#machinereliability

Explore tagged Tumblr posts

Text

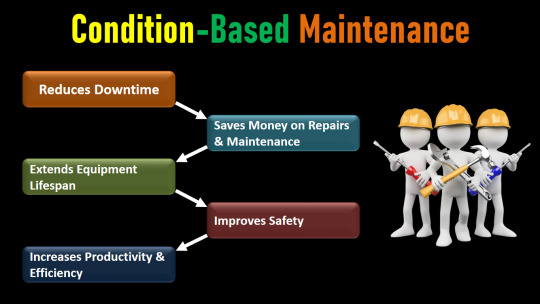

Condition-Based Maintenance: How It Works & Why It Matters

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

0 notes

Text

#seimitsu#automation#seimitsufactoryautomation#robotics#supplier#distributor#PrecisionEngineering#MachineReliability#electric

0 notes

Text

Vibration Analysis In Kalpakkam

https://www.arunstudy.com/portfolio/vibration-analysis-in-kalpakkam/

Vibration Analysis in Kalpakkam

🔧 Vibration Analysis – The key to efficient and reliable machinery!

🌟 Why is it important?

🛠️ Early fault detection to prevent costly breakdowns.

🔍 Predictive maintenance for timely repairs.

⏳ Longer equipment life & reduced downtime.

💰 Cost-effective maintenance strategies.

💡 How it works Using tools like vibration sensors, data acquisition systems, and advanced signal processing, engineers can identify issues like imbalance, misalignment, and bearing defects.

🚀 Where it’s applied

🏭 Manufacturing

✈️ Aerospace

⚡ Energy

🚗 Automotive

📈 Future Trends IoT sensors, AI-driven diagnostics, and remote monitoring are revolutionizing the way we maintain machinery.

✨ Discover how vibration analysis ensures smoother operations, reliability, and cost savings!

#VibrationAnalysis #Kalpakkam #PredictiveMaintenance #IndustrialEfficiency #IoT #MachineReliability

0 notes

Text

A good spindle should last at least 10 to 15 years under normal operating conditions. You can prevent most spindle failures by following a few simple maintenance procedures, like measuring the force of your spindle twice per year to prevent vibrations and running out due to a drop in force. Always keep fluid levels at normal and use the manufacturer’s suggested, good-quality lubrication products that are free from contaminants.

🌐 https://unitedaxleofnm.com . . . . .

spindlemaintenance #industrialmaintenance #machinecare #precisionmachining #longlastingspindles #machinereliability #manufacturingtips #maintenanceprocedures #spindlelongevity #operationalefficiency

0 notes

Text

Condition-Based Maintenance: How It Works & Why It Matters

Imagine if your car could tell you exactly when it needs an oil change rather than following a fixed schedule. Instead of guessing or changing the oil too early, you’d only do it when it’s actually necessary, saving time and money while keeping your engine in top shape. That’s the core idea behind Condition-Based Maintenance (CBM) in industries.

CBM is a smart maintenance strategy that monitors the real-time condition of machines and equipment. Instead of performing maintenance on a fixed schedule (like every three months), CBM uses sensors and data analysis to determine when maintenance is truly needed. This approach helps prevent unnecessary servicing while avoiding unexpected breakdowns.

➥ How Does Condition-Based Maintenance Work?

CBM relies on real-time monitoring and data-driven decision-making. Here’s a simple breakdown of how it works:

✅ 1. Sensors Collect Real-Time Data

Machines are equipped with sensors that track critical performance indicators such as:

Temperature – Helps detect overheating issues.

Vibration – Identifies misalignments or wear in rotating equipment.

Pressure Levels – Ensures pumps, compressors, and hydraulic systems are working properly.

Oil Quality – Measures contamination or degradation in lubricants.

✅ 2. Data Is Analyzed to Detect Problems

The collected sensor data is continuously monitored and compared to normal operating conditions. If the system detects unusual behavior, like excessive vibration or rising temperature, it signals a potential issue.

For example, if a motor starts vibrating abnormally, it could indicate a misalignment, loose parts, or an upcoming failure. Maintenance teams receive an alert, allowing them to inspect and fix the issue before the motor breaks down.

✅ 3. Maintenance Is Performed When Needed

Instead of following a fixed maintenance schedule (which can either be too frequent or too late), CBM ensures maintenance is done only when the data suggests it's necessary. This reduces unnecessary downtime and repair costs while keeping machines running efficiently.

Read in detail: https://www.knowledgewale.com/2025/03/condition-based-maintenance.html

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

1 note

·

View note

Text

All moving mechanical systems will eventually fail and require the repair or replacement of different components. Even the best quality turning machines may suffer a spindle failure, especially when you consider that spindles can rotate as fast as 65,000 RPM or more for high-speed spindles. Spindles may fail due to:

Lack of maintenance

Air contamination

Machine mishandling

Incorrect Preload

Poor lubrication

Machine overload

Spindle imbalance

Drawbar Failures

- Bearing Failures

🌐 https://unitedaxleofnm.com . . . . .

mechanicalfailures #spindleissues #machinemaintenance #highspeedspindles #mechanicalrepair #componentreplacement #machinereliability #industrialmaintenance #spindlefailureanalysis #lubricationmatters #machinehealth #bearings #machinerytroubleshooting #precisionmachining #engineeringchallenges #mechanicalsystems #machinefailuremodes #manufacturingissues #industrialengineering #preventivemaintenance #machinerycare #rotationalfailures #operationalreliability

0 notes