#nichrome flow wrap machine

Video

youtube

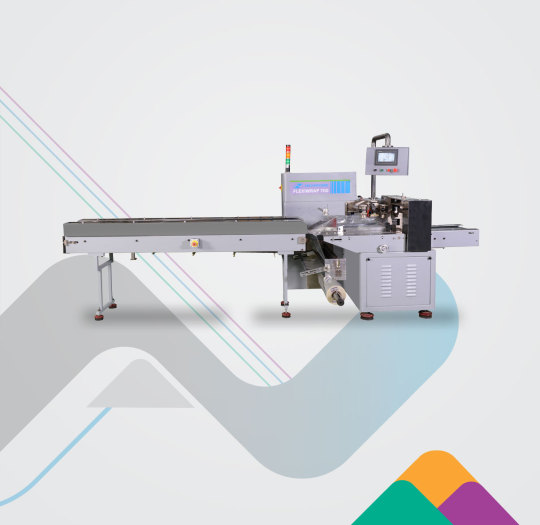

Flow Wrap Machine : Flexiwrap 700

Designed for both primary and secondary packaging, Nichrome’s new range of flow wrap machines are here. You can now customize your center seal pillow pouch with layflat width to upto 700mm and speeds for secondary packaging upto 40ppm. For enquiries, email us on [email protected]

0 notes

Text

How Choosing the Right Nichrome Jar Filling System for Your Business is Essential

Selecting the right jar filling system is crucial for businesses looking to enhance their production efficiency, maintain product quality, and achieve operational excellence. With a range of options available, including the advanced Nichrome jar filling systems, it's essential to choose the one that aligns perfectly with your production needs and product types. In this blog, let us help you explore why selecting our jar filling system is vital and how to make an informed decision for your business.

Understanding Nichrome Jar Filling Systems

Our jar filling systems are renowned for their precision, reliability, and versatility. Whether you are in the food, pharmaceutical, or cosmetics industry, we offer a variety of solutions tailored to specific applications. From powder jar filling machines to ghee jar filling machines, Nichrome’s advanced technology ensures that each fill is accurate and consistent, minimizing waste and maximizing efficiency.

Advantages of Choosing Nichrome's Jar Filling Systems

Investing in the right jar filling system is a critical decision for any business involved in the packaging of products. Nichrome, a leader in packaging solutions, offers state-of-the-art jar filling systems that cater to a wide range of industries. Here are the key advantages of choosing Nichrome’s jar filling systems for your business

Precision and Consistency

Our jar filling systems are designed to deliver high precision and consistency, ensuring that each jar is filled accurately. This is especially important for products that require exact dosages, such as pharmaceuticals and food products. The precision filling reduces product waste and ensures customer satisfaction by maintaining consistent product quality.

2. High Versatility

We offer a variety of jar filling systems like powder jar filling machine and ghee jar filling machine tailored to different types of products. Where a powder jar filling machine is used for dry goods whereas a ghee jar filling machine for viscous products. This versatility makes it easier for businesses to find a single machine that meets their specific product requirements.

3. Enhanced Efficiency

Our jar filling systems are designed for high-speed operations, which significantly boosts production efficiency. We also provide horizontal flow wrap machines that are equipped with advanced automation features that minimize downtime and ensure a smooth, continuous filling process. This efficiency translates to higher output and lower operational costs.

4. Advanced Technology

Nichrome leverages the latest technology in their jar filling systems. Features such as automated controls, real-time monitoring, and precise dosing mechanisms ensure that the filling process is not only efficient but also reliable. The integration of cutting-edge technology helps businesses stay competitive in a fast-paced market

5. Robust Construction

Our jar filling systems are built to last. Constructed from high-quality materials and designed for durability, these machines can withstand the rigors of high-volume production environments. This robustness ensures long-term reliability and reduces maintenance costs.

6. Ease of Use

User-friendly interfaces and straightforward operation are hallmarks of Nichrome’s jar filling systems. These machines are designed with operators in mind, featuring intuitive controls and easy-to-understand instructions. This ease of use reduces training time and minimizes the risk of operational errors.

7. Excellent Support and Service

Nichrome is committed to providing excellent customer support. From initial consultation and installation to ongoing maintenance and troubleshooting, Nichrome’s team of experts is available to assist you. Their comprehensive support ensures that your jar filling system operates at peak performance

8. Compliance and Safety

We manufacture top-end jar filling systems are designed to comply with industry standards and regulations. This compliance ensures that your products are safe and meet quality standards. Additionally, the systems incorporate safety features that protect operators and prevent accidents.

Conclusion

Choosing the right jar filling system is essential for optimizing your production process, ensuring product quality, and achieving operational efficiency. By understanding your production needs and evaluating the advanced solutions Nichrome offers, you can make an informed decision that will benefit your business in the long run.

Investing in our jar filling systems, along with integrated secondary packaging solutions like shrink wrapping and horizontal flow wrap machines, will set your business on the path to greater efficiency, reduced waste, and improved product quality. Contact Nichrome today to learn more about how their innovative solutions can meet your specific needs.

0 notes

Text

THE IMPORTANCE OF ACCURATE WEIGHING AND FILLING IN SNACK PACKAGING

Accurate weighing and filling are crucial aspects of snack packaging, ensuring that products are packaged efficiently and meet specific weight requirements. In this blog, we will explore the importance of accurate weighing and filling in snack packaging and how Nichrome’s provides the most reliable and efficient potato chip packaging machine, automatic sachet packing machine, pouch sealing machine, pouch packing machine and airtight food packaging machines for your business.

What comes along with Nichrome’s Snack Packaging Machines:

Product Consistency: Nichrome ensures accurate weighing and filling with its automatic sachet packing machine. It guarantees that each sachet is filled with the equal amount of product specified. Nichrome’s pouch sealing machine and pouch packing machine are designed to precisely fill and seal tins, ensuring consistency in each package.

Compliance with Regulations: Many food industries have strict codes of conduct regarding the weight and contents of their packaging. Accurate weighing and filling with automatic snack packaging machines manufactured by Nichrome your trusted food packaging manufacturer in Bangladesh can help you meet these regulations and maintain product integrity.

Reduce Product Waste: Overfilling or underfilling can result in product waste, financial loss, and dissatisfied customers. By equipping with Nichrome’s accurate snack filling machines like pouch sealing machines,

Pouch packing machines and vertical form fill seal machines; businesses can minimize waste and optimize their resources.

Improving Operational Efficiency: Reliable filling and packaging machines from Nichrome contribute to the overall operational efficiency. These machines enable faster and more efficient packaging, reducing manual labor and increasing productivity.

Customer Satisfaction: Keeping your clients satisfied at all times is a priority for any business. Being one of the top packaging machine suppliers in Bangladesh, we help businessesfill snacks accurately, to make a direct impact on customer satisfaction. When customers receive consistently filled sacks, they feel confident in the product's quality and value, leading to trust and loyalty.

Ideal Presentation: For products requiring flow wrap packagings, such as snack foods or confectioneries, accuracy in weighing and filling is essential. Horizontal flow wrap machines enable precise packaging, resulting in attractive and well-presented products on store shelves.

Snack Packaging Machines by Nichrome

Vertical Form Fill Seal Machines

These machines are designed to cater for businesses of all sizes, whether it’s startups or small & medium enterprises we have exclusive packaging solutions. We have four highly efficient VFFS machines to help you with your snack packaging. These are perfectly filling & packaging machines for

Wing 200 E-Line Snack Pack

SnackPack

Excel 400 Plus Multi-Head Weigher

Sprint 250 Plus Multi-Head Weigher

Horizontal Form Fill Seal Machines

Designed perfectly to give you both a filling and sealing solution in one machine. Also known as a flow wrap machine, it is efficient at packaging solid items of similar shape and size considering biscuits, snack bars, namkeens, confectioneries and cakes. We have designed four reliable snack packaging machines to help your industry pack efficiently.

T110

T140

T170

Pick Fill Seal Machine

In conclusion, Nichrome filling & packaging machines play a vital role in snack packaging, ensuring product consistency, regulatory compliance, waste reduction, operational efficiency, customer satisfaction and optimal presentation. Using Nichrome’s automated snack packaging machines with advanced equipment such as potato chip packaging machines, soybean oil packing machine, ointment tube filling machine, pouch sealing machine, blister packaging machine, airtight food packaging machine and small packaging machine contribute to achieving perfection in the packaging process.

#pouch sealing machine#silica gel packing machine#blister packaging machine#filling and packaging machine#vertical form fill seal machine#nichromebangladesh#packaging machine supplier in bangladesh#airtight food packaging

0 notes

Text

How do you think your Ultra-Thin Pads are made?

A Sanitary napkin or sanitary pad is an absorbent personal care product. It has been used by a woman while she is in her menstrual cycle. There is a high demand for affordable sanitary napkins among women in rural areas due to the lower cost of sanitary napkins and building hygiene consciousness. Women prefer to use pads out of cotton cloth as a domestic and cheap solution to the hygiene and comfort needs during periods. Ultra-Thin Pads Exporters are competently fulfilling the demands for all types of sanitary pads.

Varied types of sanitary pads available:

For women hygiene upkeep different types of sanitary pads are available in the market. Extra-long, cottony soft, regular, ultra-thin pads, side wings, etc. have a look on them.

Ultra-thin pads: A very compact type of thin pad. It is a choice of smart lady, as absorbent as a General or super pad but with less weight off course.

Regular: This is a middle-range absorbency pad preferred by most ladies nowadays.

Maxi or Super: It is a larger absorbency pad known as good for the start of the menstrual cycle. Menstruation flow is often the heaviest.

Overnight: A longer pad is known for more protection while the wearer is sleeping down, with absorbency suitable for overnight use.

Maternity: These sanitary pads are usually slightly longer than a regular pad. These are designed to absorb high bleeding flow occurred after childbirth and also can absorb urine.

Designing of ultrathin pads

Sanitary napkins are generally made up of three layers:

• surface layer,

• absorbent layer and

• the underlying layer.

The choice of sanitary pads should be made considering the size and relating to the materials and functions of these three layers.

Menstrual pads come in a variety of sizes and diameters. Super-absorbent and regular pads are good for the days when your period is heaviest. Ultra-thin pads are preferred on days when the period is light, or when it is used in the beginning of your period. Extra-absorbent pads are made to last long up to 4 and 6 hours. But if your flow is denser, it may need changing sooner. The same goes for sanitary pads smaller in size and less absorbent.

Manufacturing process:

First wood pulp is bought in commercially prepared sheet form. The pulp is then de-fiberated on the de-fibration machine. A carbon steel blade is used to de-fibrates the wood pulp to a needed filament length. Just as the wood pulp is de-fiberated, it is put into the core-forming machine to press the pulp essential shape of the napkin, done manually without any automation.

The formed wood pulp cores are then wrapped into a non-woven fabric and are sealed by a complex impulse sealing method. Nichrome alloy filament is a chemical that is preferably used in the manufacturing and sealing of pads. Finally, the position sticker is pasted on the napkin, and the napkins are packed.

Where to get high-quality ultra-thin pads?

Get it from Ultra-Thin Pads Exporter who can supply your high-quality products along with the following feature:

• Highest quality products

• Affordable pricing

• Hygienically produced

• Nationwide reach

• Prompt and damage-free delivery

1 note

·

View note

Text

Integrated Packaging Solutions for Spices by Nichrome

Spice It Up with Nichrome: Your Packaging Partner in Flavor

In the bustling world of spices, where every pinch counts, ensuring that your aromatic treasures reach consumers in top-notch condition is crucial. This is where Nichrome steps in, adding a dash of magic to your secondary packaging needs. With our innovative machinery and integrated solutions, we ensure your spices are packaged with the precision and care they deserve. Let’s dive into how Nichrome spices up your packaging game.

Sizzle with Streamlined Spice Solutions

Nichrome’s spice packaging machines are the secret ingredient to your success. Whether it’s our versatile powder filling machines or the groundbreaking Flexiwrap 700 horizontal flow wrap machine, we have the tools to transform your packaging process. Our machines are designed to maximize efficiency and boost productivity, making your spices look as good as they taste.

Integrated Packaging: The Recipe for Success

At Nichrome, we know that packaging isn’t just about individual machines—it’s about creating a cohesive system. Our integrated solutions blend different packaging technologies into a harmonious line, ensuring your operations run smoothly. By optimizing efficiency and enhancing product presentation, we make sure your spices steal the spotlight on the shelves.

Precision and Quality: The Perfect Blend

Consistency and accuracy are non-negotiable in spice packaging. Nichrome’s machines are engineered for precision, ensuring each pouch is filled to perfection. Our technology preserves the integrity of your spices, maintaining their aroma and flavor, so every customer experience is a delightful one.

Sustainability: Spice Up the Planet

n today’s eco-conscious world, sustainability is key. Nichrome’s machines are designed to minimize waste and optimize resource use. With energy-efficient operations and eco-friendly solutions, we help you reduce your environmental footprint while delivering top-notch packaging.

Flexiwrap 700: The Star of the Show

The Flexiwrap 700 is a game-changer in spice packaging. This innovative horizontal flow wrap machine offers customizable pouch sizes, attractive sealing options, and advanced controls. It ensures your spices are securely packaged and ready to impress. With features like intermittent motion, quick change-over design, and the ability to store different recipes, the Flexiwrap 700 is your go-to for efficient, eye-catching packaging.

Features of the Flexiwrap 700

Intermittent Motion: Smooth and efficient operation.

Stainless Steel Contact Parts: Ensuring hygiene and durability.

Quick Change-Over Design: Easy transitions for different pouch sizes.

Recipe Storage: Streamlined changeovers with PLC program storage.

Servo Motor and Pneumatic Cylinder: Precise control for center and side seals.

Laminate Compatibility: Works with materials like BOPP/PPE.

Speed: Up to 60 ppm, adjustable based on pouch length.

Conclusion

Nichrome is your spice packaging partner extraordinaire. With our cutting-edge machines and commitment to sustainability, we help you elevate your packaging operations and exceed customer expectations. From powder filling to advanced flow wrap machines, Nichrome has the solutions you need to thrive in the competitive spice market. Spice up your packaging with Nichrome and taste the difference in quality, efficiency, and innovation. Learn More: https://www.nichrome.com/blog/integrated-spice-packaging-solutions/

#spice packaging machines#Spices Packing Machine manufacturers#Spices packing machine manufacturers in india

0 notes

Text

How Choosing the Right Nichrome Jar Filling System for Your Business is Essential

Selecting the right jar filling system is crucial for businesses looking to enhance their production efficiency, maintain product quality, and achieve operational excellence. With a range of options available, including the advanced Nichrome jar filling systems, it's essential to choose the one that aligns perfectly with your production needs and product types. In this blog, let us help you explore why selecting our jar filling system is vital and how to make an informed decision for your business.

Understanding Nichrome Jar Filling Systems

Our jar filling systems are renowned for their precision, reliability, and versatility. Whether you are in the food, pharmaceutical, or cosmetics industry, we offera variety of solutions tailored to specific applications. From powder jar filling machines to ghee jar filling machines, Nichrome’s advanced technology ensures that each fill is accurate and consistent, minimizing waste and maximizing efficiency.

Advantages of Choosing Nichrome's Jar Filling Systems

Investing in the right jar filling system is a critical decision for any business involved in the packaging of products. Nichrome, a leader in packaging solutions, offers state-of-the-art jar filling systems that cater to a wide range of industries. Here are the key advantages of choosing Nichrome’s jar filling systems for your business

Precision and Consistency

Our jar filling systems are designed to deliver high precision and consistency, ensuring that each jar is filled accurately. This is especially important for products that require exact dosages, such as pharmaceuticals and food products. The precision filling reduces product waste and ensures customer satisfaction by maintaining consistent product quality.

2. High Versatility

We offer a variety of jar filling systems like powder jar filling machine and ghee jar filling machine tailored to different types of products. Where a powder jar filling machine is used for dry goods whereas a ghee jar filling machine for viscous products. This versatility makes it easier for businesses to find a single machine that meets their specific product requirements.

3. Enhanced Efficiency

Our jar filling systems are designed for high-speed operations, which significantly boosts production efficiency. We also provide horizontal flow wrap machines that are equipped with advanced automation features that minimize downtime and ensure a smooth, continuous filling process. This efficiency translates to higher output and lower operational costs.

4. Advanced Technology

Nichrome leverages the latest technology in their jar filling systems. Features such as automated controls, real-time monitoring, and precise dosing mechanisms ensure that the filling process is not only efficient but also reliable. The integration of cutting-edge technology helps businesses stay competitive in a fast-paced market

5. Robust Construction

Our jar filling systems are built to last. Constructed from high-quality materials and designed for durability, these machines can withstand the rigors of high-volume production environments. This robustness ensures long-term reliability and reduces maintenance costs.

6. Ease of Use

User-friendly interfaces and straightforward operation are hallmarks of Nichrome’s jar filling systems. These machines are designed with operators in mind, featuring intuitive controls and easy-to-understand instructions. This ease of use reduces training time and minimizes the risk of operational errors.

7. Excellent Support and Service

Nichrome is committed to providing excellent customer support. From initial consultation and installation to ongoing maintenance and troubleshooting, Nichrome’s team of experts is available to assist you. Their comprehensive support ensures that your jar filling system operates at peak performance

8. Compliance and Safety

We manufacture top-end jar filling systems are designed to comply with industry standards and regulations. This compliance ensures that your products are safe and meet quality standards. Additionally, the systems incorporate safety features that protect operators and prevent accidents.

Conclusion

Choosing the right jar filling system is essential for optimizing your production process, ensuring product quality, and achieving operational efficiency. By understanding your production needs and evaluating the advanced solutions Nichrome offers, you can make an informed decision that will benefit your business in the long run.

Investing in our jar filling systems, along with integrated secondary packaging solutions like shrink wrapping and horizontal flow wrap machines, will set your business on the path to greater efficiency, reduced waste, and improved product quality. Contact Nichrome today to learn more about how their innovative solutions can meet your specific needs.

0 notes

Text

Elevate Your Automatic Spice Packaging with Nichrome's Flexiwrap

In the vibrant world of spices, packaging is not about containment; it's an art that involves preserving flavors, enhancing aesthetics, and captivating consumers. At Nichrome, we understand the intricate dance between spice and packaging, and that's where our revolutionary Flexiwrap steps in. Join us on a tantalizing journey as we unravel how Nichrome's Flexiwrap takes spice packaging machines to new heights, making it an unforgettable sensory experience.

The Spice Symphony Begins

Imagine a jar filled with fragrant spices, ready to ignite culinary masterpieces. As chili powder packaging machines, we take pride in crafting solutions that bring your spices to life. But the journey doesn't stop there. With Flexiwrap, our spice packaging machines maestro, we orchestrate a symphony that elevates your spice packaging to a whole new level.

Flawless Powder Perfection

Spices come in various forms, and when it comes to powders, precision is paramount. Our Flexiwrap embraces the challenge, seamlessly integrating with automatic spice packaging machines to ensure every pinch of spice is meticulously packaged. No clumps, no spills – just a flawless presentation that mirrors the quality of your spices.

The Flow Wrap Flourish

Unveiling Flexiwrap's prowess, we introduce the flow wrap machine into the mix. Like an artist's brush stroke, this machine delicately wraps your spice jars, creating an enchanting visual appeal. With its customizable pouch sizes and elegant sealing options, the flow wrap machine adds a touch of sophistication that captures the essence of your brand.

The Power of Powder Filling

Food packaging machines are an art of precision, and our spice filling & sealing machines are the virtuoso. Seamlessly integrating with Flexiwrap, this machine ensures accurate fills that preserve the potency of your spices. From bold flavors to delicate aromas, every particle is measured with care, guaranteeing a sensory delight for your customers.

Beyond Just Secondary Packaging

Flexiwrap is more than just packaging; it's an experience. It's about creating a connection between your spices and your customers. With anautomatic masala packing machine that's as captivating as your spices, Flexiwrap transforms each package into an inviting treasure trove, waiting to be explored.

Crafting Experiences, One Spice at a Time

Nichrome's Flexiwrap doesn't just package; it crafts experiences. It adds a layer of intrigue to your spice jars & pouches inviting consumers to embark on a flavor-filled journey. It turns packaging into an interactive story, where each unwrapping is a moment of anticipation, and each taste is a revelation.

Conclusion:

In the world of spice packaging, Nichrome's Flexiwrap reigns supreme as the ultimate secondary packaging partner. As a harmonious ensemble of automatic spice packaging machines, powder filling machines, powder packing machine, spices filling & sealing machine, chili powder packing machine and the exquisite flow wrap machine, Flexiwrap doesn't just package your spices – it elevates them into a masterpiece. It's an interactive journey that tantalizes the senses and leaves a lasting impression on your customers. With Nichrome's Flexiwrap, your spice packaging isn't just a package; it's an experience waiting to be savored.

#packaging machine manufacturer#food packaging machine#innovative packaging solutions#spice packaging machine#integrated packaging solutions#automatic packaging machine#secondary packaging solutions#chili powder packing machine

0 notes

Text

How Nichrome plays a major role as your secondary packaging partner for your spice industry

In the fast-paced world of the spice industry, efficient and reliable packaging is the key to success. Ensuring that your spices reach consumers in pristine condition while maintaining their aroma, flavor, and freshness is essential. This is where Nichrome steps in as your ultimate secondary packaging partner. With our expertise in spice packaging, a wide range of innovative packaging machines, and integrated packaging solutions, we redefine the way spices are packaged and presented to consumers. Let's embark on a journey through the world of spice packaging and explore how Nichrome plays a major role as your secondary packaging partner.

How Nichrome makes your spice packaging better:

Streamlined Spice Packaging Solutions

Nichrome boasts an impressive array of spice packaging machines that cater to the unique needs of the spice industry. From powder filling machines to the cutting-edge Flexiwrap 700 horizontal flow wrap machine, our packaging solutions are designed to maximize efficiency and productivity. With our versatile machines, spice packaging becomes seamless, precise, and visually appealing.

2. Integrated Packaging Solutions for Spice Industry

At Nichrome, we understand that spice packaging is not just about individual machines; it is about a complete packaging ecosystem. Our integrated packaging solutions seamlessly combine different packaging machines, creating a harmonious packaging line that optimizes efficiency and enhances product presentation. With our integrated solutions, you can achieve smooth and streamlined spice packaging operations.

3. Elevating Spice Packaging with Quality and Precision

When it comes to spice packaging, consistency and accuracy are non-negotiable. Nichrome's spice packaging machines are engineered with the utmost precision, ensuring that each spice pouch is filled to perfection. Our packaging machines maintain the integrity of the spices, preserving their aroma and flavor, delighting consumers with every use.

4. Sustainable Spice Packaging

At Nichrome, we understand the importance of sustainability in today's packaging landscape. Our spice packaging machines are designed to minimize material wastage and optimize resource utilization. With energy-efficient operations and eco-friendly packaging solutions, we help you reduce your environmental impact while delivering exceptional packaging.

Flexiwrap 700: A Game-Changer in Spice Packaging

The Flexiwrap 700 is the star of the show in secondary packaging. This innovative horizontal flow wrap machine delivers top-notch packaging for your spices. With customizable pouch sizes, attractive sealing options, and advanced controls, the Flexiwrap 700 ensures that your spices are securely packaged and ready to captivate consumers.

Key Features of Flexiwrap 700

Intermittent motion

Material of construction for contact parts in SS 304

Quick change-over friendly design for use of different forming size parts

Facility to store different recipes for changeovers through PLC program.

Center seal and center conveyor driven by servo Motor.

Side seal driven by pneumatic cylinder.

Compatible with Laminate (BOPP/PPE)

Speed up to 60 ppm (Can vary depending upon the pouch length)

In conclusion, Nichrome's role as your secondary packaging partner in the spice industry is unparalleled. With our innovative spice packaging machines, including the Flexiwrap 700, and our commitment to sustainability, we help you enhance your spice packaging operations and exceed customer expectations. From powder filling machines to the most advanced flow wrap machines, Nichrome has the packaging solutions you need to succeed in the competitive spice market. Elevate your spice packaging with Nichrome and experience the difference in quality, efficiency, and innovation.

#automatic packaging machine#spice industry#spice packaging#spice packaging machines#food packaging#food packaging solution#integrated packaging solutions#automated packaging systems

0 notes

Text

Flexiwrap 700

Nichrome offers Horizontal Flow Wrap Machine (Flexiwrap 700) & Packaging System for food, pharma & Non Food industries

0 notes

Text

The Benefits of having Nichrome’s Bulk Bag Filling System for your Agrochemical Industry

The agricultural industry is highly competitive, and agro-chemical manufacturers are always looking for ways to increase efficiency and productivity while reducing costs. One way to achieve these goals is by using bulk bag filling machines or bulk bag filling systems. Agro-chemicals play a critical role in the success of modern agriculture, and agro-chemical manufacturers face many challenges when it comes to packaging and distribution. One way to streamline this process is by using bulk bag filling machines, which offer many benefits to manufacturers.

Bulk bag filling machines are designed to fill large bags with a high degree of accuracy and efficiency. These machines can handle a wide range of agro-chemical products, including powders, granules, and liquids, making them highly versatile and adaptable to the needs of the industry.

Here are some of the key benefits of using these machines for agro-chemicals.

1. Increased Efficiency

Bulk bag filling machines by Nichrome can fill multiple bags at once, significantly reducing the time and labor required to fill each bag manually. This allows manufacturers to increase production rates while reducing labor costs and improving overall efficiency. Additionally, using an automatic bottle filling machine or powder bottle filling machine can speed up the process of filling individual bottles, further increasing efficiency.

2. Reduced Waste

Nichrome’s Bulk bag filling machines can accurately dispense the exact amount of product needed for each bag, reducing waste and maximizing the amount of product that can be packaged. This is especially important for agro-chemicals, where precise dosing is critical for product efficacy and safety. The use of a shrink wrapping machine for bottles or bottle capping machine can also help reduce waste by securely sealing each bottle.

3. Improved Product Quality and Consistency

Bulk bag filling machines ensure that each bag or bottle is filled with the same precise amount of product, resulting in improved product quality and consistency. This is important for agro-chemicals, where inconsistent dosing can lead to crop damage or even failure.

4. Regulatory Compliance

Bulk bag filling machines from Nichrome are designed to meet regulatory requirements for packaging and labeling, ensuring that agro-chemical manufacturers comply with relevant regulations. Using a bottle filling line that incorporates a bottle capping machine and shrink wrapping machine for bottles can also ensure that bottles are properly sealed and labeled, meeting regulatory requirements.

5. Customizable to Specific Needs

Bulk bag filling machines can be customized to meet the specific needs of agro-chemical manufacturers, including the type of product being filled, the desired production rate, and the available space and resources. This allows manufacturers to create an integrated packaging solution that fits their unique needs and requirements.

In conclusion, using a bulk bag filling machine or bulk bag filling system, as well as an automatic bottle filling machine or powder bottle filling machine, can provide significant benefits to agro-chemical manufacturers, including increased efficiency, reduced waste, improved product quality and consistency, regulatory compliance, and customizable packaging solutions. By investing in Nichrome’s bulk bag filling machines, agro-chemical manufacturers can achieve their production goals while maintaining the highest quality standards.

Nichrome is also a prime manufacturer of tin filling machine, oil tin filling machine, tin can filling and sealing machine, can seamer machine, ghee jar filling machine, cartoning machine, box packing machine, automatic carton box packing machine, secondary packaging, flow wrap machine as well as horizontal flow wrap machine.

0 notes

Link

Nichrome offers Horizontal Flow Wrap Machine (Flexiwrap 700) & Packaging System for food, pharma & Non Food industries

0 notes

Text

Enhance your Secondary Packaging with Nichrome’s Horizontal Flow Wrap Machine

Nichrome's Integrated Packaging System is a complete packaging solution that combines multiple machines and processes into a single, cohesive system. Our system includes a range of machines, including filling machines, sealing machines, and labeling machines, which work together seamlessly to deliver efficient, high-quality packaging. Our Integrated Packaging System is fully customizable to meet the unique needs of each customer, and is designed to increase productivity, reduce downtime, and improve overall packaging efficiency.

Secondary packaging is an important aspect of the product packaging process that involves the wrapping of the primary packaging of a product to ensure its safety during transport and storage. The use of a Horizontal Flow Wrap Machine in this process can enhance the quality of your secondary packaging, providing several benefits for your business.

Nichrome is a leading manufacturer of secondary packaging machines and is a prime Shrink Wrapping Machine Manufacturer that offers a wide range of solutions for the packaging industry. Our Flow Wrap Machine & Shrink Wrapping Machine is a popular choice among manufacturers for enhancing secondary packaging.

1. Increased Efficiency

Nichrome’s Horizontal Flow Wrap Machine is designed to handle high-speed packaging processes, making it an ideal choice for manufacturers looking to increase their production efficiency. This machine can wrap several products at once, reducing the time taken to wrap each product manually. This, in turn, can increase your output, making your business more profitable in the long run.

2. Consistent Quality

The Horizontal Flow Wrap Machine is equipped with advanced technology that ensures consistency in the wrapping process. The machine can handle different sizes and shapes of products, ensuring that each product is wrapped with the same level of quality. This consistency in packaging can enhance the overall appearance of your products, improving customer satisfaction and brand recognition.

3. Versatility

Nichrome’s Case Eractor & Flow Wrap Machine can handle a wide range of packaging materials, including polypropylene, cellophane, and laminated films, among others. This makes it a versatile packaging solution for manufacturers who work with different types of products. The machines can also handle different types of packaging styles, including pillow bags, gusset bags, and stand-up pouches, among others.

4. Reduced Labor Costs

Using Nichrome’s Horizontal Flow Wrap Machine you can significantly reduce the need for manual labor in the secondary packaging process. This can save your business time and money while also reducing the risk of errors in the packaging process. With this machine, you can automate your packaging process, freeing up your employees to focus on other important tasks.

5. Enhanced Product Protection

A high level of protection for your products during transport and storage is crucial and Nichrome ensures you the same. The Horizontal Flow Wrap Machine creates a tight seal around each product, protecting it from moisture, dust, and other external factors that could damage the product. This, in turn, can reduce product waste and increase the shelf life of your products.

In conclusion, the Horizontal Flow Wrap Machine from Nichrome is a versatile and efficient packaging solution for your industry looking. With its advanced technology, consistent quality, and versatility, this machine can provide several benefits for your business, including increased efficiency, reduced labor costs, and enhanced product protection. Consider investing in this machine to improve the quality of your secondary packaging and grow your business.

We are also a leading provider of ghee jar filling machine, tin packaging machine, tin can filling and sealing machine, bottle capping machine, automatic bottle filling machine and automatic case erector , horizontal cartooning machine , vertical case erector and bulk bag filling machine.

#ghee jar filling machine#tin packaging machine#tin can filling and sealing machine#bottle capping machine#automatic bottle filling machine#automatic case erector#horizontal cartooning machine#vertical case erector#bulk bag filling machine#Integrated Packaging System#Horizontal Flow Wrap Machine#Shrink Wrapping Machine Manufacturer#Flow Wrap Machine

0 notes

Text

Enhance your Secondary Packaging with Nichrome’s Horizontal Flow Wrap Machine

Nichrome’s Integrated Packaging System is a complete packaging solution that combines multiple machines and processes into a single, cohesive system. Our system includes a range of machines, including filling machines, sealing machines, and labeling machines, which work together seamlessly to deliver efficient, high-quality packaging. Our Integrated Packaging System is fully customizable to meet…

View On WordPress

#Automatic Bottle Filling Machine#automatic case erector#Bottle Capping Machine#bulk bag filling machine#flow wrap machine#ghee jar filling machine#horizontal cartooning machine#horizontal flow wrap machine#integrated packaging system#shrink wrapping machine manufacturer#tin can filling and sealing machine#tin packaging machine#vertical case erector

0 notes

Text

NICHROME’S AUTOMATED PACKAGING SYSTEMS: A VITAL ROLE IN MEETING THE PHARMACEUTICAL INDUSTRY DEMANDS

The pharmaceutical industry has seen rapid growth in recent years, with an increasing demand for innovative and safe packaging solutions. To meet these demands, automation packaging solutions have become a key player in the pharmaceutical packaging industry. Nichrome has been a leading manufacturer of the most high tech packaging systems that not only provide efficient and accurate packaging but also help to ensure the quality and safety of the pharma drugs.

With constant research and development, Nichrome has been able to develop filling systems that are quality proven and gives the most high-end integrated packaging solutions.

TIN FILLING SYSTEMS

One of the most common applications of automation in the pharmaceutical packaging industry is tin filling. Tin filling machines are specifically designed to handle the delicate and precise packaging of pharmaceutical products. These machines use advanced technology to fill tins with the exact amount of product, ensuring that the packaging is accurate and consistent. The use of tin filling systems reduces human error, increases production speed, and helps to improve product quality.

BOTTLE FILLING SYSTEMS

Bottle filling machines are another important automated pharma packaging machine that uses advanced technology to fill bottles with the exact amount of product, ensuring that the packaging is accurate and consistent. The use of automatic bottle filling systems helps to eliminate the risk of contamination and reduces the risk of human error. It also improves production speed and product quality, making it an essential tool in the pharmaceutical packaging industry.

BLISTER FILLING SYSTEMS

Blister packaging machines use advanced technology to package pharmaceutical products into blister packs, which are commonly used for pills, capsules, and other small products. The use of blister packaging machines helps to ensure that the packaging is consistent and accurate, providing a safe and convenient way to dispense the product.

TOP-BLISTER FILLING SYSTEMS

Top-blister packaging machines use modern technology to package pharmaceutical products into top-blister packs, which are commonly used for pills, capsules, and other small medical products. These machines provide a secure and efficient way to package the product, reducing the risk of contamination and wastage of materials. They also improve production speed and product quality, making them an essential tool in the pharmaceutical packaging industry.

In conclusion, Nichrome’s automated packaging solution plays a vital role in the pharmaceutical packaging industry. The use of tin filling machines, automatic bottle filling machines, blister packaging machines, and top-blister packaging machines helps to ensure the quality and safety of the drugs, reduces human error, and improves production speed. Automated packaging systems are essential for the pharmaceutical industry to meet the increasing demands for innovative and safe packaging solutions.

Nichrome is also a top-solution provider for oil tin filling machine, shrink wrapping machine for bottles, powder bottle filling machine, carton box packing machine, bulk bag filling machine, flow wrap machine, horizontal flow wrap machine, powder filling machine which are just a few to name.

#pharmaceutical packaging#tin filling#Tin filling machines#automated pharma packaging machine#automatic bottle filling systems

0 notes

Text

NICHROME TO GLOW AT GRAINEX INDIA 2023

GrainEx, India’s renowned technology exhibition & conference for the grain milling industry, will be held between January 20-22, 2023, at the Helipad Exhibition Centre, Gandhinagar, Gujarat.

Nichrome India, the world’s leading integrated packaging solutions (IPS) manufacturer, will showcase its innovative automated packaging systems at GrainEx India 2023.

Nichrome will participate in this mega event and add lustre to the expo by its very presence because of the uniqueness of its integrated packaging solutions characterised by ease-of-use, superior design and functionality, exhaustive range, customisability, and bespoke manufacturing backed by decades of R&D.

GrainEx India 2023 is sponsored by certain prestigious Indian agricultural and food organizations like the Akhil Gujarat Rice Mill Owners Association, Gujarat Pulses Manufacturing Association, Gujarat Roller Flour Miller’s Association, and All India Dal Mills Association.

There are an estimated 1,200 roller flour mills in India. For all of them, GrainEx India 2023 will present an excellent opportunity to explore synergies with other industry players from across the country.

Nichrome’s unparalleled IPS range

A pioneer then and a leader now, Nichrome India trumps competition with its plethora of integrated packaging and filling systems for food, non-food, and pharma.

Nichrome’s Vertical Form Fill Seal (VFFS) machines for solids, liquids, and viscous material are bespoke. Nichrome’s VFFS multilane and Horizontal Form Fill Seal (HFFS) systems are the preferred choice in India and globally. Nichrome’s Map Tray Sealing Machines are the talk of the industry.

Nichrome India spearheads the manufacture of jar filling machines, case packers, shrink wrapping machines, food package machines, pharmaceutical packaging machines, and integrated packaging solutions like auto case erectors, box packing machines, and secondary packaging machines.

For projects big and small in food, non-food and pharma applications, Nichrome partners through the complete lifecycle, innovating and integrating solutions that elevate productivity through performance. Nichrome offers proven expertise and single-source convenience for pre-primary, post-primary, and end-to-end system solutions.

Nichrome grain packing solutions

Think automated grain packaging machines, think Nichrome. Nichrome offers a wide array of products for Multilane Vertical Form Fill Seal (VFFS), solid packaging, liquid packaging, viscous material packaging, Horizontal Form Fill Seal (HFFS) and tin & jar filling systems well known for their performance, durability and versatility.

Nichrome India’s integrated packaging solutions take packaging tech to the next level of capability because they are backed by extensive R&D and tailor-made design.

Nichrome’s grain filling systems, powder filling machine, tin filling machine, jar filling machine, can filling & sealing machine, carton packing machine, flow wrap machine and horizontal flow wrap machine are the preferred products in India and worldwide.

Nichrome offers a wide range of machines providing numerous solutions for your grain and seed packaging needs. Food Packaging Machines like the Excel Plus series, equipped with modern technology offer innovative packaging solutions that follow stringent packaging quality standards for a wide range of products.

Excel Plus Series

The Excel Plus series comes with an advantage of automation equipped with control engineering (CE) marked Programmable Logic Controller (PLC) and touch screen human-machine interface (HMI).

Key features include print mark scanners, servo motor driven bag length control system, and adjustable stroke of cross sealing jaws for optimum performance. It is designed as per stringent quality standards and can be easily integrated to upstream or downstream machines/systems.

Excel Vertipack 320

Excel Vertipack 320 is India's first vertical pouch packaging machine. Yet another versatile innovation from Nichrome, Excel Vertipack 320 has been developed for packaging dry fruits, snacks, pasta, and grains in a variety of stand-up pouches with or without zipper.

With its high-speed performance, sturdy design, online check weigher & metal detector, compatibility with multiple fillers, and a host of other features, Excel Vertipack 320 assures you robust performance with unmatched versatility.

Sprint 250 Plus

For pouch quantities up to 2 Kgs, Nichrome’s Sprint 250 Plus series offers speed, accuracy, and efficiency for flexible packaging of a wide variety of snacks, grains, and powders.

Sprint 250 Plus is an automated machine with CE marked PLC and touch screen HMI. Its servo motor driven sealing system can effectively seal with pressure levels maintained. It is programmed to pull the exact length of film required for packaging and offers a perforation system to deliver a chain of small pouches.

Nichrome’s Food Packaging Solutions

Nichrome is at the forefront of path breaking IPS technology with its multitude of food packaging products like the Snacks & Namkeen Packaging Machine, Ready-to-Eat Food Packaging Machine, Grains & Seeds Packaging Machine, Milk & liquids Packaging Machine, Powder Packaging Machine, Spice Packaging Machine, Coffee Packaging Machine, Sugar Packaging Machine, Oil Packaging Machine, Salt Packaging Machine, and Tea Packaging Machine.

Why Nichrome?

For enterprises big and small, for applications existing and emerging, we offer infinite possibilities in integrated, automated packaging solutions. We partner with customers through the complete product lifecycle, offering application-specific solutions, backed by dependable service and support. Based in Pune, India, our sales & service network spans India and the world. We have presence in 45 plus countries and over 10,000 plus successful installations worldwide.

Conclusion

With automated Nichrome packaging solutions, you do not just get machines to do this. We handhold you through the entire operation from kick-off to completion. We believe in providing total turnkey automated secondary packaging solutions that will fit your packaging requirements like a glove.

0 notes

Text

Nichrome’s snack pack line has the ‘knack’!

Nichrome India, a global leader in integrated and automated packaging solutions, is counted among the best in the world for its precision manufacturing, plethora of products for several use cases, and bespoke sales and service. The name Nichrome has become synonymous with integrated and automated packaging solutions especially in India and across the world.

For start-ups, SMEs or large MNCs; for current or emerging needs, Nichrome offers endless possibilities and value in packaging solutions. That too, with one-stop convenience. We partner with customers, studies their specific application, and offer integrated solutions that deliver cost savings and efficiency.

Nichrome Packaging Solutions

Think automated packaging machines, think Nichrome India. Nichrome offers a wide array of products for Multilane Vertical Form Fill Seal (VFFS), solid packaging, liquid packaging, viscous material packaging, Horizontal Form Fill Seal (HFFS) and tin & jar filling systems renowned for their performance and ease-of-use.

Nichrome India’s integrated packaging solutions take packaging tech to the next level of capability because they are backed by extensive R&D and tailor-made design.

Nichrome’s powder filling machine, tin filling machine, jar filling machine, can filling & sealing machine, carton packing machine, flow wrap machine and horizontal flow wrap machine are the preferred products in India and worldwide.

Nichrome’s Tin Filling Line

Nichrome's tin filling line is a sturdy, low-maintenance system made for accurate performance and safety. The PLC-controlled line has a digital LCD touch screen displaying settings, and safety enclosures with interlocks for rotary parts. Tin sterilization and cleaning options are on offer.

Nichrome is a superior snack packaging machine manufacturer, focused on providing high quality packaging solutions ensuring that the freshness and quality of food products is maintained.

Nichrome’s Snack & Namkeen Packaging Machine

Nichrome’s SnackPack, is a food packaging machine that provides packaging solutions for a wide range of snack and namkeen products with dedicated design solutions for snack & namkeen packaging.

Nichrome’s snack packing machines have applications in safely and aesthetically packaging Chips, Puffed Snacks, Dry Fruits, Wrapped Candies, Biscuits, Pasta, Breakfast Cereals, Potato Chips, Kurkure, Macaroni, Indian Namkeen, Nuts, Soya Chunks, High Counts Biscuits.

Nichrome’s Wing-200 E-line Snack Pack, Excel Vertipack 320, Excel 400 Plus Multihead Weigher and Sprint 250 Plus Multihead Weigher are making industry buzz.

Nichrome Jar Filling Machines

Nichrome offers a wide range of liquid packaging machines – including bottle filling machines, oil tin filling machines, and ghee jar filling machines – that can be used to package diverse liquids.

Nichrome presents a versatile jar filling & packaging system which is widely used to fill solids like tea, small biscuits, nutraceutical powders, health drinks, wrapped candies, viscous fluids like ghee, peanut butter, and mayonnaise.

Nichrome’s jar filling and sealing line can also be used to pack Chyawanprash, powders, granules, candies, and biscuits into bottles or jars. We provide end-to-end solutions for all kinds of bottle filling, foil sealing, capping, labelling and batch coding requirements.

Nichrome Wing 200 E-Line Snack Pack

The Wing 200 E-Line Snack Pack is an exclusive packaging solution for start-ups and SMEs. Nichrome Wing 200 E-Line Snack Pack demonstrates superior expertise and reliability of Nichrome, and is available in a compact, affordable format designed to fit your space and budget.

Nichrome Flow Wrap Machine (Flexiwrap 700)

In the Nichrome Flexiwrap 700, secondary CSPP Flow-wrapped pouches are formed for a wide range of lay flat widths, up to 700mm. It operates with manual product feeding into a specialized conveyor and does automatic flow wrapping.

The sterling features of the Nichrome Flow Wrap Machine (Flexiwrap 700) are intermittent motion, robust construction, quick change-over friendly design for use of different forming size parts and convenience.

Nichrome Horizontal Cartoner

Enjoy fast & efficient cartoning with Nichrome’s Horizontal Cartoning Machine. This secondary packaging machine has a rated output of up to 180 cartons per minute and handles a variety of cartons with options of both side tuck-in, both side gluing or top tuck-in with bottom gluing.

Nichrome offers both continuous and intermittent fully automatic horizontal cartoners integrated with primary packaging. The main features are flexibility for size range and quick change-over, additional positive product inserter before flap closure (special for rigid products & pouches).

This Nichrome carton packaging machine also features unique and invaluable features like auto pre-folded leaflet insertion, machine guards with positive safety interlocks, sensors for monitoring carton and pouch, and speed up to 180 cartons per minute. It is the secondary and tertiary packaging solution of choice in India and markets abroad.

Conclusion

If integrated and automated packaging systems, is your ask; then give us the task! At Nichrome India, having developed India's first indigenous milk packaging machine in 1977, we have been at the forefront of cutting-edge packaging technologies. Nichrome is a brand trusted for its rich legacy of pioneering innovation, extensive domain knowledge and manufacturing competency in fully integrated packaging systems.

Our sales & service networking spans is based in Pune and is spread across all over the globe and India. Nichrome has a footprint in more than 45 countries and has successfully done 10000+ installations worldwide.

#snack packaging#namkeen packaging#snack packing machines#liquid packaging machines#bottle filling machines#oil tin filling machines#ghee jar filling machines#Horizontal Cartoning Machine#milk packaging machine#VFFS#HFFS#powder filling machine#tin filling machine#jar filling machine#can filling & sealing machine#carton packing machine#flow wrap machine#horizontal flow wrap machine

0 notes