#microchannel reactors

Explore tagged Tumblr posts

Text

Exploring the Role of Microreactors in Green Chemistry

Green chemistry focuses on designing processes that reduce waste, improve efficiency, and minimize environmental impact. One of the most transformative technologies in this field is the use of microreactors. These small-scale reaction chambers offer precise control over chemical processes, leading to safer, more efficient, and environmentally friendly reactions. Continuous flow microreactors and microchannel reactors are revolutionizing chemical synthesis by improving reaction conditions, minimizing waste, and enhancing sustainability.

What Are Microreactors?

Microreactors are miniaturized chemical reactors that use channels on the micrometer scale to conduct chemical reactions. Unlike traditional batch reactors, these systems allow for continuous processing, enhancing reaction efficiency and control. The compact design of microchannel reactors enables precise temperature and pressure regulation, which is critical for optimizing chemical reactions.

The Advantages of Microreactors in Green Chemistry

Microreactors contribute to green chemistry in several ways:

1. Enhanced Safety

Chemical reactions in traditional reactors often involve hazardous reagents and extreme conditions. Continuous flow microreactors improve safety by reducing reaction volumes, thus limiting the risk of explosions or accidental spills. Additionally, microreactors provide precise temperature control, minimizing thermal runaways.

2. Improved Efficiency

Microreactors enhance mass and heat transfer due to their high surface-to-volume ratio. This leads to faster reaction times and improved yield, making them more efficient than conventional batch processes. Microchannel reactors allow for controlled mixing and reaction kinetics, reducing the chances of undesired side reactions.

3. Reduction in Waste

Green chemistry aims to minimize waste generation, and microreactors help achieve this by optimizing reagent usage. Since these reactors operate on a smaller scale, they require fewer chemicals and solvents, reducing the production of hazardous byproducts. Additionally, continuous processing prevents batch-to-batch variations, leading to consistent and reproducible results.

4. Energy Efficiency

Microreactors operate under controlled conditions, reducing the energy required for heating and cooling. The efficient heat exchange in microchannel reactors minimizes energy consumption, making chemical processes more sustainable and cost-effective.

5. Scalability and Automation

One of the challenges in chemical manufacturing is scaling up laboratory processes for industrial production. Microreactors offer seamless scalability by allowing multiple units to operate in parallel. Furthermore, their compatibility with automation and digital monitoring ensures consistent process control, reducing human error and improving reproducibility.

Applications of Microreactors in Green Chemistry

Microreactors find applications in various fields, from pharmaceuticals to fine chemicals. Some notable applications include:

1. Grignard Reactions

Grignard reactions, which involve the formation of carbon-carbon bonds using organomagnesium compounds, are widely used in organic synthesis. However, traditional Grignard reactions pose challenges such as exothermic behavior and moisture sensitivity. Continuous flow microreactors provide enhanced control over reaction conditions, improving yield and reducing the risks associated with traditional batch processes.

2. Pharmaceutical Manufacturing

The pharmaceutical industry benefits from microreactors by enabling safer and more efficient synthesis of active pharmaceutical ingredients (APIs). Their ability to conduct rapid reactions with precise control ensures high purity and consistent product quality. Continuous flow processing also reduces solvent consumption and waste generation, aligning with green chemistry principles.

3. Fine Chemical Production

Microreactors are widely used in the production of fine chemicals, including fragrances, flavors, and agrochemicals. The controlled reaction environment ensures high selectivity, reducing unwanted byproducts and improving process efficiency.

4. Catalytic Reactions

Heterogeneous catalysis is a crucial area of green chemistry, and microreactors play a key role in enhancing catalytic performance. The confined space within microchannel reactors improves catalyst efficiency and facilitates continuous operation, reducing catalyst degradation and extending its lifespan.

Future Perspectives

As industries shift towards greener and more sustainable chemical processes, the adoption of microreactors is expected to grow. Advances in materials science, automation, and artificial intelligence will further enhance the capabilities of continuous flow microreactors, making them more versatile and efficient. Researchers are also exploring novel reactor designs, such as 3D-printed microreactors, to expand their applications in green chemistry.

Microreactors are transforming the landscape of green chemistry by offering safer, more efficient, and environmentally friendly alternatives to traditional chemical processes. The use of continuous flow microreactors, microchannel reactors, and other advanced reactor technologies is driving sustainable innovation across various industries. As the demand for eco-friendly chemical production continues to rise, microreactors will play a pivotal role in shaping the future of green chemistry.

Industries looking to adopt greener chemical processes should explore the potential of microreactors to improve efficiency, reduce waste, and enhance safety while adhering to sustainability goals.

Discover cutting-edge continuous flow microreactors from Amar Equip, designed for precision and efficiency. Their advanced microchannel reactors enable seamless scalability and enhanced reaction control. From microreactors to specialized Grignard applications, Amar Equip delivers innovative solutions for every need.

Explore their technology today!

0 notes

Text

Lab Microstructured Reactor, Global Market Size Forecast, Top 11 Players Rank and Market Share

Lab Microstructured Reactor Market Summary

Microreactor technology is a continuous flow process based on plug flow reactors. It requires minimal reagent volume while providing fast dynamic response and robustness. The system enables excellent temperature control and efficient mixing procedures. A microreactor is a device that produces chemical reactions within the confinement of typical lateral dimensions of less than 1 mm; the most typical form of such confinement is a microchannel. Microreactors are studied in the field of microprocess engineering along with other devices where physical processes occur, such as microheat exchangers. Microreactors are typically continuous flow reactors (vs/contrast with batch reactors). Microreactors offer many advantages over conventional-scale reactors, including vast improvements in energy efficiency, reaction speed and throughput, safety, reliability, scalability, on-site/on-demand production, and finer process control. Improve.

The report mainly analyzes microstructured reactors used in laboratories.

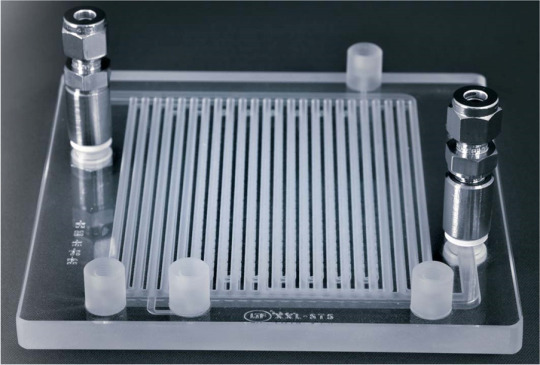

Figure. Lab Microstructured Reactor

Source:Corning

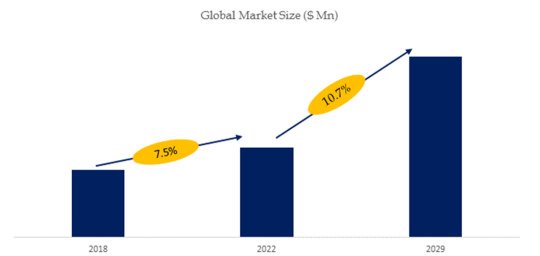

According to the new market research report “Global Lab Microstructured Reactor Market Report 2023-2029”, published by QYResearch, the global Lab Microstructured Reactor market size is projected to reach USD 0.35 billion by 2029, at a CAGR of 10.7% during the forecast period.

Figure. Global Lab Microstructured Reactor Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Lab Microstructured Reactor Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

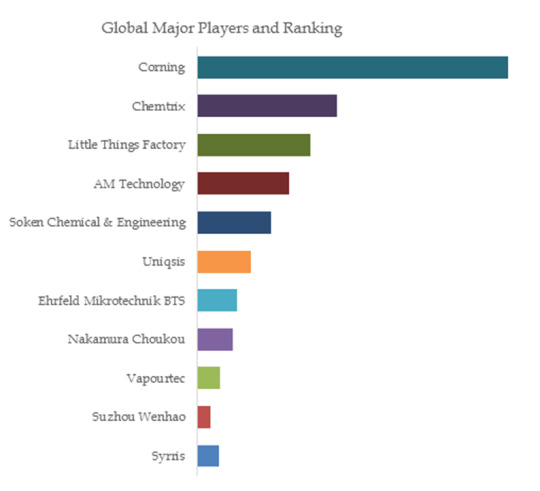

Figure. Global Lab Microstructured Reactor Top 11 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Lab Microstructured Reactor Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Lab Microstructured Reactor include Corning, Chemtrix, Little Things Factory, AM Technology, Soken Chemical & Engineering, Uniqsis, Ehrfeld Mikrotechnik BTS, Nakamura Choukou, Vapourtec, Suzhou Wenhao, etc. In 2022, the global top five players had a share approximately 51.0% in terms of revenue.

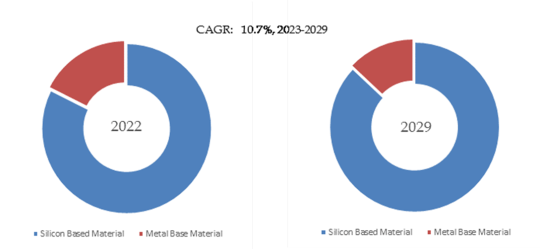

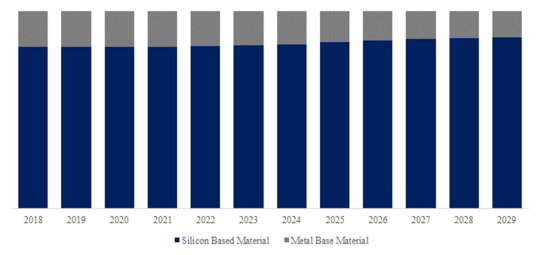

Figure. Lab Microstructured Reactor, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Lab Microstructured Reactor Market Report 2023-2029.

In terms of product type, currently Silicon Based Material is the largest segment, hold a share of 82.4%.

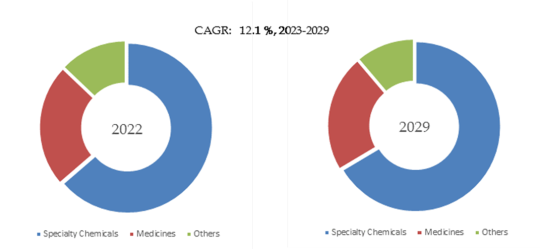

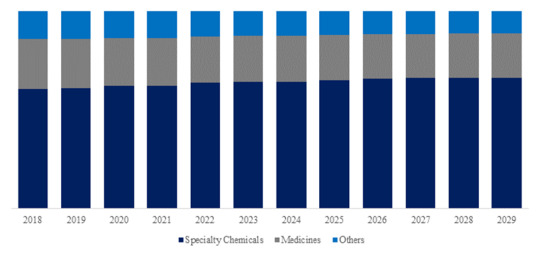

Figure. Lab Microstructured Reactor, Global Market Size, Split by Application Segment (Volume)

Based on or includes research from QYResearch: Global Lab Microstructured Reactor Market Report 2023-2029.

In terms of product application, currently Specialty Chemicals is the largest segment, hold a share of 63.7%.

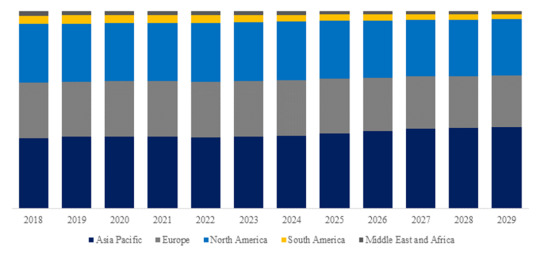

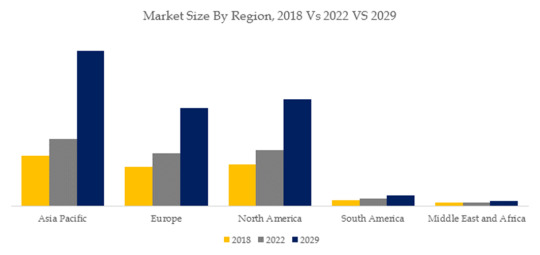

Figure. Lab Microstructured Reactor, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Lab Microstructured Reactor Market Report 2023-2029.

About The Authors

Chengping Zhang

A experienced Technology & Market Analyst. Deep experience in chemical industry, focus on electronic materials, engineering materials and mineral resources, etc. Fully engaged in the development of technology and market reports as well as custom projects.

Senior Analyst

Email: [email protected]

Website: www.qyresearch.com Hot Line:4006068865

QYResearch focus on Market Survey and Research

US: +1-888-365-4458(US) +1-202-499-1434(Int'L)

EU: +44-808-111-0143(UK) +44-203-734-8135(EU)

Asia: +86-10-8294-5717(CN) +852-30628839(HK)

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Link

0 notes

Text

Manufacture of Plug Flow Reactor

Plug flow reactor is one of the best custom products Amar offers to their clients worldwide. Amar has developed a range of flow reactors or continuous flow reaction systems including Microchannel Reactors, 3D Flow Reactor, Pinch Tube Flow Reactor, Glass Microreactor, Soliflo Catalytic Reactor, etc.

1 note

·

View note

Text

Typical application of refrigeration heating temperature control system

LNEYA Dynamic thermostatic control of cold and heat source of high pressure reaction kettle, dynamic thermostatic control of double layer glass reaction kettle, and dynamic thermostatic control of cold and hot source of double-layer reactor. Microchannel reactor thermostatic control, small temperature control system, steam - feeding system temperature control, material low temperature aging test. The thermostatic control of the combined chemical cold source heat source, the cooling heating of the semiconductor equipment and the heating temperature of the vacuum chamber are controlled.

Advantages and functions of temperature control system of refrigeration Temperature range from 120 to 350, performance superior, unique, high - precision, intelligent temperature control. High cooling power from 0.5 to 1200kW, highest production stability and repeatable results. Multi-function alarm system and safety function, use plate heat exchanger, tube type heater to increase heating and cooling rate. 7-inch and 10-inch color TFT touch screen graphics display, use magnetic drive pump, no re-seal leakage problem. Full airtight system, extended thermal conductivity liquid life, very wide temperature range, no need to change liquid media. Ultra-high temperature cooling technology can be cooled directly from 300 degrees of high temperature. The principle and the function has many advantages to using staff: because only expansion of cavity in the body heat conduction medium contact with oxygen in the air (and expansion tank temperature at room temperature to 60 degrees), can achieve lower heat conduction medium absorbed by oxidation and the risk of air moisture. No heat conduction medium evaporates at high temperature, and it can be achieved -80 ~ 190 degrees, -70 ~ 220 degrees, -88 ~ 170 degrees, -55 ~ 250 degrees, -30 ~ 300 degree continuous temperature control without pressurization. Adopt full closed pipe design, adopt high efficiency plate heat exchanger, reducing the demand for heat conduction liquid, improve the heat utilization rate of the system, reach the rapid lifting temperature.Thermal conductive medium in a closed system, with a container, expand the heat-conducting medium not participate in circulation in the container, whether high or low temperatures, expansion tank temperature to room temperature to 60 degrees, can reduce the heat conduction medium in running the risk of absorbing the moisture and volatile.

Web:https://www.lneya.com

Mail:[email protected]

0 notes

Text

Microchannel Reactors Market Size, Share and Forecast by Key Players 2024

The global Microchannel Reactors report to 2024 covers the market background and its growth prospects on the upcoming years additionally briefs about Microchannel Reactors product life span, comparing it into the services and products from across Microchannel Reactors businesses that had been commercialized.

WHAT DOES THE Microchannel Reactors REPORT CONTAIN?

This report studies in the international market using production, income, usage, sales, import and export, global Microchannel Reactors market share, and growth rate in the forecast phase 2019--2024. The market is bifurcated depending on product type, Microchannel Reactors applications, end-users, key players, and regions. This primary data provides leading players and executes a pictorial view of the overall market. Besides that, also, it offers significant Microchannel Reactors challenges, upcoming movements, and opportunities in the market.

Request Free Sample PDF of the research at: https://www.researchkraft.com/request-sample/957715

Key Players:

Corning, Chemtrix, Little Things Factory, AM Technology, Ehrfeld Mikrotechnik BTS, Microinnova Engineering, Uniqsis, Vapourtec, Future Chemistry, Syrris, Suzhou Wenhao

By the Product Types, it primarily split into:

Lab Use

Production Use

By End-Users/Application, this report covers:

Specialty Chemicals

Pharmaceuticals

Commodity Chemicals

Based on segmentation, the global Microchannel Reactors market report is made up of in-depth investigation of the leading regions, including Americas, United States, Canada, Mexico, Brazil, APAC, China, Japan, Korea, Southeast Asia, India, Australia, Europe, Germany, France, UK, Italy, Russia, Spain, Middle East & Africa, Egypt, South Africa, Israel, Turkey, GCC Countries. The Microchannel Reactors research was provided for, including developments, leading growth status, landscape analysis, and segmentation with product types and applications.

Get Discount with this Report at: https://www.researchkraft.com/check-discount/957715

Key Questions Answered in the Report are:

What are the key Microchannel Reactors sections and sub-segments covered in this report?

Which segment is anticipated to dominate or perform well in the Microchannel Reactors market throughout the forecast by 2024?

Who are the leading Microchannel Reactors competitors operating in the market?

What are the strengths and restraints?

What are the strategies adopted to expand their Microchannel Reactors market presence?

What will be the micro and macroeconomic Microchannel Reactors elements, governing facets, and evolution patterns?

What will be the trending Microchannel Reactors factors influencing the market stocks of leading regions?

What are the outcomes of this Microchannel Reactors analysis and SWOT analysis of this market?

What are the forecast growth rates and for every segment within it?

TOC of Microchannel Reactors Market Report Included:

Global Microchannel Reactors Market Research Methodology; Opportunities; Market Landscape Analysis; Segmentation Services, by Product Types, Geographies; Market Drivers, Market Restraints, Market Challenges Microchannel Reactors Market Vendors Landscape, Set of Exhibits.

For Enquiry OR Any Query? Ask Our Expert at: https://www.researchkraft.com/send-an-enquiry/957715

Customization of this Report: This Microchannel Reactors report could be customized to the customer's requirements. Please contact our sales professional ([email protected]), we will ensure you obtain the report which works for your needs.

0 notes

Photo

Catching the Light

At the base of the food chain, plants perform an everyday miracle: in the process of photosynthesis, they convert the sun’s energy into sugar, making it available to other life forms. A team of researchers has recently developed devices that use the sun’s rays to fuel chemical reactions, much as plants do. Shaped like the leaves that inspired them, these minute chemical reactors (pictured) are constructed from materials known as luminescent solar concentrators (LSCs), which absorb sunlight before re-emitting it at a specific wavelength, effectively concentrating its energy. Microchannels, visible as the veins of these artificial leaves, bring molecules into close contact with the LSCs, so the focussed solar energy they produce can power chemical reactions. Applied to processes used for drug synthesis, this versatile technique could enable medicines to be produced anywhere with daylight, efficiently, more cheaply and in an environmentally-friendly way, potentially revolutionising the pharmaceutical industry.

Written by Emmanuelle Briolat

Image by Bart van Overbeeke

Eindhoven University of Technology, Eindhoven, The Netherlands

Image copyright held by the photographer

Research published in Angewandte Chemie, December 2016

You can also follow BPoD on Twitter and Facebook

12 notes

·

View notes

Text

Micro Reactor Technology Market Technology, Applications, Growth and Region Forecast 2022

Overview:

The Micro Reactor Technology Market is cruising ahead as the utility of microreactors is gaining precedence in the chemical industry. Microreactor, also known as microstructured reactor or microchannel reactor, where chemical reactions happen in a lateral channel below 1mm and confinement. A part of the microprocessor engineering, microreactors acts like a continuous flow reactor and improves energy efficiency and reaction speed of the test. The reactor is safe and reliable, and its scalability, ability to produce on-demand, and skill to deliver better process control. The Global Microreactor Technology Market can witness a significant rise in the valuation during the forecast period (2016-2022). From USD 32,456 million in 2015 to an impressive USD 1,08,927.1 million by 2022, the microreactor technology market’s valuation can grow with a 19.05% CAGR over the review period. Market Research Future (MRFR) in their recently published article on the market included segmental analysis, impacting drivers, and updates of the notable competitors for better evaluation and prediction.

Microreactor’s ability to remove heat is better than the conventional vessels which increase the chances of nitration has gained popularity in the chemical industry. In addition, its ability to run without stop results in different concentration level which for many reactions is a boon. At the same time, pressurization can be handled in the microreactors better than any other format which is gaining prominence. Nano-pharmaceuticals are also providing much traction for the microreactor technology market growth. Microreactors are affordable that is also creating much scope for the microreactor technology market expansion.

Get a Free Sample @ https://www.marketresearchfuture.com/sample_request/1128

Segmentation:

Based on the Report published by MRFR, the Global Microreactor Technology Market can be segmented by types, applications and end users for a detailed understanding.

Based on the Type, the Microreactor Technology Market can be segmented into disposable and reusable. The reusable microreactor technology segment is expecting robust growth as the cost can be curbed substantially using this method. Disposable segment held the maximum market share in 2015 and is expected to project 18.96% CAGR during the forecast period to exceed a valuation of USD 23,043.8 million.

Based on the Applications, the Microreactor Technology Market can be segmented into chemical synthesis, polymer synthesis, process analysis, material analysis, and others. Chemical synthesis is driving the market ahead with substantial market hold.

Based on End-Users, the Microreactor Technology Market can be segmented into specialty chemicals, pharmaceuticals, commodity chemicals, and others. Nano technology is gaining more from such reactors owing to which pharmaceuticals segment can grow significantly. Specialty chemicals segment is the current market leader.

Regional Analysis:

Region-specific Microreactor Technology Market analysis as per the MRFR report encompasses North America, Europe, Asia Pacific (APAC), Latin America, and Middle East & Africa (MEA).

North America has control over 38% of the global market. The region is a pro when it comes to research and development. Hence, various laboratories and institutes have created a huge demand for Microreactor Technology. At the same time, with its increasing popularity in the pharmaceutical sector, various drug companies are incorporating the technology for better results.

Europe has almost 30% of the market share. The regional infrastructure for the experiment is quite high which provides the market with ample expansion opportunity. Government initiatives in the sector are also commendable.

The APAC market comes third and owns almost 21% of the global market. The region is witnessing substantial boom from the technological sector, and revamping industries are also favoring the product in countries such as India, China, Japan, and South Korea.

Have Any Query? Ask Our Expert @ https://www.marketresearchfuture.com/enquiry/1128

Competitive Analysis:

Notable players profiled in the MRFR report on the Global Microreactor Technology Market are Little Things Factory, AM Technology, Thaletec GmbH, Microinnova Engineering GmbH, Vapourtec Ltd, Uniqsis Ltd, Ehrfeld Mikrotechnik BTS, Chemtrix Ltd, and others.

In 2018, the U.S. government passed a law called the National Defense Authorization Act, where the Department of Energy has been asked to develop a full-scale report on the deployment of microreactors in defense. This is a good sign for the microreactor technology market as it would increase the percolation of the technology into the defense sector more.

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact: Market Research Future +1 646 845 9312 Email: [email protected]

0 notes

Text

This Synthetic Leaf Turns Sunlight Into Drugs

Pharmaceutical drugs have an environmental cost in addition to a financial one. The average pharma plant uses nearly 15 times as much energy per square foot as a commercial office building, some of which is used for the chemical reactions required to make common medicines such as anti-malarial drugs.

Now, researchers in the Netherlands say they’ve found a way to cut these energy costs by using sunlight and an artificial leaf to manufacture drugs whenever and wherever, from the jungle to the craters of Mars.

Their work, published last month in Angewandte Chemie, a journal of the German Chemical Society, demonstrated the production of medically relevant chemicals (including an intermediate form of the anti-malarial drug artemisinin) using modified solar concentrators, which capture light much like leaves do.

A team led by Timothy Noël, an associate professor at the Eindhoven University of Technology in the Netherlands, combined these solar concentrators—which, adorably, can be made to look like actual leaves—with tiny pathways called microchannels. Ingredients sit in these channels, which look a bit like the veins on a leaf, and are spurred to react by energy from sunlight. To produce ascaridole, an anti-worm drug, the researchers used a lamp equipped with a bulb that simulated typical solar conditions, but they used natural light to make the anti-malarial precursor.

“Solar energy is abundantly available but is too diffuse to be really useful to carry out chemistry,” Noël said in an email. “We have overcome this issue by making a reactor which can harvest solar energy and focus that energy to reaction channels.”

Noël and his team created a prototype version of this technology in 2016, which consisted of a silicone grid dyed red. In the years since, they switched the grid to be made of plexiglass and dyed it red, green, and blue. The leaf-shaped versions highlight the similarities between the microchannels and naturally occurring veins in leaves, but Noël said the reactors used in their experiments tend to be squares for ease of calculation. Still, the leaf-shaped design works the same as the square, he said.

In 2018, Noël’s team added a feedback system to the prototype that keeps light production from the solar concentrator constant during changes in weather and cloud cover. Noël said that the latest version has a lifetime of around 20 years and can be produced at less than $55 USD per square meter. Mass production may further lower these costs, he added.

In addition to cutting costs, the solar reactors sped up the chemical reactions tested. In one case, reaction time dipped from six hours to five minutes. Noël said this is due to the use of the microchannels, which he contrasted with the way light permeates the ocean: As you wade deeper into the sea and look down, you’ll stop seeing your feet, as light only reaches the top layers of the water. Similarly, in a large reaction chamber exposed to light, the energy will only reach the exterior and not permeate to the middle. Microchannels maximize the amount of reagent exposed to light and accelerate the reaction, he said.

The team’s nature-inspired approach could allow for the production of medicine outside a pharmaceutical lab, even locally to where specific drugs are needed.

“Using a reactor like this means you can make drugs anywhere, in principle, whether malaria drugs in the jungle or paracetamol on Mars,” Noël said in a 2016 statement. “All you need is sunlight and this mini-factory.”

This Synthetic Leaf Turns Sunlight Into Drugs syndicated from https://triviaqaweb.wordpress.com/feed/

0 notes

Text

Micro Reactors Market- Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2019-2023

Micro Reactors Market- Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2019-2023

(EMAILWIRE.COM, April 04, 2019 ) A micro reactor is a device in which chemical reactions take place in a confinement with typical lateral dimensions below 1 mm; the most typical form of such confinement are microchannels. Microreactors are studied in the field of micro process engineering, together with other devices (such as micro heat exchangers) in which physical processes occur. The…

View On WordPress

0 notes

Text

Micro Reactors Market- Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2019-2023

Micro Reactors Market- Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2019-2023

(EMAILWIRE.COM, April 04, 2019 ) A micro reactor is a device in which chemical reactions take place in a confinement with typical lateral dimensions below 1 mm; the most typical form of such confinement are microchannels. Microreactors are studied in the field of micro process engineering, together with other devices (such as micro heat exchangers) in which physical processes occur. The…

View On WordPress

0 notes

Text

Micro Reactors Market Analysis, Global Trends, Key Vendors, Drivers, Profits & Analysis by Forecast to 2023

Micro Reactors Market Analysis, Global Trends, Key Vendors, Drivers, Profits & Analysis by Forecast to 2023

A micro reactor is a device in which chemical reactions take place in a confinement with typical lateral dimensions below 1 mm; the most typical form of such confinement are microchannels. Microreactors are studied in the field of micro process engineering, together with other devices (such as micro heat exchangers) in which physical processes occur. The microreactor is usually a continuous flow…

View On WordPress

#Micro Reactors market#Micro Reactors market analysis#Micro Reactors market forecast#Micro Reactors market growth#Micro Reactors market overview#Micro Reactors market research#Micro Reactors market share#Micro Reactors market size#Micro Reactors market study

0 notes

Text

Gas-to-liquid (GTL) Industry Growth, Trends, top Manufacturers Analysis up to 2025

16th November 2018: Emerging concerns about fossil fuel depletion along with increasing demand for the alternative sources of energy is projected to fuel the growth for gas to liquid market. Rising demand for FT (Fischer-Tropsch) route so as to monetize the reserves for natural gas which are unavailable and stranded for utilization is expected to catapult the demand for the industry. Rising demand for power and depleting natural reserves from end-use industries from around the world is anticipated to propel the need for alternative energy sources. This, in turn, may significantly drive the market for gas to liquid industry. Rapid demand for conversion of methane-rich to clean synthetic fuels and economic gasses is estimated to spur the growth of GTL technology. The rise of industrial sector primarily in developed and developing countries including India, China, Germany, the United States, the U.K and China have essentially driven the concerns for conventional resource depletion and scarcity. These countries are increasing adopting gas to liquid technology in order to comply with the carbon emission target and regulations by overhauling the fuel efficiency in the operations.

Browse Full Research Report @ https://www.millioninsights.com/industry-reports/gas-to-liquid-gtl-market

Upcoming of stringent environmental regulations by the government of various countries in order to promote clean sources of fuel along with controlling pollutions is expected to positively impact the market over the next seven years. Guidelines such as Natural Gas Regulatory Board Act and Petroleum Regulatory Board Act, 2006, Oil Industry (Development) Act 1974 and Oilfields (Regulation and Development) Act of 1948 are likely to impel the GTL application in wide range of industries for the conservation of natural gas. Various companies are focusing on developing synthetic green fuels by using GTL services. According to World Bank estimates more than 150 billion meter cube of the flare gas is annually extracted which can extensively transform to convenient synthetic fuel. Attributing to these factors the demand for natural gas in countries including Iran, Saudi Arabia, Venezuela, Qatar, Russia and Iraq is anticipated to boost.

An increasing number of transportation requirement in a vast number of nations is further expected to foster the market for gas to liquid industry. This segment consumes more than fifth of the global energy supply and is projected to increase owing to emerging affordable motor vehicle sales. Abundances of natural gas reserves that can be manufactured at a potentially lower cost provide vital opportunities for the market players. One of the major challenges for the industry is the rising number of slurry based and fixed reactors along with the high initial investments required in the industry may essentially hamper the growth of the market.

On the basis of the region, the segmentation includes Asia Pacific (APAC), Middle East & Africa (MEA), Europe, South & Central America and North America. Many plants are essentially located in Qatar, Mozambique, South Africa and Nigeria resulting in high consumption rate in MEA region. Development of small sized microchannel reactors in the Asia-Pacific region is estimated to propel the industry growth. An emerging number of plants due to high energy consumption in Japan, India, Malaysia, Singapore and China is expected to fuel the market in the APAC region. Notable players in the market include Compact GTL, Royal Dutch Shell, NRG Energy, Petrobras, Chevron Corporation, Linc Energy, Velocys, Sasol Limited and Gas Techno among others.

Get a Sample Copy of This Report @ https://www.millioninsights.com/industry-reports/gas-to-liquid-gtl-market/request-sample

0 notes

Text

Gas-to-liquid (GTL) Market Sourcing Strategy, Share, Size Forecast 2021

Emerging concerns about fossil fuel depletion along with increasing demand for the alternative sources of energy is projected to fuel the growth for gas to liquid market. Rising demand for FT (Fischer-Tropsch) route so as to monetize the reserves for natural gas which are unavailable and stranded for utilization is expected to catapult the demand for the industry. Rising demand for power and depleting natural reserves from end-use industries from around the world is anticipated to propel the need for alternative energy sources. This, in turn, may significantly drive the market for gas to liquid industry.

Rapid demand for conversion of methane-rich to clean synthetic fuels and economic gasses is estimated to spur the growth of GTL technology. The rise of industrial sector primarily in developed and developing countries including India, China, Germany, the United States, the U.K and China have essentially driven the concerns for conventional resource depletion and scarcity. These countries are increasing adopting gas to liquid technology in order to comply with the carbon emission target and regulations by overhauling the fuel efficiency in the operations.

Browse Detail Market Report @ https://www.millioninsights.com/industry-reports/gas-to-liquid-gtl-market

Upcoming of stringent environmental regulations by the government of various countries in order to promote clean sources of fuel along with controlling pollutions is expected to positively impact the market over the next seven years. Guidelines such as Natural Gas Regulatory Board Act and Petroleum Regulatory Board Act, 2006, Oil Industry (Development) Act 1974 and Oilfields (Regulation and Development) Act of 1948 are likely to impel the GTL application in wide range of industries for the conservation of natural gas.

Various companies are focusing on developing synthetic green fuels by using GTL services. According to World Bank estimates more than 150 billion meter cube of the flare gas is annually extracted which can extensively transform to convenient synthetic fuel. Attributing to these factors the demand for natural gas in countries including Iran, Saudi Arabia, Venezuela, Qatar, Russia and Iraq is anticipated to boost.

An increasing number of transportation requirement in a vast number of nations is further expected to foster the market for gas to liquid industry. This segment consumes more than fifth of the global energy supply and is projected to increase owing to emerging affordable motor vehicle sales. Abundances of natural gas reserves that can be manufactured at a potentially lower cost provide vital opportunities for the market players. One of the major challenges for the industry is the rising number of slurry based and fixed reactors along with the high initial investments required in the industry may essentially hamper the growth of the market.

Request Sample Copy of Market Research @ https://www.millioninsights.com/industry-reports/gas-to-liquid-gtl-market/request-sample

The market is largely segmented on the basis of product size namely large scale and small scale plants. Also, segmentation doesn't on the basis of processing technology such as Methanol to Gasoline (MTG), Syngas to gasoline plus and Fischer-Tropsch (FT) process. FT process accounted for the largest segment attributing to the increasing need for partial oxidation of natural gas and hydrogen followed by the cracking process. MTG process is expected to experience substantial gain over the forecast period. The GTL technology can be effectively used for a diverse range of industries such as transportation, petrochemicals, energy, petrochemicals, power and industrial among others.

On the basis of the region, the segmentation includes Asia Pacific (APAC), Middle East & Africa (MEA), Europe, South & Central America and North America. Many plants are essentially located in Qatar, Mozambique, South Africa and Nigeria resulting in high consumption rate in MEA region. Development of small sized microchannel reactors in the Asia-Pacific region is estimated to propel the industry growth. An emerging number of plants due to high energy consumption in Japan, India, Malaysia, Singapore and China is expected to fuel the market in the APAC region. Notable players in the market include Compact GTL, Royal Dutch Shell, NRG Energy, Petrobras, Chevron Corporation, Linc Energy, Velocys, Sasol Limited and Gas Techno among others.

#Gas-to-liquid Market#Gas-to-liquid Industry#Gas-to-liquid Sales#Gas-to-liquid Share#Gas-to-liquid Revenue

0 notes

Text

Operation LNEYA high and low temperature cycle machine note

LNEYA high and low temperature cycle machine uses mechanical refrigeration to obtain low temperature heating tube heating to obtain high temperature. It is used with various glass reactors and reactors. What should be paid attention to when using it? High and low temperature cycle machine is suitable for dynamic constant temperature control of high pressure reactor cold and heat source, dynamic constant temperature control of double-layer glass reactor cold and heat source, dynamic constant temperature control of double-layer reactor cold and heat source, thermostat control of microchannel reactor cold and heat source, small Constant temperature control system, steaming system temperature control, material low temperature high temperature aging test, combined chemical cold source heat source constant temperature control, semiconductor equipment cooling and heating, vacuum chamber refrigeration heating constant temperature control and other industries.

When in use, the wooden box needs to be opened first to install the inlet and outlet valve on the inlet port. The upper and lower sides of the machine are marked with inlet and outlet ports, the valve is a shut-off valve, the valve medium flows in a direction, the valve is marked with a flow direction, and the valve and the reaction kettle are used. The hoses are butted, and the inlet and outlet of the reactor should be kept in and out to ensure that the reactor is kept full of liquid. The high and low temperature cycle machine opens the high and low temperature tank to add liquid holes, and the medium is added into the machine to open the machine's circulation switch, so that the liquid circulates throughout the system. Note that the air in the system is to be evacuated. When using, turn on the power and press the key to enter the working state. The upper window of the display window displays the measured temperature, the lower window displays the current set temperature, press the set button, the upper window displays 5P, with the △▽ addition and subtraction setting The temperature lower window displays the set temperature. Press the heating button, the indicator light next to the heating button lights up, and the heating starts working. Press the cooling button, the indicator next to the cooling button is on, and the refrigeration compressor starts to work. Note: * When the time is *, the compressor is delayed by about 3 minutes. The performance of the high and low temperature cycle machine is related to the operation of the entire high and low temperature cycle machine. LNEYA high and low temperature cycle machine has spent more effort in design and configuration to help users to run better.

Web:https://www.lneya.com

Mail:[email protected]

0 notes

Text

Performance Study on Microchannel Coated Catalytic Plate Reactor Using Electrophoresis Technique for Medium Temperature Shift (MTS) Reaction

Performance Study on Microchannel Coated Catalytic Plate Reactor Using Electrophoresis Technique for Medium Temperature Shift (MTS) Reaction https://www.environmentguru.com/pages/elements/element.aspx?utm_source=dlvr.it&utm_medium=tumblr&id=5096904

0 notes