#industrialmaintenance

Text

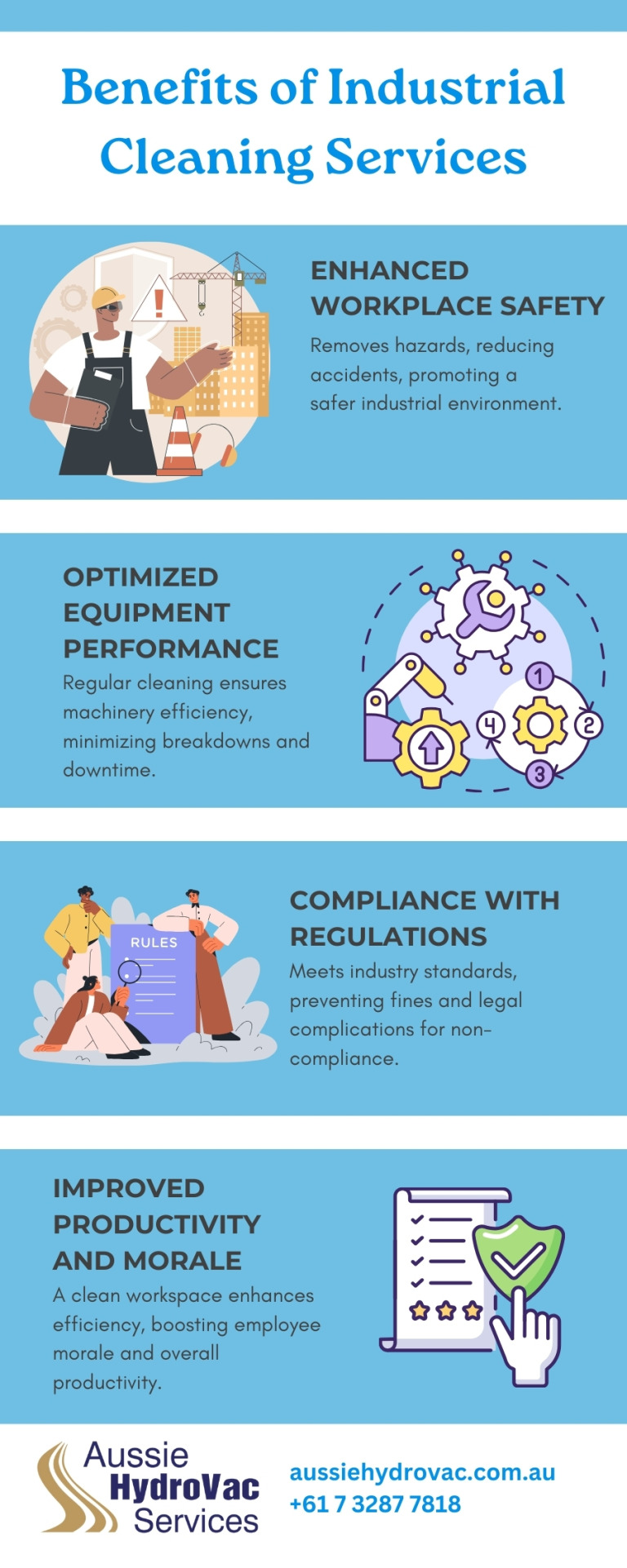

Industrial Cleaning Service

Discover unparalleled industrial cleaning services at Aussie Hydrovac. Our expert team ensures meticulous cleaning during shutdowns, utilizing cutting-edge technology for a spotless, efficient, and safe industrial environment. Experience excellence in industrial cleaning with us.

#IndustrialCleaningService#IndustrialCleaning#ShutdownCleaning#HydrovacServices#IndustrialMaintenance#SafetyFirst

2 notes

·

View notes

Text

Super Screw for Belt: The Future of Conveyor Belt Maintenance

Welcome to the future of conveyor belt maintenance! In this blog post, we are excited to introduce you to the game-changing solution for conveyor belt repairs and maintenance – the Super Screw for Belt. Say goodbye to costly and time-consuming belt replacements, and say hello to a more efficient and cost-effective way of keeping your conveyor systems running smoothly. Let's dive in and explore the incredible benefits and features of this innovative product.

Enhanced Durability:

The Super Screw for Belt is engineered with durability in mind. Made from high-quality materials, this solution provides exceptional resistance to wear, tear, and impact. Its robust construction ensures a longer lifespan for your conveyor belts, minimizing downtime and maximizing productivity.

Easy Installation:

Gone are the days of complex and time-consuming belt repairs. With the Super Screw for Belt, installation becomes a breeze. Its unique design allows for quick and hassle-free installation, eliminating the need for specialized tools or expertise. You can get your conveyor system up and running in no time, saving both time and labor costs.

Versatile Application:

No matter the industry or conveyor belt type, the Super Screw for Belt offers versatile application options. Whether you're dealing with fabric belts, steel cord belts, or even solid woven belts, this solution is compatible with a wide range of belt materials. Its flexibility ensures a reliable and secure joint, providing optimal performance in various operating conditions.

Increased Efficiency:

By minimizing maintenance time and reducing the need for belt replacements, the Super Screw for Belt significantly boosts overall operational efficiency. With fewer interruptions and improved uptime, your production lines can maintain a smooth workflow, resulting in enhanced productivity and cost savings.

Cost-Effective Solution:

Replacing entire conveyor belts can be a substantial investment. The Super Screw for Belt offers a cost-effective alternative by extending the life of your existing belts. Its affordable price, coupled with its long-lasting performance, delivers an excellent return on investment. Say goodbye to frequent belt replacements and hello to significant cost savings.

Conclusion:

The Super Screw for Belt is the future of conveyor belt maintenance, offering enhanced durability, easy installation, versatility, increased efficiency, and cost savings. Whether you operate in mining, manufacturing, logistics, or any other industry that relies on conveyor systems, this innovative solution is designed to optimize your operations. Visit our website to learn more about the Super Screw for Belt and take your conveyor belt maintenance to the next level. Upgrade to this game-changing solution and experience the benefits firsthand.

2 notes

·

View notes

Text

Why is Industrial Cleaning Important for Safety?

Industrial cleaning plays a crucial role in ensuring a safe and healthy work environment. Factories, warehouses, and other industrial facilities are prone to accumulating dust, dirt, grease, and hazardous materials. If left unaddressed, these elements can pose serious risks to workers' health and safety.

One of the primary reasons industrial cleaning is crucial for safety is to prevent accidents. Slippery floors from spilled oils or dust buildup can lead to slips, trips, and falls, which are common workplace injuries. Proper cleaning ensures that these hazards are minimized, keeping the work environment safe for everyone.

Additionally, industrial cleaning helps in controlling the spread of harmful substances. Many industrial environments involve chemicals, heavy machinery, and waste products that can be dangerous if not handled correctly. Regular cleaning reduces the chances of these substances contaminating the workspace and affecting employee health.

Industrial cleaning also ensures compliance with health and safety regulations. Failing to meet cleanliness standards can result in fines, shutdowns, and even legal action. Proper cleaning helps businesses stay compliant with local and national safety guidelines, ensuring the workspace is free from health risks.

A clean industrial facility boosts productivity. When workers feel safe and comfortable, they are more likely to perform better, leading to improved efficiency and morale. Clean workspaces also reduce downtime caused by accidents or machinery failures due to contamination or dust buildup.

In conclusion, industrial cleaning is a vital part of maintaining safety in industrial facilities. It prevents accidents, controls hazardous substances, ensures regulatory compliance, and boosts productivity.

Looking for expert industrial cleaning in Geelong? Contact us today to ensure your facility remains safe, clean, and compliant with all safety standards.

#industrialcleaning#workplacesafety#cleaningservices#geelongbusiness#industrialmaintenance#healthandsafety#cleaningcompany#facilitymanagement#safeenvironment#professionalcleaning

0 notes

Text

Fluke Temperature Calibration: Precision Instruments for Accurate Temperature Measurement

Ensure precise and reliable temperature measurement with Fluke Temperature Calibration instruments. Trusted by professionals across various industries, Fluke Calibration tools offer superior accuracy and consistency, making them ideal for critical applications such as process control, laboratory testing, and industrial maintenance. With advanced technology and user-friendly features, Fluke’s temperature calibration solutions help you maintain high standards of performance and compliance.

0 notes

Text

🛠️ Keep Your Electrogalvanized Metals in Top Shape! 🛠️ Proper maintenance ensures longevity and performance for your metals. Here are some quick tips.

Proper maintenance is key to ensuring the longevity and performance of electrogalvanized metals.

https://www.noblemetalcoating.com/

#ElectroGalvanizing#MetalMaintenance#CorrosionPrevention#ProtectYourInvestment#IndustrialMaintenance#DurableMetals#MetalCare#RustProtection#MetalFinishing#QualityPreservation

0 notes

Text

#PredictiveMaintenance#MaintenanceTechnology#IndustrialMaintenance#ConditionMonitoring#PredictiveAnalytics#IndustrialIoT#AssetManagement#SmartMaintenance#DataDrivenMaintenance#MaintenanceSolutions#OperationalExcellence#IndustrialAutomation#AIinMaintenance#MachineLearning#ManufacturingTech#TechInnovation#PreventiveMaintenance#RealTimeMonitoring

0 notes

Text

The Ultimate Guide to Online Leak Sealing in Industrial Plants

0 notes

Text

Enhance your industrial operations with SGK India's reliable plant maintenance services. Our expert team ensures seamless plant functioning, reduced downtime, and cost savings. Choose SGK India for professional maintenance solutions and experience a boost in productivity and efficiency. Secure your plant’s future with us!

#IndustrialMaintenance#PlantMaintenance#SeamlessOperations#EfficiencyBoost#ReduceDowntime#SGKIndia#IndustrialSolutions#OperationalExcellence#CostSavings#ProductivityIncrease

0 notes

Text

Discover the essential guide to flange and threaded connections in pump systems! From choosing the right connection to ensuring leak-free operations, this comprehensive resource covers everything you need to know for optimal performance and reliability. Perfect for engineers, technicians, and anyone working with pump systems.

0 notes

Video

youtube

How to Install Slide Rubber Lagging - Complete Tutorial@DCCD_Group

#youtube#conveyorsystem#rubberlagging#installationtips#industrialmaintenance#conveyormaintenance#installationguide#dccd

0 notes

Text

Maintaining Precision Machinery: The Role of shim sheets in Preventing Wear and Tear

Shim sheets are essential tools for maintaining precision machinery, helping to ensure proper alignment and reduce wear and tear. This article explains how shim sheets work, including their types and materials like stainless steel, brass, and plastic.

It highlights the importance of machinery maintenance, emphasizing how shim sheets contribute to,

Increased friction: This generates heat, which can damage machine parts.

Reduced accuracy: Misalignment can affect the precision of the machine's output.

Premature wear: Excessive stress on components due to misalignment can accelerate wear and tear.

Vibration: Misalignment can cause vibrations that can damage the machine and reduce its lifespan.

You’ll learn how to choose the right shim plates, install them correctly, and address common issues such as misalignment and wear. This article also explores some benefits of Shim sheet plates like ,

Precision Alignment: shim sheets help you achieve exact alignments, which is critical for precision machinery.

Reduced Wear and Tear: By filling gaps and ensuring proper fit, shim sheets minimize friction and wear on moving parts.

Vibration Damping: Properly installed shim sheets can help reduce vibrations, which can contribute to wear and tear.

Cost-Effective: shim sheets are often more affordable than other alignment methods and can be used in bulk.

Ease of Use: shim sheets are easy to install and adjust, making them a practical choice for regular maintenance.

This article also explores about How to Use shim sheets Effectively

To get the most out of shim plates, follow these guidelines:

Determine the Right Size and Thickness: Measure the gap or space you need to fill and select a shim plate of the appropriate size and thickness. Precut shims can simplify this process.

Choose the Right Material: Select a material based on the environment and load requirements. For example, use stainless steel for heavy-duty applications. SS shim sheet are particularly robust for high-load situations.

Install Correctly: Place the shim sheets in the correct position to ensure proper alignment. Make sure they are securely fitted.

Regular Checks: Periodically check and adjust shim sheets as needed to maintain alignment and prevent wear.

Keep Records: Document the installation and adjustments of shim sheets for future reference and maintenance planning.

The article also covers some issues that can arise with shim plates. Here’s how to troubleshoot these common problems:

Misalignment: If machinery isn’t aligned correctly, check if the shim sheets are the right size and thickness. Adjust or replace as needed. Shim sheet metal can also be used to create custom shims.

Wear on Shim Plates: Over time, shim sheets can wear out. Inspect them regularly and replace them if they show signs of excessive wear. SS shims manufacturers can provide high-quality replacements.

Vibration Issues: If you’re experiencing vibrations, ensure that shim sheets are properly installed and that there are no gaps or loose fittings. Consider using bimetallic washers for additional stability.

shim sheets are an essential tool for maintaining the health and longevity of precision machinery. By understanding their role in preventing wear and tear, you can significantly improve the performance and efficiency of your equipment. Regular inspections, proper installation, and high-quality shim sheets are key to achieving optimal results.

#precisionmachinery#machinerymaintenance#preventwearandtear#industrialmaintenance#equipmentmaintenance

0 notes

Text

A Comprehensive Guide to Troubleshooting Common Problems in Industrial Heating Systems

Industrial heating systems are essential for maintaining the proper temperatures required in various industrial processes, such as manufacturing and food processing. However, like any complex machinery, they can experience issues that disrupt operations. Efficient troubleshooting can reduce downtime and prevent costly repairs. This guide will help you understand and resolve common issues with industrial heating systems using straightforward language and practical steps.

1. Checking for Power Supply Issues

Power supply problems often cause many issues in industrial heating systems. If your system is not turning on or is shutting down unexpectedly, start by examining the power supply.

Step-by-Step Process:

Verify the Power Switch: Ensure the power switch on the heating system is in the "on" position. It might seem basic, but the switch can sometimes get turned off accidentally.

Inspect Electrical Connections: Check all electrical connections for loose or damaged wires. Over time, vibrations and wear can cause connections to loosen, leading to power issues.

Check Fuses and Circuit Breakers: Examine the fuses and circuit breakers associated with the heating system. If you find any blown fuses or tripped breakers, replace or reset them as needed. Blown fuses can occur due to overloads or short circuits.

Examine the Power Source: Ensure that the power source to the system is stable and consistent. Power surges or outages can impact system performance.

For more detailed guidance on troubleshooting power issues, visit the Electrical Safety Foundation International, which offers insights into electrical safety and maintenance.

2. Inspecting the Thermostat

The thermostat plays a crucial role in regulating the temperature within an industrial heating system. If your system is not reaching the desired temperature or is experiencing temperature fluctuations, the thermostat might be the issue.

Step-by-Step Process:

Check Thermostat Settings: Confirm that the thermostat settings are correct and match the desired temperature. Sometimes, incorrect settings can lead to improper heating.

Clean the Thermostat: Dust and debris can affect the performance of the thermostat. Gently clean the thermostat using a soft brush or cloth to remove any dirt.

Test the Thermostat: Use a multimeter to test the thermostat’s functionality. This tool will help you determine if the thermostat is providing accurate readings and signals to the heating system.

Consider Calibration: If the thermostat is still not working correctly, it may need calibration or replacement. Check the manufacturer’s guidelines for calibration procedures.

For further information on thermostat troubleshooting, visit Thermocouple Technologies, which provides in-depth resources on temperature control and measurement.

3. Examining the Heating Elements

Heating elements are responsible for generating heat in the system. Over time, these elements can wear out or become damaged, leading to reduced heating efficiency or system malfunctions.

Step-by-Step Process:

Turn Off Power: Always ensure that the power to the heating system is turned off before inspecting the heating elements. This is crucial for safety.

Inspect for Damage: Look for visible signs of damage, such as cracks, burn marks, or broken elements. Damaged heating elements can cause uneven heating or complete failure of the system.

Test Continuity: Use a multimeter to test the continuity of the heating elements. Continuity testing will help you determine if the elements are functioning properly. If the meter shows no continuity, the element may need replacement.

Replace If Necessary: If you find that the heating elements are damaged or faulty, replace them with new ones. Follow the manufacturer’s instructions for installation.

For guidance on maintaining and replacing heating elements, visit Heating Elements Experts, which offers a range of resources on heating element maintenance.

4. Looking for Airflow Problems

Proper airflow is essential for the efficient operation of industrial heating systems. Blocked or restricted airflow can lead to overheating, inefficient heating, or damage to the system.

Step-by-Step Process:

Inspect Air Filters: Check the air filters for clogging or dirt buildup. Clean or replace filters as necessary. Dirty filters can restrict airflow and reduce the system’s efficiency.

Check Vents and Ducts: Ensure that all vents and ducts are free of obstructions. Blocked vents can prevent proper circulation of warm air, leading to uneven heating.

Examine the Blower Motor: Inspect the blower motor and fan for any issues. A malfunctioning blower can affect airflow and heating performance. Ensure that the motor is operating smoothly and quietly.

Clean Components: Regularly clean vents, ducts, and the blower motor to maintain optimal airflow. Accumulated dust and debris can impact system performance.

Learn more about airflow issues and solutions at HVAC.com, which provides extensive information on heating, ventilation, and air conditioning systems.

5. Checking for Leaks or Corrosion

Leaks or corrosion in an industrial heating system can lead to significant performance issues and potential damage. Regular inspections can help identify and address these problems before they escalate.

Step-by-Step Process:

Inspect for Leaks: Examine pipes, valves, and other components for any signs of leakage. Leaks can cause loss of heat and reduce the efficiency of the system. Address leaks promptly to prevent further damage.

Look for Corrosion: Check for any rust or corrosion on metal parts. Corrosion can weaken components and lead to system failure. Clean or replace corroded parts as needed.

Repair or Replace: Depending on the extent of the damage, repair minor leaks or corrosion issues. For more severe problems, consider replacing the affected components.

Preventive Measures: Apply anti-corrosion coatings or treatments to metal parts to prevent future corrosion. Regular maintenance and inspections can help identify potential issues early.

For tips on preventing and managing leaks and corrosion, visit Industrial Equipment News, which offers insights into equipment maintenance and management.

Conclusion

Troubleshooting industrial heating systems involves a systematic approach to identifying and resolving common issues. By checking the power supply, inspecting the thermostat, examining the heating elements, ensuring proper airflow, and looking for leaks or corrosion, you can maintain the efficiency and reliability of your heating system.

Regular maintenance and prompt troubleshooting are essential for keeping your industrial heating system in optimal condition. For comprehensive services and solutions, consider reaching out to experts specializing in Industrial Heating Systems in Ajman. This will ensure that your system continues to perform efficiently and effectively, minimizing downtime and maximizing productivity.

#IndustrialHeating#Troubleshooting#HeatingSystems#IndustrialMaintenance#HeatingSolutions#SystemRepair#MaintenanceTips

0 notes

Text

2K Protective Coatings Market worth $10.8 billion by 2025

The report "2K Protective Coatings Market by Resin Type (Epoxy, Polyurethane, Alkyd, Acrylic), End-use Industry (Oil & Gas, Petrochemical, Marine, Cargo Containers, Power Generation, Water and Waste Treatment), Application, and Region – Global Forecast to 2025" The global 2K protective coatings market size will grow to USD 10.8 billion by 2025 from USD 8.6 billion in 2020, at a CAGR of 4.8% during the 2020-2025 period. The use of 2K protective coatings in offshore structures/oil & gas exploration, production, and transmission and civil building & infrastructure is expected to increase in APAC in the next five years.

Download pdf- https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=209520665

Epoxy is projected to be the largest resin type of the 2K protective coatings market.

Epoxy is the largest resin type in 2K protective coatings market in terms of volume. The properties of epoxy-based coatings can be enhanced by adding additives and modifiers to meet the required specifications. They are hard and offer resistance to humidity, abrasion, water, acid, alkali, and seawater. They possess low volatility and are water cleanable. These properties make these coatings ideal for use in metallic surfaces such as cast iron and aluminum. Epoxy-based coatings are also applied on floors that are prone to heavy foot and vehicle traffic. Fusion bonded epoxy powder coatings are used for corrosion protection in steel pipes and fittings in the oil & gas industry and water transmission lines.

Request Sample- https://www.marketsandmarkets.com/requestsampleNew.asp?id=209520665

Civil building and infrastructure is the fastest-growing pigment type of the 2K protective coatings market.

Civil building and infrastructure is the fastest growing end-use industry in 2K protective coatings market, in terms of volume. The main purpose of 2K protective coatings is to protect structures from solvents, dust, fungi, corrosion, humidity, and other threat that may affect the stability and functionality of the structures. 2K protective coatings also provide waterproofing solutions, thereby preventing water leakages. 2K protective coatings act as a protective barrier that enables structures such as buildings, dams, wells, bridges, floors, wood finishes, and exterior & interior walls to function in demanding environments and situations.

APAC is the largest 2K protective coatings market globally.

APAC is projected to lead the 2K protective coatings market and this dominance is expected to continue till 2025. China is the key market in the region, consuming close to half of the demand for 2K protective coatings. The region is seen as a lucrative market for the growth of 2K protective coatings. Increasing foreign investments increases the overall demand for 2K protective coatings. Apart from major countries such as China, India, Japan, and South Korea, countries like Taiwan and Thailand are gathering attention and are growing at a brisk pace.

The key players profiled in the 2K protective coatings market report are AkzoNobel N.V. (Netherlands), PPG Industries (US), The Sherwin-Williams Company (US), Jotun A/S (Norway), Hempel A/S (Denmark), Chugoku Marine Paints Ltd. (Japan), Nippon Paints Holdings Co. Ltd. (Japan), Kansai Paint Co., Ltd. (Japan), Sika AG (Switzerland), and RPM International Inc. (US).

#2KCoatings#ProtectiveCoatings#IndustrialCoatings#CoatingTechnology#CorrosionProtection#IndustrialPaint#SurfaceProtection#CoatingsIndustry#HeavyDutyCoatings#DurableCoatings#AdvancedMaterials#ProtectivePaints#CoatingsSolutions#PerformanceCoatings#IndustrialMaintenance

0 notes

Text

Mica Band Manufacturer is a top-tier producer of high-quality mica bands, known for their excellent electrical insulation and heat resistance. We use advanced technology and stringent quality control to deliver reliable products for various industrial applications. Trust us for durable mica bands tailored to your needs.

#MicaBandHeater#HeatingSolutions#IndustrialHeating#PrecisionHeating#EnergyEfficientHeaters#CustomHeatingSolutions#IndustrialEquipment#ManufacturingInnovation#HeaterManufacturing#IndustrialAutomation#HeatControl#IndustrialMaintenance#DurableHeaters#EcoFriendlyHeating#SmartHeatingSolutions

0 notes

Text

Lusin Clean G 410: Superior High-Temperature Purging Compound for Injection Molding

Lusin Clean G 410 is a top-tier granular purging compound designed specifically for high-temperature injection molding processes. This ready-to-use compound is crafted from high-quality thermoplastic resins and efficient cleaning additives, ensuring thorough cleaning without the use of abrasives. Lusin Clean G 410 is perfect for cleaning screws, barrels, nozzles, and hot-runners, particularly those with external heaters, operating at temperatures between 250°C (482°F) and 410°C (770°F).

The application of Lusin Clean G 410 is straightforward. Simply add the purging compound to the machine and run the process until the compound is fully discharged. For optimal results, use 2-3 times the amount of the purging compound, depending on the severity of contamination. This efficient cleaning process significantly reduces downtime and increases productivity in injection molding operations.

One of the standout features of Lusin Clean G 410 is its economical consumption. Designed to minimize waste, this purging compound offers a cost-effective solution for maintaining the cleanliness and efficiency of your injection molding machines. Additionally, its ability to withstand high temperatures makes it an ideal choice for demanding applications, ensuring your equipment remains in top condition.

#LusinCleanG410#HighTemperaturePurging#InjectionMolding#ThermoplasticResins#EfficientCleaning#IndustrialMaintenance#CostEffectiveSolution#HotRunnerCleaning#ProductivityBoost#Manufacturing

0 notes

Text

Keep Your Operations Running Smoothly with Expert EOT/Overhead Crane Repair & Maintenance

Our team of highly skilled engineers are committed to the task of repairing and servicing Gantry/Goliath cranes in order to ensure their reliability and minimize any chances of breaking down as well enhancing their operational efficiency.

Why Choose Us?

Our expert technicians team handles all your crane repair and maintenance needs.

Our scope of work extends from periodic checks to emergency fix-up services to help keep your machines running smoothly.

Our cranes ever stay in good shape as we use the best components while adhering strictly to industry standards.

Our Services Include:

Regular maintenance and inspections

Emergency repair services

Load testing and certification

Spare parts supply and replacement

Contact Us Today!

📞 +91-98-2413 5305 | ✉️ [email protected] | 🌐 www.endeavourweigh.com/mhe-spare-division-category/mhe-services/

Ensure your EOT/Overhead Cranes are always ready for action. Trust us for reliable repair and maintenance services.

#CraneMaintenance#EOTCraneRepair#OverheadCraneService#IndustrialMaintenance#EndeavourWeigh#ReliableService#HeavyDutyCranes#MaintenanceSolutions

0 notes