#manojkumarpachauri

Explore tagged Tumblr posts

Text

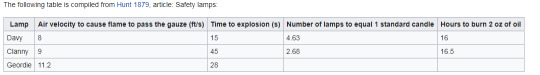

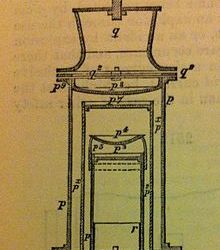

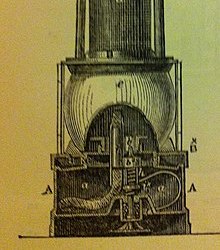

Safety Lamp

A safety lamp is any of several types of lamp that provides illumination in coal mines and is designed to operate in air that may contain coal dust or gases, both of which are potentially flammable or explosive. Until the development of effective electric lamps in the early 1900s, miners used flame lamps to provide illumination. Open flame lamps could ignite flammable gases which collected in mines, causing explosions; safety lamps were developed to enclose the flame and prevent it from igniting the surrounding atmosphere. Flame safety lamps have been replaced in mining with sealed explosion-proof electric lights.

Damps or gases

Miners have traditionally referred to the various gases encountered during mining as damps, from the Middle Low German word dampf (meaning "vapour").Damps are variable mixtures and are historic terms.

Firedamp – Naturally occurring flammable mixtures, principally methane.

Blackdamp or Chokedamp – Nitrogen and carbon dioxide with no oxygen. Formed by complete combustion of firedamp or occurring naturally. Coal in contact with air will oxidize slowly and, if unused workings are not ventilated, pockets of blackdamp may develop. Also referred to as azotic air in some 19th-century papers.

Whitedamp – Formed by the incomplete combustion of coal, or firedamp. The mixture may contain significant amounts of carbon monoxide, which is toxic and potentially explosive.

Stinkdamp – Naturally occurring hydrogen sulphide and other gases. The hydrogen sulphide is highly toxic, but easily detected by smell. The other gases with it may be firedamp or blackdamp.

Afterdamp – The gas from an explosion of firedamp or coal dust. Contains varying proportions of blackdamp and whitedamp and is therefore suffocating, toxic, or explosive, or any combination of these. Afterdamp may also contain stinkdamp. Afterdamp may be a bigger killer following an explosion than the explosion itself.

Open flame illumination

Before the invention of safety lamps, miners used candles with open flames. This gave rise to frequent explosions. For example, at one colliery (Killingworth) in the north east of England, 10 miners were killed in 1806 and 12 in 1809. In 1812, 90 men and boys were suffocated or burnt to death in the Felling Pit near Gateshead and 22 in the following year.

Wood 1853 describes the testing of a mine for firedamp. A candle is prepared by being trimmed and excess fat removed. It is held at arm's length at floor level in one hand, the other hand shielding out all except the tip of the flame. As the candle is raised the tip is observed and if unchanged the atmosphere is safe. If however the tip turns bluish-gray increasing in height to a thin extended point becoming a deeper blue, then firedamp is present.Upon detecting firedamp the candle is lowered and arrangements made for the ventilating of the area or the deliberate firing of the firedamp after the end of a shift. A man edged forward with a candle on the end of a stick. He kept his head down to allow the explosion to pass over him, but as soon as the explosion had occurred stood upright as much as possible to avoid the afterdamp. Officially known as a fireman he was also referred to as a penitent or monk from the hooded garb he wore as protection. The protective clothing was made of wool or leather and well dampened. As can be imagined this procedure did not always preserve the life of the man so employed.

When they came into regular use, barometers were used to tell if atmospheric pressure was low which could lead to more firedamp seeping out of the coal seams into the mine galleries. Even after the introduction of safety lamps this was still essential information, see Trimdon Grange for details of an accident where pressure was involved.

The lack of good lighting was a major cause of the eye affliction nystagmus. Miners working in thin seams or when undercutting the coal had to lie on their side in cramped conditions. The pick was swung horizontally to a point beyond the top of their head. In order to see where they were aiming (and accurate blows were needed), the eyes needed to be straining in what would normally be the upwards and slightly to one side direction.This straining led first to temporary nystagmus and then to a permanent disability. Mild nystagmus would self-correct if a miner ceased to perform this work but if left untreated would force a man to give up mining. The lower levels of light associated with safety lamps caused an increase in the incidence of nystagmus.

First attempts at safe lamps

Both on the continent of Europe and in the UK dried fish skins were used. From them a faint bioluminescence (often called phosphorescence) occurs. Another safe source of illumination in mines was bottles containing fireflies.

Flint and steel mills introduced by Carlisle Spedding (1696-1755) before 1733 had been tried with limited success. An example of a Spedding steel mill may be seen in the museum at Whitehaven where Spedding was manager of the collieries of Sir James Lowther, 4th Baronet. A steel disk was rotated at high speed by a crank mechanism. Pressing a flint against the disk produced a shower of sparks and dim illumination. These mills were troublesome to use and were often worked by a boy, whose only task was to provide light for a group of miners. It was assumed that the sparks had insufficient energy to ignite firedamp until a series of explosions at Wallsend colliery in 1784; a further explosion in June 1785 which the operator of the mill (John Selkirk) survived showed that ignition was possible.

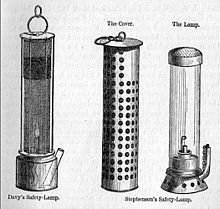

The first safety lamp made by William Reid Clanny used a pair of bellows to pump air through water to a candle burning in a metal case with a glass window. Exhaust gases passed out through water. The lamp gave out only a weak light though it was intrinsically safe provided it was kept upright. It was heavy and ungainly and required a man to pump it continuously. It was not a practical success and Clanny subsequently changed the basis of operation of later lamps in the light of the Davy and Stephenson lamps.

Oil lamps

Principles of operation

Safety lamps have to address the following issues:

Provide adequate light

Do not trigger explosions

Warn of a dangerous atmosphere

Fire requires three elements to burn: fuel, oxidant and heat; the triangle of fire. Remove one element of this triangle and the burning will stop. A safety lamp has to ensure that the triangle of fire is maintained inside the lamp, but cannot pass to the outside.

Fuel – there is fuel in the form of oil inside the lamp and fuel in the form of firedamp or coal dust outside.

Oxidant – there is an oxidant in the form of air present outside the lamp. The design of the lamp must allow the oxidant to pass into the lamp (and therefore exhaust gases to escape) or else the lamp will extinguish.

Heat – heat can be carried by the exhaust gases, through conduction and through burning of firedamp drawn into the lamp passing back down the inlet. Control of the transfer of heat is the key to manufacturing a successful safety lamp.

In the Geordie lamp, the inlet and exhausts are kept separate. Restrictions in the inlet ensure that only just enough air for combustion passes through the lamp. A tall chimney contains the spent gases above the flame. If the percentage of firedamp starts to rise, less oxygen is available in the air and combustion is diminished or extinguished. Early Geordie lamps had a simple pierced copper cap over the chimney to further restrict the flow and to ensure that the vital spent gas did not escape too quickly. Later designs used gauze for the same purpose and also as a barrier in itself. The inlet is through a number of fine tubes (early) or through a gallery (later). In the case of the gallery system air passes through a number of small holes into the gallery and through gauze to the lamp. The tubes both restrict the flow and ensure that any back flow is cooled. The flame front travels more slowly in narrow tubes (a key Stephenson observation) and allows the tubes to effectively stop such a flow.

In the Davy system, a gauze surrounds the flame and extends for a distance above forming a cage. All except the very earliest Davy lamps have a double layer at the top of the cage. Rising hot gases are cooled by the gauze, the metal conducting the heat away and being itself cooled by the incoming air. There is no restriction on the air entering the lamp and so if firedamp is entrained it will burn within the lamp itself. Indeed, the lamp burns brighter in dangerous atmospheres thus acting as a warning to miners of rising firedamp levels. The Clanny configuration uses a short glass section around the flame with a gauze cylinder above it. Air is drawn in and descends just inside the glass, passing up through the flame in the centre of the lamp.

The outer casings of lamps have been made of brass or tinned steel. If a lamp bangs against a hard piece of rock, a spark could be generated if iron or untinned steel were employed.

Examples of lamps

Davy lamp

In the Davy lamp a standard oil lamp is surrounded by fine wire gauze, the top being closed by a double layer of gauze.

If firedamp is drawn into the flame it will burn more brightly and if the proportions are correct may even detonate. The flame on reaching the gauze fails to pass through and so the mine atmosphere is not ignited. However, if the flame is allowed to play on the gauze for a significant period, then it will heat up, sometimes as far as red heat. At this point it is effective, but in a dangerous state. Any further increase in temperature to white heat will ignite the external atmosphere. A sudden draught will case a localised hot spot and the flame will pass through. At a draught of between 4 and 6 feet per second the lamp becomes unsafe. At Wallsend in 1818 lamps were burning red hot (indicating significant firedamp).

A boy (Thomas Elliott) was employed to carry hot lamps to the fresh air and bring cool lamps back. For some reason he stumbled; the gauze was damaged and the damaged lamp triggered the explosion.

At Trimdon Grange (1882) a roof fall caused a sudden blast of air and the flame passed through the gauze with fatal results (69 killed).

Stephenson ("Geordie") lamp

A development of the Geordie lamp was the Purdy. A galley with gauze provided the inlet, above the glass was a chimney with perforated copper cap and gauze outer. A brass tube protected the upper works, shielded them and kept them locked in position. A sprung pin locked the whole together. The pin could only be released by applying a vacuum to a captive hollow screw; not something that a nicotine starved miner could do at the coal face.

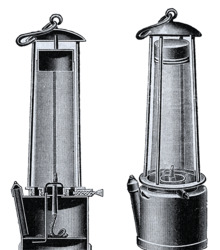

Mueseler lamp

The lamp is a modified Clanny designed by the Belgian Mathieu-Louis Mueseler. The flame is surrounded by a glass tube surmounted by a gauze capped cylinder. Air enters from the side above the glass and flows down to the flame before rising to exit at the top of the lamp. So far this is just a Clanny, but in the Mueseler a metal chimney supported on an internal gauze shelf conducts the combustion products to the top of the lamp. Some Mueseler lamps were fitted with a mechanism which locked the base of the lamp. Turning down the wick eventually released the base, but by then the flame was extinguished and therefore safe.

The lamp was patented in 1840 and in 1864 the Belgian government made this type of lamp compulsory.

In the presence of firedamp the explosive mixture is drawn through two gauzes (cylinder and shelf), burnt and then within the chimney are only burnt gases, not explosive mixture. Like a Clanny, and the Davy before it, it acts as an indicator of firedamp, burning more brightly in its presence. Later models had graduated shields by which the deputy could determine the concentration of firedamp from the heightening of the flame. Whilst the Clanny will continue to burn if laid on its side, potentially cracking the glass; the Mueseler will extinguish itself due to the stoppage of convection currents. The lamp is safe in currents up to 15 feet per second.

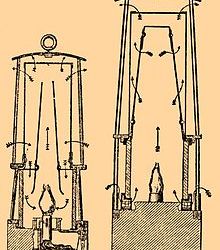

Landau's lamp

The lamp is in part a development of the Geordie. Air enters into a ring near the base which is protected by gauze or perforated plate. The air passes down the side of the lamp passing through a series of gauze covered holes and enters the base through another yet another series of gauze covered holes. Any attempt to unscrew the base causes the lever (shown at f in the illustration) to extinguish the flame. The gauze covered holes and passageways restrict the flow to that required for combustion, so if any part of the oxygen is replaced by firedamp, then the flame is extinguished for want of oxidant.

The upper portion of the lamp uses a chimney like Mueseler and Morgan lamps. The rising gases pass up the chimney and through a gauze. At the top of the chimney a dished reflector diverts the gases out sideways through a number of holes in the chimney. The gases then start to rise up the intermediate chimney before exiting through another gauze. Gas finally passes down between the outermost chimney and the intermediate chimney, exiting a little above the glass. The outer chimney is therefore effectively a shield.

Yates' lamp

The Yates lamp is a development of the Clanny. Air enters through the lower part of the gauze top and leaves through the upper part; there is no chimney. The lower glass part of the lamp has seen some development however. It is replaced by a silvered reflector having a strong lens or bull's-eye in it to allow the light out. The result was a claimed 20 fold improvement in lighting over the Davy. Yates claimed "the temptation to expose the flame to obtain more light is removed".

The base also contained an interlocking mechanism to ensure that the wick was lowered and the lamp extinguished by any attempt to open it.

The lamp was "much more expensive than the forms of lamp now in general use, but Mr, Yates states that the saving of oil effected by its use will in one year pay the additional cost".

#miningmonk#talktomanojpachaury#manoj#manojkumarpachauri#theonlydaizy#kunikasok#ashokkumarpachauri#daizytbp#zakmedios#mining#lamphandling#lampsanditstypes#typesoflamps#safetylamps#Yates' lamp#Clifford#Landau's Lamp#https://www.zakmedios.com#theonlydaizy.in#ashokpachauri#ashwanikumarsaraswat

0 notes

Text

Surface Mining

Surface mining, including strip mining, open-pit mining and mountaintop removal mining, is a broad category of mining in which soil and rock overlying the mineral deposit are removed, in contrast to underground mining, in which the overlying rock is left in place, and the mineral is removed through shafts or tunnels.

The Main Difference between Surface mining & Underground mining is that : Surface mining is suitable for large, low-grade ore deposits which occur below a thin layer of rock or sand. Underground mining is used for small, high-grade deposits covered with a thick soil or rock above the ore.

Surface mining began in the mid-16th century and is practiced throughout the world, although the majority of surface coal mining occurs in North America. It gained popularity throughout the 20th century, and surface mines now produce most of the coal mined in the United States.

In most forms of surface mining, heavy equipment, such as earthmovers, first remove the overburden. Next, large machines, such as dragline excavators or bucket wheel excavators, extract the mineral.

Image above shows the methods of surface mining.

There are five main methods of surface mining, detailed below.

1. Strip mining

2. Open-pit mining

3. Mountaintop removal

4. Dredging

5. Highwall mining

1. Strip mining

"Strip mining" is the practice of mining a seam of mineral, by first removing a long strip of overlying soil and rock (the overburden); this activity is also referred to as "overburden removal". It is most commonly used to mine coal and lignite (brown coal). Strip mining is only practical when the ore body to be excavated is relatively near the surface. This type of mining uses some of the largest machines on earth, including bucket-wheel excavators which can move as much as 12,000 cubic metres of earth per hour.

There are two forms of strip mining. The more common method is "area stripping", which is used on fairly flat terrain, to extract deposits over a large area. As each long strip is excavated, the overburden is placed in the excavation produced by the previous strip.

"Contour mining" involves removing the overburden above the mineral seam near the outcrop in hilly terrain, where the mineral outcrop usually follows the contour of the land. Contour stripping is often followed by auger mining into the hillside, to remove more of the mineral. This method commonly leaves behind terraces in mountainsides.

2. Open-pit mining

"Open-pit mining" refers to a method of extracting rock or minerals from the earth through their removal from an open pit or borrow. Although open-pit mining is sometimes mistakenly referred to as "strip mining", the two methods are different.

The El Chino mine located near Silver City, New Mexico is an open-pit copper mine.

3. Mountaintop removal

"Mountaintop removal mining" (MTR) is a form of coal mining that mines coal seams beneath mountaintops by first removing the mountaintop overlying the coal seam. Explosives are used to break up the rock layers above the seam, which are then removed. Excess mining waste or "overburden" is dumped by large trucks into fills in nearby hollow or valley fills. MTR involves the mass restructuring of earth in order to reach the coal seam as deep as 400 feet (120 m) below the surface. Mountaintop removal replaces the original steep landscape with a much flatter topography. Economic development attempts on reclaimed mine sites include prisons such the Big Sandy Federal Penitentiary in Martin County, Kentucky, small town airports, golf courses such as Twisted Gun in Mingo County, West Virginia and Stonecrest Golf Course in Floyd County, Kentucky, as well as industrial scrubber sludge disposal sites, solid waste landfills, trailer parks, explosive manufacturers, and storage rental lockers.

The technique has been used increasingly in recent years in the Appalachian coal fields of West Virginia, Kentucky, Virginia and Tennessee in the United States. The profound changes in topography and disturbance of pre-existing ecosystems have made mountaintop removal highly controversial.

4. Dredging

"Dredging" is a method for mining below the water table. It is mostly associated with gold mining. Small dredges often use suction to bring the mined material up from the bottom of a water body. Historically, large-scale dredging often used a floating dredge, a barge-like vessel which scooped material up on a conveyor belt in front, removed the desirable component on board, and returned the unwanted material via another conveyor belt in back. In gravel-filled river valleys with shallow water tables, a floating dredge could work its way through the loose sediment in a pond of its own making.

5. Highwall mining

Highwall mining is another form of mining sometimes conducted to recover additional coal adjacent to a surface mined area. The method evolved from auger mining but does not meet the definition of surface mining since it does not involve the removal of overburden to expose the coal seam.

CERB final report No. 2014-004 "Highwall Mining: Design Methodology, Safety, and Suitability" by Yi Luo characterizes it as a "relatively new semi-surface and semi-underground coal mining method that evolved from auger mining".

In Highwall mining, the coal seam is penetrated by a continuous miner propelled by a hydraulic Pushbeam Transfer Mechanism (PTM). A typical cycle includes sumping (launch-pushing forward) and shearing (raising and lowering the cutterhead boom to cut the entire height of the coal seam). As the coal recovery cycle continues, the cutterhead is progressively launched into the coal seam for 19.72 feet (6.01 m).

Then, the Pushbeam Transfer Mechanism (PTM) automatically inserts a 19.72-foot (6.01 m) long rectangular Pushbeam (Screw-Conveyor Segment) into the center section of the machine between the Powerhead and the cutterhead. The Pushbeam system can penetrate nearly 1,200 feet (366 m) into the coal seam.

One patented Highwall mining systems use augers enclosed inside the Pushbeam that prevent the mined coal from being contaminated by rock debris during the conveyance process. Using a video imaging and/or a gamma ray sensor and/or other Geo-Radar systems like a coal-rock interface detection sensor (CID), the operator can see ahead projection of the seam-rock interface and guide the continuous miner's progress.

Highwall mining can produce thousands of tons of coal in contour-strip operations with narrow benches, previously mined areas, trench mine applications and steep-dip seams with controlled water-inflow pump system and/or a gas (inert) venting system.

Recovery with tunneling shape of Drives are much better than round Augering Holes, but the mapping of areas that have been developed by a Highwall miner are not mapped as rigorously as deep mined areas.

Very little soil is displaced in contrast with mountain top removal; however a large amount of capital is required to operate and own a Highwall miner. But then this Highwall mining system is the innovative roadmap future potential and stay or being better competitive in the area of environmental friendly non mountain-top (overburden) removal operated by only 4 crew members.

Mapping of the outcrop as well as core hole data and samples taken during the bench making process are taken into account to best project the panels that the Highwall miner will cut.

Obstacles that could be potentially damaged by subsidence and the natural contour of the Highwall are taken into account, and a surveyor points the Highwall miner in a line (Theoretical Survey Plot-Line) mostly perpendicular to the Highwall.

Parallel lines represent the drive cut into the mountain (up to 1,200 feet (366 m) deep - 2015 records), without heading or corrective steering actuation on a navigation Azimuth during mining results in missing a portion of the coal seam and is a potential danger of cutting in pillars from previous mined drives due to horizontal drift (Roll) of the Pushbeam-Cuttermodule string.

Recently Highwall miners have penetrated more than 1200 feet (366 m) [2015 ongoing records] into the coal seam, and today's models are capable of going farther, with the support of gyro navigation and not limited anymore by the amount of cable stored on the machine.

The maximum depth would be determined by the stress of further penetration and associated specific-power draw, ("Torsion and Tension" in Screw-Transporters String) but today's optimized Screw-Transporters Conveying Embodiments (called: Pushbeams) with Visual Product Development and Flow Simulation Behavior software "Discrete Element Modeling" (DEM) shows smart-drive extended penetrations are possible, even so under steep inclined angles from horizontal to more than 30 degree downhole.

In case of significant steep mining the new mining method phrase should be "Directional Mining" [Commonly Used Technologies as valuable synergy Directional Drilling and Directional Mining are categorized in "Surface to In-Seam" (SIS) Techniques], dry or wet, Dewatering is developed or Cutting & Dredging through Screw-Transporters are proactive in developing roadmap of the leading global Highwall mining engineering company.

#miningmonk#talktomanojpachaury#manojkumarpachaury#[email protected]#surfacemining#Highwall mining#Dredging#Mountaintop removal#Open-pit mining#Strip mining#understanding-surface-mining-and-its-types

5 notes

·

View notes

Photo

Uranium production is an important part of the African economy, with Niger, Namibia, Libya and South Africa creating up to 18% of the world's annual production. Many African countries produce uranium or have untapped uranium ore deposits.

3 notes

·

View notes

Text

Tesla gets involved in New Caledonia mine to secure nickel supply

Electric cars maker Tesla (NASDAQ: TSLA) will become a technical adviser at the conflict-ridden New Caledonia nickel mine, as part of the company’s attempt to secure enough supply of the key battery metal, which CEO Elon Musk has singled out as the his biggest concern.

Political leaders in the French Pacific territory agreed on Thursday to sell a majority stake in Vale’s nickel business to a consortium called Prony, which includes Swiss commodity trader Trafigura.

The Brazilian miner, the world’s top nickel producer, had been on the hunt for a buyer for over a year, but the sale was complicated by the fact that New Caledonia has been debating getting its independence from France, and where nickel is one of their main sources of wealth.

The agreement inked on Thursday, Reuters reported, gives a 51% stake in the Vale (NYSE: VALE) operation to New Caledonia’s provincial authorities and other local interests. Trafigura will have a 19% stake, less than the 25% planned in the initial sale deal with Vale.

2 notes

·

View notes

Quote

Arizona, The Beautiful State Was Built on Mining

MiningMonk

1 note

·

View note

Photo

https://www.zakmedios.com

Zakmedios is a Corporate Video Makers in Delhi NCR, Corporate Ad Film Makers in Delhi NCR, Corporate Film Makers in Delhi NCR, Top Corporate Video,Ad Film Makers in Delhi NCR,Noida,Gurgaon,India

#miningmonk#robots#manojkumarpachaury#zakmedios#corporate video makers in delhi ncr#corporate film maker in delhi ncr#corporate ad films maker in delhi ncr#https://www.zakmedios.com

0 notes