#plastic recycling machine

Text

Pioneering Excellence In Plastic Recycling Machine For 19 Years

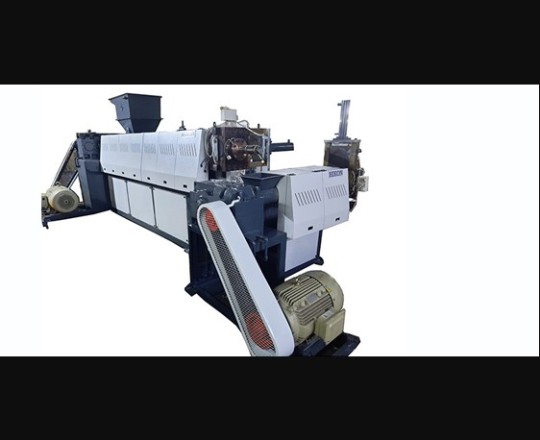

Antecs is a pioneering name in the domain of Plastic Recycling Machine, offering cutting-edge solutions to address the global challenge of plastic waste management. With a legacy spanning 19 years, we have consistently championed innovation, sustainability, and excellence in our field. Our commitment to quality craftsmanship and meticulous attention to detail sets us apart in the industry.

Our Expertise: At Antecs, we specialize in the design, development, and manufacturing of state-of-the-art plastic recycling machine. Our comprehensive range of products caters to diverse needs across the plastic recycling ecosystem, encompassing shredding, washing, drying, extrusion, and pelletizing technologies. With a deep understanding of the intricacies of plastic recycling, we deliver solutions that optimize efficiency, minimize environmental impact, and maximize resource utilization.

Core Values:

Innovation: We continuously strive to push the boundaries of technological innovation, leveraging advanced engineering principles and cutting-edge materials to create machinery that redefines industry standards.

Sustainability: Our commitment to sustainability is ingrained in every aspect of our operations. By facilitating the efficient recycling of plastic waste, we contribute to the conservation of natural resources and the reduction of environmental pollution.

Quality: Quality is the cornerstone of our business philosophy. We adhere to stringent quality control measures at every stage of production, ensuring that our machinery meets the highest standards of performance, reliability, and durability.

Customer Centricity: We prioritize the needs and preferences of our customers, fostering long-term partnerships built on trust, transparency, and mutual respect. Our dedicated team of professionals is committed to providing unparalleled service and support, guiding clients through every step of the process, from consultation to installation and beyond.

youtube

Achievements: Over the years, Antecs has garnered recognition and acclaim for its contributions to the field of plastic recycling machine. Our products have been deployed in a wide range of industrial settings, driving efficiency, productivity, and sustainability. We take pride in our role as catalysts for positive change, empowering businesses to embrace more sustainable practices and reduce their environmental footprint.

Future Outlook: As we look ahead, Antecs remains steadfast in its commitment to innovation, sustainability, and excellence. We are continuously investing in research and development to stay at the forefront of technological advancement, exploring new avenues for improvement and expansion. With a clear vision and a passionate team driving us forward, we are poised to lead the way towards a more sustainable future for generations to come.

0 notes

Text

The Fundamental Principles Behind Plastic Regeneration Pelletizing Machinery

Introduction to Plastic Regeneration and Pelletizing

Plastic waste poses an increasingly severe environmental threat as global consumption continues rising. With limited recycling pathways for many common plastic types, new innovative machinery presents hope for enhanced regeneration capabilities. Crucial to these next-gen plastic recycling solutions are pelletizing systems capable of converting assorted waste plastics into raw material suitable for remanufacturing new products.

Fundamental Components of Plastic Pelletizing Lines

Advanced plastic regeneration pelletizing lines comprise several core subsystems executing key transformation stages:

Plastic Feed Handling and Sorting

Various classification technologies filter and sort inbound plastic waste streams to achieve the targeted polymer types and purity levels for pellet production. Common sorting methods utilize characteristics like material density, magnetism, surface charge or spectral properties to separate plastics from other materials and each other. Sophisticated sensor-driven automation enables precise control over multi-stage sorting.

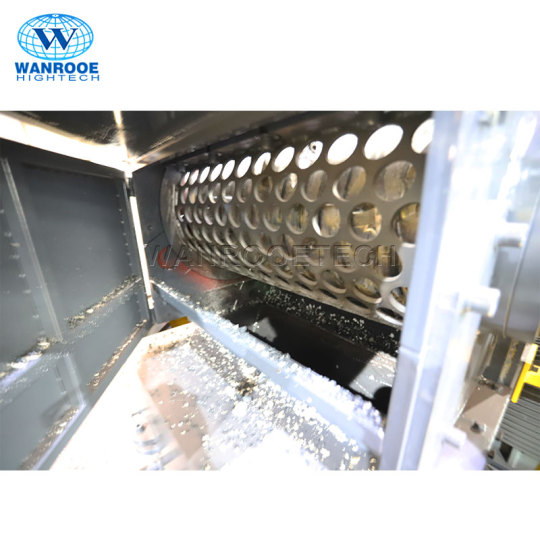

Size Reduction and Washing

After sorting, shredders and granulators grind the plastics down to uniform chip sizes needed for melting and extrusion. Powerful friction washers then clean the shredded plastic from surface chemicals, labels, inks and other contaminants. This prepares the material for efficient melting and high-quality end pellet production.

Melting and Homogenizing

Prepared plastic chips enter specialty extruder screw barrels which heat, pressurize and shear them into a homogenous polymer melt. Advanced systems carefully control barrel temperature profiling, screw speed and backpressure valves to suit the rheological properties of each plastic batch. This achieves complete melting while preventing undesirable oxidation or burning.

Filtration and Pelletizing

Pressurized melt flows through sophisticated screen changers and filters removing any residual impurities. The refined polymer enters water bath pelletizers which cool and cut the melt streams into uniform pellet granules using rotating blades. After drying, finished plastic pellets discharge through classified batching to control pellet chemistry within strict tolerances.

Fines Removal and Storage

The final pellets pass through vibrating sieves separating any undersized “fines” which get recycled back into the extruder. Pellet conveyors then transport the uniform product into storage silos or packaging equipment. Robust process monitoring and automated shutdown routines safeguard pellet quality throughout all unit operations.

Realizing Closed-Loop Recycled Plastics Through Pelletizing

Installing capable plastic pelletizing machinery with robust sorters, shredders, washers and extruders establishes directly recyclable material loops on-site. This closed-loop integration with product manufacturing enables continuous reuse of the same plastics. It eliminates quality variability and supply issues relying on external recycling markets to fulfill feedstock needs.

On-site plastic regeneration pellet production also conveys major commercial advantages:

Reduces plastic waste disposal loads and landfill impacts

Mitigates risks of rising virgin plastic costs

Provides supply stability insulating from market volatility

Unlocks revenue streams from pellet sales to third parties

Demonstrates corporate sustainability commitments

The Future of Circular Plastics Starts Now

Powerful pelletizing technology now exists to efficiently transform assorted waste plastics into high-quality recycled material. Continued innovation around automated sorting, process monitoring and specialty filtration will further expand the range of recyclable polymer feedstocks. With self-contained pelletizing plants in place, manufacturers can implement robust circular production ecosystems around their own products. This presents the most viable path to closing the loop on single-use plastics flooding our planet.

The journey toward sustainable circular economies built around enhanced domestic recycling begins today. Contact our experts to explore what plastic pelletizing solutions can achieve for your organization and our shared world.

I recommend Antecs for plastic recycling machine

0 notes

Text

Plastic Granulator Machine Manufacturer India

Empower your plastic recycling endeavors with HIKON, a leading Plastic Granulator Machine Manufacturer in India. Our cutting-edge technology and state-of-the-art manufacturing ensure precision and efficiency in plastic waste processing. HIKON's Granulator Machines are known for exceptional performance and reliability, making them the preferred choice for sustainable solutions. Choose HIKON to lead the way in reshaping plastic recycling in India. Join us in creating a greener future with our high-quality Plastic Granulator Machines.

#plastic waste recycling machine#waste plastic washing plant#plastic scrap crusher#plastic recycling india#plastic recycling machine

0 notes

Text

Plastik Geri Dönüşüm Makinaları

CRT Yoğunlaştırıcılı Extruderler plastik granül extrüzyon sistemleri arasında en yüksek teknolojiye, en kolay kullanıma, en yüksek fayda/maliyet oranına sahip sistemlerdir. Aynı zamanda CRT Yoğunlaştırıcılı Extruderler akıllı çalışma sistemleri sayesinde minimum personel ihtiyacı duyarlar.

https://www.ustunismakina.com.tr/plastik-geri-donusum-makinalari

#recycle#plastic#plastic recycling machine#plastik geri dönüşüm#plastic recycling#machine#extruder#üstün iş makina#washing line#shredder#crusher#crt#recycling#granule#grinder#screen changer#machining#manufacturing#metal manufacturing#plastik geri dönüşüm makinaları

0 notes

Text

5 Minutes to Understand Plastic Pelletizing Machine

5 Minutes to Understand Plastic Pelletizing Machine

Pelletizing plastics is the process that includes melting and cutting polymers into easy-to-handle plastic pellets. Understanding pelletizing system and feeding system will help you select the right plastic pelletizing machine!Get more news about die cutting plastic recycling machine,you can vist our website!

Pelletizing Systems

Pelletizers are the essential parts of plastic pelletizing machines. There are several types of pelletizing methods. Die face cutting system, also known as hot die cutting pelletizing system is the most popular used system among the other options. In this system, the molten polymers pass through the die head, and later on a rotating blade cuts the hot polymer at the surface of the die.

The common feeding types for plastic pelletizing recycling machines include hopper feeding and side feeding.

Hopper Feeding Pelletizing System

A feeding hopper feeds materials directly into the extruder without preheating. Harder plastic scraps or rigid regrind such as crushed HDPE bottles are suitable to be recycled by the hopper feeding system. Soft plastic materials such as crushed and washed PE films are also processable, which makes a flexible solution for the hopper feeding pelletizer.

A side feeding is a stable and continuous measure to feed materials. It allows stable extruder feeding even when the bulk density varies. So the overload and underload can be avoided, which assures maximum efficiency.

A compacting and pelletizing system combines the function of the cutter, crushing, compacting, plasticization and pelletizing in one step. It is an efficient solution for plastic film, HDPE bags, plastic raffia, zipper, nonwoven bags and foaming materials repelletizing.

Flexible Customized Pelletizing System from Genius

Upon the customer's requirements, Genius provides a flexible customized pelletizing system for each customer starting from sorting units, feeding units, to degassing units, number or type of filters, storage and packing systems. Moreover, due to the various materials to recycle, Genius helps customers with the unique screw design requirements and pelletizing units.

Through the various requirements and feedback from different customers, today we are one of the most reliable manufacturers of customized plastic recycling machines. Below, you’ll see 2 case studies of Genius’s super services.

Peru - Video Conference Support for the Installation

Recently a Peruvian customer who started in the recycling business for the first time acquired a recycling pelletizing line. However, due to the pandemic, the engineers were not able to travel abroad for the installation. For the customer that is a huge disadvantage to install a recycling machine because it is their first time acquiring this machine. Genius’s technicians have supported them through the usage of video conferencing during the installation. The customer followed the instructions and installed the whole machine by themself without any further inconvenience.

Japan - Repeat Orders to Genius

The customer was originally using Japanese recycling machines. They bought a squeeze dryer from Genius three years ago and were impressed with the quality of the machine. Then they bought another set of recycling lines. After operating and making sure about the efficiency of the line, they contacted Genius’s technicians and ordered once more another set of the same recycling line.

0 notes

Video

Neoplast is a manufacturer of completely and partially automatic waste plastic recycling machines in India. We manufacture plastic recycling machines in India, and our machines are renowned for their great productivity, low cost, and reliable after-sales service. Thermoplastic film, soft polyvinyl chloride, and plastic products are routinely recycled using the Plastic Recycling Machine Die Face Cutter. Call us at +91-79-4019-4030 if you'd like further details.

0 notes

Video

Good news! The 1-ton/h plastic pelletizing recycling line has arrived in Saudi Arabia. We have arranged for our professional engineer, Paul to go to the customer's plant in Saudi Arabia. He helped them install a plastic crusher, plastic washing tank, plastic pelletizer machine and plastic pellet cutter.

Contact us today:

https://wa.me/8619139754732

Our website: https://www.recycle-plant.com/

Email: [email protected]

0 notes

Text

2022 PE film bag LDPE HDPE plastic recycling machine pelletizing machine #plastic#recycling#waste plastics recycle

0 notes

Text

The whole "lets get rid of plastic bags 🤪🤪" and "lets get rid of plastic straws 🤪🤪🤪" campaigns were such a scam bc "oop lets get rid of these particular plastics bc of bad pr meanwhile lets do fuck all about all the other single use plastics that will 99,9% end up unrecycled and likely sent to another (much poorer) country"

#single use plastics have to be banned full stop#not just straws and bags#the only concession id give them is in medicine#if it were up to me i would make so that you can only get things the market way ir from a till from a oerson who hands it iver to you#cuz thats how its always been esp before big supermarkets and before plastic was invented#and i would replace every plastic container with glass ceramic or metal#and make those recycling machines from germany that give you a bit of change a thing everywhere#except its for reusable containers and they get shipped back to the producer#so that theres a constant cycle of reusing stuff instead if everything going to landfill#everything would be so good if i was in charge of it all

8 notes

·

View notes

Text

Do you know what is the working principle of plastic pellet cutting machine? It is mainly used to cut the plastic strips extruded from the plastic pelletizer into small particles. First, the plastic strip enters the cutting chamber of the plastic dana cutter through the conveyor belt. Here, the rotating cutting blades cut the plastic strips into uniform small particles. Once the cutting is complete, these small pellets are screened through a screen and conveyed to a collection container for further processing or use.

To know more about plastic cutter machine, you can contact us via WhatsApp at 17303831295 or read this article https://plasticrecyclingmachinery.com/plastic-cutter-machine/ to know more.

0 notes

Text

Plastic shredder crusher machine is mainly recycling crush Large diameter HDPE pipe, pp pipe, pe pipe, PPR pipe, PVC pipe, drainage pipe, water pipe, plastic pipe, big solid block of plastic, plastic purges, plastic lumps, etc. finally plastic scrap size is about 3-8mm, which can be directly used for injection and extruder machine.

0 notes

Text

Key Components of the PET Bottle Washing Line

Our innovative solutions are designed to efficiently clean and process PET bottles, ensuring high-quality recycled materials for a range of applications. Explore our PET Bottle Washing Lines to optimize your recycling efforts and promote environmental sustainability.

0 notes

Text

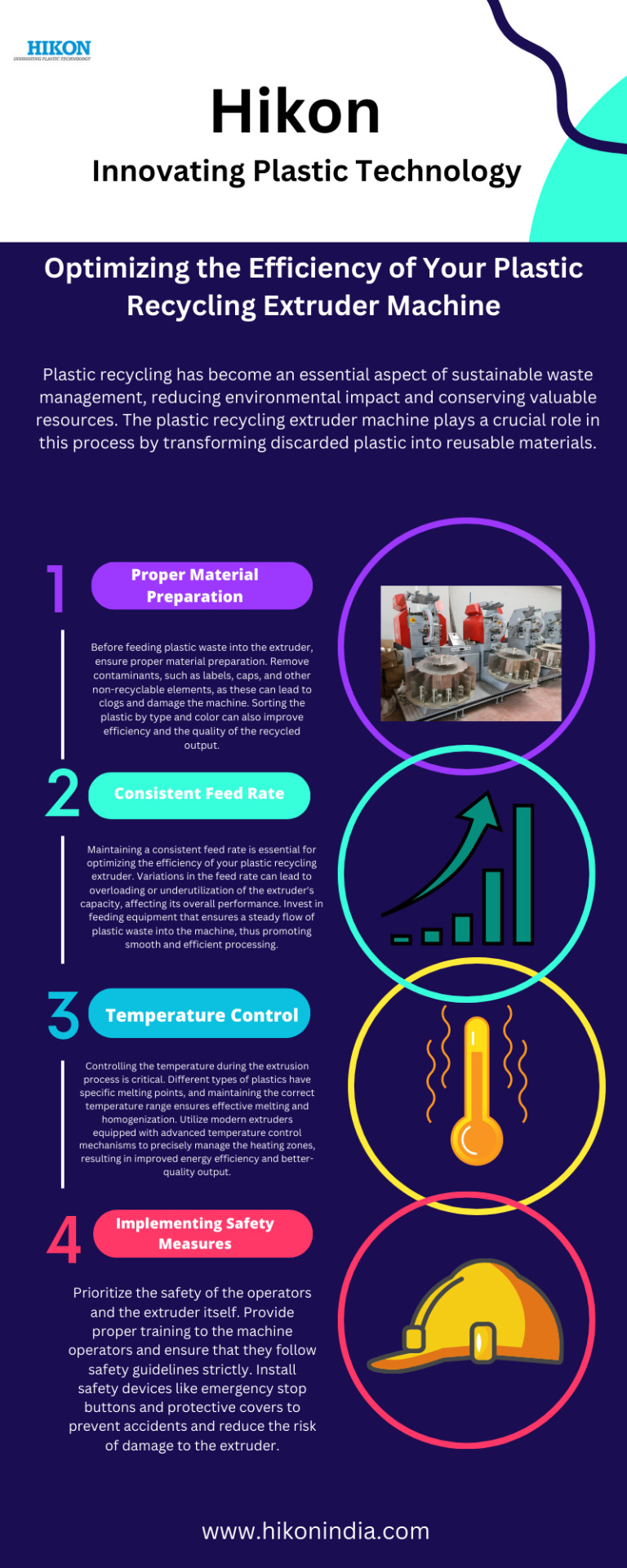

Hikon India's Plastic Recycling Extruder Machine epitomizes innovation and sustainability. It efficiently transforms discarded plastic into valuable resources, reducing environmental impact. With advanced technology, it contributes to a circular economy by producing high-quality recycled plastic pellets. Hikon's solution is a pivotal step towards a greener future.

#Plastic Waste Recycling Machine#Plastic Scrap Crusher#Plastic Recycling Machine#Waste Plastic Washing Plant

0 notes

Text

Defining Sustainable Packaging.

What does sustainable packaging mean? It is packaging that considers sustainability and minimizes environmental impact throughout its lifecycle.

For packaging to be considered sustainable, the design, manufacturing, use and disposal or repurposing of the packaging must consider everything from the raw materials it is made from through to the carbon emissions associated with the packaging and even how it is handled.

If you are wondering if the packaging, you are considering is environmentally friendly, it is worth noting these characteristics:

Material used: Packaging that is sustainable often centers around renewable and recyclable materials like paper, cardboard, and bioplastics. Eco-friendly materials are characterized by being responsibly sourced and having a lower carbon footprint.

Waste reduction: Packaging that can be easily recycled or composted and optimizing packaging design to reduce excess material usage will make it even more sustainable.

Energy and fuel efficiency: Packaging that is manufactured using energy-efficient processes and technologies to minimize greenhouse gas emissions. Plus, optimized packaging designs that minimize pack size and weight can maximize efficiency while minimizing fuel consumption.

Extended product lifecycle: More sustainable packaging will have a longer life cycle. Reuse and recycling of packaging materials is a crucial part of this.

Common Sustainable Packaging Materials: To start using sustainable packaging, you can choose from materials like recycled paper, compostable options, and bio-based plastics. Let us delve into some of the common materials used in sustainable packaging and the advantages they offer.

Recycled paper and cardboard made from recycled post-consumer waste, recycled paper and cardboard help conserve natural resources and reduce landfill waste. Recycled content materials also create fewer carbon emissions too.

Bio-based plastics: the right bioplastic can be a good sustainable packaging choice. To be as eco-friendly as possible you need to choose a bioplastic that is made from a biomass like starch, vegetable oil or sugar cane that can biodegrade. They are ideal for single-use items like packaging films and bags.

Reusable packaging: Reusable packaging aims to cut waste by designing products that can be used multiple times. Reusable packaging can be made with many materials including aluminum, wood, and plastic.

Compostable materials: compostable materials break down into nutrient-rich compost when disposed of in the right conditions. They are typically made from renewable resources like plant fibers or starches. These materials are suitable for food packaging, disposable cutlery, and other single-use items. It is worth noting that not all compostable packaging materials are equal. They need to meet certain requirements to be classed as home compostable.

By using sustainable packaging materials, businesses can demonstrate their commitment to environmental responsibility. These materials offer advantages such as reduced carbon footprint, resource conservation, and improved brand image.

Key advantages include:

-Minimizing your carbon emissions.

-Reducing packaging waste.

-Reducing overall packaging costs and mitigating associated packaging levies.

-Improving your brand image with eco-conscious consumers.

-In summary, sustainable packaging can play an integral role in your sustainability strategy.

At Quick Pak Inc, we understand the significance of sustainable packaging for businesses. We offer a wide range of eco-friendly packaging solutions that can help you achieve your sustainability goals. From recycled cardboard boxes to compostable packaging materials, we have options to suit your specific needs.

Contact us today at 813 242 6995 or [email protected] to learn more about our sustainable packaging solutions and how they can benefit your business.

#pricing news#stretch film pricing#resin pricing#quickpakinc#coreless film#stretch film#quick pak inc#free pallet wrapper#free machine#youtube#green packaging#bio plastics#reuse and recycle packaging

0 notes

Text

youtube

Waste Cable Wire Copper PVC Recycling Machine is used to process waste cables and wires to separate the precious metal, like copper or aluminum, from plastic. DY-600(200-300kg/h) Waste Cable Wire Copper PVC Recycling Machine is the most popular cable wire recycling machinery of Henan Doing Environmental Protection Technology Co., Ltd.

Welcome to contact us, if you're interested in it.

Contact address:

Email: [email protected]

WhatsApp/Wechat/Phone: +86 150 3713 8562

Website:

http://www.copperwirerecyclingmachinery.com/copper_wire/

#copper wire granulator machine#copper wire recycling machine#cable granulator#cable wire recycling machine#wire granulator#wire recycling machine#separate copper from plastic#cable wire granulator#Youtube

0 notes