#food-grade industrial gases industry

Link

Food-grade Industrial Gases Market is poised to grow at a CAGR of 6.5 % by 2027. Factors driving the Food-grade Industrial Gases Market are increasing demand for fresh products and packaged food.

#food-grade industrial gases market#food-grade industrial gases market size#food-grade industrial gases market share#food-grade industrial gases industry#food-grade industrial gases market trends

0 notes

Text

Edible insects are an environmentally attractive alternative to conventional livestock because they require less feed and water; they produce lower levels of greenhouse gases and can be raised in small spaces. Worldwide, livestock contributes to 18% of greenhouse gas emissions, which, in light of global warming and climate change, favours the less resource-intensive insect production which emits fewer greenhouse gases by a factor of 100.

Insects can be a renewable food source in the future as many edible species can consume agricultural and food waste or culinary by-products, but there remain important research gaps in understanding the effects of variable feedstocks as most case studies use high-grade feed. Such organic side streams could be used to reduce the environmental impact of insect farming while simultaneously creating a novel, circular waste-processing income. Throughout the world, 1/3 of all food is wasted, and household food waste is 70% of the post-farm total. If food waste was its own country, it would be the third largest emitter of greenhouse gases after the USA and China. Food waste is expected to increase in the future with a continually growing and increasingly urbanised global population adopting ‘modern’ lifestyles.

It is challenging and wasteful to commercialise traditional composting of multiple waste streams on a large scale, but waste can be fed directly to insects to convert low-value biomass into higher-value insect mass. By valorising waste as feed, it may mitigate the impact of the food industry. Some fly (Diptera) species are known to be able to convert agricultural manure into body mass and reduce the waste dry matter by 58%. For food waste the conversion is as high as 95% leaving the remainder as a high-grade soil improver .

40 notes

·

View notes

Text

It is a refined form of brewing that uses microorganisms to make ingredients we currently get from animals or plants. While our ancient ancestors made bread, cheese, and beer by using the microorganisms that were randomly present in their environment, today’s precision fermentation can genetically reprogramme microorganisms to make exact nutrients. Here’s how to do it:

Choose a specific microorganism such as a yeast or bacteria.

Genetically engineer the microorganism with the DNA sequences coding for the amino acids which form the protein you want to create – such as the proteins found in cow’s milk: casein and whey.

Put the microorganisms in a fermentation tank with some simple nutrients and sugars.

Ferment! (Just like beer.)

Harvest food-grade ingredients that are biologically identical to those you’d get from an animal and mix them up into sellable familiar products (like dairy milk, cream or cheese…).

According to a new analysis in the Reboot Food report, protein from microorganisms uses up to 40,900 times less land than beef, meaning that such ‘farm-free foods’ could produce the entire world’s protein requirements on just 420km2 of land – an area of land smaller than Greater London*

This would not only save 3/4s of global agricultural land for nature restoration and carbon drawdown but would also release up to 91% less greenhouse gases per calorie produced.

Precision fermentation is already used to produce 99% of the global insulin supply and 90% of the global rennet. Today PF milk proteins and PF egg whites have already reached the US grocery market.

Emma Smart, Coordinator of Replanet UK says “The precision fermentation revolution is as significant and consequential for our natural world and climate as the dawn of farming was 10,000 years ago. Only this time, today’s food revolution promises a new age for non-human life of regeneration not devastation.”

–

Solarpunk perspective:

This is huge. If we can end industrial animal agriculture in the next 5 years, we can avoid the worst climate emergency threats. We'll still have to weather mega storms for a few decades and open our hearts to a few million refugees. But we'll get through it together and we won't do it on an empty stomach.

Doomer perspective:

This is a disruptive technological application that promotes global equality. The global superpowers need animal agriculture so they can maintain their exploitation hierarchy. They want to speed-run the apocalypse. They want to be on top of the world when the world ends. And they want to see it end in their lifetime. "I was the best at this game all the way up to the end!"

So they'll do everything they can to suppress disruptive technological applications. That's why they will always choose oil over solar and animal agriculture over precision fermentation.

It won't just be a few decades of storms. We'll hit the tipping point cascade. Our entire global biodiversity system will unravel. 90% of species will go extinct. And humanity will die slowly and painfully of novel zoonotic diseases that spread globally through feral cattle. Our refusal to replace domesticated cows with domesticated microbes will ultimately lead to a feral zombie cow apocalypse plague.

Regional activism perspective:

Global superpowers are meaningless fools. As common people, we can remake society to suit our changing needs. Find out the total volume of animal protein your town consumes. Draft a municipal precision fermentation infrastructure plan. Spread flyers and leaflets everywhere. Start a RePlanet/Precision Fermentation advocacy group in your city.

The best place to meet people who would be extremely passionate about this technology is geek cafes and boardgame shops. Or better yet, a Star Trek convention. Precision fermentation is a Star Trek technology. It's called a "food replicator" in Star Trek. Rebranding from "precision fermentation" to "food replication" may help people be more open minded.

6 notes

·

View notes

Text

Alloy Steel Buttweld Fittings Available Types

There are a variety of shapes and sizes available in alloy steel buttweld fittings. Fittings like these are used in a variety of industries, including automotive and industrial. Alloy steel fittings are made from alloy steels and other metals. The alloy steel buttweld fittings can be welded, machined, and heat treated to produce a wide range of products. When purchasing a set of steel fittings, as well as larger quantities, most fitting manufacturers offer package deals. Bulk purchases may also be discounted. Find out if shipping and handling charges are included in the pricing offered by your local supplier.

The article Alloy Steel Buttweld Fittings Available Types introduces Alloy Steel Buttweld Fittings Available Types. The book explains the composition and characteristics of alloy steel. The book includes detailed information on the basic machine processes and operating conditions of Alloy Steel Buttweld Fittings Available Types, heat treatment, machining procedures, and test methods for Alloy Steel Buttweld Fittings Available Types. To get a feel for what this product is like, you can also view our sample products. Do your research before buying.

Click on the links below to learn more about Alloy Steel Buttweld Fittings Available Types. A typical size is approximately 4 inches in diameter (roughly 0.926 inches thick) and 1/2 inch in thickness (roughly 0.127 inches thick). Standardized to BS EN 642 and AIB 6073, typical values are approximately 4 inches in diameter and 1/2 inch in thickness. Based on the total weight of the alloy, the material contains approximately 0.5% carbon by weight.

The versatile alloy of alloy steel buttweld fittings is used for a wide range of applications. Weldability, pressure bearing strength, and thermal stability are excellent. For superior durability under heavy loads, it possesses chromium, molybdenum, and ferrous. While fitting in the processing system, it resists corrosion caused by hazardous gases and chemicals. Weldable alloy steel buttweld fittings have a low carbon content and are resistant to carbide precipitation.

Various types of alloy steel buttweld fittings are made with chemical compositions of great strength and hardness. These chemicals include carbon, nickel, aluminum, manganese, titanium, and iron. There are even numerous specifications for these alloy fittings, such as size, standards, grade, types, thickness, forms, ends, surfaces, finishes, lengths, widths, applications, tolerances, conditions, and pressure.

Various properties of these alloy fittings include hardness, corrosion resistance, and sustainability at annealed temperatures. The properties of alloy fittings include thermal conductivity, electrical resistance, modulus of expansion, density, melting point, elongation, and electrical conductivity. There are numerous types of these fittings, including seamless, welded, fabricated, and ERW.

Among the many industries and general works that use alloy steel Buttweld Fittings are the pharmaceutical industry, gas processing, chemical equipment, pharmaceutical equipment, offshore oil drilling, industry, heat exchangers, condensers, seawater equipment, petrochemicals, power generation, food processing, paper mills, pulp mills, rail components, road transportation components, pumps, shafts, and military applications. The alloy steel Buttweld Fittings are made with several properties that enable them to be used in annealed temperatures and chloride environments without any deformation. The fittings are resistant to crevice corrosion, stress corrosion, cracking corrosion, pitting corrosion, and impact corrosion.

Pipe fittings (as opposed to Tube fittings) are butt-welded onto the pipe. They are produced according to different ‘schedules’. Based on the nominal bore pipe size, the schedule determines the wall thickness. It is common to find schedules 10 and 40, but schedules 80 and 160 are also available.

For more information visit

1 note

·

View note

Text

PSA Nitrogen Gas Plant Manufacturer Company in India

What is PSA Nitrogen Gas Plants?

PSA nitrogen gas plants utilize the principle of adsorption to separate nitrogen molecules from other gases in the air, providing a continuous and reliable source of high-purity nitrogen gas. The process involves two adsorption towers filled with carbon molecular sieve (CMS) or zeolite materials.

During the adsorption phase, compressed air containing nitrogen, oxygen, and other impurities passes through one tower while nitrogen molecules are selectively adsorbed by the CMS or zeolite, allowing purified nitrogen gas to exit the other end. Meanwhile, oxygen and other impurities are captured by the adsorbent material.

As the adsorption process progresses, the concentration of nitrogen in the tower increases until it reaches the desired purity level. At this point, the adsorption switches to the second tower while the first undergoes regeneration by depressurization, purging the captured impurities and preparing it for the next adsorption cycle. This cyclic process continues, ensuring a continuous supply of high-purity nitrogen gas.

Advantages of PSA Nitrogen Gas Plants

On-Demand Production: PSA nitrogen gas plants offer on-site generation capabilities, eliminating the need for storage cylinders or reliance on external suppliers. This on-demand production ensures a constant and reliable nitrogen gas supply, minimizing downtime and improving operational efficiency.

Customizable Purity Levels: With PSA technology, purity levels of nitrogen gas can be tailored to meet specific application requirements, ranging from standard industrial grades (95–99.999%) to ultra-high purity levels suitable for critical processes in electronics and pharmaceutical industries.

Cost-Effective Solution: By eliminating the recurring costs associated with cylinder rentals, transportation, and refills, PSA nitrogen gas plants offer significant cost savings over the long term. Additionally, the modular design allows for scalability, enabling businesses to expand production capacity as needed without incurring excessive costs.

Energy Efficiency: PSA nitrogen gas plants are inherently energy-efficient, with low operating pressures and minimal energy consumption compared to alternative nitrogen generation methods such as cryogenic distillation. This translates to reduced utility bills and a smaller carbon footprint, contributing to sustainability goals.

Applications of PSA Nitrogen Gas Plants

The versatility of PSA nitrogen gas plants makes them indispensable across a wide range of industries and applications, including:

Food Packaging: Inert gas atmosphere created by nitrogen is used to preserve freshness and extend the shelf life of packaged foods.

Electronics Manufacturing: Nitrogen is employed for soldering, wave soldering, and reflow processes to prevent oxidation and ensure high-quality electronic components.

Pharmaceuticals: Nitrogen gas is utilized for blanketing, purging, and inerting applications in pharmaceutical manufacturing, ensuring product quality and safety.

Oil and Gas: In oil refineries and petrochemical plants, nitrogen is used for blanketing storage tanks, purging pipelines, and preventing flammable gas explosions.

Conclusion

In a world where efficiency, reliability, and cost-effectiveness are paramount, PSA nitrogen gas plants stand as a testament to innovation and ingenuity. By harnessing the power of adsorption technology, these plants provide industries with a dependable source of high-purity nitrogen gas, empowering them to optimize processes, enhance product quality, and drive sustainable growth. As industries continue to evolve and demand for nitrogen gas grows, PSA nitrogen gas plants remain steadfast in their commitment to delivering excellence, one molecule at a time.

Top PSA Nitrogen Gas Plant Manufacturer Companies in India

If you are looking for a Best PSA Nitrogen Gas Plant Manufacturer and Supplier of PSA Nitrogen Gas Plant in India, look no further than, PSG Engineering Company, we are a leading manufacturer and supplier of PSA Nitrogen Gas Plant in India.

For more details, please contact us!

Website :-https://www.psggasproject.com/medical-products/psa-nitrogen-gas-plants/

Contact No. :- +91–8126173604

Email :- [email protected]

#psa nitrogen gas plant#psa gas plant#psa nitrogen gas plant manufacturer in india#psa nitrogen gas manufacturer#psa nitrogen gas plant manufacturer in noida#psa nitrogen#nitrogen gas plant#nitrogen gas generator#psg engineering company

1 note

·

View note

Text

Stainless Steel 304 Pipes, SS 304 Tubes Supplier, Exporter - Shree Viratra Enterprises

Stainless Steel 304 Pipes & Tubes is a metallic pipe constructed of austenitic stainless steel that contains 18% chromium and 8% nickel. Shree Viratra Enterprises is a major supplier and manufacturer of all types and sizes of Stainless Steel 304 Pipes and tubes. In the ASTM requirements, the pipe specifications range from A312 to A358. The dimensions vary in accordance with ASTM, ASME, and API requirements. Welded and SS 304 pipes, as well as electric fusion welded pipes, are available.

Top supplier of SS 304 Welded Pipe, Stainless Steel 304 Square Pipe, 304 Stainless Steel Pipe, SS 304 Pipe Price, SS 304 Pipe, 304 Stainless Steel Tube, 304 Stainless Pipe, Stainless Steel 304 Seamless Pipe, SS 304 Square Tube, ASTM A213 Tp304 Seamless Pipe,stainless steel 304 pipes, ss 304 pipes, 304 SS Pipe

The 304 austenitic stainless steel alloy is used to make pipes and tubing. This alloy offers exceptional strength, endurance, and resistance to corrosion because it contains minor amounts of carbon, manganese, and silicon, along with chromium and nickel. Shree Viratra Enterprises manufactures, produces, and exports superior raw material-made stainless steel 304 pipes and tubes. It is necessary to cold-work stainless steel to boost its tensile strength. Type 304 is much less intense than type 302 because of its lower carbon concentration.

Stainless steel 304 pipes and tubes are available in the following dimensions, grades, and specifications. This alloy’s pipes and tubes are utilised in various industries, such as petrochemicals, food processing, construction, and pharmaceuticals. They are renowned for their adaptability, resilience to high temperatures, and toughness in adverse environments — 304 stainless steel. To satisfy the needs of many applications, pipes and tubes come in various diameters, forms, and thicknesses. Usually, two primary methods are employed in their manufacturing: seamless and welded. While welded pipes and tubes are created by joining two pieces of the alloy, seamless pipes and tubes are formed by extruding a solid billet.

What are some frequently asked questions about SS 304 seamless pipes and welded pipes?

What is a 304 stainless steel pipe and used for?

SS 304 Seamless Pipes – Pipe Fittings is a corrosion-resistant, versatile material primarily composed of chromium and nickel. It offers excellent resistance to corrosion, oxidation, and high temperatures, making it ideal for a wide range of applications. Commonly used in industries such as food processing, pharmaceuticals, chemical processing, and construction, it’s favored for its durability and sanitation properties. Its non-reactive nature also makes it suitable for transporting various fluids and gases. Whether in structural frameworks, piping systems, or architectural designs, 304 stainless steel pipes are valued for their strength, longevity, and resistance to both internal and external environmental factors.

What is the difference between TP304 and 304 stainless steel?

The terms TP304 and 304 stainless steel represent identical materials but find application in distinct contexts. “TP304” serves as a specialized designation within the domain of piping and tubing, specifically denoting a stainless steel variant suitable for the fabrication of seamless pipes and tubes. Conversely, “304 stainless steel” assumes a broader usage across diverse industries, acting as a descriptor for a particular grade of stainless steel alloy encompassing various manifestations such as sheets, bars, and pipes, irrespective of whether they are seamless or welded. Fundamentally, while TP304 and 304 stainless steel denote the same alloy, their utility and reference contexts diverge accordingly.

0 notes

Text

Food Grade Gases Market Forecast 2024-2033

Overview and Scope

Food-grade gases refer to the gases that are involved in processing aids and/or additives in order to ensure that standards are followed. They contribute to the quality and freshness of food and beverages. They are used in packaging that enhance the shelf life of convenience foods.

Sizing and Forecast

The food grade gases market size has grown strongly in recent years. It will grow from $7.92 billion in 2023 to $8.41 billion in 2024 at a compound annual growth rate (CAGR) of 6.1%. The growth in the historic period can be attributed to environmental concerns and sustainability, globalization of food trade, demand for ready-to-eat foods, modified atmosphere packaging (map) adoption..

The food grade gases market size is expected to see strong growth in the next few years. It will grow to $10.97 billion in 2028 at a compound annual growth rate (CAGR) of 6.9%. The growth in the forecast period can be attributed to increasing demand for packaged foods, growth in convenience food segment, focus on food safety and quality, expansion in beverage industry, globalization and international trade.. Major trends in the forecast period include sustainable and eco-friendly practices, regulatory compliance, modified atmospheric storage (mas), freezing and cooling applications, carbonation in beverages, quality and safety assurance..

Segmentation & Regional Insights

The food grade gases market covered in this report is segmented –

1) By Type: Carbon Di Oxide, Nitrogen, Oxygen, Sulfur Dioxide, Other Types

2) By Application: Freezing and Chilling, Packaging, Carbonation, Other Applications

3) By End Use: Dairy and Frozen, Fish and Sea Food, Meat, Beverages, Fruit and Vegetables, Bakery and Confectionery, Other End-Users

North America was the largest region in the food grade gases market share in 2023. The regions covered in the food grade gases market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa

Major Driver Impacting Market Growth

The increasing consumer demand for frozen and chilled food products is expected to propel the food grade gases market going forward. Frozen and chilled food products refer to food products preserved by rapid freezing and stored in the freezer until used. Food grade gases are used in the packaging of frozen and chilled foods to prevent them from spoiling and ensure they stay fresh for the customers, thus an increase in demand for frozen and chilled foods will help to propel market growth. For instance, according to the 2022 State of the Industry Report, published by the Association for Talent Development, a US-based non-profit association, the demand for frozen and chilled food products has increased significantly as a result of a variety of circumstances. Frozen food sales in the United States will surpass $72 billion in 2022. Therefore, the increasing consumer demand for frozen and chilled food products is driving the food grade gases market.

Key Industry Players

Major companies operating in the food grade gases market report are Linde Group & Praxair Inc., Air Products & Chemicals Inc., Air Liquide SA, The Messer Group GmbH, Taiyo Nippon Sanso Corporation, Coregas Pty Ltd., PT Aneka Gas Industri TBK, Massy Group Inc., Air Water Inc., Sol Group S.p.A., Gulf Cryo Holding W.L.L., National Gases Limited, Gruppo SIAD S.p.A., Les Gaz Industriels Ltd., Aditya Air Products Pvt. Ltd., Sidewinder Dry Ice & Gas LLC, Axcel Gases, Chengdu Taiyu Industrial Gases Co. Ltd., Yingde Gas Group Ltd., Siddhi Vinayak Industrial Gases Pvt. Ltd., American Welding & Gas Inc., Airgas USA LLC, Cryogenic Gases LLC, Ellenbarrie Industrial Gases Ltd., Iwatani Corporation, Matheson Tri-Gas Inc., Nippon Gases Europe S.A., The Southern Gas Limited, Yara International ASA .

The food grade gases market report table of contents includes:

1. Executive Summary

2. Food Grade Gases Market Characteristics

3. Food Grade Gases Market Trends And Strategies

4. Food Grade Gases Market — Macro Economic Scenario

5. Global Food Grade Gases Market Size and Growth

.

.

.

31. Global Food Grade Gases Market Competitive Benchmarking

32. Global Food Grade Gases Market Competitive Dashboard

33. Key Mergers And Acquisitions In The Food Grade Gases Market

34. Food Grade Gases Market Future Outlook and Potential Analysis

35. Appendix

Explore the trending research reports from TBRC:

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

0 notes

Text

PVC Steel Wire Hose Suppliers in Delhi

Advantages of Fire Fighting Products, Suppliers, and Distributors by ManxImpex

the bustling capital city of India, is home to a myriad of industries and businesses. Among the

essential components for these industries are PVC steel wire hoses, crucial for various applications

due to their durability, flexibility, and resilience. Manx Impex stands out as a leading supplier and

distributor of these hoses, along with a range of fire fighting products that are indispensable for

safety and operational efficiency.

PVC Steel Wire Hoses: An Overview

PVC Steel Wire Hoses are reinforced with steel wire, making them robust and flexible. These hoses

are used extensively across industries for the transportation of liquids, gases, and even solid

materials. Their construction, typically a blend of PVC and embedded steel wire, ensures they can

withstand high pressure and resist kinks and collapses, making them suitable for a variety of

demanding environments.

Uses of PVC Steel Wire Hose

Industrial Applications: Widely used in factories and manufacturing units for the transfer of

chemicals, oils, and other fluids.

Agricultural Use: Essential for irrigation and the transfer of pesticides and fertilizers.

Construction Sites: Used for the movement of water, cement, and other construction materials.

Food and Beverage Industry: Ensures hygienic transfer of food products, as many hoses are designed

to be food-grade.

Domestic Applications: Utilized in gardening and small-scale water transfer needs.

Advantages of PVC Steel Wire Hose

Durability: The steel wire reinforcement provides strength, making the hoses resistant to wear and

tear.

Flexibility: Despite their strength, these hoses are highly flexible and can be maneuvered easily.

Transparency: Allows for visual inspection of the material being transported.

Chemical Resistance: Suitable for transporting a wide range of chemicals without degradation.

Versatility: Can be used in various temperatures and pressure conditions.

Fire Fighting Products: Essential Advantages

Fire safety is a critical concern for all sectors, and having reliable fire fighting equipment is

paramount. ManxImpex offers a range of fire fighting products designed to ensure safety and

compliance with stringent fire safety standards.

Advantages of Fire Fighting Products

Safety Assurance: High-quality fire fighting equipment ensures rapid and effective response to fire

emergencies, minimizing damage and loss.

Regulatory Compliance: Using certified fire fighting products helps businesses comply with local and

international fire safety regulations.

Durability: Products designed to withstand extreme conditions, ensuring long-term reliability.

Efficiency: Advanced technology in fire fighting products ensures quick and effective fire

suppression.

Cost-Effective: Investing in quality fire fighting equipment can prevent costly damages and potential

legal liabilities.

Manx Impex: Leading Suppliers and Distributors

Based in Delhi, ManxPower is a renowned name in the supply and distribution of PVC steel wire

hosesand fire fighting products. The company has built a reputation for delivering high-quality

products and exceptional customer service.

Why Choose ManxPower?

Extensive Range: Offers a comprehensive range of PVC steel wire hoses and fire fighting products to

meet diverse industrial needs.

Quality Assurance: Products undergo rigorous quality checks to ensure they meet the highest

standards.

Expertise: With years of experience, the company provides expert advice and solutions tailored to

specific customer requirements.

Customer Support: Dedicated support team to assist with product selection, installation, and after-

sales service.

Competitive Pricing: Ensures value for money with competitively priced products without

compromising on quality.

In the dynamic industrial landscape of Delhi, having reliable suppliers for essential products like PVC

steel wire hoses and fire fighting equipment is crucial. ManxImpex not only meets these needs but

exceeds expectations with their commitment to quality, safety, and customer satisfaction. Whether

for industrial, agricultural, construction, or safety applications, their products offer the durability,

efficiency, and peace of mind that businesses require to operate smoothly and safely.

For more information:

Visit our website: https://manximpex.com/pvc-steel-wire-reinforced-hose/

Contact us on: 7065192900

0 notes

Text

FIBC Bulk Bags: The Ultimate Guide

FIBC Bulk Bag Manufacturers in Gujarat, commonly known as bulk bags, are essential in various industries for transporting and storing bulk materials. These versatile containers are designed to handle a wide range of materials, from fine powders to large granules, and are favored for their durability, cost-effectiveness, and convenience. This guide delves into the various aspects of FIBC bulk bags, including their types, uses, benefits, and frequently asked questions.

What are FIBC Bulk Bags?

FIBC bulk bags are large, woven polypropylene containers used for storing and transporting dry, flowable products. They can carry loads ranging from 500 to 2,000 kilograms, making them ideal for industries such as agriculture, construction, mining, and chemicals. These bags are known for their strength, flexibility, and ability to protect contents from contamination and moisture.

Types of FIBC Bulk Bags

There are several types of FIBC Bulk Bag Manufacturers in India, each designed to meet specific needs:

Type A: Standard bulk bags made from woven polypropylene. They are suitable for non-flammable products and environments where no electrostatic hazards exist.

Type B: Similar to Type A but with a lower breakdown voltage. These bags are used to transport dry, flammable powders but not in flammable environments.

Type C (Conductive Bags): Made from conductive threads, these bags are used for transporting flammable powders where grounding is essential to prevent static discharge.

Type D (Anti-static Bags): These bags are designed with anti-static properties that dissipate static electricity safely without grounding. They are ideal for transporting flammable products in environments with explosive dust or gases.

Food-Grade Bags: Manufactured in clean rooms and meet stringent food safety standards. They are used for transporting food products and pharmaceuticals.

Ventilated Bags: These bags have ventilated strips for products that need airflow, such as potatoes and onions.

UN Certified Bags: Designed for transporting hazardous materials, these bags comply with international safety standards and regulations.

Uses of FIBC Bulk Bags

FIBC Bulk Bag Manufacturers in Ahmedabad are used across various industries due to their versatility:

Agriculture: For storing and transporting seeds, grains, fertilizers, and animal feed.

Construction: For handling sand, gravel, cement, and other building materials.

Chemicals: For transporting chemical powders, granules, and other industrial materials.

Food: For bulk storage and transport of sugar, flour, grains, and other food products.

Mining: For handling mined materials like ores, minerals, and coal.

Benefits of Using FIBC Bulk Bags

Cost-Effective: FIBC bulk bags are more affordable compared to other bulk packaging options. Their reusability and durability further enhance cost savings.

Space-Saving: These bags are designed to be stackable, optimizing storage space. When not in use, they can be folded flat, reducing storage requirements.

Durability: Made from high-quality woven polypropylene, FIBC bulk bags are resistant to punctures and tears, ensuring safe transport and storage of heavy materials.

Versatility: With various types available, FIBC bulk bags can be used for a wide range of materials and industries.

Environmental Impact: Many FIBC bulk bags are recyclable and reusable, contributing to sustainability efforts by reducing waste.

Safety: Designed with safety in mind, these bags come with features such as lifting loops, discharge spouts, and anti-static properties to ensure safe handling.

Conclusion

FIBC bulk bags are an indispensable tool for industries that handle bulk materials. Their versatility, durability, and cost-effectiveness make them a preferred choice for transporting and storing a wide range of products. By understanding the different types of FIBC bulk bags and their applications, businesses can select the right bag for their needs, ensuring safe and efficient handling of materials. Whether you are in agriculture, construction, chemicals, or food industries, FIBC bulk bags offer a reliable solution to your bulk packaging requirements.

Frequently Asked Questions (FAQs)

What are FIBC bulk bags made of?

FIBC bulk bags are primarily made from woven polypropylene, a durable and flexible plastic material. Some bags include additional materials like conductive threads for specific applications.

How much weight can an FIBC bulk bag hold?

FIBC bulk bags can typically hold between 500 and 2,000 kilograms (1,100 to 4,400 pounds), depending on the design and type of bag. It's essential to choose a bag rated for the specific weight of the material being transported.

Are FIBC bulk bags environmentally friendly?

Yes, FIBC bulk bags are considered environmentally friendly because they are often reusable and recyclable. Using these bags can reduce the reliance on single-use packaging materials, contributing to sustainability efforts.

How should FIBC bulk bags be stored?

FIBC bulk bags should be stored in a dry, clean environment away from direct sunlight. They should be kept off the ground to prevent moisture absorption and contamination. Proper storage ensures the bags maintain their integrity and usability.

What are anti-static FIBC bulk bags?

Anti-static FIBC bulk bags (Type D) are designed to dissipate static electricity safely. These bags are used for transporting flammable products in environments where static discharge could ignite dust or gases, ensuring safe handling and transport.

Can FIBC bulk bags be customized?

Yes, many suppliers offer customization options for FIBC bulk bags. Customizations can include size, shape, material, and additional features like liners, printing, and specific filling and discharge mechanisms. Custom bags ensure they meet the specific requirements of your application.

0 notes

Text

Comparing Nitrile Rubber Hoses with Other Types of Rubber Hoses

Rubber hoses are essential components in various industrial and commercial applications, providing flexibility and resilience in the transportation of liquids and gases. Among the different types of rubber used in hose manufacturing, nitrile rubber stands out for its unique properties. This article compares nitrile rubber hoses with other common types of rubber hoses, such as EPDM, silicone, and natural rubber, focusing on their performance, durability, and suitability for various environments.

Nitrile Rubber (NBR) Hoses

Nitrile rubber, also known as NBR, is a synthetic rubber copolymer of acrylonitrile (ACN) and butadiene. Nitrile rubber hoses are renowned for their excellent resistance to oils, fuels, and other petroleum-based products, making them ideal for automotive, industrial, and oil and gas applications.

Key Advantages:

Oil and Fuel Resistance: Nitrile rubber's resistance to petroleum products is its most significant advantage. This makes nitrile hoses ideal for fuel lines, hydraulic hoses, and other applications where exposure to oils and fuels is common.

Durability: Nitrile rubber is highly durable and resistant to abrasion, punctures, and tears. This durability extends the lifespan of nitrile hoses, reducing the need for frequent replacements.

Temperature Tolerance: Nitrile hoses can operate effectively in a wide temperature range, typically from -40°C to 100°C (-40°F to 212°F), making them suitable for both hot and cold environments.

EPDM Rubber Hoses

EPDM (ethylene propylene diene monomer) rubber is another widely used material in hose manufacturing. EPDM hoses are particularly valued for their excellent resistance to weathering, ozone, and UV exposure, making them ideal for outdoor applications.

Key Advantages:

Weather Resistance: EPDM rubber is exceptionally resistant to weathering, ozone, and UV radiation, which makes EPDM hoses suitable for outdoor use in harsh environmental conditions.

Chemical Resistance: EPDM hoses offer good resistance to a range of chemicals, including acids, alkalis, and some solvents.

Temperature Range: EPDM rubber can withstand temperatures from -50°C to 150°C (-58°F to 302°F), making it suitable for high-temperature applications.

Comparison with Nitrile Rubber:

Oil Resistance: Unlike nitrile, EPDM is not resistant to oils and petroleum products, limiting its use in applications involving fuels and lubricants.

Environmental Exposure: EPDM hoses outperform nitrile hoses in resistance to weathering and UV exposure, making them preferable for outdoor applications.

Silicone Rubber Hoses

Silicone rubber hoses are known for their flexibility, high-temperature resistance, and biocompatibility. They are commonly used in the medical, food and beverage, and automotive industries.

Key Advantages:

Temperature Resistance: Silicone hoses can withstand extreme temperatures, typically from -60°C to 200°C (-76°F to 392°F), making them ideal for high-temperature applications.

Flexibility: Silicone rubber remains flexible at both low and high temperatures, providing excellent performance in dynamic applications.

Biocompatibility: Silicone is non-toxic and biocompatible, making it suitable for medical and food-grade applications.

Comparison with Nitrile Rubber:

Temperature Range: Silicone hoses have a wider temperature range compared to nitrile hoses, making them suitable for more extreme temperature conditions.

Oil Resistance: Nitrile hoses have better oil and fuel resistance than silicone hoses, which are more susceptible to swelling and degradation when exposed to petroleum products.

Natural Rubber Hoses

Natural rubber, derived from latex, is known for its excellent elasticity and tensile strength. Natural rubber hoses are commonly used in general-purpose applications where high elasticity and abrasion resistance are required.

Key Advantages:

Elasticity: Natural rubber provides superior elasticity, making hoses highly flexible and resistant to kinking.

Abrasion Resistance: Natural rubber has good resistance to wear and tear, making it suitable for abrasive applications.

Comparison with Nitrile Rubber:

Oil Resistance: Natural rubber lacks the oil and fuel resistance of nitrile rubber, limiting its use in applications involving petroleum products.

Durability: While natural rubber offers excellent elasticity, nitrile rubber provides better overall durability and resistance to chemicals and environmental factors.

Conclusion

Each type of rubber used in hose manufacturing has its unique advantages and limitations, making them suitable for specific applications. Nitrile rubber hoses excel in oil and fuel resistance, making them ideal for automotive and industrial applications. EPDM hoses are preferred for outdoor use due to their superior weather resistance. Silicone hoses offer exceptional temperature tolerance and flexibility, suitable for high-temperature and medical applications. Natural rubber hoses provide excellent elasticity and abrasion resistance for general-purpose use.

Understanding these differences is crucial for selecting the right hose material for your specific needs, ensuring optimal performance, durability, and safety in your applications.

0 notes

Text

Supplier of SS Industrial Flanges in Rajasthan

Meghmani Metal Industries is a Manufacturer and Supplier of SS Industrial Valves in Rajasthan, India.

Founded in 2011, Meghmani Metal Industries is committed to delivering outstanding products to the metal industry.

We offer a comprehensive range of stainless steel products, including plates, coils, bars, pipes, tubes, flanges, valves, fittings, fasteners, channels, and flats. Each item is meticulously crafted to meet diverse industrial needs.

SS Industrial Flanges are crucial components in numerous industrial applications, ensuring the controlled flow of liquids, gases, and slurries.

Our SS industrial Flanges are made from high-grade stainless steel, offering superior resistance to corrosion and rust. This makes them ideal for use in harsh environments and industries dealing with corrosive substances.

Our SS industrial flanges are available in various types, including ball valves, gate valves, butterfly valves, and check valves, SS industrial valves cater to a wide range of industries.

Stainless steel's non-porous surface is easy to clean and does not harbor bacteria, making these valves suitable for industries where hygiene is paramount, such as pharmaceuticals and food processing.

SS industrial flanges are designed with precision to ensure tight sealing and minimal leakage. This precision engineering enhances operational efficiency and reduces maintenance costs.

Our SS industrial flanges, known for corrosion resistance and durability, regulate flow in various industries, including oil, gas, chemicals, and water treatment, ensuring efficient, safe, and reliable operations.

Meghmani Metal Industries is a Manufacturer and Supplier of SS Industrial Flanges in Rajasthan and locations like Ajmer, Alwar, Amer, Barmer, Beawar, Bharatpur, Bhilwara, Bikaner, Bundi, Chittaurgarh, Churu, Dhaulpur, Dungarpur, Ganganagar, Hanumangarh, Jaipur, Jaisalmer, Jalor, Jhalawar, Jhunjhunu, Jodhpur, Kishangarh, Kota, Merta, Nagaur, Nathdwara, Pali, Phalodi, Pushkar, Sawai Madhopur.

Feel free to reach out for further details and inquiries. We're here to assist you.

Read the full article

0 notes

Text

Best Activated Carbon Manufacturers in Kerala

Southern Carbon and Chemicals (SCC) isn't just another name among activated carbon manufacturers in Kerala. They've established themselves as a frontrunner, driving innovation and providing high-performance, eco-friendly solutions for diverse industries throughout the state. Their unwavering focus on quality, sustainability, and client collaboration empowers businesses across Kerala to achieve operational excellence.

Understanding Activated Carbon: A Multifaceted Workhorse

At the heart of SCC's success lies activated carbon, a remarkable material with a highly porous structure. Imagine a microscopic sponge with an enormous internal surface area – that's essentially what activated carbon is. This vast network of pores grants it exceptional adsorptive capabilities, allowing it to trap and remove unwanted gases, liquids, and impurities from various substances. SCC harnesses this power through a meticulous manufacturing process, creating activated carbon solutions that serve a multitude of Kerala's key industries:

**Kerala's Breath of Fresh Air: **Air purification is crucial in Kerala, a state known for its natural beauty. SCC's activated carbon finds application in industrial air filtration systems, effectively removing harmful chemicals and pollutants, contributing to a cleaner and healthier work environment.

Crystal-Clear Water for Kerala's People: Water purification is another vital aspect for Kerala. SCC's activated carbon plays a key role in municipal water treatment plants and industrial processes, removing contaminants and ensuring clean water for various purposes.

Elevating Kerala's Culinary Delights: From ensuring sparkling clear beverages to enhancing the taste and color of processed foods, activated carbon plays a vital role in Kerala's food and beverage industry. SCC's products help purify ingredients, extend shelf life, and contribute to the overall quality of food and beverage items produced in the state.

Supporting Kerala's Medical Industry: Purity is paramount in the medical field. SCC's activated carbon finds application in various pharmaceutical processes, helping remove unwanted colors and odors, and ensuring the quality of life-saving medicines.

SCC: Where Quality Reigns Supreme

SCC understands that quality is the cornerstone of their success. They are unwavering in their commitment to excellence throughout the manufacturing process:

Uncompromising Local Sourcing: Whenever possible, SCC prioritizes sourcing high-grade raw materials from within Kerala, supporting the local economy and minimizing their environmental footprint.

Cutting-Edge Activation Techniques: They employ advanced activation processes to maximize the surface area and porosity of the activated carbon, significantly enhancing its ability to trap impurities.

Rigorous Quality Control: SCC maintains a watchful eye on quality. Rigorous quality control measures are implemented at every stage of production, guaranteeing consistent performance and adherence to strict quality standards.

Innovation: Charting the Course for Kerala's Future

SCC isn't content with the status quo; they constantly push boundaries through research and development:

Pioneering New Applications: Their dedicated research team relentlessly explores new applications for activated carbon specifically tailored to address the unique needs and challenges faced by Kerala's industries.

Sustainable Solutions for a Greener Kerala: SCC prioritizes eco-friendly practices. Their research focuses on optimizing manufacturing processes to minimize environmental impact and resource consumption, while maximizing the efficiency and reusability of their activated carbon products.

Sustainability at the Core: A Responsible Manufacturer in Kerala

SCC recognizes that success is not just about profits; it's about responsible manufacturing within Kerala:

Local Sourcing with Global Standards: SCC strives to strike a balance by sourcing raw materials locally whenever possible, while maintaining globally recognized quality standards.

Minimizing Waste Generation: SCC implements innovative techniques to minimize waste generation during the manufacturing process. This not only reduces environmental impact but also optimizes resource utilization.

Rejuvenating Spent Carbon: SCC offers reactivation services for used activated carbon within Kerala. This allows clients to regenerate and reuse their spent carbon, minimizing waste and extending the product's lifespan.

Beyond Manufacturing: Building Strong Partnerships in Kerala

SCC goes beyond simply being a manufacturer; they strive to be a reliable and trusted partner for their clients in Kerala:

Technical Expertise for Kerala's Needs: SCC's team of experts offers comprehensive technical guidance and support. They understand the specific challenges faced by Kerala's industries and help clients select the most appropriate activated carbon solution.

Customization is Key: SCC understands that a one-size-fits-all approach doesn't work. They offer customized activated carbon solutions tailored to address unique industry requirements and application-specific challenges faced by businesses in Kerala.

Reliable Supply Chain Network: SCC maintains a robust supply chain network within Kerala. This ensures timely and consistent delivery of their activated carbon products, allowing clients to focus on their core operations without worrying about supply disruptions.

0 notes

Text

Supplier of SS Pipes and Tubes in Rajasthan

Keshar Bhawani Metal & Tubes Pvt. Ltd is a leading provider Manufacturer and Supplier of SS Pipes and Tubes in Rajasthan, India.

Stainless Steel Pipes and Tubes (SS Pipes and Tubes) are essential components in various industries due

to their durability, corrosion resistance, and versatility.

Crafted from stainless steel, an alloy primarily composed of iron with a significant percentage of

chromium and often other elements like nickel, molybdenum, or titanium.

The addition of chromium provides stainless steel with its signature corrosion-resistant properties, making it ideal for challenging environments.

SS Pipes and Tubes find extensive applications across numerous sectors, including construction,

automotive, aerospace, food and beverage, pharmaceuticals, oil and gas, and more.

Their robustness and resistance to corrosion make them suitable for transporting fluids, gases, and other materials safely and efficiently.

Additionally, their aesthetic appeal and hygienic properties make them popular in architectural and decorative applications.

These pipes and tubes come in various shapes, sizes, and grades to cater to diverse needs and

requirements, including round, square, rectangular, and oval shapes.

Sizes range from small-diameter tubes to large-diameter pipes used in heavy-duty industrial applications.

Key Features:

Durability: Designed to withstand long-term use without significant degradation.

High Strength: Capable of handling high pressure and stress.

Corrosion Resistance: Ideal for harsh environments due to enhanced resistance to rust and corrosion.

Heat Resistance: Can tolerate high temperatures, making them suitable for various industrial processes.

Low Maintenance: Requires minimal upkeep due to their resilient nature.

Compatibility: Suitable for a wide range of applications and can be used with different types of fluids and gases.

Keshar Bhawani Metal & Tubes Pvt. Ltd is Supplier of SS Pipes and Tubes in Rajasthan Including Ajmer,

Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi,

Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar,

Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Jodhpur,

Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand,

Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur.

For detailed information and inquiries, please feel free to contact us.

Read the full article

#Ajmer#Alwar#Anupgarh#Balotra#Banswara#Baran#Barmer#Beaware#Bharatpur#Bhilwara#Bikaner#Bundi#Chittorgarh#Churu#Dausa#Deeg#Dholpur#Didwalna-Kuchaman#Dudu#Dungarpur#Ganganagar#GangapurCity#Hanumangarh#India#Jaipur#Jaisalmer#Jalore#Jhalawa#Jhunjhunu#Jodhpur

0 notes

Text

Unlocking the Power of Hydrochloric Acid: From Production to Purpose!

Hydrochloric acid. It sounds intimidating, maybe even dangerous. And let's be honest, it can be. But this strong acid also plays a surprising role in our everyday lives. From the steel in our skyscrapers to the PVC pipes under our sinks, hydrochloric acid has its industrial fingerprints on a surprising number of things.

In this blog, we'll delve into the world of hydrochloric acid, exploring its surprising versatility. We'll see how it helps make everything from the disinfectants that keep us healthy to the bubbly fun of swimming pools. So, buckle up and get ready to see a new side of this powerful chemical!

Introduction

Hydrochloric acid, also known as muriatic acid, is a water-based solution of hydrogen chloride gas (HCl). Widely utilized in chemical research facilities and industrial settings, its uses range from mass-producing specific compounds like vinyl chloride for PVC plastic, to removing rust and scale from metals, aiding in petroleum production, and processing ores.

Hydrochloric acid is generated as a by-product in the production of various chemicals, such as chlorinated solvents, isocyanates, organic and fluorocarbon compounds, magnesium, and vinyl chloride monomer. Another method involves the direct reaction between hydrogen and chlorine. Hydrochloric acid of varying grades finds applications across industries including manufacturing, food, and pharmaceuticals. Its versatile uses span from producing organic and inorganic compounds to serving as a cleaning agent, aiding in fertilizer production, dye manufacturing, steel pickling, leather tanning, electroplating, and rubber production.

Manufacturing Processes

Approximately 40 processes produce HCl as a byproduct, while around 110 chemical manufacturing processes incorporate hydrochloric acid as a primary ingredient. Hydrogen chloride is also produced by direct synthesis as well.

Direct Synthesis

Hydrogen chloride can be generated through the rapid combination of chlorine gas (Cl2) and hydrogen gas (H2), a process that occurs swiftly at temperatures exceeding 250°C (482°F).

In one scenario, a process for manufacturing hydrogen chloride involves retrieving chlorine gas from a redox flow cell battery system. Subsequently, hydrogen and the acquired chlorine gas are introduced into a photochemical chamber equipped with a source or sources of ultraviolet radiation.

Activation of the ultraviolet radiation sources leads to the exposure of hydrogen and chlorine to ultraviolet rays, resulting in the production of hydrogen chloride. The generated hydrogen chloride is then gathered or combined with water to create a solution of hydrochloric acid. Additionally, the chamber may be equipped with at least one sensor to monitor the concentration ratio of hydrogen to chlorine during the process.

In an alternative method, a process for generating hydrogen chloride involves gathering hydrogen gas and chlorine gas from a redox flow cell battery system. These gases are then introduced into at least one photochemical chamber equipped with at least one source of ultraviolet radiation. Activation of the ultraviolet radiation source(s) exposes the hydrogen and chlorine to ultraviolet radiation, leading to the formation of hydrogen chloride. The resulting hydrogen chloride is either collected or blended with water to produce a solution of hydrochloric acid.

In other method, a redox flow cell battery system comprises a redox flow cell housing a pair of electrodes placed in distinct half-cell compartments, separated by a porous or ion-selective membrane, and an electrolyte circulated through these compartments, consisting of chromium ions and iron ions.

Connected to one or both of these half-cell compartments is a chamber containing an ultraviolet light source. During the system's operation, the chamber accumulates hydrogen and/or chlorine gas from one or both half-cell compartments, and/or a rebalance compartment, and generates hydrogen chloride from the gathered gas.

Techniques used by Major Hydrochloric Acid Manufacturers

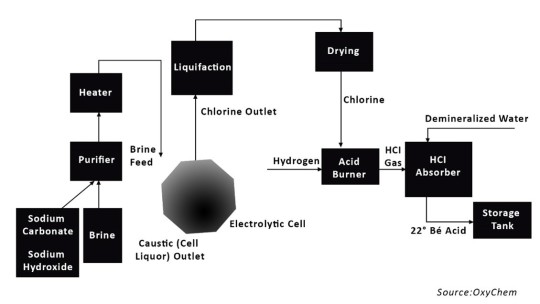

OxyChem uses a direct synthesis method to make hydrochloric acid. They combine hydrogen and chlorine gas in special reactors called "acid burners". The reaction produces hydrogen chloride gas, which is then captured by dissolving it in purified water. This process results in high-purity hydrochloric acid.

Applications of Hydrochloric Acid

Steel

Hydrochloric acid plays a crucial role in pickling processes, where it effectively eliminates rust and other contaminants from carbon, alloy, and stainless steel surfaces. This preparatory step ensures the steel's readiness for diverse applications in construction projects, including building structures, as well as in manufacturing car bodies and household appliances. Furthermore, its utility extends to aluminum etching, facilitating the intricate shaping of this metal, and in various metal cleaning applications, where it aids in the removal of stubborn residues, ensuring the surfaces are pristine and ready for subsequent processing or use.

2. Disinfectants & Cleaners

Hydrochloric acid finds application as an active ingredient in household cleaning products like toilet bowl cleaners, bathroom tile cleaners, and other porcelain cleaners. Its corrosive nature makes it highly effective in tackling stubborn stains, grime, and mineral deposits, rendering surfaces sparkling clean. By virtue of its powerful cleaning properties, hydrochloric acid aids in effortlessly removing tough stains and buildup from various surfaces, ensuring a hygienic and pristine environment in households. However, its potent nature necessitates careful handling and adherence to safety precautions during usage to prevent any potential hazards.

3. Food

Hydrochloric acid serves an essential role in the food industry, particularly in processing a diverse array of food products. It is integral in the production of corn syrups utilized in soft drinks, cookies, crackers, ketchup, and cereals, contributing to their taste, texture, and preservation. Additionally, hydrochloric acid acts as an acidifier in sauces, vegetable juices, and canned goods, aiding in flavor enhancement and spoilage prevention. Its carefully regulated usage ensures food safety standards are met while optimizing flavor profiles and extending shelf life, thereby contributing to the quality and palatability of various food items consumed worldwide.

4. Chemical Intermediates

When hydrochloric acid interacts with limestone, it undergoes a chemical reaction, yielding calcium chloride, a specific type of salt commonly employed in de-icing road surfaces. Beyond its role in road maintenance, calcium chloride finds diverse applications in the food industry. It serves as a stabilizer and firming agent in food production, notably in baked goods, where it enhances texture and prolongs freshness. Additionally, calcium chloride functions as an antimicrobial agent, contributing to food safety by inhibiting microbial growth and extending shelf life in various food products. Its multifaceted utility underscores its significance across industries, from infrastructure maintenance to food manufacturing.

Market Outlook

The steel industry relies heavily on hydrochloric acid for the pickling process, essential for removing impurities like stains, rust, and scale from various metals including ferrous metals, copper, precious metals, and aluminum alloys. This demand has surged, with hydrochloric acid often supplanting sulfuric acid in steel pickling facilities, consequently driving up its usage in steel production plants. Looking ahead, the demand for hydrochloric acid is anticipated to further escalate owing to its versatility across industries. Particularly noteworthy is its role in the food industry, where its preservative and acidifying properties make it indispensable. As such, a significant uptick in hydrochloric acid consumption is projected in the foreseeable future, underscoring its pivotal position in various sectors.

Hydrochloric Acid Major Global Players

Significant players in the Global Hydrochloric Acid market are Dow Chemical, BASF SE, Qingdao Haijing Chemical (Group) Co., Ltd., Gujarat Alkali & Chemicals Limited., Akzo Nobel N.V., DCM Shriram, HF Chlor-Alkali LLC, and Others.

Conclusion:

Hydrochloric Acid is a versatile acid in numerous processes. Hydrochloric acid (HCl) serves various crucial purposes across industries. In steel pickling, it removes iron oxides and scale from steel surfaces, vital for subsequent processing like wire production and coating. Additionally, it aids in aluminum etching and metal cleaning. In oil well acidizing, HCl eliminates rust and carbonate deposits, stimulating crude oil or gas flow by enlarging pore structures in formations. The food industry extensively uses HCl, particularly in producing high-fructose corn syrup (HFCS), where it regenerates ion exchange resins. HFCS finds significant application in soft drink production. Furthermore, HCl is essential in calcium chloride production from limestone. A projected rise in demand for food preservatives and steel pickling within their respective industries is expected to significantly bolster the hydrochloric acid market. Hydrochloric acid's inherent acidic, preservative, and reducing properties contribute to its diverse industrial applications, thereby fostering anticipated growth in demand for the foreseeable future.

0 notes

Text

27 Materials For Custom Gaskets And Their Purposes

Facilities involved with the manufacturing of foodstuffs are often required to use on equipment gaskets and seals that adjust to FDA (or similar) requirements for non-toxicity and chemical compatibility. In this weblog we spotlight the sealing materials which meet requirements issued by the FDA or different our bodies, and which must be used to fabricate gaskets and seals for food grade functions. Typically, silicone products made for EMI shielding are made conductive by placing a conductive filler in the material, typically silver, aluminum, copper, or nickel. This sort of material is highly versatile and may be made to suit a extensive variety of sizes and designs. It normally doesn’t stand up to very harsh environmental situations — like publicity to sunlight, caustic chemical compounds, fuels or oils — which might leave shielding and sealing capabilities impaired.

With that stated, sponge rubber remains to be robust and sturdy, so it’s capable of prevent fluids and gases from leaking. In phrases of gross sales income, Garlock reported gross sales of approximately $500 million in the non-asbestos gasket sheet market in the latest fiscal 12 months. These companies are expected to keep up their market leadership positions and drive further growth within the coming years. In many situations, our clients come to us with nothing more than an issue or a need, corresponding to desirous to decrease vibration or prevent leaks. Then we can recommend a few several types of industrial gasket options to meet your needs and exceed your expectations. Understanding and knowing the several types of industrial gaskets could be confusing.

While we now know that asbestos is a harmful material, it was originally used for its heat-resistant properties to fill and seal gaps and cracks. With asbestos not available on the market, firms and consumers want different non-asbestos gaskets to fill the gap asbestos left behind. Another key participant, Flexitallic, has also been witnessing growth within the Industrial Gaskets Market. They are recognized for their high-quality gaskets which are designed to meet trade standards and rules. Their market size has been expanding due to increased demand for dependable gasket options. Rubber gaskets additionally improve total tools performance by providing a dependable sealing answer.

“Think about water-conserving taps and toilets, smart home equipment that maximize vitality and water efficiency, and other options that make residing more sustainably even simpler,” he says. Insulated and laminated influence windows and doorways do wonders for reducing a home’s total energy consumption, explains Manny Angelo Varas, president and CEO of homebuilder MV Group USA. If you’re changing home windows in a house, take a more in-depth look at triple-glazed windows, also called triple-pane home windows. “These have a much better insulation worth, and with the best movies, can minimize down on not solely solar warmth achieve however UV rays that can injury artwork, fabrics, and finishes,” says Schneeberger. Georg Fischer is proud of it is lengthy history of success with roots going back more than 200 years when Johann Conrad Fischer laid the inspiration.

sustainable gasket materials

Clay is reasonably priced and versatile, and because of its pure properties, it is very power environment friendly. Clay can additionally be very durable and can final upwards of a hundred years, making it an ideal sustainable material to be used in construction. Clay can also be extremely resilient to weather harm, withstanding rain and wind with out deteriorating or changing into broken. First and foremost, it is a sustainable building material, as it's being reused and is not coming from a brand new source. This eliminates the necessity for additional assets, serving to to preserve the setting. It also eliminates the necessity for additional processing and manufacturing, helping to reduce energy consumption.

These specs are more aggressive – water sealing towards pressurized jets. Due to the high pressures and water volumes, profitable sealing is shared between a good enclosure design and the right gasket material. The customer was utilizing graphite gasketing material with a tanged stainless core and encountered a number of failures even with the gasket material being nicely within the temperature and strain limitations. LGG Industrial partnered with Leader Gasket to design a specialty LeaderTherm NXT Gasket that would cope with low seating stresses in addition to the medium Nitrogen Oxides (NOx). The right gasket, in combination with the proper installation, reduced costs and fugitive emissions while improving safety and reliability. Leader Gasket, part of LGG Industrial, produces top-tier semi-metallic and delicate gaskets together with sheeting material.

#durlon sealing products#durlon gaskets#industrial gaskets#sheet gaskets#metallic gaskets#sustainable gasket materials#high-quality gaskets#PTFE sheet gaskets

0 notes

Text

Clearing the Air: Exploring the Benefits of Clean Vapor Technology

In an age where environmental consciousness and health awareness are at the forefront of consumer concerns, innovative technologies continue to emerge to address these pressing issues. One such advancement is Clean Vapor technology, a revolutionary approach to vaping that promises a cleaner, purer experience for users. Let's delve into the world of Clean Vapor to uncover its benefits, mechanisms, and implications for the vaping industry and beyond.

Clean Vapor technology represents a significant leap forward in the design and functionality of vaping devices. Traditional vaporizers often rely on combustion or heating elements that produce harmful byproducts such as tar, carbon monoxide, and other toxins. In contrast, Clean Vapor devices utilize advanced heating systems, such as convection or induction, to vaporize the active ingredients in e-liquids without generating harmful combustion byproducts.

The primary benefit of Clean Vapor technology lies in its ability to deliver a smoother, more flavorful vaping experience while minimizing exposure to potentially harmful substances. By eliminating combustion, Clean Vapor devices produce vapor that is free from the carcinogens and toxins commonly associated with traditional smoking methods. This not only reduces health risks for users but also creates a more enjoyable and satisfying vaping experience.

Furthermore, Clean Vapor technology offers environmental benefits by reducing air pollution and minimizing the carbon footprint associated with vaping. Traditional smoking methods release a plethora of harmful chemicals and greenhouse gases into the atmosphere, contributing to air pollution and climate change. Clean Vapor devices, with their cleaner-burning technology, help mitigate these environmental impacts, making them a more sustainable choice for conscientious consumers.

One of the key components of Clean Vapor technology is the use of high-quality, pharmaceutical-grade ingredients in e-liquids. Unlike traditional cigarettes, which contain thousands of harmful chemicals and additives, Clean Vapor e-liquids are formulated with carefully selected ingredients, including food-grade flavorings, nicotine (optional), and base liquids such as propylene glycol and vegetable glycerin. This ensures a cleaner, purer vaping experience without compromising on taste or quality.

Moreover, Clean Vapor devices are designed with user safety and convenience in mind. Many modern vaporizers feature built-in safety mechanisms such as temperature control, short-circuit protection, and automatic shut-off functions to prevent overheating and ensure a safe vaping experience. Additionally, Clean Vapor devices often come equipped with user-friendly features such as adjustable airflow settings, refillable tanks, and rechargeable batteries, allowing users to customize their vaping experience to suit their preferences.

As Clean Vapor technology continues to evolve, researchers and manufacturers are exploring new ways to enhance its effectiveness and accessibility. From advancements in heating technology to innovations in e-liquid formulations, the future of Clean Vapor holds great promise for both users and the vaping industry as a whole. By prioritizing health, sustainability, and user experience, Clean Vapor technology represents a paradigm shift in the way we approach vaping and tobacco harm reduction.

Clean Vapor technology offers a cleaner, safer, and more enjoyable alternative to traditional smoking methods. By eliminating combustion and minimizing exposure to harmful chemicals, Clean Vapor devices provide users with a purer vaping experience while reducing environmental impacts. With its focus on health, sustainability, and user satisfaction, Clean Vapor technology is poised to shape the future of the vaping industry and empower consumers to make informed choices about their nicotine consumption.

For more info:-

clean vapor

cleanvapor.com

0 notes