#electronic batch record system

Explore tagged Tumblr posts

Text

The Art of Crafting Batch Manufacturing Records

A batch manufacturing records serves as a comprehensive document, capturing the entire manufacturing history of a product batch. This terminology finds widespread application in the Pharmaceutical & Chemical industries and is a key reference in various pharmaceutical and food regulatory agency guidelines. According to the US Food and Drug Administration's definition, a batch represents a specific quantity of a drug or material, intended to possess consistent characteristics and quality, adhering to defined limits. It is manufactured in a single production order during the same manufacturing cycle.

Batch Manufacturing Records

Batch Manufacturing Records play a crucial role in ensuring the attainment of quality standards and meeting regulatory requirements. These essential documents typically encompass information pertaining to various aspects of product batch manufacturing, including:

Commencement and completion dates of the manufacturing process.

A comprehensive list of all materials used, along with their respective quantities.

Inventory of packaging materials utilized in the process.

Detailed description of each step in the manufacturing process, including the corresponding completion times.

Identification of the responsible person's initials at each stage.

Documentation of all in-process checks, along with their outcomes.

Reference to any equipment used during the manufacturing.

Batch yield and reconciliation data.

Any deviations or variations encountered during the process.

Information related to Quality Control measures and assessments.

The Electronic Batch Manufacturing Records are often presented in an instructional format, allowing operators to input processing details as needed. It is of utmost significance to furnish the required information in the designated sections of these records.

During vital procedures like raw material weighing, an additional individual is required to verify calculations, confirm material identities, and endorse the Batch Manufacturing Records.

Furthermore, a unique batch number is assigned to each production batch and is clearly indicated on the corresponding Batch Manufacturing Record.

The Batch Manufacturing Records are required to adhere to the following guidelines:

Readable

Enduring

Precise

Authentic

Signed

Every correction and deviation must be documented and approved within the Batch Manufacturing Records.

Mandates the inclusion of specific information in a Batch Manufacturing Record. The details that must be documented are as follows:

The identity of the dietary supplement or dietary ingredient used in the manufacturing process.

The quantity of each component used.

A statement of the actual income and percentage of theoretical income.

A description of the packaging and labeling process used.

Documentation of any product specifications established to ensure the quality of the finished product.

Written procedures for the calibration of instruments, if applicable.

Written procedures for the manufacturing process and control of each batch.

Documentation of the reevaluation of any manufacturing process that is not controlled by the specifications.

Documentation of the review and approval of any deviation from the batch record, including the reason for the deviation and the signature of the individual responsible for the decision.

Documentation of the date and time of the signature of the person responsible for the manufacturing operation and the quality control unit.

Ensuring that these specific pieces of information are included in the Batch Manufacturing Record is crucial for compliance with FDA regulations and maintaining product quality and safety.

Process XE is web based, flexible and user-friendly software solutions for Business process automation.

This Digital, Smart Manufacturing process automation is principally developed for Pharmaceutical, Life science and Healthcare industries to simplify their manufacturing execution system of various processes such as data capture, batch information exchange, batch production management, data security maintenance, data integrity and report production, ensuring compliance to cGMP requirements.

For more details on MES, Contact our sales team. <Book A Demo>

#batch records#batch manufacturing record#batch records pharmaceutical#batch packaging record#electronic batch manufacturing records#electronic batch records#electronic batch record software#electronic batch record system

0 notes

Text

When Russian troops seized control of the Chernobyl nuclear power plant last year, following the invasion of Ukraine, President Volodymyr Zelensky called it “a declaration of war” against Europe. Others warned that Russia’s reckless seizure of the plant could trigger a nuclear disaster to rival Chernobyl’s 1986 radiological accident.

Their fears seemed well-founded when, on the night of the invasion, sensors began reporting sudden spikes in radiation levels in the Chernobyl Exclusion Zone (CEZ)—a 1,000-square-mile forested zone around the plant where radioactive soil from the 1986 disaster had settled.

Forty-two sensors recorded spikes that night and the next morning—some at levels hundreds of times higher than normal. The State Nuclear Regulatory Inspectorate of Ukraine (SNRIU) eased concerns that nuclear material had leaked from the plant, however, when it said the spikes were likely due to “resuspension” of radioactive soil stirred up by Russian military vehicles—an explanation widely accepted by many nuclear experts and the media.

But a group of environmental radiation experts disputes this conclusion. In a paper published in June by the Journal of Environmental Radioactivity, they detail why there’s no way soil resuspension could have caused the spikes and speculate that interference from an electronic warfare weapon was behind the surge instead.

Now, in what is becoming a deepening mystery, noted cybersecurity researcher Ruben Santamarta says he believes something else was the cause—data manipulation, possibly through a cyberattack.

Based on patterns he found in the spikes—batches of sensors geographically distant from one another recorded spikes at the exact same moment, while sensors closer to them recorded no elevation—he thinks a remote hacker or someone with direct access to the server processing the data manipulated the numbers.

After an extensive review of the data and other materials, Santamarta says he finds it hard to believe the explanation about soil resuspension was ever considered plausible. And he is surprised that authorities never bothered to examine the data for patterns or, if they did, kept that information from the public. He thinks those patterns discount theories about interference from electronic weapons, and he plans to present his findings at the BlackHat security conference in Las Vegas next week.

“I have collected a significant amount of evidence by different means, including OSINT [open source intelligence], hardware and software reverse engineering, and data analysis of the radiation levels,” he says “I think it is enough to seriously consider the possibility that these radiation spikes were fabricated.”

If Santamarta is right, his finding could have far-reaching implications for radiation-monitoring systems around the world, says a former nuclear safety official who asked to remain anonymous in order to speak freely about the matter. If the data was manipulated, it could undermine trust in radiation-monitoring systems or change how data from them gets reported publicly. Data from radiation monitors is often distributed publicly in near real time so that governments and nuclear experts can actively monitor conditions in populated cities and around nuclear facilities. But this creates a risk that hackers or others could alter data to trigger public alarm before proper verification can occur.

Monitoring Networks

Russian troops entered the CEZ early on the morning of February 24 last year because it’s the shortest and most direct route from Russia-friendly Belarus to Kyiv, Ukraine’s capital 80 miles south of the plant. But some feared Russia’s interest in Chernobyl was more than strategic. They worried the military could cause a disaster using radioactive waste at the plant or drum up false claims that Ukraine was building a dirty bomb there.

After a day-long battle with Ukrainian troops and three hours of negotiations to establish parameters for Russia’s occupation of the plant, Russia took control of Chernobyl’s facilities. At 8:40 pm local time, 10 minutes after the SNRIU indicated that Russia had formally taken control of the plant, seven monitoring stations in the CEZ suddenly began reporting elevated radiation levels. The readings ranged from two to five times the normal radiation rate each sensor had historically detected, but one station showed a level eight times higher than normal.

Ukraine has two networks of sensors to monitor radiation at Chernobyl. A set of 10 sensors inside the plant is operated by the state-owned nuclear energy company Energoatom. A second network, known as a radiation-monitoring and early-warning system (the Ukrainian acronym for it is ASKRS), consists of about 68 battery-powered GammaTracer detectors spread throughout the CEZ (with a few positioned outside it). This network is managed by the State Specialized Enterprise Ecocenter (Ecocenter, for short), under the State Agency for the Management of the Exclusion Zone.

These detectors continuously record ambient gamma radiation levels in the CEZ, process the readings to calculate an average, then transmit that figure once an hour (or every two minutes in an emergency) to a base station in the Ecocenter’s office in the town of Chernobyl, about 10 miles from the plant. The data is transmitted via radio over a dedicated channel using a SkyLink protocol.

The data then gets analyzed and processed with DataExpert software and a custom Ecocenter program before being posted to the Ecocenter’s website. It’s also distributed to the SNRIU, the International Atomic Energy Agency (IAEA)—the UN body that monitors nuclear programs around the world—and other governments.

The data can be difficult to find on Ecocenter’s site, so a Ukrainian nonprofit called SaveEcoBot scrapes it and republishes the data on its own site for easier access. It’s these two sites that many people around the world were using to track radiological conditions at Chernobyl in real time on the day of the invasion, and that triggered alarm when people began posting screenshots of them on Twitter.

The Spikes

Radiation levels at Chernobyl are measured as “ambient dose equivalent” rates—essentially the amount of energy, due to ionizing radiation, that the human body would absorb if exposed to the level of radiation a sensor detects. Dose rates are reported as microSieverts per hour (aka μSv/h).

Following the first spikes at 8:40 pm on February 24, 2022, the next cluster of spike occurred at 9:50 pm, when 10 different sensors reported elevated radiation levels, as well as one that had been in the earlier cluster.

More cluster spikes occurred at 10:20 pm, 11:30 pm, and 11:50 pm, involving nine, six, and five sensors, respectively, and then the pattern switched. From 12:01 am to 12:20 am on February 25, there were several spikes involving just one or two sensors each time. Then at 9:20 am, 10 sensors spiked simultaneously, including one that increased nearly 600 times its normal radiation reading. At 10:40 am, nine sensors spiked. And at 10:50 am, the last spike occurred with a single sensor. This sensor spiked three times in all. Called Pozharne Depo, its baseline reading of 1.75 μSv/h spiked to 8.79 (at 8:40 pm), 9.46 (at 9:50 pm), and 32.2 (at 10:50 am the next morning). The sensors may have continued spiking, but the Ecocenter website stopped updating its data.

Like other European countries, Finland carefully tracks Ukraine’s radiation levels. According to Tero Karhunen, a senior inspector with STUK, Finland’s radiation and nuclear safety authority, if ambient dose rates rose above 100 μSv/h for more than 48 hours, it would generally trigger an evacuation of affected regions.

Two sensors nearly reached that threshold at 93 μSv/h, but then they and all the other sensors stopped reporting updates—or at least the Ecocenter stopped posting updated data to its website. It’s not clear why this stopped. The invasion caused internet disruptions in Ukraine, but this would not have prevented the sensors from transmitting their data to the base station; it would only have prevented the Ecocenter from publishing new data to its website.

Yet the Ecocenter did continue to publish new data for some sensors. Shortly after the sensors spiked, online updates of data from 30 of them stopped; but data for the remaining ones continued until they stopped updating at different times. Most of the sensor data was updating online again the following Monday, February 28—at which point all the sensors were reporting normal radiation levels. But by March 3, Ecocenter had stopped posting data altogether.

This may be because Russian troops began stealing and damaging equipment at Chernobyl—including the server and software Ecocenter used to receive and process sensor data. In a French TV news interview after Russian troops left Chernobyl at the end of March, Mykola Bespalyi, head of the Ecocenter’s central analytical lab, showed an empty cabinet that had housed the server, explaining that the center had lost its connection to the radiation sensors in the CEZ. Data transmissions only restarted in June when the IAEA and others helped Ukraine restore the radiation-monitoring system.

Official Response

The spikes were initially attributed to shelling. In a news story published about an hour after the spikes began, an unnamed Ukrainian official said Russian shelling had hit a “radioactive waste repository” and implied that radiation levels had risen as a result. Anton Herashenko, advisor to Ukraine’s Interior Ministry, then warned that the attack could send radioactive dust into Belarus and the EU.

But the next morning, on February 25, the SNRIU said the cause of the spikes couldn’t be determined. Later it released a statement saying Ecocenter experts attributed the spikes to topsoil stirred up—or “resuspended”—by military equipment. At that point, media attention turned to ongoing battles elsewhere in Ukraine, and talk of the spikes dropped.

Not everyone bought the explanation, however. Karine Herviou, deputy director general in charge of nuclear safety at France’s Institute for Radiation Protection and Nuclear Safety, told reporters there was no coherent explanation for the spikes, though her group later issued a statement saying they didn’t have any information “to confirm or refute” the SNRIU’s assertion about soil resuspension.

Bruno Chareyron, a nuclear physics engineer and laboratory director for France’s nongovernmental Commission for Independent Research and Information on Radioactivity, also scoffed at the soil explanation. Instead, he told reporters at the time that the spikes might be the result of interference—from a cyberattack.

If you look at a map showing the places where the results had been increasing, “there was no logic” to the soil suspension explanation, he now says. And given that Russia had been prolifically hacking Ukrainian systems at the time of the invasion, it was reasonable to wonder whether a cyberattack had resulted in false data.

Hours after the SNRIU’s statement, the IAEA released its own. Apparently accepting that the radiation spikes were real, the agency said the elevated radiation levels posed no threat to the public. Oddly, though, it referred to the spikes as topping out at 9.46 μSv/h—a figure it received from Ukraine’s nuclear regulator. But the agency only had to look at the Ecocenter’s website to see that some sensors were reporting levels magnitudes higher than this at 58 and 65 μSv/h.

Only some of the GammaTracers are considered “regulatory” sensors—meaning the SNRIU is required to submit data from them to the IAEA. At least three of these regulatory sensors were among those reporting exceptionally high data spikes. But it appears that the SNRIU didn’t provide data from those sensors to the IAEA. It’s not clear why; the SNRIU didn’t respond to inquiries from WIRED.

Notably, there was chatter on Twitter at the time, among nuclear and radiation experts, that the spike data might be erroneous. But if the sensor readings being reported by Ecocenter on its website were accurate, then contrary to the IAEA’s statement that the spikes posed no threat to the public, “this would have been a very dangerous situation for the people in the area,” Chareyron says.

Why did the IAEA only reference the lower radiation spikes in its statement and not the higher ones? The IAEA, after asking WIRED to submit questions in writing, didn’t respond to this or any of the other detailed questions submitted to it, including whether it attempted to investigate the veracity and cause of the spikes.

In the US, the National Security Council followed events in Chernobyl closely but did not respond to repeated requests to discuss the mystery around the radiation spikes.

Soil Suspension, Debunked

As noted, Mike Wood, a professor of applied ecology at the University of Salford in the United Kingdom who studies environmental radiation, including in the CEZ, examined the spike data with four colleagues and ruled out soil resuspension as the cause.

Wood says there isn’t enough radiation in the CEZ soil to cause the level of spikes that occurred—not to mention that military vehicles traveled primarily on asphalt and hardened dirt roads, not in places where loose soil would have been stirred up.

“Even with conservative assumptions, you cannot get anything like the rises that we’ve seen in those dose rate spikes,” he says.

What’s more, experts told WIRED that if soil resuspension were the cause, the radiation levels should have dropped gradually over days as the soil and dust resettled. Instead, many of the sensors were back to reporting normal levels within 30 minutes to a couple of hours after reporting a spike, despite heavy military traffic continuing in the region.

There was also no uniformity or expected patterns to the spikes. Instead of sensors spiking at different times as radiation levels near them rose, multiple sensors in different locations spiked at exactly the same time. Some sensors reported spikes 12 to 38 times their baseline level, others 300 times above baseline. The sensor that spiked nearly 600 times its base level was 18 miles southeast of the plant, located along what Wood calls a “minor” road where “there is no logical explanation as to why there would be significant military activity.”

Olegh Bondarenko, director of the Ecocenter until 2011, agrees with Wood’s conclusions and calls the air suspension explanation “fantastical.” But he doesn’t think Wood’s alternate theory—that the spikes were caused by interference from electronic warfare weapons—was the cause either.

Electronic Warfare

Electronic warfare weapons are used as jamming devices to hinder or block an enemy’s communications and signals.

But Karhunen says Finnish researchers conducted limited tests on the effects of electronic warfare weapons on radiation sensors and found that they could also cause sensors to report false readings up to 30 μSv/h—300 times the base levels for the test systems.

William Radasky, former chair of an International Electrotechnical Commission subcommittee on electromagnetic weapons and their effects, says interference can cause data spikes and, depending on a weapon’s strength, permanently damage sensors. If a weapon were close to a radiation detector when it was fired, “they would probably kill the electronics used with the sensor,” says Radasky, who has conducted research for the US government and military on effects of electromagnetic pulses on defense systems and the electric grid. The pulses wouldn’t interfere with the sensors’ ability to detect radiation, but they would affect the electronics that are used to translate the radiation signals from the sensor into saved data and then transmit that data to the Ecocenter. It’s worth noting that the IAEA visited Chernobyl after Russian soldiers left and reported that many radiation-monitoring stations were damaged and out of service. The agency never identified which sensors or explained the nature of the damage, however.

But if such weapons can produce spikes in the sensor data, that still doesn’t explain the anomalous nature of the spikes, Radasky and Bondarenko say. There were no reports of other equipment in the CEZ being affected by electromagnetic weapons. And radiation sensors in other parts of Ukraine where fighting occurred—and presumably where electromagnetic weapons would likely have been used—did not experience spikes.

Most significantly, sensors that showed spikes in their data were near sensors that didn’t record spikes, and the geographical distance between sensors that spiked defied logic. Many of the sensors that showed simultaneous spikes in the CEZ were more than 30 kilometers apart. Radasky says it would be possible to have a single weapon affect sensors geographically apart, but only at limited distances.

“The most powerful [electromagnetic weapon] I know about could create a high field over [only] a kilometer,” he says. “There is no way to simultaneously affect widely dispersed sensors … from a single weapon.”

If troops dispersed throughout the CEZ carried portable electromagnetic weapons and fired them at the same time, it would be possible to affect sensors far apart, Radasky says. “But … the likelihood that they would have set off those weapons at the exact same moment, causing simultaneous spikes, seems highly unlikely,” he says, noting that a pulse generally lasts for one microsecond.

This, plus patterns that Santamarta found in the spikes, “really does sound like … this is a hacking attempt and not an electromagnetic weapon attack,” Radasky says.

Bondarenko agrees. Every other explanation is “practically implausible or impossible.” It would have been easy, he says, to “write a script that causes certain sensors to elevate at a certain time and then to go back to normal at a certain time.”

Jan Vande Putte, a lead radiation specialist at Greenpeace Belgium, led a team that visited Ukraine last July to measure radiation levels in one part of the CEZ. He agrees that none of the other given explanations are plausible. But he cautions that Santamarta’s theory of data manipulation, while convincing, is still speculation without a forensic investigation to support it.

“I have seen so many examples of coming to wrong conclusions,” he says.

Data Manipulation

Santamarta began looking at the issue last year, after a non-Ukrainian nuclear engineer who has done research in the CEZ asked him to consider whether the sensors could have been hacked. Santamarta specializes in critical infrastructure vulnerabilities and in 2017 found unpatched flaws in radiation-monitoring systems that would let someone falsify data with the aim of simulating a dangerous radiation leak.

He studied the type of sensors used in Chernobyl—a model made by the France-based company Saphymo (later purchased by Bertin Technologies)—and obtained raw sensor data Ecocenter posted to its website, which contained time stamps identifying when each sensor spiked.

He identified 42 radiation sensors that reported spikes in four different patterns—patterns that he says support his assertion that the radiation spikes were fabricated. In the first pattern, 18 sensors reported spikes before going offline. In the second pattern, 17 sensors each reported spikes two times. The second spike was always incrementally higher than the first. For example, a monitoring station called Buryakovka showed a moderate spike on the night of February 24, from 2.19 to 3.54 μSv/h. But at 9:20 am the next morning, it shot up to 52.7 μSv/h.

The third pattern involved two sensors that each spiked three times. The fourth pattern involved five sensors that experienced two spikes—the first spike occurred at 8:40 pm and the second at 11:30 pm the night of the invasion. In each case, the second spike involved a lower value than the first spike—in other words, the second reading was still higher than the baseline level, but lower than the earlier spike. For example, a sensor station called Gornostaypol normally reported a baseline of .092 μSv/h, but during the first spike at 8:40 pm it shot up to .308 μSv/h and at 11:30 pm it reported a level of .120 μSv/h—about midway between the two.

Santamarta believes the patterns strongly suggest that someone wrote code to inject false data into the Ecocenter’s DataExpert database at intervals. The code then posted the false data to the Ecocenter’s website while suppressing legitimate data that came in from the sensors.

“After characterizing the spikes, which are clearly structured, it’s difficult not to assume some kind of human intervention behind them,” he says.

WIRED sent the State Agency for the Management of the Exclusion Zone a list of detailed questions about the patterns Santamarta found and asked whether it had conducted any investigation to determine the cause of the spikes. The agency declined to answer most of the questions and said it was unable to answer others because the events occurred when Russian forces controlled the CEZ and Ecocenter personnel weren’t in a position to know what occurred or to carry out “any corrective actions on the systems.”

Because Ecocenter staff weren’t present, “there is almost no information about the situation around the sensors and servers of Ecocenter in the described period,” Maksym Shevchuk, deputy head of the state agency, said in an emailed statement that his agency translated into English. He noted that any data transmitted by the sensors during that time was automatically received and “automatically transmitted in ‘as-is’ mode” to “various departments outside the exclusion zone,” suggesting that any data posted to the Ecocenter website and transmitted to the IAEA was automatically processed and sent without involvement from Ecocenter staff.

With regard to Santamarta’s findings, Shevchuk said his agency’s “competence does not include the assessment of hypotheses and assumptions on this topic coming from third parties,” and he therefore can’t comment on them.

Who and Why

Santamarta doesn’t speculate in his presentation about who was behind the manipulation if it occurred—he wanted to focus on finding a sound technical and plausible explanation of the cause. But there are two obvious suspects—Russia and Ukraine—both of which have means and motive.

Russia has repeatedly threatened a nuclear event to assert dominion in the conflict and, some argue, to warn NATO against getting involved. And Russian authorities have made numerous claims before and after the invasion that Ukraine was developing a radioactive dirty bomb. A Russian scientist told state media that Russian troops seized Chernobyl to prevent Ukraine from creating a dirty bomb, and the radiation spikes could have been used as “evidence” of illicit nuclear activity on the part of Ukraine.

What’s more, in an April 2022 report about the war, Microsoft revealed that Russian hackers affiliated with the FSB intelligence service had breached a Ukrainian “nuclear safety organization” in December 2021 and stolen data for three months with the aim of obtaining data that would support Russia’s disinformation claims about Ukraine, including claims that it was building a dirty bomb. The report didn’t identify the organization, but the breach shows that Russia had a particular interest in hacking nuclear organizations in Ukraine with the aim of supporting its disinformation campaign.

These suggest a potential method and motive for Russia. But there’s a hitch in this theory. After Ukrainian officials cited the spikes in their denunciation of Russia’s “reckless” seizure of the plant, Russian Ministry of Defense spokesperson Igor Konashenkov denied that any spikes had occurred. He didn’t say how he knew this, but Bondarenko believes Russian troops likely carried handheld radiation meters with them into the CEZ, where they may have gotten very different readings from those the Ukrainian sensors were reporting. A Russian scientist also told Russian media that once data from the CEZ sensors started being posted online again “it would be clear that the radiation situation at Chernobyl was under control.”

If Russia planned to use the spikes to bolster claims that Ukraine was building a dirty bomb at Chernobyl, why didn’t it seize the opportunity to further that claim, instead of disputing that the spikes were real.

As for Ukraine’s potential motives, on the day of the invasion and for days after, Ukraine was struggling to secure timely financial and military aid from Europe. Radiation spikes could have helped underscore the potential nuclear threat to EU leaders if they didn’t act quickly to help Ukraine expel Russian troops.

But there’s another possible motive as well. A Chernobyl worker may have inadvertently revealed it in an interview with the Economist after Russian troops left Chernobyl at the end of March.

He told the publication that during the occupation of the plant, Chernobyl staff had “exaggerated the threat of radiation” to Russian troops, identifying “problematic areas” that they should avoid—all as part of a “cheeky plan” to control where the soldiers went. He didn’t mention the radiation spikes, but they could conceivably have been part of this plan.

After Russian troops left Chernobyl, workers also told reporters that some of the troops had exhibited signs of radiation poisoning—they “developed huge blisters and were vomiting after ignoring warnings about digging trenches in radioactive soil.” Reporters have not been able to independently verify the claims. The IAEA conducted tests after the soldiers left and determined that the digging would not have posed a radiation threat to the soldiers, raising questions about whether the reports of radiation sickness were falsified to instill fear in Russian soldiers.

It may be noteworthy that, in June of this year, as tensions around the Zaporizhzhia plant heated up during Russia’s occupation of that facility, Moscow ordered its troops to halt the automatic transmission of data from the plant’s radiation sensors. The sensors continued to monitor radiation levels, but the data was manually collected from the sensors by IAEA staff.

Verifying Spikes

There were a number of ways to verify the veracity of the spikes when they occurred last year, but there’s no sign anyone in Ukraine questioned the integrity of the data or ordered an investigation. Vande Putte says this was never discussed when his Greenpeace group traveled to Ukraine.

More than two dozen wireless sensors in the CEZ have aerosol filters attached to them that detect radiation levels in the air. Karhunen says the filters are “a hundred million times more sensitive” to small changes in radiation than the digital sensors. Before the invasion, Chernobyl workers collected the filters once a week to test them in a lab. These could have been tested to see if they detected the same radiation levels as the digital sensors. But it seems this didn’t happen during the Russian occupation of the plant when the activities of Chernobyl workers were strictly curtailed, and it’s not clear if the filters were collected and tested afterward. Vande Putte says the Russians left land mines behind in the CEZ, and this may have made it too dangerous for workers to collect the filters after they left.

Once the occupation ended, it would also have been possible to conduct a forensic investigation. Even though the Ecocenter data server, and any digital evidence of manipulation it contained, was no longer available because the Russians stole the server, investigators could have extracted data from the memory of the digital sensors in the CEZ—land mines permitting—to see if data stored in the devices matched what was posted to the Ecocenter website. If it didn’t, this could have bolstered the theory that the data was manipulated on the Ecocenter server. It’s not clear anyone did this, however. Ukraine’s computer emergency response team would likely have been involved in such an investigation, but a source with knowledge of the CERT’s activities says the organization never received a request to investigate the Ecocenter’s systems, and the Ecocenter didn’t respond to WIRED’s inquiries.

It’s possible Ukraine and the IAEA didn’t investigate the spikes because they simply had other more pressing things to address—for example, an ongoing crisis at the Zaporizhzhia nuclear plant. The State Scientific and Technical Center for Nuclear and Radiation Safety told WIRED that it did do a radiological survey after Russian troops left Chernobyl, but this was to determine if Russian forces had absconded with any nuclear materials or planted them in occupied regions to leave behind a nuclear hazard, according to Yuliya Balashevska, who headed the survey. The survey focused only on Kyiv and southeast border regions, and Balashevska said her organization has no access to the Chernobyl sensors and could not have examined them if it wanted to do so.

It may be the case that authorities simply never questioned the authenticity of the spikes and therefore saw no reason to investigate.

Santamarta, however, believes the IAEA and Ecocenter didn’t investigate because of the potential geopolitical implications if such an investigation reached “an inconvenient conclusion” that risked adding “more complexity to an already extremely complicated situation.”

Either way, he, like everyone else WIRED interviewed, says the truth about what occurred is more important than whatever the findings might reveal about who was involved.

Although it’s not clear whether, 18 months after the invasion, evidence still exists that could resolve the mystery of the radiation spikes. Greenpeace’s Vande Putte says an investigation is merited, and that Santamarta’s research is high-quality and “very valuable” as a starting point.

The implications, if the cause was intentional data manipulation, are global, given the potential precedent for manipulating sensors in other regions.

“The truth in these matters is really important. Where did it go wrong? Was it purely technical? Was it deliberate?” he says. “We need to get to the bottom.”

9 notes

·

View notes

Text

2004 Rules on Notarial Practice (2004 Notarial Rules)

2004 Rules on Notarial Practice, effective March 4, 2025, focusing heavily on digitization and electronic submission requirements for notaries public. It details new qualifications for notarial commissions, including mandatory professional email addresses and continuing legal education compliance. The document specifies prohibited fees related to digitization and sets out rigorous rules for electronic notarial registers, including PDF formatting, file naming conventions, and secure email transmission protocols for documents to clerks of court. Furthermore, it mandates the electronic transmittal of notarized documents to signatories and addresses the digitization of existing court archives of notarized acts, emphasizing the preservation of signatures, thumbmarks, and seals in digital formats.

The Court en banc issued a Resolution dated March 4, 2025, which amends the 2004 Rules on Notarial Practice as part of the Court's efforts to digitalize court processes and documents, based on recommendations from the Committee on Computerization and Library.

Salient points of the amendments and directives include:

Digitization Capacity of Clerks of Court The Office of the Court Administrator and the Management Information Systems Office are directed to ensure that clerks of court are equipped to host, accept, store, and archive digitized notarized documents in PDF or PDF Archival format, with necessary equipment and technical requirements.

Commissioning of Notary Public (Rule III)

Petitions for notarial commission must now include a petitioner's valid and professional email address, professional tax receipt, Integrated Bar of the Philippines (IBP) membership and compliance numbers (Mandatory Continuing Legal Education, Legal Aid Service), along with other personal qualifications.

Applicants must submit three unretouched passport-size color photographs taken within 30 days, with the petitioner's signature at the bottom.

Each notary public with a valid commission must notify their executive judge of a valid and professional email address of record, which must follow the [local-part]@[domain] syntax and be capable of receiving external emails. Personal, non-professional email accounts are prohibited to preserve confidentiality, privacy, and security. Prompt notification of any email changes is mandatory, with failure to do so being a ground for denial of commission renewal.

Fees of Notary Public (Rule V)

No fees or compensation are to be collected for the digitization of any instrument or document, their transmittal, storage, disposal, or any associated processing costs.

Notarial Register and Electronic Documents (Rule VI)

Notaries public must keep an original copy of contracts and retain an exact copy in a prescribed electronic file format, which serves as the duplicate original copy for the clerk of court.

This duplicate original for the clerk of court must be a complete, exact, and legible PDF reproduction of the paper original, reproducing all colors and marks as far as practicable.

Each duplicate original copy must be in its own PDF file, not split across multiple files or contained within archive files like ZIP or RAR. The filename must contain the document's title, notarial act date, and, if necessary for uniqueness, short forms of parties' names.

A certified copy of each month's entries and electronic duplicate originals must be forwarded to the clerk of court within the first ten days of the following month.

Electronic transmission to the clerk of court must use only the notary public's email address of record. The email subject must follow a specific format (e.g., "Notarial Report of [Name] for [Month and Year]"). For large files exceeding email attachment limits, documents can be sent in batches, with the subject clearly indicating the batch number and total batches (e.g., "Notarial Report... (batch 1 of 3)").

The transmittal email body must include the notary's name, compliance period, details of the notarial report submission, number of documents, and an inventory list of duplicate originals. All PDF files must be direct attachments, not external links.

Mandatory Transmittal to Signatories: A notary public must transmit, at no additional cost, an electronic copy of the document to each signatory within five days of the notarial act completion or the deadline for transmittal to the clerk of court. Signatories can waive this electronic copy.

Discrepancies and Penalties: If a signatory finds material discrepancies between their document and the electronic copy, they must promptly notify the notary public in writing to request rectification. Failure to rectify material discrepancies or respond to a signatory's notice is a ground for nonrenewal of a notarial commission and temporary disqualification. Transmitting an unrectified duplicate original or one with reported material discrepancies to the clerk of court is a ground for revocation and permanent disqualification.

Signature and Seal of a Notary Public (Rule VII)

Notaries are enjoined to ensure their official seal's mark, image, or impression is visible when digitized, using ink, shading, or similar mechanisms. The use of a secondary reproduction of the official seal, such as a stamp, is not a substitute.

Digitization of Court Archives (Rule XII)

Courts retaining duplicate original copies are directed to inventory and assess these documents for feasibility of digitization, particularly focusing on digital preservation of markers like signatures, thumbmarks, and seals.

The resolution was signed by various Supreme Court Justices and other officials, including the Chief Justice and members of relevant committees involved in computerization and the revision of notarial rules.

0 notes

Text

Top Packaging Manufacturers in UAE: What You Need to Know

In today’s fast-paced business environment, packaging plays a crucial role not just in protecting products, but also in enhancing brand identity and customer experience. Whether you’re a retailer, manufacturer, or e-commerce business, choosing the right Packaging Manufacturers In UAE is essential to meet your packaging needs efficiently and cost-effectively. With the UAE becoming a significant hub for logistics and exports, the demand for high-quality and innovative packaging has seen a sharp rise. The best Packaging Manufacturers In UAE offer comprehensive solutions that are both functional and sustainable, making them a preferred choice for businesses across various industries. From basic corrugated boxes to premium Custom Boxes UAE, manufacturers in the UAE continue to set global standards in quality and customization.

Why Packaging Matters More Than Ever

Packaging is more than just a container; it is the first impression your product makes. In retail environments, well-designed packaging can influence consumer purchasing decisions. For online sellers, sturdy and presentable packaging ensures product integrity during transit and contributes to brand reputation. Businesses today are shifting towards customized, eco-friendly, and functional packaging — a trend that Packaging Manufacturers In UAE are quick to adapt to. From design to delivery, every element of packaging reflects your brand’s values and professionalism.

Core Services Offered by Leading Manufacturers

Professional packaging manufacturers in the UAE provide a wide range of services that go beyond basic box creation. Some of the common offerings include:

Custom Design and Printing: Many manufacturers offer bespoke packaging solutions, including Custom Boxes UAE with branding, graphics, and sizing tailored to client needs.

Material Selection: From corrugated cardboard and kraft paper to eco-friendly and biodegradable options, manufacturers provide a range of materials suited to different industries.

Product-Specific Solutions: Whether it’s food-grade packaging, electronics, cosmetics, or industrial goods, you’ll find manufacturers in the UAE with industry-specific expertise.

Prototyping and Sampling: Before full-scale production, many manufacturers offer mock-ups or samples to ensure client satisfaction with design and functionality.

Bulk Production and Timely Delivery: Scalability and efficiency are key strengths, especially for businesses that rely on consistent packaging supply.

Qualities to Look for in a Packaging Manufacturer

Choosing the right packaging partner can significantly impact your business operations and brand perception. When evaluating Packaging Manufacturers In UAE, consider the following:

Experience and Reputation: Long-standing manufacturers often have streamlined processes and a proven track record of customer satisfaction.

Customization Capabilities: The ability to produce Custom Boxes UAE tailored to your brand is essential, especially for marketing-focused industries.

Quality Assurance: Consistent quality across batches is critical. Look for companies that follow international standards and have strict quality control systems.

Sustainability: With growing environmental awareness, manufacturers offering recyclable or biodegradable packaging options stand out.

Support and Communication: Transparent pricing, responsive communication, and technical support make the production process smoother and more reliable.

Innovation and Trends in UAE’s Packaging Industry

The UAE’s packaging sector is rapidly evolving to meet the modern needs of businesses and consumers. Among the key trends:

Smart Packaging: QR codes, RFID tags, and other smart packaging elements are being increasingly integrated into products to enhance customer interaction and supply chain transparency.

Eco-Friendly Materials: A noticeable shift toward recyclable and compostable materials is evident, in line with the UAE's commitment to sustainability.

Minimalist and Functional Design: Simplicity and practicality are driving packaging aesthetics, especially in sectors like e-commerce and FMCG.

Digitally Printed Custom Boxes: Advancements in digital printing have made it easier and more affordable for brands to print high-quality graphics on Custom Boxes UAE.

How Packaging Manufacturers Support Various Sectors

One of the strengths of the UAE’s packaging industry lies in its ability to serve a diverse range of sectors. Whether you're a local startup or a multinational exporter, Packaging Manufacturers In UAE can cater to your specific requirements. Key sectors served include:

Retail and FMCG: Shelf-ready packaging with attractive graphics and durable construction.

E-commerce and Logistics: Tamper-proof and secure packaging for nationwide and international shipping.

Food and Beverage: Hygienic, food-grade materials that meet health and safety standards.

Industrial and Construction: Heavy-duty packaging for tools, machinery, and industrial parts.

Final Thoughts

Selecting the right packaging partner is more than a procurement decision — it's a strategic move that can influence everything from logistics to customer satisfaction. With a reputation for quality, adaptability, and innovation, Packaging Manufacturers In UAE are among the best choices for businesses seeking excellence in packaging. If you are looking for a reliable partner who can deliver tailored solutions, high-grade materials, and expert craftsmanship, Bedyahpack stands out as a trusted name in the UAE’s packaging industry. Their commitment to quality, customization, and client success ensures that your packaging needs are met with precision and professionalism.

0 notes

Text

Best E-Accounting institute in Delhi

Bookkeeping has grown beyond worksheet plus basic journals in the fast-paced technological world. In the rapid world, in addition to having a solid and excellent grasp of accounting basics, companies right now need specialists who are skilled at using modern applications, i.e., Tally ERP, GST software, and other cloud-based bookkeeping systems. This is where online bookkeeping comes into the picture, and selecting a good institute can have major consequences. Registering at the finest e-accounting school in delhi is the first step toward achieving professional success if you want to work in the finance and bookkeeping industry.

The importance of digital accounting

In the modern industry, employing digital tools and systems to record, oversee, and examine spending is know as digital accounting. Almost all companies, irrespective of size, now use digital bookkeeping systems as a result of the introduction of the gst and the Digital India efforts. whether youre a fresh hire or a seasoned expert looking to advance your career, e-accounting provides you with real-world knowledge that is extremely pertinent to the demands of the industry today. Delhi's top e-accounting school, a step in the right direction with its extensive curriculum, industry-focused training, and placement support, insert institute name here distinguishes itself among the many other institutes in the capital. Here's why its regarded as the greatest.

The premier online accounting institutes main characteristics consist of industry-related curriculum important subjects including tally prime gst filing income tax payroll excel sap and quickbooks are covered in the courses skilled faculty instructors have years of hands on experience in E- accounting and finance and company professionals provides hand on practioners to assist children develop the confidence instructonal vedios like live projects that are incorporated 100 inclusion support that provide students can get employment quickly finishing the education thanks to the institutes partnerships with top businesses reasonably priced tuition instruction at an pocket friendly cost customised batches children and working proffessionals can enroll from the website weekend and evening programs.

Students' feedback

In just three months, I gained more than I did in my whole accounting education in college. In just 30 days i was ready to secure my first job thanks to the employment assistance verma anjali the course material is current, and the staff is very helpful. Highly recommended for anyone who takes bookkeeping seriously. Rohit Sharma's

conclusion

choosing the best electronic accounting systems school is a necessity if you wish to remain active in the employment market delhi an important center of both education and business has a lot to offer yet very few of them are truly worthwhile with its advanced resources practical learning and recruitment assistance insert institute name turns out to be the most worthwhile decision you could possibly make for the days to come

1 note

·

View note

Text

How an Automated EMR Patient Eligibility Verification System Transforms Physician Revenue Cycles

Introduction

In today’s complex healthcare environment, ensuring accurate and timely patient eligibility verification is critical to maintaining a healthy revenue cycle. For physicians and medical practices, denied claims due to eligibility issues can cause significant financial losses, administrative burden, and frustration. This is where an Automated EMR Patient Eligibility Verification System becomes a game-changer.

This blog explores how integrating automated eligibility verification within your Electronic Medical Record (EMR) system can significantly enhance operational efficiency, reduce claim denials, and ultimately benefit physicians in the healthcare RCM landscape.

The Need for Accurate Eligibility Verification

Patient eligibility verification is the first and arguably most important step in the revenue cycle. It involves confirming a patient’s insurance coverage, policy status, co-pay, deductible, and service authorization before care is delivered. A single error or oversight can lead to:

Claim denials or rejections

Delayed reimbursements

Increased A/R days

Loss of patient trust

Physicians are often burdened with administrative tasks that take time away from patient care. Manual eligibility checks using payer portals or phone calls can be inefficient, error-prone, and inconsistent.

What is an Automated EMR Patient Eligibility Verification System?

An Automated EMR Patient Eligibility Verification System is an integrated software solution that checks insurance eligibility in real-time or batch mode directly within the EMR. It eliminates the need for manual data entry and reduces the risk of human error.

These systems automatically verify:

Active insurance coverage

Plan-specific benefits

Deductibles and co-pays

Referral or authorization requirements

Coverage for specific services or procedures

Automation ensures that practices have the correct insurance details before the patient arrives, leading to faster billing cycles and fewer surprises.

Key Benefits for Physicians

Let’s explore the various ways in which physicians benefit directly from using an automated eligibility verification system:

1. Reduces Claim Denials and Rework

Denied claims often stem from eligibility issues. With an automated system, physicians can significantly reduce denials by verifying patient insurance information ahead of time. This proactive approach ensures:

Fewer billing errors

Decreased rework for the billing team

Faster reimbursements from payers

By avoiding denials, physicians can maintain consistent cash flow and reduce delays in payments.

2. Improves Front-Office Efficiency

Automation lightens the administrative load on front-desk staff, allowing them to focus more on patient engagement and less on navigating payer websites. Eligibility checks that once took several minutes per patient are now completed in seconds.

This efficiency is especially important during busy clinic hours or in high-volume practices.

3. Enhances Patient Experience

Patients appreciate transparency. When their benefits, out-of-pocket costs, and co-pays are accurately known before the visit, it reduces confusion and builds trust.

Physicians benefit from better-informed patients who are more likely to pay at the time of service, which contributes to:

Higher point-of-service collections

Fewer patient disputes

Improved satisfaction scores

4. Supports Accurate Pre-Authorization

Certain procedures and treatments require prior authorization. An automated system flags these requirements early, helping providers avoid performing non-covered services.

By staying compliant with payer rules, physicians minimize the risk of non-payment and protect their practice from audits or penalties.

5. Streamlines Scheduling and Workflows

With integrated eligibility verification, scheduling systems can check patient coverage at the time of booking. This ensures that only eligible appointments are confirmed, reducing no-shows and last-minute cancellations.

For physicians, this leads to:

Better use of clinical time

More predictable revenue streams

Improved staff coordination

6. Real-Time and Batch Verification

Physicians benefit from the flexibility to verify patient eligibility either in real time (for walk-ins or urgent cases) or in batches (for scheduled appointments). This dual mode ensures full coverage without adding complexity.

Batch verification the night before appointments allows staff to resolve issues before the patient arrives.

How it Works: A Quick Workflow Example

Patient schedules an appointment

EMR system triggers automatic eligibility check

System retrieves payer data and updates EMR

Staff reviews any issues (inactive coverage, referrals needed)

Patient notified if action is required

Physician proceeds with visit knowing eligibility is verified

This seamless workflow eliminates last-minute surprises and strengthens the entire revenue cycle.

Integrating with Your Current EMR System

Most modern EMRs now offer eligibility verification as a native or add-on feature. Integration is straightforward and often supported by:

HL7 or FHIR-based APIs

Clearinghouses or third-party RCM platforms

Direct payer connections

Choosing a solution that supports real-time eligibility checks with major insurance providers ensures broader coverage and fewer gaps.

Real-World Impact: A Case Study

Dr. Patel, an independent cardiologist in Texas, implemented an Automated EMR Patient Eligibility Verification System and saw the following results within 90 days:

27% reduction in claim denials

40% less time spent on insurance calls

Improved patient collections by 18%

Increased overall staff satisfaction

The automation allowed his team to shift focus from troubleshooting to patient engagement, ultimately driving practice growth.

Final Thoughts

Physicians today are under immense pressure to balance patient care with practice profitability. By adopting an Automated EMR Patient Eligibility Verification System, they can streamline one of the most critical steps in the revenue cycle.

Whether you run a solo practice or a multi-provider clinic, eligibility automation enhances accuracy, reduces denials, and frees up valuable time for what matters most—caring for patients.

0 notes

Text

Curved Surface Printer Market [2025] Size, Share and Trends upto 2033

Global “Curved Surface Printer Market” research report is a comprehensive analysis of the current status of the Curved Surface Printer industry worldwide. The report categorizes the global Curved Surface Printer market by top players/brands, region, type, and end-user. It also examines the competition landscape, market share, growth rate, future trends, market drivers, opportunities, and challenges in the global Curved Surface Printer market. The report provides a professional and in-depth study of the industry to help understand its current state and future prospects. What Are The Prominent Key Player Of the Curved Surface Printer Market?

AMI

IQDEMY

Unique Assembly

Roland DG Corporation

Micro-tec

Systematic Automation

NEWLONG

Fuxinlong Machinery

DOMSEM

Liberty Clark

TAOXING Technology

Hang Lap

Jiamei Screen Printing Equipment

Fine Cause

The Primary Objectives in This Report Are:

To determine the size of the total market opportunity of global and key countries

To assess the growth potential for Curved Surface Printer

To forecast future growth in each product and end-use market

To assess competitive factors affecting the marketplace

This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals.

Regional Segment of Curved Surface Printer Market:

Geographically, the report includes research on production, consumption, revenue, market share, and growth rate of the following regions:

United States

Europe (Germany, UK, France, Italy, Spain, Russia, Poland)

China

Japan

India

Southeast Asia (Malaysia, Singapore, Philippines, Indonesia, Thailand, Vietnam)

Latin America (Brazil, Mexico, Colombia)

Middle East and Africa (Saudi Arabia, United Arab Emirates, Turkey, Egypt, South Africa, Nigeria)

The global Curved Surface Printer Market report answers the following questions:

What are the main drivers of the global Curved Surface Printer market? How big will the Curved Surface Printer market and growth rate in upcoming years?

What are the major market trends that affecting the growth of the global Curved Surface Printer market?

Key trend factors affect market share in the world's top regions?

Who are the most important market participants and what strategies being they pursuing in the global Curved Surface Printer market?

What are the market opportunities and threats to which players are exposed in the global Curved Surface Printer market?

Which industry trends, drivers and challenges are driving that growth?

Browse More Details On This Report at - https://www.businessresearchinsights.com/market-reports/curved-surface-printer-market-104432

Contact Us:

Business Research Insights

Phone:

US: (+1) 424 253 0807

UK: (+44) 203 239 8187

Email: [email protected]

Web: https://www.businessresearchinsights.com

Other Reports Here:

Mechanical Keyboards Market

Lining Fabrics Market

E-Ticketing System Market

Mobile Car Washing Market

Compound Bow Market

Fabric Cutting Machines Market

Electronic Batch Record Software Market

Laser Micro Perforation Market

Automotive Recycling Market

Conjugated Linoleic Acid (CLA) Market

Other Reports Here:

Swimming Pool Clean Robots Market

Mini Tiller Cultivator Market

Torque Calibration Services Market

Spiral Separator Market

Invisible Dog Fence Market

SD-Branch Market

Garbanzo Flour Market

Leather Luggage and Suitcases Market

MOSFET and IGBT Gate Drivers Market

Knowledge Payment Platform Market

0 notes

Text

Affordable CNC Milling India , Best Manufacturers & Suppliers

Need affordable CNC machining in India? Choose from leading CNC Milling Suppliers that offer quality work at competitive prices. Call us now.

CNC (Computer Numerical Control) machining is a manufacturing process that uses pre-programmed software to control machinery. It allows for precise cutting, drilling, and shaping of materials like metal, plastic, and wood. Imagine a robotic sculptor working with extreme accuracy—that’s CNC machining.

Why Choose CNC Machining in India?

India offers top-tier CNC machining services with a unique edge:

Lower operational costs

Highly skilled engineers

Advanced equipment

Faster project turnaround

That’s why global brands are outsourcing their CNC needs to Indian suppliers—it saves money without sacrificing quality.

Suppliers: Bridging Industries and InnovationEqually important to the CNC Milling Manufacturers chain are CNC Milling Suppliers, who connect industries with the right equipment and services. They offer a range of products, from compact desktop milling units to high-end industrial machines. These suppliers act as consultants, helping clients choose the most appropriate technology based on application, budget, and output requirements.

Modern suppliers provide value added services like installation, training, preventive maintenance, and troubleshooting. Their role is indispensable in sectors that demand minimal downtime and continuous productivity. They also facilitate customization, offering different table sizes, control units, and compatibility with CAD/CAM software systems.

Key Benefits of CNC Machining

High Precision: Ensures accuracy to within microns.

Consistency: Identical results even in large batches.

Efficiency: Faster production with less waste.

Complex Designs: Capable of producing intricate shapes and structures.

Whether you need a single prototype or thousands of units, CNC machining is up to the task.

Applications :

CNC machining is used everywhere, including:

Automotive: Engine parts, gear systems

Aerospace: Aircraft components

Medical Devices: Surgical tools, implants

Consumer Electronics: Device casings, connectors

Defense: Precision hardware

Indian CNC manufacturers cater to all these sectors and more.

How Indian CNC Suppliers Ensure Quality

Top suppliers in India use:

ISO-certified processes

CMM inspection tools

Real-time monitoring

Highly trained operators

They don’t just meet global standards—they exceed them.

Top CNC Machining Manufacturers in India

Some of the most reputable names include:

Deccanew

Ace Micromatic Group

Jyoti CNC Automation

LMW (Lakshmi Machine Works)

Micromatic Grinding Technologies

These companies have global reach, export capabilities, and strong quality control systems.

Factors That Affect CNC Machining Costs

CNC machining is affordable in India, but prices vary based on:

Material type

Part complexity

Volume (single or batch production)

Surface finishing

Machine run time

India’s lower labor and energy costs make even complex jobs more budget-friendly.

CNC Milling India Is Gaining Momentum

India offers a blend of affordability, engineering talent, and high-precision outputs. Many global and local manufacturers are tapping into CNC services in India for prototype development, mass production, and custom fabrication. By investing in CNC milling, industries are reducing human error, minimizing waste, and significantly improving operational efficiency. CNC machines are digitally programmed, allowing for consistent results with excellent repeatability.

How to Select the Right CNC Supplier

Here’s what to look for:

Experience in your industry

Custom capabilities

Certifications like ISO, AS9100

Prompt delivery records

After-sales support

It’s not just about cost—it’s about reliable performance.

Materials Commonly Used in CNC Machining

Indian CNC machining shops work with:

Metals: Aluminum, steel, brass, titanium

Plastics: Nylon, ABS, PEEK, acrylic

Composites: Carbon fiber, fiberglass

Make sure the supplier has experience with your specific material needs

Deccanew is one of India’s emerging leaders in CNC Milling India. They offer:

Custom CNC solutions

Fast delivery

Affordable pricing

Reliable customer service

From design to delivery, Deccanew combines technical precision with business-friendly pricing.

Trends in Indian CNC Machining Industry

Modern Indian CNC firms are embracing:

AI and machine learning

Smart factories (Industry 4.0)

Eco-friendly machining

Digital twins and cloud-based design

These trends ensure sustainability, efficiency, and innovation for future manufacturing.

Visit: https://www.deccanew.com/cnc-milling-manufacturers-suppliers-india.phpContact: +91 9657039991

0 notes

Text

Best Home Health Care Software 2025

Is your agency looking for the most promising software to upgrade operations? Streamlining Home Health Care Operations has become the trend of 2023. Going paperless reduces caregiver documentation and billing time, and improves efficiency, client satisfaction, and profits. We’ll answer the million dollar question of how to find the best Home Health Care Software for your agency.

What Features are Important?

What exactly should you be looking for when searching for the best Home Health Care Software? Let’s break it down into 9 important ingredients:

Hassle-Free Billing

Electronic Documentation

Paperless Timesheets

Signature Fraud Protection

Reliable Visit-Tracking

Simplified Scheduling

Fast Insurance Verification

Easy Client Texting System

HIPAA & DHS Compliant EVV

Hassle-Free Billing

Do claim denials and billing inaccuracies wreak havoc on your agency? In your search for the ultimate software to streamline your agency, take into consideration how big of a factor billing is. An automated billing system simplifies the process. Being able to easily track remittances, send bills in batches, and integrate with insurance payers will take a load off your shoulders, and save tremendous time. Benefits of Digital billing include:

Batch Billing to save time

Reduce Filing Errors, Lost Revenue, And Claims Corrections

Get Accurate And Detailed Billing Reports

Generate Claims and Financial Reports Fast

Streamline Home Care Billing And Save Money

Post Payments Received With Follow Up On Unpaid Bills

Save Agency Resources, Cost, and Time

Remittance Integration with Insurance Payers

Electronic Documentation

Is documentation a time-consuming process for your agency? If so, you’re certainly not alone. Finding a permanent solution will save you money, time, and energy. Paperless timesheets and electronic documentation allows caregivers to spend more one-on-one time with clients, improving patient relations and satisfaction. Going paperless provides the following advantages:

Faster Client Intake Process

Electronic QP Documentation

Ability to Email and Fax Forms

Collect E-Signatures of Clients and Caretakers

Compatible With any Device

HIPAA & DHS Compliant

Fraud Protection & Electronic Visit Verification

Have you had to deal with fraud or unreliable tracking of caregiver visits? What if you could have a trustworthy built-in point of care EVV system? Let’s go over how reliable software can save your agency from fraudulent attempts:

Built-in Signature Fraud Protection & GPS Tracking

Real-Time Reporting Of Location, Shift Start Time And End Time

Records Exact Date, Time, And Location As Per 21st Century Cures Act

Responsible Parties Can Verify And Electronically Sign Timesheets Remotely At Point of Care

Caregivers Are Assigned Updated Tasks in Real Time

Analyze Care Delivered Based On Location, Time And Activities

Verify Logs And Make Corrections Instantly Before Submission

Telephonic Visit Verification Available in the Recipient’s Home

Simplified Scheduling

Simplifying the process of scheduling caregiver visits to accommodate patients’ needs will improve how your agency is perceived, and ease the process for clients. The best home health care scheduling software will provide your agency with the following:

Schedule Clients With Multiple Caregivers

Weekly, Bi-Weekly, Monthly And Custom Scheduling

Automated Schedule Alerts For The Caregivers For Punctual Visits

Avoid Schedule Overlapping

Convenient State of the Art System

Fast Insurance Verification

Why waste hours on the phone verifying insurance for clients when you can have it at your fingertips instantly? Real time insurance eligibility verification is an in-demand tool that gives you eligibility reports within seconds. Here’s how insurance verification software will improve your agency:

Get Accurate Insurance Verifications in Seconds

Easily Pull Up All Recent Eligibility Reports

Web Based Platform with Access from Anywhere

Reduce Client Wait Time

No More Wasting Hours on the Phone

2-Way Texting System

Communication between caregivers and patients should be easy and accommodating. Modern messaging systems will allow you to send confidential SMS texts to patients, and notifies you when clients send a message. You’ll be able to send caregivers and patients appointment reminders, documents, follow up information and more:

Send and Receive Bulk Text Messages to/from Staff & Clients

Caretap Messaging Application with 100% HIPAA Compliance

Independent Section for Viewing All Communication Records

Get Instant Messages from Staff and Clients On-the-Go

Most Convenient Communication Tool for Home Health Care Agencies

Conclusion

Upgrading to adopt the best home health care software for your agency is made simple by knowing what features are of most importance. The success of your agency is proportional to the effort you put into accommodating the needs of clients and caregivers. By making intelligent adjustments to daily operations, you can eliminate manual operations, insurance errors, fraud attempts, and boost efficiency.

Streamlining your agency with Caretap’s hassle-free billing, electronic documentation, paperless timesheets, fraud protection, Electronic Visit Verification, Fast insurance verification, and 2-Way SMS will save hours of backbreaking labor, and improve caregiver and patient satisfaction. Learn how Caretap can streamline your operations.

0 notes

Text

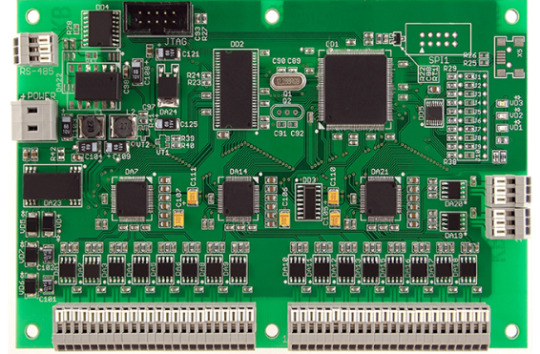

Quality Control Standards for Printed Circuit Board Suppliers

In the fast-evolving world of electronics manufacturing, reliability and precision are not optional—they are essential. For businesses that rely on printed circuit boards (PCBs) to power their devices, quality assurance must be a top priority. At Pcb-Togo Electronic, Inc., we understand this responsibility. As a trusted Printed Circuit Board Supplier, we have built our reputation on a foundation of strict quality control standards designed to meet the most demanding performance and safety requirements.

Below, we explore the comprehensive approach we take at Pcb-Togo Electronic, Inc. to ensure every PCB we deliver is tested, traceable, and built to last.

Why Quality Control Is Critical for PCB Manufacturing

Unlike many components in the electronics supply chain, PCBs are the foundation of all electrical functionality in a device. Even a minor defect—such as a poor solder connection or microscopic short—can cause device failure, product recalls, or worse, safety hazards. For that reason, choosing a Printed Circuit Board Supplier with a proven quality control system is not just important—it’s mission-critical.

Poorly controlled PCB manufacturing can lead to:

Intermittent circuit failures

Early device breakdowns

Excessive rework costs

Damaged brand reputation

This is why at Pcb-Togo Electronic, Inc., we don’t just manufacture PCBs—we verify and validate every detail throughout the production process.

Our Quality Control Process: Built for Precision

At the core of our operations is a multi-phase quality control framework designed to ensure consistency, compliance, and performance. Our system covers every stage of PCB production, from material sourcing to final delivery.

1. Verified Materials and Supplier Audits

We begin quality control long before production starts. Every PCB at Pcb-Togo Electronic, Inc. starts with certified raw materials. We conduct strict inspections and maintain detailed supplier records to ensure that copper laminates, solder masks, and surface finishes meet global standards.

Regular supplier audits help us track quality at the source. Any vendor that fails to meet our benchmarks is removed from our approved list.

To explore how material quality affects PCB performance, Find Out More on our supplier verification page.

2. In-Process Inspections

Our in-house team conducts detailed inspections at every major production checkpoint:

Etching Accuracy – To prevent shorts or open circuits

Layer Alignment – Verified via X-ray scanning for multilayer boards

Hole Wall Quality – Assessed with microsectioning techniques

Solder Mask Integrity – Checked for uniform thickness and absence of bubbles

These real-time evaluations prevent defects from carrying forward, saving both time and cost. This proactive approach distinguishes us as a forward-thinking Printed Circuit Board Supplier.

3. Final Electrical Testing

No PCB leaves our facility without undergoing 100% electrical testing. Each board is verified for:

Continuity

Shorts

Component placement (if assembly is included)

Whether you're producing high-frequency boards or standard FR4 circuits, this final validation ensures that your boards will perform flawlessly in your application.

If you're curious about our advanced testing procedures, you can find out more by contacting our engineering team or viewing our testing guidelines online.

4. Strict Packaging & ESD Protection

Even after production, PCBs must be handled with care. Our packaging process includes:

Moisture barrier bags

ESD foam and shielding

Vacuum sealing for long-distance shipments

Each order is labeled for traceability, allowing clients to track batch origin, production data, and inspection results. This complete chain-of-custody approach ensures that your PCBs arrive in top condition—no matter where in the world you are.

For more on logistics and shipping support, go right here to our delivery resource center.

Continuous Quality Improvement (CQI)

Being a Printed Circuit Board Supplier means constantly adapting to evolving industry standards and customer requirements. At Pcb-Togo Electronic, Inc., we use data from inspections and customer feedback to refine our production lines. Our engineers regularly review:

First-pass yield rates

Customer return data

Root cause analyses

This commitment to Continuous Quality Improvement helps us remain flexible and responsive, while maintaining high yield rates and low defect percentages.

Why Choose Pcb-Togo Electronic, Inc.?

With over two decades of experience, we are a leading Printed Circuit Board Supplier known for our ability to deliver reliable, high-performance boards at competitive prices. What sets us apart is our end-to-end commitment to quality—from the raw copper to the final shipment box.

Clients from industries such as medical, automotive, aerospace, and consumer electronics trust us for:

Fast lead times

Transparent communication

Flexible order quantities

Proven reliability

When you partner with Pcb-Togo Electronic, Inc., you’re choosing a supplier that backs every board with traceability, testing, and total accountability.

Final Thoughts

Selecting a reliable Printed Circuit Board Supplier is essential to the long-term success of any electronics product. At Pcb-Togo Electronic, Inc., quality isn’t a department—it’s the DNA of our entire operation. From stringent inspections and automated testing to supplier audits and proactive improvement, we take every step necessary to ensure our PCBs are ready for real-world performance.

If you’re ready to raise the bar for your electronics production, Find Out More by speaking with our technical experts or requesting a custom quote today.

Original Link: https://pcbtogo.blogspot.com/2025/06/quality-control-standards-for-printed.html

0 notes

Text

ProcessXE - Batch Records

#Batch records#Batch manufacturing Record#batch manufacturing record in pharmaceutical industry#batch records pharmaceutical#electronic batch record system#electronic batch manufacturing records

0 notes

Text

Avoid Costly Downtime with Accurate Cable Harness Testing Solutions

When clients hear “downtime,” they also hear revenue loss and start thinking if you’ve skipped Testing Cable Harness. Make sure that every production batch incorporates accurate harness testing to avoid any potential issues down the line.

You guarantee your consumers worry-free, continuous performance and safeguard your reputation as a reliable supplier for their needs. The High Cost of Untested Cable Harnesses Intermittent signals, short circuits, or even complete system failure can result from faulty or badly assembled wire harnesses. The repercussions of harness failure in vital applications, such as medical devices, automobile electronics, or aircraft systems, can range from costly recalls to safety risks. You can prevent these hazards and ensure continuous operations by incorporating through “Testing Cable Harness” processes into your quality-control workflow. Potential Benefits of Accurate Cable Harness Testing - Decreased Warranty Claims: Avoiding flaws early on results in fewer returns and less expensive repairs later.

- Improved Product Reliability: Maintaining consistent test results boosts brand reputation and customer confidence.