#direct-to-substrate printer

Explore tagged Tumblr posts

Text

Efficient Fabric Printing with DTGPRO DTF Printers

DTF Printers have become a game-changer for fabric printing businesses. Known for their precision and versatility, these printers offer an efficient way to produce high-quality prints on various fabrics. At DTGPRO, we take pride in delivering advanced printing solutions that empower businesses to meet customer demands seamlessly.

What Makes DTF Printers Special?

DTF Printers (Direct-to-Film Printers) use advanced printing technology to transfer designs directly onto fabrics. Unlike traditional methods, DTF printing ensures vibrant colors, fine details, and long-lasting results. Whether you're printing on cotton, polyester, or blended fabrics, DTGPRO ensures that every print stands out with clarity.

Why Choose Direct-to-Substrate Printer?

A direct-to-substrate printer is another efficient printing technology that allows designs to be directly printed onto surfaces without the need for intermediate transfers. This reduces production time and material waste, making it a cost-effective choice for businesses.

At DTGPRO, our DTF Printers and direct-to-substrate printer solutions are designed to offer efficiency, consistency, and unmatched quality in every print job.

Benefits of Using DTGPRO DTF Printers

High-Quality Prints: Achieve sharp, detailed designs with vibrant colors.

Versatility: Suitable for multiple fabric types.

Cost-Effective: Reduce material waste and save on production costs.

Easy to Use: User-friendly interfaces ensure smooth operation.

Reliable Support: DTGPRO offers dedicated support to keep your operations running smoothly.

Applications of DTF Printing

Customized T-shirts

Branded Uniforms

Fashion Apparel

Home Textiles

No matter the application, DTF Printers from DTGPRO always ensure consistent results.

Final Thoughts

In the world of textile printing, efficiency and quality are non-negotiable. With DTF Printers and direct-to-substrate printer technology from DTGPRO, businesses can enjoy seamless operations and deliver exceptional customer results.

0 notes

Text

The Role of DTF Printing in Promotional Merchandise”

Introduction

In today's fast-paced world, promotional merchandise has become a vital tool for businesses to enhance their brand visibility and connect with their audience. Among the various printing technologies available, Direct to Film (DTF) printing has emerged as a revolutionary method that offers unique advantages over traditional techniques. This article delves into the role of DTF printing in promotional merchandise, exploring its benefits, applications, and why it’s becoming the go-to choice for businesses looking to create impactful promotional items.

What is DTF Printing? Understanding Direct to Film Printing

Direct to Film (DTF) printing is a relatively new technology that allows designs to be printed on a special film which can then be transferred onto various substrates like fabric, plastic, and more. Unlike traditional methods such as screen printing or heat transfer printing, DTF utilizes advanced inks and adhesives that provide superior adhesion and vibrant colors.

How Does DTF Printing Work?

The process of DTF printing involves several key steps:

Design Creation: A digital design is created using graphic design software. Film Printing: The design is printed onto a special transfer film using a direct to film printer. Powder Adhesive Application: A powder adhesive is sprinkled over the wet ink on the transfer film. Curing Process: The film is heated to cure the adhesive, ensuring it sticks well during transfer. Heat Transfer: Finally, the film is applied to the substrate using a heat press.

This method ensures high-quality prints that are durable and long-lasting.

The Role of DTF Printing in Promotional Merchandise

DTF printing plays an essential role in creating promotional merchandise due to its versatility and efficiency. Businesses can produce custom apparel, bags, hats, and other items quickly while maintaining quality and detail.

youtube

Benefits of Using DTF for Promotional Merchandise 1. Versatile Applications https://www.openpr.com/news/3525667/eazydtf-introduces-fast-and-affordable-dtf-printing-services

One of the standout features of DTF printing is its versatility. It can be used on various materials including cotton, polyester, leather, and even hard surfaces like mugs or phone cases.

2. High-Quality Prints

With DTF transfers, businesses can achieve vibrant colors and intricate designs that stand out — perfect for attracting attention at events or trade shows.

3. Cost-Effective Production

For small runs or large orders alike, DTF printing can be cost-effective since it eliminates many setup costs associated with traditional methods.

4. Quick Turnaround Times

DTF technology enables quick production times without sacrificing quality. This means businesses can meet tight deadlines for promotional campaigns easily.

5. Durability

DTF prints are known for their durability; they withstand multiple washes without fading or cracking — an essential factor for promotional items like T-shirts or tote bags.

Applications of DTF Transfers in Promotional Merchandise

2 notes

·

View notes

Text

Printing Custom Mylar Bags: An In-Depth How to Exploration of Digital and Flexo Printing Techniques

Custom Mylar bags are a stellar choice for brands looking to combine robust packaging with eye-catching design, especially prevalent in sectors like food, cannabis, and health care products. In the world of printing on these durable, barrier-enhancing bags, two primary technologies reign supreme: digital printing and flexographic (flexo) printing. This extensive guide delves into each method, detailing their processes, benefits, and when to use one over the other.

Decoding Mylar Bags

Mylar, technically known as biaxially-oriented polyethylene terephthalate (PET), is favored for its excellent protective qualities, including moisture resistance and durability. It’s a go-to for products needing a longer shelf life and consistent freshness.

Before You Print: Key Steps

Before setting the printing wheels in motion, consider these critical steps:

Design Mastery: The right design transcends aesthetics, reflecting your brand’s ethos and meeting packaging specifications with flair.

Choosing the Right Bag: Factor in the product’s needs—size, features like zip-locks or clear windows, and the overall style of the bag.

Prep the Material: Mylar often requires specific treatments to ensure ink adherence during printing.

Digital Printing on Mylar Bags

Digital printing impresses with its direct approach, where designs from digital files spring to life on the substrate through inkjet or laser technology.

Step-by-Step Process

Digital Design: Transform your creative vision into a digital file compatible with the printing machinery, using tools like Adobe Illustrator.

Set Up: Position the Mylar bags in the printer, tuned to accommodate the material’s specifics.

The Printing Dance: The printer interprets the digital file, meticulously layering CMYK inks to recreate your design on the bag.

Ink Setting: Post-printing, some inks may need curing to secure their bond with the Mylar.

Why Go Digital?

Quick Turnaround: Skip the setup complexities and dive straight into printing.

Small Batch Friendly: No hefty setup fees, making it perfect for limited runs or bespoke orders.

Precision and Color: Achieve sharp, vibrant prints that catch the eye.

Adaptable: Easily tweak designs between runs without financial heartache.

Potential Drawbacks

Ink Stability: May require additional protective measures to enhance durability.

Cost Efficiency: Larger orders can become costly compared to flexo printing.

Flexographic Printing on Mylar Bags

Flexo printing, a sophisticated evolution of letterpress, uses flexible plates to apply ink onto materials like Mylar, marrying old-school technique with modern efficiency.

How It Works

Plate Crafting: Each color in your design calls for its own flexible plate.

Inking Up: Plates kiss the ink rollers, transferring the design sequentially to the Mylar as it moves through the press.

Curing the Print: A drying phase ensures the ink melds flawlessly with the Mylar.

Flexo’s Strengths

Bulk Efficiency: Once the setup is complete, flexo churns out large volumes swiftly, making it cost-effective.

Lasting Impressions: Uses robust inks that endure, ideal for long-term display and functionality.

Material Versatility: Adapts to a wide range of inks and materials.

Considerations

Upfront Investment: Initial costs can be high due to the need for custom plates.

Rigidity: Switching designs or running small batches can be economically impractical.

Which Printing Path to Take?

Your choice between digital and flexo printing will hinge on several factors:

Volume: Digital suits low quantities, while flexo excels at high-volume orders.

Budget: Consider digital for minimal upfront costs; flexo for larger investments but lower costs over time.

Design Complexity: Digital is king for intricate, colorful designs.

Durability Demands: Opt for flexo when longevity and wear resistance are paramount.

Wrapping Up

Printing on custom Mylar bags is not just about aesthetics; it’s a strategic choice that enhances product integrity and elevates brand presence. Whether opting for the swift adaptability of digital or the enduring power of flexo, aligning your method with your project’s needs ensures your product stands out beautifully and effectively.

2 notes

·

View notes

Photo

obviously this will be different for each printer - your best bet is to ask your printer what rich black they use for the print process you're going with!

the above rich black formulation comes to a Total Area Coverage of 300% (adding together the percentages of each of the CMYK values). that TAC would be too high for my UV ink high speed digital printer because the curing lamps wouldn't have enough time to penetrate that amount of ink and the result would be uncured ink that would easily scrape off the substrate.

generally during prepress i substitute whatever rich black is in artwork for our formulation (C25 M15 Y15 K99 - believe it or not, that -1% in the black makes a difference for the curing lamps), but if you're in direct contact with a printer and want to be best friends with prepress — just ask! i generally only print on coated material, but if you're printing on uncoated (usually matt materials) that rich black formulation will change again.

and this changes yet again depending on the type of ink (or toner) — non-uv inkjet cures by regular old drying out, so ink concentration can mean the difference between long drying times and high TAC could lead to curling paper. and i'm still just thinking about digital — this isn't even getting into offset printing which is a whole other can of worms!

and yes PLEASE do not use rich black in text on uncoated material (or any body copy really), and omg please don't use it in your barcodes or QR codes because you're just asking for blurry unscannable messes (the time I had to change barcodes on 250 artworks to K100 hahaha IT'S FINE)

anyway just talk to your printer - we're fucking nerds we love when designers actually care about this shit instead of swanning in with visionary designs that have no basis in material reality 😅

Reblog to save a life

#although being a dream killer is mmmmmmm satisfying when it comes to certain types of designers#you can imagine what i mean lol

217K notes

·

View notes

Text

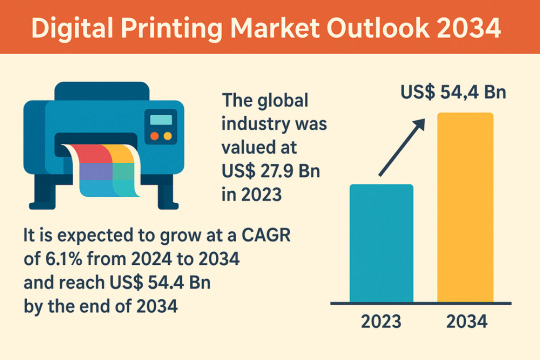

Digital Printing Market to Reach $54.4 Billion by 2034 Amid Rising Demand for On-Demand Solutions

The global digital printing market reached a valuation of US$ 27.9 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.1% between 2024 and 2034, culminating in a market worth US$ 54.4 billion by December 31, 2034. Digital printing bypasses the need for traditional printing plates by transferring digital files directly onto substrates such as paper, canvas, textiles, and synthetics. This seamless workflow supports on-demand production, reduces waste, and delivers high-throughput performance of up to 4,800 sheets per hour once printing begins.

Industry analysts anticipate that continued investments in print manufacturing efficiencies, supply chain integration, and time-to-market acceleration will drive digital printing adoption. Key growth verticals include textile and packaging, where high-definition, on-demand print capabilities facilitate product personalization and rapid iteration. The rise of direct-to-consumer printing models—particularly in can printing further cements digital printing’s role as a versatile, customer-centric technology.

Market Drivers & Trends

Technological Upgrades in Printing: Major players are embedding automation, AI-driven color management, and new printheads into their presses. For instance, in 2022, Hewlett Packard unveiled its Indigo 15K and 100K Digital Press platforms to enhance automation, reduce labor and plate costs, and slash turnaround times for medium to high-volume short runs.

Textile & Packaging Industry Growth: The global textile sector, valued at US$ 4.4 trillion, is rapidly embracing digital print to enable limitless design options and shorter production cycles. Likewise, packaging manufacturers are deploying UV LED and single-pass inkjet presses to deliver variable data printing—such as QR codes and barcodes—at scale.

On-Demand & Personalized Printing: Digital technology empowers brands to engage customers directly by crowdsourcing can designs, securing approvals, and fulfilling orders without intermediaries. This strategy has spurred increased consumer engagement and brand loyalty.

Latest Market Trends

High-Speed Single-Pass Inkjet: Next-generation presses with robust sheet feeders are driving throughputs that rival and often exceed traditional lithography, enabling signage and packaging that formerly required multiple litho sheets to be completed in a single digital pass.

Water-Based Polymer Inks: Sustainability concerns have prompted Canon’s 2022 launch of an automated production facility in Venlo for water-based CMYK inks, designed to curtail waste while ensuring consistent, premium output.

Strategic Partnerships & Acquisitions: Industry consolidation remains robust. In October 2023, ARC Document Solutions partnered with Canon Solutions America to integrate Arizona printing and Colex cutting systems, bolstering its digital color printing services.

Explore pivotal insights and conclusions from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86049

Key Players and Industry Leaders

Prominent companies shaping the digital printing landscape include:

Amcor plc

Avery Dennison Corporation

Canon Inc.

ColorJet Group

DIC Corporation

Durst Group

Electronics for Imaging, Inc.

Hewlett Packard Enterprise

Inca Digital Printers Ltd.

Konica Minolta, Inc.

Mimaki Engineering Co., Ltd.

The Ricoh Company, Limited

Roland DG Corporation

Seiko Epson Corporation

Toshiba Corporation

Xeikon B.V.

Xerox Holdings Corporation

Other

Recent Developments

April 2023: Kyocera Corporation acquired NIKKA S.A.S., enhancing its inkjet print engine capabilities and strengthening its presence in Japan’s digital printing market.

January 2022: Smurfit Kappa invested over US$ 33 million to install high-end printers in Brazil, supporting the booming e-commerce packaging segment.

September 2023: Fiery LLC inked an R&D partnership with Esko to advance digital print technologies with a focus on color and workflow automation.

Market Opportunities and Challenges

Opportunities:

Sustainability Focus: Development of eco-friendly inks and substrates presents new revenue streams as brands seek greener packaging solutions.

Emerging Economies: Rapid industrialization in Asia Pacific and Latin America offers fertile ground for new installations and service offerings.

4.0 Factory Integration: Combining IoT, AI, and advanced robotics with digital print presses can revolutionize mass customization.

Challenges:

High Capital Expenditure: Upfront costs of advanced digital presses may deter smaller enterprises despite long-term ROI advantages.

Skill Shortages: Operating and maintaining sophisticated digital printing systems requires specialized training.

Ink and Substrate Compatibility: Ensuring consistent print quality across diverse materials remains a technical hurdle.

Future Outlook

By 2034, digital printing is expected to account for more than half of global print volumes in packaging and textiles, driven by:

Automation & AI: Presses will self-optimize color, media handling, and maintenance schedules.

Personalization at Scale: Brands will offer hyper-customized products with batch sizes as low as one, unlocking new business models in retail and direct-to-consumer markets.

Hybrid Production Lines: Integration of digital and traditional printing methods will enable seamless transitions between high-definition short runs and high-volume lithography.

Market Segmentation

By Printing Type:

Inkjet (leading segment due to superior tonal range)

Laser

By Ink Type:

Aqueous

UV-Cured

Solvent

Latex

Dye Sublimation

Others

By Substrate Type:

Paper

Textile

Plastic Films or Foils

Ceramic

Glass

Others

Regional Insights

Asia Pacific dominated the digital printing market in 2023 and is forecast to maintain its leadership through 2034. China’s pivot toward end-to-end digitized value chains and strategic investments—such as Tomato Cloud Technology’s order for 10 Fujifilm Jet Press 750S machines in October 2021—have underpinned regional growth. In April 2023, Kyocera’s acquisition of NIKKA S.A.S. further underscores Japan’s commitment to inkjet innovation. North America and Europe remain important hubs for R&D, particularly in sustainable ink and substrate development.

Why Buy This Report?

Comprehensive Market Analysis: In-depth quantitative and qualitative insights covering 2020–2022 historical data, 2024–2034 forecasts, Porter’s Five Forces, value chain assessment, and SWOT analysis.

Competitive Landscape: Detailed profiles of leading players, product portfolios, strategic initiatives, market share breakdowns, and financial comparisons.

Actionable Segmentation: Granular analysis by printing type, ink, substrate, and region to inform targeted investment and expansion strategies.

Excel & PDF Formats: Ready-to-use data tables in Excel for custom modeling, alongside an executive-ready PDF report.

Explore Latest Research Reports by Transparency Market Research:

Ring Laser Gyroscope Market: https://www.transparencymarketresearch.com/ring-laser-gyroscope-market.html

Lithography Equipment Market: https://www.transparencymarketresearch.com/lithography-equipment-market.html

Compact Camera Module Market: https://www.transparencymarketresearch.com/compact-camera-module-market.html

Grow Light Market: https://www.transparencymarketresearch.com/grow-light-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Revolutionizing Print Technology: The Power of UV Curing Systems for Printing

In the ever-evolving world of industrial printing, efficiency, precision, and sustainability have become top priorities. Among the technologies leading this transformation is the UV curing system—a method that has dramatically changed the way inks, coatings, and adhesives are dried and hardened. At the forefront of this innovation are UV curing systems for printing, powered by advanced UV LED technology, which offer unparalleled performance for modern printing applications.

If your industry relies on printing, whether in packaging, signage, or label production, understanding the benefits and functionality of UV curing systems is essential to staying competitive. This article explores how this cutting-edge technology works, its advantages, and why it’s rapidly becoming the go-to solution for high-quality, energy-efficient printing.

What Are UV Curing Systems for Printing?

UV curing systems for printing use ultraviolet light to instantly cure or dry inks, varnishes, and coatings. Traditional drying methods often require heat or airflow, which can be time-consuming and energy-intensive. In contrast, UV curing uses focused UV light to trigger a photochemical reaction that hardens the ink or coating in a fraction of a second.

When paired with UV-reactive inks, these systems ensure a fast, clean, and efficient drying process. Today’s most advanced systems leverage UV LED technology, which further improves energy efficiency, control, and longevity compared to traditional mercury vapor lamps.

How UV LED Curing Works

UV LED curing systems emit light at specific UV wavelengths—commonly in the UVA range (365nm–405nm)—to match the photoinitiators in the ink or coating formulation. When exposed to this UV light, a polymerization process occurs, turning liquid ink into a solid film instantly.

This process offers multiple advantages in printing environments:

Faster production speeds

Improved substrate compatibility

Longer lamp life and lower maintenance costs

Cooler operating temperatures (ideal for heat-sensitive materials)

Benefits of UV Curing Systems for Printing

Modern UV curing systems for printing offer a suite of benefits that elevate print quality and streamline workflows:

1. Instantaneous Drying

Because UV light initiates curing the moment it hits the surface, printers can achieve immediate handling and stacking of printed materials. This reduces turnaround time and minimizes production bottlenecks.

2. Energy Efficiency

UV LED curing consumes significantly less power than traditional curing methods. The system uses energy only when actively curing, and the LEDs generate less heat, reducing cooling requirements and electricity consumption.

3. Superior Print Quality

UV curing allows for sharper, more vibrant colors and precise dot placement. The ink sits on the surface instead of being absorbed, resulting in higher resolution and better adhesion on a variety of substrates.

4. Eco-Friendly Operation

Without mercury lamps or ozone emissions, UV LED curing is safer for both operators and the environment. There are also fewer consumables, reducing waste and simplifying compliance with environmental regulations.

5. Low Maintenance and Long Life

UV LED lamps have a lifespan of up to 20,000 hours or more, significantly reducing downtime and maintenance costs associated with lamp replacement and recalibration.

Applications of UV Curing in the Printing Industry

UV curing systems for printing are widely used across various sectors due to their versatility:

Label and Packaging Printing: High-speed production lines benefit from quick curing and high adhesion on plastic, foil, and coated substrates.

Commercial Printing: For brochures, catalogs, and direct mail, UV curing enhances color vibrancy and durability.

Inkjet Printing: UV-curable inks make it possible to print on non-porous materials like glass, metal, or acrylic.

Textile and Garment Printing: UV technology enables detailed prints on heat-sensitive fabrics without distortion.

As print applications expand, the demand for UV curing systems continues to rise, especially in businesses looking for cost-effective, high-performance solutions.

Choosing the Right UV Curing System

When selecting a UV curing system for printing, it’s essential to consider factors like:

Curing width and speed

Substrate compatibility

Power requirements and energy efficiency

Integration with existing printing presses

Control systems for precise curing

Our UV LED curing systems are designed to meet the unique needs of industrial printers. With adjustable output, compact design, and intelligent controls, they ensure consistent, high-quality results while reducing operational costs.

Why Upgrade to UV LED Curing Technology?

While traditional UV systems served the industry for decades, UV LED curing represents the next step in print evolution. Printers worldwide are upgrading to LED-based systems for their reliability, efficiency, and scalability. Whether you’re replacing outdated technology or setting up a new production line, UV LED curing offers the flexibility and performance modern printing demands.

Experience the Future of Printing

At the heart of every efficient, modern print operation is the right curing technology. Our UV curing systems for printing are engineered to maximize productivity, reduce energy consumption, and deliver exceptional print quality across all applications.

We invite you to explore how our UV LED solutions can transform your printing process. With tailored solutions and expert support, we help businesses across the globe stay ahead of the curve.

Final Thoughts

As industries continue to demand faster, cleaner, and more cost-effective printing solutions, UV LED curing has emerged as the gold standard. From improving print quality to enhancing sustainability, UV curing systems for printing are the ideal choice for future-focused manufacturers.

Whether you're in packaging, commercial print, or specialized industrial applications, our innovative curing systems are built to elevate your output and efficiency. Visit our website today to learn more about our products and see how our solutions can meet your printing challenges head-on.

Contact us:

On Facebook

On Instagram

On Youtube

On Linkedin

0 notes

Text

"Beyond the Printer: How GIS is Redefining the Future of Packaging in a Digital World"

The Challenges and Opportunities of Digital Print in Packaging Introduction GIS has spent over 15 years developing systems for inkjet applications, collaborating with major printhead manufacturers and OEMs to deliver digital solutions across packaging, labels, and Direct-to-Substrate (DTS) markets. According to GIS, digital printing only succeeds when there is both an economic rationale and a…

0 notes

Text

Why UV DTF Transfers Are Ideal for Vibrant and Durable Prints

Introduction

In the world of printing technology, the quest for vibrant colors and durable finishes has always been a top priority. Among the various printing methods available today, one that stands out due to its unique advantages is UV Direct to Film (DTF) printing. This method combines the efficiency of DTF with the robustness of ultraviolet (UV) curing, resulting in prints that are not only eye-catching but also incredibly long-lasting. DTF Printer In this comprehensive article, we will explore why UV DTF transfers are ideal for vibrant and durable prints, shedding light on their benefits, applications, and how they compare to traditional printing methods.

Understanding DTF Printing What is DTF Printing?

Direct to Film (DTF) printing https://lifestyle.countrylegends1059.com/story/52703969/eazydtf-expands-capacity-with-major-investment-in-large-format-dtf-printing-technology is a relatively new technique that allows for high-quality prints directly onto a transfer film. This process involves printing an image onto a special film using specialized inks. Once printed, the design can be transferred onto various substrates using heat and pressure.

The Process of DTF Transfer Printing Film Preparation: The first step involves preparing the transfer film by ensuring it is clean and free from dust. Printing: A direct-to-film printer applies ink to the film in reverse order. Heat Transfer: After the ink dries, a heat press is used to transfer the design onto the desired substrate.

This multi-step process creates stunning visuals with vibrant colors that stand out.

Why Choose DTF Transfers?

DTF transfers provide numerous advantages over traditional methods like screen printing or heat transfer vinyl. They offer flexibility in design, ease of application, and compatibility with various materials.

youtube

The Rise of UV Technology in DTF Printing What are UV DTF Transfers?

UV DTF transfers combine traditional DTF technology with ultraviolet curing methods. This innovation allows printers to instantly cure inks using UV light, leading to faster production times and improved durability.

Advantages of UV Technology in Printing Instant Curing: Unlike conventional inks that require drying time, UV inks cure instantly upon exposure to ultraviolet light. Vibrant Colors: The use of UV technology results in more saturated colors compared to traditional prints. Durability: Prints created using UV curing are resistant to fading from sunlight and other environmental factors. How Does It Work?

The process begins similarly to standard DTF printing but incorporates a UV curing unit that uses specific wavelengths of light to harden and set the ink as it is printed onto the film.

Benefits of Using UV DTF Transfers Why UV DTF Transfers Are Ideal for Vibrant Prints

One primary reason why many businesses choose UV DTF transfers is their ability to produce vibrant prints that truly pop. The rich color saturation achieved through this method captures attention immediately.

Color Accuracy

UV inks provide exceptional color accuracy across various substrates, ensurin

0 notes

Text

A Deep Dive into the Science of Direct to Film Printing

Introduction

Welcome to this comprehensive exploration of Direct to Film (DTF) Printing! If you've wandered into the world of custom apparel or graphic design, you've likely stumbled across the term "DTF." With its rise in popularity, many are curious about what DTF printing entails and how it stacks up against other printing methods. In this article, we will peel back the layers on DTF printing—its science, processes, advantages, and applications. So grab your favorite beverage and settle in for a detailed journey into the realm of DTF transfers and printing services.

What is Direct to Film Printing? Understanding DTF Printing

Direct to Film Printing is a modern technique that allows for high-quality, vibrant prints directly onto a film substrate. The process involves printing designs onto a special film using specialized inks, which are then transferred onto fabric using heat and pressure. Unlike traditional methods such as screen printing or heat transfer printing, DTF is known for its versatility and ability to produce intricate designs with ease.

How Does DTF Work?

The basic workflow of DTF involves several steps:

Design Creation: First, you create your design digitally using graphic design software. Printing on Film: The design is printed onto a PET film using a direct-to-film printer, typically utilizing water-based inks. Powder Adhesive Application: A powdered adhesive is applied to the wet ink on the film. Curing: The film is then passed through an oven or heat tunnel to cure the adhesive. Transfer Process: Finally, the printed film is placed on the fabric and subjected to heat and pressure using a heat press.

This method not only provides bright colors but also ensures durability and washability.

youtube

The Science Behind DTF Transfers Understanding Ink Composition

One of the standout features of DTF printing lies in its ink composition. Typically, it uses water-based inks that contain pigments instead of dyes. These pigments offer better opacity, allowing colors to pop even on dark fabrics—a challenge often faced by other methods like heat transfer printing.

Adhesive Properties in DTF Transfers

The adhesive used in DTF transfers plays a crucial role in ensuring that prints remain intact even after multiple washes. When cured properly, this adhesive forms a strong bond between the ink and fabric fibers.

Advantages of Direct to Film Printing 1. Versatility Across Fabrics

One major advantage of DTF printing is its ability to print on various fabric types—cotton, polyester blends, nylon—you name it! This flexibility makes it an excellent choice for businesses looking to diversify their offerings.

2. High-Quality Prints

Unlike some other methods that may https://storage.googleapis.com/eazydtf-dtf-transfers/eazy-dtf.html result in faded colors over time, DTF prints retain their vibrancy wash after wash thanks to their unique composition.

DTF Transfer 3. Cost-Effective Solutions for Small Runs

For small businesses or custom orders requir

0 notes

Text

DTF Transfers Explained: Process, Benefits, and Applications

Introduction

In the ever-evolving world of printing technologies, Direct to Film (DTF) printing has emerged as a revolutionary method that's capturing the attention of businesses and enthusiasts alike. This innovative approach allows for high-quality transfers that can be applied to various surfaces, making it a versatile solution in the realms of fashion, promotional products, and more. But what exactly are DTF transfers, how do they work, and why should you consider them for your printing needs? In this comprehensive guide, we will delve deep into the process of DTF printing, its benefits over traditional methods like heat transfer printing, its applications across different industries, and much more.

youtube

DTF Transfers Explained: Process, Benefits, and Applications

DTF transfers represent a significant advancement in the printing landscape. Unlike traditional methods that may involve direct screen printing or vinyl cutting, DTF employs a specialized printer that prints designs onto a film using water-based inks. This film is then DTF Transfers coated with an adhesive powder before being heat-activated onto the desired surface. The result? Vibrant prints that adhere beautifully to fabrics while maintaining their color and detail even after numerous washes.

Understanding the DTF Printing Process What is DTF Printing?

Direct to Film (DTF) printing is a modern technique that allows for high-quality image transfers to fabric. Using specialized printers known as direct to film printers, this process involves several key steps:

youtube

Design Creation: First, you create or choose a design on graphic design software. Printing: Using a direct to film printer with special ink cartridges, the design is printed directly onto a film substrate. Adhesive Application: Once printed, an adhesive powder is applied to the wet ink on the film. Curing: The film is then heated in an oven or through a heat press to cure the adhesive powder. Transfer: Finally, the cured image can be transferred onto fabric using a heat press. The Equipment Required for DTF Printing

To embark on your DTF journey, you'll need some essential equipment:

Direct to Film Printer: The heart of your setup; look for models branded as "the best DTF printer" based on reviews and specifications. Heat Press Machine: For transferring prints onto fabric effectively. Adhesive Powder: Specially formulated powders that bond with both ink and fabric. Film Sheets: High-quality films suitable for DTF printing. Advantages of DTF Transfers Over Traditional Methods High Quality and Detail

One of the standout features of DTF transfers is their ability to achieve stunning detail in designs. While traditional heat transfer methods can sometimes lead to pixelation or loss of fine details due to DTF Transfer layering processes, DTF ensures crisp lines and vibrant colors that pop.

Versatility Across Fabrics

Whether you're working with cotton, polyester blends, or even dark fabrics, DTF transfers adhere seamlessly without compromising quality. This vers

youtube

1 note

·

View note

Text

The Evolution of Professional Photo Labs in the Digital Age

In an era where everyone has a camera in their pocket, professional photo labs continue to play a vital role for photographers and memory-keepers alike. These specialized facilities bridge the gap between digital capture and physical preservation, offering services that go far beyond what home printers can achieve.

Why Professional Photo Labs Still Matter

Quality photo labs provide:

Archival-grade printing that lasts generations

Color accuracy calibrated to professional standards

Specialty materials from fine art papers to canvas

Expert retouching and image optimization

For photographers seeking the highest quality output, professional photo lab services offer the technical expertise and equipment to bring digital files to life as physical artworks.

Services Modern Photo Labs Offer

Today's full-service labs typically provide:

Fine art printing for exhibitions and galleries

Custom framing with museum-quality materials

Photo book production with layflat designs

Film development and scanning for analog shooters

Large format printing for statement pieces

The Technical Side of Photo Labs

Behind the scenes, professional labs utilize:

Wide-format pigment printers for longevity

Color-managed workflows for consistency

ICC profiling for different paper types

Densitometers to ensure print quality

Choosing the Right Lab

Photographers should consider:

Paper options available for different projects

Turnaround time for professional deadlines

Color proofing process to ensure accuracy

Packaging and shipping for delicate prints

The Future of Photo Labs

Emerging trends include:

Sustainable printing with eco-friendly materials

Direct-to-substrate printing on unique surfaces

Hybrid services combining digital and analog processes

Online proofing systems for remote collaboration

Professional photo labs remain essential partners for photographers who value quality and longevity. In a world of disposable digital images, these facilities preserve our most important memories in physical form, creating heirlooms that can be passed down through generations. The best labs don't just print photos - they help photographers realize their creative vision through technical expertise and artistic collaboration.

For serious photographers and memory-keepers alike, finding a reliable photo lab is an investment in preserving their work for the future. Whether creating fine art prints, wedding albums, or professional portfolios, the right lab can elevate digital files into lasting physical artifacts.

0 notes

Text

Custom DTF Designs: Bringing Your Ideas to Life

Introduction

In the fast-paced world of fashion and custom merchandise, the demand for unique and personalized designs has skyrocketed. Enter Direct to Film (DTF) printing, a revolutionary method that allows businesses and individuals alike to bring their creative visions to life. With the rise of Custom DTF Designs, artists, entrepreneurs, and hobbyists can now easily create stunning prints that are vibrant, durable, and ideal for various applications. This article will explore the ins and outs of Custom DTF Designs, providing you with valuable insights into how this innovative printing technique works, its benefits, and how you can leverage it for your projects.

What is DTF Printing?

DTF Printing stands for Direct to Film printing. It involves printing designs onto a special film using high-quality inks. After printing, a powdered adhesive is applied before curing the ink with heat. The film can then be transferred to various substrates such as textiles or apparel using a heat press.

The Process of DTF Transfer Printing

The process of DTF transfer printing consists of several key DTF Transfer steps:

Design Creation: Start with a digital design, often created using graphic design software. Printing: Use a direct-to-film printer to print your design onto specialized transfer film. Adhesive Application: Apply a heat-activated adhesive powder onto the printed film. Curing: Cure the ink and adhesive using heat, ensuring they bond well. Heat Transfer: Finally, use a heat press to apply the design onto your chosen material. Benefits of Custom DTF Designs 1. Vibrant Colors and High Detail

One of the standout features of Custom DTF Designs is their ability to produce vibrant colors with exceptional detail. Because DTF uses specialized inks tailored for this process, your designs will pop on any surface.

2. Versatility in Materials

Another significant advantage is versatility; DTF transfers can be applied to various materials including cotton, polyester, canvas, and even some leather products.

3. Durability

Unlike traditional screen printing methods that can fade over time, DTF prints are designed to withstand multiple washes without losing their integrity.

4. Cost-Effective Production

For small businesses or individual creators looking for affordable options, Custom DTF Designs offer cost-effective solutions that allow for low minimum order quantities without sacrificing quality.

Exploring Direct to Film Printers

When considering starting EazyDTF DTF Printer with DTF printing or enhancing your current setup, choosing the right equipment is crucial. A good quality direct-to-film printer can significantly impact the outcome of your designs.

Best DTF Printers on the Market Epson SureColor F2100 Brother GTX Pro Mimaki UJF-3042 Roland VersaUV LEF Series

These printers are known for their reliability and quality output, making them ideal choices for businesses seeking professional results.

youtube

Who

1 note

·

View note

Text

How Does Digital Printer Printing Support On-Demand Printing Needs?

In the fast-paced world of modern business, efficiency and flexibility in printing are crucial. Digital Printer Printing has revolutionized the industry by offering rapid turnaround times, high-quality outputs, and cost-effective solutions for businesses of all sizes. With the increasing demand for personalized, short-run, and quick printing services, digital printing has become the go-to option for various industries.

What Is Digital Printer Printing?

Digital Printer Printing is a method of printing that transfers digital images directly onto various materials without the need for traditional printing plates. Unlike offset printing, which requires significant setup time, digital printing allows for on-demand production with minimal preparation. This makes it an ideal solution for businesses looking to print small to medium-sized batches quickly and efficiently.

Advantages of Digital Printer Printing for On-Demand Needs

1. Faster Turnaround Times

One of the key benefits of Digital Printer Printing is its ability to deliver high-quality prints in a fraction of the time compared to traditional methods. Since there are no printing plates involved, the setup process is significantly reduced, enabling businesses to receive their printed materials faster. This is particularly beneficial for industries that require last-minute changes or urgent printing solutions.

2. Cost-Effective for Short Runs

Traditional printing methods can be expensive due to the costs associated with plate-making and setup. Digital Printer Printing eliminates these costs, making it a more affordable option for businesses needing short print runs. Companies can print exactly what they need without the financial burden of high-volume printing.

3. High-Quality Output

Thanks to advancements in digital printing technology, businesses can achieve sharp, vibrant, and detailed prints. Whether printing brochures, business cards, flyers, or marketing materials, Digital Printer Printing ensures consistent quality without color variations, making it an excellent choice for brand consistency.

4. Customization and Personalization

In today’s market, personalization is key to engaging customers. Digital Printer Printing allows businesses to customize each print with unique text, images, or designs, making it an ideal solution for personalized marketing campaigns, direct mail, and variable data printing. This capability enhances customer engagement and improves response rates for businesses targeting specific audiences.

5. Eco-Friendly Printing Option

Sustainability is a growing concern in the printing industry. Digital Printer Printing reduces waste by eliminating excess materials and unnecessary prints. It also consumes less energy and produces fewer emissions compared to traditional offset printing. Additionally, digital printers often use eco-friendly inks, further minimizing environmental impact.

6. Versatility in Printing Materials

Unlike conventional printing methods, which may be limited in material options, Digital Printer Printing can accommodate a variety of substrates, including paper, cardstock, vinyl, fabric, and even metal. This flexibility allows businesses to explore creative printing solutions that align with their branding needs.

Industries That Benefit from Digital Printer Printing

Retail and E-Commerce

Retailers and e-commerce businesses rely on Digital Printer Printing for product packaging, promotional materials, and custom labels. The ability to print on demand helps brands maintain flexibility in their marketing efforts and product presentations.

Marketing and Advertising

Marketing agencies and advertisers benefit from digital printing’s ability to produce high-quality, short-run promotional materials like posters, banners, and direct mail campaigns. The quick turnaround and customization options make it an essential tool for effective marketing.

Education and Publishing

Schools, universities, and publishers use Digital Printer Printing for booklets, study materials, and custom-printed educational content. The cost-effective nature of digital printing allows institutions to print only the required quantity, reducing waste and unnecessary expenses.

Healthcare and Pharmaceutical Industry

Medical facilities and pharmaceutical companies require on-demand printing for patient information leaflets, prescription labels, and medical brochures. Digital Printer Printing ensures that these materials are produced quickly and accurately, adhering to strict industry regulations.

The Future of Digital Printer Printing

As technology continues to evolve, Digital Printer Printing is expected to become even more advanced, offering higher speeds, better quality, and increased sustainability. With the growing need for on-demand printing, businesses across all industries are embracing digital solutions to enhance efficiency, reduce costs, and meet customer demands in real time.

Conclusion

The rise of Digital Printer Printing has transformed the way businesses approach their printing needs. Its speed, cost-efficiency, and flexibility make it an invaluable solution for on-demand printing. Whether for marketing, retail, education, or healthcare, digital printing provides unparalleled benefits that cater to modern business requirements. As technology advances, this innovative printing method will continue to drive growth, sustainability, and efficiency in the industry.

0 notes

Text

The Ultimate Guide to Digital Printer Printing: Benefits, Process, and Best Practices

Introduction

In today’s fast-paced world, digital printing has revolutionized the printing industry by providing high-quality, efficient, and cost-effective solutions. Whether you need business cards, marketing materials, or customized products, digital printer printing offers versatility and precision. This guide explores the benefits, process, and best practices for achieving optimal results with digital printing.

What is Digital Printer Printing?

Digital printing is a modern printing method that involves transferring digital images directly onto various materials, such as paper, plastic, fabric, and metal. Unlike traditional printing methods like offset printing, digital printing eliminates the need for printing plates, making it a faster and more flexible option for small to medium print runs.

Benefits of Digital Printing

High-Quality Output: Digital printers produce sharp, vibrant, and detailed prints, making them ideal for marketing and branding materials.

Quick Turnaround Time: Without the need for setup processes like plate-making, digital printing significantly reduces production time.

Cost-Effectiveness: Ideal for short-run projects, digital printing allows businesses to print on demand without incurring high setup costs.

Customization and Personalization: Variable data printing (VDP) enables customization of prints, such as personalized direct mail campaigns and promotional materials.

Eco-Friendly Option: Digital printing reduces waste, uses less ink, and minimizes chemical emissions compared to traditional printing techniques.

The Digital Printing Process

File Preparation: Ensure your design files are high-resolution (300 dpi or higher) and saved in appropriate formats such as PDF, TIFF, or JPEG.

Color Management: Use CMYK color mode for accurate color reproduction and consider using ICC profiles for consistency.

Material Selection: Choose the right paper or substrate based on your project requirements (e.g., glossy, matte, recycled, or specialty materials).

Printing: The digital printer applies the ink or toner directly to the substrate without using plates.

Finishing Touches: Additional processes like lamination, varnishing, embossing, or cutting enhance the final product’s appearance and durability.

Best Practices for Optimal Digital Printing Results

Use High-Quality Images: Avoid low-resolution images to prevent pixelation and blurry prints.

Optimize Fonts and Graphics: Convert text to outlines and embed fonts in your files to avoid formatting issues.

Select the Right Printer: Choose a printer with advanced technology that supports high-resolution printing for crisp and vibrant results.

Perform Test Prints: Always print a proof to ensure color accuracy and alignment before running a large batch.

Consider Coatings and Finishing: Depending on your project, coatings such as UV or aqueous coatings can enhance durability and aesthetics.

Applications of Digital Printing

Digital printing is widely used across various industries for:

Business and Marketing Materials: Brochures, flyers, posters, business cards, and catalogs.

Packaging and Labels: Custom labels, stickers, and packaging prototypes.

Apparel and Merchandise: Custom T-shirts, bags, and promotional items.

Photography and Art Prints: High-quality prints for professional photography and artwork.

Conclusion

Digital printer printing continues to grow as a preferred printing method due to its speed, quality, and cost efficiency. By understanding the process, benefits, and best practices, businesses and individuals can leverage digital printing for high-impact results. Whether you need small-batch promotional materials or personalized prints, digital printing provides a reliable and innovative solution.

For more insights on digital printing and how to optimize your print projects, stay updated with the latest industry trends and advancements!

#car wrapping varsity lakes#offset printing#offset printers#a frame signs gold coast#booklet binding#commercial printing#digital printer printing#large format print

0 notes

Text

Industrial & Commercial Barcode Printers: Market Insights & Innovations

The global barcode printer market size is estimated to reach USD 7,521.7 million by 2030, registering to grow at a CAGR of 8.2% from 2025 to 2030 according to a new report by Grand View Research, Inc. Barcode printers are also called specialty printers that print barcode tags, receipts, and labels to be directly printed on or attached to physical objects. They are generally used to label cartons, receipts, and label retail, medical, and food items with European Article Numbers (EANs) or Universal Product Codes (UPCs) before shipment.

Moreover, the market is experiencing rapid advancements in technology. These advancements are leading to the introduction of more efficient and user-friendly barcode printers. For instance, the latest barcode printers can print on a variety of substrates, such as paper, plastic, metal, and wood. This helps reduce production costs and improve the quality of the final product.

The market is projected to be driven by the rising demand for industrial printers across various industrial sectors. The growing adoption of barcode printers owing to their ability to streamline logistics operations is driving the growth. While barcode printers are providing an efficient way to monitor products during their movement along the supply chain, they are also helping in storing IoT numbers and serial numbers to handle the information while the product moves through different channels, thereby encouraging the adoption of barcode printers.

Several manufacturing entities are adopting modern printing technologies to rake in various benefits, such as simplified workflows, reduced prices, and increased quality assurance, thereby driving the adoption of barcode printers across the globe. Market players are responding to the situation by introducing innovative solutions in line with the evolving demands from the incumbents of various end-use industries and industry verticals. Moreover, the growing demand for packaged food in countries such as China and India is particularly expected to fuel the demand for barcode printers over the forecast period.

Aggressive investments by the government to encourage the industry incumbents to adopt the latest technologies, including barcode technology, bode well for market growth. Barcode technology is increasingly being used for robotics, which means the continued implementation of robots across various industries translates into a growing demand for barcode printers. For instance, as per the statistics provided by the International Federation of Robotics (FIR), almost 21,700 industrial robots have been deployed across the industrial sector in the U.K.

The outbreak of the COVID-19 virus across the globe took a severe toll on the global economy. However, it played a significant role in fueling the growth of the barcode printer industry. While the launch and distribution of several products had to be deferred owing to the lockdowns and restrictions on the movement of people and goods executed as part of the efforts to arrest the spread of coronavirus, the installation of barcode systems gained noticeable traction in the manufacturing industry, where barcodes were installed to maintain social distancing without compromising the efficiency of the inventory management.

The market is consolidated and is anticipated to witness increased competition due to the presence of several key players. In January 2023, AVERY DENNISON CORPORATION signed an agreement to acquire Thermopatch, expanding its Retail Branding as well as Information Solutions (RBIS) Apparel Solutions division. Additionally, leverage Thermopatch's know-how and services to drive growth in external embellishments.

Barcode Printer Market Report Highlights

The industrial printers segment is expected to dominate the market and expand at a CAGR of 8.4% from 2025 to 2030

The direct transfer technology segment is projected to grow at the highest CAGR over the forecast perio

The manufacturing segment dominated the overall market with a revenue share of 33.5% in 2024 and is expected to witness a CAGR of over 6.2% during the forecast period

The primary source markets for barcode printers are the U.S., Japan, China, India, the U.K., Canada, Germany, France, and Mexico. The U.S. dominated the market in 2022. The country is home to several leading market players, all of which are investing aggressively in advancing their technology and introducing innovative barcode printers for various industries and industry verticals

Barcode Printer Market Segmentation

Grand View Research has segmented the global barcode printer market based on product, technology, end-user, and region:

Barcode Printer Product Outlook (Revenue, USD Million, 2017 - 2030)

Desktop Printers

Mobile Printers

Industrial Printers

Barcode Printer Technology Outlook (Revenue, USD Million, 2017 - 2030)

Thermal transfer

Direct Transfer

Laser

Impact

Inkjet

Barcode Printer End-user Outlook (Revenue, USD Million, 2017 - 2030)

Healthcare

Manufacturing

Retail & E-commerce

Transportation & Logistics

Government

Others

Barcode Printer Regional Outlook (Revenue, USD Million, 2017 – 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Asia-Pacific

China

India

Japan

South Korea

Australia

Latin America

Brazil

Middle East & Africa

UAE

KSA

South Africa

Key Players in Barcode Printer Market

AVERY DENNISON CORPORATION

Canon Inc.

Dascom

Honeywell International Inc.

Oki Electric Industry Co., Ltd.

Printronix

SATO Holdings Corporation.

Zebra Technologies Corp

Toshiba Tec Corporation

Order a free sample PDF of the Barcode Printer Market Intelligence Study, published by Grand View Research.

0 notes

Text

How to Scale Your Shirt Printing Business with the Right Machine

Scaling a shirt printing business is an exciting yet challenging endeavor. As demand for your custom apparel grows, so too does the need for efficient, high-quality production. Whether you’re a small business owner or looking to expand your operations, choosing the right shirt printing machine plays a pivotal role in taking your business to the next level. The right machine can help you meet customer demand, increase your production capacity, reduce costs, and improve the quality of your prints. In this article, we’ll guide you through the process of scaling your shirt printing business with the right machine.

1. Assess Your Current and Future Needs

Before purchasing a new shirt printing machine, it’s crucial to understand your business’s current needs and future goals. Scaling means you're likely moving from a small to medium or large production operation. Ask yourself the following questions:

What is the volume of orders you currently handle, and what do you expect it to be in the near future?

What types of designs and materials do you frequently print?

What is your budget for new equipment?

Are you looking for speed, quality, or a balance of both?

By understanding where your business is heading, you can determine what kind of machine will fit your specific scaling needs.

2. Consider Your Production Volume

One of the key factors in choosing the right machine is the volume of prints you need to produce. As your orders increase, you’ll need a machine that can handle higher quantities without compromising on quality.

a. For Small-Scale Operations (Low Volume)

If you’re still in the early stages of scaling and anticipate moderate growth, a digital printing machine like Direct-to-Garment (DTG) might be the right choice. DTG printers are perfect for on-demand printing with minimal setup and can print full-color designs directly onto shirts. They are best suited for smaller quantities or custom orders.

Pros:

Fast turnaround times.

No need for large batches.

Excellent for detailed, multi-color designs.

Cons:

Higher per-unit cost for large runs.

Requires regular maintenance for long-term use.

b. For Medium-Scale Operations (Moderate Volume)

As your production volume increases, you might need a machine that balances speed with print quality. Screen printing machines are highly efficient for medium-volume operations, especially if you are producing large batches of the same design.

Pros:

Lower cost per unit for larger print runs.

Great for bold, simple designs with few colors.

Long-lasting prints.

Cons:

High setup time for each design.

Limited in terms of design complexity compared to DTG.

c. For High-Volume Operations (Large Scale)

For large-scale operations where speed and efficiency are critical, consider investing in automatic screen printing presses or hybrid machines that combine different printing methods. Automatic screen printing presses can handle thousands of shirts per day with minimal human intervention, making them ideal for large orders and high-volume production.

Pros:

Extremely fast production.

Capable of printing on a wide variety of materials.

Can handle large orders efficiently.

Cons:

Significant initial investment.

Requires space and maintenance.

3. Choose a Machine That Fits Your Product Variety

As your business grows, you may want to diversify your offerings. The ability to print on a variety of materials and shirt types will help you attract more customers. Consider what types of apparel and materials you’ll be printing on:

For T-shirts and Apparel: Most printers handle cotton and polyester blends, but you should confirm that the machine can accommodate different fabrics, like hoodies, sweatshirts, or even performance wear.

For Other Products: If you're planning to expand into other custom items like tote bags, hats, or hoodies, ensure that the machine you choose can print on a variety of substrates, not just shirts. Machines like sublimation printers can print on polyester fabrics, mugs, and even phone cases.

4. Factor in Quality and Consistency

As you scale, maintaining high-quality prints and consistency becomes more important than ever. The right machine should be able to produce prints that meet your quality standards, whether that means sharp text, vibrant colors, or intricate designs.

DTG Printers: These are ideal for detailed, high-quality prints but may require some attention to detail for color accuracy and print consistency.

Screen Printing Machines: Known for producing long-lasting, high-quality prints, screen printing is great for bulk orders, though it may require more manual oversight for consistency.

Make sure you research the reputation of different brands and machine models to ensure they produce consistent results over time, even as your production volume increases.

5. Automate for Efficiency

As your business grows, you’ll likely need to automate certain aspects of the production process to keep up with demand and reduce labor costs. Some machines offer automatic features that can drastically increase efficiency, such as automatic feeders, dryers, and take-up systems.

Automatic Screen Printing Presses: These presses can handle much higher volumes, with the ability to print multiple shirts simultaneously and quickly, making them an excellent choice for scaling businesses.

Hybrid Machines: Some modern machines combine both digital and traditional printing techniques. For instance, a hybrid machine that offers both DTG and screen printing capabilities allows you to choose the best method depending on the order size, design complexity, and material type.

6. Understand the Total Cost of Ownership

When scaling your business, it’s essential to consider not just the initial cost of the machine but also its long-term operating costs. Keep in mind:

Maintenance Costs: All machines require maintenance, and high-volume machines may need more frequent repairs and part replacements.

Consumables: Printing ink, transfer paper, screen mesh, and other materials can add up quickly, so factor these costs into your decision-making process.

Energy Consumption: Some machines consume more energy than others, especially high-speed printing presses. Make sure to choose a machine that fits within your energy budget.

7. Look for a Machine with Support and Training

When scaling your business, you’ll need reliable technical support and training to ensure your team can operate the machine effectively. Look for manufacturers or distributors that offer comprehensive support, including:

Training: Many manufacturers offer on-site or online training to help you get up to speed with your new machine.

Customer Support: Ensure that the manufacturer provides excellent customer service to troubleshoot issues, offer advice, and supply spare parts when needed.

Conclusion

Scaling your shirt printing business requires careful planning and investment, and selecting the right shirt printing machine is key to your growth. Whether you choose a DTG machine for flexibility, a screen printing press for bulk orders, or an automatic press for high-volume efficiency, the right machine will enable you to increase production while maintaining quality and consistency. By evaluating your current and future needs, considering your production volume, diversifying your product offerings, and ensuring reliable support, you can successfully scale your business and meet the demands of a growing customer base.

0 notes