#continuous flow microreactors

Explore tagged Tumblr posts

Text

Exploring the Role of Microreactors in Green Chemistry

Green chemistry focuses on designing processes that reduce waste, improve efficiency, and minimize environmental impact. One of the most transformative technologies in this field is the use of microreactors. These small-scale reaction chambers offer precise control over chemical processes, leading to safer, more efficient, and environmentally friendly reactions. Continuous flow microreactors and microchannel reactors are revolutionizing chemical synthesis by improving reaction conditions, minimizing waste, and enhancing sustainability.

What Are Microreactors?

Microreactors are miniaturized chemical reactors that use channels on the micrometer scale to conduct chemical reactions. Unlike traditional batch reactors, these systems allow for continuous processing, enhancing reaction efficiency and control. The compact design of microchannel reactors enables precise temperature and pressure regulation, which is critical for optimizing chemical reactions.

The Advantages of Microreactors in Green Chemistry

Microreactors contribute to green chemistry in several ways:

1. Enhanced Safety

Chemical reactions in traditional reactors often involve hazardous reagents and extreme conditions. Continuous flow microreactors improve safety by reducing reaction volumes, thus limiting the risk of explosions or accidental spills. Additionally, microreactors provide precise temperature control, minimizing thermal runaways.

2. Improved Efficiency

Microreactors enhance mass and heat transfer due to their high surface-to-volume ratio. This leads to faster reaction times and improved yield, making them more efficient than conventional batch processes. Microchannel reactors allow for controlled mixing and reaction kinetics, reducing the chances of undesired side reactions.

3. Reduction in Waste

Green chemistry aims to minimize waste generation, and microreactors help achieve this by optimizing reagent usage. Since these reactors operate on a smaller scale, they require fewer chemicals and solvents, reducing the production of hazardous byproducts. Additionally, continuous processing prevents batch-to-batch variations, leading to consistent and reproducible results.

4. Energy Efficiency

Microreactors operate under controlled conditions, reducing the energy required for heating and cooling. The efficient heat exchange in microchannel reactors minimizes energy consumption, making chemical processes more sustainable and cost-effective.

5. Scalability and Automation

One of the challenges in chemical manufacturing is scaling up laboratory processes for industrial production. Microreactors offer seamless scalability by allowing multiple units to operate in parallel. Furthermore, their compatibility with automation and digital monitoring ensures consistent process control, reducing human error and improving reproducibility.

Applications of Microreactors in Green Chemistry

Microreactors find applications in various fields, from pharmaceuticals to fine chemicals. Some notable applications include:

1. Grignard Reactions

Grignard reactions, which involve the formation of carbon-carbon bonds using organomagnesium compounds, are widely used in organic synthesis. However, traditional Grignard reactions pose challenges such as exothermic behavior and moisture sensitivity. Continuous flow microreactors provide enhanced control over reaction conditions, improving yield and reducing the risks associated with traditional batch processes.

2. Pharmaceutical Manufacturing

The pharmaceutical industry benefits from microreactors by enabling safer and more efficient synthesis of active pharmaceutical ingredients (APIs). Their ability to conduct rapid reactions with precise control ensures high purity and consistent product quality. Continuous flow processing also reduces solvent consumption and waste generation, aligning with green chemistry principles.

3. Fine Chemical Production

Microreactors are widely used in the production of fine chemicals, including fragrances, flavors, and agrochemicals. The controlled reaction environment ensures high selectivity, reducing unwanted byproducts and improving process efficiency.

4. Catalytic Reactions

Heterogeneous catalysis is a crucial area of green chemistry, and microreactors play a key role in enhancing catalytic performance. The confined space within microchannel reactors improves catalyst efficiency and facilitates continuous operation, reducing catalyst degradation and extending its lifespan.

Future Perspectives

As industries shift towards greener and more sustainable chemical processes, the adoption of microreactors is expected to grow. Advances in materials science, automation, and artificial intelligence will further enhance the capabilities of continuous flow microreactors, making them more versatile and efficient. Researchers are also exploring novel reactor designs, such as 3D-printed microreactors, to expand their applications in green chemistry.

Microreactors are transforming the landscape of green chemistry by offering safer, more efficient, and environmentally friendly alternatives to traditional chemical processes. The use of continuous flow microreactors, microchannel reactors, and other advanced reactor technologies is driving sustainable innovation across various industries. As the demand for eco-friendly chemical production continues to rise, microreactors will play a pivotal role in shaping the future of green chemistry.

Industries looking to adopt greener chemical processes should explore the potential of microreactors to improve efficiency, reduce waste, and enhance safety while adhering to sustainability goals.

Discover cutting-edge continuous flow microreactors from Amar Equip, designed for precision and efficiency. Their advanced microchannel reactors enable seamless scalability and enhanced reaction control. From microreactors to specialized Grignard applications, Amar Equip delivers innovative solutions for every need.

Explore their technology today!

0 notes

Text

Laurie Clarke at TNR (05.11.2025):

The radical libertarian city builders of the tech-bro set have an audacious new proposal: They want to convert Guantánamo Bay, host to the infamous prison, into the high-tech charter city of their wildest imaginations, which will double as a “proving ground” for migrants seeking to enter the United States. The Charter Cities Institute, or CCI, which has lobbied the Trump administration on setting up so-called freedom cities in the U.S, suggests the president take advantage of Guantánamo’s special legal status to convert the controversial detention camp into “a beacon of 21st-century prosperity.” CCI promotes the worldwide development of charter cities, semiautonomous zones designed to be exempt from the regulations and taxes of the nations in which they’re located. The freedom cities idea pushed by CCI and other groups fits this mold: tech hubs that would be exempt from some federal laws. Adherents to this movement argue that these arrangements drive innovation and prosperity. But as New Republic contributor J.J. Anselmi explained back in March, there’s not much innovation to be had—freedom cities are little more than spit-shined reboots of the “company towns” of yesteryear. Nevertheless, the president has proven receptive to the idea, and the groups have claimed that his inner circle is engaging with their proposals. Now they’ve come up with an eye-catching new site for him to consider. “By transforming Guantanamo Bay into a charter city, the U.S. government can catalyze economic growth, manage immigration flows, and project America’s unparalleled capacity for innovation and statecraft—all while requiring no legislation,” claims the CCI proposal from earlier this year. “This parcel of federal land on the Caribbean coastline presents a striking opportunity to reimagine American governance and reassert U.S. global leadership.” CCI argues in its proposal that the substantial development it plans to unleash would bypass the “multi-tiered hurdles” of “zoning boards, county regulations, city councils, and environmental legal frameworks” that the group claims is holding back similar charter city projects in the U.S. It further argues that this relaxed regulatory environment would encourage cutting-edge R&D in areas like biotech, artificial intelligence, and nuclear microreactors, likening the new enterprise to an American Dubai, capable of attracting billions of dollars in capital over the next five to 20 years.

More controversially, CCI proposes to do something very akin to what the Emiratis are best known for doing—erecting a labor economy that more readily resembles modern-day slavery. The big selling point for its GITMO haven suggests that the hypothetical city could house migrants who wish to move to the U.S., keeping them under surveillance for a “probationary period” while “evaluating their contributions to the local economy and society.”

[...] Charter cities have long been a fascination of Silicon Valley’s libertarian right. Tech billionaire Peter Thiel was an early investor in “seasteading,” the dream of seaborne libertarian enclaves floating beyond sovereign jurisdiction. In recent years, high-profile Silicon Valley investors Marc Andreessen and Balaji Srinivasan have joined the movement, which has turned its attention to land-based fiefdoms. CCI promotes the establishment of these kinds of projects worldwide. It was an early champion of Próspera, a charter city in Roatán, Honduras, which is currently engaged in a legal battle with the Honduran government over its continued existence. It is also involved in several city projects in Africa, including one in Nigeria called Itana. Próspera and Itana have both received funding from Pronomos Capital, a venture capital firm backed by Thiel and Andreessen, whose right-leaning Silicon Valley faction has grown in influence since Trump entered the White House.

CCI told The New Republic that it had “spoken to staff within the administration and both aisles of Congress” about freedom cities and issues relating to housing and economic dynamism but said it wasn’t actively lobbying for freedom cities. However, CCI founder Mark Lutter is still listed online as part of the Frontier Foundation team, a nonprofit advocating for freedom cities. CCI didn’t comment on whether the Guantánamo proposal had been presented to anyone in government. Guantánamo experts aren’t convinced this plan will ever come to fruition. “I don’t think there is anything inherently wrong with using space for a more productive, beneficial purpose than a military base,” said Joseph Margulies, professor of the practice of government at Cornell University and author of Guantánamo and the Abuse of Presidential Power. “But what’s troublesome is the idea that you are seeking a place that is beyond the law. That is the perennial attraction of Guantánamo, right?”

The libertarian-aligned Charter Cities Institute has some dastardly plans for Gitmo: turn it into a techbro hellhole.

#Guantánamo Bay#Broligarchy#Charter Cities Institute#Próspera#Itana#Marc Andreessen#Peter Thiel#Mark Lutter

2 notes

·

View notes

Text

Why Demand for High-Purity Solvents Is Surging in the Pharma Sector

Introduction: Redefining the Role of Solvents in Pharma

Pharmaceutical solvents have traditionally played a supporting role in drug manufacturing processes such as extraction, synthesis, and purification. However, with the rise of continuous manufacturing (CM) in the pharmaceutical industry, their function is rapidly evolving. No longer chosen simply for compatibility or cost, solvents are now being engineered to meet the performance demands of continuous, real-time production systems.

This shift marks an important but often underexplored development in the pharmaceutical solvents market. As CM adoption accelerates, solvents are becoming key components in achieving operational efficiency, regulatory compliance, and green chemistry integration.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-1939

Solvents and Continuous Manufacturing Systems

Continuous manufacturing involves the uninterrupted flow of materials and consistent production of finished products. In such systems, process variability must be minimized, and equipment compatibility becomes a priority. Solvents used in these settings must align with stringent requirements related to boiling point, thermal stability, vapor pressure, and solubility.

Examples of solvents being used in this space include:

2-Methyltetrahydrofuran (2-MeTHF) for improved miscibility and reaction kinetics

Dimethyl sulfoxide (DMSO) for protein solubilization in biopharmaceuticals

Cyclopentyl methyl ether (CPME) for stable reaction environments in flow reactors

These solvents support the intensification and precision of pharmaceutical processes, particularly in microreactors and inline systems.

Key Takeaways

Continuous manufacturing is changing solvent selection criteria from general availability to specific functional performance.

High-purity, thermally stable, and low-toxicity solvents are gaining prominence in real-time manufacturing systems.

Solvents like DMSO and 2-MeTHF are enabling advanced applications, including biopharmaceutical production and green synthesis.

Demand is shifting from volume-based metrics to application-specific performance and regulatory alignment.

Regulatory bodies are promoting greener, lower-risk solvents that comply with evolving safety and environmental standards.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/pharmaceutical-solvents-market

From Commodity to Function-Driven Demand

Traditionally, solvent market trends were assessed by total volume, with ethanol, acetone, and methanol leading due to their widespread use. However, the growing adoption of CM by major pharmaceutical companies and CDMOs is transforming demand patterns. High-performance solvents with specialized roles in crystallization, formulation, and purification are gaining market share.

Regions such as North America, Western Europe, and Japan are leading this transition, driven by advanced R&D infrastructure and evolving regulatory landscapes. Agencies like the FDA and EMA are reinforcing this shift by supporting CM and requiring adherence to ICH guidelines.

Sustainability and Regulatory Alignment

Solvents are also under scrutiny for their environmental and safety impact. With stricter regulatory controls on toxicity and emissions, there is rising interest in eco-friendly alternatives. Bio-based solvents like Cyrene, derived from cellulose, are emerging as viable replacements for hazardous solvents such as NMP.

This trend aligns with broader sustainability goals and ESG frameworks, encouraging companies to adopt safer, greener manufacturing practices.

Future Outlook: Solvents as Enablers of Smart Manufacturing

The pharmaceutical solvents market is poised to evolve from being commodity-driven to becoming a key enabler of smart, digital manufacturing. Future solvents will need to be compatible with Process Analytical Technology (PAT), support automated dosing, and contribute to data-integrated quality control systems.

Markets with strong investment in pharmaceutical innovation, such as Germany, South Korea, and Japan, are expected to be leaders in developing and deploying these next-generation solvents.

Industrial and Institutional Chemicals Industry Analysis: https://www.futuremarketinsights.com/industry-analysis/industrial-and-institutional-chemicals

0 notes

Text

Microfluidics: The Strategic Technology

Microfluidic chips have garnered significant interest from both academic and industrial sectors since their inception. The launch of the journal "Lab on a Chip" in 2001 marked a pivotal moment, quickly establishing itself as a cornerstone publication and catalyzing further global research in microfluidic chips. In 2004, Business 2.0 magazine featured chip laboratories prominently, identifying them among the "seven technologies that will change the future" on its cover. Subsequently, in July 2006, Nature dedicated a special issue to "Chip Laboratories," offering insights into their research history, current status, and future applications. The editorial highlighted the potential of chip laboratories to become the defining technology of the 21st century, underscoring their strategic importance recognized by both academia and industry on a global scale.

The significance of microfluidic chips stems from several factors. Firstly, the trend of miniaturization aligns with the societal drive towards optimizing resource utilization amidst concerns of resource depletion on an already strained Earth. Secondly, the manipulation of fluids at the micrometer scale unveils novel phenomena, some yet to be fully understood, amidst the plethora of existing technologies and fluid manipulations. Thirdly, there exists a pressing need for systemic research tools capable of comprehensively examining interconnected components within complex systems. Throughout history, such tools have been lacking, making microfluidic chips—with their ability to accommodate diverse unit technologies and facilitate flexible combination and scale integration—a pivotal platform for systemic research.

In the 20th century, the strategic significance of "information" flowing through semiconductors or metals via electronics paved the way for breakthroughs in information science and technology. Similarly, in the 21st century, the exploration of life processes, understanding of biological phenomena, and even partial manipulation of biological entities through microfluidic channels may herald a new era of strategically vital science and technology: microfluidics. This is because "life" and "information" form the cornerstone of modern scientific inquiry and technological advancement.

The advent of microfluidics-based point-of-care testing (POCT) technology represents a paradigm shift in healthcare. By delivering rapid and precise biochemical indicators directly at the

patient's bedside, Microfluidics-based POCT facilitates real-time guidance for medication, revolutionizing the continuum of detection, diagnosis, and treatment and significantly enhancing early disease detection and intervention capabilities.

The future trajectory of POCT instruments entails miniaturization and user-friendliness, enabling simple operation without necessitating specialized personnel. Direct input of bodily fluid samples should yield swift diagnostic outcomes, which can be seamlessly transmitted to remote monitoring centers for medical guidance. While simpler flow tests suffice for basic diagnostics, the complexity of testing demands the precision afforded by microfluidic technology. The adaptability and scalability of microfluidic chips make them the preferred platform for modern POCT applications. Notably, recent years have witnessed numerous successful instances of molecular and immunodiagnostic POCT leveraging microfluidic chip technology.

Introducing two immiscible liquids into microfluidic chip channels and dispersing one into small droplets within the continuous phase at high speeds unlocks a versatile approach for microreactors or carriers of micro-biochemical samples. These microfluidic droplets serve as indispensable microreactors, enabling rapid, large-scale, and ultra-low-concentration reactions at the single-molecule and single-cell levels. Characterized by flexible manipulation, uniform sizing, and excellent heat and mass transfer properties, droplets exhibit immense potential in high-throughput drug screening and material selection realms, boasting frequencies ranging from tens to hundreds of kHz.

0 notes

Text

Why the Flow Chemistry Market Is Gaining Traction in Pharmaceutical Manufacturing

The global flow chemistry market was valued at USD 1.76 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 11.6% from 2024 to 2030. Several factors are driving this growth, including a rising awareness surrounding sustainable development and the increasing demand from the pharmaceutical and chemical industries. As industries look for more efficient and environmentally friendly production methods, flow chemistry is emerging as a key solution to address these needs. Additionally, advancements in flow chemistry technologies and the growing importance of fine and specialized chemicals are contributing to the market's expansion.

However, the flow chemistry market faced some setbacks during the COVID-19 pandemic. The pandemic led to an oil price collapse, which in turn reduced the cost advantages for chemical companies that depend on feedstocks derived from petroleum. This decline in feedstock availability had a ripple effect, leading to decreased demand for reactors—one of the major drivers of revenue within the chemical industry. The effects were particularly noticeable in the petrochemical and pharmaceutical sectors, where the demand for flow reactors slowed down, negatively impacting overall market growth during this period.

Despite these challenges, the future outlook for the flow chemistry market remains positive, driven by several key factors. The adoption of flow reactors offers numerous benefits, such as smaller equipment sizes, reduced waste generation, lower operational costs, and faster time-to-market for new pharmaceuticals.

Gather more insights about the market drivers, restrains and growth of the Flow Chemistry Market

Reactor Type Insights

The flow chemistry market is segmented by reactor type, with several different types of reactors used in industrial applications. The continuous stirred tank reactor (CSTR) segment led the market in 2023, accounting for over 36.4% of global revenue. CSTRs are widely adopted due to their simple construction, excellent temperature control capabilities, low cost, and adaptability to two-phase runs. These factors make CSTRs ideal for a range of applications, including chemical production, water treatment, and wastewater processing. As industries continue to focus on optimizing their manufacturing processes, the demand for CSTRs is expected to grow, further solidifying their dominant position in the market.

Additionally, CSTRs are increasingly being used in water and wastewater applications, which is expected to boost their adoption in environmental and waste treatment sectors. The ability of CSTRs to efficiently handle continuous flows of reactants makes them particularly well-suited for large-scale chemical production and treatment processes.

Another important reactor type is the plug flow reactor (PFR), also known as a tubular reactor. PFRs are frequently used for gas-phase reactions and are valued for their absence of moving parts, which reduces maintenance requirements and lowers overall production costs. The simple mechanism of PFRs and their ability to deliver a high conversion rate per reactor volume make them an attractive option for chemical manufacturers looking to increase efficiency and reduce operational expenses. Given these advantages, demand for PFRs is expected to grow over the forecast period.

The microreactor segment, which is a newer innovation in flow chemistry, is also expected to experience significant growth in the coming years. Microreactors are valued for their small size, low capital investment requirements, and ability to safely handle highly reactive and hazardous chemicals. These features make microreactors particularly attractive to pharmaceutical companies and fine chemicals producers who need to scale up reactions efficiently while minimizing risk and maintaining safety standards.

Microreactors are increasingly being used for the production of pharmaceuticals, where precise control over reaction conditions is crucial. Their compact size and ability to scale up quickly make them ideal for laboratories and small-scale production runs. As the demand for customized drugs and fine chemicals grows, the adoption of microreactors in pharmaceutical applications is expected to accelerate.

Another innovation in flow chemistry is microwave-assisted organic synthesis (MAOS), which has seen growing attention in recent years. Microwave-assisted reactors provide fast reaction rates, lower byproduct formation, higher product yields, and greater purity. These reactors have been especially useful in academic and laboratory settings, where fast reaction times and ease of scale-up are important. While microwave-assisted continuous reactors are still limited by size constraints, advancements in this area are expected to drive their adoption in more commercial applications in the future.

Order a free sample PDF of the Flow Chemistry Market Intelligence Study, published by Grand View Research.

#Flow Chemistry Market#Flow Chemistry Market Report#Flow Chemistry Market Analysis#Flow Chemistry Industry

0 notes

Text

Flow chemistry, also known as continuous flow chemistry or microreactor technology, involves the use of continuous flow reactors for chemical synthesis. Unlike traditional batch processes, where reactions are conducted in a single vessel, flow chemistry utilizes a continuous stream of reactants flowing through a reactor.

0 notes

Text

Flow Chemistry Market Size and Share Analysis: Key Growth Trends and Projections

Global Flow Chemistry Market Report

The Flow Chemistry Market research report offers an in-depth analysis of market dynamics, competitive landscapes, and regional growth patterns. This comprehensive report provides businesses with the strategic insights necessary to identify growth opportunities, manage risks, and develop effective competitive strategies in an ever-evolving market.

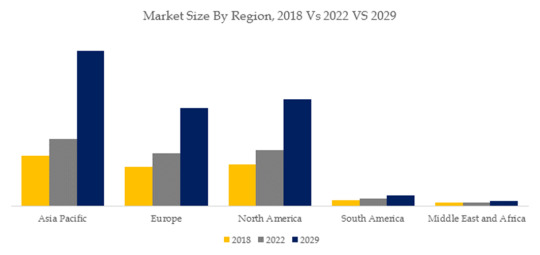

According to Straits Research, the global Flow Chemistry Market market size was valued at USD 1.43 Billion in 2021. It is projected to reach from USD XX Billion in 2022 to USD 3.73 Billion by 2030, growing at a CAGR of 11.24% during the forecast period (2022–2030).

Request a Sample Report Today @ https://straitsresearch.com/report/flow-chemistry-market/request-sample

Global Flow Chemistry Market Segmental Analysis

As a result of the Flow Chemistry market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Reactor Type

Continuous Stirred Tank Reactor (CSTR)

Plug Flow Reactor (PFR)

Microreactor

Microwave Systems

Others

By Application

Pharmaceutical

Biotechnology Companies

Chemicals

Academia and Research

Food And Beverage Industries

Petrochemicals

Agriculture And Environmental Sector

Nutraceutical Firms

Analytical Laboratories

Others

By Technology

Gas-Based Flow Chemistry

Photochemistry-Based Flow Chemistry

Microwave Irradiation Based Flow Chemistry

You can check In-depth Segmentation from here:

Why Invest in this Report?

Leverage Data for Strategic Decision-Making: Utilize detailed market data to make informed business decisions and uncover new opportunities for growth and innovation.

Craft Expansion Strategies for Diverse Markets: Develop effective expansion strategies tailored to various market segments, ensuring comprehensive coverage and targeted growth.

Conduct Comprehensive Competitor Analysis: Perform in-depth analyses of competitors to understand their market positioning, strategies, and operational strengths and weaknesses.

Gain Insight into Competitors' Financial Metrics: Acquire detailed insights into competitors' financial performance, including sales, revenue, and profitability metrics.

Benchmark Against Key Competitors: Use benchmarking to compare your business's performance against leading competitors, identifying areas for improvement and potential competitive advantages.

Formulate Region-Specific Growth Strategies: Develop geographically tailored strategies to capitalize on local market conditions and consumer preferences, driving targeted business growth in key regions.

List of Top Leading Players of the Flow Chemistry Market -

Biotage

Lonza

Corning Incorporated

Vapourtec Ltd

Syrris Ltd.

Chemtrix BV

CEM Corporation

Uniqsis Ltd.

Milestone Srl.

Reasons to Purchase This Report:

Access to Comprehensive Information: Gain access to an extensive collection of analysis, research, and data that would be challenging to acquire independently. This report offers valuable insights, saving you considerable time and effort.

Enhanced Decision-Making: Equip yourself with detailed insights into market trends, consumer behavior, and key industry factors. This report provides essential information for strategic planning, including decisions on investments, product development, and marketing strategies.

Achieving Competitive Advantage: Stay ahead in your industry by understanding market dynamics and competitor strategies. This report delivers deep insights into competitor performance and market trends, enabling you to craft effective business strategies and maintain a competitive edge.

Credibility and Reliability: Trust in the expertise of industry professionals and the accuracy of thoroughly researched data. Authored by experts and grounded in rigorous research and analysis, this report enhances credibility and reliability.

Cost-Effective Research: Reduce research expenses by investing in this comprehensive report instead of conducting independent research. It provides a cost-effective means of accessing detailed analysis and insights on a specific topic without requiring extensive resources.

Regional Analysis Flow Chemistry Market

The regional analysis section of the report offers a thorough examination of the global Flow Chemistry market, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Flow Chemistry market in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

To Understand How Covid-19 Impact Is Covered in This Report - https://straitsresearch.com/buy-now/flow-chemistry-market

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Flow Chemistry Market#Flow Chemistry Market Share#Flow Chemistry Market Size#Flow Chemistry Market Research#Flow Chemistry Industry#What is Flow Chemistry?

0 notes

Text

Microreactors Market: Innovations Transforming Chemical Processing

Introduction to Microreactors market

The microreactors market is gaining significant traction due to their efficiency in handling chemical reactions on a microscale, leading to faster reaction times, improved yields, and better safety. These compact systems enable continuous flow chemistry, enhancing scalability and cost-efficiency. Industries such as pharmaceuticals, chemicals, and energy are increasingly adopting microreactors to streamline production. The global demand is fueled by the need for sustainable manufacturing processes and advancements in microfluidics and nanotechnology. However, market growth faces challenges like high R&D costs and technological integration barriers.

The Microreactors Market is Valued USD 0.34 billion in 2024 and projected to reach USD 1.6 billion by 2032, growing at a CAGR of 19.00% During the Forecast period of 2024-2032. These compact, highly efficient reactors enable faster, safer, and more controllable chemical reactions compared to conventional reactors. Growing demand across industries such as pharmaceuticals, petrochemicals, and fine chemicals, coupled with rising interest in sustainable and continuous manufacturing, drives the expansion of the market. Continuous flow systems, portability, and enhanced scalability make microreactors an attractive solution in high-tech sectors.

Access Full Report :https://www.marketdigits.com/checkout/3455?lic=s

Major Classifications are as follows:

By Types

Pressurized Water Reactors (PWRs)

Boiling Water Reactors (BWRs)

High-Temperature Gas[1]Cooled Reactors (HTGRs)

Molten Salt Reactors (MSRs)

Fast Neutron Reactors (FNRs)

Other

By Fuel Types

Low-Enriched Uranium (LEU)

High-Assay Low Enriched Uranium (HALEU)

Thorium

Other

By Application

Remote Power Generation

Industrial Process Heat

Space Exploration

District Heating

Others

By End Users

Government and Military

Utilities and Energy Companies

Industrial and Manufacturing

Space Agencies

Key Region/Countries are Classified as Follows:

◘ North America (United States, Canada,) ◘ Latin America (Brazil, Mexico, Argentina,) ◘ Asia-Pacific (China, Japan, Korea, India, and Southeast Asia) ◘ Europe (UK,Germany,France,Italy,Spain,Russia,) ◘ The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, and South

Key Players of Microreactors market

Elysium Industries, X-energy, TerraPower, HolosGen, Ultra Safe Nuclear Corporation (USNC), Nuscale Power, INL - Idaho National Laboratory, Moltex Energy, Westinghouse Electric Company, Canadian Nuclear Laboratories (CNL), Starfire Energy, Seaborg Technologies, ThorCon Power, LeadCold, Kairos Power and Others.

Market Drivers in the Microreactors Market:

Efficiency in Chemical Processes: Microreactors offer superior control over reaction conditions, enhancing yield and minimizing waste.

Sustainability: The reduction in energy and resource usage makes them ideal for companies focused on green chemistry.

Pharmaceutical Growth: Increased demand for precision in pharmaceutical synthesis drives the need for advanced microreactor systems.

Market Challenges in the Microreactors Market:

High Initial Costs: The development and integration of microreactor systems can be costly for small- and medium-sized enterprises.

Limited Awareness: Many industries are unfamiliar with the benefits of microreactor technology, limiting widespread adoption.

Regulatory Issues: Complex regulatory environments in different regions can slow down market penetration.

Market Opportunities of Microreactors Market:

Pharmaceutical Industry: The growing demand for personalized medicine and batch production presents significant opportunities.

Sustainable Manufacturing: Companies looking to reduce their environmental footprint can benefit from the efficiency of microreactors.

Renewable Energy: Microreactors offer potential in biofuel and renewable energy production, contributing to the global shift towards clean energy.

Conclusion:

The microreactors market is poised for significant growth as industries seek to optimize chemical processes through efficiency, scalability, and sustainability. While there are challenges related to cost, integration, and scalability, the opportunities offered by microreactors in enhancing precision and reducing environmental impact are vast. As technology continues to evolve, the microreactors market will play a crucial role in transforming industries like pharmaceuticals, petrochemicals, and beyond, pushing them toward greener and more efficient production methods.

0 notes

Text

Lab Microstructured Reactor, Global Market Size Forecast, Top 11 Players Rank and Market Share

Lab Microstructured Reactor Market Summary

Microreactor technology is a continuous flow process based on plug flow reactors. It requires minimal reagent volume while providing fast dynamic response and robustness. The system enables excellent temperature control and efficient mixing procedures. A microreactor is a device that produces chemical reactions within the confinement of typical lateral dimensions of less than 1 mm; the most typical form of such confinement is a microchannel. Microreactors are studied in the field of microprocess engineering along with other devices where physical processes occur, such as microheat exchangers. Microreactors are typically continuous flow reactors (vs/contrast with batch reactors). Microreactors offer many advantages over conventional-scale reactors, including vast improvements in energy efficiency, reaction speed and throughput, safety, reliability, scalability, on-site/on-demand production, and finer process control. Improve.

The report mainly analyzes microstructured reactors used in laboratories.

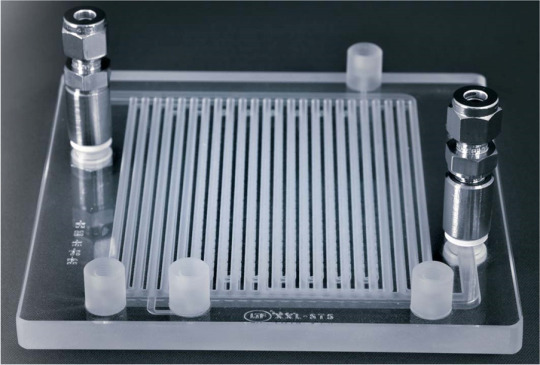

Figure. Lab Microstructured Reactor

Source:Corning

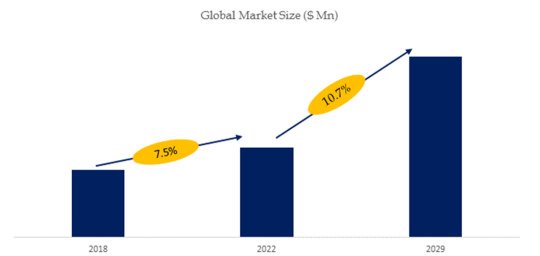

According to the new market research report “Global Lab Microstructured Reactor Market Report 2023-2029”, published by QYResearch, the global Lab Microstructured Reactor market size is projected to reach USD 0.35 billion by 2029, at a CAGR of 10.7% during the forecast period.

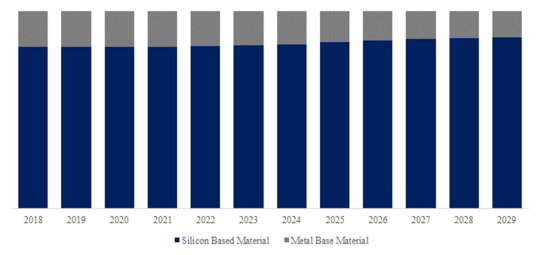

Figure. Global Lab Microstructured Reactor Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Lab Microstructured Reactor Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

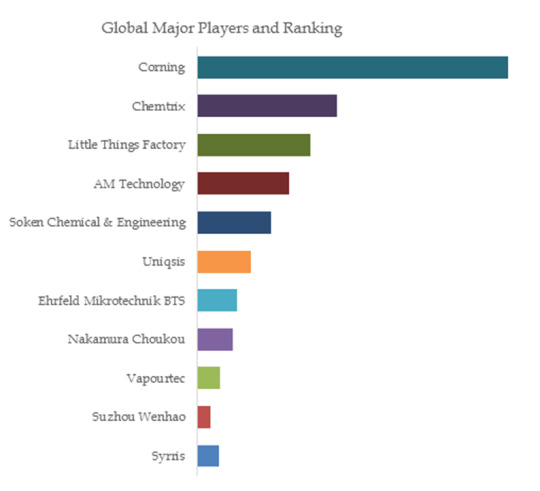

Figure. Global Lab Microstructured Reactor Top 11 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Lab Microstructured Reactor Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Lab Microstructured Reactor include Corning, Chemtrix, Little Things Factory, AM Technology, Soken Chemical & Engineering, Uniqsis, Ehrfeld Mikrotechnik BTS, Nakamura Choukou, Vapourtec, Suzhou Wenhao, etc. In 2022, the global top five players had a share approximately 51.0% in terms of revenue.

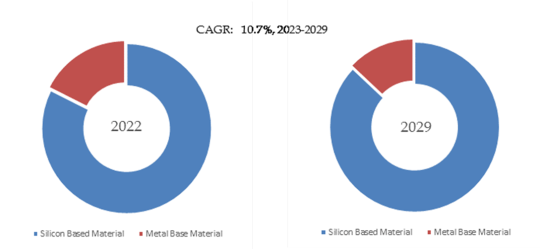

Figure. Lab Microstructured Reactor, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Lab Microstructured Reactor Market Report 2023-2029.

In terms of product type, currently Silicon Based Material is the largest segment, hold a share of 82.4%.

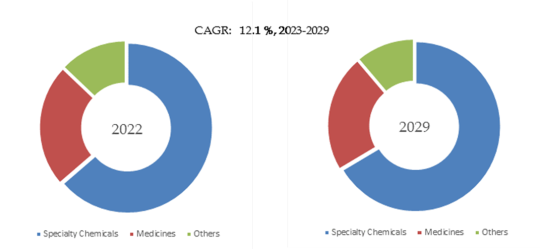

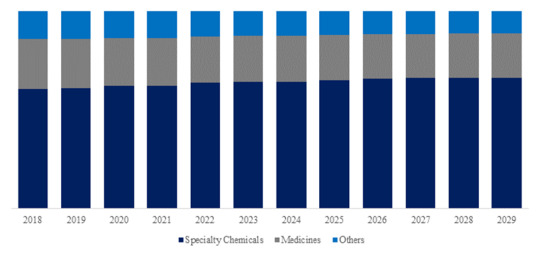

Figure. Lab Microstructured Reactor, Global Market Size, Split by Application Segment (Volume)

Based on or includes research from QYResearch: Global Lab Microstructured Reactor Market Report 2023-2029.

In terms of product application, currently Specialty Chemicals is the largest segment, hold a share of 63.7%.

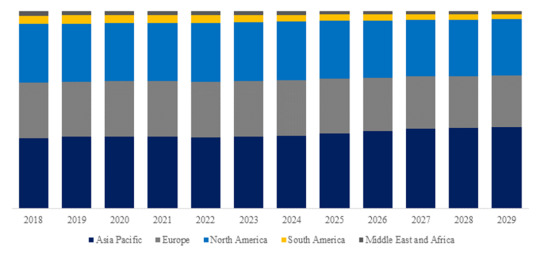

Figure. Lab Microstructured Reactor, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Lab Microstructured Reactor Market Report 2023-2029.

About The Authors

Chengping Zhang

A experienced Technology & Market Analyst. Deep experience in chemical industry, focus on electronic materials, engineering materials and mineral resources, etc. Fully engaged in the development of technology and market reports as well as custom projects.

Senior Analyst

Email: [email protected]

Website: www.qyresearch.com Hot Line:4006068865

QYResearch focus on Market Survey and Research

US: +1-888-365-4458(US) +1-202-499-1434(Int'L)

EU: +44-808-111-0143(UK) +44-203-734-8135(EU)

Asia: +86-10-8294-5717(CN) +852-30628839(HK)

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Fluid Dynamics in Chemistry: Flow Chemistry Market Size Gears Up for Rapid Expansion, Riding on Technological Trends in the Next Decade

The global flow chemistry market is poised for substantial growth in 2023, marking a transformative period in chemical synthesis and manufacturing. With a focus on emerging market trends, significant growth forecasts, and the forces propelling this chemistry evolution, the flow chemistry sector is reshaping the landscape of chemical processes.

Key Trends Propelling Flow Chemistry Innovation:

Continuous Processing Revolution: The flow chemistry market is witnessing a shift from batch processing to continuous flow synthesis. Continuous processing offers advantages such as improved safety, scalability, and efficiency in chemical production, driving the adoption of flow chemistry across diverse industries.

Green and Sustainable Chemistry: Sustainability is a key focus in flow chemistry, with an emphasis on reducing environmental impact and resource usage. Green solvents, renewable feedstocks, and energy-efficient processes are becoming integral to flow chemistry innovations, aligning with global efforts towards sustainable chemical manufacturing.

Integration of Automation and AI: Automation and artificial intelligence (AI) are transforming flow chemistry processes, enabling precise control and optimization of reactions. Automated systems, combined with AI algorithms, enhance the efficiency, reproducibility, and speed of chemical synthesis, providing a new dimension to flow chemistry capabilities.

Free Sample Copy of This Report at: https://www.econmarketresearch.com/request-sample/EMR0011/

Anticipated Market Growth:

The flow chemistry market is set for significant growth, driven by factors such as the demand for sustainable and efficient manufacturing processes, advancements in technology, and the increasing adoption of flow chemistry across pharmaceuticals, chemicals, and petrochemical industries. With a projected compound annual growth rate (CAGR) of [insert percentage], the market is positioned as a key player in the future of chemical synthesis.

Forces Steering and Challenges to Overcome:

Pharmaceutical and Fine Chemical Applications: The pharmaceutical and fine chemical industries are at the forefront of adopting flow chemistry. However, challenges such as process validation, regulatory compliance, and technology integration must be addressed to maximize the potential of flow chemistry in these sectors.

Market Education and Adoption: Industry stakeholders are actively working on educating end-users about the benefits of flow chemistry. Collaborative efforts are needed to facilitate the adoption of flow chemistry technologies, especially among smaller manufacturers and research institutions.

Ask For Discount: https://www.econmarketresearch.com/request-discount/EMR0011/

Segmentations

Application Outlook

Pharmaceuticals

Chemicals

Academia & Research

Petrochemicals

Others

Reactor Type Outlook

CSTR (Continuous stirred-tank reactor)

Plug Flow Reactor

Microreactor

Microwave Systems

Others

Regional Outlook

North America

Europe

Asia-Pacific

South America

The Middle East and Africa

Flowing Towards a Future of Innovation:

As the flow chemistry market continues to surge, industry leaders are actively collaborating to overcome challenges and unlock the full potential of continuous flow processes. The focus remains on developing scalable, sustainable, and accessible solutions that redefine the way chemical synthesis is approached.

About Us:

Econ Market Research is an all-inclusive resource for providing useful insight gleaned through industry research. Through our syndicated and consulting research services, we assist our clients in finding solutions to their research needs. Industries including semiconductor and electronics, aerospace and defence, automobiles and transportation, healthcare, manufacturing and construction, media and technology, chemicals, and materials are among our areas of expertise.

Contact Us:

Econ Market Research Private Limited.

E-mail: [email protected]

Phone: +1 812 506 4440

Website: - https://www.econmarketresearch.com

Connect with us at LinkedIn | Facebook | Twitter | YouTube

0 notes

Text

Optimizing Chemical Processes: Unveiling the Power of Flow Chemistry

In the ever-evolving landscape of chemical engineering, the emergence of flow chemistry has revolutionized traditional methodologies, offering a more efficient and sustainable approach to process development. This dynamic and innovative technique involves the continuous flow of reactants through a reaction chamber, enabling precise control over reaction parameters. As industries strive for greener and more cost-effective solutions, flow chemistry stands out as a game-changer, streamlining processes and enhancing overall productivity.

Understanding Flow Chemistry: A Paradigm Shift

Flow chemistry, also known as continuous-flow or microreactor chemistry, has gained prominence for its ability to overcome the limitations of batch processes. In traditional batch reactions, reactants are mixed in a vessel and allowed to react for a set period. However, this approach often leads to inefficiencies, longer reaction times, and challenges in controlling temperature and pressure.

In contrast, flow chemistry involves the continuous pumping of reagents through a reaction system, where they mix and react in a controlled environment. This continuous flow allows for precise control over reaction parameters, resulting in improved selectivity, reduced waste, and enhanced safety. As a result, flow chemistry has become an integral part of process development across various industries, from pharmaceuticals to specialty chemicals.

Key Advantages of Flow Chemistry in Process Development

Improved Reaction Control: Flow chemistry enables tight control over reaction parameters, including temperature, pressure, and mixing ratios. This level of precision leads to increased reproducibility and product consistency, essential elements in process development.

Enhanced Safety Profile: The continuous nature of flow chemistry minimizes the accumulation of potentially hazardous intermediates, reducing the risk of undesired side reactions. This feature enhances overall safety in the production environment.

Increased Efficiency and Productivity: Flow chemistry allows for rapid mixing and shorter residence times, resulting in faster reactions and higher throughput. This efficiency translates into increased productivity and reduced production costs over time.

Resource Optimization: The ability to use smaller amounts of reagents and catalysts in a controlled manner reduces waste generation. This not only contributes to a more sustainable approach but also helps in optimizing resource utilization.

Expanded Reaction Scope: Flow chemistry facilitates the exploration of reactions that may be challenging in batch processes. This expanded reaction scope opens doors to innovative synthetic routes and the discovery of novel compounds.

Applications of Flow Chemistry in Various Industries

1. Pharmaceutical Industry: The pharmaceutical sector has embraced flow chemistry as a means to streamline drug development processes. The rapid and controlled reactions afforded by flow systems enable the synthesis of complex drug molecules with improved yields and purity. This approach has significantly reduced development timelines and enhanced the efficiency of pharmaceutical manufacturing.

2. Specialty Chemicals: In the production of specialty chemicals, where precision and purity are paramount, flow chemistry has become a preferred choice. The ability to perform reactions under optimized conditions ensures the synthesis of high-quality specialty chemicals with minimal impurities.

3. Petrochemicals: Flow chemistry finds applications in the petrochemical industry for the synthesis of intermediates and additives. The continuous nature of flow reactors is advantageous for handling high-temperature reactions and complex transformations, contributing to the overall efficiency of petrochemical processes.

4. Fine Chemicals and Agrochemicals: The synthesis of fine chemicals and agrochemicals often involves intricate reactions and requires a high degree of selectivity. Flow chemistry allows for precise control over reaction conditions, enabling the production of fine chemicals and agrochemicals with improved purity and efficiency.

Key Steps in Process Development using Flow Chemistry

1. Design of Continuous Flow System: The first step in leveraging flow chemistry for process development is the design of a continuous flow system tailored to the specific reaction requirements. This involves selecting appropriate materials for the reactor, optimizing flow rates, and ensuring compatibility with the chosen reaction conditions.

2. Reaction Optimization: Once the flow system is in place, the next crucial step is the optimization of reaction parameters. This includes fine-tuning factors such as temperature, pressure, residence time, and concentrations to achieve maximum yield and selectivity.

3. Scale-up Considerations: Scaling up a process from the laboratory to industrial production is a critical aspect of process development. Flow chemistry allows for a smoother scale-up process compared to traditional batch methods, as the continuous nature inherently lends itself to larger-scale operations.

4. Integration of Analytical Techniques: To monitor and control reactions effectively, integrating online analytical techniques is essential. Techniques such as in-line spectroscopy and real-time monitoring enable researchers to adjust parameters in real-time, ensuring the desired outcome and minimizing experimental deviations.

5. Automation and Control: The incorporation of automation and control systems further enhances the efficiency of flow chemistry processes. Automated pumps, temperature controllers, and feedback loops contribute to a more robust and reproducible process.

Challenges and Future Outlook

While flow chemistry presents numerous advantages, certain challenges need addressing. The initial setup costs, especially for small-scale laboratories, can be a deterrent. Additionally, the expertise required for designing and operating flow systems may pose a barrier to adoption.

However, ongoing research and development in flow chemistry technologies are actively addressing these challenges. As the industry gains experience and the technology becomes more accessible, it is likely that flow chemistry will become a standard tool in the chemist's arsenal.

Conclusion: A Paradigm Shift in Chemical Process Development

Flow chemistry has emerged as a transformative force in chemical process development, offering a more efficient, sustainable, and controlled approach to synthesis. Its applications span across diverse industries, from pharmaceuticals to petrochemicals, with each sector benefiting from the precision and productivity it brings to the table.

As the demand for greener and more cost-effective solutions continues to rise, the adoption of flow chemistry is poised to increase. Researchers and industry professionals alike are recognizing its potential to revolutionize not only how chemical processes are conducted but also the outcomes they can achieve. In the quest for optimized and sustainable process development, flow chemistry stands as a beacon of innovation, guiding the way to a more efficient and environmentally friendly future.

For more information visit - https://virujgroup.com/

0 notes

Text

Flow Chemistry Solutions: Market Insights and Emerging Opportunities

The global flow chemistry market size is expected to reach USD 3.75 billion by 2030, according to a new report by Grand View Research, Inc. It is expected to expand at a CAGR of 11.2% from 2022 to 2030. Advantages over batch reactors and growing investments in the pharmaceutical and chemical industries are projected to boost the market growth. The COVID-19 pandemic has accelerated the need to move away from chemical commodities to specialty chemicals as per the requirement of customers. Moreover, the adoption of continuous manufacturing has increased due to the supply chain disruptions caused by the pandemic, which is expected to augment the demand for flow chemistry over the forecast period.

Flow Chemistry Market Report Highlights

The pharmaceuticals application segment is anticipated to expand at a lucrative CAGR of 12.0% from 2023 to 2030, in terms of revenue, due to the growing demand for technology that uses renewable energy sources and reduced manufacturing cost

By reactor type, microreactor is expected to witness significant growth over the forecast owing to the increasing demand for environmentally-friendly equipment and the ability to increase selectivity

Asia Pacific is estimated to expand at a significant CAGR of 12.4% over the forecast period on account of the rapidly growing petrochemical industries and a rise in academia and research in South Korea and Australia

In Europe, Germany accounted for the largest revenue share of over 30.0% in 2021 owing to the advanced infrastructure, growing pharmaceutical and chemical industries, and skilled workforce

For More Details or Sample Copy please visit link @: Flow Chemistry Market Report

Significant reductions in trash output and the eradication of non-renewable industrial methods are global environmental concerns. As a result, major economies are enacting policies to mitigate environmental damage. Several governments are implementing policies to meet the targets for reducing greenhouse gas emissions.

Continuous Stirred Tank (CST) reactor systems require little human involvement to operate, resulting in reduced labor costs associated with their deployment. Furthermore, both reactor systems have a high output rate, which leads to reduced production costs. The aforementioned factors are likely to boost the demand for CST reactor systems over the forecast period.

#ContinuousFlowChemistry#FlowChemistryIndustry#FlowChemistryMarket#GreenChemistry#ChemicalSynthesis#ChemicalEngineering#ChemicalProcessing#ChemicalReactionEngineering#PharmaceuticalManufacturing#FlowChemistrySystems#ChemicalProduction#FlowChemistryEquipment#FlowChemistryAnalysis#ScalableSynthesis#FlowChemistryApplications#ChemicalR&D#FlowChemistrySolutions

0 notes

Text

Flow Chemistry Market Tracking Report Analysis 2023-2031

The Flow Chemistry Market was valued at USD 2.45 billion in 2022, and it is anticipated to increase at a CAGR of 12.90% from 2023 to 2031. The method of carrying out chemical reactions between reactive chemicals in a single, flowing stream is referred to as flow chemistry. It is frequently employed in diazotization, halogenation, oxidation, and hydrogenation reactions. The mixture of substances is pumped into the vessel and passed via a pipe, chamber, or Microreactor that is temperature-controlled.

Get Sample Copy of this Reports@ https://www.econmarketresearch.com/request-sample/EMR0011/

Top Key Players:

• AM Technology

• Chemtrix BV

• Corning Inc.

• Ehrfeld Mikrotechnik GmbH

• FutureChemistry Holding B.V.

• HEL Ltd.

• Lonza Group AG

• Milestone Srl (Koch Media GmbH)

• Parr Instruments Company

• Syrris Ltd (Asahi Glassplant Inc.)

• ThalesNano Inc.

Market Growth:

The enormous reactive capabilities that plug flow is gifted with have increased the need for flow chemistry on the global market. Instead of occurring in batches or sections of the stream, chemical reactions in flow chemistry are carried out constantly in a single stream. Numerous industries, including those in the chemical, pharmaceutical, and petrochemical sectors, have benefited from flow chemistry, which has recently fueled the expansion of the flow chemistry market on a global scale. Compared to other reactors, pressurizing flow reactors is simpler, and this propensity leads to faster reactions.

Ask for Discount@ https://www.econmarketresearch.com/request-discount/EMR0011/

Market Segmentation:

Flow Chemistry Market Size, Share & Trends Analysis Report By Reactor Type (CSTR, PFR, Microreactor, Microwave Systems), By Application (Pharmaceuticals, Chemicals), By Region, And Segment Forecasts, 2023 – 2031

Market Drivers:

The primary factors driving the market expansion are flow chemistry's low emissions and safety-focused production method. The demand for more environmentally friendly and sustainable production methods is fueling the expansion of the flow chemistry market. Additionally, flow chemistry solves both environmental and safety concerns by reducing the waste produced in chemical reactions during the manufacturing process.

Market Opportunities:

There may be opportunities in the near future due to the expanding usage of flow chemistry in the manufacturing of bulk chemicals, biofuels, and nanoparticles. They are extensively employed in the continuous manufacture of nanostructures that are used in photovoltaic, displays, and biochemical sensing. Therefore, it is anticipated that the growing use of flow chemistry in bulk chemicals and nanoparticles will promote the growth of the flow chemistry market.

Enquire Before Buy @ https://www.econmarketresearch.com/enquiry/EMR0011/

About Us:

Econ Market Research is a one-stop provider of industry research and actionable intelligence. Through our syndicated and consulting research services, we help our clients get solutions to their research requirements. We specialise in industries such as semiconductors and Electronics, Aerospace and Défense, Energy, Automotive and Transportation, Healthcare, Manufacturing and Construction, Media and Technology, Chemicals, and Materials.

Contact Us:

If you have any queries about this report or if you would like further information, please contact us:

E-mail: [email protected]

Phone: (+1) 812 506 4440.

Website:- https://www.econmarketresearch.com

0 notes

Text

Flow Chemistry Market 2022 Growth Opportunities, Top Players, Regions, Application, and Forecast to 2030

Flow Chemistry Market is presently worth USD 1.60 billion and is poised to amplify at a CAGR of 11.2% over 2022-2030, thereby accumulating USD 3.75 billion by end of the assessment timeframe.

The introduction of new items, technological advancements, process updates, rising annual productivity, and operation optimization over the anticipated timeframe all have an impact on the market. In Asia, for instance, Syrris debuted their automatic reagent injector. Due to automatic sample insertion over two separate channels, the product offers great throughput and has the ability to build intricate matrix libraries.

Bulk chemicals, nanomaterials, and biofuels can all be produced via flow chemistry. With the help of this technology, it is possible to continuously create nanostructures that can be applied to photovoltaics, displays, and biochemical sensing. It is anticipated to address issues with the quality of the nanomaterial, irreproducibility of size, and particle size distribution. Additionally, flow chemistry can operate at high pressures and temperatures while improving the reaction's safety, which is necessary for the synthesis of nanostructured materials.

GET A FREE SAMPLE REPORT:- https://wemarketresearch.com/upcomingreports/sample-request/flow-chemistry-market/35/

Global Flow Chemistry Market: Segmental Analysis By Reactor: • Microreactor Systems • Continuous Stirred Tank Reactor (CSTR) • Plug Flow Reactor • Meso Reactor By End-User: • Pharmaceutical • Chemical • Academic & Industrial Research • Petrochemical

Competitive Intelligence The prominent players operating in the market are Am Technology, CEM Corporation, Milestone Srl, Biotage AB, Syrris Ltd., Vapourtec Ltd., ThalesNano Inc., Hel Group, Uniqsis Ltd., Chemtrix BV, Ehrfeld Mikrotechnik BTS, Future Chemistry Holding BV, Corning Incorporated, Cambridge Reactor Design Ltd., PDC Machines Inc., and Parr Instrument Company.

Major Regions And Countries Covered: • North America- (US, Canada) • Europe- (UK, Germany, Spain, Italy, France) • Asia-Pacific- (South Korea, China, India, Japan) • Latin America- (Brazil, Argentina, Mexico) • Middle East and Africa- (GCC Countries, Egypt, South Africa)

Rising Demand From Pharmaceuticals Is Bolstering The Industry Growth There has been a widespread adoption of flow chemistry in the pharmaceutical sector. This is powered by the fact that this process facilitates the intermediate synthesis of pharmaceutical ingredients and also ensures high productivity, reduced waste, lesser manufacturing footprint, and decreased operational costs. This in turn is augmenting the outlook of this business vertical.

Interested in purchasing this Report:- https://wemarketresearch.com/upcomingreports/purchase/flow-chemistry-market/35/?license=single

Frequently Asked Questions (FAQs)

What will be the growth of Flow Chemistry Market in the foreseeable future?

Who are the key players in the Flow Chemistry Market?

Which region is expected to be the fastest growing Flow Chemistry Market?

Which reactor type is expected to remain dominant in the Flow Chemistry Market?

About We Market Research

WE MARKET RESEARCH is an established market analytics and research firm with a domain experience sprawling across different industries. We have been working on multi-county market studies right from our inception. Over the time, from our existence, we have gained laurels for our deep rooted market studies and insightful analysis of different markets.

Our strategic market analysis and capability to comprehend deep cultural, conceptual and social aspects of various tangled markets has helped us make a mark for ourselves in the industry. WE MARKET RESEARCH is a frontrunner in helping numerous companies; both regional and international to successfully achieve their business goals based on our in-depth market analysis. Moreover, we are also capable of devising market strategies that ensure guaranteed customer bases for our clients.

Contact Us:

We Market Research

Phone: +1(929)-450-2887

Email: [email protected]

Web: https://wemarketresearch.com/

0 notes

Text

Manufacture of Plug Flow Reactor

Plug flow reactor is one of the best custom products Amar offers to their clients worldwide. Amar has developed a range of flow reactors or continuous flow reaction systems including Microchannel Reactors, 3D Flow Reactor, Pinch Tube Flow Reactor, Glass Microreactor, Soliflo Catalytic Reactor, etc.

1 note

·

View note

Text

Flow Chemistry is a technology for process intensification that improves chemical process control and efficiency

A chemical reaction in Flow Chemistry is carried out in a continuous stream rather than in batches. In other words, pumps transport fluid into a reactor, and the fluids come into contact where tubes meet. A reaction occurs if certain fluids are reactive.

Flow Chemistry Market is a well-known technique for producing huge quantities of a particular material on a wide scale. However, scientists only recently invented the phrase for use on a laboratory scale, and it now refers to small pilot plants and lab-scale continuous plants. Microreactors are frequently utilised.

In batch production, reaction stoichiometry is determined by the concentration of chemical reagents and their volumetric ratio. The concentration of reagents and the ratio of their flow rate describe this in flow. In batch manufacturing, residence time is determined by how long a vessel is kept at a specific temperature. When using plug flow reactors, the volumetric residence time is determined by the ratio of the reactor's volume to the overall flow rate.

Because the capacity of laboratory instruments is often modest, the reaction temperature can be elevated above the boiling point of the solvent. Non-compressible fluids are typically utilised with no gas volume, resulting in a minimal expansion factor as a function of pressure.

Read more @ https://influentialblogging.blogspot.com/2022/05/flow-chemistry-continues-to-advance-and.html

#Flow Chemistry#Flow Chemistry Market#Bulk Chemicals#Coherent Market Insights#chemical process control

0 notes