#motioncontrolsystem

Explore tagged Tumblr posts

Text

Screw-driven Linear Actuator | Toyo Robotics

Looking for high-speed, high-precision, and durable solutions for your industrial automation needs?

Toyo Robotics is bound to deliver seamless motion control, maximizing productivity across a range of applications.

Screw-driven linear actuators efficiently convert rotational input into precise linear motion, tailored for diverse applications. With recirculating balls reducing friction, ball screws offer high efficiency, load capacity, and minimal backlash for precision tasks.

To know more please visit https://www.toyorobotics.co/screw-driven-modular-linear-actuator.html

0 notes

Text

Linear Motion Solutions

Linear motion solutions refer to the various technologies and systems designed to provide controlled, precise linear movement. These solutions are used across a wide range of industries and applications, including industrial automation, robotics, machinery, and more.

Here are some key aspects of linear motion solutions:

Types of Linear Motion Systems: Ball screw systems,Lead screw systems,Linear motor systems,Belt-driven systems,Air/fluid bearing systems,Rack and pinion systems,Linear slide systems Key Components:, Linear actuators (e.g. ball screws, lead screws, linear motors),Linear guides (e.g. linear bearings, rails, slides),Drive mechanisms (e.g. stepper motors, servo motors),Control systems (e.g. motion controllers, drivers),Feedback sensors (e.g. encoders, limit switches) Design Considerations: Application requirements (e.g. load, speed, precision),Environmental factors (e.g. temperature, humidity, contaminants),Space constraints and mounting configurations,Integration with other systems and equipment,Maintenance and lubrication needs Common Applications: Industrial automation and robotics,CNC machines and machine tools,Semiconductor manufacturing equipment,Packaging and material handling systems,Medical devices and instrumentation,Test and measurement equipment,3D printing and additive manufacturing Trends and Advancements:,Increased use of linear motors for high-speed, high-accuracy applications,Integration of smart sensors and Industry 4.0 connectivity,Advancements in control algorithms and software,Developments in materials and lubrication for improved performance and reliability

You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#Linearbearingsandshafts#LinearGuides#LinearMotionBearings#LinearMotionComponents#Linearmotionsolutionsandapplications#LinearMotionStages#Linearmotionsystems#linearslidesandpositioningsystems#LinearXYStages#MotionControlSystem#Top-QualityLinearMotionSupplies

0 notes

Text

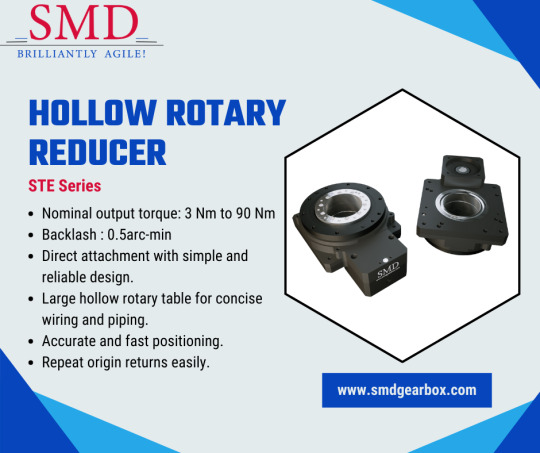

SMD Hollow Rotary Gearbox: Precision, Power, and Reliability

Looking to upgrade your business's precision engineering game? Meet the SMD Hollow Rotary Gearbox (STE) Series. It's small but mighty, designed to handle the toughest tasks with ease. Why Choose Our Gearbox? •Precision Performance: Precision is the key when it comes to motion control, whether you're into robotics, gadgets, or other high-tech stuff. •Efficient: Due to very low Gearhead inertia. Less Power is required my motor to transmit motion which increases the efficiency. •Compatibility with various Servo motors offers compatibility and ease of integration into existing setups. •Hollow Design makes it easier for installation in tight spaces •Versatile mounting options allow for installation in vertical, horizontal, or top-down positions, enhancing flexibility and adaptability to various setups. Ready to Elevate Your Business? Say goodbye to average and hello to awesome with our SMD Hollow Rotary Gearbox. Join the ranks of satisfied customers who've taken their businesses to new heights. Get in touch today to learn more! https://www.smdgearbox.com/hollow-rotary-gearbox

0 notes

Text

SMD AGV Wheels and Mobile Workstations

The integration of SMD AGV Wheels with Mobile Workstations is a testament to the transformative power of innovation in modern industry. As we stand at the forefront of a new industrial age, the collaboration between precision engineering and mobile flexibility promises a future where efficiency is not just a goal but a fundamental aspect of the manufacturing and logistics landscape. The journey continues, and with SMD AGV Wheels leading the way, the future of industrial operations looks not only efficient but also sustainable and adaptable to the ever-evolving demands of the global marketplace.

To know more please click on https://medium.com/@s.darshan/smd-agv-wheels-and-mobile-workstations-fc24549a84d8 or you can mail us on [email protected] for assistance.

#smdgearbox#servogearbox#motioncontrolsystem#automatedguidedvehicle#agvwheelmanufacturers#agvwheel#agvtype#agv

0 notes

Text

Are You Looking Motion Control System Suppier in Gujarat

Unity Automation System is the fastest-growing service provider for Motion Control System Suppliers in Gujarat. Motion control systems are essential for precise and efficient movement in manufacturing and automation processes. Since they need in varied industries, their time-to-time service is mandatory to keep them working, reduce downtime, save costs, and extend their lifespan. And for their constant working, you need to service them time-to-time. If you are looking for a trusted Suppliers for Motion Control System in Gujarat, reach us now. We use advanced resources to ensure that there is no compromise in the quality of our services and that clients get the best experience.

0 notes

Text

"Motion Control Innovations: Market Dynamics and Forecast (2024-2033)"

Safety Motion Control is revolutionizing how industries approach workplace safety by integrating advanced technology to prevent accidents and enhance operational efficiency. By employing sophisticated sensors, automated systems, and real-time data analysis, these systems ensure that machinery and robots operate within safe parameters, reducing the risk of injuries and downtime. As industries adopt these cutting-edge solutions, they're not only boosting productivity but also setting new standards for safety and reliability in the workplace.

#SafetyMotionControl #WorkplaceSafety #IndustrialAutomation #TechInSafety #SafetyFirst #MotionControlSystems #RealTimeMonitoring #AutomatedSafety #InjuryPrevention #IndustrialSafety #EfficiencyBoost #SmartTech #SafetyStandards #RoboticSafety #AdvancedSensors #WorkplaceInnovation #SafeOperations #ProductivityEnhancement #TechForGood #OperationalExcellence #SafetyInnovation

0 notes

Text

Indexer |Hollow Rotary Reducer| SMD Gearbox

SMD hollow rotary gearboxes are important parts in many industries. They help control movement and transfer power smoothly. Offering unparalleled motion control and power transmission capabilities. Featuring a low backlash of 30 arc-sec and a compact design, these gearboxes are adaptable to both vertical and horizontal orientations, as well as top-down configurations, ensuring seamless integration into diverse industrial setup’s. Advantages • Versatile mounting options allow for installation in vertical, horizontal, or top-down positions, enhancing flexibility and adaptability to various setups. • Robust construction ensures durability and reliability in harsh operating environments. • Customizable options such as gear ratios and torque capacities allow for tailored solutions to specific application requirements. • Smooth and quiet operation minimizes noise and vibration, contributing to a comfortable working environment. • Maintenance-free design reduces downtime and maintenance costs, improving overall efficiency and productivity. • Compatibility with various motors and drive systems offers compatibility and ease of integration into existing setups. • Enhanced performance and efficiency optimize industrial processes, leading to improved product quality and higher throughput.To know more please visit https://www.smdgearbox.com/hollow-rotary-gearbox

#hollowrotaryreducer#indexer#servogearbox#gearboxmanufacturers#gearboxsupplier#motioncontrolsystem#powertransmission

0 notes

Text

Motion Control Solution | SMD Gearbox

Elevate your Game with SMD Gearbox. SMD Gearbox Is a leading brand in precise servo gearboxes. Why you should use SMD Servo Gearbox?

Precision Control: SMD Servo gearboxes offer precise control over speed, torque, and position, making them ideal for applications requiring accuracy and repeatability.

Efficient Power Transmission: SMD servo gearboxes are designed to optimize power transmission, ensuring minimal energy loss during operation, which contributes to overall efficiency.

Great Customer Support: - Whether is pre-sales or after sales. The Technocrats at SMD Gearbox are ready to address your query. Also, Will help you in selecting the right Gearbox depending upon your application

Compact Design: SMD servo gearboxes often have a compact and lightweight design, making them suitable for applications with limited space and allowing for more versatile system configurations.

Low Backlash: SMD harmonic gearbox are know for their very low backlash. Due to which it can deliver precise movement used in robotics and AGV Wheel

High Torque Capacity: SMD Servo gearboxes are known for their ability to handle higher torque loads, allowing them to deliver the required output torque for various applications without the need for complex mechanisms.

SMD Servo gearboxes seamlessly integrate with automation systems, allowing for precise and synchronized movements, a crucial aspect in modern industrial automation. To know more please visit https://www.smdgearbox.com/

#speedreducer#reducer#powertransmission#gearboxsupplier#planetarygearbox#rightanglegearbox#gearboxmanufacturers#motioncontrolsystem#zerobacklash#servogearbox#smdgearbox

0 notes

Text

What is Gearhead Inertia | SMD Gearbox

youtube

Servo systems are designed for precise motion control and frequent change in direction. This change in direction generates inertia and the motor has to give more energy to overcome it. The more the gearhead inertia the more energy is needed to change the direction of motion.

You may have felt inertia when traveling in a bus and suddenly the driver applies brake and your body tend to lean forward. The same effect is applied in SMD servo gearboxes which we call gearhead inertia. Some of the great features comes with SMD gearbox due to low gearhead inertia are as follows:

Improved Responsiveness

Energy Efficiency

Reduced Wear and Tear

Optimal Performance

Dynamic Motion Control

Reduced Heat Generation

Versatility

To know more some of the features of SMD Gearbox please visit www.smdgearbox.com

#gearheadinertia#motioncontrolsystem#rightanglegearbox#harmonicgearbox#planetarygearbox#gearboxmanufacturers#servogearbox#smdgearbox#Youtube

0 notes

Text

Right Angle Reducer | Spiral Bevel Gearing

SMD Right angle gearbox uses Spiral bevel gears in its internal mechanism. Spiral gears provide a gradual tooth engagement, enhances contact between gears. They can accommodate higher loads due to their improved tooth contact and distribution of forces. It also reduces vibration and noise during operation. Spiral gears also enhance the life span of gearboxes. These are more versatile in terms of mounting positions, allowing for flexibility in the design and installation of machinery. Some of the features are as follows:

Smoother Operation

Higher Efficiency

Greater Load Capacity

Reduced Vibration and Noise

Enhanced Lubrication

Versatility in Mounting Positions

Increased Gearbox Lifespan

To know more please visit our website at https://www.smdgearbox.com/right-angle-gearbox.html

#smdgearbox#rightanglegearbox#rightanglereducer#rightanglebevelgearbox#bevelgearbox#90degreegearbox#gearboxmanufacturers#motioncontrolsystem#gearboxsupplier#powertransmission

0 notes

Text

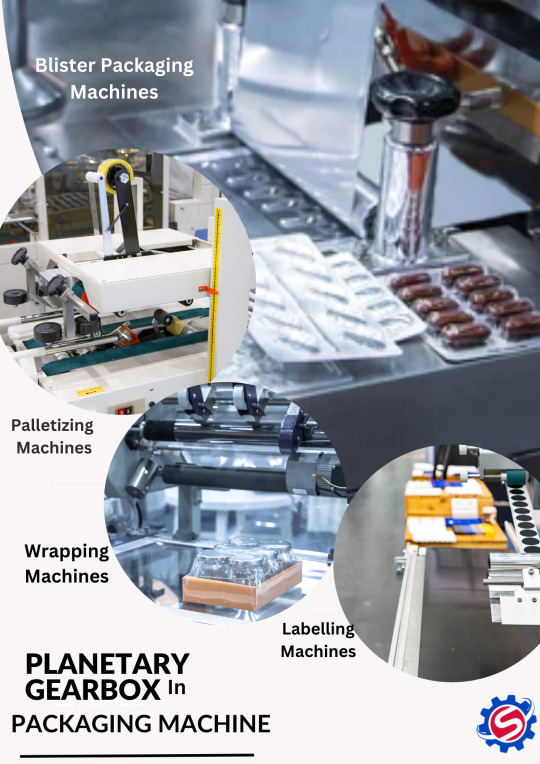

Packaging Machine Industry | SMD Planetary Gearbox

Gearboxes are fundamental mechanical components within packaging machines, providing the necessary power transmission and control to automate the packaging process. These versatile devices convert high-speed, low-torque input from a motor into the low-speed, high-torque output required for various packaging operations. Automating your packaging process, to enhancing efficiency and productivity in the packaging industry select SMD Gearbox as your automation partner.

To learn more https://www.smdgearbox.com/planetary-gearbox-with-output-flange

#servogearbox#planetarygearbox#harmonicdrive#gearboxmanufacturer#packagingmachine#motioncontrolsystem#palletizingmachine

0 notes

Text

We Are Best PLC Control Panel Manufacturers in Gujarat

PLC Control Panel is used in industrial automation to control & monitor several electrical and mechanical processes. It executes programmed logic, generates outputs to control machinery & ensures efficient automation & better productivity. Nowadays, it has become important in varied manufacturing or environmental processes. If you want to reap its benefits, ease your work, boost your productivity, and reduce work errors at a low cost, Unity Automation System got you covered. Being one of the preeminent PLC Control Panel Manufacturers in Gujarat, we offer highly durable & dependable solutions designed to meet your diverse needs.

1 note

·

View note

Text

Packaging machine Industry | SMD Planetary Gearbox

Gearboxes are essential components in many packaging machines, as they play a crucial role in controlling and transmitting power from the machine's motor to various parts of the packaging process. They are responsible for adjusting the speed and torque of the machine to match the specific requirements of the packaging task. This low-cost planetary gearbox is specially used in packing machines such as Filling Machines, Capping Machines, Sealing Machines, Labelling Machines, Wrapping Machines, Carton packaging Machines, Form-Fill-Seal Machines (FFS), Blister Packaging Machines, Vacuum Packaging Machines, Strapping Machines, Coding and Marking Machines, Palletizing Machines.

SMD High-precision servo gearboxes offer SPE (SMD Planetary Economical Series), and SPE-S (SMD Planetary Economical Series- Spur Gears) which can deliver high torque in compact space in wide reduction ratios. SPE-S and SPRE-S series are developed to deliver high torque and ratio in economical range. To know more please visit https://www.smdgearbox.com/planetary-gearbox-with-output-shaft or you can contact us on following details

📞📲 +91 7030669818 ✉️ [email protected]

#cartonpackaging#vacuumpackaging#blisterpackaging#packagingmachine#labellingmachine#epicyclicgearreducer#gearboxmanufacturer#planetarygearbox#inlinegearbox#motioncontrolsolutions#motioncontrolsystems#servogearbox#smdgearbox

0 notes

Text

Motion Control Systems | SMD Gearbox

Innovation and precision are the driving forces of progress. At the heart of this automation revolution, you'll find a “Servo Gearboxes” leading the way into the future.

The automation will continue to transform industries, making processes more efficient, safer, and environmentally friendly. SMD gearbox will be at the forefront of this transformation, ensuring that precision remains the cornerstone of automation.

Please visit our website to know more about us at www.smdgearbox.com or you can contact us on following details:

📞📲 +91 7030669818

#smdgearbox#harmonicgearbox#planetaryreducer#manufacturing#gearboxmanufacturerinindia#cycloidal#motioncontrolsystems

0 notes

Text

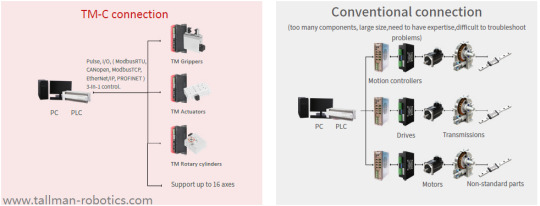

Motion Controller

Motion Controller: Tallman Robotics Limited provides one-stop solution for intelligent, reliable and affordable Motion Controller for servo electric cylinders in China. With strong independent R&D capabilities, the Company independently develops and manufactures servo grippers, servo pushers, servo slides, servo rotary cylinders and integrated drive and control controllers, and offers servo electric cylinders with reliable quality, high precision, low cost, ease of use and less maintenance, etc. by integrating its self developed servo control algorithms, electronic circuits, software design and high-precision force control technology, which promotes the widespread application of servo electric cylinders in China.

1. What are the features of Tallman Robotics Limited’s motion controller? Independent research and innovation, Mast core technology! Powerful and easy to use! Support multiple programming language control! Multilingual control TM provides complete programming, teaching, parameter modification and other API interfaces. It supports and is not limited to Lab view, C #, C ++, Python and other programming language controls. Three-in-one communication control Modbus control I / O mode control (maximum 16 bits, 256 points) Pulse control (perfectly compatible with all pulse mode controllers on the market)

Hybrid control of force and position Control modes can be selected for a variety of flexible combinations. Position, travel, speed control; clamping force, pushing pressure control; measurement control. Simple torque mode control Controlled by the TM software platform, it is more convenient to coordinate equipment. Quick adjustment through the external knob of TM-C controller. No additional sensors Without additional sensors, it can realize the functions of built-in area signal, return to mechanical origin, software limit and so on. Communication and IO isolation Block interference introduced by communication and improve system stability. Vibration suppression Reduce waiting time, reduce production costs, effectively improve accuracy and production efficiency. Self-adjusting and finishing function Reduce debugging difficulty, improve power utilization, and use it out of the box! Get started quickly No code is required, and the visual programming can complete the point programming, saving a lot of man-hours. 2. Multiple Operating Modes from TM Motion Controllers: Positioning action Area output function Based on the origin, set the target position to move to, and set the speed, acceleration, and deceleration zone. Set a "regional signal output range", and trigger the running event when moving to this region. Push action Relative displacement Set an output force value. When the target module moves to contact with the work piece, it stops moving and maintains a force value. Based on the current position, move a relative distance to the next position. 3. Simple connection, Apply out of the box: 4. Why choose Sango Automation? 5. Related knowledge: Motion Controller Motion control usually refers to the conversion of predetermined control schemes and planning instructions into desired mechanical motions under complex conditions to achieve precise position control, speed control, acceleration control, torque or force control of mechanical motions. The motion controller is a special controller that controls the operation mode of the motor: for example, the motor is controlled by the travel switch to control the AC contactor and the motor drags the object up to the specified position and then runs down, or the time relay is used to control the motor to reverse Or stop for a while and then stop for a while. The application of motion control in the field of robots and CNC machine tools is more complicated than in special machines, because the latter form of motion is simpler and is commonly referred to as general motion control (GMC). Motion controller defines a dedicated controller that controls the operation of the motor is widely used in the packaging, printing, textile and assembly industries Basic introduction: Motion control (Motion Control) usually refers to the conversion of predetermined control schemes and planning instructions into the desired mechanical motion under complex conditions to achieve precise position control, speed control, acceleration control, torque or force control of mechanical motion. According to the different power sources used, motion control can be divided into electric motion control with motor as power source, gas-liquid control with gas and fluid as power source and thermal engine motion control with fuel (coal, oil, etc.) as power source Wait. According to statistics, more than 90% of all power sources come from electric motors. The motor plays a very important role in modern production and life, so in these kinds of motion control, electrical motion control is the most widely used. Electric motion control is developed by motor dragging. Electric dragging or electric drive is a general term for a control system targeted by an electric motor. There are many kinds of motion control systems, but from the basic structure, the hardware of a typical modern motion control system is mainly composed of a host computer, a motion controller, a power drive device, a motor, an actuator, and a sensor feedback detection device. The motion controller refers to a control device that takes the central logic control unit as the core, the sensor as the signal sensitive element, and the motor or power device and the execution unit as the control objects. The motion controller is a special controller that controls the operation mode of the motor: for example, the motor is controlled by the travel switch to control the AC contactor and the motor drags the object up to the specified position and then runs down, or the time relay is used to control the motor to reverse Or stop for a while and then stop for a while. The application of motion control in the field of robots and CNC machine tools is more complicated than in special machines, because the latter form of motion is simpler and is commonly referred to as general motion control (GMC). The motion controller is the main device that determines the performance of the automatic control system. For the Mitsubishi series, the motion CPU is the motion controller. For a simple motion control system, a motion controller designed with a single-chip microcomputer can meet the requirements and has a high cost performance. Domestic products At present, the products provided by domestic motion controller manufacturers can be roughly divided into three categories: Take SCM or PC processor as the core The motion controller with a single-chip computer or a microcomputer processor as the core. This type of motion controller has a slow speed, low accuracy, and relatively low cost. It is used in some contour motion control applications that only require low-speed point motion control and low trajectory requirements. Use a dedicated chip as the core processor The motion controller with a dedicated chip as the core processor has a relatively simple structure, but this type of motion controller can only output pulse signals and work in an open-loop control mode. This type of controller basically meets the requirements for single-axis point control occasions, but for devices that require multi-axis coordinated motion and high-speed trajectory interpolation control, such motion devices cannot meet the requirements. Because this type of controller can not provide continuous interpolation function and no forward-looking function, especially for the occasion of continuous movement of a large number of small line segments, this type of controller cannot be used. In addition, due to the limitation of hardware resources, the circular interpolation algorithm of this type of controller usually uses the point-by-point comparison method, so that the accuracy of circular interpolation is not high. Using DSP and FPGA as core processors based on PC bus An open motion controller based on the PC bus with DSP and FPGA as the core processor. This type of motion controller uses the DSP chip as the core processor of the motion controller, the PC as the information processing platform, and the motion controller with a card The form is embedded in the PC, that is, the "PC + motion controller" mode. In this way, the information processing capability and open characteristics of the PC are combined with the motion trajectory control capability of the motion controller, which has the characteristics of strong information processing capability, high degree of openness, accurate motion trajectory control, and good versatility. This type of controller makes full use of the high-speed data processing capability of DSP and the super logic processing capability of FPGA, which is convenient for designing a motion controller with perfect functions and superior performance. This kind of motion controller can usually provide on-board multi-axis coordinated motion control and complex motion trajectory planning, real-time interpolation calculation, error compensation, and servo filter algorithm, which can achieve closed-loop control. Because FPGA technology is used for hardware design, it is convenient for motion controller suppliers to personalize customization according to customers' special process requirements and technical requirements to form unique products. The main function: Exercise planning function It is actually the reference quantity that forms the speed and position of the movement. Appropriate reference quantity can not only improve the accuracy of the trajectory, but also reduce the requirements on the rotating system and mechanical transmission elements. General motion controllers usually provide motion planning methods based on the limits of impact, acceleration and speed, which can affect the accuracy of dynamic trajectory. Users can directly call the corresponding functions. A motion plan that limits acceleration produces a trapezoidal velocity curve; a motion plan that limits impact produces an S-shaped velocity curve. Generally speaking, for CNC machine tools, the use of motion planning methods limited by the reference amount of acceleration and speed has already obtained an excellent dynamic characteristic. For the fast positioning system with high acceleration and small stroke movement, the positioning time and overshoot have strict requirements, and often require continuous motion planning methods with higher order derivatives. Multi-axis interpolation, continuous interpolation function The multi-axis interpolation function provided by the universal motion controller is widely used in the CNC machinery industry. In recent years, due to the rapid development of the engraving market, especially the mold engraving machine market, the continuous interpolation function of the motion controller has been promoted. There are a large number of short and short line processing in the mold engraving, which requires that the processing speed fluctuation between the sections should be as small as possible, and the inflection point of the speed change should be smoothly transitioned. This requires the motion controller to have the functions of speed preview and continuous interpolation. The continuous interpolation type motion controller specially developed by Googol Technology for small line processing technology has been well applied in the fields of mold engraving, laser engraving and plane cutting. Electronic gear and electronic cam function Electronic gears and electronic cams can greatly simplify the mechanical design, and can achieve many functions difficult to achieve by mechanical gears and cams. The electronic gear can realize the simultaneous movement of multiple motion shafts according to the set gear ratio, which makes the motion controller have a good application in fixed-length cutting and register printing without shaft rotation. In addition, the electronic gear function can also achieve a motion axis to follow a function with a set gear ratio, and this function is determined by the movement of several other motion axes; one axis can also follow the other two axes at a set ratio Synthesis speed. The electronic cam function can change the shape of the cam through programming without grinding the mechanical cam, which greatly simplifies the processing process. This function makes the motion controller have good applications in the fields of quenching of mechanical cams, cutting of special-shaped glass and all-motor driven springs. Comparison output function It means that during the movement process, when the position reaches the set coordinate point, the motion controller outputs one or more switching values, but the movement process is not affected. For example, in AOI flight detection, the comparison output function of the motion controller enables the system to run to the set position, that is, to start the CCD quick camera, and the motion is not affected, which greatly improves efficiency and improves image quality. In addition, in the application of laser engraving, this function of Googol's universal motion device has also been well applied. Probe signal latch function It can latch the moment when the probe signal is generated, the position of each motion axis, its accuracy is only related to the hardware circuit, and is not affected by the inertia of software and system operation. It has good applications in the CCM measurement industry. In addition, more and more OEM manufacturers hope that their own rich industry application experience will be integrated into the motion control system, and the functions of the motion controller will be personalized for different applications and control objects. Googol has developed a universal motion controller application development platform, which makes the general motion controller have a truly object-oriented open control structure and system reconfiguration capabilities. Users can load their own designed control algorithms into the memory of the motion controller In this way, a special motion controller for a special purpose can be reconstructed without changing the structural design of the control system. Architecture composition A motion controller is used to generate a trajectory point (expected output) and a closed position feedback loop. Many controllers can also close a speed loop internally. A driver or amplifier is used to convert the motion controller's control signals (usually speed or torque signals) into higher power current or voltage signals. More advanced intelligent drive can close the position loop and speed loop by itself to obtain more precise control. An actuator such as a hydraulic pump, cylinder, linear actuator or motor is used to output motion. A feedback sensor, such as a photoelectric encoder, resolver, or Hall effect device, is used to feed back the position of the actuator to the position controller to close the position control loop. Many mechanical components are used to convert the movement form of the actuator into the desired movement form. It includes gearboxes, shafts, ball screws, toothed belts, couplings, and linear and rotary bearings. Generally, the functions of a motion control system include: speed control and point control (point-to-point). There are many ways to calculate a motion trajectory, they are usually based on the speed curve of a movement such as triangular speed curve, trapezoidal speed curve or S-shaped speed curve. Such as electronic gear (or electronic cam). That is, the position of the driven axis mechanically follows the position change of a master axis. A simple example is that a system contains two turntables, which rotate according to a given relative angle relationship. The electronic cam is more complicated than the electronic gear. It makes the following relationship curve between the driving shaft and the driven shaft a function. This curve can be non-linear, but it must be a functional relationship. Advantages Advantages of motion controller: (1) The hardware composition is simple, insert the motion controller into the PC bus, and connect the signal line to form a system; (2) You can use the rich software that the PC already has for development; (3) The code versatility and portability of the motion control software are good; (4) There are many engineering personnel who can carry out development work, and development can be carried out without much training. Disadvantages Disadvantages of motion controllers: (1) The motion controller adopting the card structure is connected with gold fingers and fixed on one side. It is not suitable for long-term work in most industrial sites with poor environment (severe vibration, dust and oil pollution). (2) PC resources are wasted. Due to the bundled sales of PCs, users actually only use a small part of PC resources. Unused PC resources not only cause idleness and waste, but also cause maintenance trouble. (3) The overall reliability is difficult to guarantee, because the PC selection can be an industrial control machine or a commercial machine. After the system is integrated, the reliability varies greatly and is not guaranteed by the motion controller. (4) It is difficult to highlight industry characteristics. development trend Due to the strong demand for motion controllers from downstream machinery equipment manufacturers, China's general motion controller (GMC) market capacity is expected to reach US$1.065 billion in 2014, while the market size of CNC motion controllers will reach US$1.239 billion. Experts believe that the machine tool, textile machinery, rubber and plastic machinery, printing machinery and packaging machinery industries account for more than 80% of China's motion control market sales, and will be the main market for motion controllers now and in the future. The demand for motion controllers in the food and beverage machinery, tobacco machinery, medical equipment and scientific research equipment industries is closely related to people's lives. These terminal consumptions have been steadily increasing, so the demand for motion controllers in this type of machinery industry is stable Growing. Although the electronics and semiconductor machinery equipment industry suffered some shocks at the end of 2008, the application of motion controllers in electronics and semiconductor machinery has been growing. Read the full article

#ElectricLinearSlides#LargeStrokeMiniGripers#MicroRotaryServoGrippers#MiniServoRotaryTables#MotionControlSystem#MotionController#PrecisionSoftForceControl#ServoElectricCylinders#SmartMicroGrippers#SmartMiniServoGripper#SmartServoCylinders

0 notes