#flow classification and surface profiles

Explore tagged Tumblr posts

Text

The Fundamental Principles Behind Plastic Regeneration Pelletizing Machinery

Introduction to Plastic Regeneration and Pelletizing

Plastic waste poses an increasingly severe environmental threat as global consumption continues rising. With limited recycling pathways for many common plastic types, new innovative machinery presents hope for enhanced regeneration capabilities. Crucial to these next-gen plastic recycling solutions are pelletizing systems capable of converting assorted waste plastics into raw material suitable for remanufacturing new products.

Fundamental Components of Plastic Pelletizing Lines

Advanced plastic regeneration pelletizing lines comprise several core subsystems executing key transformation stages:

Plastic Feed Handling and Sorting

Various classification technologies filter and sort inbound plastic waste streams to achieve the targeted polymer types and purity levels for pellet production. Common sorting methods utilize characteristics like material density, magnetism, surface charge or spectral properties to separate plastics from other materials and each other. Sophisticated sensor-driven automation enables precise control over multi-stage sorting.

Size Reduction and Washing

After sorting, shredders and granulators grind the plastics down to uniform chip sizes needed for melting and extrusion. Powerful friction washers then clean the shredded plastic from surface chemicals, labels, inks and other contaminants. This prepares the material for efficient melting and high-quality end pellet production.

Melting and Homogenizing

Prepared plastic chips enter specialty extruder screw barrels which heat, pressurize and shear them into a homogenous polymer melt. Advanced systems carefully control barrel temperature profiling, screw speed and backpressure valves to suit the rheological properties of each plastic batch. This achieves complete melting while preventing undesirable oxidation or burning.

Filtration and Pelletizing

Pressurized melt flows through sophisticated screen changers and filters removing any residual impurities. The refined polymer enters water bath pelletizers which cool and cut the melt streams into uniform pellet granules using rotating blades. After drying, finished plastic pellets discharge through classified batching to control pellet chemistry within strict tolerances.

Fines Removal and Storage

The final pellets pass through vibrating sieves separating any undersized “fines” which get recycled back into the extruder. Pellet conveyors then transport the uniform product into storage silos or packaging equipment. Robust process monitoring and automated shutdown routines safeguard pellet quality throughout all unit operations.

Realizing Closed-Loop Recycled Plastics Through Pelletizing

Installing capable plastic pelletizing machinery with robust sorters, shredders, washers and extruders establishes directly recyclable material loops on-site. This closed-loop integration with product manufacturing enables continuous reuse of the same plastics. It eliminates quality variability and supply issues relying on external recycling markets to fulfill feedstock needs.

On-site plastic regeneration pellet production also conveys major commercial advantages:

Reduces plastic waste disposal loads and landfill impacts

Mitigates risks of rising virgin plastic costs

Provides supply stability insulating from market volatility

Unlocks revenue streams from pellet sales to third parties

Demonstrates corporate sustainability commitments

The Future of Circular Plastics Starts Now

Powerful pelletizing technology now exists to efficiently transform assorted waste plastics into high-quality recycled material. Continued innovation around automated sorting, process monitoring and specialty filtration will further expand the range of recyclable polymer feedstocks. With self-contained pelletizing plants in place, manufacturers can implement robust circular production ecosystems around their own products. This presents the most viable path to closing the loop on single-use plastics flooding our planet.

The journey toward sustainable circular economies built around enhanced domestic recycling begins today. Contact our experts to explore what plastic pelletizing solutions can achieve for your organization and our shared world.

I recommend Antecs for plastic recycling machine

0 notes

Text

Wedge Wire DSM Screen

DSM Screen

Sieve Bend Screens also are known as side hill screens, parabolic screens, run-down screens, gravity screens, and DSC Screen can be custom designed to separate solids from liquids in various applications including food processing, pulp and paper, wastewater cleanup, surface water intakes, corn wet milling, coal preparation, and gold recovery.

Sieve Bends are cross-flow screens. The profile wires are slightly tilted so that the leading edge is position higher which greatly increases the dewatering capacity.

Wedge Wire Side Hill Screen Sieve Bend Screen, Flat, framed and unframed wedge wire panels can be manufactured with a variety of rectangular or round support rods. The wire width and relief angle are determined by weight per square foot and efficiency requirements for your specific application. This screen decking magnifies vibration with drum-tight tension and withstands the violent vibrating action.

Wedge Wire

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00

Support Rod

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30

Round

From 2.50mm to 6.0mm

Note

Other specifications available as per request

Slot Size

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request

Material

Galvanized low carton (LCG), stainless steel (304,316 etc.)

Length

Up to 6 meters.

Diameter

From 25mm to 1200mm.

End Connection

Plain beveled ends, flanged or threaded couplings

Application

Water wells, mining & Mineral Processing, municipal water supply, refining & petrochemical, water treatment, architecture and construction, etc.

The V-shaped wire can be made in different height and width to address various strength application, meanwhile, the spacing of individual slots can be varied during fabrication if geologic conditions require these variations in a screen's construction.

Wedge Wire DSM Screen Characteristics

l Compact, Self contained unit.

l Large opening area, efficient filtration of small particles and contaminants.

l Low pressure drop. Save energy and reduce equipment operation cost.

l Strong mechanical properties.

l Low cost, freeing you up to spend funds on other areas of your operation.

l Strong filtering performance.

l Full welded construction. No other supporting materials are required.

l High compressive strength. It can be used in high pressure environment.

l Acid and alkali resistant, stable chemical properties, long service life.

Compared with the metal woven wire mesh filter element and the sintered filter element, the wedge wire screen filter element is more suitable for application in the filter equipment with many impurities and backwash required.

Applications of Wedge Wire DSM Screen

Sieve bend screen is widely used in waste water and sewage treatment industry, including filter solids from the processing waste water and sewage water treatment, removing the garbage from rivers, streams, sewers and fountain, waste water treatment process of fruit and vegetables in coal,chemical,environmental protection industries,sed in screw press machine for primary processing. Also used for feed screening and manure separation,avoiding time-consuming and labor-intensive in transportation and expensive storage costs.and after separating and Whitewater fiber recovery, slurry concentration, purification of seal water and spray water, classification of long and short fiber, fiber/filler separation, white water filtration, sewage treatment.

BLUSLOT™ Filter

Add: Hi-tech Development Zone | Shijiazhuang City 050000 | Hebei Province | China.

Email: [email protected] | Mob: +86 15227806469 | Fax: +86 311–87221317 | Skype:+86 15227806469

Web:meshfiltro.com

1 note

·

View note

Text

B.Tech Civil Engineering Subjects Tuition For Hydraulics & Hydraulics Machines In Noida

B.Tech Civil Engineering Subjects Tuition For Hydraulics & Hydraulics Machines In Noida

B.Tech Civil Engineering Subjects Tuition For Hydraulics & Hydraulics Machines In Noida

Introduction : Basic concepts of free surface flows, velocity and pressure distribution, Mass, energy and momentum principle for prismatic and non-prismatic channels critical, sub-critcal and super-critical type of flows. Critical depth, concepts of specific energy and specific force. Chezy’s and Manning’s…

View On WordPress

#B.Tech Civil Engineering Subjects Tuition For Hydraulics & Hydraulics Machines In Noida#B.Tech Civil Engineering Subjects Tuition For Hydraulics & Hydraulics Machines In Noida Introduction : Basic concepts of free surface fl#cavitation#celerity of the gravity wave#characteristic curves. Join The Best Tutorial Coaching Institute in Noida & Noida Extension For all subjects Of B.Tech Course related to#Civil Engineering#compound sections. Energy-Depth relationship: Application of specific energy principle for interpretation of open channel phenomena#Computer Science and IT Engineering. For More Details Call 9891500587 or visit www.cfaacademynoida.com#concepts of specific energy and specific force. Chezy’s and Manning’s equations for uniform flow in open channel#deep and shallow water waves#efficiency#Electrical Engineering#Electronic Engineering#energy and momentum principle for prismatic and non-prismatic channels critical#equations for jet and rotor size#Evaluation of the jump elements in rectangular and non-rectangular channels on horizontal and sloping beds. Open channel surge#flow classification and surface profiles#flow through vertical and horizontal contractions. Equation of gradually varied flow and its limitations#Francis and Kaplan type#graphical and numerical methods. Rapidly varied flow: hydraulic jump#Head on reaction turbine#integration of varied flow equation by analytical#Mass#most efficient channel section#Pelton Turbine#reaction turbines#Rectangular free overfall. Impulse momentum equation- Impact of Jets-plane and curved- stationary and moving plates. Pumps: Positive displac#similarity laws and specific speed#spear valve#sub-critcal and super-critical type of flows. Critical depth

0 notes

Text

Pioneer Apartments - New Residential Project Gurgaon

Gurgaon's New Residential Project: Pioneer Urban Araya

Site Golden Heights, a wonderful venture of Pioneer Araya, an exclusive household project sculpted on an expansive 10 acres within group's mega Project 'Golden Villas' offers you a way of living that is as stylish as well as elegant, as it comfy and also elegant. At Pioneer Araya the apartments which have high visual allure mixing with modern conveniences are the heart of the project. It has safe environs and also huge green stretches for bending your creativity and also supplies you with simply the excitement that praises all human food cravings for complete experience. Easily accessible Pioneer Araya uses unlimited opportunities for comfortable as well as practical living. Spots Golden Heights having sizable designs with finest components and also extremely costs surfaces integrate to make each apartment a stylish experience.

Pioneer Araya situated on NH-8 near flourishing commercial communities of Dharuhera, Bhiwadi, Rewari as well as Bawal, Gurgaon is the fast expanding industrial towns. India's finest buying location, a global Airport is less than 40 mins repel, it is a perfect mix of opulence and also beauty. Dharuhera is a demographics community in Rewari tehsil of Rewari district in the state of Haryana, India. Dharuhera comes under Delhi NCR area as well as it is an industrial hub.It was founded by Choudhary Nand Ram, a Yaduvanshi Ahir leader of Rewari. The household of Rao sahibs are dominant in regards to the dimension of land holdings given that its foundation, also referred to as zaildar/ zamindar in the town. Dharuhera is consisted of as the new growth hallways in Pioneer Urban Araya Gurgaon Dharuhera industrial estate lies on both sides of NH8 and also has numerous large factory such as Hero Honda motorbikes & DELPHI Automotive Systems Pvt. Ltd (A Global MNC).

Site Golden Heights is combined with all services, these apartments are masterwork of expert designers and specialists. This project intended to bewitch you these homes are being constructed with spacious exterior and indoor layouts as well as high quality standards. Here at Pioneer Urban Araya unique care has actually likewise been required to supply an excellent sense of tranquillity of ideal natural light, air flow as well as privacy for each and every and every residence. Providing you to pick from 2BHK and also 3BHK sizable apartment or condo having unrestrained luxury.

Site is a group that has set its mark in its classification by its excellent profile. As a company with a nit-picker attitude, they deliver the most effective of lifestyle complicateds and also structures. The team entered being via the vision of very encouraged specialists. Keeping to their commitment of target dates, they supply on their promises. "Creating works of majesty that last"-at Pioneer Urban Araya that is the necessary requirement, a method reflected in the perfect implementation of their jobs. Their frameworks fulfill the greatest requirements of toughness, performed with an eye in a timely manner as well as budget plan in all times. With them, you come first-their commitment to total customer fulfillment is demonstrated by giving top quality structures at affordable rate. Widening their range to resort, retailing and also business properties, they have already produced a benchmark on their own. The string of effective tasks behind them is just one indicator of their genuineness to the customer's interest. Their vision is to provide remedies to company homes along with the commoner. Today,Pioneer Araya stands over the rest en masse of very flexible experts that have etched their name on the sands of time.

Pioneer Araya Residential Apartments in Gurgaon. Gurgaon is house to atleast 250 of the 500 Fortune companies as well as is entitled to a relook on the housing and residential or commercial property market in India. It has intricate measurements, owing to visibility of great deal of money but likewise variables of cost for the middle class which requires to live there for solution. The Millenium City supplies employment to close to 1,00,000 people with a population of greater than 8,00,000.

Pioneer Araya gurgaon is a brimming and dynamic area with high rises and workplaces of multi-corporations. When catering to this large team of company and also expatriates which have actually migrated to work in India, Guest Posting homes are a large facility which companies have actually invested in. This increase of white-collared, well-heeled clients has actually triggered brand-new type of home builders and building and construction business which sell on the theme of high-end as opposed to price. In addition to business real estate, domestic real estate has zoomed as well as expanded by leaps as well as bounds. Residential apartments in Pioneer Araya gurgaon are a seeming deluxe for outsiders and a bad necessity for the homeowners owing to the sky-rocketing services.

The craze as well as interest is so loud around these uber-luxury apartments that IMRB has actually conducted research on top luxury houses to look at the performance of all this deluxe.

Some of the renowned names in deluxe in Pioneer Araya apartments Gurgaon are - Paras Trinity, Paras Trade Centre, Paras Twin Towers, Paras Downtown, Paras Downtown Square Mall, Paras Quartier, Paras Dew's, Paras Irene, Paras Seasons, Paras Tierea, Paras Panorama, CenterHamilton Court, The Laburnum, The World Spa, Aralias, Raheja Atlantis, Gurgaon One, Wellington Estate, DLF Park Place, Belvedere Towers, Orchid Petals, Jal Vayu Towers, The Close North, Vatika City, Ridgewood Estate as well as Sispal Vihar AWHO Society.

Besides the houses for uber-rich, top middle class additionally has a variety of apartments to pick from. Seeing the rush, the government has also come out with the economical housing schemes in Pioneer Araya apartments Gurgaon with the evident disadvantage that these apartments will certainly be in brand-new areas which probably have less connection today.

Leas permanently 2 bhk will start anywhere from Rs 20,000 to no limits, depending upon the sector choice, facilities in the apartment complex and also closeness to necessities. Building contractors are trying to construct the housing complexes into a full town with even entertainment alternatives and requirements such as shopping centers, theatres, institutions, health centers.

Pioneer Araya sector 62 Gurgaon houses have come to be a huge financial investment asset in the cats of many ultra-rich with although with high EMIs, the rental rise is making these buildings really profitable for their owners. Developer custom made apartments such as in Huda Plots, DLF, Sushant Lok, South City and also Sohna road are the prime locations.

After all this hype and walk in costs, people have actually had to consider shelling out high costs to building contractors for getting bookings carried out in the economical real estate classification. Haryana government is dealing with streamlining the reservation procedure and making it clear on the internet site.

The most significant problem in Pioneer Araya sector 62 Gurgaon real estate has been absence of civic facilities such as water drainage as well as piping which was a concern even with high where waste would not non reusable. Various other problems are power cuts and also criminal activity rate.

Pioneer Araya sector 62 Gurgaon, additionally known as the Millenium City is anticipated to have around 2,500 multi-storey towers by 2018. For Gurgaon to not simply continue to be a high-end as well as Richie rich location, government will certainly need to pro-actively function to make the wheels transform and also solve difficulties for price.

Get in touch with us [email protected] +91 8860646116

#Pioneer Araya#Pioneer Urban Araya#Pioneer Araya gurgaon#Pioneer Araya sector 62#Pioneer Araya apartments#pioneer araya#pioneer araya sector 62#pioneer urban araya#pioneer araya gurgaon#pioneer araya apartments

0 notes

Text

What Types of Valves Can You Find at a China Valve Supplier?

Valves are used in numerous industries and this comes as no surprise considering their numerous applications. A China valve supplier is a leader when it comes to valves and he can provide any type you need such as butterfly valve, check valve, ball valve and others. Each type of valve has different uses and it is important to know what you need it for to find one that suits your needs best. When selecting valves, you should take your time to learn more about their features, applications, media and so on.

What Are the Benefits of the Ball Valve?

Some of the most popular valves out there are ball valves, which are shut-off valves used to allow or obstruct the flow of fluid. As far as their operation is concerned, this can be done manually or by an actuator. The ball valve is available in different types and the classification is made according to the housing assembly, the design of the ball and the bore profile. The most important aspect is that these valves are available in numerous designs in order to meet the needs of any industry. The design of the ball is usually selected based on the working pressure.

The advantages offered by the ball valve are numerous: • Versatility in design and sizes- most people want to have options when they shop for the right valve for their intended use. There are ball designs suitable for pressure reliefs, variable flow rate control, flow splitting and others. • The pressure drop they induce is low due to the fact that there are minimal restrictions to the flow. • It can be open or shut with a one quarter turn, thus restricting or allowing flow. • The valve can be rotated by a small actuator • It does not require any lubrication because of the surface of the seats • There is no risk of leakage when using such a valve • These valves are affordable.

If you are in the market for high-quality valves, you should see whether ball valves are what you need. It is worth mentioning that these have certain limitations that should not be ignored: they are not designed for throttling applications, you should pay attention to the maximum allowable temperature of the seats and they require frequent maintenance to perform at their best. These devices can be used pretty much everywhere where fluid flow has to be shut off.

What Type of Valves Are Available at a China Valve Supplier?

A reliable supplier knows that customers appreciate quality and diversity in terms of designs, size and materials. Therefore, a China valve supplier strives to keep its customers happy and to put at their disposal a wide range of designs. For the ball valves, the most common ones are: • One-piece valve, which consists of a single-piece body that integrates all the internal components of the valve. Its parts are welded together and this is done to eliminate risk of leakage. Its drawback is that it is difficult to clean and it cannot be repaired once damaged. • Split-body valves are available in two pieces or three pieces.; they can be cleaned and maintained provided the valve is removed from the pipe. Three-piece valves are suitable for applications that require frequent maintenance and they are common in food and beverage industries as well as in pharmaceutical ones. • Floating ball valves have a simple design, they are usually available in small diameters and they can be used with liquids and gases that have low to moderate pressure. • Trunnion ball valves- they come in small and large diameters, they are more expensive in floating designs and they can operate without any problems in wide range of pressures. • The vented ball valve is common in compressed air systems and cryogenic processing.

These are just some of the types of valves that you can find at a China valve supplier that focuses on the specific needs of its customers. When it comes to valves materials, it is useful to know that the most common ones are brass, which is tough, strong, and durable, designed to withstand high temperatures; brass is quite common because of its chemical, corrosion and biofouling resistance; stainless steel has great strength, toughness and durability is not an issue; PVC has lower strength compared to the other materials but it is more affordable.

Why Use the Ball Valve?

This type of valve is a great choice for it can be used in various industries, it is made from different materials and it comes in various designs and sizes. The ball valve is available online at reliable suppliers and it can be purchased easily with just a few clicks of the mouse. If you are in doubt as to whether it is the best choice for you or not, you should read more about it and see what it has to offer.

The China valve supplier is at your disposal should you need more details about his products, their application, delivery time and so on. When you place a significant order for valves there is no room for mistakes. As such, the more you know about the available types, the pros and cons of each and recommended applications, the easier it will be for you to decide. It is in your best interest to educate yourselves on the matter so that you get the best value for your money.

In fewer words, a China valve supplier is the first choice of individuals across globe that need valves; this is because of the diversity it offers and because of the quality of its products. Individuals who do not want to make any compromises as far as quality is concerned should place their order with a reputed source. The good news is that ordering valves online is quite easy once you are certain about the type and quantity you want. When you work with the best in this niche, you benefit from excellent customer-service, secure payment methods and fast delivery.

0 notes

Text

Why is fiberglass mesh needed?

Composite sheets of fiberglass mesh for marble reinforced polycarbonate were prepared by hot compress molding. The effects of lay-up structure, lay-up angle, area density of fiberglass mesh and the thickness of PC film on tensile property were studied. The results reveal that the alternative lay-up structure of reinforcement mesh and matrix film is optimal and tensile property declines as lay-up angle increases. Fiberglass mesh with lower area density is appropriate for thinner composites. Composite sheets fabricated with thinner PC film show better tensile property. SEM analysis shows that alternative lay-up structure is favorable to the immersion of the fiber bundle of marble mesh cloth with low area density in the melting matrix, and thus the improvement of tensile property.

This paper investigates the effect of surface treatment for glass fiber, stainless steel wire mesh on tensile, flexural, inter-laminar shear and impact properties of glass fiber/stainless steel wire mesh reinforced epoxy hybrid composites. The glass fiber fabric is surface treated either by 1 N solution of sulfuric acid or 1 N solution of sodium hydroxide. The stainless steel wire mesh is also surface treated by either electro dissolution or sand blasting. The hybrid composites are fabricated using epoxy resin reinforced with glass fiber and fine stainless steel wire mesh by hand lay-up technique at room temperature. The hybrid composite consisting of acid treated glass fiber and sand blasted stainless steel wire mesh exhibits a good combination of tensile, flexural, inter-laminar shear and impact behavior in comparison with the composites made without any surface treatment. The fine morphological modifications made on the surface of the glass fiber and stainless steel wire mesh enhances the bonding between the resin and reinforcement which inturn improved the tensile, flexural, inter- laminar shear and impact properties.

The fiberglass mesh filter is an inorganic non-metallic material with excellent performance. It has a wide variety of advantages. The advantages are good insulation, strong heat resistance, good corrosion resistance, and high mechanical strength, but its disadvantages are brittleness and poor wear resistance. It is made of glass balls or waste glass as raw materials through high-temperature melting, drawing, winding, weaving, and other processes. In this article, we will take a closer look at the characteristics and types of fiberglass mesh filters.

Characteristics of Fiberglass Mesh Filters

The filter has high tensile strength and low elongation (3%).

The filter has a high elastic coefficient and good rigidity.

The filter has large elongation within the elastic limit and high tensile strength, so it can absorb impact energy.

The filter is made of inorganic fiber, which is non-flammable and has good chemical resistance.

Its water absorption is small.

High-temperature resistance.

High filtration efficiency.

Types of Fiberglass Mesh Filters

ULPA(Ultra Low Penetration Air) Filter

ULPA (Ultra Low Penetration Air) filter has a filtration efficiency of more than 99.999% for 0.1~0.2μm particles, smoke and microbes, and other dust particles.

ULPA filter characteristics: Its filter element is made of ultra-fine glass fiber filter material by gluing and folding. The outer frame can be made of laminated wood, galvanized copper, stainless steel, and aluminum alloy, and it is tightly bonded by polyurethane glue. It has the characteristics of lightweight, large air permeability, dust collection rate as high as 99.95-99.999%, and alkali resistance, and high-temperature resistance.

ULPA filter applications: It is suitable for class 10000-100 clean systems, air conditioning systems, so the product has been widely used in electronics, microelectronics, semiconductors, optical devices, biological and medical circuits, cameras, and optical instruments, precision machinery, and other fields.

High-Temperature Air Filter

The high-temperature air filter still has a partition structure. It is assembled with high-temperature resistant glass fiber or ultra-fine glass fiber filter paper, aluminum foil partition, stainless steel frame, and special high-temperature resistant sealant.

High-temperature air filters are mainly used in ultra-clean ovens that require drying in the production process of food, pharmaceuticals, etc., or high-temperature air purification equipment and systems. The maximum working temperature is 350 degrees.

High Humidity Resistant Air Filter

The high-humidity air filter has a partition structure, using special moisture-proof ultra-fine glass fiber filter paper, special rubber sheet or aluminum foil partition, galvanized sheet, or aluminum alloy profile frame. It is suitable for high humidity under normal temperature and pressure, especially in high humidity environments such as infusion production in the pharmaceutical industry. The maximum working humidity is 100%.

The Disadvantage of Fiberglass Mesh Filters

Due to the poor ductility of glass fiber, the glass fiber filter is easily damaged, so be careful when installing it.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the characteristics and types of marble fiberglass cloth. If you want to learn more about fiberglass mesh filters, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

As a leading supplier of fiberglass mesh filters across the world, SAM enjoys over two decades of experience in the manufacture and sale of fiberglass mesh filters, offering customers high-quality fiberglass mesh filters to meet their R&D and production needs. As such, we are confident that SAM will be your favorite fiberglass mesh filter supplier and business partner.

Fiberglass mesh is a neatly woven, crisscross pattern of fiberglass thread that is used to create new products such as tape and filters. When it is used as a filter, it is not uncommon for the manufacturer to spray a PVC coating to make it stronger and last longer. The most common place to find fiberglass mesh is in tape products.

Sheetrock finishers use the mesh frequently. In fact, it is common to replace the paper tape used to float the joint between two pieces of sheetrock. The mesh that sheetrock finishers use comes on a roll just like paper sheetrock tape. The added benefit for the sheetrock finisher is to roll out the mesh over a great distance before having to apply the first coat of joint compound. Not only does it help them in this manner, but it also causes a stronger bond between the joint compound, the tape and the wall.

Sheetrock finisher's also use this tape to patch holes. The most common hole in the sheetrock generally occurs where a doorknob has hit a wall too many times. If it is only slightly damaged, a couple of short pieces of the tape will be formed into a square and placed over the hole. A joint compound will then be applied directly to it. If the hole is too large to patch with fibreglass mesh for wall alone, a piece of metal flashing can be added behind the tape before applying joint compound. Construction work is not the only use for fiberglass mesh.

As a filtering system, fiberglass mesh works really well. As the water flows through it, the mesh catches even the smallest impurities. In addition to this use, it can also be used as a mosquito net.

Finally, fiberglass mesh is sometimes woven into protective clothing used by those who work with dangerous chemicals or firefighters. Tightly woven mesh is put together and shaped into jackets that firemen wear when they are battling a blaze. It protects them from any fire that might ignite their clothing while fighting a fire. Fiberglass mesh can also be used in mold making and as protection against corrosives.

In your letter dated January 31, 2008, on behalf of your client, SpiderLath, Inc., you requested a tariff classification ruling on a woven fiberglass article. A sample of a piece of the material comprising this product was submitted with your ruling request.

The subject article, identified as “SpiderLath”, is a woven fiberglass mesh/fiberglass lath system with ethylene vinylacetate (EVA) backing strips that will be imported in rolls 4 feet wide by 75 feet long. You indicated in a telephone conversation that the fiberglass mesh is coated with a stiffener.

According to the information that was submitted with your ruling, the fiberglass mesh/fiberglass lath system is used as a cladding masonry support. The product can be used to install stucco and stone veneer. It can also be used over existing surfaces to apply masonry finishes.

In your presentation, you suggest classification under subheading 7019.31.0000, Harmonized Tariff Schedule of the United States (HTSUS), which provides for glass fibers (including glass wool) and articles thereof...thin sheets (voiles), webs, mats, mattresses, boards and similar nonwoven articles: mats. This subheading does not apply since the product is a woven article.

The applicable subheading for the woven fiberglass mesh for construction/fiberglass lath system with EVA backing strips will be 7019.90.1000, HTSUS, which provides for glass fibers (including glass wool) and articles thereof (for example, yarn, woven fabrics (con.): other: woven. The rate of duty will be 4.8 percent ad valorem.

Duty rates are provided for your convenience and are subject to change. The text of the most recent HTSUS and the accompanying duty rates are provided on World Wide Web at http://www.usitc.gov/tata/hts/.

This ruling is being issued under the provisions of Part 177 of the Customs Regulations (19 C.F.R. 177).

A copy of the ruling or the control number indicated above should be provided with the entry documents filed at the time this merchandise is imported. If you have any questions regarding the ruling, contact National Import Specialist Jacob Bunin at 646-733-3027.

0 notes

Text

mold manufacturers in China | Topworks-China Mold maker | 30% COST LOWER,10 DAYS LESS

Mold manufacturers in China

Many people assume that mold manufacturers in China are going to be of poor quality. However, a huge number of companies- including multinational corporations- still choose to buy such plastic molds. Does that mean these companies are naive or making a mistake? Of course not. In fact, Topworks plastic mold company, as one of the Top mold manufacturers in China, is capable of making some of the best molds on the market- for a much lower price( 35% COST LOWER,15 BUILDING DAYS LESS) than European and American companies can possibly offer. China has seen a steady increase in the number of manufacturers of plastic injection molds as the industry has grown to be globally competitive. Not only do Mold manufacturers in China have the skills required to make superior injection molds, but we also possess excellent English skills for technology and business. That extends into the Topworks marketing departments, too- most of our sales staff have a strong grasp of CAD drawing, and the technical capability to choose the right mold building project for you. This allows them to speed up the communication process between Topworks and the customer. When making a new plastic injection mold, not only in China but all over the world, the process usually starts with a rendering of the final product drawing. After reading the drawing, engineers can then adjust how to build the mold based on things like the size and structure of the intended parts, the choice of material and how to keep the cost as low as possible – all while considering everything the customer asks for. China mold maker Our factory has worked with multiple European and American companies for many years now, so all you need to do is send us your drawings- we’ll be happy to carry out a test to show you what we have to offer. https://res.cloudinary.com/dl8a9jvpa/video/upload/v1572574321/plastic%20mold.mp4 Mold manufacturing has been around in China for over 30 years, meaning there are plenty of high-quality manufacturers operating today. Many China mold makers possess the same skills and experience as their western counterparts. While those injection mold manufacturers in China may only be paid around 65% of what they could make doing the same job in the US, they will still produce top-quality molds that you can really rely on. " order_by="sortorder" order_direction="ASC" returns="included" maximum_entity_count="500"]

How should I go about choosing mold manufacturers in China?

To clarify, the reason why a lot of US and European clients are declining to get their plastic injection mold from China is mainly that they are often more affordable (up to 35% cheaper than in their country). It should not, however, be the only factor you evaluate when weighing your options- you should also consider the following as a second factor to make sure that the mold manufacturers in China you choose are likely to provide you with a comprehensive task when it comes to developing the mold. - Can they afford to serve customers worldwide? - Consumers who used the service earlier and gave us their recommendations - Tool steel quality - The China mold factory manufacturing plant and their gear are of an industry standard. - Measures for quality control and validation - If you opted for a service provider who doesn't understand what they are dealing with, you may not have to waste your time. - Ability– will the China mold maker be able to carry out the entire task themselves, or will they have to employ a third party to help them with it?

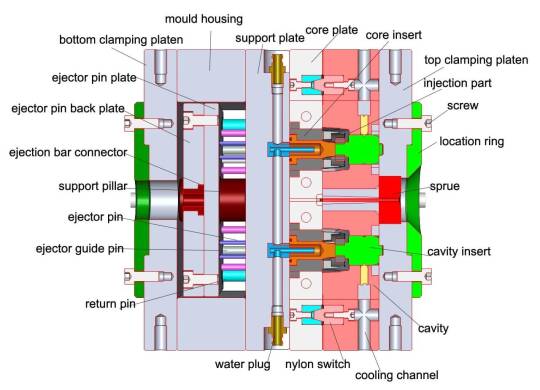

plastic mold structure

The process of China mould making

A design engineer is generally responsible for drawing a component pattern of the new part before the china mold factory can start the actual production of the mold. This blueprint gives the toolmaker an idea of what the new component will look like, so he can start designing the mold before proceeding with the work. In order to design a mold in a way to replicate the finished part very precisely, the specifications of the final part must be carefully reviewed. By performing the initial design on the computer, the mold designer who worked at mold manufacturers in China can get accurate results. The designer of a mold has to consider not only the gate on the part, but also the flow of water in the mold, to decide where the parting line will be on the part, and also to determine how the parts will be pushed out of the mold. Once these decisions have been made, the actual machining steps then begin. There are a variety of operations that need to be carried out in order to make a mold, the raw metal blocks need to be cut into rough dimensions. To obtain exact dimensions, precision machining is required, with this precision machining, this machining generally entails milling operations, grinding, drilling, and the use of electrical discharge machining or EDM. The process of using the lathe to polish the surface of the mold once it has been completed. There have been several trials done to determine how well the mold is able to produce good parts in an appropriate cycle time.

China mould making tips

It is a prevalent understanding that injection molds are as varied in profile, complexity, and size as are the parts they are used to produce. The most simple form of injection molding involves two pieces of steel plates (core and cavity plate) that can be easily installed in a small injection machine and which can also be molded using directly cutting the impression of the article to be molded into the steel. More complex injection molds made by China mold companies will have more cooling channels for controlling the temperature and means for ejecting the moldings. A sliding block may be provided for undercut sections of the part, unscrewing devices for moldings that have a screw thread, and plastic in the runner of the mold may be kept hot to provide a good fluid path. For the purpose of ejecting the moldings after injection molding, there are sometimes hydraulic devices installed, and sometimes compressed air is applied. The process of the production of an injection mold generally begins with the design and construction of the mold. Care must be taken to optimize the design of the components so that they can be molded by China mold makers, and then it must be ejected in the construction of the mold itself. Then, if necessary, it will be tested in the China mold factory and, if necessary, modified before the mold production department is entrusted with producing the mold. Steel is traditionally used to manufacture molds, and it is still the most common material that is used. Cavities and core inserts are crafted from high-quality tool steel that can be hardened as needed. Ejector pins and other ejectors are made with hard tool steel when it comes to the ejection systems, so the same goes for the guide pins and bushes as well. The molding housing, or bolster, is made of mild steel that is softer than the hard steel. In fact, in the production of the mold, it is best to use this grade of steel for all the parts that do not have to endure frictional wear and tear, as it results in minimizing the mold builder’s costs. Also, the steel grade must be selected carefully so that the surface finish required matches the demand is. In the past, like some other molders, injection mold manufacturers in China have been unwilling to accept other materials, such as POM, PVC, on the basis of the assumption that the abrasive action of the plastic passing through the mold will gradually wear away the surface polish. Thermosetting materials and compression are what happen in this process, and the process of making transfer molds is nearly always hardened and chromium plated.

mold manufacturers in China In retrospect, thermoplastics have little abrasive action, and therefore most of the time, even when runs have run as high as one million or more, soft materials have been used after hardening, especially for household ware plastic mold. These materials include aluminum, brass, zinc, aluminum-zinc alloys (Kirksite). The two last materials are ideal for prototype work since they can be cast easily from them using machines. You need to always look for the best possible mold when it comes to long-run products. Such molds are very costly. However, their cost per unit item is calculated out of ten and one hundred thousand items per mold, which is very small. Over a long period of time, the value of a well-made mold will grow, and in its turn, the cost of the mold will rise. This is because a well-made mold will not require frequent repairs, while the value per unit of the finished product will be very high.

EDM shop Nowadays, more and more customers want injection mold manufacturers in China to make prototypes so they can evaluate the market and then ask them to make several thousand pieces of the mold design with hardened steel. A prototype mold is exactly what its title suggests, a mold that is being created to serve as a prototype for a product. In rare instances, from a product mold from China, one could find a way to make a long production run, but this is never a matter of course in a business world. The good thing about a prototype mold is that it teaches us a lot about how molds should be manufactured and makes us a lot more confident that we will produce a good mold, but that is probably the extent to which a prototype mold can be helpful.

China Mould Classification

China Mould Classification is generally classified into three general categories: - prototype molding (25 to 1,000 pieces) - Production molding (from 1,000 to 10,000 pieces) - High volume molding (from 10,000 to 2,000,000 pieces) - China Prototype Moulds Creating a prototype thermoplastic injection mold is one of the preliminary steps in building a new product. To evaluate the properties of the resin for injection molding and the set-up requirements for the mold, original prototypes have to be produced from the resin to monitor the dimensional control, the set-up process, and the setting of the mold. In certain products, prototype moldings are designed to meet specifications for product Quality Control testing. Therefore, they are generally used for product quality control testing and (occasionally) as the basis for the initial market testing requirement. As China prototype molds are intended to mimic the production part before launching a production run, they can be used as a relatively inexpensive learning device to point out and correct potential design issues or material selection issues before moving forward on a production run. An existing prototype mold may be fabricated utilizing an existing mold frame, interchangeable soft cavity inserts, manual loading and unloading systems, and a simple cooling system. - China Production Moulds The construction of china production molds utilizes a low-cost mold base and hardened tool steel cavities; the cavities should be machined into predefined shapes and sizes on demand according to specifications at established production rates. The mold must allow for the ease of repair as well as facilitate the escape of trapped air and volatile materials during the molding cycle employing facilitating the venting of the cavities. In this context, a production mold must also incorporate an automatic ejection system and thermoplastic melting temperature control for continuous cooling, ensuring shorter cycle times, lower costs, and consistently high quality. - China High Volume Production Moulds For the China moulds to fully meet the requirements of production tools, the molds must have multiple cavities and be composed of interchangeable mold components. In addition, an efficient high-volume production mould made in China should be easy to maintain and be designed to be resistant to adverse outside forces. For instance, - How often do you begin dismantling a mold only to discover too many inserts that are not numbered or labeled with positions? - What about slots for pry bars? - Could jack screw holes be useful in the removal of cavities? A well-configured mold can help minimize the risks of its design and construction and prevent corrosion and erosion. In addition, a customized preventative maintenance program can be incorporated, as well as surface coatings. Read the full article

0 notes

Text

Cell Isolation Market Size, Share, Classification, Opportunities, Types and Applications, Status and Forecast to 2027

This analysis of the Global Cell Isolation Market aims to offer relevant and well-researched insights into the contemporary market scenario and the emergent growth dynamics. The report on Cell Isolation Market also gives the market players and fresh contenders a holistic view of the global market landscape. The comprehensive study will help both established and emerging players formulate lucrative business strategies and realize their short-term and long-term goals. The Cell Isolation industry has witnessed a stable growth rate in the past decade and is expected to continue on the same path in the forthcoming decades. Therefore, it is crucial to recognize all investment opportunities, potential market threats, restraining factors, challenges, market dynamics, and technological development to intensify footholds in the Cell Isolation sector. This report has evaluated all the above mentioned aspects to present a detailed assessment to the reader to assist them in achieving the desired growth in their businesses.

This report covers the recent COVID-19 incidence and its impact on Cell Isolation Market. The pandemic has widely affected the economic scenario. This study assesses the current landscape of the ever-evolving business sector and the present and future effects of COVID-19 on the market.

Get a sample of the report @ https://www.reportsanddata.com/sample-enquiry-form/2237

Key players of this industry are Thermo Fisher Scientific, Beckman Coulter, Becton, Dickinson and Company, GE Healthcare, Merck KgaA, Miltenyi Biotec, pluriSelect, STEMCELL Technologies Inc., Terumo BCT and Bio-Rad Laboratories Inc.

The forecast estimation states the global Cell Isolation market is expected to dominate the economic sphere of the world with significant growth in the coming years. The growth is boosted by a change in demand patterns, rapidly developing infrastructure, technological advancements, and product advancements. The current and emerging trends are expected to shape up the industry and help in gaining a strong foothold in the global market to contribute to the revenue generation.

The Global Cell Isolation market is further analyzed on the basis of key companies operating in the business sphere and major geographical regions where the market has a substantial size and growth rate.

Product (Revenue in USD Billion, 2018 - 2026)

Reagents, kits, media, and sera

Beads

Disposables

Centrifuges

Flow cytometers

Filtration systems

Magnetic-activated cell separator systems

Cell Type (Revenue in USD Billion, 2018 - 2026)

Differentiated Cells

Stem Cells

Technique (Revenue in USD Billion, 2018 - 2026)

Centrifugation

Surface marker

Filtration

To read more about the report @ https://www.reportsanddata.com/report-detail/cell-isolation-market

Application (Revenue in USD Billion, 2018 - 2026)

Biomolecule Isolation

Cancer Research

Stem Cell Research

Tissue Regeneration & Regenerative Medicine

Vitro Diagnostics

End Use (Revenue in USD Billion, 2018 - 2026)

Research laboratories and institutes

Biotechnology and biopharmaceutical companies

Cell banks

Hospitals and diagnostic laboratories

Zonal Partition of the Market: North America, Latin America, Europe, Asia-Pacific, and the Middle East & Africa.

The report covers extensive analysis of market segments that are anticipated to lead by the end of the forecast period (2020-2027). The report puts a special emphasis on the upstream raw materials, downstream buyers, industrial chain analysis, technological and product advancements, and production and manufacturing capacities of the Cell Isolation market. Moreover, the report provides an in-depth analysis of the core segments of the market by analysis of the applications, types, consumption patterns, market drivers and restraints, and challenges to be faced in the market.

The research study focuses on the emerging development patterns and manufacturing processes anticipated to boost the growth of the market. It also includes extensive profiles of prominent contenders of the industry and provides a complete analysis inclusive of their market share, market size, production capacity, sales and distribution network, import/export activity, and product portfolios.

Major objectives of the Global Cell Isolation Report:

· Analysis and forecast estimation of the Global Cell Isolation Market based on the market segmentation into types, applications, and regions

· Analysis of micro and macroeconomic factors affecting the global Cell Isolation market

· Valuable insight into the major drivers, limitations, opportunities, and challenges faced by the global Cell Isolation market and its players

· In-depth analysis of the prominent contenders along with their business strategies and expansion plans

· Strategic recommendations to the established companies as well as new entrants to assist in the formulation of investment plans

· Comprehensive analysis of the competitive landscape of the Cell Isolation industry

To summarize, the report provides a better understanding to the reader about the Cell Isolation industry by offering a detailed explanation of the competitive landscape, industry environment, market projections, growth driving and restraining factors, limitations, entry barriers, and opportunities. The report also covers the regulatory framework, investment opportunities, and other growth driving factors. The report allows the reader to gather insightful information about each segment of the market and provides a historical, present, and prospective outlook of the market.

Thank you for reading our report. To know more about the report or for any queries regarding customization, please connect with us. Our team will provide excellent assistance and make sure the report is tailored to meet your requirements.

Ask for Discount @ https://www.reportsanddata.com/discount-enquiry-form/2237

Contact Us

John W

Head of Business Development

40 Wall St. 28th floor New York City

NY 10005 United States

Direct Line: +1-212-710-1370

0 notes

Text

Custom aluminium profiles factory XJ

The full-automatic extruder has high efficiency, good quality and reasonable price. It is equipped with main engine and auxiliary machine production line, with complete tonnage, high precision and good quality, The principle of aluminum profile extrusion is to apply >aluminium profiles factory</a> external force to the metal blank placed in the container (extrusion cylinder) to make it flow out of the specific die hole to obtain the required section shape and size.

2、 The structure of aluminum profile extrusion press

the aluminum profile extrusion press is composed of frame, front column frame, tension column, extrusion cylinder, hydraulic system under electrical control, and also equipped with die base, thimble, scale plate, sliding plate, etc.

3、 Classification of extrusion methods for aluminum profiles According to the type of metal in the aluminum extrusion cylinder, stress-strain state, extrusion direction, lubrication state, extrusion temperature, extrusion speed, type or structure of tools and dies, shape or number of blank, shape or number of products, etc., it can be divided into forward extrusion method and reverse extrusion method (including plane deformation extrusion, axisymmetric deformation extrusion, General three-dimensional deformation extrusion) lateral extrusion, glass lubrication extrusion, hydrostatic extrusion, continuous extrusion and so on.

4、 Most of the hot deformation extrusion enterprises use the forward hot deformation extrusion method to obtain the aluminum with the required cross-section shape through the specific dies (flat die, conical die, split die)This is an aluminum production method adopted by jinhuochun aluminum industry so far!

the forward extrusion process is simple, the equipment requirements are not high, the metal deformation ability is high, the production range is wide, the aluminum performance is controllable, the production flexibility is large, the tooling is easy to maintain and repair.

The defect is that the friction between the inner surface of extrusion cylinder and aluminum material is strong, which accounts for a large proportion of extrusion energy consumption. The friction is easy to make the ingot heat in the cylinder, increase the instability of the profile, damage the efficiency of the finished product, limit the extrusion speed of aluminum and aluminum alloy, accelerate the wear and service life of the extrusion die, and the structure and performance of the products are uneven.

5、 Types, properties and applications of hot deformed aluminum alloys

the types of hot deformed aluminum alloys can be divided into eight categories according to the performance and application requirements, and the performance and application are different.

1. Pure aluminum (L Series) corresponds to international grade 1000 series pure aluminum,

industrial pure aluminum, with excellent processability, corrosion resistance, surface treatment and conductivity, but with low strength, it is used for household goods, electrical products, medicine and food packaging, power transmission and distribution materials, etc.

2. Hard aluminum (ly) corresponds to international grade 2000al Cu alloy.

It is used in large components and supports, with high Cu content and poor corrosion resistance.

3. Antirust aluminum (LF) corresponds to 3000al Mn alloy.

Heat treatment can not be strengthened, machinability, corrosion resistance is equivalent to pure aluminum, strength has been improved, welding performance is good, widely used in daily necessities, building materials, devices and other aspects.

4. Special aluminum (LT) corresponds to international grade 4000al Si alloy.

It is mainly made of welding materials, low melting point (575-630 degrees), good fluidity and fluidity.

5. Anti rust aluminum (LF) corresponds to the international brand of 5000al Mg alloy.

Heat treatment can not be >klik</a> strengthened, corrosion resistance, weldability and surface gloss are excellent. By controlling Mg content, alloys with different strength levels can be obtained. Less for decorative materials, advanced devices. For ships, vehicles, building materials. High for ships, vehicles, chemical plants welding components.

6. 6000al mg Si alloy

Mg2Si precipitation hardening heat treatment can strengthen the alloy with good corrosion resistance, medium strength and excellent hot workability. Therefore, it is widely used as extrusion material with good formability and high hardness by quenching. A large number of them are used for building profiles, and they are also the main source of materials in industry.

7. Ultra hard aluminum (LC) corresponds to international grade 7000al Zn mg Cu high strength aluminum alloy and Al Zn mg welding alloyIt has high strength, excellent welding and >aluminium door manufacturers</a> quenching properties, but poor stress corrosion cracking resistance, which needs to be improved by appropriate heat treatment. The former is mainly used for aircraft and sporting goods, while the latter is mainly used for welding structural materials for railway vehicles.

8, 8000 (Al-Li) Al Li alloy

is characterized by density less than 7000 series of 8% ~ 9%, high rigidity, high strength and light weight. This series is under development (the anti decay ability of aluminum alloy metal under complex conditions has not been fully overcome), and it is mainly used in military applications such as aircraft and engines.

0 notes

Text

KITCHEN RANGE

With the ongoing benefit of home value to numerous property holders across America, the top home improvement ventures have included redesigning kitchens. Kitchens and washrooms appear to lose their style/work quite quick and getting new machines in a kitchen will tidy things up. Purchasing another range stove for your kitchen can be an overwhelming undertaking with all the choices and brand names available.

A range is truly 2 machines in one - burners that sit on head of the unit and a coordinated stove down underneath. Start with the fundamental estimations of what size you will require - decide the heigh, width and profundity of the space your range will be going into. Electric reaches are commonly more affordable than their gas partners Performance levels are reliable and you can utilize them for an assortment of cooking purposes.

Electric reaches are magnificent when you need ver low warmth (not generally conceivable on gas ranges). Standard loop burners and smooth-top electric reaches are the 2 electric range alternatives. Loop burners are more suspectible to spills (dribble skillet can dispose of cleaning bothers) and by and large more affordable than smooth-top models. In smooth-top electric ranges the brilliant components are introduced under a glass surface that is generally seemless which makes cleaning these units simple. The brilliant components heat up quick and equally.

Purchasing Guide - Gas ranges give you more exact temperature control, are more costly than electric models to purchase, however are less expensive to run. Gas run burners let you heat things up in minutes while top quality gas ranges have unique burners offering higher, quicker warmth creation for fast singing and bubbling.

Numerous gas extends likewise have burners extraordinarily intended to hold a low warmth that will stew fluids/sauces. Search for a gas extend that has fixed gas burners since they are a lot simpler with regards to tidying up. Double fuel gas and electric reaches are the best since you get the prompt reaction of gas burners and the even warmth of an electric broiler.

Business style home reaches are beginning to spring up in family units also with home cooks searching for the best hardware. You should consider limit in a range as well. Consider the # of individuals in your family: 1 to 2 individuals would liken to a 2-3 cubic feet stove limit size, 3-4 individuals is 3-4 cubic feet, and 4+ individuals (enormous family) ought to have a 4+ cubic feet of limit. Range styles are detached, drop-in extents, and slide-in ranges.

An unsupported range has completed sides and controls on the backsplash. Slide-in ranges have controls on the front segment of the range and look only an inherent with a consistent completion. A drop-in range will have incomplete sides and may need to have a few alterations done to it so it fits flush with your cupboards. Purchasing a range with a convection broiler is obligatory nowadays. Convection broilers have heaps of advantages over customary stoves, for example, concocting meats to 30% quicker, having a third warming component around the back fan and you can do convection heating or simmering.

Top kitchen go brands are Viking, Wolf, DCS, GE, Jenn-Air, Thermador, Frigidaire, Whirlpool, Maytag, Amana, Bosch, Dacor, Kenmore, KitchenAid and Hotpoint. Costs extend from $350 as far as possible up to $5000+. Pick cautiously and read our surveys underneath on the best ranges in every class. You can see the vast majority of these kitchen extents and broilers in stores like Sears or HomeDepot. You can see a rundown of the top selling ranges online here.

GE reliably rates close to the head of all shopper surveys with it's profile ranges. The GE Profile PGB910SEMSS Stainless Steel Gas Kitchen Range($1500) is our pick for best gas go. You get a self cleaning broiler, huge stove limit (5 cubic feet), a profound recessed cooktop, a focal oval burner, non-stick iron, and PowerBoil 17,000 BTU burner. Clients acclaim the warming draw and state the GE cooks equally and reliably.

The force burner does something amazing in bubbling water rapidly. The GE JGB400SEPSS ($850) is another top merchant from GE with exact temperature control, no problem cleaning, and magnificent warming rate. Subsequent to perusing audits we are glad to state that the Hotpoint RGB745 is the best spending range under $600. Created in England, the Hotpoint has 1 high yield burner and 1 stew burner alongside 2 9500 BTU burners.

It doesn't have all the top end highlights on found on more extravagant models, however preparing, searing, or stewing on the Hotpoint is simple. The best twofold broiler gas extend with convection is the GE Profile JGB918SELSS ($1950) - home culinary specialists like the convection stove for its capacity to flow air all through the broiler depression giving preparing and simmering results dissimilar to different models.

You get one enormous convection stove and the lower broiler offers "an extra 1.0 cu. ft. of limit with regards to helpful heating from 150 degrees to 450 degrees". The cooktop has 5 components including the focal oval burner extraordinary for huge cookware. See a rundown of top of the line gas runs here.

We had heard that Kenmore models were evaluated exceptionally high in this classification, and surveys from driving shopper magazines returned really sure on pre-warming capacity and sturdiness. The best smoothtop electric range is the GE Cafe CS980SN Stainless Steel Electric Kitchen Range ($2800) with a sharp plan, in any event, warming, auto cleaning, and a recessed cooktop to contain spills. Proprietors state the advanced controls work extraordinary and a few state it's the best range they have ever purchased.

Since model #'s change consistently with refreshes from GE, we suggest checking the GE site for the freshest kitchen ranges. For an electric loop run again Hotpoint has the best spending model - the Hotpoint RB757 for under $350. In exploring range stoves we understood that loop top electric broilers are a withering variety however the Hotpoint gets extraordinary surveys. Buyers state it's dependable, however functions as effectively as more expensive models they've possessed previously.

A few disadvantages do incorporate a little broiler entryway window, a difficult to arrive at control board, and a somewhat plain plan and shading alternative.

The top double fuel extend is the Jenn-Air Double Oven Free-Standing Dual-Fuel Range (Model JDR8895AAS). In the wake of perusing surveys and checking home machine gatherings for the first class goes, this Jenn-Air won out. With a sticker price over $2000 for the hardened steel choice, buyers state it's justified, despite all the trouble.

You get a gas cooktop with 5 burners, double fuel electric broilers, the base stove is a convection stove while the best one is a touch littler and better for warming food. Proprietors state the base convection stove is extraordinary for huge turkeys and the broilers pre-heat shortly. One purchaser said the handles rust effectively and the cooktop isn't even, in spite of the fact that that was one separated analyst.

As we referenced above there are an ever increasing number of homes supplanting obsolete kitchen reaches and ovens with present day, business level extents from Viking, DCS, and Wolf. We lean toward the Viking ranges thus do the majority of the buyer reports we read on them. Viking works superbly with double fuel ranges by joining elite gas surface burners with electric self-cleaning stoves. They run in cost from $4300-$9500.

The more customary Viking gas ranges are intended to fit standard 24" profundity cabinetry and they come as extensive as 60". Hope to pay at least $3500 and upwards of $9000 for a Viking gas go. DCS is another range producer that produces proficient looking reaches. The RGT305 DCS 30" Gas Professional Range for $3700 is an amazing home range that give eatery quality highlights.

The Wolf 36 inch Gas Range is another very good quality apparatus for cooking fans with a gigantic convection broiler, an infrared kettle, and the cooktop can be designed with up to 6 burners. .

1 note

·

View note

Text

KITCHEN RANGE

With the ongoing godsend of home value to numerous property holders across America, the top home improvement ventures have included redesigning kitchens. Kitchens and washrooms appear to lose their style/work truly quick and getting new apparatuses in a kitchen will tidy things up. Purchasing another range broiler for your kitchen can be an overwhelming errand with all the choices and brand names available. A range is truly 2 apparatuses in one - burners that sit on head of the unit and a coordinated stove down underneath. Start with the essential estimations of what size you will require - decide the heigh, width and profundity of the space your range will be going into.

Electric extents are commonly more affordable than their gas partners Performance levels are reliable and you can utilize them for an assortment of cooking purposes. Electric extents are superb when you need ver low warmth (not generally conceivable on gas ranges). Standard curl burners and smooth-top electric extents are the 2 electric range alternatives. Loop burners are more suspectible to spills (dribble skillet can dispose of cleaning bothers) and for the most part more affordable than smooth-top models. In smooth-top electric ranges the brilliant components are introduced under a glass surface that is moderately seemless which makes cleaning these units simple. The brilliant components heat up quick and uniformly.

extend

Purchasing Guide - Gas ranges give you more exact temperature control, are more costly than electric models to purchase, however are less expensive to run. Gas extend burners let you heat things up in minutes while top quality gas ranges have extraordinary burners offering higher, quicker warmth creation for fast singing and bubbling. Numerous gas extends additionally have burners uniquely intended to hold a low warmth that will stew fluids/sauces.

Search for a gas run that has fixed gas burners since they are a lot simpler with regards to tidying up. Double fuel gas and electric extents are the best since you get the prompt reaction of gas burners and the even warmth of an electric stove. Business style home extents are beginning to spring up in families also with home cooks searching for the best gear. You should consider limit in a range as well. Consider the # of individuals in your family: 1 to 2 individuals would liken to a 2-3 cubic feet stove limit size, 3-4 individuals is 3-4 cubic feet, and 4+ individuals (huge family) ought to have a 4+ cubic feet of limit. Range styles are detached, drop-in extents, and slide-in ranges.

A detached range has completed sides and controls on the backsplash. Slide-in ranges have controls on the front segment of the range and look only an inherent with a consistent completion. A drop-in range will have incomplete sides and may need to have a few alterations done to it so it fits flush with your cupboards. Purchasing a range with a convection broiler is obligatory nowadays. Convection broilers have loads of advantages over customary stoves, for example, concocting meats to 30% quicker, having a third warming component around the back fan and you can do convection heating or cooking. Top kitchen run brands are Viking, Wolf, DCS, GE, Jenn-Air, Thermador, Frigidaire, Whirlpool, Maytag, Amana, Bosch, Dacor, Kenmore, KitchenAid and Hotpoint. Costs go from $350 as far as possible up to $5000+. Pick cautiously and read our audits underneath on the best ranges in every classification. You can see the majority of these kitchen extents and broilers in stores like Sears or HomeDepot. You can see a rundown of the top selling ranges online here.

Best Gas Range:

GE reliably rates close to the head of all purchaser surveys with it's profile ranges. The GE Profile PGB910SEMSS Stainless Steel Gas Kitchen Range($1500) is our pick for best gas run. You get a self cleaning broiler, enormous stove limit (5 cubic feet), a profound recessed cooktop, a focal oval burner, non-stick iron, and PowerBoil 17,000 BTU burner. Clients acclaim the warming draw and state the GE cooks equally and reliably. The force burner does something amazing in bubbling water rapidly. The GE JGB400SEPSS ($850) is another top dealer from GE with exact temperature control, no problem cleaning, and magnificent warming rate.

Subsequent to perusing audits we are glad to state that the Hotpoint RGB745 is the best spending range under $600. Created in England, the Hotpoint has 1 high yield burner and 1 stew burner alongside 2 9500 BTU burners. It doesn't have all the top end highlights on found on more extravagant models, however heating, searing, or stewing on the Hotpoint is simple. The best twofold stove gas go with convection is the GE Profile JGB918SELSS ($1950) - home culinary experts like the convection broiler for its capacity to flow air all through the stove cavity giving heating and cooking results dissimilar to different models. You get one enormous convection broiler and the lower stove offers "an extra 1.0 cu. ft. of limit with respect to helpful heating from 150 degrees to 450 degrees". The cooktop has 5 components including the focal oval burner extraordinary for huge cookware. See a rundown of top of the line gas extends here.

Best Electric Ranges:

We had heard that Kenmore models were appraised high in this class, and audits from driving customer magazines returned truly certain on pre-warming capacity and sturdiness. The best smoothtop electric range is the GE Cafe CS980SN Stainless Steel Electric Kitchen Range ($2800) with a sleek plan, in any event, warming, auto cleaning, and a recessed cooktop to contain spills. Proprietors state the computerized controls work extraordinary and a few state it's the best range they have ever purchased.

Since model #'s change normally with refreshes from GE, we suggest checking the GE site for the freshest kitchen ranges. For an electric curl go again Hotpoint has the best spending model - the Hotpoint RB757 for under $350. In investigating range broilers we understood that loop top electric stoves are a perishing breed yet the Hotpoint gets extraordinary audits. Purchasers state it's solid, however fills in as effectively as more expensive models they've possessed previously. A few disadvantages do incorporate a little stove entryway window, a difficult to arrive at control board, and a somewhat plain plan and shading choice.

The top double fuel extend is the Jenn-Air Double Oven Free-Standing Dual-Fuel Range (Model JDR8895AAS). Subsequent to perusing audits from and checking home apparatus gatherings for the first class goes, this Jenn-Air won out. With a sticker price over $2000 for the tempered steel alternative, purchasers state it's justified, despite all the trouble.

You get a gas cooktop with 5 burners, double fuel electric stoves, the base broiler is a convection stove while the main one is a touch littler and better for warming food. Proprietors state the base convection broiler is incredible for huge turkeys and the stoves pre-heat shortly. One shopper said the handles rust effectively and the cooktop isn't even, in spite of the fact that that was one disengaged analyst.

Business Quality Ranges:

As we referenced above there are an ever increasing number of homes supplanting obsolete kitchen reaches and ovens with present day, business level extents from Viking, DCS, and Wolf. We favor the Viking ranges thus do the greater part of the buyer reports we read on them. Viking works admirably with double fuel ranges by consolidating superior gas surface burners with electric self-cleaning stoves.

They go in cost from $4300-$9500. The more conventional Viking gas ranges are intended to fit standard 24" profundity cabinetry and they come as extensive as 60". Hope to pay at least $3500 and upwards of $9000 for a Viking gas extend. DCS is another range producer that produces proficient looking reaches. The RGT305 DCS 30" Gas Professional Range for $3700 is a superb home range that give eatery quality highlights. The Wolf 36 inch Gas Range is another very good quality machine for cooking lovers with an immense convection stove, an infrared evaporator, and the cooktop can be designed with up to 6 burners. .

1 note

·

View note

Text

Soil Composition and Color

Soil color and other properties including texture, structure, and consistence are used to distinguish and identify soil horizons (layers) and to group soils according to the soil classification system called Soil Taxonomy.

Color development and distribution of color within a soil profile are part of weathering. As rocks containing iron or manganese weather, the elements oxidize. Iron forms small crystals with a yellow or red color, organic matter decomposes into black humus, and manganese forms black mineral deposits.

These pigments paint the soil. Color is also affected by the environment: aerobic environments produce sweeping vistas of uniform or subtly changing color, and anaerobic ( lacking oxygen), wet environments disrupt color flow with complex, often intriguing patterns and points of accent. With depth below the soil surface, colors usually become lighter, yellower, or redder.

Source: https://tinyurl.com/y6kglnvr

0 notes

Text

Innovative Dyson Cyclone V10 cord-free vacuum

Of course, the English Dyson company needs no introduction. This brand has long become a common synonym for a cyclone vacuum. As known, cyclone filtration separates air and dust particles by means of vortex flows. Most modern powerful vacuums use this technology to clean the air from dust. Dyson has an innovative high-tech center in Singapore that conducts research and develops new products for the company. As a result, Dyson products regularly take leading positions among the most innovative models. Of course, 2018 was no exception. The company has improved its previous Dyson V8 vacuum, offering an innovative Dyson Cyclone V10 cord-free model.

Today, it rightfully heads the list of the most innovative vacuums in this segment. The company offers three modifications of the Dyson Cyclone V10 - Motorhead with three nozzles and a dust collector volume of 0.54 liters, Animal with five nozzles and Absolute with six nozzles. In addition, the volume of the Animal and Absolute dust collectors reaches 0.76 liters. Respectively, Dyson Cyclone V10 Absolute is the most functional but also the most expensive.

For the rest, all these models are identical. Compared with the Dyson V8, the novelty has a higher suction power and an increased volume of dust collector. In addition, the design of the new dust collector provides more convenient emptying.

New Dyson V10 engine with digital control

The company has significantly improved its own digital-controlled brushless motor. Today, it's the most compact, lightweight and powerful model. The rotational speed of its rotor reaches 125,000 rpm. Of course, this speed creates a huge load on the axle, which is too great for traditional steel. Therefore, the company uses ceramics. The ceramic motor shaft is sintered at 1600 ° C. As a result, it is 3 times stronger and 2 times lighter compared to a traditional steel shaft. Additionally, the company shifted the impeller from the front of the engine to the rear. As a result, the flow of cold air further reduces the temperature during the passage along the axis of the engine. These solutions allowed engineers to increase the rotation speed to 125,000 rpm. In addition, placing the engine, container and cyclones on the same line reduces air resistance. In fact, the air passes from the nozzle to the cyclone in a straight path unlike the previous V8.