#Non Woven Geotextile Manufacturers

Text

NON-WOVEN GEOTEXTILE

Nonwoven geotextiles are produced with regular filament yarn or short-staple fiber. The fibers are joined by chemical, thermal-mechanical, mechanical, or any combination of these techniques. The thickness of ground fibers created through mechanical interlocking and thermal bonding ranges from 0.5-1 millimeter. The chemically-bonded nonwoven is approximately around 3 millimeters.

It is a new technology in high-tech processes in which filaments or synthetic polymer fibers are extruded continuously and laid in moving conveyor belts. The mass of fibers or filaments are needle punched where filaments are mechanically bound through a set of tiny needles that allow fibers to be connected by heat or pressure at the point of contact within an unwoven mass.

0 notes

Photo

PP Woven Geotextiles Manufacturer are made from Polypropylene or high tenacity polyester yarns. These woven geotextile fabrics individual extruded yarns are then twisted together. These twisted yarns are then woven together to provide relative dimensional stability to each other and form a geotextile.

For more details contact us on 99255 01713 or Visit us @ https://geosyntheticindia.com/

#Geogrid Manufacturers in India#Needle Punched Non Woven Geotextile#PP Woven Geotextiles Manufacturer#Non Woven Fabric Geotextile#Non Woven Geo Fabric Sheet#Non Woven Geotextile Manufacturers#Non Woven Polypropylene Geotextile Fabric#Non-Woven Geotextile Fabric

0 notes

Text

Finding Geotextile Fabric Manufacturers in India?

Shankar Pack is one of the largest PP Geotextiles manufacturers in India. We provide high-strength polypropylene is widely used to filter, stabilize, reinforce, separate, drain, and isolate soils in geotextile manufacturers categories of civil construction applications, our products are quality tested on various parameters to ensure compliance with international industrial standards.

#pp woven geotextiles#pp non woven geotextile#plastic polyethylene sheeting#geotextile manufacturers#non woven geotextile suppliers#non woven geotextile fabric manufacturers#geotextile fabric suppliers#woven geotextile manufacturers in india#geotextile fabric manufacturers in india#geotextile fabric manufacturers in gujarat

0 notes

Text

The Benefits of Using Geotextile Fabric for Waterproofing!

Shankar Techx is a leading geotextile manufacturers in India. We offer 5 Common Types of Geotextile Fabric for Waterproofing. Like; Non woven geotextile, woven geotextile, Composite geotextiles, etc. To know about Advantages of Using Geotextile Fabric for Waterproofing, visit our blog!

#geotextile manufacturers in India#Non woven geotextile#woven geotextile#geotextile fabric for waterproofing#fabric for waterproofing#benefits of using geotextile#geo fabric manufacturers#geotextile fabric#woven filter fabric manufacturer#ground cover suppliers

0 notes

Text

What Are the Benefits of Using Non-Woven Fabric?

The non-woven fabrics are materials that are produced by thermal, mechanical and chemical processes. These are engineered fabrics that are used in various industrial and consumer products, by itself or with other materials. It is hygroscopic, UV resistant and flame retardant.

The non-woven fabrics have various benefits, including minimising solid wastes, and landfills and releasing no pollutants in the air and soil. In this blog, we will look into the various benefits of using non-woven fabrics that make them more practical and versatile than other traditional fabrics.

What is Non Woven Fabrics?

The non woven fabric is an engineered material manufactured from different fibers. These materials need not be converted to fibres into yarn, as the fibre yarns are bonded together due to inherent friction from one fibre to another.

Benefits of Using Non Woven Fabrics

Light Weight: The pp non-woven fabrics are the primary raw material for production. Its specific gravity is only 0.09, which is ⅗ of cotton. It is super-soft and pleasant to touch.

Softness: Its softness makes it ideal for non woven fabric bags. The bags are soft and comfy.

Eco-friendly: The reason why geotextile fabric manufacturers in Gujarat are in demand for its non-woven fabrics is its eco-friendly nature. This makes it applicable in different industries. With the rising concerns over environmental consciousness and sustainability, woven materials have gained immense popularity.

Air-Permeable: The non woven bags are made of fiber that exhibits excellent air permeability. This makes it easy to clean and maintain.

Non-Toxic and Non-irritant: The non woven bag material is non-toxic, non-irritant, odourless and stable. The manufacturers use food-grade materials, which makes it ideal for industries like pharmaceutical, personal care, cosmetics and other products.

Water Resistant: The non woven fabric manufacturer in India caters to different industries that need water-repellent materials. The non woven materials are made of polypropylene chips and are non-absorbent and water resistant properties. This makes the end-product exhibit excellent breathabilty and porous.

Excellent Physical Properties: As the material is made of PP spinning directly into the mesh and thermally bonded, it gives the products exceptional strength than other fibre materials.

Uses of Non Woven Fabric

The Non Woven Fabric is Used in a Variety of Applications, Such as:

Medical: The non-woven fabrics have gained a lot of popularity, especially during the pandemic. It is widely used in the manufacturing of various medical products like gloves, masks, surgical drapes, plastic, medical packaging, cleanroom wipes, disposal face masks and more.

Health & Hygiene: The spunboud non woven material has brought an evolution in the hygiene industry. It is used in producing various hygiene products like sanitary pads, diapers, make-up wipes, nail wipes, facial pads, and other products.

Geotextile and Construction: The PP cover manufacturers provide non-woven geotextiles that are used in various applications in the construction and engineering industry. It is primarily used for drainage systems, separation, canal construction, filtration, landfill lining and others.

Household: We are surrounded by non woven geotextiles. It is a part of everyday lives, ranging from water and air filters, household wipes, floor wipes, coffee filter material and much more. Shankar Packaging Ltd. is a prominent filtration fabric manufacturer. We offer a range of filtration materials in 100% multifilament, monofilament spun and other combinations.

Conclusion

Woven fabrics are used in different industrial sectors and play a pivotal role in the technical industry globally. Its soil stability, tear and puncture resistance, UV resistance, breathability, excellent weather ability and tensile strength make it a versatile material. Shankar Packaging Ltd. is a leading geotextile manufacturer and supplier in India.

We offer a comprehensive range of technical textiles, indu-tech, geo-tech, agro-tech and pack-tech products to clients across the globe. Our geotextile is also ideal for geo tubes and geo bags. At SPL, we provide technical textiles in 3 different yarns viz PES multifilament, PP tape yarns and PPMF. To know more about geotextiles and other products, contact us.

#non woven fabric#non woven fabric bags#geotextile fabric manufacturers in Gujarat#non woven bags#non woven bag material#non woven fabric manufacturer in India#spunboud non woven material#PP cover manufacturers#filter material

0 notes

Text

Versatile Nonwoven: Fabric, Geotextile, Wallpaper & More

Explore the world of nonwoven material with our premium non woven fabric. As a leading non-woven fabric manufacturer, we offer versatile options, including non-woven geotextile and non-woven wallpaper. Elevate your projects with durable and innovative nonwoven solutions for various applications.

0 notes

Text

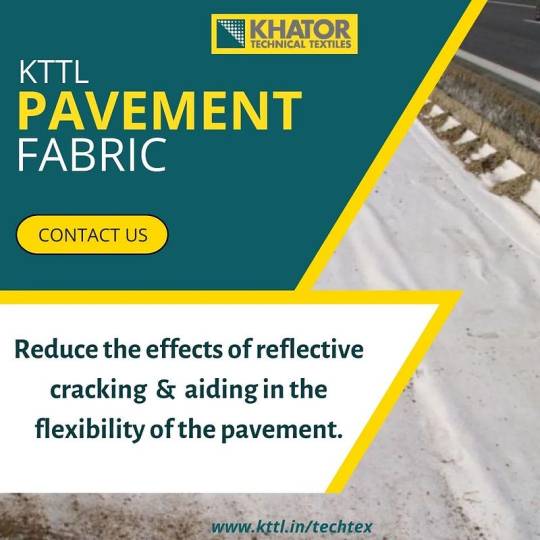

SAMI Layer Pavement Fabrics: Boost Road Durability

SAMI Layer Pavement Fabrics: Boost Road Durability

Introduction:

In the ever-evolving landscape of road construction, innovations like SAMI layer pavement fabrics are transforming the way we approach durability and longevity in infrastructure. This blog post explores the key benefits and applications of SAMI layer fabrics, shedding light on how they play a crucial role in enhancing the resilience of our roads.

Understanding SAMI Layer Pavement Fabrics:

How SAMI Layer Fabrics Boost Road Durability

SAMI layer pavement fabrics strengthen the road in multiple ways:

Crack Prevention

Acting as a barrier, the SAMI fabric inhibits cracks from appearing and spreading across the road surface. This adds years to the pavement life. The bonded fabric intercepts cracks at the surface level preventing downward propagation into the base layers.

Enhanced Structural Stability

The integration of the high-modulus SAMI layer evenly distributes traffic loads over a broader pavement area. This reduces concentrated stresses and deformations leading to pavement failures. The outcome is improved stability and strength.

All-Weather Reliability

SAMI fabrics are engineered using polymers like polyester, polyethylene or glass fibers that can withstand diverse environmental conditions from freezing winters to scorching summers. This makes roads more reliable through changing seasons.

Extended Lifespan

The collective impact of crack prevention, load distribution and weather resistance provided by SAMI layers is a significantly extended road lifespan. The surface maintains integrity for longer periods without requiring repairs and rehab.

Sustainable Construction

Applications of SAMI Layer Pavement Fabrics

Some prominent applications that highlight the benefits of SAMI layers include:

Road Rehabilitation

Applying SAMI fabrics provide an economical overlay solution for rehabilitating aged, damaged road surfaces. The fabric strengthens the existing base while providing a new wearing course.

New Road Construction

Integrating a SAMI layer into new road construction leads to more crack-resistant, durable surfacing that extends the period between overlays.

Preventing Reflective Cracking

SAMI layers serve as effective crack retarders at the interface of old and new pavement sections. This addresses reflective cracking, a common issue in road overlays.

Bridge Deck Protection

In conclusion:

SAMI layer pavement fabrics are a game-changer in the realm of road construction, offering a sustainable and effective solution for enhancing the durability of our infrastructure. As we pave the way to the future, these innovative fabrics prove to be an indispensable asset in creating roads that can withstand the test of time.

#geotextile#pavement#non woven fabrics#woven mesh fabric#pp woven bags#woven#woven fabric manufacturers#fabrics

0 notes

Text

Non-woven geotextiles are an important category of geosynthetics used across a wide range of infrastructure and construction applications. This guide provides a deep dive into what non-wovens are, their types, key properties, manufacturing processes, installation methods, advantages, applications, and more.

Introduction to Non-Woven Geotextiles

Geotextiles refer to permeable, polymeric textile materials used in contact with soil or rock in civil engineering applications. They can be woven or non-woven.

Non-woven geotextiles are made by bonding polymeric fibers together through processes like needle punching, heat bonding or resin bonding. The random arrangement of fibres produces a strong, porous and flexible material.

Geotextiles that are non-woven are better than those that are woven. They are better at filtering, draining, and cushioning, and are easier to install. In addition, they are more budget-friendly. These characteristics make non-wovens ideal for many functions like filtration, drainage, separation, and reinforcement.

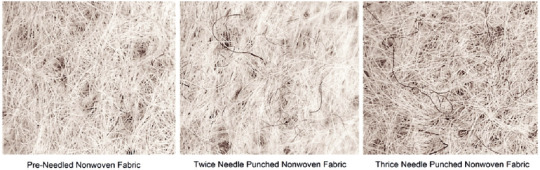

Needle Punched Non-Woven Geotextiles

Needle-punched non-wovens are a major type of non-woven geotextile produced by mechanically orienting and entangling fibers. Hundreds of fine needles repeatedly penetrate a fibre web to tangle the fibres into a strong, porous and stable fabric.

Compared to other non-wovens, needle-punched variants have high permeability and drainage capacity along with good puncture resistance. This makes them ideal for filtration and drainage applications.

Types of Needle-Punched Non-Woven Geotextiles

Needle-punched non-wovens can be categorized into three main types based on weight and fiber thickness:

Lightweight Needle Punched Wovens

Made from fine fibres and low fiber weights between 20-100 gsm. Mainly used in applications that do not require high strength.

Medium Weight Needle Punched Non Wovens

Heavier fibers and medium basis weights of 100-250 gsm. Provides moderate strength for functions like separation.

Heavyweight Needle Punched Non-Wovens

Very coarse, thick fibres and high basis weights above 250 gsm. Imparts maximum strength for reinforcement uses.

Selections depend on the target function. Non-woven fabrics can be categorized into lightweight and heavyweight variants.

Key Functions and Applications of Non-Woven Geotextiles

Non-woven geotextiles perform various functions that make them indispensable for major infrastructure and construction projects:

Filtration Applications

The porous structure allows water to pass through while blocking soil particles. This filtration ability is useful in:

Roadway drainage systems

Retaining walls

Landfill drainage

Water treatment plants

Drainage Applications

Nonwovens have high water flow rates in the principal direction. This makes them excellent for drainage purposes like:

Landfill drainage layers

Sports field drainage

Retaining wall and slope drainage

Separation Applications

The fabric physically separates dissimilar materials. Key applications include:

Roadway base and subbase separation

Railroad bed separation

Foundations separation

https://www.aakarperiwal.com/blogs/wp-content/uploads/2023/09/geotextile-500x500-3.webp

Reinforcement Applications

Non-wovens provide reinforcement for additional strength when wrapped around soil. Uses include:

Embankments over soft soils

Retaining walls with stacked blocks

Slopes requiring improved bearing capacity

Erosion Control Applications

The fabric acts as a permeable layer to protect against wind and water erosion while allowing water passage. Some uses are:

Covering slopes along railways and highways

Coastal embankments erosion control

Riverbanks and canal protection

Transportation Applications

Within road construction, non-wovens assist with filtration, separation, drainage and stabilization. Common applications:

Separation between sub-base and subgrade

Filtration in edge drains alongside pavements

Soil stabilization for improved load-bearing

Construction Applications

Foundations and walls drainage

Vapor barriers in concrete slabs

Flooring reinforcement and crack prevention

This demonstrates the versatility of non-woven geotextiles across diverse functions in C&I projects. Their adaptive properties drive widespread adoption.

Key Properties of Non-Woven Geotextiles

Non-woven geotextiles exhibit unique properties derived from their material composition, manufacturing method and overall structure:

Raw Materials

Most non-wovens use polypropylene as the raw material which is cost-effective and provides required properties. High-end variants use polyester or a polypropylene-polyester blend.

Basis Weight

Basis weight is the mass per unit area measured in g/m2. Heavier basis weights produce stronger fabrics with higher puncture resistance. Typical range is from 20 g/m2 to 300 g/m2.

Thickness

Thickness depends on fiber density and varies from 1mm to 15mm. Affects permeability, cushioning ability and separation effectiveness.

Hydraulic Properties

Non-wovens have high water permeability (normal to the plane) and adequate transmissivity. Allows swift drainage while blocking soil passage.

Mechanical Properties

Tensile strength, tear strength, puncture resistance and burst strength are key mechanical properties. Non woven selection depends on the required load capacity.

Endurance Properties

Long-term resistance against environmental exposure, chemicals, microbes and mechanical stresses comes under endurance properties. Requires proper polymer choice.

These characteristics directly impact the effectiveness and lifespan of the non-woven geotextile for its intended function.

Overview of Manufacturing Processes

Non-woven geotextile production involves specialized processes to achieve the desired fiber arrangement and properties:

Web Formation

The first step is creating a uniform web of fibres laid out in overlapping, random orientations using air, mechanical or wet-laid techniques.

Web Bonding

The fiber web undergoes thermal, chemical or mechanical bonding. This interlocks the fibres to impart strength, stability and thickness.

Finishing

Additional treatments enhance properties - for instance, calendering uses heated rollers to achieve smoothness. Fabric edges are trimmed to create rolls.

Testing and Inspection

Extensive testing under certified labs evaluates parameters like strength, permeability, opening size etc. This ensures compliance with specifications.

Keeping manufacturing consistent and monitoring variabilities is vital for non-woven quality assurance. Automation allows scalable production with minimal defects.

Design and Installation Factors for Non-Woven Geotextiles

Proper design, handling and deployment of non-wovens ensures successful project outcomes:

Site Preparation

The installation site must be graded uniformly and cleared of debris/rocks to avoid damage. Burial depth is determined. Subsurface drainage may be added.

Installation Techniques

Non wovens can be unrolled on site and placed loose or tense. Joints are sewn or bonded. Additional layers can be installed to enhance functioning. Fixings like sandbags or pegs may be used.

Seams and Overlaps

Adjoining rolls are overlapped for continuity. End overlaps depend on joint strength. Edges can be sewn, welded, glued or kept loose. Key consideration for soil retention uses.

Design Factors

Careful specifications of geotextile properties like strength, permeability, and opening size based on engineering requirements and testing. Survivability and performance lifetime also key.

Following recommended practices for non-woven deployment optimizes field performance and prevents failures.

Key Benefits and Advantages of Using Non-Woven Geotextiles

Non-woven geotextiles offer numerous benefits that make them advantageous over traditional materials:

Cost-Effectiveness

Made from polypropylene, non-wovens are an affordable alternative to CMP pipe drains or graded aggregates for drainage. Limited overlap joints also reduce the quantity required.

Rapid Drainage Performance

The high porosity provides greater flow capacity compared to sand filters or gravel layers. Useful in applications like retaining walls.

Good Puncture and Burst Resistance

The entangled fibrous structure provides better resistance against punctures during installation compared to woven geotextiles.

Ease of Installation

Flexible, lightweight non-wovens are simpler to install in field conditions compared to rigid materials. No special equipment needed.

Enhanced Properties

Specialized manufacturing processes like calendering and bonding create improved non-wovens with the right balance of filtration, separation, cushioning and strength.

Wider Widths

The ability to produce up to 5m wide rolls compared to just 1m for wovens leads to faster deployment with fewer joints.

These advantages have positioned non-wovens as a material of choice for major construction activities and geotechnical engineering applications.

Applications and Case Studies Demonstrating Non-Woven Geotextiles in Action

Non-woven geotextiles have delivered value across many real-world projects:

Landfill Construction - Needle-punched non-wovens used in leachate collection systems increased design life while reducing clogging through superior filtration compared to gravel layers.

Retaining Wall Drainage - Heat-bonded non-wovens used as wall wraps maintained water drainage and prevented soil washout, keeping 100km of critical rail walls safely stabilized through extreme weather.

Riverbank Protection - Durable non-woven wraps applied on embankments prevented erosion along highly flood-prone rivers through monsoons. Filtered runoff while retaining soil stability.

Roadway Improvement - Calendered non-wovens beneath motorway overpasses provided vital reinforcement to stabilize compressible soil while facilitating drainage and preventing pumping.

Coastal Reinforcement - Wide-width non-wovens encasing sandy coastal cliffs added shear strength and tensile reinforcement. Protected against collapse from rising sea levels and storm surges.

This demonstrates how non-wovens of different compositions can be adapted for specialized needs in infrastructure projects where performance and longevity are critical.

Industry Trends and Ongoing Innovations in Non-Woven Geotextiles

Several interesting trends, developments and innovations are shaping the non-woven geotextiles sector:

High Growth Potential - The non-wovens market is projected to grow steadily at 6% CAGR driven by major public infrastructure investments and demand from emerging economies.

Raw Material Advances - Enhanced polymers like high-density polypropylene and high-modulus polyester are creating improved non-wovens with greater functionality.

Manufacturing Improvements - Process enhancements and new techniques are allowing more fine-tuned manipulation of fiber properties during production.

Multifunctional Products - Combining non-wovens with drainage nets or reinforcing grids creates single products that provide filtration, separation and reinforcement together.

Application R&D - Ongoing research into novel uses for non-wovens like landfill caps, nuclear waste containment and offshore geotextiles to drive adoption across new domains.

Conclusion

Non-woven geotextiles have become an indispensable resource for civil engineering and infrastructure applications where their high permeability, strength, and versatility can enhance project outcomes and lifespan.

As materials and manufacturing continue evolving, non-wovens are poised to meet more specialized demands. With a thorough understanding of their capabilities, civil engineers can apply these adaptable fabrics for a sustainable future.

0 notes

Text

Exploring the Advancements in Textile Manufacturing: How Companies are Innovating the Industry

The textile industry is constantly evolving and advancing, and textile manufacturing companies are at the forefront of these changes. One area in which we are seeing significant innovation is in the production of woven fabrics. Woven fabrics, which are made by interlacing two sets of yarns or threads at right angles to each other, are used in a wide variety of products, including clothing, home furnishings, and industrial products.

One of the most exciting developments in the world of woven fabrics is the use of new and advanced weaving technologies. These technologies allow manufacturers to create fabrics with unprecedented levels of precision and control, resulting in fabrics that are stronger, more durable, and more consistent in quality.

One example of these new technologies is the use of computer-controlled looms. These looms, which are operated by computers, can be programmed to create a wide variety of patterns and designs, allowing manufacturers to produce fabrics that are truly unique and customized to their customers' needs. This technology also enables textile manufacturing companies to produce fabrics at a much faster rate, increasing productivity and efficiency.

Another area in which textile manufacturing companies are innovating is in the use of sustainable and eco-friendly materials. Many companies are now using natural fibers like cotton and linen, as well as synthetic fibers made from recycled materials, in their woven fabrics. This not only helps to reduce waste and conserve resources, but it also allows manufacturers to create fabrics that are kinder to the environment.

Finally, textile manufacturing companies are also exploring new ways to use technology to improve the overall supply chain of textile manufacturing. The use of automation in textile manufacturing process has enabled companies to increase efficiency, improve quality control and reduce costs.

In conclusion, the textile industry is constantly evolving and textile manufacturing companies are at the forefront of these changes. From new weaving technologies to sustainable materials, textile manufacturers are finding new and exciting ways to innovate and improve the products they produce. This is an exciting time for the textile industry, and we can expect to see even more advancements in the future.

Kabadi Shankarsa is one of the leading textile manufacturers in India. Upgrade your textile production with our state-of-the-art manufacturing equipment. Our machines are designed to increase efficiency and reduce waste, resulting in cost savings for your business.

Don't miss out on this opportunity to take your textile manufacturing to the next level. Contact us today to schedule a consultation and see how we can improve your bottom line.

#fabric manufacturers#textile manufacturing companies#embroidered fashion fabrics#textile manufacturers#silk scarves for women#non woven fabric manufacturer#woven cotton fabric#sustainable fabric suppliers#woven geotextile fabric#automotive fabric suppliers#polyester woven fabric#organic fabric suppliers

1 note

·

View note

Text

Non Woven Fabric Prices Trend, Pricing, Database, News, Index, Chart, Forecast

Non Woven Fabric Prices have become increasingly integral in various industries due to their versatility and cost-effectiveness. These fabrics are manufactured using short and long fibers bonded together by mechanical, chemical, or thermal processes, rather than weaving or knitting. The absence of interlacing yarns distinguishes them from traditional textiles, making them suitable for diverse applications such as medical, automotive, construction, and hygiene products.

One of the primary factors influencing non-woven fabric prices is the raw material used in their production. Polypropylene, polyester, and viscose are among the most commonly used materials, each varying in cost and performance characteristics. Polypropylene, for instance, is favored for its affordability and resistance to moisture, making it ideal for disposable products like face masks and surgical gowns. Polyester, on the other hand, offers durability and strength, often used in geotextiles and automotive components. The choice of raw material significantly impacts the final cost of non-woven fabrics, reflecting market fluctuations in petroleum-derived products.

Manufacturing processes also play a crucial role in determining non-woven fabric prices. Techniques such as spunbonding, meltblowing, and needle punching each have distinct advantages in terms of strength, texture, and permeability. Spunbonded fabrics, produced by extruding continuous filaments onto a conveyor belt, offer uniformity and strength at a competitive price point. Meltblown fabrics, known for their fine fibers and efficient filtration properties, are relatively more expensive due to intricate production processes involving high-temperature extrusion. Needle punching, involving mechanical entanglement of fibers, is favored for its versatility in applications requiring enhanced thickness and insulation.

Get Real Time Prices of Non Woven Fabric: https://www.chemanalyst.com/Pricing-data/non-woven-fabric-1089

Market demand and supply dynamics heavily influence non-woven fabric pricing. The COVID-19 pandemic, for instance, sparked unprecedented demand for medical-grade non-wovens, resulting in price spikes driven by supply chain disruptions and increased production costs. Conversely, fluctuations in crude oil prices impact the cost of raw materials used in non-woven fabric production, influencing pricing trends across industries. Global trade dynamics, tariffs, and geopolitical factors further contribute to price volatility, necessitating strategic sourcing and pricing strategies by manufacturers and end-users alike.

Quality standards and certifications also impact non-woven fabric pricing. Products meeting stringent regulatory requirements for safety, hygiene, and environmental sustainability command higher prices due to increased production costs associated with compliance and certification processes. Manufacturers investing in research and development to enhance product performance or develop eco-friendly alternatives may also reflect these expenditures in pricing, targeting discerning consumers seeking reliability and environmental stewardship in their purchasing decisions.

Geographical factors and regional market conditions further shape non-woven fabric pricing. Production costs, labor wages, and energy expenses vary across countries, influencing manufacturers' pricing strategies to remain competitive in global markets. Proximity to raw material sources and transportation infrastructure also impact operational efficiencies and cost structures, contributing to price differentials observed in international trade of non-woven fabrics.

Technological advancements continue to drive innovation in non-woven fabric production, influencing pricing trends through improved efficiencies and material utilization. Automation and digitalization in manufacturing processes reduce labor costs and enhance product consistency, potentially lowering overall production costs and subsequently affecting market pricing dynamics. Investments in sustainable manufacturing practices, such as recycling and waste reduction initiatives, may also influence pricing strategies, appealing to environmentally conscious consumers and regulatory requirements focused on carbon footprint reduction.

In conclusion, non-woven fabric prices are influenced by a complex interplay of factors ranging from raw material costs and manufacturing processes to market dynamics and regulatory requirements. Understanding these factors is essential for industry stakeholders seeking to navigate pricing volatility, optimize supply chain efficiencies, and capitalize on emerging opportunities in diverse application sectors. As demand for lightweight, durable, and cost-effective materials continues to grow across global markets, non-woven fabrics are poised to play an increasingly pivotal role in shaping future industrial and consumer landscapes.

Get Real Time Prices of Non Woven Fabric: https://www.chemanalyst.com/Pricing-data/non-woven-fabric-1089

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Non Woven Fabric#Non Woven Fabric Price#Non Woven Fabric Prices#Non Woven Fabric Pricing#Non Woven Fabric News#Non Woven Fabric Price Monitor

0 notes

Text

Europe Geotextiles Market Analysis, Growth, Forecast 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the Europe Geotextiles Market size by value at USD 3.02 billion in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the Europe Geotextiles Market size to expand at a CAGR of 8.65% reaching a value of USD 5.22 billion by 2030. The Geotextiles Market in Europe is propelled by the increasing urbanization and industrialization and rising civil engineering projects. Geotextiles are preferred for their cost-effectiveness and durability compared to alternative materials. Also, increased attention to environmental issues like soil erosion is likely to boost demand for these products in Europe. Notably, geotextiles are experiencing substantial growth as governments enforce strict regulations on their commercial use.

By volume, BlueWeave estimated the Europe Geotextiles Market size at 370.2 billion sq. meters in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the Europe Geotextiles Market size by volume is projected to grow at a CAGR of 8.11% reaching the volume of 395.6 billion sq. meters by 2030. The spurring demand for geotextiles is due to their unique functional properties, such as mechanical strength, filtration capabilities, and chemical resistance, which outclass other materials.

Impact of Escalating Geopolitical Tensions on Europe Geotextiles Market

Geopolitical tensions can have a multifaceted impact on the Europe Geotextiles Market. Political instability, trade conflicts, and international sanctions disrupt supply chains, leading to delays in raw material sourcing and increased transportation costs. These disruptions can raise production costs and create uncertainty among manufacturers, affecting pricing stability and market competitiveness. Also, geopolitical tensions may lead to stricter import/export regulations, hindering the movement of geotextiles across borders. It can reduce market expansion opportunities and make it challenging for companies to meet customer demands. Overall, such tensions contribute to a volatile business environment, discouraging investment and impeding the long-term growth of the European Geotextiles Market.

Sample Request @ https://www.blueweaveconsulting.com/report/europe-geotextiles-market/report-sample

Europe Geotextiles Market

Segmental Coverage

Europe Geotextiles Market – By Product

By product, the Europe Geotextiles Market is divided into Woven, Non-woven, and Knitted segments. The non-woven segment holds the highest share in the Europe Geotextiles Market by product. Non-woven geotextiles play a crucial role in the geotextile market, offering permeable solutions made from nonwoven fabrics designed to work with soil, rock, or other geotechnical materials as part of civil engineering projects, structures, or systems. Their ability to facilitate water flow makes them ideal for road construction, drainage, and erosion control. Innovations in drainage subsystems and the extended lifespan of landfills are expected to further boost market growth. Additionally, non-woven geotextiles are increasingly in demand for transportation infrastructure projects due to their high tensile strength and cost-effectiveness, underscoring their importance in this rapidly expanding sector.

Competitive Landscape

The Europe Geotextiles Market is fragmented, with numerous players serving the market. The key players dominating the Europe Geotextiles Market include CETCO, TenCate Geosynthetics, HUESKER Synthetic GmbH, Naue GmbH & Co. KG, Bontex Geo NV, Mahina-TST, Internationale Geotextil GmbH, Tessilbrenta Srl, BontexGeo NV, and Geotex SA. The key marketing strategies adopted by the players are facility expansion, product diversification, alliances, collaborations, partnerships, and acquisitions to expand their customer reach and gain a competitive edge in the overall market.

Contact Us:

BlueWeave Consulting & Research Pvt Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

From Conception to Implementation: The Journey of Geo Fabric

Geo fabric, often known as geotextile, plays a crucial role in modern civil engineering and construction projects. It is a permeable fabric that, when used in association with soil, has the ability to separate, filter, reinforce, protect, or drain. This versatile material is used in a wide range of applications, from road construction and erosion control to drainage and containment systems. Understanding the journey of geo fabric from its conception to its practical implementation provides insights into its significance and the processes involved in its production and use.

The Conceptualization of Geo Fabric

The concept of geo fabric emerged from the need to enhance the performance and longevity of civil engineering projects. Traditional methods of soil stabilization and erosion control were often inadequate, leading to frequent maintenance and higher costs. The idea was to create a material that could provide structural support and protection while being easy to install and maintain. Early innovators in the field of civil engineering began experimenting with different types of materials to create a fabric that could meet these needs. The result was the development of geotextiles, which could be used in various applications to improve soil stability and manage water flow.

Materials and Manufacturing of Geo Fabric

Geo fabric is typically made from synthetic materials such as polypropylene or polyester, chosen for their durability, flexibility, and resistance to degradation. The manufacturing process involves several steps, starting with the selection of high-quality raw materials. The chosen materials are then processed through a series of steps, including extrusion, weaving or non-woven processes, and finishing treatments to enhance specific properties such as UV resistance or permeability.

Leading geo fabric manufacturers invest heavily in research and development to create fabrics that meet the diverse needs of their customers. These manufacturers employ advanced technologies and quality control measures to ensure that their products meet industry standards and perform effectively in the field. The Geo fabric manufacturers price their products based on factors such as material quality, manufacturing processes, and market demand, ensuring competitive pricing without compromising on quality.

The Role of Suppliers

Geo fabric suppliers play a critical role in the distribution and availability of geotextiles. These suppliers act as intermediaries between manufacturers and end-users, ensuring that the right products are available when and where they are needed. They maintain extensive inventories of various types of geo fabrics, catering to different applications and project requirements.

In addition to providing products, Geo fabric suppliers often offer technical support and consultation services to help customers select the most suitable geotextiles for their specific needs. By working closely with both manufacturers and end-users, suppliers ensure that the products meet the required specifications and are delivered on time. This collaborative approach helps in optimizing the use of geo fabrics in various projects, enhancing their effectiveness and longevity.

Applications and Implementation of Geo Fabric

The practical implementation of geo fabric spans a wide range of applications in civil engineering and construction. One of the most common uses is in road construction, where geo fabric is used to stabilize the soil and prevent erosion. It acts as a barrier between different layers of soil, providing reinforcement and enhancing the structural integrity of the road. This helps in extending the lifespan of roads and reducing maintenance costs.

Geo fabric is also widely used in erosion control projects. It is installed on slopes, riverbanks, and shorelines to prevent soil erosion caused by water flow. The fabric allows water to pass through while holding the soil in place, thus preventing erosion and promoting vegetation growth. In drainage systems, geo fabric is used to filter and manage water flow, preventing clogging and ensuring efficient drainage.

Another important application of geo fabric is in containment systems, such as landfill liners and pond liners. Here, the fabric acts as a barrier to contain liquids and prevent contamination of the surrounding soil and groundwater. Its durability and resistance to chemical degradation make it an ideal choice for such applications.

Challenges in the Geo Fabric Industry

Despite its numerous benefits, the geo fabric industry faces several challenges. One of the main challenges is the variability in soil conditions and project requirements, which necessitates the development of specialized geotextiles tailored to specific applications. This requires ongoing research and innovation to create products that can meet diverse needs effectively.

Another challenge is the environmental impact of synthetic materials used in geo fabric production. While these materials offer durability and performance advantages, their production and disposal can have negative environmental effects. To address this, geo fabric manufacturers are exploring the use of recycled and biodegradable materials, as well as improving manufacturing processes to reduce environmental impact.

The cost of geo fabric is also a consideration for many projects. While the initial investment in high-quality geo fabric can be higher, the long-term benefits in terms of reduced maintenance and enhanced performance often justify the cost. However, budget constraints can sometimes limit the use of geo fabric in certain projects.

Conclusion

The journey of geo fabric from conception to implementation is a testament to the ingenuity and innovation in the field of civil engineering. From its early days as a novel concept to its widespread use in modern construction projects, geo fabric has proven to be an invaluable tool in enhancing the performance and longevity of various infrastructures. The collaboration between Geo fabric manufacturers, suppliers, and end-users has been instrumental in driving the development and application of geotextiles.

As the industry continues to evolve, the focus on sustainability, innovation, and smart technologies will pave the way for even more advanced and eco-friendly geo fabrics. By addressing the challenges and leveraging the opportunities, the geo fabric industry is set to play a pivotal role in shaping the future of construction and environmental management.

FAQs

Can geo fabric be used for environmental applications?

Yes, geo fabric is commonly used for environmental applications such as erosion control and promoting vegetation growth. There are also biodegradable geo fabrics made from natural fibers that offer environmentally friendly alternatives.

How do I ensure proper installation of geo fabric?

Proper installation of geo fabric involves following detailed guidelines provided by manufacturers and suppliers. Key steps include preparing the site, ensuring correct fabric placement, and securing the fabric to prevent displacement or tearing. Training for construction personnel is also recommended to achieve the desired performance.

What are the future trends in geo fabric?

Future trends in geo fabric include the development of smart geo fabrics with embedded sensors for real-time soil condition monitoring and the use of more sustainable materials like recycled polymers and biodegradable fibers. These innovations aim to enhance performance and reduce environmental impact.

0 notes

Text

Planning to Purchase a needle punched textile fabric sheet?

Water, as crucial as it is for human life on earth, it tends to become a huge problem, especially, when you are living near a water body because the movement of water can never be predicted beforehand. Water bodies live river and sea have a tendency to change their course which can bring massive floods to the regions surrounding them. This sudden change in course can lead to massive destruction and pictures in news outlets of multi-storey buildings falling because of water bodies is not uncommon. The best and the most economical solution to this problem is needle punched non-woven Geo textile. These the needle punched non-woven Geo textile is easy to use and does not require any kind of expertise when it comes to establishing it on the shore of the water body.

Non-woven Geo fabric sheet can we easily purchased from its manufacturer or the showroom of the distributor. These fabric sheets are made up of strong raw material called polypropylene full stop the speciality of this material is that it does not break even under strong pressure. Non-woven Geo fabric sheet can sustain the erosional activity of corroding sources like continuous exposure to sunlight, water and heat. Unlike Geo bags, the needle punched non-woven Geo textile is easy to use and does not require hard work. Geo bags have to be first filled with sand or small stones and they can we used only after so much of hard work. The non-woven Geo fabric sheet acts as an additional layer on the top soil which does not allow water to sweep away the top most layer of soil. The non-woven Geo fabric sheet has helped large number of people in times when rivers flood their banks.

Given the fact that needle punched non-woven Geo textile does not allow water to pass through it easily, it is used in a large number of places other than river banks or sea shores full stop the best example of efficient use of needle punched non-woven Geo textile fabric is its use in road construction full stop it is placed at the bottom of the entire construction because it is strong material which can hold the entire structure together. It is also used in fields because it can channelize the flow of water efficiently and farmers have now become capable of transporting water to specific spots of their field. Non-woven Geo textile fabric sheets are available in multiple colours and you can use them according to your preferences. Non-woven Geo fabric sheet is also used in creating small size ponds for water storage because of their capacity to hold water. These bonds have to be created for a small amount of time which is why it would be foolish to use costly raw material to build it.

#Non Woven Fabric Geotextile#Non Woven Geo Fabric Sheet#Non Woven Geotextile Manufacturers#Non Woven Polypropylene Geotextile Fabric#Non-Woven Geotextile Fabric#Geo Bag Manufacturer#Multifilament Woven Geotextile#Woven Geotextile Fabric#Woven Polypropylene Geotextile

0 notes

Text

What Are the Benefits of Using Non-woven Fabric?

You didn't know What Are the Benefits of Using Non-woven Fabric? Here, Shankar Packaging gave all info on Uses & Applications of Non Woven Fabric, and Benefits of Using Non Woven Fabrics, like Light Weight, Softness, Eco-friendly, etc. For more details on Non Woven Fabric Manufacturer in India, visit us!

#non woven fabric#non woven fabric bags#geotextile fabric manufacturers in Gujarat#non woven bags#non woven bag material#non woven fabric manufacturer in India#spunboud non woven material#PP cover manufacturers#filter material

0 notes

Text

Everything You Need To Know About Geotextiles

Shankar Techx is one of the prominent Geotextile fabric manufacturers and suppliers in India and we provide all over the world with our superior quality filtration fabrics, coating substracts, ground covers, and technical textiles, we are well-known as leading FIBC bag exporters, for more information visit our blog.

#geotextile fabric for soil stabilization#woven geotextile fabric#geotextile suppliers in India#non-woven geotextile fabric#geotextile fabric manufacturers#geotextile fabric India

0 notes

Text

The demand for high-performance non-woven fabrics is increasing in fields such as construction, geotextiles, automotive manufacturing, and filtration.

Contact us today: www.yuzhimu.com

#Spunbondnonwovenfabric

#Nonwovenfabricmanufacturer

#Nonwovenmaterial

#NonwovenFabric

0 notes