#micropile installation procedure

Text

Ground Anchor | Earth Anchor | Spar Geo Infra

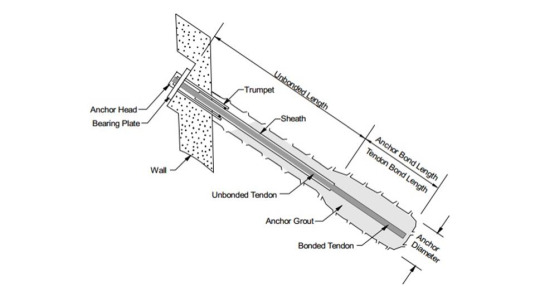

A Ground Anchor, also known as Earth Anchor, is a structural member which transmits an applied tensile force to capable ground. The tensile force is resisted by shear strength of the surrounding ground. An ground anchor may comprise of following three main components

Tension pile

Rock bolt

Deadman

Nowadays, a High strength steel tendons are installed at an inclination to resist the applied tensile load efficiently.

Anchor should have enough capacity required to keep the movement of the structure and the ground mass are kept to tolerable levels.

Characteristics of Anchor Tendons

The tendon transmits the tensile force to the surrounding ground via the grout annulus.

The tie back is usually a high strength steel member surrounded by grout.

The tendon must be adequately protected against corrosion.

For more details visit: https://www.spargrp.com/all-about-ground-anchors/

#rockfall mitigation#ground anchor#drilling and grouting services#jet grouting#shotcrete#micropiling#foundation engineering services#geotechnical companies in india#compaction grouting services#micropile installation procedure

2 notes

·

View notes

Text

Foundation Repair Choices

This day and age homeowners have many choices when faced with a structural foundation problem. The choices include helical piles, push piers, helical tie-back anchors and plate anchors. Each one of these solutions should only be implemented under the supervision of a qualified engineer and foundation repair contractor. Foundation repair is not a do-it-yourself home improvement project. Intimate knowledge of structures, soils and available products are necessary requirements before repair design can be implemented. Know more about ép cọc bê tông here.

Homeowners must educate themselves to keep ignorant or slick talking salespeople from selling them a bill of goods. Many times the salesman does not represent all of the products that your structure may need to completely solve your foundation repair needs. If he only does waterproofing he will, at best, only slow down or prevent further problems. If he is only a pier guy, he may not have the knowledge of what caused the problem (i.e. water). This is why contacting a qualified foundation engineer is a form of checks and balances to allow for the best possible solution.

Foundation engineers will give you a written assessment of your structure including a recommended procedure to solve your homes issues. This evaluation is conducted on site and usually takes over an hour to complete. The written assessment involves an examination of the interior and exterior of the home, interior floor elevations, load calculations and recommendations on repair methods. The written report should include an imprint of his seal with the date and signature across the seal. Many times the engineer will recommend a foundation repair specialist, that he has worked with before, in his report.

You first must understand what different foundation repair methods can and cannot do to determine if they are the correct method of repair for your home. There is no such thing as one size fits all in foundation repair. Each has their place and their benefits, so make sure that the tool that you pick is the correct one for your job.

Resistance piers, also known as push piers, steel piers and Micropiles. This type of pier is an end-bearing pier that does not rely upon, nor requires, skin friction to produce support. Each pier is field load tested after it is installed. The piers are able to develop a factor of safety because the piers are installed and load tested individually using the weight of the structure as the reaction force. Unlimited lifting capability is offered in continuous lift systems. These lifts should only be performed with a manifolded hydraulic system using single or double acting hydraulic cylinders.

Steel push piers are best suited to any structural problem that requires a large lift. No other system is as suited for these large lifts. Due to the fact that these resistance piers are an end bearing pier, thus developing their support from solid contact on a load bearing stratum. Continuous lift type steel piers are the best of the steel resistance piers due to the fact that they can support and lift a structure to unlimited heights.

Helical piers are an ideal choice when you are supporting or lifting a light structure. They are the ideal choice for light structures due to the fact that they do not need the structures weight to advance into the soil. Helical anchors are screwed in the soil with a hydraulic torque motor as opposed to be pressed into the soil like steel push piers. Like the resistance piers you should only lift the structure with a manifolded hydraulic system using single or double acting hydraulic cylinders.

Helical piers consist of a shaft fabricated from either solid square steel bar or tubular steel. Welded to the shaft are one or more helical plates. Typically the plate diameters increase from the bottom of the shaft upward and vary in thickness from 3/8" to ½". The torque required to install the anchor correlates to their capacity. When used to support or lift light weight structures, helical piers are an excellent choice, due to their many benefits. These benefits include the ability to be quickly installed with little or no disturbance to the site and soil removal is unnecessary, they don't require a reaction force and are extremely versatile in their applications.

While steel resistance piers and helical torque anchors are excellent choices for supporting sinking foundation elements, helical tie-back anchors and plate anchors are just as able to support or straighten concrete or block walls. When a basement wall or retaining wall bows inward one must resist this inward movement to maintain the integrity of the structure. If such a system is not installed catastrophic consequences are forthcoming.

Tie-back anchors and plate anchors resist the lateral soil and water forces exerted on basement and retaining walls. While both systems have different advantages they both provide the same function. They use the surrounding stable soils to resist the pressures of unstable consolidating soils near the foundation.

While one or more of these systems my be needed to fix your foundation problem, understanding each method is the key to determining the solution that best fits your situation. The hiring of a foundation engineer is the most effective method of making this determination.

1 note

·

View note

Text

Why Pilling Techniques In Australia Are Important.

Piling is mainly the support that is needed for any structure and thus is considered as the very basis of every construction project. There are different piling techniques to ensure that foundations are deep-set into the ground for stability.

Since piling involves inserting large amounts of concrete, steel, or wood into the soil, safe and environmentally friendly techniques must be considered to avoid harming the earth and the environment in the long run. As such, it is essential to opt for pilling in Australia since the procedure is eco-friendly and safe piling techniques are applied.

Piling specialists available in Australia are always on the lookout for eco-friendly methods and materials that can ensure a sturdy and safe solution for both the earth and your structure. The use of an auger cast or CFA pile is one eco-friendly piling technique that involves drilling into the ground with a hollow-stemmed and continuous flight auger, without any casing.

The cement grout mix is pumped down the auger's stem, and as the grout is pumped, the drill is slowly removed to transport the soil upward along with flights. The result is a shaft of fluid cement grout that arises to ground level. Reinforcement may be placed to support any load or weight through tripod piles, micro piles, soldier piles, suction piles, and sheet piles, depending on the architectural or infrastructure concept of the project.

Driven piles are known to be environmentally friendly, too. They are slender and long columns that offer support for effective resistance forces. Look for groundworks and piling specialists in Australia who can craft the driven piles into predetermined sizes and shapes, so they can be physically inspected before or during installation, which is possible via vibrating, impact hammering, or by simply pushing them into the soil.

Environmentally friendly driven piles are made of natural materials that conform to the standards of ASTM. When manufacturing them, their quality must be consistent throughout the first to the last pile.

Importance of pilling techniques in Australia:

• Saves the environment- Eco-friendly piling techniques will help in saving the surrounding.

• They can help you save money in the long run, too. Driven piles, for instance, are usually cost-effective since you pay only for what you need without any hidden costs and surprise expenses related to clean-up.

• Installations typically do not produce spoils, so you do not have to worry about the disposal of contaminated or hazardous materials.

• Ensures a sturdy foundation through the installation of heavy posts in the subsurface.

There are different types of deep foundation piling in Australia, and the micropile is one of them. They are deep foundations built with heavy-duty steel casings and threaded bars that are small.

The casing is installed using specialized drilling equipment and method. An all-thread bar serves as reinforcing steel in mini piling, and it is usually inserted in the micropile casing.

In conclusion, opt for the pilling available in Australia since great techniques are applied during the process. This not only provides a sturdy foundation but also saves the environment through eco-friendly methods.

0 notes

Text

Sinorock self drilling anchor bolt system provides a longer service life

Self drilling anchor bolt system combines the geotechnical load-bearing system with the creation of a borehole. Thanks to this system with simultaneous grout flushing, the installation procedure can be decisively eased and shortened. The hollow bar now serves as a steel tendon and can be used both as a soil nail or rock bolt and as a micropile. The grout flushing simultaneously serves as slurry to stabilize the borehole and ensures the efficient retroflush of the borehole cuttings. Once the required installation length has been reached, the grouting unit is switched to grouting mortar because it reaches higher compression strengths and thus ensures better load-bearing capacities.

Sinorock is a trusted self drilling anchor bolt system manufacturer that provide quality anchor bolt system for the client around the world. Except the normal anchor bolts and accessories Sinorock also manufactures high quality anticorrosion rock bolt with variety of materials, such as stainless self drilling rock bolt, duplex coating rock bolt and so on. Sinorock self drilling anchor bolt system engineering products provide a service life in excess of 10 years based on research which has been accepted by both Railtrack and the Highways Agency.

0 notes

Text

A Brief Guide On Helical Piles

Foundation repair isn't a do-it-yourself home improvement project. Intimate knowledge of products that are available and structures, soils are necessary requirements before repair design could be implemented. Homeowners must educate themselves to keep slick or ignorant talking salespeople from selling them a bill of goods. Often the salesman doesn't represent all of the products your structure may need to completely solve your foundation repair needs. If he does waterproofing, he'll, at best, only slow down or prevent further problems. He might not have the knowledge of what caused the problem, if he's a pier guy. This is the reason why contacting a qualified foundation engineer is a form of checks and balances.You will be given a written assessment of your structure including a recommended procedure to solve the issues of your home by foundation engineers.This evaluation is conducted on site and takes over an hour.

The written assessment involves an examination of exterior and the interior of interior floor elevations, the home, load calculations and recommendations on repair methods. The written report should include an imprint of his seal with all signature and the date across the seal. Often the engineer will recommend a foundation repair specialist, that he has worked with before, in his report. You first must understand what different foundation repair methods can and can't do to determine if they're the correct method of repair for your home. Each has their benefits as well as their place, so make sure the tool that you pick is the correct one for your job. Resistance piers, also known as steel piers, push piers and Micropiles. This type of pier is an end-bearing pier that does not rely upon, nor requires, support to be produced by skin friction. Each pier is field load after it's installed, tested. Since the piers are installed, the piers can produce a factor of safety, and load tested individually using the weight of the structure as the reaction force. Unlimited lifting capability is offered in continuous lift systems. These lifts should only be performed with a manifold hydraulic system using single or double acting hydraulic cylinders. Steel push piers are suited to any structural problem that requires a large lift. No other system is suited for these large lifts.

Because these resistance piers are an end bearing pier, thus developing their support from solid contact on a load bearing stratum. Continuous lift type steel piers are the best of the steel resistance piers because they could support and lift a structure to unlimited heights. Helical piers are an ideal choice if you are supporting or lifting a light structure. They're the ideal choice for structures that are light because they do not need the structure's weight to advance into the soil. Helical anchors are screwed in the soil with a hydraulic torque motor as opposed to being pressed into the soil like steel push piers. Like the resistance piers, you need to lift the structure with a manifold hydraulic system using single or double acting hydraulic cylinders. Helical piers consist of a shaft fabricated from either solid square steel bar or tubular steel. Welded to the shaft are one or more helical plates. The torque required to install the anchor correlates to their capacity. When used to support or lift light weight structures, helical piers are an excellent choice, because of their many benefits. These benefits include the ability to be quickly installed with little or no disturbance to the site and soil removal is unnecessary, they do not require a reaction force and are extremely versatile in their applications. While one or more of these systems might be needed to fix your foundation problem, understanding each method is the key to determining the solution that best fits your situation. The hiring of a foundation engineer is the most effective method of making this determination.

0 notes

Text

Geotechnical Engineering | Spar Geo Infra

Geotechnical engineering is a branch of civil engineering that deals with the engineering behaviour of Earth materials. It is the practical application of geology. It uses principles of soil and rock mechanics to investigate various geological factors and properties mainly to assess if the location and land mass are fit for construction work.

In addition to civil engineering, geotechnical engineering also has applications in military, mining, petroleum, coastal engineering, and offshore construction. The fields of geotechnical engineering and engineering geology have knowledge areas that overlap, however, while geotechnical engineering is a specialty of civil engineering, engineering geology is a specialty of geology: They share the same principles of soil mechanics and rock mechanics, but differ in the application.

Geotechnical engineering is a sub-discipline of civil engineering and can be defined as the use of earth material (soil and rock) for improving and defending society and life. Until about the last 100 years geotechnical engineering was largely empirical and based on observation and careful reflection. Remarkable scientific advancement in this specialty within civil engineering has been achieved in the post-World War II era and continues today with the aid of high-performance computers, sensors, data visualization, and advanced soil testing.

Geotechnical engineering is a critical component of nearly all infrastructure related endeavors whether they be civilian or military. This is because everything except space structures such as satellites is founded on the earth. Furthermore, if there are issues with the foundation, then the entire structure is in trouble. Therefore, geotechnical engineers play a critical role in every constructed project.

Geotechnical engineering relies on the continuous application of engineering judgment. This judgment can be best developed by careful study of past successes and failures, and years of experience. Through continued education and mentorship, experiences are passed from one generation to the next leading to continued advancement of the profession.

Know more about Geotechnical engineering: https://www.spargrp.com/need-know-geotechnical-engineering/

#geotechnical engineering#jet grouting#rockfall mitigation#micropiling#ground anchor#drilling and grouting services#shotcrete#compaction grouting services#foundation engineering services#micropile installation procedure#geotechnical companies in india

3 notes

·

View notes

Text

Jet Grouting | Spar Geo Infra

Jet grouting creates in situ columns of soilcrete (grouted soil), using a grouting monitor attached to the end of a drill stem. The jet grout monitor is advanced to the maximum treatment depth. Then high velocity jets (cement grout with optional water and air) are initiated from ports in the monitor. The jets erode and mix the in situ soil with grout as the drill stem and monitor are rotated and raised.

Depending on the application and types of soils, one of three variations is used: the single fluid system (slurry grout jet), the double fluid system (slurry grout jet surrounded by an air jet) and the triple fluid system (water jet surrounded by an air jet, with a separate grout port). The jet grouting process constructs soilcrete panels, full columns, or partial columns with designed strength and/or permeability.

The soilcrete geometry and physical properties are designed based on the in-situ soils. Because it is an erosion-based system, soil erodibility plays a major role in predicting geometry, quality, and production. Cohesionless soils are typically more erodible by jet grouting than cohesive soils.

For More Details Visit: https://www.spargrp.com/jet-grouting/

#Jet Grouting#rockfall mitigation#drilling and grouting services#shotcrete#ground anchor#micropile installation procedure#geotechnical companies in india#micropiling#foundation engineering services#compaction grouting services

1 note

·

View note

Text

Slope Stabilization Services | Spar Geo Infra

Slope stabilization is the process of establishing and implementing resistive measures against failure of slopes or fill embankments.

Factors creating destabilization and Mechanism behind it – There are mainly two slope destabilization activities namely; Natural and Man induced factors. Natural factors include slope failure occurring due to rainfall, seismic event, and time age weathering due to climatic conditions. Man induced factors include various anthropogenic activities such as un-engineered road cutting in hilly terrain; turning slope in more vulnerable condition, un-controlled blasting; this creates the various faults/fractures in the rock slope mass; continuous seepage action wash away the joint in filled material and thereby reduce the shear strength.

For more: https://www.spargrp.com/slope-stabilisation/

#Slope Stabilization#ground anchor#jet grouting#drilling and grouting services#foundation engineering services#micropiling#rockfall mitigation#shotcrete#compaction grouting services#micropile installation procedure

0 notes

Text

Shotcrete Technology | Spar Geo Infra

Shotcrete is a process in which mortar or concrete is conveyed through a hose and applied pneumatically. The sprayed material when applied to the surface, fills the cracks and fissures, provide resistance to loose material from slope from falling. Shotcrete serve as protective layer on the slope surface as well as provide resistance against the failure when used with anchoring support systems. This helps in achieving high strength and low permeability.

The shotcreting process is carried out form the base of slope to upwards so as to reduce rebound rate during the application of shotcrete on the surface. The stabilization scheme for stabilization of slope using shotcrete can be designed and used with or without steel mesh. Design of shotcrete depends upon the purpose of project, design life, rock/soil strata.

There are two types of Shotcrete:

1. Dry-Mix

2. Wet-Mix

Dry-Mix Shotcrete

The cementing material and aggregate are mixed in proper proportions, bagged in a dry condition and are transported right to a pneumatically operated gun to deliver a continuous flow of material through the supply hose to the nozzle. The nozzle’s interior is fitted with a water ring which uniformly injects water into the mixture as it is being discharged from the nozzle over the receiving surface.

Wet-Mix Shotcrete

The cementing material, aggregate, water and admixtures are properly mixed similar to what is done for conventional concrete. The mixture of material is supplied to the delivery equipment, like a concrete pump, which pushes the mixture through the delivery hose by positive displacement or by compressed air. Supplementary air is added at the nozzle to escalate the nozzle discharge velocity.

Advantages:

Little or no framework required.

Cost effective method.

Ideal for irregular surface application.

Material handling is easier.

Excellent corrosion resistance.

For more visit: https://www.spargrp.com/shotcrete/

#shotcrete#ground anchor#jet grouting#micropiling#geotechnical companies in india#foundation engineering services#compaction grouting services#drilling and grouting services#top geotechnical engineering companies#slope stabilization mesh#anchor block slope stabilization#micropile reinforcement#micropile installation procedure#soil anchoring#micropile grouting method#rockfall barrier#rockfall mitigation#sprayed concrete solutions#rock anchor installation procedure#Sprayed Concrete Solutions#Micropile Installation Procedure#tam injection

1 note

·

View note