#lead oxide manufactures

Text

#gallium based liquid alloys#indium tin oxide#solder alloys#silver brazing alloys#lead alloys#tin alloys#radiation shielding products#radiation shielding material#tin sheet manufacturers#low melting point alloys#indium wire#indium sheet

1 note

·

View note

Text

"The Environmental Protection Agency (EPA) finalized a rule Tuesday [April 9, 2024] that will require 218 chemical plants to reduce toxic and carcinogenic airborne pollutants, aiming to reduce the number of people with elevated cancer risk by 96% nationwide.

The rulings principally address chloroprene: used to make rubber products, and ethylene oxide, used primarily for sterilizing medical supplies. Long-term exposure to these chemicals and their manufacturing have been identified as possible carcinogens, or cancer-causing agents.

According to a report in the Washington Post, this can include lymphoma, leukemia, breast cancer, and liver cancer.

Across a strip of Louisiana and Texas where half of the 218 chemical manufacturing facilities set to be affected by the new regulations are located, cancer rates of these kinds are substantially higher than national averages, leading it to be colloquially called “Cancer Alley.”

EPA Administrator Michael Regan visited Cancer Alley during the open-comment period of the proposed ruling, and said that across the 85 miles dotted with communities, he failed to meet a single person who didn’t know a loved one or friend who had either developed cancer, died of it, or knew someone who had.

Once implemented, the ruling will reduce more than 6,200 tons of toxic air pollution each year, according to the Post."

-via Good News Network, April 15, 2024

#I was going to say “wait isn't it normal for everyone to know someone who got cancer”#then I remembered that I grew up three miles from the site of a gigantic nuclear meltdown#which hardly anyone knows about it because they fucking covered it up btw#so it's possible I'm wrong and that is not a normal thing#united states#epa#environmental protection agency#louisiana#texas#cancer#cw cancer#public health#pollution#air pollution#environmental racism#environmental justice#oncology#good news#hope#cancer alley

329 notes

·

View notes

Text

Excerpt from this story from The American Prospect:

The Clean Air Act (CAA) has been fiercely opposed by polluters and their allies since its passage in 1970. Industry has never quite stopped fighting to prevent the government from protecting American lives and communities at the expense of even a bit of their profits. But over the past few years, opposition to the law has reached new feverish heights. Multiple cases seeking to gut the CAA have been filed by (or with the support of) oil and gas organizations, their dark-money front groups, and their political allies since 2022.

The ringleaders of this effort are the usual trade groups driving climate apocalypse, including the American Fuel and Petrochemical Manufacturers (AFPM) and the American Petroleum Institute (API), as well as oil giants themselves, like ExxonMobil.

Yet the coordinated attacks on this lifesaving, popular, and historically successful regulation go beyond the singularly destructive interests of the oil industry alone. And they go beyond the federal rule too, and are working their way into litigation against state enactments of the CAA.

Of course, many of the companies driving these suits are some of the biggest names in corporate greenwashing, like Amazon, FedEx, SoCalGas, and more.

These companies have continuously insisted that they are committed to leading the clean-energy transition, even while they fight for the right to poison the general public for profit, and have endeavored—at every turn—to destroy any opportunity the public may have to pursue recourse for it.

Last year, the Truck and Engine Manufacturers Association (EMA) threatened a lawsuit against the California Air Resources Board (CARB) over the state regulator’s Advanced Clean Fleets (ACF) rule.

The rule, which would mandate a “phased-in transition toward zero-emission medium- and heavy-duty vehicles,” threatens the transportation sector’s historically noxious way of doing business; the sector accounts for more than 35 percent of California’s nitrogen oxide emissions and nearly a quarter of California’s on-road greenhouse gas emissions. CARB’s rule could go a long way toward actualizing rapid reductions in the state’s annually generated emissions.

However, later that year EMA and some major truck manufacturers reached an agreement with CARB not to sue over the rules, in exchange for the state’s loosening of some near-term emissions reductions standards.

EMA has by and large kept its promise to not intervene with the regulation in courts, but litigation challenging CARB’s rule would soon be picked up by the California Trucking Association (CTA). Enforcement of the rule has since been on hold, as CARB waits to be issued an ACF-related waiver from the EPA in return for CTA not filing for preliminary injunction against the law.

Even despite these agreements, some of EMA’s own members—and even some of those specifically signed on to the CARB deal—pop up on CTA’s member rolls, as per CTA’s own 2023 membership directory. Daimler Trucks North America and Navistar, Inc., are specifically listed as Allied Members of CTA for 2023.

Amazon is listed among CTA’s Carrier Members, while separately making routine promises to be a partner in the fight against climate change. While Amazon announced its “Climate Pledge” in 2019 of reaching net-zero emissions by 2040 to great fanfare, and has since branded itself a climate leader, the Center for Investigative Reporting has detailed how the e-commerce giant is overselling its green credentials by drastically undercounting its carbon emissions.

In truth, Amazon’s emissions have increased more than 40 percent in the time since it issued the pledge. Amazon also remains the largest emitter of the “Big Five” tech companies, producing no less than 16.2 million metric tons of CO2 every year. Without question, the corporation should be regarded as an industry leader in greenwashing, rather than in actual climate action.

FedEx is also a CTA Carrier-level member. Like Amazon, the company has also made promises “to achieve carbon neutral operations by 2040,” an initiative FedEx has labeled “Priority Earth.” In the years since, FedEx has funneled intensive time and resources into lobbying directly against climate action while pushing its net-zero greenwashing narrative.

UPS is another CTA Carrier-level member. UPS has historically been less effusive in its climate promises than have other corporations on this list, but the delivery giant has continuously reinforced its stance that “everyone shares responsibility to improve energy efficiency and to reduce GHG emissions in the atmosphere.”

7 notes

·

View notes

Text

Preserving Assets: The Role of Corrosion Inhibitors in Industrial Maintenance

Corrosion is a persistent threat to industrial assets, causing billions of dollars in damages annually across various sectors. From oil and gas facilities to manufacturing plants, the impact of corrosion can be devastating, leading to equipment failures, production downtime, and costly repairs. However, with the right preventive measures in place, such as corrosion inhibitors, industrial facilities can effectively mitigate the risk of corrosion and prolong the lifespan of their assets. As a leading chemical company in Vadodara, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) understands the critical role of corrosion inhibitors in industrial maintenance. In this blog post, we'll explore the importance of corrosion inhibitors, their applications, and the expertise of ICPL as a corrosion inhibitor manufacturer and exporter in India.

Understanding Corrosion Inhibitors

Corrosion inhibitors are chemical compounds designed to protect metal surfaces from the damaging effects of corrosion. By forming a protective barrier on the metal surface or altering the corrosion process, inhibitors prevent or slow down the oxidation and deterioration of metals in corrosive environments. Corrosion inhibitors are widely used in various industries, including oil and gas, petrochemicals, power generation, water treatment, and manufacturing, to safeguard critical assets and infrastructure from corrosion-related failures.

The Importance of Corrosion Inhibitors in Industrial Maintenance

1. Asset Protection: Industrial facilities rely heavily on equipment and infrastructure made of metal, such as pipelines, tanks, vessels, and machinery. Corrosion inhibitors play a crucial role in protecting these assets from corrosion, extending their service life and reducing the need for frequent repairs or replacements.

2. Cost Savings: Corrosion-related failures can result in significant financial losses due to equipment downtime, production disruptions, and repair expenses. By incorporating corrosion inhibitors into maintenance programs, industries can minimize the risk of corrosion-related failures and realize substantial cost savings in the long run.

3. Safety and Reliability: Corrosion compromises the structural integrity of industrial assets, posing safety hazards to personnel and the surrounding environment. Corrosion inhibitors help maintain the reliability and safety of critical infrastructure, reducing the likelihood of accidents, spills, and environmental contamination.

4. Environmental Protection: Corrosion-related leaks and spills can have detrimental environmental consequences, polluting soil, water bodies, and ecosystems. By preventing corrosion and minimizing the risk of leaks and spills, corrosion inhibitors contribute to environmental protection and sustainability efforts.

Applications of Corrosion Inhibitors

Corrosion inhibitors find applications across various industrial sectors, where metal components are exposed to corrosive environments. Some common applications of corrosion inhibitors include:

Oil and Gas Production: In the oil and gas industry, corrosion inhibitors are used to protect pipelines, well casings, and production equipment from corrosion caused by corrosive fluids, gases, and environmental conditions.

Water Treatment: Corrosion inhibitors are added to cooling water systems, boilers, and wastewater treatment facilities to prevent metal corrosion caused by dissolved oxygen, scale formation, and aggressive ions.

Manufacturing: In manufacturing processes involving metal components, such as automotive, aerospace, and electronics manufacturing, corrosion inhibitors are used to protect parts, components, and machinery from corrosion during production, storage, and transportation.

Marine and Offshore Structures: Corrosion inhibitors are applied to marine vessels, offshore platforms, and coastal structures to protect against corrosion in seawater environments.

ICPL: Your Trusted Corrosion Inhibitor Manufacturer and Exporter in India

As the best chemical company in Vadodara, ICPL is dedicated to delivering high-quality corrosion inhibitors tailored to the specific needs of industrial clients. Here's why ICPL is the preferred choice for corrosion inhibitors in India:

Expertise and Experience: With decades of experience in the chemical industry, ICPL possesses the expertise and technical know-how to develop and manufacture corrosion inhibitors that meet the highest quality standards and regulatory requirements.

State-of-the-Art Facilities: ICPL operates state-of-the-art manufacturing facilities equipped with advanced technologies and production processes to ensure the consistent quality and performance of its corrosion inhibitors.

Customized Solutions: ICPL offers customized corrosion inhibitor formulations tailored to the unique requirements and operating conditions of industrial applications. Our team of experts works closely with clients to develop solutions that address specific corrosion challenges and performance objectives.

Global Reach: As a corrosion inhibitor exporter in India, ICPL serves clients worldwide, exporting its products to diverse markets across Asia, Africa, the Middle East, and beyond. With a strong global presence and distribution network, ICPL delivers reliable corrosion protection solutions to industries around the globe.

Conclusion

In conclusion, corrosion inhibitors play a crucial role in industrial maintenance by protecting metal assets from the damaging effects of corrosion. As a leading corrosion inhibitor manufacturer and exporter in India, ICPL is committed to providing high-quality corrosion inhibitors that safeguard critical infrastructure, ensure operational reliability, and promote cost-effective maintenance practices. With ICPL's expertise, customized solutions, and global reach, industries can effectively mitigate the risk of corrosion and preserve the integrity of their assets for years to come. Contact ICPL today to learn more about our corrosion inhibitor products and solutions.

#Corrosion inhibitor Vadodara#Best chemical company in Vadodara#Corrosion Inhibitor exporter in India#Corrosion inhibitors manufacturer in India#Oxygen scavenger Chemical in Vadodara#Oxygen scavenger Chemical supplier in Gujarat#Oxygen scavenger Chemical Manufacture India#Oxygen scavenger Chemical exporter in Gujarat#Oil and gas industry#Oil and gas companies#Oil and gas pipelines#leading Oilfield Chemicals manufacturer and exporter in India

7 notes

·

View notes

Text

Aluminum Boat Maintenance Q&A: Expert Insights

As an aluminum boat owner, you know that proper maintenance is key to ensuring your vessel's longevity and performance on the water. However, with the unique properties of aluminum, there are specific considerations to keep in mind. In this comprehensive Q&A, we'll tap into expert insights to address some of the most common questions and concerns regarding aluminum boat maintenance.

Cleaning and Protecting the Hull

How should I clean the aluminum hull of my boat? According to experts, the best way to clean aluminum boat hull is to use a dedicated aluminum boat hull cleaner or a mild soap and water solution. Avoid harsh chemicals or abrasive cleaners, as they can damage the aluminum's protective oxide layer. Regular cleaning helps prevent the buildup of salt, dirt, and other contaminants that can lead to corrosion. Experts recommend using a soft brush or cloth to gently scrub the hull, paying extra attention to areas where dirt and grime tend to accumulate, such as around hardware and fittings. Rinse thoroughly with fresh water after cleaning to remove any residual soap or cleaner.What's the best way to protect the aluminum hull from corrosion? Applying a high-quality aluminum boat wax or sealant is crucial for protecting the hull from corrosion. These products create a barrier against moisture, salt, and other corrosive elements, while also enhancing the boat's appearance. Experts recommend waxing or sealing the hull at least once a year, or more frequently if you use your boat in harsh conditions. When selecting a wax or sealant, look for products specifically formulated for aluminum boats. These products often contain additives that help inhibit corrosion and provide additional protection against UV rays and other environmental factors.

Dealing with Dents and Scratches

How can I repair minor dents in my aluminum boat? For small dents, you can often use specialized aluminum dent repair tools or techniques, like suction cups, to gently massage the metal back into shape. However, for larger or more severe dents, you may need to seek professional assistance from a reputable boat repair shop or mobile fiberglass repair service near you. Aluminum Boat Hull Repair: Unraveling the CostsWhat's the best way to remove scratches from an aluminum boat? Depending on the depth and severity of the scratches, you can try using a fine-grit sandpaper or aluminum polish to buff them out. For deeper scratches, you may need to consider professional assistance, as they may require more extensive repair work, such as welding or patching. When addressing scratches yourself, start with the finest grit sandpaper or aluminum polish, and work your way up to coarser grits if necessary. Be sure to follow the manufacturer's instructions and take care not to over-sand or create additional scratches or swirl marks.

Corrosion and Electrolysis Prevention

How can I identify and address corrosion on my aluminum boat? Corrosion often manifests as pitting, discoloration, or flaking on the aluminum surface. To address it, you'll need to remove the affected areas, either by sanding or using a chemical treatment, and then apply a protective coating or paint. In severe cases, you may need to seek professional assistance for more extensive repairs or even partial replacement of corroded components. Identifying corrosion early is key to preventing it from spreading and causing more significant damage.What causes electrolysis in aluminum boats, and how can I prevent it? Electrolysis is a form of corrosion caused by electrical currents passing through the aluminum and the surrounding water. It can be prevented by ensuring proper bonding and grounding of your boat's electrical systems, as well as by using sacrificial anodes or zincs to protect the aluminum from galvanic corrosion. Restoring Aluminum Boats: Addressing Frequent Concerns

Leak and Hole Repairs

How can I repair a small hole or leak in my aluminum boat? For minor leaks or holes, you can often use a marine-grade epoxy or aluminum patching compound to seal the affected area. However, for larger holes or more extensive damage, you may need to seek professional assistance for welding or patching services.Can aluminum boats be repaired if they have significant hull damage? Yes, in many cases, even severe hull damage can be repaired on aluminum boats. Reputable boat repair shops and mobile fiberglass repair services can often perform welding, patching, or even partial hull replacement to restore the structural integrity of your vessel.By following these expert insights and addressing common concerns, you can keep your aluminum boat in top condition and enjoy many years of safe and enjoyable adventures on the water. Remember, proper maintenance is key to preserving the longevity and value of your aluminum vessel.

3 notes

·

View notes

Text

Discharged in large quantities by textile, cosmetic, ink, paper and other manufacturers, dyes carry high-toxicity and can bring potential carcinogens to wastewater. It's a major concern for wastewater treatment -- but researchers in Drexel University's College of Engineering may have found a solution, using a tiny nanofilament.

A study lead Michel Barsoum, Ph.D., Distinguished University professor in the College of Engineering, and his team, including researchers from Drexel's College of Arts and Sciences, found that a one-dimensional, lepidocrocite structured titanium oxide photocatalyst material has the ability to break down two common dye pollutants -- rhodamine 6G and crystal violet -- under the visible light spectrum. The material also reduced those dye concentrations in the water by 90% and 64%, respectively, in just 30 minutes, when the starting catalyst to dye mass ratio was 1 to 1.

"This is an exciting finding because it helps to address a problem that has been a real challenge for the water treatment process," Barsoum said. "We anticipate that integrating our titanium-oxide photocatalyst into the current processes could improve its effectiveness in removing these chemicals, as well as reducing the amount of energy required to do so."

Read more.

#Materials Science#Science#Dyes#Toxicity#Waste#Water#Drexel University#Titanium oxide#Titanium#Adsorption

15 notes

·

View notes

Text

China has slapped export controls on antimony metals, ores and oxides effective September 15. Companies seeking to export these materials will have to apply for export licenses for dual-use products. That's bad news for resource import-dependent American arms manufacturers.

In its explanation of last Thursday's decision to introduce export controls on antimony, China's Commerce Ministry said the measure was not aimed against any country, but at assuring China’s national security and fulfilling the PRC’s “non-proliferation obligations.” But with China accounting for nearly half of global antimony ore production in 2023, and the US a top buyer, it’s not hard to discern who the restrictions may hit the hardest.

The US International Trade Commission considers antimony “critical to economic and national security – similar to rare earth elements, plus cobalt and uranium.” US business media have described it as “the most important mineral you never heard of.”

That’s because in addition to a long list of civilian uses ranging from flame retardants, lead-acid batteries, and plastics, to ceramics, consumer electronics and safety clothing, antimony has a dizzying array of military applications, from armor-piercing bullets and tracer ammo to night vision goggles, laser sights, communications equipment and even components in nuclear weapons.

3 notes

·

View notes

Text

How does ETO Sterilization work?

What is ETO Sterilization?

Ethylene oxide (ETO) sterilization is a process used to sterilize medical and pharmaceutical products that cannot withstand traditional high-temperature steam sterilization methods. ETO is a gas that effectively kills microorganisms such as bacteria, viruses, and fungi by disrupting their DNA and cellular proteins.

How Does ETO Sterilization Work?

Preparation: Items to be sterilized are placed in a sealed chamber.

Exposure: ETO gas is introduced into the chamber, reaching all surfaces of the items.

Conditioning: The gas is held at specific temperature, humidity, and pressure levels for a predetermined time to ensure effective sterilization.

Aeration: Post-sterilization, the chamber is aerated to remove residual ETO gas, as ETO is toxic and potentially carcinogenic.

Monitoring: Throughout the process, parameters such as gas concentration, temperature, and exposure time are closely monitored to ensure efficacy and safety.

Applications of ETO Sterilizers

ETO sterilization is particularly suitable for:

Medical Devices: Such as surgical instruments, implants, and catheters.

Pharmaceuticals: Including drugs, ointments, and powders that are sensitive to heat and moisture.

Packaging Materials: Like plastic pouches and tubes that cannot withstand high temperatures.

Its ability to penetrate porous materials and complex devices makes ETO sterilization indispensable in many healthcare and pharmaceutical settings where other methods might be impractical or ineffective.

Considerations and Safety

While highly effective, ETO sterilization poses certain safety challenges:

Toxicity: ETO is hazardous to human health and requires careful handling. Workers must be trained in its safe use, and facilities must have adequate ventilation and monitoring systems.

Residuals: Proper aeration is crucial to remove ETO residues, which can otherwise compromise product safety.

Regulatory Compliance: Due to its potential health risks, ETO sterilization is heavily regulated by health authorities and environmental agencies worldwide.

Future Trends and Innovations

As technology advances, efforts are underway to improve the efficiency and safety of ETO sterilization processes. This includes developments in gas monitoring systems, aeration techniques, and automation to minimize human exposure.

Conclusion

ETO sterilization plays a critical role in ensuring the safety and efficacy of medical and pharmaceutical products that are sensitive to heat and moisture. While it requires careful handling due to its toxicity, advancements in technology continue to enhance its reliability and safety. As healthcare and pharmaceutical industries evolve, ETO sterilization remains a cornerstone in the arsenal of sterilization methods, ensuring that healthcare providers and patients alike can trust in the sterility of essential medical products.

Top ETO Sterilizer Manufacturer in India

If you are looking for Best ETO Sterilizer Manufacturer in India, look no further than Instech Sytems, we are a leading manufacturer and supplier of ETO Sterilizer in India.

For more details, please contact us!

Website :- www.cssdtechnologies.com

Contact No. :- +91–8896456000 , +91–9873069138

Email :- [email protected]

#ETO Sterilizer manufacturer#ETO Sterilizer manufacturer in India#Top ETO Sterilizer supplier in India#Best ETO Sterilizer manufacturer in India#Instech Systems

2 notes

·

View notes

Text

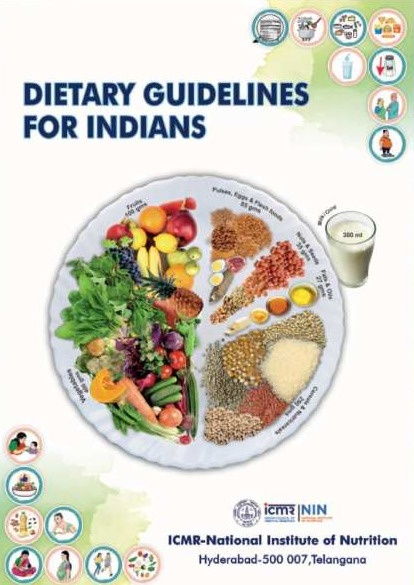

ICMR NUTRITION GUIDELINES 2024 BREAKDOWN : LSFITNESS

Statement 1 : Some protein powders, marketed in packages as protein supplements, contain protein from multiple sources. Protein powders may also contain added sugars, non-caloric sweeteners and additives such as artificial flavoring, hence, are not advisable to be consumed on a regular basis.

My Take: Protein powders that contain proteins from multiple sources are known as protein blends. These blends often include whey protein, casein protein, albumin, and others. Protein blends are completely safe for use if they are manufactured and processed in facilities that adhere to strict safety standards, such as those following HACCP (Hazard Analysis and Critical Control Points) guidelines.

Statement 2 : Protein powders may also contain added sugars, non-caloric sweeteners and additives such as artificial flavoring, hence, are not advisable to be consumed on a regular basis.

My Take: Protein powders may contain added sugars, non-caloric sweeteners, and artificial flavorings. However, these additives are commonplace in many foods we consume today. Rather than casting a negative light on whey protein supplements, it would be more beneficial to implement strict regulations that limit the use of added sugars. Additionally, encouraging the use of healthier non-caloric sweeteners, such as Fructo-oligosaccharides (FOS), and replacing artificial flavorings with natural ones could improve the nutritional quality of these supplements.

Statement 3 : Whey protein is rich in branched chain amino acids (BCAAs). Recent evidence suggests that BCAAs may increase the risk of certain non-communicable diseases (NCDs). As mentioned above, adequate non-protein energy from carbohydrate and fat is essential for dietary proteins/AA to be utilized for protein synthesis and for related functions in the body. Consuming high level of protein, especially in the form of protein supplement powders, is therefore not advisable.

My Take: Whey protein is indeed rich in branched-chain amino acids (BCAAs): leucine, isoleucine, and valine. Recent evidence has shown a direct correlation between elevated plasma levels of BCAAs and insulin resistance, but this does not necessarily mean it is caused solely by high consumption of BCAAs. The condition may also be due to dysfunctional BCAA catabolism, existing insulin resistance, or being overweight or obese.

Elevated plasma BCAA levels have been observed in individuals who are overweight or obese and exhibit insulin resistance, and these levels are higher compared to healthy individuals. Observational studies have found that plasma BCAA levels are also elevated in patients with Type 2 diabetes when compared to age and BMI-matched controls without diabetes.

Insulin plays a critical role in the metabolism of BCAAs. Results from Mendelian randomization studies indicate that insulin resistance drives higher plasma BCAA levels, and large-scale genetic studies suggest a causal role of diminished BCAA catabolism in underlying insulin resistance.

Dysfunctional BCAA catabolism may lead to the accumulation of a number of BCAA catabolic metabolites in the plasma of insulin-resistant individuals with obesity or Type 2 diabetes, including BCAA-derived acylcarnitines, 3-HIB, 2-HB, and 2-KB. These can have toxic effects on cellular functions. It has been shown that acylcarnitines can cause mitochondrial dysfunction in several tissues and anaplerotic stress, thus dysregulating glucose and fat oxidation.

While there is evidence that elevated BCAA levels can impair insulin signaling pathways, it remains unclear whether elevated BCAA levels are a cause or a consequence of insulin resistance. Most studies measure plasma BCAA levels rather than in peripheral tissues, so future research focusing on peripheral tissues could provide a better perspective on tissue-specific BCAA catabolism.

Statement 4 : Most athletes can get the recommended amount of protein through food alone, without the use of supplements. Protein powders are not required. Moreover, prolonged intake of a large amount of protein is associated with potential dangers, such as bone mineral loss and kidney damage.

My Take: Athletes can obtain the recommended amount of protein through their diet alone, depending on what they eat.

For example, a non-vegetarian athlete can easily meet protein needs from sources such as chicken breast, mutton, and whole eggs while maintaining overall caloric intake, as these sources contain fewer ancillary calories.

Conversely, let's consider an athlete who follows a vegan diet. Major vegan protein sources like tofu, cereals and millets, and pulses and legumes do provide some protein. However, if an athlete relies solely on these foods without supplements, the total calorie count may exceed caloric requirements due to the additional carbohydrates and fats in these protein sources.

Regarding the safety of protein consumption, prolonged intake of a significant amount of protein—ranging from 25-75 grams daily—has not been associated with potential dangers such as bone mineral loss and kidney damage. In fact, studies have shown a positive impact on bone mineral density.

The European Society on Parenteral and Enteral Nutrition (ESPEN) advocates for a higher protein intake of 1.0–1.5 g/kg/day to help slow age-related muscle loss.

There is no evidence to suggest that a high protein diet can cause kidney damage in individuals with healthy renal function. However, those with kidney disease, such as chronic kidney disease (CKD), should limit their protein intake.

3 notes

·

View notes

Text

Sodium Molybdate as a Catalyst in Chemical Reactions: Driving Innovation in Chemistry

Within the realm of chemistry, catalysts play a crucial role as inconspicuous protagonists, discreetly expediting chemical reactions and facilitating the advancement of innovative procedures and commodities. Sodium Molybdate, a highly adaptable chemical molecule, has emerged as a pivotal catalyst, fostering advancements across diverse industries. This article examines the importance of Sodium Molybdate, its involvement in catalytic processes, and the contributions made by Palvi Chemicals - one of the excellent Molybdenum chemicals manufacturers in India, and Sodium Molybdate exporter in UAE towards its worldwide influence.

· The Power of Catalysts:

Catalysts are chemical substances that enhance the rate of chemical reactions by reducing the energy required for activation, hence promoting faster and more efficient reaction processes. They facilitate the production of necessary goods while minimising the generation of excess materials.

· Sodium Molybdate: A Versatile Catalyst:

Sodium Molybdate, chemically represented as Na2MoO4, is classified as a sodium compound derived from molybdic acid. This compound is notable for its inclusion of molybdenum, a transition metal. The indispensability of this substance in numerous chemical processes can be attributed to its versatile nature as a catalyst.

· One of the Top Molybdenum Chemicals Manufacturers in India:

India has established itself as a prominent producer of molybdenum compounds, notably Sodium Molybdate. The primary objective of these producers is to produce chemicals of superior quality in order to cater to the varied requirements of businesses on a global scale.

· Trusted Sodium Molybdate Manufacturer in India:

The production of Sodium Molybdate in India necessitates meticulousness and compliance with global benchmarks. The manufacturers inside the nation are widely recognised for their steadfast dedication to producing high-quality products and driving innovation.

· Prominent Sodium Molybdate Exporter in UAE:

The export of Sodium Molybdate and other chemicals is of significant importance in the United Arab Emirates (UAE), which functions as a crucial centre for such activities. Exporters headquartered in the United Arab Emirates (UAE) play a vital role in facilitating the worldwide dissemination of this indispensable catalyst.

· One of the Leading Sodium Molybdate Traders in UAE:

The United Arab Emirates (UAE) is home to a network of traders who play a crucial role in the distribution of Sodium Molybdate. These traders serve as intermediaries, effectively managing the supply chain by connecting manufacturers of Sodium Molybdate with clients located worldwide. The critical nature of their position in the worldwide trade of chemicals cannot be overstated.

· A Distinct Sodium Molybdate Supplier in UAE:

Suppliers operating within the United Arab Emirates (UAE) take measures to ensure the widespread availability of Sodium Molybdate to industries on a global scale. The catalyst's reliability and efficiency play a significant role in facilitating a smooth flow of this catalyst across the global market.

· Applications of Sodium Molybdate:

Sodium Molybdate exhibits a wide range of applications across many industries, encompassing agriculture, metallurgy, and the manufacturing of chemicals and pharmaceuticals. The wide range of processes in which it is utilised highlights its indispensability, owing to its remarkable versatility.

· Catalytic Functions:

Sodium Molybdate serves as a catalyst in a wide range of chemical reactions, including oxidation, desulfurization, and nitrogen fixation. The capacity of this substance to augment reaction rates and selectivity has significant value in several industrial processes.

· Driving Innovation:

The catalytic properties exhibited by Sodium Molybdate play a pivotal role in driving innovation within the fields of chemistry and industry. The significance of this technology in enhancing the effectiveness of chemical processes, mitigating environmental consequences, and facilitating the advancement of novel materials highlights its paramountcy in contemporary society.

Final Thoughts:

Sodium Molybdate exported by a noteworthy Sodium Molybdate supplier in UAE serves as a testament to the significant influence that catalysts exert on the domains of chemistry and industry. Due to its multifunctionality and exceptional catalytic abilities, this phenomenon stimulates the development of novel ideas and facilitates progress across several industries. The collaborative endeavours of Indian manufacturers and UAE exporters, suppliers, and merchants contribute to the widespread accessibility of Sodium Molybdate in global businesses, hence facilitating advancements in the field of chemistry and beyond. As the boundaries of scientific inquiry and industrial progress are further expanded, the catalytic properties of Sodium Molybdate continue to be of utmost importance, serving as a critical driver towards a future characterised by enhanced efficiency and sustainability.

#Molybdenum chemicals manufacturers in India#Sodium Molybdate exporter in UAE#chemical#manufacturer#exporter

7 notes

·

View notes

Text

#pewter metals#white babbitt bearing metals#tin sheet manufacturers#high purity indium tin oxide#tin zinc wire#fusible alloys manufacturer#low melting point alloys#gallium based liquid alloys#cadmium sheet suppliers#radiation shielding products manufacturers#metal foils manufacturer#tin foil manufacturer#indium sheet#fusible alloys#Lead Alloys#radiation shielding products#silver brazing alloys#Solder Alloys#indium wire#indium tin oxide#radiation shielding material#thermal interface materials#lead alloys manufacturers

1 note

·

View note

Text

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes

Text

Climate Change: A Global Crisis Requiring Urgent Action

Introduction

Climate change has emerged as one of the most pressing issues of our time, impacting every corner of the globe and threatening the delicate balance of our planet's ecosystems. The consequences of climate change are far-reaching, affecting not only the environment but also human health, economies, and social stability. In this blog, we will explore the causes and effects of climate change, its implications for the world, and the urgent need for collective action to combat this global crisis.

Understanding Climate Change

Climate change refers to long-term alterations in temperature patterns and weather conditions on Earth. While natural climate variations have occurred throughout history, human activities since the Industrial Revolution have significantly accelerated the pace of change. The primary driver of climate change is the increase in greenhouse gases (GHGs) such as carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) in the atmosphere. These gases trap heat, leading to the greenhouse effect and a rise in global temperatures.

Causes of Climate Change

Burning of Fossil Fuels: The burning of coal, oil, and natural gas for energy production and transportation releases large quantities of CO2 into the atmosphere, contributing to the rise in GHG levels.

Deforestation: Trees play a crucial role in absorbing CO2 through photosynthesis. Deforestation for agriculture, urbanization, and logging reduces the planet's capacity to absorb GHGs, leading to increased atmospheric concentrations.

Industrial Processes: Industrial activities produce GHGs through various processes, including manufacturing, cement production, and chemical reactions.

Agricultural Practices: Farming methods, particularly intensive livestock production and rice cultivation, release significant amounts of methane and nitrous oxide, both potent GHGs.

Impacts of Climate Change

Rising Temperatures: Global average temperatures have been steadily increasing, resulting in heatwaves, extreme weather events, and shifts in precipitation patterns.

Melting Ice and Rising Sea Levels: Higher temperatures are causing the polar ice caps and glaciers to melt, contributing to rising sea levels. This poses a significant threat to coastal communities, ecosystems, and low-lying countries.

Changes in Ecosystems: Climate change disrupts ecosystems, causing shifts in plant and animal species' distributions, loss of biodiversity, and increased risk of species extinction.

Water Scarcity and Droughts: Changing precipitation patterns lead to water scarcity in some regions, affecting agriculture, freshwater availability, and human livelihoods.

Increased Frequency of Extreme Weather Events: Hurricanes, floods, wildfires, and droughts are becoming more frequent and intense due to climate change, causing significant human suffering and economic losses.

The Urgent Need for Action

Addressing climate change requires immediate and concerted action on a global scale. Here are some key steps that individuals, communities, governments, and businesses can take:

Transition to Renewable Energy: Governments should invest in renewable energy sources such as solar, wind, and hydropower, while individuals can support clean energy initiatives and reduce their reliance on fossil fuels.

Reduce Emissions: Governments and industries should implement stricter regulations to reduce GHG emissions. Individuals can contribute by adopting energy-efficient practices, using public transportation, and minimizing waste.

Preserve and Restore Ecosystems: Protecting and restoring forests, wetlands, and other ecosystems helps absorb CO2 and preserve biodiversity.

Promote Sustainable Agriculture: Encouraging sustainable farming practices, such as organic farming and agroforestry, can reduce agricultural emissions and improve soil health.

Educate and Raise Awareness: Public education and awareness campaigns are crucial in promoting a collective understanding of climate change and its consequences.

Conclusion

Climate change is an existential threat that demands immediate action from all sectors of society. The consequences of inaction are severe and will be felt by future generations. By adopting sustainable practices, reducing emissions, and transitioning to renewable energy sources, we can mitigate the worst effects of climate change and build a more resilient and sustainable future. It is our collective responsibility to act now and preserve our planet for generations to come.

4 notes

·

View notes

Text

Choosing the Right Gas Line Corrosion Inhibitor for Your Needs

Corrosion is a significant challenge faced by industries that rely on gas pipelines for transportation and distribution. Gas pipelines, especially those exposed to harsh environmental conditions, are highly susceptible to corrosion, which can compromise the integrity of the entire system. This is where gas line corrosion inhibitors play a crucial role. These specialized chemicals help protect gas lines from corrosion, extending the life of the infrastructure and ensuring safe and efficient operations.

In this blog, we will explore the factors involved in choosing the right gas line corrosion inhibitor for your needs. Additionally, we will look at how gas line corrosion inhibitor manufacturers in India, gas line corrosion inhibitor exporters, and chemical manufacturers contribute to this vital sector, ensuring the global supply of high-quality solutions.

Understanding Gas Line Corrosion and Its Impact

Gas pipelines are prone to different types of corrosion, including internal and external corrosion. Internal corrosion is caused by contaminants like carbon dioxide (CO2), hydrogen sulfide (H2S), oxygen, and water present in the gas. When these contaminants interact with the pipe's surface, they form corrosive compounds that degrade the metal over time. External corrosion, on the other hand, occurs due to environmental factors such as soil composition, moisture, and atmospheric conditions.

Corrosion in gas pipelines can result in:

Leaks: Even minor corrosion can weaken the pipeline walls, causing gas leaks that pose safety risks and result in product loss.

Operational inefficiency: Corrosion can restrict the flow of gas through the pipeline, reducing the efficiency of the entire transportation system.

Costly repairs: Pipeline corrosion can lead to frequent maintenance and expensive repairs, increasing operational costs.

Environmental damage: Corrosion-related pipeline failures can cause gas to leak into the environment, potentially harming ecosystems and contributing to air pollution.

To combat these issues, gas line corrosion inhibitors are commonly used.

What Are Gas Line Corrosion Inhibitors?

Gas line corrosion inhibitors are chemical compounds designed to prevent or minimize the corrosion of metal surfaces in pipelines. These inhibitors form a protective barrier on the internal and external surfaces of the gas line, preventing corrosive agents from coming into direct contact with the metal.

There are several types of gas line corrosion inhibitors available, each formulated to target specific types of corrosion and environmental conditions. Understanding the different types and how they work is key to selecting the right inhibitor for your needs.

Types of Gas Line Corrosion Inhibitors

Gas line corrosion inhibitors can be classified into several categories based on their chemical composition and mode of action:

Film-Forming Inhibitors: These inhibitors create a protective layer on the metal surface, preventing corrosive agents from attacking the metal. Film-forming inhibitors are particularly effective for internal corrosion caused by acidic gases like CO2 and H2S. They are widely used in both gas and oil pipelines.

Passivating Inhibitors: Passivating inhibitors react with the metal surface to form a passive oxide layer, which inhibits further corrosion. These inhibitors are commonly used in pipelines carrying gases that contain high levels of oxygen.

Cathodic Inhibitors: These inhibitors work by reducing the rate of the cathodic reaction in the corrosion process. They are effective in controlling external corrosion in gas pipelines buried underground or exposed to humid environments.

Oxygen Scavengers: Oxygen scavengers are chemical agents that remove dissolved oxygen from the gas, preventing it from reacting with the metal surface. Oxygen is a primary cause of internal corrosion in gas pipelines, so using oxygen scavengers is an effective way to mitigate this risk.

Volatile Corrosion Inhibitors (VCIs): VCIs release vapors that condense on the metal surface, forming a protective film that prevents corrosion. These inhibitors are often used in gas pipelines exposed to atmospheric corrosion.

Factors to Consider When Choosing a Gas Line Corrosion Inhibitor

Selecting the right gas line corrosion inhibitor for your pipeline depends on various factors, including the type of gas being transported, environmental conditions, and the specific corrosion challenges you face. Here are some key factors to consider:

Type of Gas: The composition of the gas being transported plays a significant role in determining the type of corrosion inhibitor required. For instance, pipelines transporting sour gas (gas containing H2S) will require a different inhibitor than those carrying sweet gas (gas without H2S).

Corrosion Type: It is important to identify whether the pipeline is at risk of internal or external corrosion. Internal corrosion requires inhibitors that work inside the pipeline, while external corrosion may require cathodic inhibitors or coatings that protect the outside of the pipeline.

Environmental Conditions: The location of the gas pipeline is another crucial consideration. Pipelines in coastal or humid environments are more prone to external corrosion due to the presence of moisture and salt. In these cases, external corrosion inhibitors or coatings may be necessary.

Temperature and Pressure: High temperatures and pressures can accelerate the rate of corrosion in gas pipelines. When choosing a corrosion inhibitor, ensure that it is designed to withstand the specific temperature and pressure conditions of your pipeline.

Inhibitor Compatibility: It is essential to choose an inhibitor that is compatible with the materials used in the pipeline, as well as with other chemicals that may be present in the gas stream. Incompatible inhibitors can react with the gas or pipeline materials, leading to unintended consequences.

Regulatory Compliance: Different regions may have regulations governing the use of certain chemicals in gas pipelines. When selecting a gas line corrosion inhibitor, ensure that it meets all local and international regulatory requirements.

The Role of Gas Line Corrosion Inhibitor Manufacturers in India

India has emerged as a leading player in the global market for gas line corrosion inhibitors. Gas line corrosion inhibitor manufacturers in India offer high-quality, cost-effective solutions that cater to the specific needs of the oil and gas industry. These manufacturers utilize advanced technologies and rigorous quality control measures to produce inhibitors that meet international standards.

One of the key advantages of sourcing from Indian manufacturers is their ability to provide customized solutions. Indian manufacturers work closely with clients to develop inhibitors tailored to their unique requirements, ensuring maximum protection against corrosion. Additionally, these manufacturers often offer comprehensive technical support, helping clients choose the right inhibitor and implement it effectively.

Exporting Gas Line Corrosion Inhibitors: The Indian Advantage

India’s chemical manufacturing industry has a strong presence in global markets, with many companies acting as gas line corrosion inhibitor exporters. The country’s strategic location, skilled workforce, and competitive pricing make it an attractive source of corrosion inhibitors for international clients.

Gas line corrosion inhibitor exporters from India supply high-performance products to a wide range of industries across the world. These exporters comply with international standards, ensuring that their products meet the stringent requirements of global clients. Furthermore, Indian exporters offer logistical expertise, ensuring timely delivery and reliable supply chains for businesses in need of corrosion protection.

Why Choose a Gas Line Corrosion Inhibitor Supplier from India?

Choosing an Indian gas line corrosion inhibitor supplier can provide several benefits for businesses, including:

Cost-Effectiveness: Indian suppliers offer competitive pricing without compromising on quality, making them a cost-effective choice for businesses looking to protect their pipelines.

Customization: Indian suppliers have the expertise to customize corrosion inhibitors based on the specific needs of their clients, ensuring that the product is optimized for the environment and pipeline conditions.

Regulatory Compliance: Indian suppliers ensure that their products meet both local and international regulatory standards, giving businesses peace of mind when using their products.

Conclusion: Protecting Your Gas Lines with the Right Corrosion Inhibitor

Choosing the right gas line corrosion inhibitor is critical to the longevity and safety of your gas pipeline infrastructure. By considering factors such as the type of gas being transported, the environmental conditions, and the specific corrosion challenges, you can select an inhibitor that provides effective protection.

India’s chemical manufacturers and gas line corrosion inhibitor manufacturers offer a range of high-quality products that cater to both domestic and international markets. With their ability to provide cost-effective, customized solutions, Indian manufacturers and exporters are well-positioned to meet the global demand for gas line corrosion inhibitors.

Whether you’re looking for a gas line corrosion inhibitor supplier and exporter to support your operations, India’s industry leaders can help you find the right solution to protect your pipelines and ensure smooth, safe operations.

I have attached a report, city wise. I have given you all countries’ cities’ report. It is not possible to give in-depth report of cities from USA. Kindly check the attached file of city wise where you will find traffic from all cities, all countries.

#Gas line corrosion inhibitor supplier#Gas line corrosion inhibitor exporter#Gas line corrosion inhibitors#chemical manufacturers#Gas line corrosion inhibitor manufacturer in India#Russia#Tajikistan#Kyrgyzstan#Uzbekistan#Belarus#Azerbaijan#Armenia#Kazakhstan#Moldova#Turkmenistan#Vietnam#Malaysia#Canada

4 notes

·

View notes

Text

Reignite Your Inner Fire: Testogen Testosterone Booster Review

Introduction

Are you having problem with reduced power levels, decreased muscular tissue mass, and an absence of inspiration? If so, you may be experiencing the effects of low testosterone. Testosterone is a crucial hormone that plays an essential duty in numerous aspects of guys's wellness, including muscle mass growth, bone thickness, and also sexual function.

Fortunately, there is a service to assist you restore your vitality and also improve your total performance-- Testogen Testosterone Booster. In this comprehensive testimonial, we will certainly dig deep into the globe of Testogen to give you with all the information you require to make an enlightened decision about this effective supplement.

What is Testogen?

Testogen is a natural testosterone booster that is created with a mix of potent ingredients to help boost the production of testosterone in the body. This supplement is developed especially for guys that are seeking to enhance their physical and also mental efficiency, rise muscle mass, as well as boost their general wellness.

How Does Testogen Work?

Testogen works by targeting the origin of reduced testosterone levels in the body. It contains an one-of-a-kind mix of components that work synergistically to boost the manufacturing of testosterone in the testes. This rise in testosterone levels leads to boosted power levels, boosted muscle mass development, increased sex drive, as well as better overall performance.

The Components of Testogen

D-Aspartic Acid: This amino acid plays a vital function in regulating testosterone synthesis in the body. It boosts the release of luteinizing hormone, which then indicates the testes to generate even more testosterone.

Tribulus Terrestris: This powerful natural herb has been used for centuries to enhance male potency as well as vigor. It works by raising luteinizing hormone levels, bring about a rise in testosterone production.

Panax Ginseng: Recognized for its adaptogenic residential properties, Panax Ginseng helps reduce stress and tiredness, allowing you to execute at your finest both physically as well as mentally.

Fenugreek Extract: Fenugreek is rich in substances that promote the production of testosterone. It also assists increase muscular tissue strength as well as endurance.

Zinc: This crucial mineral is involved in various biochemical procedures in the body, including testosterone production. Zinc shortage has actually been linked to low testosterone levels, so supplementing with this mineral can aid enhance hormone levels.

Vitamin D3: Vitamin D3 plays a crucial role in keeping healthy testosterone levels. It also sustains overall bone wellness as well as immune function.

Selenium: Selenium is an anti-oxidant that helps shield the testes from oxidative damage, therefore protecting testosterone production.

Vitamin B6: Vitamin B6 is involved in the synthesis of testosterone as well as other hormonal agents. It likewise supports mind feature and also mood regulation.

Red Ginseng Extract: Comparable to Panax Ginseng, Red Ginseng extract helps in reducing stress and anxiety as well as improves psychological clarity and focus.

Boron: Boron is a trace mineral that has been shown to raise free testosterone levels while decreasing estrogen levels in the body.

The Advantages of Testogen

Increased Energy Levels: One of the most recognizable benefits of Testogen is its capacity to increase power levels. With greater testosterone levels, you'll really feel extra energetic throughout the day, allowing you to tackle your workouts and day-to-day jobs with ease.

Enhanced Muscular tissue Development: Testosterone plays a critical role in muscular tissue growth and also fixing. By raising your testosterone levels, Testogen can help you attain better gains in lean muscle mass.

Improved Libido and also Sexual Performance: Low testosterone levels can cause a reduced sex drive as well as sexual performance concerns. Testogen can help revitalize your sex life by boosting your desire, boosting erections, and boosting overall sex-related performance.

Increased Focus and Mental Clearness: Testosterone not just affects physical efficiency but additionally cognitive function. By increasing testosterone levels, Testogen can enhance your emphasis, focus, as well as mental clarity.

Reduced Body Fat: Greater testosterone levels have actually been connected to a decline in body fat percent. Testogen can assist you attain a leaner figure by advertising fat loss.

Enhanced State of mind and also Health: Reduced testosterone levels are frequently related to feelings of tiredness, irritability, and also depression. By boosting testosterone manufacturing, Testogen can assist improve your state of mind and also general feeling of wellness.

Frequently Asked Concerns (FAQs)

Q1: What is the suggested dose of Testogen?

A1: The recommended dose of Testogen is four capsules each day. It is best to take one pill with each dish and an extra pill prior to bed.

Q2: Exist any adverse effects of utilizing Testogen?

A2: Testogen is made from all-natural active ingredients and also is normally secure for usage. Nevertheless, it's always a good concept to speak with your healthcare provider prior to beginning any new supplement regimen.

Q3: How much time does it take to see results with Testogen?

A3: Results may differ from person to person, but a lot of customers report experiencing noticeable improvements within a few weeks of regular use. For ideal results, it is advised to make use of Testogen for at the very least 2 months.

Q4: Can ladies make use of Testogen?

A4: While Testogen is particularly created for males, women can additionally benefit from enhanced testosterone levels. However, it is essential for women to speak with their healthcare provider prior to using any kind of testosterone-boosting supplement.

Q5: Does Testogen come with a money-back guarantee?

A5: Yes, Testogen provides a 100-day money-back warranty. If you are not pleased with the outcomes after making use of the product for at least 90 days, you can return any kind of unused bottles for a complete refund.

Q6: Where can I acquire Testogen?

A6: Testogen can be acquired directly from the official site to ensure you are getting an authentic item. Prevent buying from third-party vendors or unauthorized sellers to stay clear of counterfeit or expired products.

Conclusion

If you're aiming to renew your efficiency, increase your testosterone levels, as well as boost your general health, Testogen Testosterone Booster is a game-changer. With its powerful mix of natural ingredients, Testogen can assist you achieve your health and fitness goals, improve your sex-related performance, and also really feel extra invigorated throughout the day.

Say goodbye to low energy levels, lowered muscular tissue mass, and a dull sex life. Take control of your vigor with Testogen and also unlock your full potential. Do not go for standard-- supercharge your performance with Testogen today!

You can find out more: Testogen side effects

3 notes

·

View notes

Photo

Beyond Moore's Law: Innovations in solid-state physics include ultra-thin 2D materials and more

In the ceaseless pursuit of energy-efficient computing, new devices designed at UC Santa Barbara show promise for enhancements in information processing and data storage.

Researchers in the lab of Kaustav Banerjee, a professor of electrical and computer engineering, have published a new paper describing several of these devices, "Quantum-engineered devices based on 2D materials for next-generation information processing and storage," in the journal Advanced Materials. Arnab Pal, who recently received his doctorate, is the lead author.

Each device is intended to address challenges associated with conventional computing in a new way. All four operate at very low voltages and are characterized as being low leakage, as opposed to the conventional metal-oxide semiconductor field-effect transistors (MOSFETs) found in smartphones that drain power even when turned off. But because they are based on processing steps similar to those used to make MOSFETs, the new devices could be produced at scale using existing industry-standard manufacturing processes for semiconductors.

Read more.

19 notes

·

View notes