#laser cutting panel

Text

WHAT IS ONLINE LASER CUTTING

Laser cutting is a manufacturing process that uses a high-power laser to precisely cut materials such as metal, plastic, wood or textiles. The laser generates heat and vaporizes the material along a predetermined path guided by a computer-controlled system. This process results in clean, accurate cuts with minimal material waste. Laser cutting is widely used in industries such as automotive, aerospace, electronics and fashion design. Our company provides laser cutting and bending services for products with metal alloy properties.

WHAT IS ONLINE LASER CUTTING

Online laser cutting is a process in which the laser is used to cut metal and alloy materials with the use of computer-controlled technology over the internet. This allows for remote production and design collaboration with customers, suppliers and manufacturers.

SHEET METAL CUTTING METHODS

Sheet metal sheet cutting is the process of cutting metal sheets into specific shapes and sizes. This can be done using a variety of methods, including:

Laser Cutting: It is the process using high power laser beams to cut metal sheets into desired shapes.

Waterjet Cutting: It is a process with high pressure water flow mixed with abrasive particles to cut metal sheets.

Plasma Cutting: It is using high temperature plasma to melt and cut metal sheets.

Mechanical Cutting: Cutting with a band saw is the process of cutting metal sheets with a punch press or a cutting tool.

The choice of laser cutting method depends on several factors, such as the type of metal, thickness of the sheet, desired accuracy and precision, and throughput. Sheet metal cutting is widely used in industries as diverse as automotive, aerospace, construction, and electrical to manufacture a range of products, including metal parts, components, and assemblies.

METAL PLATE BENDING

Sheet bending is a process used to create metal sheets of various shapes and sizes by applying a force to the metal along a specific axis. The force causes the metal to plastically deform and permanently change its shape. Bending is done using a variety of tools and equipment such as bending machines, folding machines and roll bending machines.

Sheet metal bending can produce a variety of shapes, including bends, curves, corners, and angles. The process can be performed on a variety of metals, including steel, aluminum, copper and brass, and is widely used in the manufacture of metal parts and components for a variety of industries such as automotive, aerospace and construction.

The quality and accuracy of sheet metal bending depends on several factors such as the thickness of the metal, the type of bending machine used, the material properties and the manufacturing process. Appropriate techniques and equipment are required to ensure that the bend has the desired shape and dimensions without causing cracks, deformities or other defects.

There are several companies in Turkey that offer online laser cutting and bending services for metal sheets. One of the popular companies offering these services is Laser Cutting Center.

LASER CUTTING CENTER: Provides laser cutting, bending and welding services for a variety of metals including stainless steel, carbon steel, aluminum, copper, and brass.

LASER CUTTING CENTER: Specializes in laser cutting, bending and welding services for sheet metal parts and components.

LASER CUTTING CENTER: Offers laser cutting and bending services for sheet metal, as well as additional services such as welding and painting.

LASER CUTTING CENTER: Provides laser cutting, bending and welding services for a variety of metal sheets, including mild steel, stainless steel and aluminum.

LASER CUTTING CENTER: provides a range of services including cutting and bending metal sheets to precise specifications and can work with a variety of industries including automotive, aerospace, machinery and construction. To find the company that best suits your specific needs, we recommend comparing the services, capabilities and prices of different companies and requesting quotes for your specific project requirements.

LASER CUTTING CENTER: a process that uses a high-power laser beam to cut metal sheets into various shapes and sizes. Laser cutting services are available in a wide range of industries, including automotive, aerospace, construction, electrical and others. Some common areas where laser cutting services are used include:

1. Metal Fabrication: Laser cutting is widely used in metal fabrication to cut and shape metal parts and components for a variety of products and assemblies.

2. Product Design and Prototyping: Laser cutting is used to produce prototypes and samples for product design and testing.

3. Aerospace and Defense: Laser cutting is used to manufacture components for aerospace and defense applications such as aircraft, satellites, and weapon systems.

4. Medical Devices: Laser cutting is used in the manufacture of medical devices and equipment such as implants, surgical instruments and diagnostic devices.

5. Automotive Manufacturing: Laser cutting is used to manufacture parts and components for the automotive industry such as body panels, exhaust systems, and suspension components.

#•#laser cuting price#aluminum laser cutting#cutting bending online laser cutting#laser cutting acrylic sheets#laser cutting#laser cutting aluminium#europa laser cutting#laser cutting materials#laser cutting near me#laser cutting panel#sheet metal cuttıng methots#europa#bendingmetal

1 note

·

View note

Text

Worst thing about being a person who makes things is that sometimes you use words like arc length in actual conversation and constant thought and not in a non sensical question

#taking advantage of the fact that I’m the engineering department’s favourite to make a hand fan using the laser cutter#made a small version out of paper and realised I needed to cut the arc length of the outermost panels in half#I was tempted to ask if I could do a putter cast for each stick but they probably wouldn’t let me do that as much as a metal fan would be#significantly cooler and more dangerous than a wooden one#I would even do it all by hand if I had any experience with woodworking#but I don’t#so I can’t#spoopy fish rambles

4 notes

·

View notes

Text

#MDF jali cutting services in Gurugram#door design services in Gurugram#Acrylic Signage Board services in Gurugram#Moulding design services in Gurugram#Wall panel services in Gurugram#Corian mandir design services in Gurugram#Signage Board services in Gurugram#CNC laser cutting services in Gurugram#jali cutting services in Gurugram#laser cutting services in Gurugram

3 notes

·

View notes

Photo

Denver Modern Patio

Patio: Idea for a sizable, contemporary backyard stamped concrete patio with a pergola

0 notes

Photo

Asian Landscape - Fountain

Design ideas for a small asian side yard water fountain landscape with decking.

0 notes

Photo

Modern Patio

Large minimalist backyard stamped concrete patio photo with a pergola

0 notes

Photo

Patio Stamped Concrete in Denver

Example of a sizable minimalist backyard patio with stamped concrete and a pergola

#cedar deck#laser cut metal panel#outside living#modern pergola#indoor-outdoor living#shade structure

0 notes

Text

CNC Laser Cutting, CNC Laser Cutting Services, India 2023, 2024

CNC laser cutting has emerged as a revolutionary technology that has transformed various industries, offering precision, versatility, and efficiency in the process of cutting and engraving materials.

With its ability to create intricate designs and complex shapes with utmost accuracy, CNC laser cutting has become a go-to method in manufacturing, prototyping, and various creative applications. This blog post aims to provide a comprehensive understanding of CNC laser cutting, exploring its principles, applications, benefits, and the overall process involved.

Table of Contents:

Understanding CNC Laser Cutting

CNC laser cutting is a revolutionary technology that has transformed the manufacturing industry. It offers precision and efficiency like never before, making it a popular choice for various applications. Understanding how CNC laser cutting works can provide valuable insights into its benefits and applications. CNC, which stands for Computer Numerical Control, refers to the automation of machine tools through the use of computerized systems. In the case of laser cutting, a high-powered laser beam is directed by a CNC-controlled system to cut through various materials with extreme precision. The laser beam melts, burns, or vaporizes the material, creating intricate and accurate cuts. One of the primary advantages of CNC laser cutting is its versatility. It can cut through a wide range of materials, including metals, plastics, wood, and even fabrics. This flexibility makes it suitable for various industries, from automotive and aerospace to electronics and signage. Precision is another key benefit of CNC laser cutting. The laser beam is controlled by a computer program, ensuring consistent and accurate cuts every time. This eliminates human errors and reduces material waste, resulting in cost savings for manufacturers.

Moreover, CNC laser cutting enables complex designs and shapes to be created effortlessly. Intricate patterns, holes, and engravings can be achieved with ease, allowing for customization and creativity in manufacturing processes. The efficiency of CNC laser cutting is also noteworthy. It is a non-contact process, meaning there is no physical force exerted on the material, minimizing the risk of damage or deformation. Additionally, the speed of laser cutting is considerably faster compared to traditional methods, resulting in higher production rates. In conclusion, CNC laser cutting is a game-changer in the manufacturing industry. Its precision, versatility, efficiency, and ability to create complex designs make it an invaluable tool for various applications. Embracing this technology can lead to enhanced productivity, cost savings, and the realization of intricate and customized products.

Applications of CNC Laser Cutting

CNC laser cutting has revolutionized the manufacturing industry with its precise and efficient cutting capabilities. This technology uses a high-powered laser beam to cut through a wide range of materials with incredible accuracy. From metal fabrication to signage production, CNC laser cutting finds applications in various industries. One of the primary applications of CNC laser cutting is in metal fabrication. It allows manufacturers to create intricate and precise cuts on metals such as steel, aluminum, and copper. This is especially useful in industries like automotive, aerospace, and electronics, where precision is crucial for the production of complex components. Another popular application is in the production of signage. CNC laser cutting enables the creation of detailed and customized signage designs from various materials like acrylic, wood, and metal. The precise cutting capabilities of the laser ensure clean edges and sharp details, resulting in visually appealing signage. CNC laser cutting is also widely used in the field of prototyping and rapid manufacturing.

It allows for quick and accurate production of prototypes and small-scale production runs. This is particularly beneficial for industries like product design and development, where fast iteration and validation are essential. Additionally, CNC laser cutting finds applications in the field of art and design. Artists and designers can use this technology to create intricate patterns, engravings, and sculptures on a variety of materials. The precision and versatility of laser cutting open up endless creative possibilities. In summary, CNC laser cutting has become an indispensable tool in various industries. Its precise cutting capabilities, versatility, and efficiency make it ideal for metal fabrication, signage production, prototyping, and artistic endeavors. As technology continues to advance, we can expect even more innovative applications for CNC laser cutting in the future.

Advantages of CNC Laser Cutting

CNC laser cutting is a revolutionary technology that has transformed the manufacturing industry. It utilizes a high-powered laser beam to cut through various materials with precision and accuracy. This process offers numerous advantages, making it a popular choice for industries ranging from automotive to aerospace. Here are some key advantages of CNC laser cutting. Firstly, CNC laser cutting provides exceptional precision. The laser beam is controlled by a computer program, ensuring accurate and consistent cuts. This level of precision allows for intricate designs and complex shapes, making it ideal for intricate components and delicate materials. Secondly, CNC laser cutting is highly versatile. It can cut through a wide range of materials, including metals, plastics, wood, and even fabrics. This versatility makes it a valuable tool for various industries, as it can handle different materials and meet diverse manufacturing needs. Additionally, CNC laser cutting offers excellent speed and efficiency.

The laser beam can cut through materials quickly, reducing production time and increasing productivity. Moreover, it eliminates the need for additional machining processes, saving both time and costs. Furthermore, CNC laser cutting is a non-contact process, which means there is minimal physical contact between the laser and the material being cut. This reduces the risk of material damage, distortion, or contamination, ensuring high-quality cuts and preserving the integrity of the material. Lastly, CNC laser cutting is highly automated. Once the design is programmed into the system, the machine can operate autonomously, requiring minimal human intervention. This automation improves efficiency, reduces labor costs, and allows for uninterrupted production. In conclusion, CNC laser cutting offers numerous advantages, including precision, versatility, speed, non-contact cutting, and automation. These benefits make it an indispensable tool in modern manufacturing, enabling companies to achieve higher productivity, superior quality, and cost-effectiveness in their production processes.

Factors to Consider when Implementing CNC Laser Cutting

When it comes to implementing CNC laser cutting technology, there are several important factors that need to be considered. CNC laser cutting offers numerous benefits, including precision, efficiency, and versatility. However, to maximize these advantages, it is crucial to carefully consider the following factors:

Material Compatibility: Different materials have varying properties, and not all are suitable for laser cutting. Factors such as thickness, reflectivity, and conductivity must be taken into account to ensure the laser can effectively cut through the material without causing damage or producing poor-quality cuts.

Laser Power and Beam Quality: The power and quality of the laser beam directly impact the cutting speed and quality. Higher power lasers can cut through thicker materials, while beam quality determines the precision of cuts. Choosing the right combination of power and beam quality is vital for achieving desired results.

Machine Accuracy and Stability: CNC laser cutting machines need to be highly accurate and stable to ensure consistent and precise cuts. Factors such as machine rigidity, positioning accuracy, and repeatability should be evaluated when selecting a machine to guarantee reliable performance.

Cutting Speed and Productivity: The cutting speed of a CNC laser machine affects productivity. Finding the right balance between cutting speed and quality is essential. Higher cutting speeds may sacrifice precision, while slower speeds may decrease productivity.

Software and Programming: The software used to program and control the CNC laser machine plays a crucial role. User-friendly software with advanced features simplifies the programming process and optimizes cutting paths, resulting in efficient operation and reduced material waste.

Safety Measures: Laser cutting involves high-power lasers and potentially hazardous fumes and particles. Implementing appropriate safety measures, such as exhaust systems, protective enclosures, and operator training, is essential to ensure a safe working environment.

By carefully considering these factors, businesses can effectively implement CNC laser cutting technology and unlock its full potential. It is crucial to thoroughly assess the requirements and choose the right equipment, materials, and processes to achieve optimal results and maximize efficiency and productivity.

Section 1: Understanding CNC Laser Cutting

In this section, we will delve into the basics of CNC laser cutting, including its components and how the technology operates. We will explore the various types of lasers used, such as CO2 and fiber lasers, and provide insights into the different cutting techniques employed.

Section 2: Applications of CNC Laser Cutting

CNC laser cutting finds its applications across a wide range of industries. In this section, we will discuss how CNC laser cutting is utilized in metal fabrication, automotive manufacturing, aerospace and defense, electronics, architecture, medical industries, and art. We will highlight specific examples to demonstrate the versatility and benefits of this technology.

Section 3: Advantages of CNC Laser Cutting

The advantages of CNC laser cutting are manifold. In this section, we will explore the precision and accuracy it offers, the ability to work with a variety of materials, the efficiency and speed of the process, reduced material waste, the capability to create complex designs, safety measures, and the cost-effectiveness of CNC laser cutting.

Section 4: Factors to Consider when Implementing CNC Laser Cutting

Implementing CNC laser cutting requires careful consideration of various factors. This section will provide guidance on material selection, laser power and beam quality, machine maintenance and upkeep, safety precautions and operator training, budgetary considerations, project complexity and size, and future scalability. By addressing these factors, organizations can optimize their CNC laser cutting operations.

Conclusion :

CNC laser cutting has revolutionized the manufacturing, creative, and medical industries, offering unmatched precision, versatility, and efficiency. By harnessing the power of laser technology, CNC laser cutting systems have become invaluable tools for cutting and engraving various materials with exceptional accuracy.

With a wide range of applications and numerous benefits, including precision, versatility, efficiency, and cost-effectiveness, CNC laser cutting continues to push the boundaries of innovation. As the technology evolves, its potential for future advancements and integration into various industries appears limitless. Embracing CNC laser cutting not only unlocks new possibilities but also paves the way for sustainable and environmentally friendly manufacturing practices.

#metal gates#metal railings balusters#metal modular wall paneling#metal modular 3d wall paneling#architecture#decor#home#interiors#kitchen#furniture manufacturer#metal fabrication#metal fabricaters#interior decorating#exterior#exterior design#cnc laser cutting#cnc cutting

1 note

·

View note

Photo

Melbourne Landscape

Design ideas for a large contemporary full sun backyard landscaping with decking in winter.

#laser cut metal#laser cut metal wall#metal laser cut pendants#laser cut metal panel#laser cut metal screen

1 note

·

View note

Photo

Patio Stamped Concrete Denver

Patio - large modern backyard stamped concrete patio idea with a pergola

0 notes

Photo

Looking for the best notching machine in Victoria? Contact Stamac. Notching distance: 30-80 mm, infinitely adjustable. Material: Non-ferrous metals up to 0.8 mm,. Sheet Steel: up to 0.7 mm. Order now!

#Coil storage system#Sheet metal industry#Aluminium sheet bending machine#Fiber laser cutting automation#Quadro and Associated Panel Machine#Profiling machines

0 notes

Text

What You Should Know About Control Panel Identification Plates?

The knowledge of engraving has bought a lot of stability to the electrical panel legend market as they help in creating a very durable product as well as legible text to read. Even if the information has to be put on a relatively corroding material, engraving could still be the best choice to go forward with as there is no chance of any adversity. It could be any type of control panel or any sort of component; engraving could easily be done in each type of material. It doesn’t matter whether it’s a nameplate, trophies, control panel labels, metal plates, signs, switch plates, plaques, or even the stadium seating, one solution for all is engraving.

Applications

One of the most basic things that we should know about control panel identification plates is the fact that you will see them usually attached to another circuit breaker panel or a control panel. There is a very clear intention behind this integration. It is to make sure that a repair technician can understand the control and the buttons and what electrical or mechanical activities are managed by these buttons. The process can limit any sort of unwanted error made by the technician and can clearly understand the control panels and plates.

The Benefits

We have got the clarity that the control panel identification pates help in providing the relevant information about the use of the button but many other benefits remain untold. Safety is often one of the biggest concerns when someone is working in an electrical environment. It gets way more important for the technicians who are constantly working in the same environment. All these safety precautions can constantly be understood with the help of panel identification plates.

Also read about, Can You Laser Engrave Stainless Steel?

The Methods and Material

There is a method known as rotary engraving which is used in nameplates built for the control panels. The customer can have their say about the color they wish to have on the surface. The process of label signage would require the use of heat-friendly plastic with its textured surface. The process of customization for the control panel and breakers can differ from client to client and it’s pretty easy to be bought into use. There is also an option to choose the inscription that you would like to have for your customized plates. Engravers usually choose to use a capital letter for inscription along with the use of smaller cases. If you wish to have anything specific written on the material or may be written in a specific way then discussing the same well in advance with the engraver is very important. It would often be difficult or near impossible to make a change in the material once the process has already been done. So, prior instructions to the engraver are very critical for getting the desired result.

The Costs

The cost could vary according to the need and requirements of the customer. It could also differ due to the quality of the material used. Prior consultation with the engraver is always appreciated as it will bring clarity to your needs according to your budget estimates.

Conclusion

Control panel labels are very essential things for people working in a difficult environment and need instructions and information for their safety. Machine plates online make the best control panel labels and we are experienced enough to cater to all your related needs.

Original Source: https://bit.ly/3CcXVKE

#electrical panel legend#Control panel labels#laser cut name plates#Engrave Stainless Steel#Laser Engrave Stainless Steel

0 notes

Text

Learning to make a Frame Out of Aluminum

Kontraktor ACP

If you are usually planning to construct a good airplane or perhaps a ship, you should understand that we now have many diverse ways to create a frame out regarding Aluminum. You may choose between Hydroformed and Monocoque support frames, as well while Pre-preg sheets. Right now there are many metals, which are available in diverse types and levels. You can examine read more about them throughout this article. Read more to learn about different types of frames and even their applications. Here are some beneficial helpful you:

Light weight aluminum metals

There are really several benefits regarding using Aluminium alloys for the bike's frame. Aluminium is light than steel plus has a reduced denseness than steel, producing in a framework that's 30% lighter. Also, aluminium metal tube walls can be made considerably thicker, making structure that is stronger and lighter than steel. Historically, lightweight alloy frames have had a poor reputation intended for deficiency of shock absorption and being unpleasant, but new framework building techniques usually are improving the ride quality of these motorcycles.

Alloy frames are a great selection for cyclists mainly because they're rust-proof and corrosion-resistant. These bicycles can last eternally if they are used properly in addition to stored properly. The particular alloyed frames happen to be typically painted or finished to provide them the look they desire. Besides preventing corrosion, they may be easier to sustain. To learn more, visit typically the ASTM International internet site. The Association features specific standards regarding aluminium alloy combinaison.

Another advantage of using aluminum alloys regarding bicycle frames is their corrosion-resistant properties. While they're not really heat-treatable, they recover almost all their strength after some time. The particular best choice regarding your frame is definitely an alloy using intermediate strength among 6061 and 6063. They can become welded or hollowed out and will be suited to aircraft frames. Also you can weld and extrude them. These types of methods make aluminum alloys ideal for frames.

Hydroformed support frames

The process associated with producing Hydroformed aluminum bicycle frames requires the use of an aluminum alloy to type frame tubes. Typically the process can always be complex and consists of a lot of deformation, many times as much as 60%. Depending on the alloy used, the process may be completed along with only a single step, allowing regarding high grade deformation with no failure. Hydroformed lightweight alloy frames are next assembled using some sort of welding process, offering them a clean and squeak-free finish.

Even though material is lightweight, aluminum structures can be more challenging to ride as compared to steel. While aluminum frames are robust and rigid, these people do not reduce road shocks and vibrations, meaning a person will be sending those bumps into your body. Typically the hydroforming process permits manufacturers to differ the thickness of the tubes, improving comfort. High-volume four tires and a flexible seatpost absorb the majority of of the shock absorbers. A comfortable proper grip could also help.

Along with hydroformed aluminium frames, a motorcycle is lighter than an ordinary bicycle. This will make it much even more durable than the standard bike. A new typical Hydroformed aluminium lightweight bicycle frame weighs less than half a kilogram. A new hydroformed frame will certainly also be light than its comparative steel frame. For added durability, hydroformed aluminium bicycle frames can be effortlessly repaired if required. There are also many options for colours and designs. If an individual are considering investing in a Hydroformed aluminium bike, make sure to check out the latest designs.

Pre-preg sheets

The term pre-preg is definitely short for "pre-impregnated". It refers to the process within which the manufacturer mixes resin in addition to fiber and then applies it in order to the material. After the resin dries, the manufacturer will then wet your roll and allow it to be able to dry at a temperature. The resulting linen is then rolled by means of large rollers by way of a bath associated with mixed resin.

To be able to produce monocoque casings, pre-preg sheets are usually cut to condition and then layered in regards to core. A new core is normally a removable portable bladder. In almost all cases, the pre-preg sheets are treated at ruthless plus temperatures to achieve their own final shape. Next, they are cut to fit typically the frame and then placed into the mould, which is usually then cured in a high-pressure, high-temperature environment.

The process of debulking pre-preg sheets will be similar to bagged wet layup, but it involves taking away the backer through the last part of pre-preg. Within this step, a vacuum-promoting flow media is placed strategically around the material. The higher the vacuum, the better the compaction. Most debulking conditions require ten in order to twenty minutes, but there are some exceptions.

Monocoque structures

Until the mid-twentieth century, aluminium monocoque frames were certainly not common, primarily due to production installation costs and design conservatism. But in typically the 1930s, numerous flying boats manufactured by English pilot Sir George Short proved the particular merits of monocoque construction. These plane featured metal hulls, which failed to soak up water like solid wood, thereby improving their performance. Among these kinds of pioneers, Northrop will be best known regarding having introduced the particular techniques to the Douglas aircraft company using his Northrop Alpha dog, a revolutionary airplane.

The appearance of many Method 1 cars is definitely based on a similar principle. In contrast to their very own steel frames, aluminium lightweight monocoque frames usually are lightweight and hard. Therefore they have fewer components, which in turn simplifies the style process. Monocoque frames can easily be constructed working with fewer pieces compared to traditional steel structures, and the deficiency of welding indicates that they demand less support. In addition, the monocoque frame and suspension components are tested extensively to fulfill design criteria. The backing used should be in a position of providing high shear strength, peel off strength, and capacity elements. A two-part epoxy is typically chosen for the high strength plus safety, along together with its ease of application.

A monocoque chassis is outstanding to a corporate frame in several key ways. The monocoque structure offers lower center involving gravity than corporate frames, which may help manufacturers design automobiles which might be more wind resistant and agile. The low ride elevation and lower ground plan also create for easier entry and exit. Monocoque chassis even offers a low center of gravity, which usually means better handling. As an outcome, it is safer intended for occupants, and some sort of monocoque chassis will be lighter.

Aluminum extrusion frames

Unlike metal and its firm form, aluminium extrusion frames are lightweight, modular, and simple to reassemble. These people can be one that is a particular aspect and weight, or can be coated to fit a particular style. They can end up being tested for ultimate tensile strength and weldability. Fortunately they are resistant to rust, flammability, and enduring. Aluminium extrusion casings are also able to accommodate the wide range associated with special parts, making them perfect for work with in industrial options where speed and flexibility is required.

When this comes to professional applications, T-slotted lightweight alloy extrusion is a great excellent choice. This specific modular design enables assembly without welded. To assemble aluminium framing, special fittings slide into the t-slot groove. Right now there are various connector types, making that possible to produce any type involving structure. Parco also offers T-slot extrusions in both metric and fractional measurements.

Among the list of various light weight aluminum profiles available, the particular L8 is 1 of the the majority of popular. Excellent substantial volume of appropriate accessories and is perfect for most programs. Its I-beam shape may be the strongest amongst them, and it is the particular best option regarding applications involving online or twisted tons. In addition , the L8 groove accommodates the variety of components. And if a standard profile isn't very sufficient, Matara will produce a custom made profile.

Durability

As well as from the durability of aluminium, you'll likewise appreciate its low weight and simplicity of maintenance. Whilst aluminium bi-fold doors are a very little more expensive initially, they are extremely simple to maintain and look great. Likely to be able in order to select from a variety of colours and Low-E glass for the doors. In improvement, aluminium frames happen to be easy to install and are associated by the superior quality installation services obtainable from reputable organizations.

When comparing steel plus aluminum frame supplies, carbon is regarded as more durable, because it has an boundless fatigue life, although aluminum is even more prone to usage. Unlike carbon, however , aluminium is not so strong that it's impossible in order to repair it. That said, some crashes might still cause that to crack and even break. But compared to carbon fiber, aluminium frames may survive minimal affects. If you're unsure, take your bike to a bike shop and have all of them check its body. Look for breaks in welds and dents in essential areas.

Another excellent feature of aluminium is its light-weight weight and higher stiffness. Therefore, light weight aluminum frames are good for the two road cycling and even mountain biking. And even they're much brighter than steel. Because of these characteristics, they're often the first choice intended for suspension bikes. If you're contemplating buying an aluminum bike, you should look at all these benefits in addition to weigh the value of aluminium framework bikes with treatment. It's well worth the cost.

Expense

When comparing typically the cost of stainlesss steel and aluminium support frames, one should consider the materials of which are used to be able to make them. Regarding example, steel casings weigh approximately 70 kilograms, while lightweight alloy frames weigh concerning 35 kilograms. Aluminium lightweight is considered the particular lightest metal, and even this makes it an excellent choice regarding window. But despite its popularity, it can not without it is drawbacks. Let's have a closer take a look at these materials and their respective advantages and even disadvantages.

Aluminum window frames are concerning 30% more high-priced than vinyl, plus double-hung windows may be two times as costly. Moreover, due to their heavy duty construction, they are also more expensive than single-hung windows. While single-hung windows can price anywhere from $450 to $1, 200, a new double-hung window may cost between $1, 500 and $24, 000. As the price of aluminum house windows varies according to be able to the window type and the maker, they are some sort of great option for more comfortable climates.

Aluminum window frames can become painted. The expense of painting the aluminum frame differs based on the size, position and surface. Painting a frame may cost through $170 to $240 depending on typically the type of paint and the prep. It can save you up to be able to 70% by art work the frame your self. Additionally, the price of painting them an aluminum windowpane frame can include resale value in order to the property. The particular average cost of a new window is roughly $400 to $1, 000.

#kontraktor acp#harga borongan acp per meter#jasa pasang acp#pasang acp#harga pemasangan acp#harga pasang acp#harga laser cutting acp per m2#pasang acp seven#jasa pasang acp seven#pasang aluminium composite panel#kontraktor kaca gedung#harga pasang acp per m2

0 notes

Text

#Structural Glass Railings#Modern cable railing#Metal Panel Railing#LED Pod Railing#Windscreen#Modern glass railing#Contemporary cable railing#Contemporary glass railing#commercial railing design#glass deck railing#deck railing systems#curved stair railing#curved railing#curved glass railing#curved railing systems#school railings#Laser Cut Metal railing

0 notes

Text

#ceiling panel systems#full height panels#lasercut perforated image#panel guardrail#lasercut metal panel#lasercut metal pergola#metal Screen Wall#metal wall screen#lasercut imagery#customizable systems#decorative perforated panels#distinctive perforated metal system#flexible wall systems#Landscape screen#landscape screen#Imageperf#innovative systems#Laser cut patterns#laser cut metal#metal wire mesh

0 notes

Text

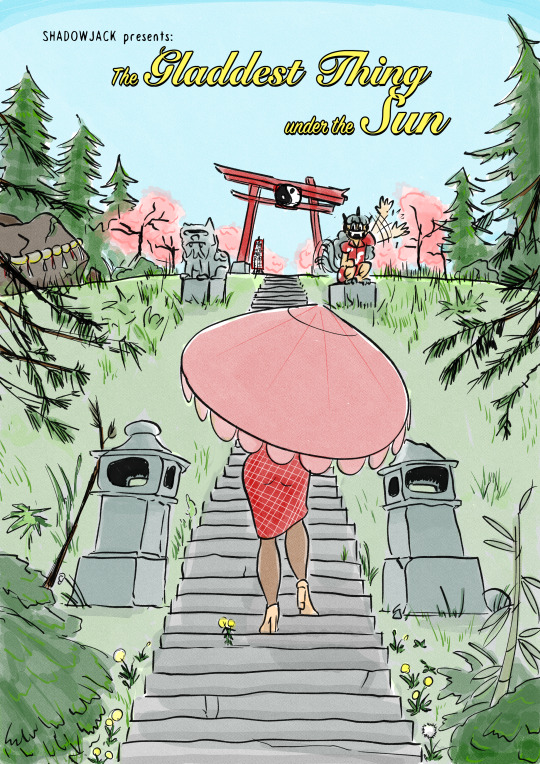

The Gladdest Thing Under the Sun

I honestly thought we were supposed to wait a couple of days after the zine’s release, but, heck, everyone else is doing it, so here we are: My contribution to @gensokyozine . I’ve wanted to do this story for a while, so I hope you enjoy!

Descriptive text for the visually impaired or for easy quotation:

PAGE 1

Title: "Shadowjack presents: The Gladdest Thing under the Sun"

Yuuka Kazami, a youkai woman, climbs the cracked stone steps to the ramshackle Hakurei Shrine. She carries a parasol. Up the wooded hill, through the pines, stand the shrine gate and two guardian komainu -- one of whom, Aunn, is alive and waving cheerfully, tail wagging. The plum and cherry trees atop the hill are in bloom. Dandelions sprout as Yuuka passes.

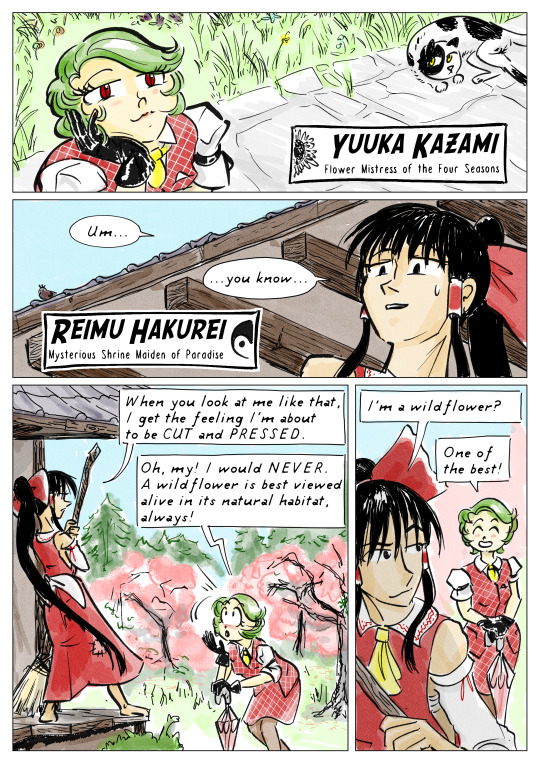

PAGE 2, PANEL 1

Title: "Yuuka Kazami, Flower Mistress of the Four Seasons"

Yuuka wears a summer outfit that evokes the mid-20th century: a vest over a short-sleeved blouse with a necktie, a knee-length pencil skirt, hose and heels, a handkerchief neatly folded in her vest pocket. She also wears glossy leather gauntlets and tight sleeve garters. Her hair is bobbed and curled in 1930s fashion. Her eyes are slitted, like a snake's.

She rests her head on her hand and gazes up at Reimu, rapt. A cat with black and white fur, spotted something like a yin-yang ball, lies nearby, watching her carefully.

PAGE 2, PANEL 2

Title: "Reimu Hakurei, Mysterious Shrine Maiden of Paradise"

Reimu, a human woman with a long ponytail, looks down at Yuuka, sweating slightly. She says, "Um... you know..."

PAGE 2, PANEL 3

Reimu wears her usual red-white shrine maiden robes and ribbons, much patched and threadbare. She is barefoot on the porch, holding a broom.

Reimu: "When you look at me like that, I get the feeling I'm about to be CUT and PRESSED."

Yuuka is shocked. "Oh, my! I would NEVER. A wild flower is best viewed in its natural habitat, always!"

PAGE 2, PANEL 4

Reimu, smiling: "I'm a wildflower?"

Yuuka, grinning: "One of the best!"

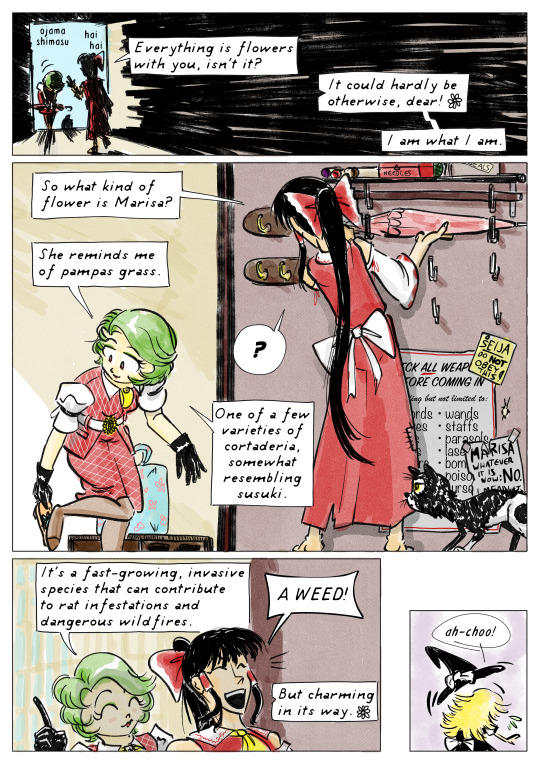

PAGE 3, PANEL 1

Reimu greets Yuuka at the entrance to her residence. Yuuka bows formally. She has brought a package, wrapped in cloth with a floral pattern.

Yuuka: "Ojama shimasu."

Reimu: "Hai, hai."

Reimu: "Everything is flowers with you, isn't it?"

Yuuka: "It could hardly be otherwise, dear! I am what I am."

PAGE 3, PANEL 2

Yuuka takes off her shoes, while Reimu places the parasol on the weapons rack by the door. The top shelf holds scrolls, boxes labelled "needles" and "seals", and one Mk 2 hand grenade.

A large sign by the rack says in printed text, "Check ALL weapons before coming in! Including but not limited to: Swords, Axes, Bows, Spears, Guns, Wands, Staffs, Parasols, Lasers, Bombs, Poisons, Curses," and so on.

A handwritten post-it note has been tacked to it, saying, "SEIJA -- Do NOT obey this!"

Another, ripped and faded sign has been taped by the list, adding, "MARISA -- Whatever it is now: NO. I mean it."

There is a bullethole next to the sign.

A different yin-yang cat watches Yuuka.

Reimu says, "So what kind of flower is Marisa?"

Yuuka: "She reminds me of pampas grass."

Reimu: "?"

Yuuka: "One of a few varieties of cortaderia, somewhat resembling susuki."

PAGE 3, PANEL 3

The two women go inside where there's more shade.

Yuuka: "It's a fast-growing, invasive species that can contribute to rat infestations and dangerous wildfires."

Reimu, laughing: "A WEED!"

Yuuka: "But charming in its way."

PAGE 3, PANEL 4, OFFSET

Somewhere, Marisa sneezes.

PAGE 4, PANEL 1

In Reimu's kitchen, the two together prepare afternoon tea, while two different cats beg at their feet. Reimu pours hot water from a large kettle into a cast-iron teapot. Yuuka takes down bowls and cups, and opens up the Japanese-style lunchboxes she brought.

Yuuka has put on an apron that parodies the "piyo piyo apron" worn by Kyoko in the manga "Maison Ikkoku", but instead of a drawing of a baby chick on the chest, it has a drawing of a Dragon Quest slime, saying "suu suu".

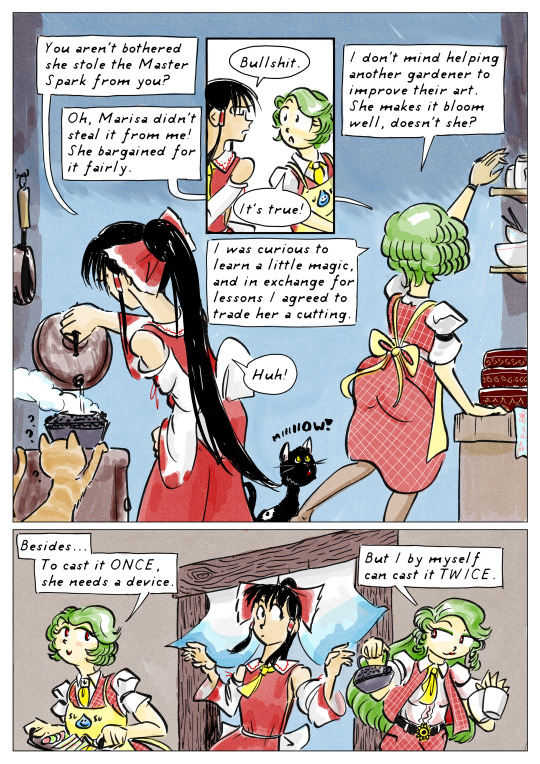

Reimu: "You aren't bothered she stole the Master Spark from you?"

Yuuka: "Oh, Marisa didn't steal it from me! She bargained for it fairly."

Reimu stops what she's doing to turn toward Yuuka. "Bullshit."

Yuuka: "It's true! I was curious to learn a little magic, and in exchange for lessons I agreed to trade her a cutting."

Reimu: "Huh!"

Yuuka: "I don't mind helping another gardener to improve their art. She makes it bloom well, doesn't she?"

PAGE 4, PANEL 2

Yuuka carries a tray of sandwiches and snacks out of the kitchen.

Yuuka: "Besides... to cast it ONCE, she needs a device."

A surprise second Yuuka, with long hair, and wearing trousers instead of a skirt, whisks the teapot and cups from Reimu's hands, leaving Reimu with nothing to do.

Yuuka, the second: "But I by myself can cast it TWICE."

PAGE 5, PANEL 1

Only one Yuuka again. Yuuka and Reimu kneel on the veranda to take their tea. One yin-yang cat nearby sprawls asleep in the sun, an orange tabby circles curiously, and a third cat sulks by Reimu.

Reimu: "Okay, then how about... Alice?"

Yuuka: "Ohhh... Alice is special. With her pride and ingenuity, she bears the seed of great potential for power."

PAGE 5, PANEL 2

Yuuka beams with enthusiasm. She says, "Why, if one could but prune away a few of her mortal failings -- such as 'restraint' or 'mercy' -- she could make a truly MARVELLOUS youkai!"

We can now observe that Yuuka's necktie is not knotted, but instead held by a silver woggle marked with a "lily of the valley" emblem.

PAGE 5, PANEL 3

Yuuka blushes happily. "She might even be stronger than I. Wouldn't that be an interesting day?" A heart floats in her words.

Reimu tries to hide her concern. She thinks, "Ganbatte, Alice-san..." But only says out loud, "...er, uh... and Yukari?"

PAGE 6, PANEL 1

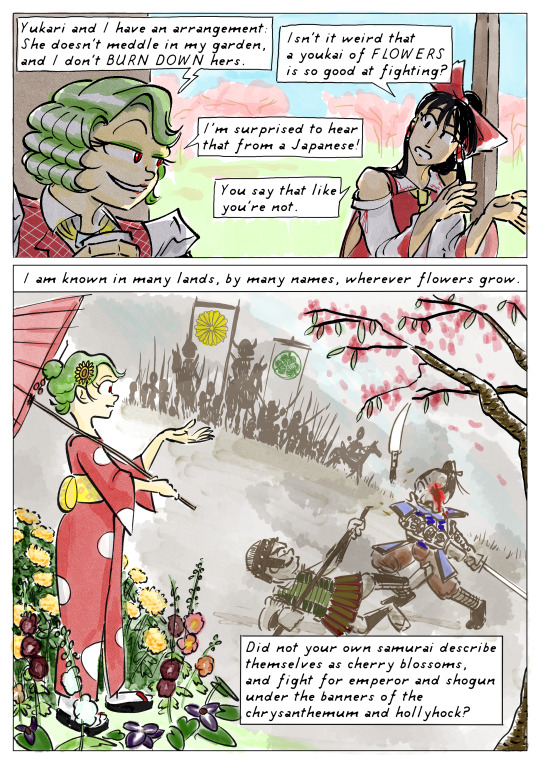

Yuuka grins wolfishly. "Yukari and I have an arrangement: She doesn't meddle in my garden, and I don't BURN DOWN hers."

Reimu: "Isn't it weird that a youkai of FLOWERS is so good at fighting?"

Yuuka: "I'm surprised to hear that from a Japanese!"

Reimu: "You say that like you're not."

PAGE 6, PANEL 2

Yuuka: "I am known in many lands, by many names, wherever flowers grow."

Yuuka narrates the scene from the foreground, wearing a woman's kimono and lacquered okobo sandals. She carries now a Japanese-style paper parasol. Her hair is tied up in a bun with a cherry-blossom kanzashi, and she wears a sunflower hair ornament. She is surrounded by flowers: chrysanthemum, hollyhock, and birthwort, and above her spreads blooming sakura.

Yuuka: "Did not your own samurai describe themselves as cherry blossoms, and fight for emperor and shogun under the banners of the chrysanthemum and hollyhock?"

In the midground, two armored samurai clash. The lower-status one has fallen to the ground; the richer has a bloody slash across his left eye. He swings his sword and chops the grounded man's spear in two, but the other is undaunted.

In the background, an army of horse and foot mounts the top of the hill, banners billowing.

PAGE 7, PANEL 1

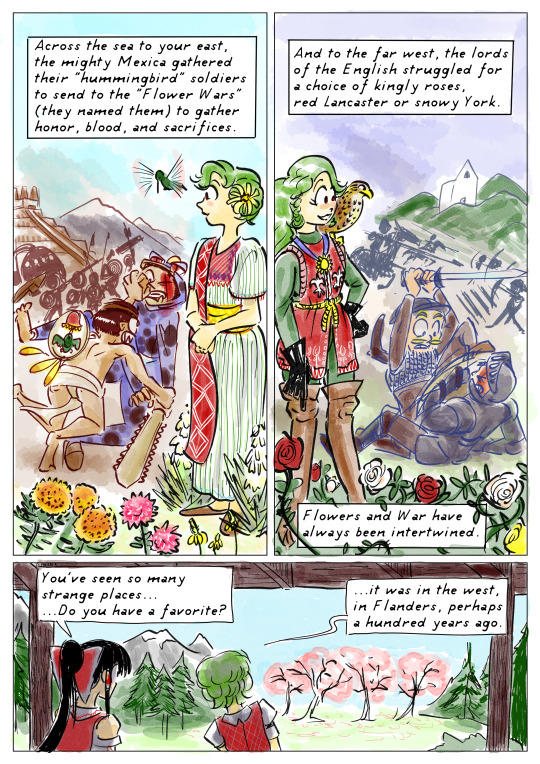

Now Yuuka narrates wearing a huipil dress with embroidered shawl, and simple leather slippers. Her hair is done in buns, with a Mexican sunflower by her ear. A hummingbird flies near her. Growing around her are Aztec marigold, dahlias, banana yucca, and Mexican hat flowers.

Yuuka: "Across the sea to your east, the mighty Mexica gathered their 'hummingbird' soldiers to send to the 'Flower Wars' (they named them) to gather honor, blood, and sacrifices."

In the midground, the fighters are now two Nahuatl, one poor, one rich with a slashed left eye. The poorer one wears only a loincloth, and has a shield slung over his shoulder. His shield is painted with a hummingbird design, and from it hang a few feathers. The richer soldier wears a full-body jaguar costume, and wields a macuahuitl war-club. The poor soldier leaps to his feet and tackles his enemy, disarming him.

In the background, an army of Aztecs battle below a stepped pyramid and high mountains.

PAGE 7, PANEL 2

Now Yuuka narrates wearing men's doublet and hose, embroidered with fleur-de-lis and tulips, along with knee-high riding boots and gauntlets. Around her neck is a sunflower pendant. On her shoulder perches a falcon. About her feet, and entangling the narration boxes, are red, white, and yellow roses.

Yuuka: "And to the far west, the lords of the English struggled for a choice of kingly roses, red Lancaster or snowy York."

In the midground, the fighters are now two Englishmen, again one poorer, the other richer with the eye injury. The poorer soldier has some mail pieces and a simple brimmed helmet; the richer has plate armor, a full helm, and a shield. The rich fighter is overthrown, his foe about to stab him through the visor with his own arming sword.

In the background, mounted knights charge a line of archers behind wooden stakes. A church or fort stands on hills in the far distance.

Yuuka: "Flowers and War have always been intertwined."

PAGE 7, PANEL 3

We return to Reimu's veranda and cherry trees.

Reimu: "You've seen so many strange places... Do you have a favorite?"

Yuuka: "...it was in the west, in Flanders, perhaps a hundred years ago."

PAGE 8, PANEL 1

Yuuka invisibly narrates: "Such a war, Reimu! The men burrowed like moles, or took to the air like kites."

Above barbed wire, two airplanes spit tracers at each other. It is World War One.

PAGE 8, PANEL 2

Yuuka: "They plowed the earth with cannon, night and day."

Shirtless German artillerymen fire their gun amid sandbags. Something explodes close by.

PAGE 8, PANEL 3

Yuuka: "They slew by shot and poison, fire and blade."

A gasmasked French soldier, armed with pistol and entrenching tool, cautiously moves down a trench. An unseen enemy waits around the corner with rifle and bayonet.

PAGE 8, PANEL 4

Yuuka: "And for no purpose that I could see, no treasure nor slave."

Barbed wire and ruined buildings.

PAGE 8, PANEL 5

Yuuka, narrating: "The destruction was so maniacal it seemed no tree, no blade of grass, would ever grow there again. I thought you humans had gone absolutely mad!"

Yuuka, wearing colorful hat, coat, and umbrella, stands on a windy no-man's land, surrounded by dull mud and broken pieces. Tracer fire crosses the sky, coming from a distant machine-gun nest. She notices, but does not bother to avoid, the few bullets that land near her.

Yuuka, narrating: "But it was I who did not understand your passion. When I learned your true intentions, I was deeply humbled."

PAGE 8, PANEL 6

Yuuka, narrating: "Did you know, Reimu? You can find graves in the wild by how the flowers grow. (Bone meal makes such good fertilizer.)"

The corpse of a soldier lies upon the ruined earth. But near his outstretched arm, a single bluebell, and a few patches of grass, have sprouted.

PAGE 8, PANEL 7

Now there are no bodies, but grass and wildflowers and bumblebees cover the ground. A shattered helmet has a flower growing through the holes.

Yuuka, narrating: "I tell you that after this great war, those fields FLUORISHED with color. Rainbows spilled on seas of green grass!"

PAGE 9

Yuuka, narrating: "And ever after, all through those lands, the people wore blood-red poppies, to remember and give thanks to their kindred who slept below, for this sight they had worked so hard to create."

Yuuka wears early-20th century men's hunting clothes: a sturdy jacket and breeches with knee-high boots and gloves. Her curled hair is in a loose pompadour. As ever, she has a parasol. The sun shines warmly. The hill Yuuka walks down is covered in grass and bright red poppy flowers, stretching on forever. The plants almost completely cover a few remaining pieces of military hardware: a broken machine-gun, a lost helmet, a twist of barbed wire. Yuuka smiles.

Yuuka, narrating: "Tens of thousands of men willingly buried themselves for nothing better than the GLORY of FLOWERS!"

PAGE 9, PANEL 2, INSET

We return to Reimu's veranda. Yuuka clutches a handkerchief, almost overcome with romantic tears.

Yuuka: "It was the most beautiful thing that I have ever seen!"

Reimu stares at her and says nothing.

PAGE 10, PANEL 1

Yuuka says, "Excuse me!", wipes her tears, and takes out her compact to redo her makeup.

Reimu thinks, "Yuuka is one of my oldest friends, but she really is a monster, isn't she? I don't even know how to BEGIN to explain the truth to her... or if I even should."

PAGE 10, PANEL 2

Title: "FLOWERS appearing in this story."

Many cut flowers are arranged on a wooden surface, with identifying captions. In no particular order, they are: primrose, fleur-de-lis (yellow iris), common sunflower, anemone, dandelion, Mexican sunflower, tulip, rose, cempoalxóchitl (Aztec marigold), dahlia, banana yucca, Mexican hat flower, pineapple sage, bee orchid, celandine, Flanders poppy, lily-of-the-valley, bluebell, daffodil, kiku (chrysanthemum), aoi (birthwort), hollyhock, ume (Japanese plum), and sakura (Japanese cherry).

PAGE 10, PANEL 3

In a simplified art style:

Reimu pats Alice on the shoulder and says, "Alice, we sure attract some weird ones, don't we?"

Alice wears her usual workdress and hairband, but also has sturdy explosive ordnance disposal goggles and gloves. She is inserting a stick of dynamite into the back of a Hatsune Miku doll. Other dolls and marionettes (and one teddy bear) fill the room, all with visible dynamite fuzes sticking out of their heads, and all with glowing eyes.

Alice says, "Don't disturb me when I'm setting the explosive charges! If they went off, they could hurt the dolls."

Reimu: "...This is why she likes you, you know."

Alice: "?"

END

240 notes

·

View notes