#metalography

Text

youtube

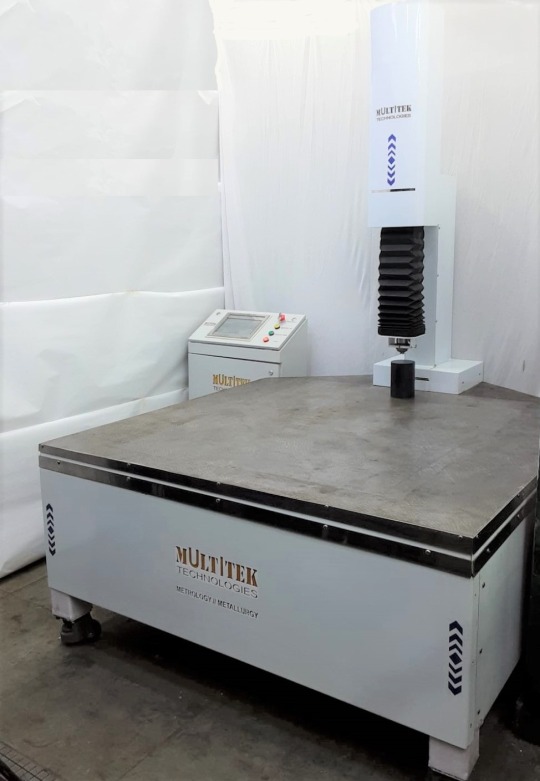

Precision Meets Excellence with Multitek Technologies!

🚀 Introducing the Load Cell Vickers Hardness Tester 🚀

At Multitek Technologies, we take pride in delivering state-of-the-art solutions that redefine industry standards. Our Load Cell Vickers Hardness Tester is designed for precision, reliability, and accuracy, ensuring your materials meet the highest quality benchmarks.

🏆 Why Choose Us?

NABL Certified Lab: Trust the certification that guarantees the highest standards of testing.

Cutting-Edge Technology: Our Load Cell Vickers Hardness Tester offers unparalleled accuracy and repeatability.

Expert Manufacturing: Engineered by industry leaders, designed for peak performance.

🔍 Whether you're in metallurgy, research, or quality control, our hardness tester is your partner in precision!

👉 Contact us today to learn more about how we can elevate your material testing process. https://www.youtube.com/watch?v=dfWwdXo07l4

MultitekTechnologies #HardnessTester #NABLCertified #VickersHardness #MaterialTesting #PrecisionEngineering

#hardness tester#micro vickers#micro vickers hardness tester#rockwell hardness tester#micro vicker#youtube#metrology#rockwell#metalography#Youtube

0 notes

Photo

Diamond süspansion Microdiamant @metallography_as @metalografi @metalography (Mtc Metalurji SAN.VE TİC A.Ş) https://www.instagram.com/p/B6TWKXLAGoE/?igshid=v6ptr1do6xyq

0 notes

Text

Effect of Phosphorous and sulfur elements on properties of Inconel 718

Phosphorous and sulfur are usually considered as the impurities that have bad impact on the performance of nickel base super alloys. Understanding the role of these elements in Inconel 718 is important. Phosphorous and sulfur do not affect their strengths and ductility at room temperature. Phosphorous does not affect mechanical strengths and elongation up to 650oC. On the other hand sulfur significantly affects stress rupture life of alloy and ductility at this temperature. Both elements are different.

A clean superalloy is required to produce aero-engine and gas turbine components. P and S are usually counted as impurities in Nickel base alloys. It is found that development of Laves phase during solidification of metal is a serious problem in the production of Inconel 718. The outcomes of segregation study during solidification through metalography and electron evaluation show that P and S severely cause dentritic segregation by reducing solidus temperature and reducing concentration of niobium in gamma solid solution and also transferring eutectic point to the higher concentration of niobium in the pseudo binary phase.

If the concentration of phosphorus and sulfur is kept in range of 130ppm and 175ppm respectively, they do not affect the tensile strengths and ductility of Inconel 718 wire at room temperature. In fact phosphorous also does not impact alloy’s strength and ductility at 650oC tensile rest. But sulfur definitely has a detrimental impact on 650oC tensile elongation.

Creep test outcomes observed at 650oC for S and P show no effect on the secondary creep rates. But P can widely extend secondary creep stage. Inconel 718 containing higher phosphorous shows longer creep failure life. Additionally alloy with low concentration of sulfur such s 15 ppm exhibits deformed and prolonged grain structure due to long stress rupture life and high ductility.

Both elements widely aggravate dendritic segregation during solidification and they are generally found concentrated at grain boundaries subsequent to heat processing of wrought Inconel 718. These effects have been clearly identified in a study. It is found that P and S increase the binding energy of atoms at grain boundaries and the equilibrium lattice constant in nickel. Segregation of these elements at grain boundaries causes embrittlement in nickel. Although Inconel 718 is a complicated multi-component alloy, a theory considers that P may interact with other element and they may occur together at grain boundaries to reduce grain boundary binding energy and increase cohesive force. Hence, P can significantly reinforce grain boundary and prevent cracking at high temperature tests.

Controlling P concentration and keeping it to the lowest level i.e. below 10ppm suggests to control segregation problem in Inconel 718. Industrial tests have not described any advantages for mechanical properties. Although lab tests show that even nominal level of phosphorous affects stress rupture life of alloy 718. But, phosphorous is found to be advantageous for enhancing stress rupture life and ductility which however is not evident yet.

0 notes

Video

NDT and Metalographi Inspection services at RU VI Pertamina Balongan. *بِسْــــــــــــــــــــــمِ اللّهِ الرَّحْمَنِ الرَّحِيْم* https://www.instagram.com/p/BtvVipaHuyW/?utm_source=ig_tumblr_share&igshid=1axsdne5grjse

0 notes

Link

There are some differences between microstructure of weld metal and austenitic base metal in austenitic stainless steels weldments. Ferrite phase often forms in weld metal. The importance of this phase reveals in study of corrosion behavior and residual welding stresses, thus in this paper the effect of welding variants and conditions on morphology and ferrite number of type 316 stainless steels have been studied. The effects of joint design, base metal thickness, type of welding electrode, number of welding passes and type of backing system have been studied. It is demonstrated that ferrite number of weld metal varies from 1 to 26 under different conditions and Schaefler diagram predictions are very close to experiments. Using metalography images shown that ferrite phase can form in various morphologies such as cellular eutectic ferrite, lathy ferrite and skeletal ferrite. Then it is attainable to get desire microstructures by controlling welding variants and conditions

0 notes

Text

Vickers Hardness Tester Repair and Up-gradation Services by Multitek: https://www.multitek.in/vicker-hardness-tester-repair-services

vickers #hardnesstester #metallurgy #metrology #Testingmachine

#youtube#micro vicker#multitek technologies#rockwell hardness tester#hardness tester#metrology#metallurgy#metalography#rockwell#micro vicker hardness tester

0 notes

Text

Enhancing Material Analysis with Cumputerized Micro Vickers Hardness Tester Machine: https://www.multitek.in/computerized-micro-vickers-hardness-tester

calibration #engineering #instrumentation #iso #metrology #automation #flowmeter #technology #tuning #engineer #sensors #environmentalmonitoring #inspection #processcontrol #testequipment #controlsystem #testing #repair #fieldinstruments #datalogging #toolsofthetrade #fieldwork #protools #remotemonitoring #electrical #technicianlife #sparkylife #toolporn #cleanenvironment #laboratory @multitektechnologies

#hardness tester#rockwell hardness tester#multitek technologies#micro vicker#metrology#metallurgy#rockwell#metalography#Micro Vickers#hardness testing machine

0 notes

Text

Enhance the performance of your Mitutoyo Micro Vickers Hardness Tester with Multitek's expert repair and upgradation services. Our certified technicians ensure precision and reliability for your testing equipment. Contact us for efficient service and support. https://www.multitek.in/mitutoyo-micro-vicker-hardness-tester-repair-and-machineupgradation-services

Mitutoyo #MicroVickers #HardnessTester #Repair #Upgradation #Metallurgy #Metrology #MechanicalEngineering #Automotive #Industrial #Equipment

#Mtutoyo#Micro Vickers#Hardness Tester#Metallurgy#Metrology#Metalography#industrialengineering#Industrial Equipment#Mechanical Engineering

0 notes

Text

If you are looking for Metallurgical Microscope Repair and Machine Up-gradation Services then contact to Multitek Technologies. https://multitek.in/metallurgical-microscope-repair-and-upgradation-services…#MetallurgicalMiroscope#Repair#upgradation#manufacturer#industrial#microscopes

@GMultitek

0 notes

Text

We specialize in state-of-the-art ball joint testing machines that ensure superior performance, reliability, and precision. Contact Us for ball joint testing machine

#ball joint#balljoint#testing machine#ball joint testing machine#Multitek Technologies#metallurgy#metrology#metalography

0 notes

Text

#Multitek Technologies#YouTube Channel\#Hardness Testing#Metallurgy#Metrology#Metalography#rockwell#Micro Vickers

0 notes

Text

Digital and Fully Automatic Rockwell Hardness Tester

If you're seeking a digital and fully automatic Rockwell hardness tester, Multitek offers an excellent solution. Multitek has supplied numerous Rockwell hardness tester machines tailored to customers' requirements. Additionally, Multitek provides efficient repair and upgrade solutions for various other brand machines, including touch screen and motherboard repairs, as well as software upgrades. https://t.ly/rV9Qe

Feel free to call us at 7836009922 or email at [email protected]

Rockwell #RockwellTester #HardnessTesting #Metallurgy #Metrology #Metalography #Industrial #Equipment #Machinary #TestingMachines #Calibration #Mechanical #technology #manufacturing #machineshop #oem #instamachinist #engineering #mfg #jobshop #factory #howitsmade #madeintheusa #automate #production

#hardness tester#rockwell hardness tester#metrology#multitek technologies#rockwell#micro vicker hardness tester#metallurgy#micro vicker#metalography#engineering#production

0 notes

Text

#micro vicker#metrology#multitek technologies#metallurgy#rockwell hardness tester#youtube#hardness tester#micro vicker hardness tester#rockwell#metalography

0 notes

Text

Modernize Your Machinery: Touch Screen & Motherboard Upgrades for Rockwell Hardness Testers: https://www.multitek.in/rockwell-hardness-tester-repair-services

HardnessTester #Rockwell #Repair #Upgradation #Futuretech #rockwell #HardnessTester #MetalHardnessTester #vickers #machinery #metallurgy #metrology #microvicker #rockwellhardnesstester #metal #mechanical #equipment #engineeringlife #manufacturer #engineering #metalography

#hardness tester#rockwell hardness tester#multitek technologies#metrology#micro vicker#metallurgy#youtube#metalography#micro vicker hardness tester

0 notes

Text

#rockwell hardness tester#metallurgy#metrology#youtube#hardness tester#metalography#multitek technologies

0 notes

Text

Rockwell Hardness Tester: A Comprehensive Guide by Multitek Technologies

What is Hardness Testing in Material Science and Engineering?

We at Multitek Technologies excited to share the knowledgebase on Rockwell Hardness Tester. In the world of material science and engineering, understanding the mechanical properties of materials is crucial for ensuring their quality and reliability in various applications. One of the key properties that engineers and manufacturers often need to measure is hardness. Hardness is defined as the resistance of a material to deformation, indentation, or scratching, and it plays a significant role in determining a material's suitability for specific uses.

Hardness testing is a widely used method for quantifying the hardness of materials. It involves applying a controlled force or pressure to the surface of a material and measuring the resulting indentation or penetration. There are several methods of hardness testing available, each with its own advantages and limitations. One of the most popular and widely used methods is the Rockwell hardness test.

Why Rockwell Hardness Tester?

The Rockwell hardness test is a non-destructive testing method used to measure the hardness of metallic materials. It is based on the depth of penetration of an indenter into the material under a specific load. The test is named after its inventor, Stanley P. Rockwell, who developed the method in the early 20th century.

The Rockwell hardness test is known for its simplicity, speed, and accuracy, making it suitable for a wide range of applications across various industries. It is particularly well-suited for quality control and materials testing in manufacturing environments.

What are the Principles of the Rockwell Hardness Tester?

The Rockwell hardness test works on the principle of measuring the depth of penetration of an indenter into the material under two loads: a minor load to establish a reference position (preliminary load), and a major load to complete the test (additional load). The difference in indentation depths between the two loads is used to calculate the Rockwell hardness number.

The Rockwell hardness scale is defined by a combination of the indenter type (diamond or ball) and the applied load. There are several Rockwell scales designated by letters, such as HRA, HRB, HRC, etc., each suitable for different types of materials and hardness ranges.

Components of a Rockwell Hardness Tester

A typical Rockwell hardness tester consists of several key components:

Indenter: The indenter is the tool that is pressed into the material to create the indentation. In Rockwell testing, the indenter can be either a diamond cone or a hardened steel ball, depending on the hardness scale being used.

Anvil: The anvil provides a stable surface against which the material being tested is placed. It ensures that the material is properly supported and prevents any deflection during the test.

Load Application System: The load application system applies the predetermined loads to the indenter. It typically consists of a mechanical or hydraulic mechanism that controls the application of the minor and major loads. Feel Free to Navigate about Multitek’s Other Products/Machines

Depth Measurement System: The depth measurement system accurately measures the depth of penetration of the indenter into the material under the applied loads. This measurement is crucial for calculating the Rockwell hardness number.

Display and Readout: The display and readout system provides the results of the hardness test in the form of Rockwell hardness numbers. It may include analog or digital indicators, depending on the model of the hardness tester.

Procedure for Performing a Rockwell Hardness Test

Performing a Rockwell hardness test involves the following steps:

Prepare the Specimen: Ensure that the surface of the specimen is clean, flat, and free from any contaminants or irregularities. Visit us to learn more about Multitek’s Calibration Services

Select the Indenter and Scale: Choose the appropriate type of indenter (diamond or ball) and the Rockwell scale based on the material being tested and the expected hardness range.

Apply the Preliminary Load: Apply the minor load to the indenter, which establishes a reference position on the specimen surface.

Apply the Additional Load: Apply the major load to the indenter, which creates the indentation on the specimen surface.

Release the Load: Release the major load while maintaining the minor load, allowing the indenter to partially retract from the specimen surface.

Measure the Depth of Penetration: Use the depth measurement system to accurately measure the depth of penetration of the indenter into the material.

Calculate the Rockwell Hardness Number: Calculate the Rockwell hardness number using the formula specified for the selected Rockwell scale.

Record the Results: Record the Rockwell hardness number along with relevant details such as the test conditions, specimen identification, and any observations.

Other Hardness Testing Machines available at Multitek Lab:

Micro Vickers or Universal Hardness Tester

Brinell hardness Testing (BHN & LCB)

Rockwell Hardness Testing (RMT-AL & RHT-LC1500-1A)

Rubber Hardness Testing Machines

Advantages of the Rockwell Hardness Test

The Rockwell hardness test offers several advantages over other hardness testing methods:

Versatility: The Rockwell hardness test can be used to measure the hardness of a wide range of metallic materials, including ferrous and non-ferrous metals.

Speed: The test is relatively quick to perform, allowing for high throughput in quality control and production environments.

Accuracy: The Rockwell hardness test provides accurate and repeatable results, making it suitable for precise materials testing and characterization.

Non-Destructive: Unlike some other hardness testing methods, such as the Brinell test, the Rockwell test is non-destructive, meaning it does not significantly alter the specimen's properties.

Ease of Use: The test is relatively simple to perform and requires minimal training, making it accessible to operators with varying levels of expertise. Reach out to us for Microscope and Hardness Testing Machine Repair and Up gradation Services!

Applications of the Rockwell Hardness Test

The Rockwell hardness test has widespread applications across various industries, including:

Manufacturing: The test is commonly used for quality control and materials testing in manufacturing processes, such as automotive, aerospace, and machinery production.

Metalworking: The test is used to assess the hardness of metal components, including forgings, castings, and heat-treated parts.

Engineering: The test helps engineers and designers select materials with suitable hardness properties for specific applications, such as tooling, dies, and machine components.

Construction: The test is used to evaluate the hardness of construction materials, such as steel beams, structural components, and concrete.

Research and Development: The test is employed in research and development activities to characterize the mechanical properties of new materials and alloys.

Visit us to know more about our Customized Rockwell Hardness Test Machines

According to Multitek Technologies the Rockwell hardness test is a versatile, accurate, and widely used method for measuring the hardness of metallic materials. Its simplicity, speed, and non-destructive nature make it an invaluable tool for quality control, materials testing, and engineering applications across various industries.

By understanding the principles, procedures, and applications of the Rockwell hardness test, engineers and manufacturers can ensure the quality, reliability, and performance of their products and components. Feel Free to Contact Us, if you have any question related to Rockwell Hardness Tester!

#rockwell hardness tester#rockwell tester#metallurgy#metrology#metalography#Metal Hardness Tester#Automotive Services#Multitek#Technologies#Delhi#India#engineering#mechanical#equipment#industrial#Machinary#Machine

0 notes