#finite-element

Explore tagged Tumblr posts

Text

i’m hiding in the passepartout!

#(voice of a guy who has so much shit to do) Hmmrgh. animatiec#song is focal point by louie zong pls go give it a listen it is a BANGER and the visuals are so fucking good#literally inspired me on a whim#myart#myanimatics#oc: wade#finally … after 2 years …. a wade-centric animatic ???!?!?#or well. as wade-centric as it gets .#oc: no way back#oc: needless separation#oc: ten elements through finite waves#had lots of fun with the coloring on this one#lasso tool animatics could be the new move#tumblr made it such ass quality oh well... maybe i'll upload it to youtube if i can be fucked

139 notes

·

View notes

Text

The fact that after all this, Hamas is keeping captured IOF troops alive at all instead of doming them where they find them is a testament to mercy, not cruelty

#even if you’re like they’re just keeping them because they’re intel sources#I could give several perfectly rational justifications for leaving them to die even with the intel#they’re a constant security risk and a drain on finite resources better put towards your fighting elements

22 notes

·

View notes

Text

I found a book specifically for finite model theory that contains like 80% of all the things that interest me in math... Let's just say my motivation is back.

#it's elements of finite model theory by libkin#math#studyblr#mathblr#mathematics#finite model theory#computational complexity

44 notes

·

View notes

Text

Surprising absolutely noone except undergraduate math students, it turns out math actually is only about numbers in the end!

#math#mathblr#mathematics#oh so you thought abstract algebra stopped being about numbers to get to more complex structures#and you thought fundamental logic is so abstract exactly because it is more general than just numbers#well guess what#gödel wants to have a word with you#my friend every statement that can possibly be made by humans ever can be made isomorphic to some structure of the natural numbers#even if that structure is a function space of the power set of the power set of the natural numbers#it is possible to write any finite set of axioms as an isomorphism to axioms about the natural numbers#however since the axiomatic definition of the naturals gives you some axioms already it is important to note that for some really fucked up#axiomatic systems you have to explicitly include axioms that prevent you from using thise axioms in sone ways#as in you can't use the set theorethic definition to choose elements of a set for example#you have to choose elements from a set with choice functions constructible from axioms provided#now for making set theory equivalent to the naturals the choice functions you can derive are equivalent to just choosing a natural#but it could be not the case

12 notes

·

View notes

Text

tbh Coppers ultimately exists in a very weird space

She’s too intertwined with a fanfic to be grouped with all the original characters I’m developing outside of online space

But she’s distinctly an oc surrounded by a different canon

So she’s just kind of on her own

#me: I love this character and developing her#also me: she has a distinctly different flavor and an element of being finite that my other characters don’t have

2 notes

·

View notes

Text

From Ansys finite element analysis to Rhino voxel Brep by deserializing the point data and associated stress values

2 notes

·

View notes

Text

Understanding CAD Modeling Approaches in SolidWorks: Cross-Section vs. Features

When it comes to creating parts in CAD software like SolidWorks, designers often dive straight into modeling without giving enough thought to the best way to approach the task. However, planning and strategising before creating a CAD model can lead to faster creation, easier editing, and better alignment with manufacturing processes. In SolidWorks training online, the words “model” and “part” are used interchangeably.

Key Factors for a Good Modeling Plan

A modeling plan is considered effective when it meets the following:

Fastest time to create the part

Ease of editing the part later

Alignment with how the part will be manufactured

These strategies are deeply discussed in any professional SolidWorks online course, helping learners build the right mindset from day one.

Two common approaches are used in modeling: the cross-section approach and the features approach.

Cross-Section vs. Features Approach

Cross-Section Approach: This is generally quicker. You sketch the entire part profile and extrude it in one go. However, it might be harder to edit later if changes are needed.

Features Approach: This method builds the part step by step, like creating a block, chamfer, and hole. It mirrors how a machinist would make the part in real life, starting from a block and then working step-by-step. While it may take longer initially, it’s more modular and easier to modify.

Many SolidWorks online classes explain both these approaches in depth with examples. Whether you're attending SolidWorks training online or self-learning through videos, understanding both styles is a must.

For example, take a chamfered block with a hole. In the cross-section approach, the sketch would include all the features (like the chamfer and the hole) in one sketch. In the features approach, you would first create a solid block, then apply a chamfer, and finally create the hole. Each of these is done as a separate feature.

Personal preferences and industry experience often influence this debate between speed and modularity. Designers with a manufacturing background may lean toward the features approach because it better reflects how parts are made in the real world.

Creating a Part in SolidWorks

Once you’ve chosen your modeling strategy, the next step is to use a CAD/CAM system like SolidWorks to create the part. This is a major part of what SolidWorks classes online focus on for beginners and intermediate learners.

SolidWorks builds a part using features. A feature can be an extrusion, a hole, or a revolve. When you add a feature, it combines with existing features to build the full 3D part. Each new addition updates the model in the feature tree.

Basic Features in SolidWorks:

Extrusion: Creates a shape with uniform thickness.

Revolve: Creates a shape by revolving a 2D sketch around an axis.

The feature creation process begins with a 2D sketch. You sketch the profile on a selected sketch plane and then use it to create a 3D feature.

SolidWorks provides two tabs: the Sketch tab and the Features tab. You can start from either tab, but starting from the Features tab is often considered more efficient because it automatically guides you into sketching mode.

Example Walkthrough

Let’s look at a simple plate example:

Create Sketch1: Select Top Plane > Use Center Rectangle > Smart Dimension for sizing > Exit sketch.

Create Block Feature: After exiting, enter the thickness (e.g., 0.5) and finish. Rename the node to “Block” and save the file.

Add Hole Feature: Select the top face of the block > Extruded Cut > Draw a circle from the origin > Dimension it (e.g., diameter 1) > Enter thickness (0.5) and finish. Rename the node to “Hole.”

This step-by-step approach mirrors what’s covered in SolidWorks training online, making complex parts easy to build.

Conclusion

In summary, the choice between the cross-section and features approach in CAD modeling depends on your goals—speed or flexibility. For educational purposes, especially in SolidWorks online class modules, using the features approach helps learners understand part creation more deeply by breaking it into manageable steps.

If you’re looking to build your skills in SolidWorks and learn both these modeling approaches with hands-on practice, check out the SolidWorks training course online. It's a great way to strengthen your CAD knowledge and get industry-ready.

0 notes

Text

Efficient MESH technique for complex geometry in ABAQUS

Efficient mesh is important to produce better results given the limited resources. Abaqus has been a favourite finite element analysis software for researchers in top engineering and research institute like MIT, IITs, Caltech, etc. It is best suited for non-linear analysis and gives huge control on the procedure to users. This video explains a simple technique to mesh a part so that memory and…

View On WordPress

0 notes

Text

vaguely having ambitions for something I'd like to do as a career so it doesn't feel like I completely threw away those years I was at uni but also having no idea how to get there ughh

#I think learning c++ might be a good start? at least two of the structural analysis programs I used in uni used it#and also learning more about finite element method#okay so I have some idea of where to start

1 note

·

View note

Text

too much

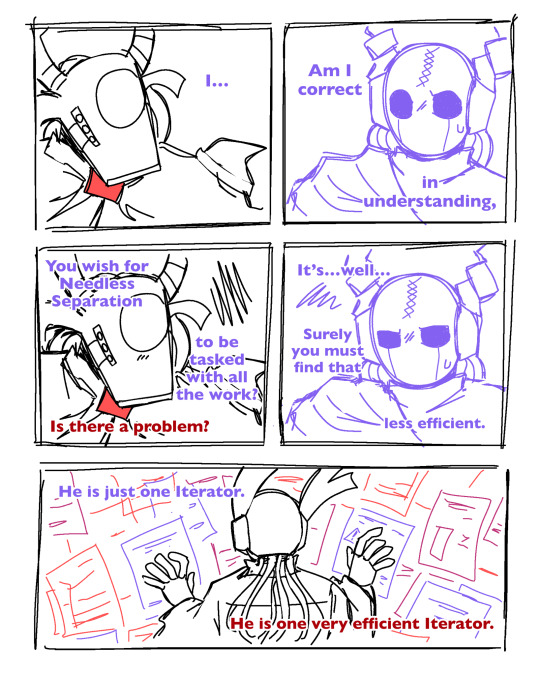

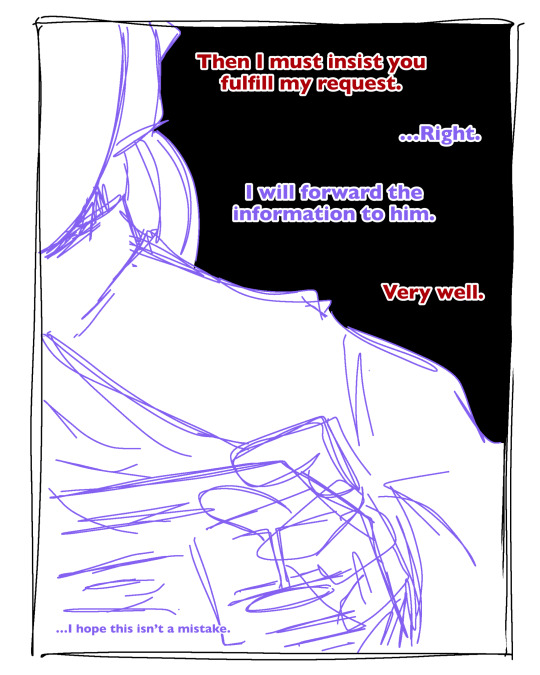

#hi. doing evil shit#for funsies#myart#mycomics#oc: weaving tales#sorry for putting weaving through it for the second time in a row . Happens to the best of us#there is just so much to think about when it comes to them#oc: ten elements through finite waves#goot god#HI WAVESSS 😁😁😁😁 im your singular fan adn biggest hater (hard to draw)#j need to be put down#wait fuck hems there too#oc: needless separation

82 notes

·

View notes

Text

Unveiling the Strength: A Comprehensive Finite Element Analysis of the Strap U-Frame

In the realm of engineering, structural integrity and performance are paramount. At Graphler Technology Solutions, our commitment to delivering cutting-edge analyses ensures that every project achieves its full potential. Recently, we undertook an extensive finite element analysis (FEA) of a Strap U-Frame. This blog delves into the highlights and insights from the study.

Objective of the Study:

The primary goal of the FEA was to evaluate the structural behavior of the Strap U-Frame under a variety of operational loads and conditions. This included assessing how the U-Frame responded to forces induced by tension in the strap, moments generated during operation, and reaction forces from components like the crank and pawl. By simulating these real-world conditions, the analysis aimed to:

Identify Critical Stress Points: Determine locations within the U-Frame where stress exceeded safe operational thresholds, particularly areas prone to potential cracking or fatigue failure.

Examine Deformation Patterns: Evaluate how the structure deforms under load to ensure that any displacements remain within acceptable limits to maintain functionality.

Validate Material Performance: Analyze whether the materials selected for the U-Frame and its components could withstand the applied loads without permanent damage or failure.

Guide Design Improvements: Provide actionable insights for optimizing the design and material usage to enhance durability, safety, and cost-effectiveness.

This holistic approach ensured that the U-Frame design met stringent performance standards while aligning with the operational demands and longevity expectations of the client.

Analysis Setup

The analysis focused on multiple load cases, including:

Belt Tension: Simulated at 26688 N, generating a significant moment of 1334400 N-mm.

Force Transmission: Evaluated through the crank lever requiring a force of 3587.10 N for operation.

Boundary conditions, material properties, and operational loads were meticulously configured to replicate real-world scenarios.

Key Findings

1. Deformation Analysis

Maximum deformation observed: 2.93 mm.

Despite localized deformation, the overall structure maintained functional integrity.

2. Stress Distribution

U-Frame: Maximum principal stress reached 1032 MPa, exceeding the material’s ultimate tensile strength. However, the stress concentration was confined to the surface peel layer, indicating potential for localized cracking without immediate failure.

Pawl: Maximum stress of 858.23 MPa surpassed yield strength at contact points. The compressive nature of stress ensured no catastrophic failure.

Shaft: Surface stress exceeded yield strength but remained within acceptable limits at the core, highlighting resilience against major deformation or breakage.

3. Reaction Forces

4. Engineering Inferences

Localized Cracking: Stress concentrations in the U-Frame and Pawl necessitate enhanced surface treatments or reinforcements to mitigate fatigue risks.

Material Performance: While the materials demonstrated high resilience, exceeding yield thresholds in localized regions requires design refinements.

Optimized Design: Potential adjustments in geometry or material distribution can enhance load-bearing capacity without significant weight increases.

Graphler Technology is one of the leading product design companies in India. We have experts in FEA services and also we are specialized in CFD consulting services, structural design services, 2D to 3D Conversion services, stress analysis services etc.

0 notes

Text

How Credible are FE Car Crash Simulation Models?

Car crash simulation is performed by means of explicit Finite Element models, containing many millions of elements. These models are computationally intensive and parallel computing is used to perform the task. Evidently, the reason car crash is simulated in computers is to reduce and/or avoid expensive physical testing. Abundant literature is available on the subject. The present blog will…

#car crash#Complexity#complexity map#Computer simulation#crash test#Finite Elements#model complexity#model credibility#QCM

0 notes

Text

Transforming Industries with Engineering Manufacturing Services and Finite Element Analysis Consultants

Engineering and manufacturing have always been at the forefront of technological advancement, driving progress in countless industries. Imagine a world where precise and innovative solutions to complex engineering challenges are readily available. This is where the synergy of engineering manufacturing services and finite element analysis consultants comes into play, revolutionizing the way products are designed, tested, and brought to market.

The Backbone of Modern Industry: Engineering Manufacturing Services

Engineering manufacturing services are essential in today's fast-paced industrial landscape. These services encompass a wide range of activities, from product design and development to prototyping, testing, and full-scale production. The role of engineering manufacturing services is pivotal in ensuring that products meet high standards of quality, reliability, and performance. The integration of advanced technologies and methodologies has elevated these services to new heights, enabling businesses to bring innovative products to market faster and more efficiently.

The Power of Finite Element Analysis in Engineering

Finite element analysis (FEA) is a powerful computational tool used by engineers to predict how a product will react to real-world forces, such as heat, vibration, and stress. By breaking down a complex structure into smaller, manageable elements, FEA allows for detailed analysis and optimization. Finite element analysis consultants play a crucial role in this process, offering their expertise to ensure accurate simulations and interpretations. This helps in identifying potential issues early in the design phase, thus reducing the need for costly revisions and enhancing product performance.

Enhancing Collaboration for Optimal Results

One of the key advantages of integrating engineering manufacturing services with finite element analysis consultants is the enhanced collaboration it fosters. This integration ensures that the transition from design to production is seamless, with potential issues being addressed at every stage. Engineers and consultants work closely to refine designs, conduct simulations, and validate results, leading to a more efficient and effective development process. Such collaboration is particularly beneficial in sectors that require high precision and reliability, resulting in superior products and reduced time to market.

The Future of Engineering and Manufacturing

The future of engineering and manufacturing is undoubtedly exciting, with continuous advancements in technology driving innovation. The integration of finite element analysis consultants with engineering manufacturing services is set to play a crucial role in this evolution. As industries become increasingly complex, the need for precise and reliable solutions will only grow. Companies that leverage these services will be better equipped to meet the challenges of tomorrow, delivering products that are not only innovative but also safe and reliable.

Conclusion

The synergy between engineering manufacturing services and finite element analysis consultants is transforming industries by providing comprehensive solutions to complex engineering challenges. This integration enhances product quality, reduces development time, and fosters innovation. For more information and to explore how these services can benefit your business, visit feamax.com. Embracing these advanced methodologies is the key to staying ahead in a rapidly evolving industrial landscape, ensuring continued success and growth.

Blog Source Url:-

0 notes

Text

finite element analysis basics book

https://3d-labs.com/product/finite-element-analysis-basics/ Ansys is basically an analysis software, which allows to analyse the CAD model of the product before producing. It is used to test its strength and test of what would it behave in its environment.

https://3d-labs.com/

0 notes

Text

Unmatched Accuracy in Precision Engineering: The Power of CNC Machining

In today's engineering landscape, precision is the foundation of quality, particularly in aerospace, automotive, and medical devices, where even the smallest margin of error can determine success or failure. CNC (Computer Numerical Control) machining has transformed manufacturing by providing unmatched precision in producing highly accurate components.

The Impact of CAD/CAM Technology

A key factor in CNC machining’s precision is the seamless integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) technologies. 3D modeling aids engineers in creating intricate 3D models of the desired part using CAD software. These digital blueprints capture every detail, ensuring that the design meets the exact specifications required for functionality.

Once the design is finalized, it is converted into CNC programs using CAM software. This process translates the digital blueprint into precise instructions for the CNC machine to follow, ensuring every dimension and specification is precisely met. By eliminating manual steps, CNC machining significantly reduces the chance of human error, ensuring consistency across both small and large production runs.

Automated Precision for Complex Geometries

CNC machines, once programmed, operate autonomously, reducing the need for continuous human oversight. This automation ensures each part is manufactured with the same high standard of accuracy, ensuring repeatability across batches. Moreover, CNC machines can work on multiple axes simultaneously, making it possible to create intricate, complex geometries that would be challenging to achieve through traditional machining methods.

Real-Time Monitoring for Maximum Accuracy

Modern CNC machines are equipped with advanced real-time monitoring systems that track the machining process. If any deviation from the programmed path occurs, the system immediately corrects it, ensuring precise output and minimizing waste. This results in a highly efficient, cost-effective process that guarantees optimal material usage and consistent accuracy.

At Engineering DNA, we harness the power of advanced CNC machining technology, combined with expert engineering knowledge, to produce precision-engineered parts for industries that demand the highest levels of accuracy. Whether you need a prototype or full-scale production, our CNC machining capabilities ensure consistent, unparalleled quality in every project.

#reverse engineering services#3d modeling for 3d printing#3d cad services#finite element analysis#3d modeling services#3d prototype in mumbai

0 notes

Text

FEA - Finite Element Analysis Comprehensive Guide

Finite Element Analysis (FEA) is an essential tool used by engineers to simulate how a product will react to forces like heat, pressure, and vibration. It breaks down a complex design into small elements connected by nodes. This helps engineers see how a structure behaves before it’s built.

0 notes