#geo sheet manufacturers india

Text

The Environmental Benefits of Using Geotextile Fabric

In recent years, there has been a growing emphasis on sustainable construction practices and environmental conservation. One such innovation that has gained prominence is the use of geotextile fabric. This synthetic material, produced by Geo fabric manufacturers in India, is revolutionizing the construction and environmental industries. From erosion control to waste management, the applications of geotextile fabric are vast and varied. This article delves into the environmental benefits of using geotextile fabric, highlighting its significance in promoting eco-friendly practices.

What is Geotextile Fabric?

Geotextile fabric, commonly referred to as geo fabric sheet in India, is a permeable textile material. It is manufactured using synthetic polymers such as polypropylene or polyester. The fabric's unique structure allows water to pass through while retaining soil particles, making it ideal for various civil engineering and environmental applications.

Erosion Control: One of the primary environmental benefits of geotextile fabric is its effectiveness in erosion control. Soil erosion is a significant environmental concern that can lead to land degradation, loss of biodiversity, and sedimentation in water bodies. Geo fabric sheet in India is used to stabilize slopes, embankments, and riverbanks, preventing soil erosion caused by water runoff and wind.

Soil Reinforcement: Geo fabric manufacturers in India produce geotextile fabric that enhances the mechanical properties of soil. When used in soil reinforcement applications, the fabric acts as a stabilizing agent, increasing the soil's bearing capacity and reducing settlement. This minimizes the need for extensive earthworks, thereby conserving natural resources and reducing carbon emissions associated with heavy machinery.

Waste Management: Geotextile fabric plays a crucial role in waste management practices. It is commonly used in landfill liners and caps to prevent the leaching of contaminants into the soil and groundwater. Additionally, geo fabric sheet in India is utilized in wastewater treatment systems to filter out impurities, ensuring cleaner discharge into the environment.

Infrastructure Development: The use of geotextile fabric has become increasingly prevalent in infrastructure development projects such as roads, railways, and airports. It serves as a separation layer between different construction materials, preventing intermixing and maintaining structural integrity. This prolongs the lifespan of infrastructure assets and reduces the need for frequent repairs and maintenance, leading to long-term environmental benefits.

Cost-Effective Solution: Aside from its environmental advantages, geotextile fabric offers a cost-effective solution for various construction and environmental challenges. By reducing the need for traditional construction materials and techniques, geo fabric manufacturers in India help in lowering project costs while delivering sustainable outcomes.

The Role of Geo Sheet Manufacturers in India

Geo sheet manufacturers in India play a pivotal role in promoting the adoption of geotextile fabric for environmental conservation. By producing high-quality Geo fabric sheet in India, these manufacturers enable construction companies, government agencies, and environmental organizations to implement sustainable solutions for various projects. Moreover, local manufacturing reduces the carbon footprint associated with importing geotextiles, making it an environmentally friendly choice.

Geo sheet manufacturers in India play a crucial role in advancing sustainable construction and environmental conservation practices. By producing high-quality geotextile fabrics tailored to meet diverse project requirements, these manufacturers enable the implementation of eco-friendly solutions across various sectors. Their commitment to quality, innovation, and environmental responsibility contributes to reducing the carbon footprint associated with construction activities while promoting the efficient use of natural resources.

Conclusion

The environmental benefits of using geotextile fabric are undeniable, making it an indispensable material for sustainable development. From controlling soil erosion and promoting sustainable construction to improving drainage systems, geotextiles offer versatile solutions that protect our planet's natural resources and ecosystems. With the active involvement of geo sheet manufacturers in India, the adoption of geotextile fabric is expected to grow, driving positive change towards a greener and more sustainable future.

Frequently Asked Questions

What are the different types of geotextile fabric available?

Geotextile fabric is available in various types, including woven, non-woven, and knitted. Each type has specific characteristics suited for different applications, such as erosion control, soil stabilization, and drainage systems.

How does geotextile fabric contribute to soil conservation?

Geotextile fabric acts as a barrier that prevents soil erosion by stabilizing the soil structure and reducing the impact of external factors like rainfall, wind, and water currents. This helps in preserving soil fertility and maintaining the integrity of the landscape.

Are geo sheet manufacturers in India producing eco-friendly products?

Yes, many geo sheet manufacturers in India are committed to producing eco-friendly geotextile fabric by using sustainable materials and manufacturing processes. This ensures that the products meet international environmental standards while promoting responsible consumption and production.

Can geotextile fabric be recycled?

Yes, geotextile fabric can be recycled and reused in various applications, reducing the demand for new materials and minimizing waste. Recycling geotextiles contributes to circular economy principles and enhances sustainability efforts in the construction and environmental sectors.

0 notes

Text

0 notes

Text

Geomembrane Sheet: Durable Waterproof Barrier for Environmental Protection

Introduction

In the realm of environmental protection and civil engineering, geomembranes play a pivotal role as durable waterproof barriers. These engineered sheets, manufactured by leading companies like Geo membrane manufacturers in India and Geomembrane manufacturers in Ahmedabad, serve multifaceted purposes across various industries. Let's explore the uses, benefits, advantages, and overall impact of geomembrane sheets in environmental conservation and infrastructure development.

Uses

Waste Containment: One of the primary uses of geomembranes is in waste containment systems. They prevent the migration of contaminants into surrounding soil and groundwater, thus safeguarding the environment from pollution caused by landfills and hazardous waste sites.

Water Storage: Geomembrane liners are used in reservoirs, ponds, and canals for efficient water storage. They prevent seepage and leakage, ensuring water conservation and supply reliability.

Mining Industry: Geomembranes are utilized in mining operations to contain and manage mine tailings, reducing environmental impact by preventing the release of harmful substances. Geomembrane manufacturers in India offer high-quality solutions tailored to the specific needs of mining projects, ensuring effective containment and environmental protection.

Landscaping: They are employed in landscaping projects for lining artificial ponds, golf course water features, and decorative water bodies.

Agricultural Applications: Geomembranes aid in irrigation and water management by lining canals and agricultural ponds, optimizing water usage and preventing water loss.

Benefits and Advantages

Waterproofing: They provide effective waterproofing, crucial in applications like reservoirs and containment systems, where preventing leakage is paramount.

Chemical Resistance: Geomembranes exhibit resistance to a wide range of chemicals, making them suitable for applications involving exposure to various substances.

Environmental Protection: By containing pollutants and preventing soil contamination, geomembranes contribute significantly to environmental conservation.

Ease of Installation: Geomembranes are relatively easy to install, reducing labor costs and project timelines.

Conclusion

In conclusion, geomembrane sheets manufactured by industry leaders like Geo membrane manufacturers in India and Geomembrane manufacturers in Ahmedabad represent a vital component in modern environmental engineering and infrastructure development. Their versatility, durability, and effectiveness make them indispensable in projects aimed at protecting our natural resources and promoting sustainable practices.

FAQs (Frequently Asked Questions)

Q1: What materials are geomembranes typically made from?

Ans- Geomembranes are commonly made from materials such as HDPE (High-Density Polyethylene), PVC (Polyvinyl Chloride), EPDM (Ethylene Propylene Diene Monomer), and LLDPE (Linear Low-Density Polyethylene).

Q2: How are geomembranes installed?

Ans- Geomembranes are typically installed by unrolling the sheets over prepared surfaces and sealing the seams using heat fusion, adhesive bonding, or mechanical methods.

Q3: Can geomembranes be recycled?

Ans- Yes, some types of geomembranes, especially those made from recyclable plastics like HDPE, can be recycled after their service life, contributing to sustainability efforts.

Q4: What factors should be considered when selecting a geomembrane for a project?

Ans- Important factors include the type of containment, site conditions (including soil characteristics and potential chemical exposure), required longevity, and installation method.

In summary, geomembrane sheets are a cornerstone of environmental protection, offering effective solutions for waterproofing and containment across a spectrum of applications. Collaborating with reputable manufacturers like those in India ensures access to high-quality geomembrane products that meet stringent industry standards and contribute positively to sustainable development goals.

#geo membrane manufacturers in india#geomembrane manufacturers in Ahmedabad#geomembrane manufacturers in india

0 notes

Text

0 notes

Link

#Black Poly Sheet Supplier#HDPE Sheet Suppliers#Pond Lining Sheet#Agricultural Sheet Manufacturer#Canal Lining Sheet Suppliers#Polythene Sheet Manufacturer#Road Construction Poly Sheet Suppliers

0 notes

Photo

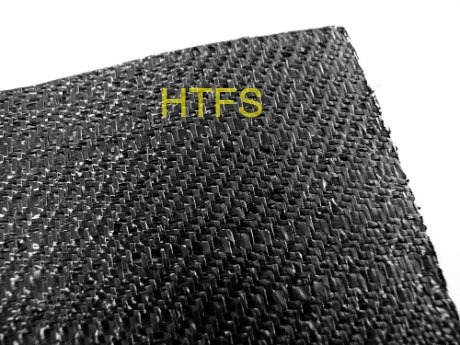

We deal in a wide range of Polyethylene Woven Geotextile Fabric, which is used for different industrial applications such as filtration, separation and for coating purposes. These industrial fabrics are stringently tested at our premises and are hygienically packaged as per client order. Manufactured from well-tested and quality material, these industrial fabrics are manufactured with the aid of latest technology which ensures quality range of product.

For more details contact us on 99255 01713 or Visit us @ https://geosyntheticindia.com/

#Geogrid Manufacturers in India#PP Woven Geotextiles Manufacturer#Non Woven Geo Fabric Sheet#Non Woven Polypropylene Geotextile Fabric#Non-Woven Geotextile Fabric

0 notes

Text

PolyDAAD Modular Solution and its primary product polydadmac have achieved great fame in recent years due to its wide range of applications and amazing performance. This is a state of the art tool that enables custom-made components for electronic systems to be developed and produced by companies of any size. The polydad modules are modular and have the ability to integrate themselves into the existing manufacturing process without any additional work.

The polydadmac Industry Research study, conducted by CAGR, a French company specializes in polydad enclosures and other poly-related technologies, provides deep insight into the poly-DAAD Market covering almost all the key aspects of this unique market. The report also provides forecast details over the next five years, giving a clear picture of how polydadmac is likely to evolve in the next five years. The analysis covers key issues such as market evolution, key competitors, market share, cost structure, sales growth, geographic expansion, and future outlook. The full scope of the research covers various poly-related technologies from polyvinyl chloride to polypropylene to polyiodide-based thermoplastics. It also covers the automotive, industrial, commercial, and residential segments.

https://www.reportmines.com/synthetic-menthol-market-in-indonesia-r185439

https://www.reportmines.com/synthetic-menthol-market-in-thailand-r185440

The market growth of polydadmac is very fast due to the high demand in the industrial, commercial, and residential segments of the paper industry. With polydadmac installations, companies can generate environmentally sound waste water treatment solutions and at the same time generate electricity and increase productivity. Many environmental organizations have welcomed polydadmac with open arms due to the many advantages it offers. The advantages include fiber-based paper, which can reduce the usage of trees and also helps in reducing the harmful effects caused by non-fiber-based papers. It is used in refrigerators, paper mills, pulp mills, and other manufacturing plants for its ability to withstand moisture, heat, chemicals, and fire.

The polydadmac market has been the subject of intense research and development by many companies, both Asian and European based. Leading companies such as Omaxe and Tetra have been working on new polyadammaforming methods and products for quite some time. The polyadammaforming methodologies involve injecting polystyrene pellets into molds. The polystyrene is then allowed to cool and solidify. The solidified polystyrene is then shaped into sheets and the sheets are used for a variety of products including building insulation, automobile bumpers, oilfield linings, and oilfield firefighting.

As discussed above, polydadmac offers a number of advantages that contribute to its broad and diversified applications across a number of applications. In addition, polydadmac has several key regional advantages, as discussed below. The polydadmac market is concentrated in two locations: in the United States and in Mexico. While the polydadmac supply base in the United States is limited by the physical infrastructure of the country, it is fairly widespread across the United States. This gives polydadmac an advantage over competitors in other countries due to the relatively low barriers to entry for the supply chain in the United States.

https://www.reportmines.com/synthetic-menthol-market-in-vietnam-r185441

https://www.reportmines.com/synthetic-menthol-market-in-malaysia-r185442

The polydadmac market segment in Mexico is also limited by infrastructure constraints. This means that there are not nearly the same amount of manufacturers in Mexico that have access to polydadmac. The lack of international shipping opportunities contributes to the relatively high price of polydadmac in Mexico compared to the cost of polydadmac produced in the United States. This price differential is most notable when comparing the cost of polydadmac imported from the United States to polydadmac produced domestically in Mexico. While imports of polydadmac from the United States have historically always been considerably cheaper than the cost of domestically produced polydadmac, recent fluctuations in the price of imported polydadmac indicate that this differential may be changing rapidly in the near future.

Polydadmacs are also competitive in several different price points. While they typically start at about a 20% premium over domestically produced polydadmac, they can vary widely in price once shipping and delivery costs are factored in. They are competitive in their premium over the leading brands in the polydad marketplace, but their relative lack of differentiation gives them a difficult challenge to gain market share in regions where they do not already have a significant customer concentration or presence. Many retailers believe that the segment will continue to expand as the polydadmac business continues to mature and acquire more retailers. In many regions, polydadmac is considered to be on the cusp of being "too small to compete" in the next few years.

As discussed above, polydadmac is currently seeing growth in the United States but is relatively slow to catch up to its competitors in the rest of the world. This is due primarily to lower pricing in the U.S., an absence of significant marketing budgets in some regions and poor visibility on store shelves. Due to these factors, polydadmac in the major regions of north America will continue to grow at a slower pace until the coming of more competitive retailers with better marketing budgets. This will allow for an eventual battle between these companies for sales in future years. For now, polydadmac in the United States are profitable and poised to continue growing in the coming years.

Summary

https://www.reportmines.com/synthetic-menthol-market-in-uk-r185443

Further key aspects of the report indicate that:

Chapter 1: Research Scope: Product Definition, Type, End-Use & Methodology

Chapter 2: Global Industry Summary

Chapter 3: Market Dynamics

Chapter 4: Global Market Segmentation by region, type and End-Use

Chapter 5: North America Market Segmentation by region, type and End-Use

Chapter 6: Europe Market Segmentation by region, type and End-Use

Chapter 7: Asia-Pacific Market Segmentation by region, type and End-Use

Chapter 8: South America Market Segmentation by region, type and End-Use

Chapter 9: Middle East and Africa Market Segmentation by region, type and End-Use.

Chapter 10: Market Competition by Companies

Chapter 11: Market forecast and environment forecast.

Chapter 12: Industry Summary.

The global PolyDADMAC market has the potential to grow with xx million USD with growing CAGR in the forecast period from 2021f to 2026f. Factors driving the market for @@@@@ are the significant development of demand and improvement of COVID-19 and geo-economics.

Based on the type of product, the global PolyDADMAC market segmented into

Transformers

Switchgear

Others

Based on the end-use, the global PolyDADMAC market classified into

Electric Utilities

Others

Based on geography, the global PolyDADMAC market segmented into

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of Middle East and Africa]

And the major players included in the report are

ABB

Siemens

Schneider Electric

Hitachi

Alstom

Crompton Greaves

Eaton

BHEL

GE

HYOSUNG

China XD Group

Toshiba

TBEA

Mitsubishi Electric

Shanghai Electric

Baoding Tianwei Group Tebian Electric

SPX Transformer Solutions

Fuji Electric

Frequently Asked QuestionsWhat is the USP of the report?

PolyDADMAC Market report offers great insights of the market and consumer data and their interpretation through various figures and graphs. Report has embedded global market and regional market deep analysis through various research methodologies. The report also offers great competitor analysis of the industries and highlights the key aspect of their business like success stories, market development and growth rate.

What are the key content of the report?What are the value propositions and opportunities offered in this market research report?Related Reports

Polycarbonates Market

Polycarbonate Diol Market

Polybutene-1 Market

Polyalumnium Chloride Market

Contact us: https://www.reportmines.com/contact-us.php

0 notes

Text

Geocomposite Market Overview,Competitive Landscape, Growth Factors, Analysis, 2020–2028

Market Size – USD 385.8 million in 2018, Market Growth – CAGR of 11.9%, Market Trends – Product Launches and Research for Advanced Tech Developments

Based on current analysis, the global Geocomposite Market was valued at USD 385.8 million in 2018 and is expected to reach USD 956.0 million by 2026, at a CAGR 11.9% Geocomposites are planar sheets made of composite materials that contain at least one layer of geosynthetic products involving geotextile, geogrid, geonet, geomembrane, etc. They are mainly used as liners in drainage facilities, for erosion control, road constructions and in several other applications. Geocomposite materials are the combinations of different materials in such a way that different applications are addressed in an optimal manner and at a minimum cost. Geocomposites maximize the benefit/cost ratio. The geotextiles provide increased resistance to puncture, tear propagation, and friction related to sliding, as well as providing tensile strength in and of themselves. Quite often, however, the geotextiles are of the nonwoven, needle-punched variety and are of relatively heavy weight. Several large-scale construction undertakings are expected to take place over the coming years, which may suggestively enhance the demand for recomposites materials during the forecast period.

Get a sample of the report @ https://www.reportsanddata.com/sample-enquiry-form/1483

The following are the key industry participants:

GSE Environmental (US),

TenCate Geosynthetics (US),

Maccaferri S.P.A. (Italy),

SKAPS industries (US),

ABG Ltd. (UK),

Hans Geo Components (US),

Huesker Synthetics GmbH (Germany),

and Thrace Group (Greece)

To know more about the report @ https://www.reportsanddata.com/report-detail/geocomposite-market

Type :

Geotextile–geonet

Geotextile-geocore

Geotextile-geogrid

Geotextile-geomembrane

Others

Applications :

Water & wastewater management

Road & highway

Landfill & mining

Soil reinforcement for civil construction

Others

Regional analysis covers:

US

Canada

Mexico

Germany

UK

Italy

France

BENELUX

Rest of Europe

China

India

Japan

South Korea

Rest of APAC

Brazil

Rest of LATAM

Saudi Arabia

UAE

South Africa

Rest of MEA

Request a discount on the report @ https://www.reportsanddata.com/discount-enquiry-form/1483

Key findings from the report

Growing competition among the local and global producers is primarily leading towards expansion of advanced products to expand the dominance in the market. Substantial investments in the research and development sector for the production of efficient and innovative products is an ongoing trend in the geocomposites market

Large-scale operations, namely, One Belt and One Road, Maritime Silk Road, and Silk Road Economic Belt projects in China are anticipated to uplift the demand for geocomposites in the region over the coming years

Geotextiles exhibit a relatively wide range of volumetric flow rate per unit area across the plane of the fabric, with discharge capacity again being largely determined by attributes of the polymer strand and the manufacturing process

Asia-Pacific regional segment of the geocomposite market is expected to register itself as highest growing segment during the forecasted period, at a CAGR of 13.0%; owing it to the qualitative as well as quantitative market potential offered in developing nations such as China & India

About Us:

Our in-house experts assist our clients with advice based on their proficiency in the market that helps them in creating a compendious database for the clients. Our team offers expert insights to clients to guide them through their business ventures. We put in rigorous efforts to keep our clientele satisfied and focus on fulfilling their demands to make sure that the end-product is what they desire. We excel in diverse fields of the market and with our services extending to competitive analysis, research and development analysis, and demand estimation among others, we can help you invest your funds in the most beneficial areas for research and development.

Contact Us:

John W

Head of Business Development

Reports And Data | Web: reportsanddata.com

Direct Line: +1-212-710-1370

E-mail: [email protected]

0 notes

Text

Geocomposite Market Outlook,Overview, Trends, Major Players, Share Analysis & Forecast Till 2026

Large scale growing infrastructure, roads and highways construction and the property of durability are the key factors contributing to the high CAGR of the geocomposite market. Furthermore, technological progressions, collaborations and product launches are fueling the growth of geocomposite market

Based on current analysis, the global Geocomposite Market was valued at USD 385.8 million in 2018 and is expected to reach USD 956.0 million by 2026, at a CAGR 11.9% Geocomposites are planar sheets made of composite materials that contain at least one layer of geosynthetic products involving geotextile, geogrid, geonet, geomembrane, etc. They are mainly used as liners in drainage facilities, for erosion control, road constructions and in several other applications. Geocomposite materials are the combinations of different materials in such a way that different applications are addressed in an optimal manner and at a minimum cost. Geocomposites maximize the benefit/cost ratio. The geotextiles provide increased resistance to puncture, tear propagation, and friction related to sliding, as well as providing tensile strength in and of themselves. Quite often, however, the geotextiles are of the nonwoven, needle-punched variety and are of relatively heavy weight. Several large-scale construction undertakings are expected to take place over the coming years, which may suggestively enhance the demand for recomposites materials during the forecast period.

Market Size – USD 385.8 million in 2018, Market Growth – CAGR of 11.9%, Market Trends – Product Launches and Research for Advanced Tech Developments

Growing demand for water inhibitions and canaling projects is also one of the driving factors for the growth of the geocomposites material market in various regions. On the other hand, fluctuation of raw material prices is may hamper the overall progress of the geocomposite market. Due to solid infrastructure, North America is successful in dominating the geocomposite market with market share of 43.5% and will continue to do so during the forecasted period.

Get a sample of the report @ https://www.reportsanddata.com/sample-enquiry-form/1483

The following are the key industry participants:

GSE Environmental (US),

TenCate Geosynthetics (US),

Maccaferri S.P.A. (Italy),

SKAPS industries (US),

ABG Ltd. (UK),

Hans Geo Components (US),

Huesker Synthetics GmbH (Germany),

and Thrace Group (Greece)

To know more about the report @ https://www.reportsanddata.com/report-detail/geocomposite-market

Type :

Geotextile–geonet

Geotextile-geocore

Geotextile-geogrid

Geotextile-geomembrane

Others

Applications :

Water & wastewater management

Road & highway

Landfill & mining

Soil reinforcement for civil construction

Others

Regional analysis covers:

US

Canada

Mexico

Germany

UK

Italy

France

BENELUX

Rest of Europe

China

India

Japan

South Korea

Rest of APAC

Brazil

Rest of LATAM

Saudi Arabia

UAE

South Africa

Rest of MEA

Request a discount on the report @ https://www.reportsanddata.com/discount-enquiry-form/1483

Key findings from the report

The geotextile-geocore product type accounted for a major market share of 48% in 2018, due to its large-scale application in road & highway applications

Water and wastewater application are the fastest growing application with a growing CAGR of 12.5 %

The polyester woven geotextile reinforced open graded asphalt concrete overlay shows the largest fabric effectiveness factor of 4.349 units and the largest base isolation effectiveness factor of 7.871units in opening mode of displacement. Hence it is the best choice in purely opening mode of displacement

Growing competition among the local and global producers is primarily leading towards expansion of advanced products to expand the dominance in the market. Substantial investments in the research and development sector for the production of efficient and innovative products is an ongoing trend in the geocomposites market

Large-scale operations, namely, One Belt and One Road, Maritime Silk Road, and Silk Road Economic Belt projects in China are anticipated to uplift the demand for geocomposites in the region over the coming years

Geotextiles exhibit a relatively wide range of volumetric flow rate per unit area across the plane of the fabric, with discharge capacity again being largely determined by attributes of the polymer strand and the manufacturing process

Asia-Pacific regional segment of the geocomposite market is expected to register itself as highest growing segment during the forecasted period, at a CAGR of 13.0%; owing it to the qualitative as well as quantitative market potential offered in developing nations such as China & India

About Us:

Our in-house experts assist our clients with advice based on their proficiency in the market that helps them in creating a compendious database for the clients. Our team offers expert insights to clients to guide them through their business ventures. We put in rigorous efforts to keep our clientele satisfied and focus on fulfilling their demands to make sure that the end-product is what they desire. We excel in diverse fields of the market and with our services extending to competitive analysis, research and development analysis, and demand estimation among others, we can help you invest your funds in the most beneficial areas for research and development.

Contact Us:

John W

Head of Business Development

Reports And Data | Web: www.reportsanddata.com

Direct Line: +1-212-710-1370

E-mail: [email protected]

0 notes

Text

North America - Polydad Mania

PolyDAAD Modular Solution and its primary product polydadmac have achieved great fame in recent years due to its wide range of applications and amazing performance. This is a state of the art tool that enables custom-made components for electronic systems to be developed and produced by companies of any size. The polydad modules are modular and have the ability to integrate themselves into the existing manufacturing process without any additional work.

The polydadmac Industry Research study, conducted by CAGR, a French company specializes in polydad enclosures and other poly-related technologies, provides deep insight into the poly-DAAD Market covering almost all the key aspects of this unique market. The report also provides forecast details over the next five years, giving a clear picture of how polydadmac is likely to evolve in the next five years. The analysis covers key issues such as market evolution, key competitors, market share, cost structure, sales growth, geographic expansion, and future outlook. The full scope of the research covers various poly-related technologies from polyvinyl chloride to polypropylene to polyiodide-based thermoplastics. It also covers the automotive, industrial, commercial, and residential segments.

The market growth of polydadmac is very fast due to the high demand in the industrial, commercial, and residential segments of the paper industry. With polydadmac installations, companies can generate environmentally sound waste water treatment solutions and at the same time generate electricity and increase productivity. Many environmental organizations have welcomed polydadmac with open arms due to the many advantages it offers. The advantages include fiber-based paper, which can reduce the usage of trees and also helps in reducing the harmful effects caused by non-fiber-based papers. It is used in refrigerators, paper mills, pulp mills, and other manufacturing plants for its ability to withstand moisture, heat, chemicals, and fire.

The polydadmac market has been the subject of intense research and development by many companies, both Asian and European based. Leading companies such as Omaxe and Tetra have been working on new polyadammaforming methods and products for quite some time. The polyadammaforming methodologies involve injecting polystyrene pellets into molds. The polystyrene is then allowed to cool and solidify. The solidified polystyrene is then shaped into sheets and the sheets are used for a variety of products including building insulation, automobile bumpers, oilfield linings, and oilfield firefighting.

As discussed above, polydadmac offers a number of advantages that contribute to its broad and diversified applications across a number of applications. In addition, polydadmac has several key regional advantages, as discussed below. The polydadmac market is concentrated in two locations: in the United States and in Mexico. While the polydadmac supply base in the United States is limited by the physical infrastructure of the country, it is fairly widespread across the United States. This gives polydadmac an advantage over competitors in other countries due to the relatively low barriers to entry for the supply chain in the United States.

The polydadmac market segment in Mexico is also limited by infrastructure constraints. This means that there are not nearly the same amount of manufacturers in Mexico that have access to polydadmac. The lack of international shipping opportunities contributes to the relatively high price of polydadmac in Mexico compared to the cost of polydadmac produced in the United States. This price differential is most notable when comparing the cost of polydadmac imported from the United States to polydadmac produced domestically in Mexico. While imports of polydadmac from the United States have historically always been considerably cheaper than the cost of domestically produced polydadmac, recent fluctuations in the price of imported polydadmac indicate that this differential may be changing rapidly in the near future.

Polydadmacs are also competitive in several different price points. While they typically start at about a 20% premium over domestically produced polydadmac, they can vary widely in price once shipping and delivery costs are factored in. They are competitive in their premium over the leading brands in the polydad marketplace, but their relative lack of differentiation gives them a difficult challenge to gain market share in regions where they do not already have a significant customer concentration or presence. Many retailers believe that the segment will continue to expand as the polydadmac business continues to mature and acquire more retailers. In many regions, polydadmac is considered to be on the cusp of being "too small to compete" in the next few years.

As discussed above, polydadmac is currently seeing growth in the United States but is relatively slow to catch up to its competitors in the rest of the world. This is due primarily to lower pricing in the U.S., an absence of significant marketing budgets in some regions and poor visibility on store shelves. Due to these factors, polydadmac in the major regions of north America will continue to grow at a slower pace until the coming of more competitive retailers with better marketing budgets. This will allow for an eventual battle between these companies for sales in future years. For now, polydadmac in the United States are profitable and poised to continue growing in the coming years.

Summary

Further key aspects of the report indicate that:

Chapter 1: Research Scope: Product Definition, Type, End-Use & Methodology

Chapter 2: Global Industry Summary

Chapter 3: Market Dynamics

Chapter 4: Global Market Segmentation by region, type and End-Use

Chapter 5: North America Market Segmentation by region, type and End-Use

Chapter 6: Europe Market Segmentation by region, type and End-Use

Chapter 7: Asia-Pacific Market Segmentation by region, type and End-Use

Chapter 8: South America Market Segmentation by region, type and End-Use

Chapter 9: Middle East and Africa Market Segmentation by region, type and End-Use.

Chapter 10: Market Competition by Companies

Chapter 11: Market forecast and environment forecast.

Chapter 12: Industry Summary.

The global PolyDADMAC market has the potential to grow with xx million USD with growing CAGR in the forecast period from 2021f to 2026f. Factors driving the market for @@@@@ are the significant development of demand and improvement of COVID-19 and geo-economics.

Based on the type of product, the global PolyDADMAC market segmented into

Transformers

Switchgear

Others

Based on the end-use, the global PolyDADMAC market classified into

Electric Utilities

Others

Based on geography, the global PolyDADMAC market segmented into

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of Middle East and Africa]

And the major players included in the report are

ABB

Siemens

Schneider Electric

Hitachi

Alstom

Crompton Greaves

Eaton

BHEL

GE

HYOSUNG

China XD Group

Toshiba

TBEA

Mitsubishi Electric

Shanghai Electric

Baoding Tianwei Group Tebian Electric

SPX Transformer Solutions

Fuji Electric

PolyDADMAC Market report offers great insights of the market and consumer data and their interpretation through various figures and graphs. Report has embedded global market and regional market deep analysis through various research methodologies. The report also offers great competitor analysis of the industries and highlights the key aspect of their business like success stories, market development and growth rate.

Polycarbonates Market

Polycarbonate Diol Market

Polybutene-1 Market

Polyalumnium Chloride Market

Contact us: https://www.reportmines.com/contact-us.php

0 notes

Text

What is the Frac Sand Industry ?

What is the Frac Sand Industry ?

The latest trend in the frac sand industry is the development of online web-based tools for frac sand marketing. These frac sand Marketing tools are a combination of online software, frac sand models, videos, frac sand drawing sheets, as well as from sand supply lists. One can easily learn from sand modeling techniques through frac sand market analysis, which is essentially a form of market research that aids in establishing new frac sand marketing strategies. frac sand market trend analysis provides essential information about frac sand usage and its various benefits.

For a frac sand Industry Association (FRA) to continue its strong and increasing presence on the market, it is important that the frac sand Industry Association provides the frac sand model that meets the requirements and preferences of various organizations in the frac sand Industry. The various frac sand industry organizations include: frac sand retailers, frac sand manufacturers, chemical manufacturers, importers and suppliers, as well as government and non-profit organizations. This paper discusses the market share that each business has on the market and frac sand trend analysis.

According to the most recent studies from sand industry analysts forecasted that frac sand will continue to grow steadily in the coming years. This is attributed to the growing demand for frac sand among users. These users are reported to be looking at frac sand for industrial, residential and commercial applications. Furthermore, frac sand is used for pumping and wastewater treatment facilities, mines, and other industries including those found at sea. As a result, frac sand market is expected to be a large one.

Current frac sand market trends show that demand for frac sand in the frac sand industry is growing rapidly. Various products in the frac sand market include: sand, gravels, coagulants, pigments, fillers, additives, grading solutions, surfactants, lubricants, as well as the various chemical frac sand additives. The price of frac sand can be competitively addressed by varying suppliers at different prices. With more manufacturers entering the frac sand market, competition has been increasing, leading to frac sand products becoming more efficient, durable, cost-effective and environmentally sound.

As per the records, the frac sand industry is believed to have entered a recession, with new projects canceled and workers laid off. However, it is not possible to draw any conclusion on this aspect, considering the fact that the frac sand market is dynamic and very unpredictable. Based on the above, it is believed that the frac sand market will experience long-term growth. It is projected that sand will emerge from a recession to grow in the coming years at a fast and steady rate.

In addition, the frac sand market is becoming an attractive investment opportunity for both private individuals and organizations. With the frac sand industry expanding its footprint in several countries, it is gaining enough popularity for businesses and individuals to invest. These businesses and individuals are looking forward to the frac sand supply, which is expected to grow in the coming years. Moreover, it is also a good opportunity to earn profits while indulging in a rewarding activity.

One can find sand in various forms including granular, fine aggregate, loose powder, in-situ sand and high-solids. As far as the usage is concerned, frac sand is used in the fields of construction and industry. In addition, it can be used to generate electricity at power plants. In addition, frac sand is used in mining, frac sand is also considered to be a potential energy alternative. Other uses of frac sand include in the lubricating of bearings, in the rejection of turbine blades, in the lubrication of moving parts in engines, etc.

To sum it all up, frac sand market is a dynamic one and is not only confined to the frac sand sector alone. It is widely known that there is a frac sand market boom in Australia, frac sand is also very much in demand in China and in the Middle East. It is an interesting fact that most of the people are unaware of frac sand and the benefits it offers. In order to grab a share in the frac sand market, you should be aware of frac sand and its uses.

Summary

Further key aspects of the report indicate that:

Chapter 1: Research Scope: Product Definition, Type, End-Use & Methodology

Chapter 2: Global Industry Summary

Chapter 3: Market Dynamics

Chapter 4: Global Market Segmentation by region, type and End-Use

Chapter 5: North America Market Segmentation by region, type and End-Use

Chapter 6: Europe Market Segmentation by region, type and End-Use

Chapter 7: Asia-Pacific Market Segmentation by region, type and End-Use

Chapter 8: South America Market Segmentation by region, type and End-Use

Chapter 9: Middle East and Africa Market Segmentation by region, type and End-Use.

Chapter 10: Market Competition by Companies

Chapter 11: Market forecast and environment forecast.

Chapter 12: Industry Summary.

The global Frac Sand market has the potential to grow with xx million USD with growing CAGR in the forecast period from 2021f to 2026f. Factors driving the market for @@@@@ are the significant development of demand and improvement of COVID-19 and geo-economics.

Based on the type of product, the global Frac Sand market segmented into

Northern White Sand

Brown (Brady) Sand

Others

Based on the end-use, the global Frac Sand market classified into

Oil Exploitation

Natural Gas Exploration

Based on geography, the global Frac Sand market segmented into

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of Middle East and Africa]

And the major players included in the report are

U.S Silica

Fairmount Santrol

Preferred Sands

Badger Mining Corporation

Unimin Corporation

Chieftain Sand

Emerge Energy Services LP

Carbo Ceramics

Hi-Crush Partners LP

Smart Sand Inc.

Chongqing Changjiang

Contact us - https://www.reportmines.com/contact-us.php

0 notes

Text

What Are The Properties of Fluoropolymer ?

What Are The Properties of Fluoropolymer ?

Fluoropolymer is an amazing polymer with many varied uses in industries. In dentistry, it plays a role of curing tooth decay and gum disease, and also prevents tooth sensitivity. In food processing, it prevents food from spoiling, preserves raw foods, aids in the removal of protein from meat and dairy products, and adds flavor and color to products. There are several uses of Fluoropolymer, and almost all industries that use Fluoropolymer can see great performance benefits.

Fluoropolymer materials are widely used for packaging and other industries, because it is highly flexible, easy to use, and safe. The high performance fluoropolymers can be made into all shapes and sizes without sacrificing strength, as well as providing flexibility and durability. There are many advantages associated with Fluoropolymer materials. They are flexible, which means they can be cut to almost any shape, while the polymers are strong and have excellent chemical and physical properties. Additionally, Fluoropolymer provides a great degree of resistance to a wide range of chemicals and acids.

Fluoropolymer has been shown to be useful in a number of industries. With the use of high pressure manufacturing methods, the high performance polymers can be made into sheets that are stronger, lighter, more durable, and much more affordable than comparable materials. These superior products have an array of applications and can be found in a wide range of industries. These include pharmaceuticals, where Fluoropolymer sheets are commonly used as probes and in injectables, such as medication droplets. In addition, the polymers are also being utilized as packaging materials, such as in bubble wraps and packaging tape.

The material has also shown promise as protective coatings for a variety of nonporous surfaces. It is effective in preventing damage from chemicals and acids, as well as from ultraviolet light, and it can also reduce cracking and warping of many materials, including metals and concrete. It has also been found to be effective as an antimicrobial, meaning it repels and destroys bacteria. Additionally, Fluoropolymer can also provide a protective shield against radiation, meaning it is useful in the aerospace industry.

Fluoropolymer has also been found useful in other manufacturing processes, including in the production of plastic, rubber, paper, and textiles. The material can also be found in many medical and dental applications, particularly as a white blood cell generator. As Fluoropolymer's ability to create a protective layer between tissues has been enhanced, this material has been found to be helpful in treating and preventing a host of painful medical conditions, such as allergies, asthma, eczema, boils, bone cancer, and even psoriasis and psoriatic arthritis.

As Fluoropolymer's benefits have been realized by the manufacturing industry, the material has begun to find its way into many other areas of science and industry. Fluoropolymer has recently found application in the fields of electronics, medicine, and biotechnology. The material has also been used in a variety of packaging materials, such as polyethylene (PE), polystyrene (PS), and polycarbonate (PC). Furthermore, Fluoropolymer's versatility makes it a very valuable commodity in the real estate and gardening industries.

Polymer technology is also responsible for the creation of many new varieties of plastics that are much more durable and flexible than their predecessors. These materials are particularly suited for use in a range of the consumer product market, including food and beverage packaging, cushions, fabrics, and packaging. As Fluoropolymer's strength and flexibility continue to improve, it is certain to find a number of applications in numerous industries. Additionally, Fluoropolymer has led to the development of a number of advanced materials that have even greater utility, including anti-freeze and diesel fuels.

In addition to being versatile, Fluoropolymer has an impressive number of advantages over most man-made materials. The material is extremely elastic, capable of quickly and easily expanding to accommodate any size demand placed on it. Additionally, it has high wear resistance and high tensile strength, which make it ideal for a wide range of applications. Fluoropolymer has no scale structure, so it does not require any extra support or alignment, which allows it to be applied to a wide variety of surfaces. Finally, the material is highly resistant to the influence of weather, making it safe to use in a wide range of venues and conditions. These unique properties make Fluoropolymer a clear choice for a large number of applications.

Summary

Further key aspects of the report indicate that:

Chapter 1: Research Scope: Product Definition, Type, End-Use & Methodology

Chapter 2: Global Industry Summary

Chapter 3: Market Dynamics

Chapter 4: Global Market Segmentation by region, type and End-Use

Chapter 5: North America Market Segmentation by region, type and End-Use

Chapter 6: Europe Market Segmentation by region, type and End-Use

Chapter 7: Asia-Pacific Market Segmentation by region, type and End-Use

Chapter 8: South America Market Segmentation by region, type and End-Use

Chapter 9: Middle East and Africa Market Segmentation by region, type and End-Use.

Chapter 10: Market Competition by Companies

Chapter 11: Market forecast and environment forecast.

Chapter 12: Industry Summary.

The global Fluoropolymer Materials market has the potential to grow with xx million USD with growing CAGR in the forecast period from 2021f to 2026f. Factors driving the market for @@@@@ are the significant development of demand and improvement of COVID-19 and geo-economics.

Based on the type of product, the global Fluoropolymer Materials market segmented into

Polyvinyl Fluoride

Fluoroelastomers

Fluoroinated Ethylene Propylene

Others

Based on the end-use, the global Fluoropolymer Materials market classified into

Automotive & Transportation

Chemical Processing

Electricals & Electronics

Industrial

Others

Based on geography, the global Fluoropolymer Materials market segmented into

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of Middle East and Africa]

And the major players included in the report are

Daikin Industries

Solvay

Arkema

Dongyue Group

Halopolymer OJSC

Kureha Corp

Ei Dupor De Nemours

Asahi

3M

Gujarat Fluorochemicals

Honeywell International

Saint-Gobain

Fuxin Heng Tong Fluorine Chemicals

Whitford

Shanghai 3F New Material

Contact us - https://www.reportmines.com/contact-us.php

0 notes

Text

IITB Monash PhD Program 2021 – Online Applications Invited

New Post has been published on https://biotechtimes.org/2021/02/04/iitb-monash-phd-program-2021-online-applications-invited/

IITB Monash PhD Program 2021 – Online Applications Invited

IITB Monash PhD Program 2021

IITB Monash PhD Program 2021 – Applications Invited. IITB Monash Research Academy has announced PhD Program admissions for the year 2021. Interested and eligible candidates can check out Application Requirements, Research Projects, Fees Structure. Scholarship, How to Apply, and Last Date below.

Ph.D. Program Outline

The Research Academy, co-located at IIT Bombay in Mumbai, India, will host candidates enrolled in the joint IITB-Monash PhD 2021 program.

It takes an average of 3.5 years of full-time research to complete the PhD program (or part-time equivalent). Students will spend a minimum of 3 months with their appointed co-supervisor, but usually 6-12 months* of their PhD candidacy at Monash University in Australia. To encourage this experience, students will be given a generous grant.

Students will be associated to the student body of IIT Bombay and will be entitled for on-campus student housing. In addition to being supervised on their PhD studies, opportunities for professional development including research methods and preparation for research leadership will also be offered to students.

*Depending on the study conditions, the amount of time spent at Monash University can be longer.

Research Projects

In a team-based approach, the study will be performed. The Academy’s study would be very multi-disciplinary, enabling discoveries to be made at the interface between disciplines.

The aim of the Academy is to organize research into categories of issues that seek to address a main research topic or sector target.

Eight key themes for research have been identified:

Advanced Computational Engineering, Simulation and Manufacture

Infrastructure Engineering

Clean Energy

Water

Nanotechnology

Biotechnology and Stem Cell Research

Humanities and Social Sciences

Design

Application Requirements

Outstanding candidates whose planned area of study is aligned with the IITB-Monash Research Academy’s research priorities are encouraged to apply for a joint Doctoral program.

The minimum entry criteria for admission to the PhD are:

First-class or equivalent Master’s degree in a range of disciplines

First-class Bachelor’s degree and a valid GATE score

Fulfilling Monash University’s academic qualification criteria and English language proficiency.

For Admission criteria

For English language proficiency

NOTE: Candidates without a valid GATE score or research fellowship can be considered for admission if they have a minimum of two years of professional experience. Competition for places is high and a competitive selection process is applied to all applicants.

Scholarships

Students in the joint IITB-Monash Ph.D. program will benefit from the following funding arrangements:

Rs 4,20,000 per annum scholarship for the first two years

Rs 4,68,000 per annum after first two years

A grant of up to A$29,000 per annum in Australia

A minimum of one year in Australia working with your Monash University co-supervisor (some projects may require you to be in Australia for a longer period of time or undertake more than one trip), Waiver of international student tuition fees at Monash University.

NOTE: The above-mentioned figures are of a typical scholarship. The actual scholarships that will be awarded to a specific student will depend on their qualifications, marks and performance.

How to Apply

For Ph.D. candidates

Expression of Interest, applications are open. The last date for submission is 7 March.

Step 1: EOI

The first step of the admissions process is the Expression of Interest (EOI) stage. In this stage, candidates fill in an EOI form Online.

Please click on the Expression of Interest (EOI) form to enable us to adequately evaluate your background, academic record and research interests. If your EOI form is found to be suitable, you will receive an email indicating you are able to proceed to Step 2 of the application stage.

If your EOI Form is found to be suitable, you will need to download and complete the full application form, Form A. Candidates who are successful in this EOI stage will be invited to go Step-2 once the EOI stage is completed. Contained in this invitation email will be a unique Form A Number (FAN). This email will be sent only after the EOI stage is completed

Step 2: Form A

If your EOI form is found to be suitable, you will be notified via email and you will receive a unique FAN number. You need the FAN number to upload your Form-A online. At this stage you will need to upload your transcripts, publications, certificates, etc and make project selections too. For logging in to the Form A site, use your unique Form A Number (FAN). Do not give this FAN to anyone else. It is for your use only. Moreover, you can use your FAN only once. At the site, you will need to upload your Form A as well as copies of all of your academic transcripts, publications GATE score sheet, and other supporting documentation. Remember again that you will only have one opportunity to use your FAN to login to the site to upload all of your documentation related to the applications-process.

It will therefore be best if you collect all the documentation relating to your application before you visit the site.

Research Clusters

The Academy has made a bunch of clusters to better describe the submitted research projects. This will help in a more structured hiring process for students and other benefits in categorizing the research undertaken at The Academy.

Material Science/Engineering (including Nano, Metallurgy)

Energy, Green Chem, Chemistry, Catalysis, Reaction Eng

Math, CFD, Modelling, Manufacturing

CSE, IT, Optimisation, Data, Sensors, Systems, Signal Processing, Control

Earth Sciences and Civil Engineering (Geo, Water, Climate)

Bio, Stem Cells, Bio Chem, Pharma, Food

Semi-Conductors, Optics, Photonics, Networks, Telecomm, Power Eng

Design, HSS, Management

Step 3: Short-listing for Interview

If your Form-A is found to be suitable, you will be notified via email and you will receive an interview invitation. The Interview short-list will be announced only after the Form-A stage is complete.

Step 4: Interviews and Successful Candidates

After the interviews, successful candidates will be notified by email..

In case you have any doubts, please read the Applications Process FAQ before sending your doubts to [email protected]. We will not respond to queries that have already been adequately answered in the FAQ document.

The last date for submission is 7 March.

Apply Online

0 notes

Link

#LDPE Sheet Manufacturer#Geomembrane Sheet#HDPE Plastic Sheet#LDPE Sheet#HDPE Sheet#Canal Lining Sheet Suppliers

0 notes

Photo

PP Woven Geotextiles Manufacturer are made from Polypropylene or high tenacity polyester yarns. These woven geotextile fabrics individual extruded yarns are then twisted together. These twisted yarns are then woven together to provide relative dimensional stability to each other and form a geotextile.

For more details contact us on 99255 01713 or Visit us @ https://geosyntheticindia.com/

#Geogrid Manufacturers in India#Needle Punched Non Woven Geotextile#PP Woven Geotextiles Manufacturer#Non Woven Fabric Geotextile#Non Woven Geo Fabric Sheet#Non Woven Geotextile Manufacturers#Non Woven Polypropylene Geotextile Fabric#Non-Woven Geotextile Fabric

0 notes

Text

GEOCOMPOSITES MARKET ANALYSIS

Geocomposites Market, by Primary Function (Separation, Filtration, Drainage, and Containment), by Product Type (Geotextile-geonet, Geotextile-geomebrane, Geomebrane-geogrid, Geotextile-geogrid, Geotextile / Polymer-core), by Application (Road Construction, Railways, Dams / Riverbanks / Waterworks, Landfill & Erosion Control, and Others), and by Region (North America, Latin America, Europe, Asia Pacific, and Middle East & Africa) – Size, Share, Outlook, and Opportunity Analysis, 2019 – 2027

Request Sample

https://www.coherentmarketinsights.com/insight/request-sample/2585

A material containing at least one layer of geosynthetic products (polymeric products) such as geogrid, geomembrane, geotextile, and others, with another material (e.g. steel cables, deformed plastic sheets or steel anchors) is known as geocomposite. Geocomposites find application in structural fill, bridge abutment, tunnel and construction repair of existing tunnel, lightweight void fill, metro underground stations, railway tunnels, and others. Geotextiles-geogrid geocomposites are used to provide reinforcement and stabilization under railway tracks. Moreover, these are used as a sub-grade, providing lateral drainage system and filter separator between ballast.

Download PDF

https://www.coherentmarketinsights.com/insight/request-pdf/2585

Market Dynamics:-

Geocomposites find application in roadways such as drainage, filtration, reinforcement, and separation. Geocomposites are used to enhance the stability and strength of underlying soil in roadways. Among product type, geotextiles-geogrid geocomposites are the most preferred geosynthetics used in highway and road application. Geocomposites are cost-effective and enhances road life. Significant growth in the construction segment is expected to drive growth of the geocomposites market during the forecast period. For instance, the Government of India has set a target to construct 10,000 km national highway in 2019 from 9,829 km in 2018 and also total of 200,000 km national highways are expected to complete by 2022. According to India Brand Equity Foundation, Government of India set a target to complete 300 highway projects by March 2019. The total amount of investment is expected to be US$ 2.25 billion in 2019.

Market Outlook:-

Asia Pacific is expected to be the fastest growing region in the geocomposites market during the forecast period. This is owing to increasing construction and infrastructure activities in emerging countries such as India and China. Growing infrastructure activities in the region is a major driver for growth of the geocomposites market as these act as a cost-effective alternative in various applications. Therefore, significant growth in construction & infrastructural projects and supportive government policies and increasing environmental protection regulations is expected to boost the geocomposites market growth over the forecast period in Asia Pacific. For instance, according to the National Bureau of Statistics of China, the total investment in real estate development in 2018 was US$ 1,749 billion from US$ 1,308 billion in 2017.

Key Players:-

Major players operating in the global geocomposites market include, GSE Environmental, Officine Maccaferri Spa, Huesker Synthetics GmbH, Thrace Group, SKAPS Industries, Leggett & Platt, Inc., Hans Geo Components, TenCate Geosynthetics, ABG Ltd, ABG Ltd, Terram Geosynthetics Pvt. Ltd., Tenax, and HUESKER Inc.

Market Taxonomy:-

On the basis of primary function, the global geocomposites market can be segmented as:

Separation

Filtration

Drainage

Containment

On the basis of product type, the global geocomposites market can be segmented as:

Geotextile - geonet composite

Geotextile – geomembrane composite

Geomembrane – geogrid composite

Geotextile – geogrid composites

Geotextile/polymer – core composites

On the basis of application, the global geocomposites market can be segmented as:

Road construction

Railways

Dams, Riverbanks, Waterworks

Landfill & Erosion Control

Others

On the basis of region, the global geocomposites market can be segmented as:

North America

Europe

Latin America

Asia Pacific

Middle East & Africa

U.S.

Canada

Mexico

U.K.

Germany

Italy

France

Spain

Russia

Rest of Europe

Brazil

Argentina

Rest of Latin America

China

India

Japan

South Korea

ASEAN

Australia

Rest of Asia Pacific

Talk to analyst

https://www.coherentmarketinsights.com/insight/talk-to-analyst/2585

Geocomposites Market Key Developments:

In December 2018, Southern Geosynthetics Supplies Pty. Ltd introduced new geomembrane. The new DG200 is a 0.8mm polyvinyl chloride (PVC) geomembrane bonded on either side with 200 gsm nonwoven geotextile. This composite provides geomembrane with high puncture as well as tear resistance, and high surface friction, coupled with the greater flexibility and durability of PVC.

In March 2019, TENAX SPA, an Italy based advanced materials company, introduced new geocomposite, ‘GRAVEL LOCK’. This new geocomposite has rolls of 1.50×20 m which are synthesized with cuspated high density polyethylene (HDPE) grid along with a polypropylene non-woven fabric which can be used for retaining gravel. GRAVEL LOCK is expected to an effective, durable, and economical solution which can be used as a stable gravel floor for pedestrian and vehicular passage.

In June 2019, Groupe Solmax Inc, a company based in Canada which is engaged in development of polyethylene geomembrane, announced its plans to expand its operations in U.S. For this expansion, a new geosynthetics manufacturing facility will be established in Nevada, Western U.S. which is expected to be operational by mid of 2020.

About Us:

Coherent Market Insights is a global market intelligence and consulting organization focused on assisting our plethora of clients achieve transformational growth by helping them make critical business decisions.

What we provide:

Customized Market Research Services

Industry Analysis Services

Business Consulting Services

Market Intelligence Services

Long term Engagement Model

Country Specific Analysis

Contact Us:

Mr. Shah

Coherent Market Insights Pvt. Ltd.

Address: 1001 4th ave, #3200 Seattle, WA 98154, U.S.

Phone: +1-206-701-6702

Email: [email protected]

Source

https://www.coherentmarketinsights.com/ongoing-insight/geocomposites-market-2585

0 notes