#digital voltage converter

Text

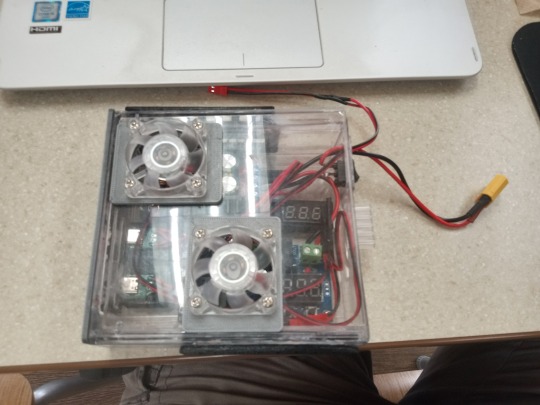

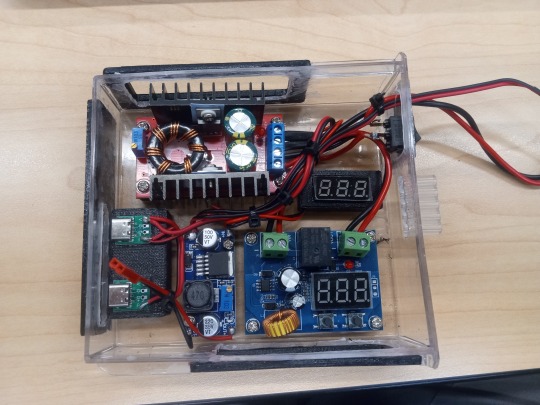

#DC power supplies#this is my first time on this site and this will be my first post I have constructed a DC power supply to charge my laptops by using 150W#to limit the amount of power to what's appropriate to charge the laptop#I also use 0.28 Inch Two-Wire Voltage Meter Micro LED Digital Tube Voltmeter. to allow me to know how much power is coming out of the suppl#40mmx40mmx10mm 2PIN to cool down the DC Boost Converter & the#DC Voltage Protection Module Digital Low Voltage PrLM2596S DC-DC 3A Buck Adjustable Step-down Power Supply Converter Module just otector Di#and also have to design and 3D printed the parts to make everything work properly then I tested this device out and it works perfectly wel#all it all you have to do is to adjusted down to 12v or as much as you charger can handle at this point I got mostly these parts from Ama

0 notes

Text

I’m curious how binary cant work for admech since day 1. At first, I thought it’s just high speed alternation in frequencies of sounds to denote 0 and 1, just like how computer cable does with voltage. So I wrote a python script to convert natural language to binary code then to sound based on the idea (so that I can curse in binary in ttrpg). However, since the human auditory cortex can only distinguish sound about 20ms apart, the current commonly used binary coding method (Unicode) that requires 8 bits to encode for one letter (16 bits for one character in Mandarin) would make binary cant less efficient than natural language through the bare ear. As a result, binary cant users not only need vocal implants but also auditory implants to receive info (or perhaps cortex implants to decode). Based on these assumptions, binary cant would be able to happen in sound frequencies not perceivable by the original human cochlea so techpriests conversation can be extremely quiet. And more efficiently, just through data cables.

Or it could be the other way around, scientists might develop more efficient binary language without basing it on the symbol system of natural languages (I’m not that familiar with linguistics so I don’t know if this is possible or not).

However, the sound techpriests made in the game mechanicus doesn’t sound like my assumption. There are definitely more than 2 pitches used in the conversations (which makes it less binary...) and they seem to be faster than natural language. I still couldn’t figure out what’s happening here. Do the twisting pitches actually encode more than one bit? Is binary cant actually an analog signal encoding a digital signal? Or is the sound effect just mean to sound better for the game?

The binary curse program (turn the sound on!):

#warhammer 40k#adeptus mechanicus#binary cant#question#I should think about my BDNF & depression paper now but#each time I have a paper due I start to think about every irrelevant thing

1K notes

·

View notes

Text

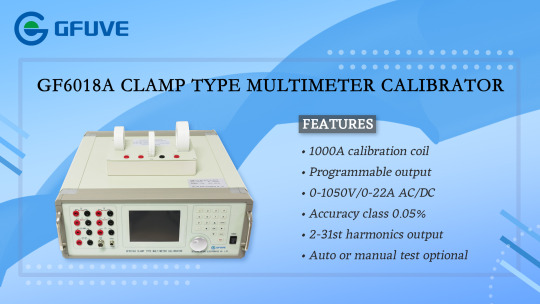

GF6018A High precisition 6.5bit portable AC DC multi product calibrator for multimeter calibrator

This GF6018A high precision multi-product calibrator is compliance with national verification regulation: JJG124-2005 Ammeter, voltmeter, power meter and resistance meter verification rules" and related national standards. 0.05% single-phase standard AC/DC voltage and current source, can verify level 0.2 and the following AC/DC voltmeter, ammeter, frequency meter, resistance meter & clamp meter. The source signals by using DSP and 16-bit high-speed A/D converters of controllable sine wave, the distorted wave signal source. Multifunction calibrator GF6018A is designed as universal calibration tool for electrical calibration laboratories. Measurement range from 0-1050V and 0-20A AC/DC;With 200A, 600A, 1000A calibration coil.

The GF6018A clamp type multimeter calibrator with RS-232 port, it can be connected with PC to control, become automatic verification system. It has precise interface and multi-functions including verification, storage and query. The GF6018A multimeter calibrator adopts color LCD screen, chart character display is clear, with high precision, stable and reliable, convenient operation and flexible characteristics. It fully meets ISO17025 laboratory standards and is a good ideal test equipment for electrical engineers.

APPLICATION

■ Power plant;

■ Universities;

■ Panel manufacturer;

■ Research institutes;

■ Electrical testing center;

■ Multimeter manufacturers;

■ Oscilloscope manufacturer;

■ Clamp meter manufacturers;

■ Digital meter manufacturers;

■ ISO17025 Electrical laboratory;

■ Electricity power bureau & power company;

■ Power engineering commissioning company;

■ Electrical Department of industrial and mining enterprises;

2 notes

·

View notes

Text

Custom Clock Inserts

Quartz Clock Movements Open Your Vistas

Quartz clock movements are the modern-day electronic matching of conventional, mechanical control centers for timekeeping. However quartz clock movements (likewise referred to as clock electric motors) have no springs, weights, wheels, or gears to track time; instead, the quartz crystal generates a stream of pulses that are extremely fast and extremely steady, meaning that checking and subdividing the pulses provides an exact step of elapsed time. Let us see how these marvelous tools can open up a brand-new globe to you.

Non-quartz clock movements run mechanically, utilizing rotational force to turn a flywheel and a collection of equipments to determine specific time units (i.e., secs). Without regulation, the flywheel would certainly spin also quick, which is where pendulums and escapement systems can be found in. The pendulum is limited to turn one extent in half a second, and the gear network converts the oscillation right into secs, minute, and hours.

Modern electronic motors work identically-- at the very least to the onlooker-- although a completely different method is utilized to obtain the exact same outcomes. The first thing one requires to comprehend is that quartz crystals normally vibrate at their resonating regularities when a voltage decrease is related to them. Next, one must realize that the entire point of clocks is to track elapsed time (resetting every 12 or 24 hr), which whether this is done mechanically or electronically is a non-issue.

Nonetheless, the electronic strategy has lots of advantages that exceed just removing the bulk of flywheels, weights, and gears. Electronic motors in essence digitize the entire process, transforming what made use of to be performed in hardware into software program. This gives them a lot better adaptability and adaptability than their mechanical equivalents, and actually they can carry out essentially whatever functionality can be thought up due to the fact that shows has no hardware restraints.

As an example, suppose we intend to extend the resetting time, or the duration at which whatever wraps around to where it began? Twelve hours and twenty-four hours are prominent alternatives, but there's absolutely nothing preventing one from going a full week, and even a month!

Naturally, there's no factor implementing such time expansions if you couldn't reveal them, implying particularly adjusted dials and potentially an additional hand. For the once a week period, the days are printed in the center of the dial and the (short) extra hand leaps to the next day every 24 hr. In a similar way, for once-a-month durations, dates of the month are published along the dial's circumference and a lengthy hand ticks to the following once a day.

A neat option "clock" movement that you can obtain monitors tide level. The only actual distinction is going from a solar cycle to the lunar cycle, which is 24 hr and 50 mins. The motion has to be initialized and calibrated for neighborhood problems, but once this is done the tide degree will certainly always be accurate.

The tide-level motion (which can be combined with common timekeeping to display time and trend on one face), is a kind of lead-in to movements that depart from periodicity. Right here, the thing revealed is a weather phenomenon, such as moisture or temperature, and the single hand revolves between two extremes of a scale. Sensors are made use of to discover present worths, and the electric motor converts the value into hand position.

The astute viewers will certainly understand that we are no longer in the world of quartz movements, as there is no reason to track elapsed time. But the digital quartz innovation has freed up the imagination to assume in regards to software instead of hardware. clock parts

A fascinating by-product of all this is that there is a market for clocks and attributes of the past, such as grandfather clocks with oscillating pendulums. The digital movements can suit such needs via simulation, even though pendulums are no more working components; this is particularly valuable for clockmakers that want to bring back an old, non-functioning heirloom. Obviously, quartz clock movements open your panoramas.

youtube

2 notes

·

View notes

Text

Allen Bradley Analog Input Modules 1734-IE2C & 1734-IE2V

youtube

Allen Bradley Analog Input Module is an electronic device used in industrial automation, data acquisition, and control systems to interface analog signals from the physical world to digital systems for processing, monitoring, and analysis. These modules play a crucial role in converting continuous analog signals, such as voltage or current levels, into discrete digital values that can be easily processed by microcontrollers, programmable logic controllers (PLCs), computers, or other digital devices.

Show on more :- https://youtu.be/it9_cN-eEs8?si=HSdS2r2TDsJaFG9g

🌐Website :- https://asteamtechno.com

👉Contact us :- +919537840404

📧Email :- [email protected]

#tumblr trends#automation#viralpost#viral#trendingnow#bestdeals#allen bradley#trending#plc#rockwell automation#Youtube

2 notes

·

View notes

Text

Closer Look at 400G QSFP-DD Optical Transceiver Module

Recent years have seen the evolution towards the 5G, Internet of Things (IoT), and cloud computing, increasing pressure on data centers to ramp up both network capacity to 400G and driving providers to search for new solutions to achieve their 400G Data Center Interconnects (DCIs). 400G QSFP-DD optical transceiver module is becoming one of the most popular cutting-edge 400G DCI solutions. This article will provide a basic understanding of QSFP-DD optical transceiver modules.

What is the QSFP-DD Optical Transceiver Module?

Quad small form-factor pluggable-double density (QSFP-DD) is designed with eight lanes that operate at up to 25 Gbps via NRZ modulation or 50 Gbps via PAM4 modulation. It supports data rates of 200 Gbps or 400 Gbps and doubles the density. QSFP-DD is backward compatible with current 40G and 100G QSFPs. It is compliant with IEEE802.3bs and QSFP-DD MSA standards. QSFP-DD is available in single-mode (SM) and multi-mode (MM) fiber optic cables and includes digital diagnostics monitoring (DDM) to monitor parameters such as power, temperature, and voltage.

Types of 400G QSFP-DD Optical Transceiver Module

400G SR8 QSFP-DD

400G SR8 QSFP-DD optical transceiver module is suitable for short-distance interconnection or multi-channel data communication. The transmission rate is up to 425Gbps, and the central wavelength is 850nm. The transmission distance is up to 70m or 100m through multi-mode OM3 and OM4 fiber.

400G DR4 QSFP-DD

400G DR4 QSFP-DD optical transceiver module achieves the transmission over single-mode fiber (SMF) with an MPO-12 connector. It supports a max transmission distance of 500m on SMF.

400G FR4 QSFP-DD

400G FR4 QSFP-DD optical transceiver module supports link lengths of up to 2km SMF with a duplex LC connector. It uses wavelength division multiplexing(CWDM ) technology, eight channels of 53Gbps PAM4 signals on the electrical side, and four channels of 106Gbps PAM4 signals on the optical side, which is twice the rate of the electrical side.

400G LR4 QSFP-DD

400G LR4 QSFP-DD optical transceiver module is designed with a built-in Gearbox chip that multiplexes the two channels' electrical input data into a single-channel outputs signal and then modulates it to the optical receiver end. The digital signal processor (DSP) basis gearbox converts eight channels of 25GBaud PAM4 signals into four channels of 50GBaud (PAM4) over an SMF cable with duplex LC connectors. It supports a transmission distance of up to 10km.

400G LR8 QSFP-DD

The 400GBASE-LR8 optical transceiver module supports link lengths of up to 10km over a standard pair of G.652 SMF with duplex LC connectors.

400G ER8 QSFP-DD

The 400G ER8 QSFP-DD optical transceiver module supports link lengths of up to 40km over a standard pair of G.652 SMF with duplex LC connectors.

400G ER4 QSFP-DD

400G ER4 QSFP-DD optical transceiver module supports link lengths of up to 40km over a standard pair of G.652 SMF with duplex LC connectors. It has only four wavelengths for 4 LAN WDM channels 1295.56/1300.05/1304.58/1309.14nm.

Advantages of 400G QSFP-DD Optical Transceiver Module

Backward compatibility: Allowing the QSFP-DD to support existing QSFP modules (QSFP+, QSFP28, QSFP56, etc.). It provides flexibility for end-users and system designers.

Adopting the 2x1 stacked integrated cage/connector to support the one-high cage connector and two-high stack cage connector system.

SMT connector and 1xN cage design: Enable thermal support of at least 12W per module. The higher thermal reduces the requirement for heat dissipation capabilities of transceivers, thus reducing some unnecessary costs.

ASIC design: Supporting multiple interface rates and fully backward compatible with QSFP+ and QSFP28 modules, thus reducing port and equipment deployment costs.

Applications

400G QSFP-DD optical transceiver module is used in 400G Ethernet, data centers, telecommunications networks, cloud networks, Infiniband interconnects, high-performance computing networks, 5G, 4K video, IoT, etc.

Conclusion

400G QSFP-DD optical transceiver module offers high speed, performance, scalability, and low power in 400G Ethernet. Sun Telecom specializes in providing one-stop total fiber optic solutions for all fiber optic application industries worldwide. Contact us if any needs.

2 notes

·

View notes

Text

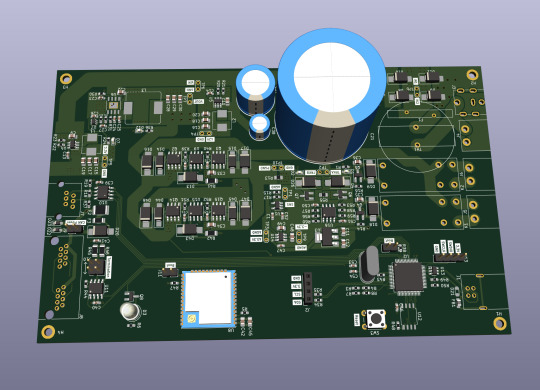

Let me introduce my current main WIP. It's not fandom related, it's for my model railroad, and it's not yet finished.

This is a rendering of a circuit board that I'm designing at the moment. It will be a DCC command station. My model railroad is run digitally, which means the tracks carry digital signals that tell each locomotive and switch individually how to run, which lights to turn and so on. The command station is the device that generates that. I have a number of different layouts, one of which has a good command station, one of which has a crappy old one, and the final one isn't even digital yet. So this will be the one that solves all issues for me, hopefully.

The design above isn't finished yet, and even the parts that are are not yet fully representative. The different capacitors are just there as options; some screen print overlaps; and some components (in particular all plugs and the relays that control the programming track) don't have 3D models so they don't show up.

Planned features:

Four layer board

10-25 V DC output, software controllable

Up to 5A output power, limited mainly by the main switching regulator.

Input 15-25V either AC or DC with polarity protection, selectable with some solder bridges (not yet in there). Optionally you can also bypass the main power regulator with another solder bridge (that I haven't added yet); useful in case you use e.g. a laptop power supply with a switchable voltage and don't need any regulation after that.

Railcom support

USB connection; not yet sure what for, but the main chip I'm using has USB support and I have some spare USB connectors here, so in it goes.

Speaking: The chip is an STM32L433RCT6P, chosen because I found it in stock at an electronics distributor. 64 kB RAM, 256 kB EEPROM, with support for an additional up to 256 MB externally (there's a spot for that on the board) and lots of fun extras that I don't technically need. It has an FPU! I don't need an FPU, but I will definitely do some floating point math computation on it just for fun.

Main external connection is WLAN using an ESP32 WROOM U module. I haven't decided on the housing, but I may go for extruded aluminum, so it's the U version that allows and requires an external antenna

It supports XBUS/XpressNet connections for old throttles from Lenz and Roco that I should probably throw away, but I paid good money for them, dang it.

It supports CAN for LCC / OpenLCB. I may not populate this part on all boards that I'm building, because I haven't actually decided whether I am interested. But the chip has CAN functionality built in, so why not.

There's an I2C connection to connect a cheap tiny OLED display for status messages.

Test points for all important signals (in particular the different internal voltage levels; yes, there is 3.3V, A3.3V and -3.3V and I need all of them).

Stuff still to add:

I will add pin headers (or space for pin headers anyway) for all the remaining pins on the STM32, and perhaps some on the ESP32, for future expansions.

Status LED and stop/go button on the front

Wire it all up, maybe move some stuff (mostly the STM32 around), which will cause all sorts of fun new routing issues.

Adjustments to make the jacks line up with the front panel once I've decided on a housing.

Features I'm not considering adding:

s88. I vaguely know what it is but I don't have any devices like that, and if that ever changed I could probably build (or perhaps buy) a converter that connects them via CAN.

Other buses like LocoNet.

Ethernet. I don't need it and it's actually more expensive than WLAN in this day and age.

In terms of software, I'm planning to use DCC-Ex on it. The whole project actually started out as a DCC-Ex shield, but once I realised that this wouldn't fit, I decided to make it standalone. Now, DCC-Ex is designed for Arduino, not STM32, and it doesn't support XpressNet, nor OpenLCB, nor Railcom, and their Wifi protocol is pretty weird and annoying which will be an issue (I'm planning to write my own control app for iPhone for it), so I'll probably change that or just replace it with the z21 one… so really, the software will not look a lot like DCC-Ex once I'm done with it.

Will this all work? I have honestly no idea. I mean, I'm fairly confident, I'd have given up on this long ago otherwise, but I have no guarantees either way until I've spent a lot of money on components and circuit boards and start soldering. Turns out doing it this way is not really cheaper than just buying a half-way decent one. That's what makes it exciting, though!

If it does work, obviously this will be released as open source. But it's still going to be a few days (more realistically weeks) before it's even ready to order the parts, and then a lot of soldering (current BOM stands at 194 actual components), and then a lot of software development before it's ready for that.

5 notes

·

View notes

Text

Thrift store find, and a project:

Got this Alesis QX25 MIDI controller in as-is condition for $12. The most obvious problems when I got it were that the fader cap and one rotary encoder knob were missing, and one of the black keys was broken. In addition, there were solfege stickers on the keys, implying the previous owner was pretty young; that impression was backed up when I opened it to find maybe half a container of assorted glitter inside.

The fader cap I haven't come up with yet, and I've put a temporary knob on the encoder — the one at the far right — and I was able to partially disassemble the keybed and glue the key back together. (I'm using Gorilla Glue's superglue formulation, which is supposed to be better than usual cyanoacrylates at bonding plastics; if this doesn't hold, I know where to order replacements.) From a quick once over, the current status is that some of the tact switches are broken somehow — the ones, at least, for octave up and transpose down don't work. I've only given those the most cursory inspection, so I don't know if it's the switches themselves or something in the wiring; I'll have to see if my big box of tact switches has anything I can swap in for them.

But the "project" part is the part that has me enthused. Unlike a lot of more recent MIDI controllers, this one has both a USB jack for connecting to a computer and a 5-pin DIN jack for traditional MIDI instruments. It's also got a lot of spare room inside the case. So I'm looking at taking an Arduino or a Teensy and some little digital-to-analog converters and adding the ability to output CV and gate signals for modular synthesizers. Basically the Arduino will listen to the MIDI signal and interpret that; the minimal feature set is a single note off channel 1, just the CV and gate corresponding to the most recently struck key, but may expand to multiple notes and/or handling the drum pads as their own gate/trigger outs, and probably an extra CV out that can follow the mod wheel or pitch bend.

I'm debating which DACs to use. I have some lying around — the spoils of a time when Linear, Analog Devices, and Maxim were separate companies, and they, Microchip, and Texas Instruments would give out free samples if you had a plausible-sounding company name — but a lot of them aren't particularly well-suited for this. I want to run everything off the existing 5V supply — either a wall wart or USB — and not need elaborate external analog circuits to do things. I'm looking at the MCP4811, a single-channel 10-bit device, which has the advantage of an internal voltage reference at 2.048V, and a ×2 output, for a full range of 0V-4.096V that's very reliable even when run off a unreliable 5V power supply, like the keyboard's USB power input.

(In an ideal world, I'd have a perfect 1v reference, and a precision adder, so that the full precision of the part, all the bits, could be applied to just the 0-1V range, and then I could add single volts as needed to specify the octave. If we're calling 0V C0, then with the 10-bit setup over the 4.096V spread, you have to use value 396 to get G1, and you're imperceptibly sharp; with ten bits over a single volt, you'd use value 597 and add an extra volt and you'd be... slightly closer but flat this time. So the ideal world can fuck itself, and I'll see how the thing I actually have works.)

2 notes

·

View notes

Text

Etekcity Food Kitchen Scale, Digital Grams and Ounces for Weight Loss, Baking, Cooking, Keto and Meal Prep, LCD Display, Medium, 304 Stainless Steel

About this itemAccurate Measurement: Weigh up to 5 kg/11 lb precisely in 1 g increments.Unit Conversion: Select your preferred units, oz/lb:oz/fl’oz/g/mL to follow recipes more conveniently. Power is provided by 2 AAA batteries (included), making the scale portable and ensuring that you can easily acquire replacement batteries.Tare Function: Use the tare function to remove container weight from the final measurement of your foodLCD Display: Easily read measurements on the backlit LCD displayQuality Material: Measure food, small items, and liquids with confidence on the 304 food-grade, stainless steel platformNote: Products with electrical plugs are designed for use in the US. Outlets and voltage differ internationally and this product may require an adapter or converter for use in your destination. Please check compatibility before purchasing.

2 notes

·

View notes

Text

How to adjust the speed of a geared stepper motor

1.A brief explanation of a geared stepper motor

A geared stepper motor is an electromechanical device that converts electrical pulses into discontinuous mechanical motion. It achieves precise position control by receiving digital control signals (electrical pulse signals) and converting them into corresponding angular displacements or linear displacements. The main feature of a geared stepper motor is that its output angular displacement or linear displacement is proportional to the number of input pulses, and its speed is proportional to the pulse frequency, which makes it important in systems that require high-precision motion control. As an important component of a stepper motor, the gearbox achieves precise control of speed and torque through its precise control function, thereby ensuring the irreplaceability of stepper motors in open-loop high-resolution positioning systems.

2.Advantages of geared stepper motors

1.Reduce speed and increase output torque: Through different reduction ratios, geared stepper motors can reduce the speed of the input shaft while increasing the output torque, which is very useful for applications that require large torque output.

2.Compact structure and small footprint: The design of the geared stepper motor makes its structure very compact, thereby reducing the required installation space.

3.High transmission efficiency and precise speed ratio: The geared stepper motor has high transmission efficiency and can ensure the accuracy of the speed ratio, which is critical for applications that require precise control of speed and position.

4.Reduce the inertia of the load: By reducing speed, the geared stepper motor can reduce the inertia of the load, which is very beneficial for applications that require fast response and precise control.

5.Provide more accurate timing than the chain system, reduce friction loss and noise: Compared with the chain system, the geared stepper motor provides more accurate timing, while reducing friction loss and noise, improving the reliability and durability of the system.

3.Methods for adjusting the speed of the geared stepper motor

1.Change the main frequency of the controller: By adjusting the main frequency of the controller to change the pulse frequency output to the motor, the speed of the motor is controlled. The higher the main frequency, the higher the output pulse frequency, and the faster the motor speed.

2.Use PWM (pulse width modulation) control: Use the PWM signal to control the duty cycle of the pulse output, and then adjust the pulse frequency to achieve fine adjustment of the motor speed.

3.Table lookup speed regulation: According to the set speed value, by looking up the corresponding table of the pre-set speed value and pulse frequency, select the appropriate pulse frequency output to achieve a specific speed.

4.Adopting S-type acceleration curve: By adopting S-type acceleration curve, the motor can be smoothly accelerated and decelerated, providing better start and stop control.

5.Closed-loop control system: The real-time speed of the motor is fed back by the encoder, and the output of the pulse frequency is adjusted after comparison with the set value to achieve accurate speed tracking and enhance control accuracy.

4.Drive mode of gear stepper motor

1.Single voltage drive: In this mode, only one direction voltage is used to power the winding during the operation of the motor winding. The advantages of this mode are simple circuit structure, few components, low cost and high reliability. However, due to the increased power consumption, the efficiency of the entire power drive circuit is low, and it is only suitable for driving low-power stepper motors.

2.High and low voltage drive: In order to enable the winding to quickly reach the set current when power is on, and the winding current quickly decays to zero when power is off, while maintaining high efficiency, high and low voltage drive modes have emerged. This method uses high voltage power supply at the front edge of conduction to increase the front rise rate of the current, and uses low voltage to maintain the current of the winding after the front edge. High and low voltage drive can obtain better high-frequency characteristics, but may cause oscillation at low frequencies.

3.Full-step drive: including single-phase full-step drive and two-phase full-step drive. Full-step drive changes the direction and magnitude of the current to make the stepper motor rotate according to the set step angle. The advantage of this method is that it is simple and intuitive, and it is suitable for occasions where the torque requirement is not high. However, due to its relatively small torque, it may need to be used in combination with other drive methods.

4.Half-step drive: By changing the direction and magnitude of the current, the stepper motor rotates according to half a step angle. Compared with full-step drive, half-step drive has higher resolution and smoother movement, and is suitable for occasions with higher positioning requirements.

5.Micro-step drive: By controlling the magnitude and direction of the current in segments, the stepper motor rotates according to a smaller micro-step angle. Microstepping drives can achieve higher resolution and smoother motion, and are suitable for situations where high-precision positioning and control are required.

1 note

·

View note

Text

Analog Semiconductor Market Current Trends, Technology and Industry Analysis 2032

Analog semiconductors are critical components in the electronics landscape, enabling the processing of real-world signals such as sound, light, and temperature. Unlike digital semiconductors, which operate on discrete values, analog semiconductors process continuous signals, making them essential for applications requiring high fidelity and real-time response. These devices encompass a wide range of components, including operational amplifiers, voltage regulators, and analog-to-digital converters (ADCs).

The demand for analog semiconductors is driven by the proliferation of electronic devices and the increasing complexity of signal processing requirements. As industries embrace advancements in automation, IoT, and consumer electronics, the need for high-performance analog solutions is growing. Innovations in analog semiconductor technology are enabling more efficient power management, enhanced signal integrity, and improved performance in diverse applications.

The Analog Semiconductor Market is expanding due to the rising need for analog components in various applications, including automotive, telecommunications, and industrial electronics, driven by trends toward greater connectivity and automation.

Future Scope

The future of analog semiconductors is promising, with significant growth anticipated across various sectors. As the demand for connected devices continues to rise, the need for high-quality analog components will be paramount. Analog semiconductors will play a vital role in enabling the seamless integration of analog signals with digital processing systems, particularly in applications such as IoT devices, smart sensors, and automotive electronics.

Moreover, the transition to electric vehicles (EVs) and renewable energy systems will create new opportunities for analog semiconductor solutions. These applications require advanced power management and signal processing capabilities, driving innovation in analog device design and manufacturing. The ongoing evolution of technology will necessitate the development of analog components that can operate efficiently in diverse environments and handle complex signal processing tasks.

Trends

Several key trends are shaping the analog semiconductor market. One significant trend is the increasing integration of analog and digital functions within a single chip, known as mixed-signal integration. This approach simplifies circuit design, reduces board space, and enhances performance, making it particularly relevant for portable and compact electronic devices.

Another trend is the growing emphasis on energy efficiency and power management. As industries seek to reduce energy consumption and improve sustainability, analog semiconductors that offer low power consumption and high efficiency are becoming increasingly important. This trend is particularly evident in applications such as battery-powered devices and energy harvesting systems.

Application

Analog semiconductors find applications across various sectors, including consumer electronics, automotive, industrial automation, and telecommunications. In consumer electronics, they are essential for audio and video processing, enabling high-fidelity sound and image quality in devices such as smartphones, TVs, and home theater systems.

In the automotive sector, analog semiconductors play a vital role in power management, sensor interfaces, and advanced driver-assistance systems (ADAS). These devices ensure the reliability and performance of critical automotive systems, contributing to enhanced safety and efficiency.

In industrial automation, analog semiconductors are used in control systems, sensor interfaces, and power management solutions. Their ability to process real-world signals is crucial for monitoring and controlling industrial processes, enabling greater efficiency and productivity.

Key Points

Enable the processing of real-world signals in electronic devices.

Driven by the growing demand for high-performance and integrated solutions.

Promising future with growth opportunities in IoT, EVs, and renewable energy.

Trends include mixed-signal integration and energy efficiency.

Applied in consumer electronics, automotive, industrial automation, and telecommunications.

Read More Details: https://www.snsinsider.com/reports/analog-semiconductor-market-4538

Contact Us:

Akash Anand — Head of Business Development & Strategy

Email: [email protected]

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

The Evolving Landscape of the AC-DC Power Adapters Industry

The AC-DC Power Adapters Market is projected to be valued at USD 37.38 billion in 2024 and is expected to reach USD 93.72 billion by 2029, growing at a compound annual growth rate (CAGR) of 20.18% during the forecast period (2024-2029)

In an increasingly digital world, the demand for reliable power solutions is more critical than ever. AC-DC power adapters, essential devices that convert alternating current (AC) from wall outlets into the direct current (DC) required by most electronic devices, are foundational components in our daily lives. From smartphones and laptops to household appliances and industrial equipment, AC-DC adapters are omnipresent. As industries evolve and technological advancements continue, let’s explore the trends and factors shaping the AC-DC power adapters market.

1. Growing Demand for Consumer Electronics

The surge in consumer electronics is a major driving force in the AC-DC power adapter market. The proliferation of smartphones, laptops, tablets, and gaming consoles, coupled with the trend toward smart homes, has led to an increased need for power adapters. As consumers seek more efficient and compact chargers, manufacturers are responding with advanced, energy-efficient designs that meet these evolving demands.

2. Advancements in Energy Efficiency

One of the key trends reshaping the industry is the push for more energy-efficient solutions. Governments worldwide are enforcing strict regulations to minimize energy consumption and reduce carbon footprints. This has led to the development of energy-efficient AC-DC adapters that comply with international standards such as Energy Star and the EU’s Ecodesign directive. These innovations help reduce energy wastage, ensuring that power adapters consume less electricity during standby mode.

3. Rise of Universal Power Adapters

Universal AC-DC power adapters are gaining popularity, especially with consumers looking for more flexible charging solutions. These adapters, capable of powering multiple devices with a single unit, offer convenience and sustainability. As a result, manufacturers are focusing on creating versatile products that support various voltage and current requirements, allowing consumers to use one adapter for multiple devices.

4. Integration with USB-C Technology

With USB-C emerging as the standard for power delivery across devices, AC-DC power adapters are increasingly integrating USB-C technology. USB-C’s ability to deliver faster charging speeds, coupled with its universal compatibility across various devices, makes it a preferred choice for manufacturers and consumers alike. This shift towards USB-C-powered AC-DC adapters is streamlining the consumer experience while promoting sustainability through fewer adapters.

5. Expanding Applications Across Industries

Beyond consumer electronics, the AC-DC power adapter market is expanding across several industrial sectors. The increasing use of automation in manufacturing, healthcare devices, and renewable energy solutions has created a need for reliable power sources. In sectors like healthcare, where precision and reliability are critical, advanced AC-DC adapters are essential for powering medical equipment and devices. Similarly, industrial applications like automation systems and IoT devices rely on stable power adapters to ensure operational efficiency.

6. Challenges in the Market

While the AC-DC power adapter market is growing, it faces challenges such as fluctuating raw material prices, particularly for metals and semiconductors. Additionally, counterfeit products in some regions are a growing concern, affecting both product quality and brand reputation. Addressing these challenges will require manufacturers to focus on innovation, maintain strict quality controls, and adopt sustainable sourcing practices.

7. Market Outlook and Future Trends

The future of the AC-DC power adapter market looks promising, driven by innovations in power delivery, rising consumer demand for faster charging solutions, and growing applications in industries beyond electronics. The adoption of GaN (Gallium Nitride) technology in adapters is expected to revolutionize the industry, offering smaller, faster, and more efficient chargers. With growing interest in renewable energy sources, the integration of solar-powered charging systems into AC-DC adapters could open up new growth avenues.

Conclusion

As technology continues to evolve, the AC-DC power adapter industry is undergoing significant transformation. Manufacturers are focusing on delivering more energy-efficient, versatile, and sustainable products to meet the needs of today’s tech-savvy consumers. With advancements in USB-C, universal adapters, and energy efficiency, the industry is poised for continued growth and innovation in the coming years.

This dynamic market, influenced by environmental regulations, technological advancements, and shifting consumer preferences, is a critical component in the global power supply chain. As it adapts to new challenges and opportunities, the future of AC-DC power adapters looks brighter than ever.

#AC-DC Power Adapters Market trends#AC-DC Power Adapters Market size#AC-DC Power Adapters Market share#AC-DC Power Adapters Market analysis#AC-DC Power Adapters Market forecast

0 notes

Text

8 Bit Microcontroller Marvels: How They’re Changing Consumer Electronics

8 Bit Microcontroller Market , where tiny processors wield enormous power. These microcontrollers, the unsung heroes of the tech realm, are designed to perform essential tasks in embedded systems. From controlling household gadgets to driving sophisticated industrial machinery, they ensure that our daily lives run smoothly. The 8 Bit Microcontroller Market emerged in response to a growing need for efficient, cost-effective solutions to perform fundamental computing tasks. As industries began automating processes, the demand for reliable control mechanisms surged. Picture the late 1970s: a time when bulky, expensive computing systems dominated. Enter the 8-bit microcontroller, a game changer that democratized technology, making automation accessible to many.

The journey began in 1976 with the introduction of the Intel 8048 microcontroller. Intel, a pioneer in semiconductor technology, laid the groundwork for the 8 Bit Microcontroller Market. This breakthrough not only simplified design but also inspired countless innovations, setting the stage for a thriving ecosystem of microcontrollers that we see today. The evolution of the 8 Bit Microcontroller Market is a testament to human ingenuity. Initially, these microcontrollers served basic functions like turning lights on and off, controlling motors, and managing simple tasks. Fast forward to today, and you’ll find them integrated into everything from smart refrigerators to wearable fitness trackers. With advancements in technology, today’s 8-bit microcontrollers boast features like integrated peripherals, enhanced memory, and higher processing speeds. As the Internet of Things (IoT) gained momentum, the market transformed, catering to the need for connectivity and smart functionality. The 8 Bit Microcontroller Market has diversified, with innovative solutions emerging from unexpected corners, driven by startups and established giants alike.

Understanding the 8 Bit Microcontroller Architecture

At its core, the 8-bit microcontroller is defined by its ability to process data in 8-bit chunks, meaning it can handle 8 bits of data simultaneously. While this may seem limited compared to more advanced 16-bit or 32-bit microcontrollers, 8-bit devices excel in simplicity and efficiency, especially for tasks that do not require complex processing. Their reduced architecture translates to lower energy consumption, a vital trait in a world increasingly driven by portable and battery-powered devices.

Within the 8-bit microcontroller ecosystem, various peripherals and modules play essential roles. These include timers, analog-to-digital converters (ADCs), pulse-width modulation (PWM) controllers, and communication interfaces like I²C, UART, and SPI. Together, they form the backbone of any embedded system, allowing microcontrollers to interact with sensors, actuators, and other digital systems. For instance, in automotive applications, PWM controllers manage motor speeds, while ADCs convert real-world signals like temperature or voltage into data the microcontroller can process.

Developers find the simplicity of 8-bit microcontrollers appealing, as they can often design effective solutions with minimal programming effort. Moreover, a wealth of open-source libraries and development tools exists to support 8-bit microcontroller development, lowering barriers to entry and encouraging rapid prototyping.

Innovation and Advancements in 8 Bit Microcontrollers

Innovation in the 8 Bit Microcontroller Market is far from stagnant. The evolution of semiconductor technologies has allowed these microcontrollers to pack more features into smaller, cheaper packages. Manufacturers are constantly pushing the limits of what an 8-bit microcontroller can achieve by incorporating more memory, enhanced peripherals, and optimized power management techniques.

One particularly interesting development is the integration of Artificial Intelligence (AI) capabilities into 8-bit microcontrollers. While AI is typically associated with high-performance computing platforms, microcontrollers are finding a place in edge computing applications, where data processing occurs locally on the device rather than in the cloud. In such scenarios, lightweight AI algorithms allow 8-bit microcontrollers to perform tasks like object detection or predictive maintenance with minimal latency and power consumption.

Another notable advancement is the rise of open-source hardware platforms that leverage 8-bit microcontrollers, such as Arduino. This platform has democratized electronics, making it accessible for hobbyists, students, and professionals alike. The combination of low-cost hardware and easy-to-use software tools has spurred a new wave of innovation, with 8-bit microcontrollers at the heart of countless DIY projects, from home automation systems to robotic devices.

The Role of 8 Bit Microcontrollers in IoT and Industry 4.0

As the Internet of Things (IoT) continues to proliferate, 8-bit microcontrollers have become vital players in building the infrastructure of connected devices. These microcontrollers are particularly suited to applications where simplicity, cost, and low power consumption are paramount. Whether it’s a smart thermostat, a wearable fitness tracker, or a remote sensor in an agricultural field, the 8-bit microcontroller can collect data, process simple instructions, and communicate wirelessly with other devices or cloud systems.

Industry 4.0, the next wave of industrial automation, also finds significant use for 8-bit microcontrollers. In smart factories, these microcontrollers enable the automation of various processes, monitor machine health, and ensure that production lines run smoothly. The microcontroller’s ability to interface with both digital and analog signals makes it indispensable in environments where real-time control is necessary. Moreover, with the advent of predictive maintenance, 8-bit microcontrollers help gather and analyze data from machinery, anticipating breakdowns and reducing downtime.

Challenges Facing the 8 Bit Microcontroller Market

While the 8 Bit Microcontroller Market is thriving, it faces several challenges. The most prominent of these is competition from more advanced microcontroller architectures, such as 16-bit and 32-bit microcontrollers, which offer greater computational power and memory. As the complexity of embedded systems grows, developers may opt for more powerful processors that can handle more intensive tasks, such as real-time video processing or machine learning inference.

Additionally, supply chain disruptions have impacted the availability of semiconductor components, including 8-bit microcontrollers. The COVID-19 pandemic, geopolitical tensions, and natural disasters have all contributed to global semiconductor shortages, leading to extended lead times and increased costs. This has forced manufacturers to rethink their sourcing strategies and invest in local production capabilities to mitigate risks.

Environmental sustainability is another challenge for the 8 Bit Microcontroller Market. As the world moves towards greener technologies, microcontroller manufacturers are under pressure to reduce the environmental impact of their products, from raw material sourcing to end-of-life disposal. Innovations in packaging materials, energy-efficient design, and recyclable components will be critical to the future success of the market.

Conclusion: The Everlasting Legacy of 8 Bit Microcontrollers

In summary, the 8 Bit Microcontroller Market is on an upward trajectory, driven by technological advancements and the growing need for automation. Its adaptability and cost-effectiveness ensure that it will remain a cornerstone of modern electronics for years to come, fostering innovation and connectivity in an ever-evolving digital landscape. From industrial automation to consumer electronics, the humble 8-bit microcontroller continues to be a powerful tool for developers worldwide, ensuring that technology remains accessible, efficient, and future-proof.

Read More :

Seeds drive agricultural innovation and sustainable growth.

Lithium Carbonate is key for battery production in electric vehicles.

Ambient Intelligence enhances environments with smart, responsive technologies.

Aerospace 3D Printing revolutionizes aircraft manufacturing with precision and speed.

5G Services power the future of connectivity with lightning-fast communication.

0 notes

Text

LMZ21701SILT Nano Module: Key Features and Specifications

The LMZ21701SILT is a compact nano power module from Texas Instruments, designed to simplify the power supply needs of small electronics. With its tiny footprint and efficient performance, it is ideal for space-constrained applications that require a reliable and efficient voltage regulator.

What is the LMZ21701SILT Nano Module?

The LMZ21701SILT is a step-down DC-DC converter (also known as a buck converter) that integrates several key components into a single module. This includes the controller, inductor, and passives, making it a plug-and-play solution for power management.

This nano module can output 1A of continuous current with input voltages ranging from 2.7V to 17V, while regulating the output voltage down to as low as 0.9V. Its small size, along with its built-in components, allows for a reduced component count and simplified design process, which is particularly beneficial for engineers working on compact devices.

Key Features of LMZ21701SILT

1. Tiny Form Factor

One of the standout features of the LMZ21701SILT is its incredibly small size. Measuring just 3mm x 3.8mm, it is perfect for applications where space is at a premium, such as wearables, portable electronics, and Internet of Things (IoT) devices.

2. High Efficiency

This nano module boasts an impressive efficiency of up to 90%, making it an energy-efficient choice for designs that prioritize low power consumption. The module's efficiency remains high across a wide range of loads, further enhancing battery life in portable applications.

3. Adjustable Output Voltage

The LMZ21701SILT allows for adjustable output voltages from 0.9V to 6V, giving designers flexibility when selecting the operating voltage for their devices. This feature enables its use in diverse applications, from powering low-voltage microcontrollers to supplying voltage to communication modules.

4. Integrated Protection Features

To ensure reliability, the LMZ21701SILT includes several protection features:

Thermal shutdown to prevent overheating.

Short circuit protection to safeguard against faults.

Overcurrent protection to handle excessive loads.

These built-in protections help extend the life of the device while preventing damage to the overall system.

5. Low Ripple and Noise

The module is designed to produce minimal output ripple and noise, which is critical for sensitive applications like medical devices, precision instrumentation, or audio equipment, where clean power is a necessity.

Applications of LMZ21701SILT

1. Portable and Wearable Devices

Thanks to its compact size and high efficiency, the LMZ21701SILT is ideal for wearables, smartphones, and other portable gadgets. Its small footprint allows it to be used in space-constrained designs, while its efficiency extends battery life.

2. Industrial Sensors and IoT Devices

In IoT applications, where devices are often deployed remotely and run on battery power, the low power consumption and versatility of this module make it a suitable choice. It ensures that sensors and other IoT nodes can operate efficiently for extended periods without frequent battery replacements.

3. Consumer Electronics

Consumer devices like smart home products, audio systems, and digital cameras can benefit from the LMZ21701SILT. It ensures stable power delivery with low noise, which is essential for devices that require consistent performance.

4. Embedded Systems

This module is also useful in embedded systems, where compact and reliable power delivery is crucial. Its adjustable output voltage makes it a versatile option for powering microcontrollers, communication modules, and other components in embedded designs.

Specifications at a Glance

Input Voltage Range: 2.7V to 17V

Output Voltage Range: 0.9V to 6V

Output Current: Up to 1A

Efficiency: Up to 90%

Package Size: 3mm x 3.8mm

Protection Features: Thermal shutdown, short circuit protection, overcurrent protection

Operating Temperature Range: -40°C to 125°C

Conclusion

The LMZ21701SILT Nano Module is a powerful and compact solution for efficient power management. Its tiny form factor, high efficiency, and integrated protection features make it an excellent choice for modern electronics that require reliable and space-saving power solutions. Whether you're working on wearables, IoT devices, or embedded systems, the LMZ21701SILT offers the flexibility and performance you need to create cutting-edge designs.

Understanding its key specifications and potential applications can help you choose the right module for your project, ensuring that your devices run efficiently and reliably.

0 notes

Text

LMZ21701SILT Nano Module: Key Features and Specifications

The LMZ21701SILT is a compact nano power module from Texas Instruments, designed to simplify the power supply needs of small electronics. With its tiny footprint and efficient performance, it is ideal for space-constrained applications that require a reliable and efficient voltage regulator.

What is the LMZ21701SILT Nano Module?

The LMZ21701SILT is a step-down DC-DC converter (also known as a buck converter) that integrates several key components into a single module. This includes the controller, inductor, and passives, making it a plug-and-play solution for power management.

This nano module can output 1A of continuous current with input voltages ranging from 2.7V to 17V, while regulating the output voltage down to as low as 0.9V. Its small size, along with its built-in components, allows for a reduced component count and simplified design process, which is particularly beneficial for engineers working on compact devices.

Key Features of LMZ21701SILT

1. Tiny Form Factor

One of the standout features of the LMZ21701SILT is its incredibly small size. Measuring just 3mm x 3.8mm, it is perfect for applications where space is at a premium, such as wearables, portable electronics, and Internet of Things (IoT) devices.

2. High Efficiency

This nano module boasts an impressive efficiency of up to 90%, making it an energy-efficient choice for designs that prioritize low power consumption. The module's efficiency remains high across a wide range of loads, further enhancing battery life in portable applications.

3. Adjustable Output Voltage

The LMZ21701SILT allows for adjustable output voltages from 0.9V to 6V, giving designers flexibility when selecting the operating voltage for their devices. This feature enables its use in diverse applications, from powering low-voltage microcontrollers to supplying voltage to communication modules.

4. Integrated Protection Features

To ensure reliability, the LMZ21701SILT includes several protection features:

Thermal shutdown to prevent overheating.

Short circuit protection to safeguard against faults.

Overcurrent protection to handle excessive loads.

These built-in protections help extend the life of the device while preventing damage to the overall system.

5. Low Ripple and Noise

The module is designed to produce minimal output ripple and noise, which is critical for sensitive applications like medical devices, precision instrumentation, or audio equipment, where clean power is a necessity.

Applications of LMZ21701SILT

1. Portable and Wearable Devices

Thanks to its compact size and high efficiency, the LMZ21701SILT is ideal for wearables, smartphones, and other portable gadgets. Its small footprint allows it to be used in space-constrained designs, while its efficiency extends battery life.

2. Industrial Sensors and IoT Devices

In IoT applications, where devices are often deployed remotely and run on battery power, the low power consumption and versatility of this module make it a suitable choice. It ensures that sensors and other IoT nodes can operate efficiently for extended periods without frequent battery replacements.

3. Consumer Electronics

Consumer devices like smart home products, audio systems, and digital cameras can benefit from the LMZ21701SILT. It ensures stable power delivery with low noise, which is essential for devices that require consistent performance.

4. Embedded Systems

This module is also useful in embedded systems, where compact and reliable power delivery is crucial. Its adjustable output voltage makes it a versatile option for powering microcontrollers, communication modules, and other components in embedded designs.

Specifications at a Glance

Input Voltage Range: 2.7V to 17V

Output Voltage Range: 0.9V to 6V

Output Current: Up to 1A

Efficiency: Up to 90%

Package Size: 3mm x 3.8mm

Protection Features: Thermal shutdown, short circuit protection, overcurrent protection

Operating Temperature Range: -40°C to 125°C

Conclusion

The LMZ21701SILT Nano Module is a powerful and compact solution for efficient power management. Its tiny form factor, high efficiency, and integrated protection features make it an excellent choice for modern electronics that require reliable and space-saving power solutions. Whether you're working on wearables, IoT devices, or embedded systems, the LMZ21701SILT offers the flexibility and performance you need to create cutting-edge designs.

0 notes

Text

How SINAMICS G120 Meets the Demands of Modern Industry?

There has never been a greater need for innovative automation solutions as companies want to boost productivity, flexibility, and efficiency. This is where the SINAMICS G120, a powerful drive system that is transforming industry operations, comes into action.

In this post, we'll explore how the Drive G120 is transforming the industrial sector and why it's a game-changer for businesses looking to future-proof their operations.

Industrial Potential with SINAMICS G120

The G120 is a versatile drive system, designed to meet the diverse needs of modern industry. It is a low-voltage converter that offers a perfect balance of performance, flexibility, and ease of use. This frequency converter is part of the Siemens SINAMICS family, renowned for its advanced automation solutions.

Powerful Performance: The G120 is a workhorse, capable of handling demanding applications with ease. It provides a wide power range from 0.55 kW to 132 kW, making it suitable for various industrial processes.

Flexibility and Adaptability: One of the standout features of the G120 is its modular design. This allows for easy configuration and expansion, ensuring the system can adapt to changing industrial requirements. Whether it's adding more drives or integrating new technologies, the G120 is future-proof.

User-Friendly Interface: Siemens has designed the G120 with simplicity in mind. Its intuitive interface and easy commissioning make it a breeze for operators to use. This not only reduces training time but also minimizes downtime, ensuring maximum productivity.

Key Features and Benefits

#1 Energy Efficiency

Regenerative Capabilities: One of the standout features is its regenerative capacity. In many industrial applications, drives often need to decelerate or stop loads. The G120 can feed the energy generated during deceleration back into the power grid, reducing energy costs and improving overall efficiency.

Energy-Saving Functions: The ac drive g120 incorporates various energy-saving functions, such as power optimizer and sleep mode. These features automatically adjust the drive's performance to match the load, reducing energy waste.

Efficient Cooling Systems: Efficient cooling is essential for drive systems to maintain optimal performance. The G120 offers innovative cooling methods, including air-to-air heat exchangers and optional liquid cooling, ensuring the drive operates at its best while minimizing energy consumption.

#2 G120 Power Module

The G120 power module is the core component of the G120 drive system designed for high performance and reliability, ensuring the drive operates efficiently even in demanding conditions.

Advanced Power Electronics: The power module utilizes the latest power electronics technology, including Insulated Gate Bipolar Transistors (IGBTs) and fast-switching diodes. This enables high-speed switching, reducing energy losses and improving overall efficiency.

Robust Design: Built to withstand harsh industrial environments, the power module features a robust design. It is protected against dust, moisture, and other contaminants, ensuring reliable operation even in challenging conditions.

Easy Maintenance: Siemens has designed the power module with maintenance in mind. Its modular construction allows for easy replacement of components, minimizing downtime and reducing maintenance costs.

#3 Digitalization

PROFINET and Industrial Ethernet: The SINAMICS G120 supports PROFINET and Industrial Ethernet, enabling seamless integration into modern industrial networks. This allows for real-time data exchange, remote monitoring, and control, enhancing overall system efficiency.

Digital Operator Panel: The G120 features a digital operator panel, providing a user-friendly interface for easy operation and monitoring. It offers clear diagnostics and status information, enabling operators to make informed decisions quickly.

Data Management and Analytics: With its advanced data management capabilities, the G120 can collect and analyze drive performance data. This enables predictive maintenance, allowing users to optimize drive performance and minimize unexpected downtime.

Real-World Applications

Conveyor Systems: In logistics and manufacturing, efficient material handling is crucial. The G120 ensures smooth and controlled movement of goods, optimizing production and distribution processes.

Pump and Fan Control: Precise control of pumps and fans is essential in many industries, from water management to HVAC systems. The G120 delivers exceptional control accuracy, ensuring optimal performance and energy savings.

Machine Tools: In precision engineering, the G120 enables high-speed and accurate positioning, making it ideal for CNC machines and other advanced manufacturing equipment.

Mixing and Stirring Applications: Whether it's in the food and beverage industry or chemical processing, consistent mixing is vital. The SINAMICS G120 provides the necessary control and flexibility to ensure uniform results.

Why Choose SINAMICS G120?

In a market flooded with automation solutions, what sets the SINAMICS G120 apart? Here are some compelling reasons:

Proven Track Record: Siemens is a trusted name in the industry, and the G120 has a proven track record of success. Its reliability and performance have been validated across various sectors, making it a safe and reliable choice.

Comprehensive Support: Siemens offers extensive support and documentation for the G120, ensuring users have the resources they need. This includes online tools, training materials, and a global network of experts for assistance.

Future-Proof Technology: With its modular design and easy upgradability, the G120 is built to evolve with your business. As your industrial needs change, the G120 can adapt, ensuring you stay ahead of the competition.

The World's Leading Brands Choose Naksh: Discover Why

With a proven track record of delivering excellence, Naksh Technology has become the go-to partner for businesses seeking to optimize their industrial operations. From manufacturing and logistics to energy and infrastructure, we serve key industries, providing end-to-end automation solutions.

Our partnerships with global leaders like Pepperl+Fuchs and LAPP further enhance our capabilities, allowing us to deliver state-of-the-art sensor technology and high-performance cabling solutions. Contact Naksh Technology today, and let's discuss how we can power your success with Siemens automation solutions.

0 notes