#inkjet and batch printing machine

Explore tagged Tumblr posts

Text

Domino Presents New Monochrome Inkjet Printer at Labelexpo Southeast Asia 2025

Domino Printing Sciences (Domino) is pleased to announce the APAC launch of its new monochrome inkjet printer, the K300, at Labelexpo Southeast Asia. Building on the success of Domino’s K600i print bar, the K300 has been developed as a compact, flexible solution for converters looking to add variable data printing capabilities to analogue printing lines.

The K300 monochrome inkjet printer will be on display at the Nilpeter stand, booth F32, at Labelexpo Southeast Asia in Bangkok, Thailand from 8th–10th May 2025. The printer will form part of a Nilpeter FA-Line 17” hybrid label printing solution, providing consistent inline overprint of serialised 2D codes. A machine vision inspection system by Domino Company Lake Image Systems will validate each code to ensure reliable scanning by retailers and consumers whilst confirming unique code serialisation.

“The industry move to 2D codes at the point of sale has led to an increase in demand for variable data printing, with many brands looking to incorporate complex 2D codes, such as QR codes powered by GS1, into their packaging and label designs,” explains Alex Mountis, Senior Product Manager at Domino. “Packaging and label converters need a versatile, reliable, and compact digital printing solution to respond to these evolving market demands. We have developed the K300 with these variable data and 2D code printing opportunities in mind.”

The K300 monochrome inkjet printer can be incorporated into analogue printing lines to customise printed labels with variable data, such as best before dates, batch codes, serialised numbers, and 2D codes. The compact size of the 600dpi high-resolution printhead – 2.1″ / 54mm – offers enhanced flexibility with regards to positioning on the line, including the opportunity to combine two print stations across the web width to enable printing of two independent codes.

Operating at high speeds up to 250m / 820′ per minute, the K300 monochrome inkjet printer has been designed to match flexographic printing speeds. This means there is no need to slow down the line when adding variable data. Domino’s industry-leading ink delivery technology, including automatic ink recirculation and degassing, helps to ensure consistent performance and excellent reliability, while reducing downtime due to maintenance. The printer has been designed to be easy to use, with intuitive setup and operation via Domino’s smart user interface.

“The K300 will open up new opportunities for converters. They can support their brand customers with variable data 2D codes, enabling supply chain traceability, anti-counterfeiting, and consumer engagement campaigns,” adds Mountis. “The versatile printer can also print variable data onto labels, cartons, and flatpack packaging as part of an inline or near-line late-stage customisation process in a manufacturing facility, lowering inventory costs and reducing waste.”

Code verification is an integral part of any effective variable data printing process. A downstream machine vision inspection system, such as the Lake Image Systems’ model showcased alongside the K300, enables converters and brands who add 2D codes and serialisation to labels and packaging to validate each printed code.

Mark Herrtage, Asia Business Development Director, Domino, concludes: “We are committed to helping our customers stay ahead in a competitive market, and are continuously working to develop new products that will help them achieve their business objectives. Collaborating with Lake Image Systems enables us to deliver innovative, complete variable data printing and code verification solutions to meet converters’ needs. We are delighted to be able to showcase an example of this collaboration, featuring the .”

To find more information about the K300 monochrome printer please visit: https://dmnoprnt.com/38tcze3r

#inkjet printer#variable data printing#biopharma packaging#glass pharmaceutical packaging#pharmaceutical packaging and labelling#Labelexpo Southeast Asi

2 notes

·

View notes

Note

How do you make stickers?

Long answer: I use a cricut machine. I source photos online, edit them onto a plain white background (using Picsart or photoshop), organize the pictures onto one page on the cricut app, print on inkjet sticker paper, load printed sticker sheets onto cricut and the machine cuts them using the outline I made on the app. This is very tedious and definitely a labour of love so I have to be super idle to go this route or I make stickers in big batches so I don’t have to do it again for a while.

Simple answer: print sourced photos onto sticker paper (or regular paper) and use a precision knife or scissors to cut. Use glue if printing on regular paper.

Pictures are either from idol instagrams, Pinterest or Twitter. I use a cricut precision knife but I also have a pen like cutter I got from shein a long time ago and it was super cheap. I’d be happy to give more details on my exact supplies and yt videos I watched to learn but this is pretty much the gist of it 😊

4 notes

·

View notes

Text

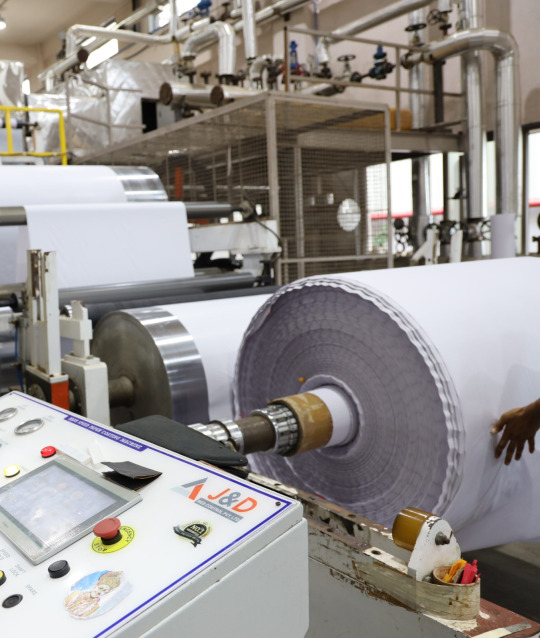

Hidden Costs of Choosing the Wrong Industrial Coding Machine

Understand the many applications of industrial coding with Technopack's inkjet coders. These machines deliver high-speed, accurate printing for batch numbers, expiration dates, and barcodes, supporting diverse production lines across food, pharma, and logistics sectors.

1 note

·

View note

Text

Label Printer Machine: The Ultimate Guide for Efficient and Professional Product Labeling

What is a Label Printer Machine?

A label printer machine is a device that prints custom or standardized labels for products, containers, cartons, and shipping packages. It can print on paper, plastic, thermal material, or synthetic labels using technologies like thermal transfer, direct thermal, or inkjet. Label printer machines are essential in packaging, inventory management, retail, pharmaceuticals, logistics, and food processing.

Types of Label Printer Machines

1. Thermal Transfer Label Printers

These use heat to transfer ink from a ribbon onto the label. Ideal for long-lasting, waterproof, smudge-resistant labels, commonly used in pharmaceuticals, electronics, and industrial labeling.

2. Direct Thermal Label Printers

No ribbon is used; heat-sensitive label paper darkens when heated. Best for short-term applications like shipping labels, receipts, and food packaging.

3. Inkjet Label Printers

Produce high-resolution, colorful labels. Suitable for custom branding, marketing labels, and retail packaging.

4. Laser Label Printers

Offer speed and sharpness. Used when mass label printing is needed, especially for office or warehouse environments.

5. Portable Label Printers

Handheld or mobile devices used in field service, retail, logistics, and inventory control.

6. RFID Label Printers

Print and encode RFID tags and barcodes for real-time tracking and supply chain automation.

Common Applications Across Industries

1. Food and Beverage

Nutritional labels, expiry dates, batch codes

Tamper-evident and waterproof labels

2. Pharmaceuticals

Regulatory-compliant labels with dosage info, QR codes, batch numbers

High print precision and barcode clarity

3. Cosmetics

High-resolution brand and ingredient labels

Sleek, colorful, water-resistant finishes

4. Manufacturing

Asset labels, compliance tags, quality control stickers

5. Logistics and Warehousing

Shipping and barcode labels

SKU and inventory management tags

6. Retail

Price tags, promotional stickers, and shelf labels

Key Features of High-Quality Label Printer Machines

1. Print Resolution

Measured in DPI (dots per inch). For clear text and barcodes, 203 DPI is standard, while 300–600 DPI is used for high-definition images and small text.

2. Print Speed

Ranges from 2 to 14 inches per second (IPS). Higher speeds are ideal for bulk printing operations.

3. Connectivity Options

USB, Ethernet, Bluetooth, Wi-Fi—essential for integration with POS systems, warehouse management software, or industrial PLCs.

4. Media Compatibility

Should support a variety of label rolls: paper, PET, PP, BOPP, synthetic, glossy, and matte.

5. Software Integration

Compatibility with label design software like BarTender, NiceLabel, or ZebraDesigner.

6. Auto-Cutter and Peeler

Helps in high-speed workflows by automatically cutting or peeling off printed labels.

Advantages of Using a Label Printer Machine

Professional Packaging: Clean, precise labels reflect product quality

Customization: Easily print logos, barcodes, and QR codes on demand

Efficiency: Reduce dependency on pre-printed labels and minimize stockouts

Compliance: Meet legal labeling requirements effortlessly

Traceability: Boost product tracking across supply chains

Cost-Saving: In-house label printing reduces outsourcing costs

0 notes

Text

How Digital Textile Printing is Revolutionizing the Fabric Industry

The Need for Innovation in Textile Printing

Historically, fabric printing relied on methods like screen printing or rotary printing. These techniques are cost-effective for large runs but are inefficient for small batches or designs requiring intricate detail. Enter the digital textile printing revolution. This method allows for direct-to-fabric printing using inkjet technology, providing limitless design freedom without the setup costs of conventional techniques.

The Role of the Modern Printing Machine

At the heart of this innovation lies the printing machine itself. Today’s advanced machines come equipped with high-resolution nozzles, AI-based controls, and specialized software that ensure sharp, vibrant prints. These machines can handle complex designs, multiple colors, and even print on various types of fabrics—from cotton and silk to synthetic blends.

More importantly, digital textile printers enable on-demand production. This means that designers can now test patterns, release limited collections, or even allow customers to personalize products—without worrying about inventory waste or long lead times.

Delivering on True Colour Accuracy

One of the standout features of digital textile printing is its ability to maintain true colour accuracy across batches. Traditional methods often suffer from color bleeding or tone shifts due to manual ink mixing and inconsistent application. But with digital technology, color management systems ensure consistency and precision.

This fidelity is crucial for fashion brands where brand identity depends heavily on specific color palettes. Interior designers also benefit, as they can now match fabrics precisely to walls, furnishings, or other décor elements.

Sustainability and Efficiency Go Hand-in-Hand

In an era where environmental responsibility matters, digital textile printing scores high on sustainability. It uses less water, reduces chemical waste, and minimizes leftover stock—making it a greener choice for both small and large textile businesses.

Traditional dyeing methods consume vast amounts of water and produce effluents that are difficult to treat. Digital systems, however, print only what is needed, drastically cutting down pollution and energy usage. A modern textile printing machine can now create hundreds of designs per day with minimal environmental impact.

Applications Beyond Fashion

While fashion remains the most visible industry adopting this technology, digital textile printing also plays a pivotal role in sportswear, accessories, interior décor, and even technical textiles. Whether it’s vibrant cushions, printed upholstery, or personalized yoga mats, the possibilities are endless.

For startups and indie brands, this levels the playing field. High-quality, custom products can be created with relatively low capital investment—thanks to compact printing machines suited for studio-scale operations.

Final Thoughts

The rise of digital textile printing marks a shift from mass production to mass customization. With capabilities that ensure true colour, faster turnaround times, and eco-conscious operations, the modern textile printing machine is more than just a tool—it’s a gateway to the future of design and manufacturing. As technology advances further, the textile industry can only expect better precision, scalability, and creative freedom.

0 notes

Text

Shirt Printing Machines: A Complete Guide to Choosing the Right One for Your Business

The custom apparel industry has exploded in recent years, driven by demand for personalized fashion, promotional clothing, and branded merchandise. At the heart of this booming sector is the shirt printing machine—an essential piece of equipment for anyone in the garment printing business. Whether you're a startup launching a T-shirt brand or a print shop expanding your services, investing in the right shirt printing machine can make a significant impact on your productivity, quality, and profitability.

This guide covers everything you need to know about shirt printing machines: how they work, the different types available, their benefits, and how to choose the best one for your business needs.

What Is a Shirt Printing Machine?

A shirt printing machine is a device used to transfer designs, graphics, or text onto fabric—most commonly cotton, polyester, or blends. These machines use various printing techniques to apply ink, heat transfers, or dye directly onto the garment, resulting in professional-grade, durable prints.

Shirt printing machines are used for:

Custom T-shirt production

Sportswear and team uniforms

Corporate apparel

Promotional clothing

Fashion brands and online stores

Types of Shirt Printing Machines

There are several types of shirt printing machines, each with its own strengths, costs, and applications.

1. Screen Printing Machines

Best for: High-volume orders with the same design

How it works: Uses stencils (screens) and ink pushed through a mesh onto the shirt

Pros: Excellent print quality, cost-effective in bulk, durable prints

Cons: Time-consuming setup, not ideal for multicolor or small orders

2. Direct-to-Garment (DTG) Printers

Best for: Small batches and full-color designs

How it works: Works like an inkjet printer but prints directly onto the fabric

Pros: No setup time, great for detailed artwork, supports full-color designs

Cons: Slower than screen printing, requires pre-treatment of shirts, best on cotton

3. Heat Press Machines

Best for: Beginners, low-cost startups, or adding names/numbers

How it works: Transfers a design (printed on special paper or vinyl) onto a shirt using heat and pressure

Pros: Affordable, easy to use, compact

Cons: Not as durable as screen or DTG, limited to transfer material quality

4. Sublimation Printers

Best for: Polyester garments and light-colored fabrics

How it works: Dye turns into gas and embeds into fabric under heat and pressure

Pros: Long-lasting, high-resolution prints

Cons: Only works on light-colored, polyester-rich garments

5. Embroidery Machines (Bonus)

Not a printer, but a popular shirt decoration tool that uses thread for logos and text

Pros: Professional, high-end look

Cons: Limited to simpler designs, not ideal for full-color images

Key Factors to Consider When Buying

Choosing the right shirt printing machine depends on your production needs, budget, and goals. Here are the key things to evaluate:

Volume: High-volume businesses may prefer screen printing, while small-batch producers may opt for DTG or heat press.

Print Quality: DTG and sublimation offer high-resolution results ideal for photo-realistic prints.

Fabric Type: Sublimation is best for polyester; DTG works best on cotton.

Colors: For multicolor or full-color prints, DTG or sublimation is more efficient than traditional screen printing.

Budget: Heat press is the most affordable option; DTG and sublimation have higher upfront costs but offer better detail and flexibility.

Maintenance: DTG printers need regular cleaning and maintenance; heat press and screen printing setups are easier to maintain.

Benefits of Shirt Printing Machines

Customization – Produce personalized designs for individual clients or events

Speed & Efficiency – Complete bulk orders in less time

Business Scalability – Easily expand your offerings and production capacity

Profitability – High margins on custom apparel

Creative Control – Print your own designs without outsourcing

Brand Building – Great tool for starting and growing a fashion or merchandise brand

Ideal Users of Shirt Printing Machines

Startup Clothing Brands – Launch your designs with minimal investment

E-commerce Sellers – Create print-on-demand products for Shopify or Etsy

Promotional Agencies – Produce branded clothing for events or corporate clients

Print Shops – Offer a wider range of printing services

Schools & Teams – Make uniforms, team shirts, and spirit wear in-house

Final Thoughts

A shirt printing machine is a vital investment for anyone looking to enter or expand in the custom apparel industry. With the right machine, you can produce high-quality shirts efficiently and cost-effectively while offering endless creative possibilities. Whether you're printing a single design or fulfilling hundreds of orders, there's a solution tailored to your needs.

0 notes

Text

How to Choose the Right Printing Technique for Custom T-Shirts in Chennai

Custom T-shirts have become a powerful medium for brand expression, event promotion, personal fashion, and more. From startups to college fests to wedding parties, the demand for personalized T-shirts in Chennai is booming. But one key factor often overlooked is the printing technique. The success of a custom T-shirt doesn't just lie in the design—it largely depends on how well it is printed. With several methods available, choosing the right one can feel confusing. Here’s how you can make the right decision and get the most value from your custom apparel.

Understanding the Impact of Printing Techniques

Choosing the wrong printing method can lead to faded designs, poor color reproduction, or a T-shirt that doesn’t last beyond a few washes. On the other hand, the right technique ensures your designs remain vibrant, the shirt feels comfortable, and your message stays visible for a long time. That’s why working with professional t shirt manufacturers in chennai becomes essential—they can guide you with the right method based on your design, quantity, and budget.

Screen Printing: Durable and Cost-Effective for Bulk Orders

Screen printing is one of the oldest and most trusted methods in the custom apparel world. It involves using stencils (screens) to apply layers of ink onto the T-shirt. The result is a rich, vibrant print that lasts. This method is ideal for simple designs with limited colors and is especially cost-effective for large quantities. However, it’s not suitable for designs with many intricate details or color gradients. If you're planning a bulk order for your event, screen printing is a reliable choice offered by most t shirt manufacturers in chennai.

Digital Printing: Best for Detailed, Multi-Color Designs

Also known as Direct-to-Garment (DTG) printing, this method is perfect for complex designs that include photographic images or multiple shades. DTG works like a regular inkjet printer but for clothing. It prints directly onto the fabric, allowing for high-resolution output. Although slightly more expensive than screen printing for bulk orders, DTG is ideal for short runs or one-off designs. Many t shirt manufacturers in chennai now use advanced DTG machines to cater to the growing trend of unique, personalized fashion.

Heat Transfer Printing: Flexible and Affordable for Small Orders

Heat transfer involves printing your design on special paper and then applying it to the T-shirt using heat and pressure. This method is easy, affordable for small batches, and allows vibrant full-color prints. It’s commonly used for promotional T-shirts, short-run events, or even single custom pieces. While not as durable as screen or DTG printing, it remains a popular choice for people looking to experiment with new ideas or test a design. Some of the experienced t shirt manufacturers in chennai also offer sublimation heat transfer for polyester fabrics, which improves durability.

Vinyl Printing: Perfect for Text and Logos

Vinyl printing uses a machine to cut shapes and letters from colored vinyl sheets, which are then heat-pressed onto the garment. It’s ideal for bold, high-impact text designs or logos. The finish is clean and slightly raised, making it visually striking. Vinyl is durable and offers a sleek finish but isn't ideal for large images or designs with many colors. For sports teams, uniforms, or branded T-shirts with simple logos, this method works well and is offered by several professional t shirt manufacturers in chennai.

Factors to Consider Before Choosing a Printing Method

Before making your final decision, consider your design complexity, number of T-shirts needed, the type of fabric, and how long you expect the T-shirts to last. Cotton works well with all techniques, but polyester and blended materials may require specific methods like sublimation. The number of colors in your design also influences your choice—DTG is better for multiple colors, while screen printing excels in simplicity.

Your budget and timeline also matter. Bulk orders benefit from screen printing due to cost savings, while rush orders or one-off prints may lean towards DTG or heat transfer. It’s always recommended to consult with local t shirt manufacturers in chennai who understand the regional demand, fabric availability, and can deliver your order on time with quality assurance.

Why It Pays to Partner with Experienced Manufacturers

Chennai has a vibrant apparel market with many printing houses and manufacturers. However, not all offer the same level of service, quality, or customization options. Working with experienced and well-reviewed t shirt manufacturers in chennai ensures your ideas are brought to life with the right materials and techniques. They can also advise you on trends, bulk pricing, delivery schedules, and long-term partnerships for recurring business needs.

Final Thoughts

Custom T-shirts are more than just clothing—they're a voice for your brand, your group, or your individual style. Choosing the right printing technique ensures that voice is heard clearly and lasts long. Whether you're printing for a brand launch, a college fest, or a social cause, t shirt manufacturers in chennai your choice of printing method will influence the final result.

0 notes

Text

T-Shirt Printing Technology: Understanding DTG, DTF, and Heat Transfer Methods

T-shirt printing has evolved significantly over the years, offering businesses and individuals a variety of methods to create custom designs. Whether you're starting a printing business or simply want to personalize your wardrobe, selecting the right T-shirt printer is crucial. This guide explores different types of T-shirt printers, their features, and how to choose the best one for your needs.Get more news about T-shirt Printer,you can vist our website!

Types of T-Shirt Printers There are several types of T-shirt printing technologies available, each with its own advantages:

Direct-to-Garment (DTG) Printers: DTG printers use inkjet technology to print directly onto fabric. They are ideal for detailed designs and small-batch printing.

Direct-to-Film (DTF) Printers: DTF printers print designs onto a special film, which is then transferred onto fabric using heat and pressure. This method is versatile and works on various fabric types.

Heat Transfer Printers: These printers use heat to transfer designs from special paper onto fabric. They are commonly used for vinyl and sublimation printing.

Screen Printing Machines: Traditional screen printing involves creating stencils and applying ink through a mesh screen. It is best suited for bulk printing.

Key Features to Consider When choosing a T-shirt printer, consider the following factors:

Print Quality: High-resolution printing ensures vibrant colors and sharp details.

Fabric Compatibility: Some printers work better with cotton, while others are suitable for polyester and blended fabrics.

Production Speed: If you're running a business, a fast printer can improve efficiency.

Cost and Maintenance: Consider the initial investment, ink costs, and maintenance requirements.

Best T-Shirt Printers of 2025 Several brands offer high-quality T-shirt printers, including Epson, Brother, and Roland. The Epson EcoTank ET-3850 is a popular choice for heat transfer printing due to its efficiency and ink-saving features. For professional-grade DTG printing, the Epson SureColor F-Series provides excellent image quality and hybrid printing capabilities.

Starting a T-Shirt Printing Business If you're considering launching a T-shirt printing business, follow these steps:

Choose the Right Printer: Select a machine that suits your production needs.

Invest in Quality Materials: Use high-quality inks and fabrics for better results.

Learn Design Software: Programs like Adobe Illustrator and CorelDRAW help create professional designs.

Market Your Products: Utilize social media and e-commerce platforms to reach customers.

Conclusion T-shirt printing is a thriving industry with endless creative possibilities. Whether you're printing for personal use or starting a business, understanding different printing technologies and selecting the right equipment will ensure success. With advancements in DTG, DTF, and heat transfer printing, creating custom T-shirts has never been easier.

0 notes

Text

DTF Printing: Everything You Need To Know (2024)

DTF Printing Overview

What is DTF Printing?

It is a brand-new technology. Direct-to-Film uv dtf printing is the process of printing images of design on a transfer film that is later transferred to fabric by heating. It is a reliable modern alternative to DTG and screen printing with regard to fabric adaptability and ease of use, and price. In the field of garment printing, DTF has gained popularity due to its capability to create high-quality prints that are vivid and long-lasting on a variety of fabrics.

Preliminary Thoughts in DTF Printing

While DTF printing isn't very old, however, it is a part of the printing history that started with screen printing, and then evolved to more automated processes similar to DTG. The first ideas of DTF were first conceived in the mid-2010s and then became a commercially viable technology around the year 2017 as advances in transfer film and ink advanced. In the year 2020, small-scale businesses began to be interested because of its cost-effective setup and its capability for printing onto a variety of materials such as dark textiles.

Important Distinctions Between DTF, DTG Printing, and Screen Printing

DTF and. DTG: DTF and DTG printers differ because DTG can print designs directly onto clothes using inkjet technology; however, in DTF printing, the design is printed on the film that is then transferred onto the fabric later. DTF is more flexible in the fabrics it prints onto, compared to DTG. However, DTG printing is generally better suited to light-colored clothes.

DTF Vs. Screen printing: Like DTF Screen printing directly prints designs on clothing using stencils. It is typically suitable for large-scale projects. In contrast and contrast to DTF screen printing, screen printing is not as flexible as DTF regarding the quality, color, as well as batch size configuration.

How is DTF Printing Done?

A Guide on How to Get DTF Printed Step by Step

The first step is focused on the graphic design process, and the export of an image template is the first priority. After that then a prepress procedure can be defined prior to printing.

Screen DTF printer produces the artwork onto a specially designed transfer film, also known as DTF film. The print has strong colors as well as precise elements.

When the print is completed then a layer of glue powder that's hot-melting is sprayed onto the printed design while it's still damp. Then, the paper is placed in a baking machine, so that the powder will melt and stick to the print.

Transfer Step: Finally, the design is printed on the film, which is then placed on the fabric, and then heated. The bondable powder that is heated secures the design to the fabric.

Equipment Needed For DTF Printing

In the case of DTF printing, you'll require:

Printer DTF Printer DTF: A printer specially designed to be used for DTF printing, as it makes use of specific transfer film and inks.

Filmid Derivati: They're designed to be used for DTF printing.

Heating Transfer Press: A machine that heats and presses the design onto the fabric to make it stick.

DTF Ink: A type of ink designed specifically to be used in DTF printing.

Powder Binder Hot Melt powder is used to hold the ink on the cloth while it is transferred.

The Impact of Using The Correct Materials For DTF Printing

Utilizing high-quality materials for DTF printing is essential to ensure you get the desired outcomes. The quality of film binder, powder, and film can have a huge impact on the overall strength and sharpness of the printed.

Benefits of DTF Printing

Exceptional Prints On Different Types of Fabrics

Through DTF printing, you will be able to get excellent results printing on various types of fabric like polyester, cotton, leather, as well as certain synthetic materials. This flexibility is perfect for printing your designs on clothing, accessories and other fabrics.

Relative Completeness of Other Methods

As compared with other printing techniques like screen printing, which requires a significant amount of setup as well as manual labor, DTF printing is more efficient. The capability to print directly onto transfer films minimizes the number of setups needed, and also, the speedier production speeds are perfect for small and medium-sized businesses.

Efficiency Of DTF Printing

Even with the lower overall cost related to DTF printing, that are typically less expensive than other printing methods because there isn't a need to purchase expensive materials like documents, the set-up costs tend to be more expensive than other types of printing. This is due to the absence of the need for training specialized for DTF printing, which makes it simpler for businesses that are new to utilize this printer.

Consequences of DTF Printing

Fragile on Some Fabrics

Although DTF prints are vivid and clear, they might not last as long on certain fabrics as contrasted with prints created using other techniques. It is important to note that the durability of prints printed on high polyester fabric could be a problem and consequently, require more care in order for the design to be protected.

Initial Investment is Higher

For small-sized businesses with limited funds uv dtf printer and specialized powders and films could be regarded as costly. However, the low cost of materials, as well as the capacity and willingness to print smaller amounts, could reduce the cost.

Additional steps for setting up and maintaining this DTF printing process are characterized by preventative maintenance methods to limit the chance of bleeding, blockage of ink, as well as film overlap. Additionally, application of the powder adhesive requires a specific technique, and some processes may require specialized skills to perform.

0 notes

Text

Boost Traceability and Compliance with an Inkjet Batch Coding Machine

Stay ahead of industry standards and meet regulatory demands effortlessly with an Inkjet batch coding machine. Designed for precision and adaptability, these machines provide fast, non-contact coding for a wide range of materials and packaging formats. Ideal for fast-moving consumer goods, pharmaceuticals, and industrial products, an Inkjet batch coding machine allows you to print detailed data—like manufacturing dates, expiry information, and serial numbers—directly onto your products. With features like quick-dry ink, variable font sizes, and customizable settings, it enhances traceability, prevents counterfeiting, and boosts brand credibility. Make your packaging smarter and your production line more efficient with this powerful tool.

1 note

·

View note

Text

Cobra Flex Printers vs Canon

Cobra Flex Printers vs Canon: Which One Is Right for You?

When it comes to high-performance printing—especially for apparel and promotional goods—businesses are often torn between two popular names: Cobra Flex Printers and Canon. Both offer top-tier equipment, but which one meets their production needs, budget, and creative demands?

Let’s break it down by features, performance, and value.

Print Technology & Output Quality

Cobra Flex Printers are specifically designed for direct-to-film (DTF) and hybrid textile printing, making them ideal for t-shirt businesses and custom merchandise companies. They’re known for vibrant color output, white ink precision, and consistent film transfers that hold up to multiple washes.

Canon, on the other hand, is a legacy brand with a broad range of printers — from home and office inkjets to large-format graphic design printers. Their imagePROGRAF series excels at photo-realistic printing, posters, signage, and fine art reproduction. Canon’s strength lies in color accuracy and detail, especially for paper or vinyl surfaces.

Winner for Apparel Printing: Cobra Flex Winner for Graphic & Poster Printing: Canon

Maintenance & Durability

Cobra Flex machines require regular head cleanings and ink line checks — common for any DTF setup. However, they’re built with heavy-duty components for commercial longevity and large-batch jobs.

Canon printers are typically lower-maintenance, especially the inkjet models. However, larger Canon machines do require ongoing calibration and ink replacement, which can be expensive over time depending on usage.

Winner for Rugged Apparel Production: Cobra Flex Winner for Low-Maintenance Design Studios: Canon

Price & Business ROI

Cobra Flex is positioned for commercial apparel businesses, with pricing often ranging from $8,000–$20,000+ depending on model and setup. The ROI comes from quick turnaround and scalability for custom apparel printing.

Canon offers a wider price spectrum. A professional Canon photo printer may cost $500–$2,000, while a wide-format imagePROGRAF can range from $3,000–$10,000+.

Best for Apparel-Based Business ROI: Cobra Flex Best for Design Studios or Art Print Shops: Canon

Final Verdict: Which Printer Should You Choose?

If your business revolves around custom t-shirts, DTF transfers, or hybrid textile printing, Cobra Flex Printers are built for you. They offer the robust performance and workflow speed needed to grow in the apparel and merchandise space.

If you’re in photography, poster production, or high-resolution visual media, Canon delivers color accuracy and detail unmatched in its price range.

0 notes

Video

youtube

Auto L sealer machine with Shrink tunnel machine

Royal Inks & Equipments Pvt. Ltd.

Pioneering Excellence in Printing Inks & Industrial Machinery Since 1994.

At Royal Inks & Equipments Pvt. Ltd., we are a trusted manufacturer and supplier of high-quality printing inks and industrial coding & marking solutions. With over 25 years of industry expertise, we have been at the forefront of innovation, precision, and reliability in the printing and packaging industry, catering to both domestic and international markets.

Our Product Range 🔹 Printing Inks: ✔️ Marking Inks – Ensuring long-lasting impressions and superior adhesion. ✔️ Water-Based Flexographic Inks – Ideal for eco-friendly, high-speed printing applications. ✔️ Solvent-Based Poly Inks – Designed for flexible packaging and high-quality prints. ✔️ Lino Inks & Offset Inks – Delivering sharp, vibrant, and consistent color output. 🔹 Industrial Coding & Packaging Machinery: ✔️ Handy Coder Machines – Reliable for batch coding and marking. ✔️ Batch Coding & Inkjet Coding Machines – Enabling seamless product labeling and traceability. ✔️ Auto Coder Machines – Designed for automated, high-speed printing requirements. ✔️ Filler & Packing Machines – Enhancing efficiency in packaging operations.

0 notes

Text

Batch Coding Machine: Revolutionizing Efficiency in Manufacturing

In today’s rapidly evolving manufacturing landscape, batch coding machines have become indispensable tools for businesses striving to maintain accuracy, efficiency, and compliance. These machines ensure that products are labeled with critical information, such as batch numbers, expiration dates, and barcodes, which is essential for both consumers and regulatory agencies. Below, we dive deep into the world of batch coding machines, exploring their types, functionalities, benefits, and how they are transforming industries worldwide.

What is a Batch Coding Machine?

A batch coding machine is a device designed to print or emboss essential information on products or packaging. This information includes manufacturing dates, expiration dates, batch numbers, and other identifiers that help track products throughout the supply chain. These machines are widely used across industries such as pharmaceuticals, food and beverages, cosmetics, and electronics.

With advancements in technology, batch coding machines now incorporate features like high-speed printing, automated adjustments, and error detection, making them more reliable and efficient than ever.

Types of Batch Coding Machines

1. Inkjet Batch Coding Machines

Inkjet printers are among the most common batch coding solutions. They use tiny nozzles to spray ink onto surfaces, creating clear and precise codes. These machines are suitable for high-speed production lines and can print on a variety of surfaces, including paper, plastic, glass, and metal.

Advantages:

High-speed printing

Suitable for various surfaces

Low maintenance requirements

2. Laser Batch Coding Machines

Laser coding machines use focused laser beams to etch information onto surfaces. These machines are ideal for industries requiring permanent and tamper-proof markings.

Advantages:

Permanent markings

No need for consumables like ink

Eco-friendly and cost-effective over time

3. Thermal Transfer Batch Coding Machines

Thermal transfer printers use heat to transfer ink from a ribbon onto the surface of a product or label. These machines are commonly used in industries where high-resolution printing is required.

Advantages:

High-quality prints

Ideal for flexible packaging

Durable codes resistant to smudging

4. Contact Coding Machines

Contact coders use a stamping mechanism to transfer ink onto a product. Though older than other methods, they are still used in industries where simplicity and cost-effectiveness are priorities.

Advantages:

Simple operation

Low initial cost

Reliable for low-volume production

Key Features of Modern Batch Coding Machines

1. Versatility

Modern batch coding machines are designed to handle a wide range of materials, including cardboard, plastic, glass, and metal. This versatility makes them suitable for diverse industries.

2. Integration with Production Lines

Advanced models can seamlessly integrate with production lines, ensuring that coding operations do not disrupt workflow.

3. User-Friendly Interfaces

Most machines now come equipped with touchscreen interfaces and intuitive software, allowing operators to easily adjust settings and monitor performance.

4. Compliance with Regulations

Batch coding machines ensure adherence to regulatory standards, such as those set by the FDA, ensuring that products meet legal requirements.

Benefits of Using Batch Coding Machines

1. Improved Traceability

Batch coding ensures that products can be tracked from production to distribution, which is critical for quality control and recall management.

2. Enhanced Brand Reputation

Accurate and professional-looking batch codes enhance the perceived quality of a product, boosting customer confidence and brand loyalty.

3. Cost Savings

By automating the coding process, manufacturers can reduce labor costs and minimize errors, leading to significant cost savings over time.

4. Increased Efficiency

Modern machines operate at high speeds and require minimal supervision, allowing businesses to optimize their production workflows.

Applications of Batch Coding Machines

1. Pharmaceutical Industry

In the pharmaceutical sector, batch coding is crucial for ensuring product safety and compliance. Machines print batch numbers, expiration dates, and barcodes on medicine bottles, blister packs, and cartons.

2. Food and Beverage Industry

Batch coding machines help maintain food safety by providing essential information, such as expiry dates and batch details, on packaging.

3. Electronics Industry

In the electronics industry, batch coding is used to label components with serial numbers and manufacturing details, ensuring proper assembly and quality control.

4. Cosmetics Industry

Batch coding machines play a vital role in labeling cosmetic products with lot numbers and expiration dates, meeting both consumer demands and regulatory requirements.

Choosing the Right Batch Coding Machine

When selecting a batch coding machine, consider the following factors:

Type of Material: Ensure the machine is compatible with the materials used in your products.

Production Speed: Choose a model that matches your production line’s output.

Budget: Factor in both initial costs and long-term operational expenses.

Regulatory Compliance: Opt for machines that meet industry-specific standards.

Ease of Use: Look for user-friendly features like touchscreen interfaces and automated adjustments.

Future Trends in Batch Coding Technology

1. AI Integration

Artificial Intelligence is being integrated into batch coding systems to enhance error detection and predictive maintenance.

2. Sustainability

Manufacturers are focusing on eco-friendly solutions, such as laser coding and biodegradable inks, to reduce their environmental impact.

3. IoT Connectivity

The Internet of Things (IoT) allows machines to be connected to central systems, enabling real-time monitoring and data analysis.

Conclusion

Batch coding machines are essential for modern manufacturing, offering unparalleled efficiency, accuracy, and compliance. By investing in the right batch coding solution, businesses can streamline their operations, enhance product traceability, and build consumer trust.

0 notes

Text

Sublimation Printing vs. Digital Textile Printing: Which is Right for You?

When it comes to textile printing, businesses and creatives are often faced with the choice between two popular methods: sublimation printing and digital textile printing. Each of these techniques offers unique advantages, and understanding which one suits your needs can make a significant difference in your production process. At True Colors Group, we specialize in helping you navigate the world of textile printing, ensuring that your products meet the highest standards of quality.

In this article, we’ll explore the key differences between sublimation printing and digital textile printing to help you decide which method is best for your next project.

What is Sublimation Printing?

Sublimation printing is a process where heat is used to transfer dye onto materials such as polyester fabric, ceramics, or metal. The dye changes from a solid to a gas and bonds with the fibers of the fabric, resulting in vibrant, long-lasting colors. This method works best on synthetic fabrics like polyester, which allows the dye to infuse deeply into the material.

Advantages of Sublimation Printing:

Vivid Colors: Sublimation creates vibrant, full-color prints that are hard to match with other methods.

Durability: Because the dye is embedded into the fibers, the prints are resistant to fading, cracking, or peeling, even after extensive washing.

No Feel: The print becomes part of the fabric, so there's no thick layer on top, giving the garment a smooth, soft feel.

At True Colors Group, we use state-of-the-art printing machines to deliver high-quality sublimation prints that provide excellent color accuracy and exceptional durability.

What is Digital Textile Printing?

Digital textile printing, on the other hand, uses inkjet technology to apply water-based inks directly onto fabric. This method works on both natural and synthetic fabrics, giving it a broader range of applications than sublimation. With digital textile printing, the fabric is printed with the ink directly onto its surface, allowing for intricate designs and smaller production runs.

Advantages of Digital Textile Printing:

Versatility: Digital textile printing can be used on a wider variety of fabrics, including cotton, linen, and silk, in addition to polyester.

High Detail: This technique allows for printing complex, detailed images with fine lines and vibrant colors.

Eco-Friendly: Water-based inks used in digital textile printing are generally more environmentally friendly, reducing harmful emissions and chemical waste.

Digital textile printing has become a go-to choice for custom fabrics, making it a perfect solution for everything from fashion design to home décor. At True Colors Group, we offer cutting-edge digital textile printing that ensures precise, high-quality results.

Key Differences Between Sublimation and Digital Textile Printing

Fabric Type: Sublimation works best on synthetic fabrics like polyester, whereas digital textile printing can be used on a broader range of natural and synthetic materials.

Color Quality: Sublimation typically produces brighter and more vibrant colors, while digital textile printing excels at reproducing intricate designs and fine details.

Durability: Sublimation prints are more durable and resistant to fading, while digital prints may require more careful handling to ensure longevity.

Cost-Effectiveness: Sublimation printing tends to be more cost-effective for larger production runs, while digital textile printing can be more economical for smaller, custom batches.

Which Printing Method is Right for You?

The choice between sublimation printing and digital textile printing depends largely on your specific needs and the type of product you're creating. If you're looking for vibrant prints on polyester fabrics and need a durable, long-lasting result, sublimation is the way to go. However, if you need to print on a variety of fabrics or require fine details and intricate designs, digital textile printing may be the better option.

At True Colors Group, we pride ourselves on offering both sublimation printing and digital textile printing solutions. Whether you're producing custom apparel, home textiles, or promotional products, we have the expertise and the printing machines to bring your vision to life.

Conclusion

Both sublimation printing and digital textile printing have their unique strengths, and the choice between the two will depend on your project’s requirements. With True Colors Group, you can be confident that we’ll help you select the right method to achieve the best results, no matter what type of textile you're working with.

0 notes

Text

A Comparative Analysis for Variable Data Printing vs. Traditional Printing

The printing industry has seen significant advancements over the years, particularly with the introduction of variable data printing (VDP). This technology allows for the printing of individualized information on each sheet, such as alphanumeric characters, addresses, barcodes, QR codes, and logos.

What is Variable Data Printing?

Variable data printing (VDP) involves printing unique data on each sheet, which is crucial for applications requiring personalized information. This technology supports high-speed printing on various substrates like Colour Wove, Maplitho, Art Paper, Duplex Board up to 350 gsm, and NCR Sheet. The Autoprint Reckoner VDP65 is an example of a machine that leverages HP Inkjet Technology to offer efficient numbering, barcoding, mail addressing, and online perforation.

Traditional Printing

Traditional printing methods, such as offset and digital printing, produce identical copies of a print job. These methods are cost-effective for large volumes of the same print material but do not offer the flexibility of VDP. Traditional printing is best suited for mass production where the content remains consistent across all copies.

Advantages of Variable Data Printing

1. Personalization: VDP allows for the customization of each printed piece, making it ideal for direct mail, marketing materials, and personalized invitations.

2. Efficiency: By printing variable information directly, VDP eliminates the need for pre-printed stock and separate personalization steps, reducing production time.

3. Cost-Effectiveness: Although the initial setup cost may be higher, VDP can be more cost-effective in the long run by reducing waste and inventory costs.

4. Versatility: VDP can be applied to various substrates and formats, offering flexibility for different applications.

Autoprint Reckoner VDP65

The Autoprint Reckoner VDP65 is an offline sheetfed variable data printing machine using HP Inkjet Technology. It is designed for high-speed, accurate printing of variable data such as numbers, barcodes, and addresses. As an authorized oil-free air compressor dealer, AS Equipment ensures that customers receive top-quality products along with exceptional support and service, maximizing the performance and reliability of their compressed air systems.

Batch Coding Systems

A batch coding system is crucial for marking products with unique codes or batch numbers, ensuring traceability throughout the supply chain. These systems are vital for industries like food and beverage, pharmaceuticals, and cosmetics, where product safety and quality are paramount. Batch coding can be integrated with VDP machines to streamline processes and ensure accurate, consistent coding.

Steps Involved in Batch Coding

1. Prepare the Design: Create the design for the batch code, including relevant information such as the date of manufacture and product batch number.

2. Set Up the Machine: Calibrate the batch coding machine and load the necessary ink or ribbon.

3. Load the Product: Position the product or packaging correctly on the machine’s conveyor.

4. Set Parameters: Configure printing speed, number of copies, and other settings.

5. Start Coding: Activate the machine to print the batch code.

6. Verify Codes: Check the printed codes for accuracy and legibility.

Both variable data printing and traditional printing have their unique advantages and are suited to different applications. VDP offers unparalleled flexibility and efficiency for personalized printing needs, while traditional printing remains the best choice for large-scale, uniform print jobs. By understanding the strengths of each method, businesses can choose the right technology to optimize their production processes. For high-quality VDP solutions, the Autoprint Reckoner VDP65 stands out as a reliable choice, supported by AS Equipment’s excellent service as an authorized dealer.

Read more posts Maximizing Efficiency with Automatic UV Coating Machines: Tips and Best Practices Role of prepress in offset printing

0 notes

Text

T-Shirt Printing Machines for Sale: A Comprehensive Guide

The t-shirt printing industry has experienced exponential growth in recent years, driven by the increasing demand for custom apparel. Whether you're an entrepreneur looking to start your own clothing line or a business seeking to expand your product offerings, investing in a t-shirt printing machine is a crucial step. These machines allow you to print custom designs on t-shirts, offering a level of creativity, personalization, and profitability. In this guide, we’ll explore the different types of t-shirt printing machines available for sale, their features, and what you should consider before making a purchase.

Types of T-Shirt Printing Machines

When it comes to t-shirt printing, there are several different technologies to choose from. The right machine for your needs will depend on factors like the volume of prints you plan to produce, the types of designs you want to print, and your budget. Below are the most common types of t-shirt printing machines for sale:

Screen Printing Machines Screen printing, or silk screening, is one of the oldest and most popular methods for printing on t-shirts. It involves creating a stencil (or screen) for each colour in the design and using it to apply ink to the t-shirt. This method is ideal for bulk production and is known for its durability and vibrant colours.

Advantages: High-quality prints, cost-effective for large orders, durable prints.

Disadvantages: Time-consuming setup, not suitable for highly detailed or multi-coloured designs, best for bulk runs.

Heat Press Machines Heat press machines use heat and pressure to transfer a design onto a t-shirt, typically using vinyl or sublimation transfer sheets. This method is user-friendly and relatively inexpensive, making it a great option for small businesses or hobbyists.

Advantages: Low cost, easy to use, ideal for small batches and customized designs.

Disadvantages: Limited to simpler designs or single-colour prints, slower compared to screen printing for large volumes.

Direct-to-Garment (DTG) Printers DTG printers work similarly to inkjet printers, directly applying water-based inks onto the t-shirt fabric. This method allows for full-colour, high-quality prints, including intricate designs and photographs. DTG printing is perfect for small to medium orders and offers incredible detail.

Advantages: High-quality, full-colour prints, no setup required, ideal for complex designs and photos.

Disadvantages: Higher initial investment, slower printing speeds, and ongoing maintenance costs.

Sublimation Printing Machines Sublimation printing uses heat to transfer dye onto synthetic fabrics like polyester. Unlike other methods, the dye becomes part of the fabric, ensuring vibrant colours that won’t fade or peel. Sublimation is primarily used for all-over prints or polyester-based t-shirts.

Advantages: Long-lasting, high-quality prints, great for full-colour designs.

Disadvantages: Only works on polyester or polymer-coated fabrics, limited to light-coloured garments.

Vinyl Cutters Vinyl cutters are machines that use a blade to cut out designs from sheets of coloured vinyl, which are then heat-pressed onto t-shirts. This method is especially popular for creating custom text and logos and is often used in small businesses or for personalisation.

Advantages: Cost-effective for small runs, easy to use, ideal for simple text and logos.

Disadvantages: Limited to solid colours, no gradient or photographic designs.

Key Features to Look for in a T-Shirt Printing Machine

When shopping for a t-shirt printing machine, several factors can influence your decision. Here’s a look at the key features to consider:

Print Resolution and Quality The resolution of your t-shirt printer will determine how sharp and detailed your designs will look. For professional results, you’ll want a machine with high resolution and excellent colour reproduction, especially if you’re planning to print photos or intricate designs.

Production Speed The speed of the printer is an important consideration, particularly if you plan to handle large volumes of orders. Machines like DTG printers offer high-quality results but may print more slowly, while screen printing machines are faster for bulk production.

Compatibility with Different Fabrics Some printing machines are only suitable for specific types of fabrics. For example, DTG printers work best on cotton, while sublimation printers are ideal for polyester. Make sure your chosen machine is compatible with the materials you intend to print on.

Ease of Use and Setup Depending on the type of machine, the complexity of setup and operation can vary. Heat press machines and vinyl cutters are generally straightforward to use, while screen printing and DTG printers may require more technical expertise. Ensure the machine you select is easy to operate and comes with sufficient training or support resources.

Size and Space Requirements Printing machines, particularly those for screen printing or DTG, can be large and require substantial workspace. Before purchasing, measure the space where you intend to use the machine and ensure it can accommodate the equipment, as well as any additional accessories or supplies.

Maintenance and Durability Regular maintenance is essential for keeping your t-shirt printing machine in good working condition. Some machines, particularly DTG printers, may require more frequent upkeep, such as cleaning the printheads or changing inks. Ensure that spare parts are readily available and that the machine is durable enough for your production needs.

Cost and Budget T-shirt printing machines vary widely in price. While heat press machines and vinyl cutters are affordable and accessible for small businesses, DTG printers and screen printing setups can have a higher initial investment. Consider not only the upfront cost but also the long-term expenses, including ink, maintenance, and consumables.

Where to Find T-Shirt Printing Machines for Sale

T-shirt printing machines are available from a variety of sources. Here are a few places to consider:

Online Marketplaces Websites like Amazon, eBay, and Alibaba offer a wide range of t-shirt printing machines, from entry-level models to industrial-grade equipment. Be sure to read reviews, compare prices, and check the seller's reputation.

Specialized Printing Suppliers Many suppliers specialize in printing equipment and offer expert advice, installation, and customer support. These businesses can provide a more personalized experience and may offer additional services such as training and maintenance.

Local Dealers and Resellers Local dealers and resellers often carry t-shirt printing machines, and buying from them allows you to see the equipment in person. You may also be able to take advantage of in-person demos, warranties, and after-sales support.

Trade Shows and Expos Printing industry trade shows and expos are a great place to see the latest t-shirt printing technology in action. You can meet with manufacturers and distributors, compare machines, and learn more about the capabilities of different models.

Conclusion

Investing in a t-shirt printing machine can be a game-changer for your business, offering you the ability to create high-quality, custom apparel with ease. Whether you're interested in screen printing, heat transfer, DTG, or sublimation, there's a machine suited to your specific needs. Before making a purchase, carefully consider factors like print quality, speed, ease of use, and your budget to ensure you choose the best option for your printing business. By selecting the right equipment, you’ll be able to produce high-quality t-shirts that satisfy your customers and help your business grow.

0 notes