meet the most stringent industry standards, providing our clients with peace of mind knowing their products are stored safely and securely.

We pride ourselves on our ability to customize our tanks to meet the specific needs of each client, ensuring that they receive the ideal solution for their food and beverage storage needs.

For companies in the food and beverage industry, ensuring that storage tanks meet the highest standards of hygiene, safety, and durability is crucial. Center Enamel’s food-grade stainless steel tanks provide an ideal solution, offering corrosion resistance, ease of cleaning, and compliance with international food safety standards. Whether you need a tank for dairy, beverages, oils, or sauces, our stainless steel tanks are designed to maintain the integrity of your products.

Choose Center Enamel for your next food-grade stainless steel tank project and experience unmatched quality and performance. Contact us today to learn more about our storage solutions and how we can help meet your specific needs.

0 notes

Text

The Nitto HYDRAUTICS Heidelberg PRO-LF1 membrane can be used to treat desulfurization wastewater from power plants, concentrating and reducing high salt concentration water for evaporation and crystallization, achieving zero discharge of wastewater.

0 notes

Text

Applications of Iron Oxide Desulfurization Technology

Applications of Iron Oxide Desulfurization Technology

Iron oxide desulfurization is quite possibly the most reliable method of desulfurization of fuel gases and liquids. In this particular article, we examine the use of Iron oxide desulfurization technology in various processes focusing on how it assists in limitation of emissions while improving process efficiency.Most of the benefitsSustainable fire pollution control will aid in controlling works and most of the benefits.Get more news about Iron oxide desulfurization,you can vist our website!

There are several environmental benefits The main advantage of iron oxide desulfurization technology is that it makes it possible to cut down the sulfur dioxide emissions levels substantially. SULFUR is primarily found in fossil fuels and when they are burnt sulfur dioxide (SO2) associated with acid rain and air pollution is formed. It instead employs Iron Oxide Desulfurization technology to cut down these effects in the environment in turn improving the measures geared towards solving climate change and deprivation of air.

Process efficiency

The pollutant, sulfur, is toxic to catalysts, used for instance in refining processes, and chemical processes as catalytic converters in the oil industry. The removal of sulfur from a substance using iron oxide desulphurization guarantees high integrity and long service of the catalysts used when processing the substance.

Versatility across industries

Iron oxide desulfurization has applications in different industrial sectors like oil refining, gas processing, and also in new energy storage systems. Furthermore, in these new technologies, iron oxide desulfurization will be important in removing any contaminants that would impair the performance of the solid oxide fuel cell.

Research and development

The improvement of Iron Oxide Desulfurization technology is mainly concentrated on increasing its desulfurization efficiency, improving its regeneration efficiency, and more ingestion of this technology into other de-sulfurization techniques to enhance the degree of desulfurization. Our Yihang are in the cutting edge of these developments by enhancing the development of more advanced and environmentally friendly Iron Oxide Desulfurization.

0 notes