#nitrogen gas cylinder

Text

Nitrogen gas

Nitrogen (N2) is a highly versatile gas that finds extensive use in a broad spectrum of applications and industries.

DSW commits to providing a reliable supply of nitrogen to meet the evolving demands of various industries. We offer nitrogen in multiple purities and supply modes to cater to diverse customer requirements and ensure optimal performance in their respective applications.

Nitrogen cylinder supplied by DSW is available in various sizes and purity requirements, and we provide solutions for your customer to meet your nitrogen gas needs.Nitrogen gas can be categorized as high purity or low purity depending on the ratio of pure gas tothe contaminants like oxygen, water vapor, carbon monoxide, and carbon dioxide. Nitrogen (N2) is a versatile gas used across various applications and industries and in multiple purities in various grades specifc to different applications.The industrial nitrogen cylinders are all made of high-quality seamless steel pipe, consistent height, smooth painting, and excellent properties, widely used for steel cutting, welding,electronic, medical, and other felds.

1 note

·

View note

Text

#oxygen gas#calibration gas supplier#carbon dioxide gas#oxygen gas supplier#co2 cylinder supplier in jaipur#co2 gas manufacturer in jaipur#co2 gas#liquid nitrogen supplier in jaipur#dry ice manufacturer

0 notes

Text

Helium Gas For Balloons Dubai:-

Looking for a company that deals in distributing high-quality gases to different industries. If so, look no further other than us. We Gasontrade are the distributor where the gas application is dominant. For more info: https://gasontrade.com/helium-gas-distributor-in-dubai

#Co2 Cylinder for beer Dubai#Dry Ice Price In Dubai#Helium Gas For Balloons Dubai#Nitrogen Gas Supplier In Dubai#Liquid Nitrogen Price Dubai

0 notes

Text

Medical gas cylinders - Arasan gas solutions

The requirement for medical oxygen is very crucial at hospitals during emergency situations like covid spread. We have an oxygen gas plant to manufacture and bottle in various capacity cylinders as per the purpose of usage.

Arasan Gas is an established manufacturer of medical gases with an established delivery network meeting any emergency situations. Arasan gas solutions also installs centralised oxygen delivery pipelines at hospitals.

For more info

Visit : www.arasangassolutions.com

Contact No : 91 9842174805

#hospital gas cylinders#hospital gas cylinder installers in Madurai#hospital bed pipe installation#medical gas pipe installing company#hospital bed cylinder fixing#Medical Gas Pipe Line Systems#modular operation theatre#gas manufacturing company in madurai#industrial gas manufacturer#oxygen cylinder manufacturer in Madurai#Oxygen manufacturer#O2 manufacturers#Nitrogen gas manufacturer#N2 Gas manufacturer#Argon gas manufacturer#Ar gas manufacturer#Dissolved Acetylene manufacturer#Nitrous Oxide manufacturer#N2O manufacturer#Carbon dioxide manufacturer#Co2 manufacturer

0 notes

Text

Radiocarbon

A recent article touched on how radiocarbon dating works in relation to the impacts of cosmic rays and the secondary particles they create on Earth. Now, let’s focus on radiocarbon dating itself.

Types of Dating

Radiocarbon dating is an invaluable tool to the fields of archaeology and history. Within the process of dating artifacts, there is absolute dating and relative dating. Relative dating establishes if something is older or younger than another artifact, usually within the same excavation. For example, excavations can expose the stratigraphy of the ground: layers of rock and sediment deposit that build up over time and can be visually distinct, though sometimes bleed into each other. Artifacts found in a lower layer can be theorized to be older than artifacts in layers above it.

Absolute dating provides more specific dates for the origin of artifacts, and often relies on chemical processes. Radiocarbon dating is one such method.

Radioactive Isotopes

Radiocarbon dating works on the fact that isotopes of carbon exist in nature, and it is their nature to decay over time.

Isotopes are variations of the same chemical element. They have the same atomic number -and therefore number of protons- as the base element, but different amounts of neutrons in the atom’s nucleus. So all carbon isotopes have six protons, but instead of six neutrons like C-12, they can have seven or eight neutrons, which are known as C-13 and C-14, respectively.

Though an isotope, C-13 is stable, meaning it does not decay into another form or element over time. It has enough binding energy to keep the protons and neutrons in its nucleus together.

C-14 is not stable. Over time, C-14 decays into stable Nitrogen through one of the neutrons becoming a proton. In this process it also loses an electron, which are negative particles that ‘orbit’ the nucleus.

C-14 Dating

From secondary particles produced by cosmic rays, C-14 or 14C becomes 14CO, then 14CO2 (carbon-14 dioxide), entering Earth’s carbon cycle. In this way, C-14 absorbs into living tissues through photosynthesis and the food chain. When the living tissue dies, no more C-14 is introduced, starting the time of radioactive decay.

C-14 has a half-life of 5,700± 30 years, meaning that after that many years, the amount of C-14 in the subject has decreased by half. The amount of C-14 present in a material can be measured in three ways: gas proportional counting, liquid scintillation counting, and accelerator mass spectrometry.

In gas proportional counting, the sample of organic material is converted to carbon dioxide gas before being put into cylinders where beta particles are measured. Beta particles are produced by radiocarbon decay, so the dating measures how much more C-14 is left to decay at the time of evaluation.

Similarly, liquid scintillation measures beta particles by the scintillator producing a flash of light when interacting with a beta particle. In this process, the organic material is in liquid form and put between two photomultipliers, devices that convert photons into electrical signals to register when the scintillator indicates a beta particle.

Accelerator mass spectrometry does not measure beta particles. It measures the proportion of C-14 to C-13 and C-12 present in the sample.

The results of these methods are compared to an international standard reference, which has changed throughout the years. For some time, sugar beets harvested in the 1950s were used as comparison for the amount of C-14 present, as well as wood from 1890 and beet molasses from 1977. These varieties of organic material have helped provide reference for the measurements of C-14 isotopes.

Radiocarbon dating has been a useful source of knowledge when examining artifacts. The science behind it is expansive and requires piecing together many different properties of the universe, such as how C-14 enters the atmosphere from cosmic rays, and how it naturally changes form over time as a radioactive isotope. Understanding these different elements can help demystify the processes of scientific discovery, and help us better understand specific case studies in the future.

Additional Resources

1. https://www.nature.com/articles/s43586-021-00058-7#

2. gml.noaa.gov/ccgg/isotopes/chemistry.html

3. https://news.uchicago.edu/explainer/what-is-carbon-14-dating4. https://www.radiocarbon.com/about-carbon-dating.htm#

#radiocarbon#radiocarbon dating#radioactive decay#science#archaeology#anthropology#article#research#resources#environment#human history#stratigraphy#relative dating#absolute dating#We'll look at some case studies maybe next week#more to come#spectrometry#photomultipliers#scientific discovery

2 notes

·

View notes

Text

Cosmic Gas Watermelon Candy Cream Charger - 1100G | 2.2 Litre

High-volume franchises and caterers can use the Cosmic Gas Infusion N2O Tank for dinner rushes and maximum capacity events. A regulator is required for optimal performance, as the 1-liter tank can hold 615 Grams of narcotics. consistent results of fluffy whipped cream as the regulator works in unison with the nitrogen dioxide cylinder. Are you a food vendor or a large-scale franchisee who handles…

0 notes

Text

Welded insulated liquid dewar cylinder

Dewar cylinders are ultra-vacuum insulated stainless steel pressure vessels designed for storage, transportation and use of liquid oxygen, liquid nitrogen, liquid argon or carbon dioxide.

The DPL series containers are vacuum insulated, stainless steel containers designed to store and transport cryogenic liquid oxygen, nitrogen or argon. Containers may be used for over the road transportation of cryogenic fluids, as well as on-site storage and supply in a wide range of applications.

As rugged, long holding time, self-contained gas supply systems, these cylinders are capable of providing contonuous flow rates of up to 350cfh(9.2 cu.m/h)with a delivery pressure of approxomately 100psig (6.9bar/690 kpa)

The DPL Series containers are very rugged liquid cylinders. All cryogenic liquid cylinderd have an inner container and an outer container with an insulated vacuum space between them. Any abuse(dents, dropping, tip-over,etc) can affect the integrity of containers insulation system.

Company Name:Huzhou Baihui Cryogenic Equipment Co., Ltd

Web:https://www.brightwaycryogenic.com/products/dewar-cylinder/welded-insulated-liquid-dewar-cylinder.html

ADD:Building A38, China Energy Conservation and Environmental Protection Industrial Park, No. 1506, Yishan Road, Wuxing District, Huzhou City, Zhejiang Province, China

Phone:86-18257285710

Email:[email protected]

0 notes

Text

Nitrogen for Sale: Unlocking the Power of Versatile Gas Solutions

In the realm of industrial gases, nitrogen stands out as one of the most essential and versatile elements. With its myriad applications across various industries, the demand for high-quality nitrogen is ever-present. For businesses and researchers alike, finding reliable sources for nitrogen for sale can be a game-changer, enabling them to harness the full potential of this indispensable gas.

Understanding Nitrogen and Its Applications

Nitrogen, a colorless, odorless, and inert gas, constitutes approximately 78% of the Earth's atmosphere. Its inert nature makes it highly valuable in a range of applications. In the industrial sector, nitrogen is primarily used as a protective gas in processes that require an oxygen-free environment. This includes the manufacturing of electronic components, where nitrogen helps prevent oxidation and ensures the longevity and reliability of sensitive electronics.

In the food and beverage industry, nitrogen plays a crucial role in preserving freshness. It is used in packaging to displace oxygen, thereby extending the shelf life of perishable items. The pharmaceutical industry also benefits from nitrogen's properties, utilizing it for cryopreservation of biological samples and in various production processes that require a controlled environment.

Additionally, nitrogen is employed in laboratories for a variety of purposes, including cooling, flushing, and as a carrier gas in analytical instruments. Its role in creating a safe, controlled atmosphere makes it indispensable for numerous scientific and industrial applications.

Choosing the Right Nitrogen Supplier

When sourcing nitrogen for sale, quality and reliability are paramount. A reputable supplier should offer high-purity nitrogen that meets industry standards. For applications requiring ultra-high purity, such as semiconductor manufacturing or specialized research, ensuring that the nitrogen meets these rigorous specifications is crucial.

Suppliers often provide nitrogen in different forms: as a gas, liquid, or in high-pressure cylinders. Liquid nitrogen is particularly useful for applications requiring extremely low temperatures, such as cryogenic preservation. On the other hand, compressed nitrogen gas is more suited for processes that involve a steady supply of nitrogen at ambient temperatures.

Factors to Consider When Buying Nitrogen

Purity Levels: Depending on your application, you may need nitrogen of varying purity levels. Ensure that the supplier can provide nitrogen that meets the specific purity requirements for your needs.

Delivery Options: Consider the delivery options offered by the supplier. Reliable delivery services are essential to ensure that your operations remain uninterrupted. Some suppliers offer bulk delivery services, while others provide smaller quantities in cylinders or dewars.

Storage Solutions: Proper storage of nitrogen is essential for maintaining its quality. If you are purchasing liquid nitrogen, you will need appropriate storage tanks. For gas, ensure that you have the necessary infrastructure to handle high-pressure cylinders safely.

Cost and Availability: While cost is a significant factor, it should be weighed against the quality and reliability of the supply. Establishing a long-term relationship with a trustworthy supplier can often lead to better pricing and service.

Conclusion

In conclusion, nitrogen is a vital gas with a wide range of applications across various industries. Finding a reliable source for nitrogen for sale can significantly impact the efficiency and effectiveness of your operations. By considering factors such as purity, delivery options, and cost, you can ensure that you are getting the best possible value for your investment. Whether you are in manufacturing, research, or any other field that relies on nitrogen, choosing the right supplier will enable you to leverage the full potential of this versatile gas and achieve your operational goals with confidence. For more details visit our website: www.adchemgas.com

#ethanol#liquid nitrogen#dry ice for sale#denatured ethanol#nitrogen for sale#pure ethanol#co2 for sale#heptane for sale#dry ice pellets for sale#pentane for sale#high purity butane#extraction grade butane#food grade ethanol#high purity hydrocarbons#High Purity Hydrocarbons#Ethanol#Denatured Ethanol#Food Grade Ethanol#Pure Ethanol#High purity butane#High purity butane for sale#Extraction grade butane#Diamond grade butane#nbutane#Butane extraction gas#Propane extraction gas#isobutane extraction gas#Refined butane for extraction#Pure butane 99.5%#High purity solvents “for sale”

0 notes

Text

The Role of Nitrogen Generators in Food Packaging

In the food industry, maintaining product freshness and extending shelf life are critical factors in delivering quality products to consumers. Nitrogen gas plays a vital role in food packaging by creating a protective atmosphere that preserves the quality and integrity of food items. Traditional methods of nitrogen supply, such as gas cylinders, have limitations that can impact efficiency and cost-effectiveness. However, nitrogen generators have revolutionized the way nitrogen is supplied, offering numerous advantages that benefit food manufacturers. In this blog, we'll explore the role of nitrogen generators in food packaging and why they are becoming essential for modern food production.

1. Extending Shelf Life

One of the primary benefits of using nitrogen gas in food packaging is its ability to extend the shelf life of perishable products. Nitrogen displaces oxygen within packaging, creating an inert atmosphere that slows down the oxidation process and prevents spoilage. This is particularly important for products like snacks, baked goods, and processed foods, where freshness is key to consumer satisfaction. By using nitrogen generators to produce nitrogen on-site, food manufacturers can ensure a consistent and reliable supply of nitrogen, which is crucial for maintaining product quality.

2. Maintaining Product Quality

In addition to extending shelf life, nitrogen helps maintain the quality of food products by preventing the growth of aerobic bacteria and molds. When food is exposed to oxygen, it can undergo chemical changes that affect its taste, texture, and appearance. Nitrogen generators allow manufacturers to control the nitrogen atmosphere within packaging, ensuring that products retain their original quality throughout their shelf life. This control over the packaging environment is essential for delivering high-quality food products to consumers.

3. Reducing Packaging Costs

Using nitrogen generators can lead to significant cost savings in the food packaging process. Traditional nitrogen supply methods, such as gas cylinders, involve recurring costs for purchasing, transporting, and storing nitrogen. On-site nitrogen generation eliminates these expenses, as the gas is produced directly at the point of use. This not only reduces packaging costs but also minimizes the logistical challenges associated with managing nitrogen supplies. The cost savings realized from on-site nitrogen production can be reinvested into other areas of the business, enhancing overall profitability.

4. Enhancing Food Safety

Food safety is a top priority for manufacturers, and nitrogen generators contribute to a safer production environment. By producing nitrogen on-site, manufacturers reduce the risk of contamination associated with handling and transporting gas cylinders. Nitrogen generators provide a clean and consistent source of nitrogen, which is critical for maintaining the safety and integrity of packaged food products. Additionally, the use of nitrogen generators reduces the need for chemical preservatives, allowing manufacturers to offer cleaner label products that appeal to health-conscious consumers.

5. Supporting Sustainable Packaging

Sustainability is becoming increasingly important in the food industry, and nitrogen generators support environmentally friendly packaging practices. Traditional nitrogen supply methods can have a significant carbon footprint due to the energy-intensive processes involved in producing and transporting the gas. Nitrogen generators produce nitrogen using ambient air, which is a more sustainable and energy-efficient method. By reducing the environmental impact of nitrogen supply, food manufacturers can enhance their sustainability credentials and meet the growing demand for eco-friendly packaging solutions.

Conclusion

The role of nitrogen generators in food packaging is crucial for maintaining product freshness, extending shelf life, and ensuring food safety. By providing a reliable and cost-effective supply of nitrogen, nitrogen generators help food manufacturers optimize their packaging processes and deliver high-quality products to consumers. Additionally, the use of nitrogen generators supports sustainability efforts by reducing the carbon footprint associated with nitrogen supply. For food manufacturers looking to enhance their packaging operations, investing in a nitrogen generator is a smart and sustainable choice.

0 notes

Text

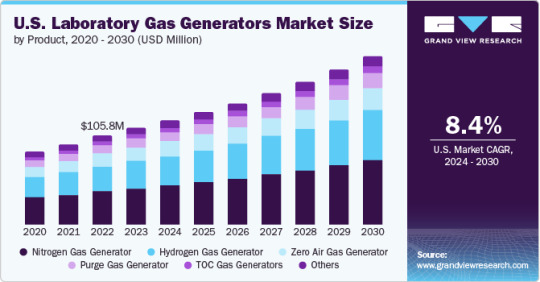

Laboratory Gas Generators Market To Reach $777.4 Million By 2030

The global laboratory gas generators market size is anticipated to reach USD 777.4 million by 2030 and is expected to expand at a CAGR of 8.3% during the forecast period, according to a new report by Grand View Research, Inc. The growth of the market is attributed to the growing importance of analytical techniques in drug and food safety testing, growing safety concerns related to the use of conventional gas cylinders, and increasing R&D spending in the life science sector.

Laboratory gas generators operate across diverse applications, including chromatography and mass spectrometry, wherein they provide high-purity gas essential for accurately identifying various substances within samples, contributing to drug development and quality control. Further in drug detection and analysis, gas supplied from generators ensures efficient and accurate analysis of drug composition, purity, and potential contaminants.

In pharmaceutical packaging, nitrogen gas generators create an inert environment, shielding products from oxidation and degradation during transport and storage, ultimately preserving their integrity and efficacy. However, their role goes beyond mere protection. The nitrogen blanketing facilitated by generators also helps improve the quality of pharmaceutical products. Oxygen exposure can degrade various medications, affecting their potency and shelf life. By creating an oxygen-free environment, generators maintain product quality and extend their usable window.

The laboratory gas generators industry is characterized by intense competition, with numerous manufacturers and suppliers vying for market share. Some of the key players operating in the market include Peak Scientific Instruments, PerkinElmer Inc., Linde plc., VICI DBS, Dürr Technik GmbH & Co. KG, Erre Due S.p.a., and CLAIND srl. Companies are focusing on product innovation, technological advancements, and strategic collaborations to differentiate their offerings and gain a competitive edge. In addition, the growing trend towards customization and modularization in gas generation systems allows end-users to tailor solutions to their specific requirements, further driving market growth and adoption.

Request a free sample copy or view report summary: Laboratory Gas Generators Market Report

Laboratory Gas Generators Market Report Highlights

The nitrogen gas generator segment led the market and accounted for 38% in 2023. The adoption of nitrogen gas generators is driven by their ability to provide high-purity nitrogen on-demand, eliminating the need for gas cylinder handling and storage.

Growing Liquid Chromatography-Mass Spectrometry (LC-MS) field, crucial for drug discovery and metabolomics, drives the need for high-purity nitrogen and helium gas generators for nebulization and collision gas.

The life science sector represents a significant end-user segment for laboratory gas generators, driven by the increasing demand for analytical instruments in drug discovery, development, and quality control processes.

North America dominated the market owing to the increasing investments in the life science, food & beverage, and chemical sectors in the region.

In July 2023, Peak Scientific Instruments introduced nitrogen gas generation solutions with the release of the Corona 1010A. This innovative solution delivers high-purity, filtered nitrogen gas, empowering various applications with a reliable and potent source. Capable of delivering flows up to 5 liters per minute at pressures reaching 80psi.

Laboratory Gas Generators Market Segmentation

Grand View Research has segmented the global laboratory gas generators market based on product, application, end-use, and region:

Laboratory Gas Generators Product Outlook (Revenue, USD Million, 2018 - 2030)

Nitrogen Gas Generator

Hydrogen Gas Generator

Zero Air Gas Generator

Purge Gas Generator

TOC Gas Generators

Others

Laboratory Gas Generators Application Outlook (Revenue, USD Million, 2018 - 2030)

Gas Chromatography

Liquid Chromatography-mass Spectrometry (LC-MS)

Gas Analyzers

Others

Laboratory Gas Generators End Use Outlook (Revenue, USD Million, 2018 - 2030)

Life Science

Chemical & Petrochemical

Food & Beverage

Others

Laboratory Gas Generators Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

UK

Germany

France

Spain

Italy

Asia Pacific

China

India

Japan

South Korea

Australia

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

South Africa

List of Key Players in the Laboratory Gas Generators Market

Peak Scientific Instruments

PerkinElmer Inc.

Linde plc.

VICI DBS

Dürr Technik GmbH & Co. KG

Erre Due S.p.a.

Tisch Environmental, Inc.

CLAIND srl

Isolcell

OXYMAT

0 notes

Text

Laboratory Gas Generators Market worth $686 million by 2026

The Global Laboratory Gas Generators Market is projected to reach USD 686 million by 2026 from USD 353 million in 2021, at a CAGR of 14.2% during the forecast period. The growth of the laboratory gas generators market is primarily driven by the growing importance of analytical techniques in drug and food approval processes, rising food safety concerns, increasing adoption of laboratory gas generators owing to their various advantages over conventional gas cylinders, growing demand for hydrogen gas as an alternative to helium, and the increasing R&D spending in target industries. On the other hand, reluctance shown by lab users in terms of replacing conventional gas supply methods with modern laboratory gas generators and the availability of refurbished products are the major factors expected to hamper the growth of this market.

Download PDF Brochure:

Global Nitrogen gas generators Market Dynamics

Market Growth Drivers

Increasing R&D spending in target industries

Growing importance of analytical techniques in drug approval processes

Rising food safety concerns

Increasing adoption of laboratory gas generators owing to their various advantages over conventional gas cylinders

Growing demand for hydrogen gas as an alternative to helium

Market Growth Opportunities

Growing demand for laboratory automation

Opportunities in the life sciences industry

Cannabis testing

Proteomics

Market Challenges

Reluctance to replace conventional gas supply methods with modern laboratory gas generators

Availability of refurbished products

Request 10% Customization:

The hydrogen gas generators segment accounted for the highest growth rate in the Labortaory gas generators market, by type, during the forecast period

Based on type, the laboratory gas generators market is segmented into nitrogen gas generators, hydrogen gas generators, zero air generators, purge gas generators, TOC gas generators, and other gas generators. The hydrogen gas generators segment accounted for the highest growth rate in the Labortaory gas generators market in 2020. This can be attributed to the growing preference for hydrogen as a cost-effective alternative to helium, as it offers faster analysis and optimal results.

Gas chromatography segment accounted for the highest CAGR

Based on application, the laboratory gas generators market is segmented into gas chromatography (GC), liquid chromatography-mass spectrometry (LC-MS), gas analyzers, and other applications. In 2020, gas chromatography accounted for accounted for the highest growth rate. The major factors driving the growth of this is the adoption of hydrogen over helium due to the latter's high cost and scarcity in gas chromatography.

Life science industry accounted for the largest share of the laboratory gas generators market in 2020

Based on end user, the laboratory gas generators market is segmented into the life science industry, chemical and petrochemical industry, food and beverage industry, and other end users (environmental companies and research & academic institutes). The life science industry accounted for the largest share of the global laboratory gas generators market. The major factors driving the growth of this segment are the rising demand for laboratory analytical instruments, increase in drug research activities, and stringent regulations relating to the drug discovery process.

North America accounted for the largest share of the hydrogen gas generators market in 2020

The laboratory gas generators market is divided into five regions, namely, North America, Europe, Asia Pacific, and Rest of the World. North America dominated the global laboratory gas generators market. The large share of the North American region is mainly attributed to the high investments in R&D in the US and Canada, which has led to a higher demand for efficient and advanced laboratory equipment.

Recent Developments:

In 2020, PeakGas launched various laboratory gas generators such as Genius XE SCI 2, MS Bench (G) SCI 2, MS Bench SCI 2, and i-Flow O2 oxygen gas generator.

In 2019, Laboratory Supplies Ltd. (Ireland), a supplier of scientific, industrial, and laboratory apparatus, joined the distributor network of the Asynt Ltd.

Report Highlights

To define, describe, and forecast the laboratory gas generators market by type, application, end user, and region

To provide detailed information regarding the factors influencing the market growth (such as drivers, opportunities, and challenges)

To strategically analyze micromarkets with respect to individual growth trends, prospects, and contributions to the laboratory gas generators market

To analyze market opportunities for stakeholders and provide details of the competitive landscape for market leaders

To forecast the size of the market segments in North America, Europe, Asia Pacific, and the Rest of the World (RoW)

To profile the key players and comprehensively analyze their product portfolios, market positions, and core competencies

To track and analyze competitive developments, such as product launches, expansions, agreements, and acquisitions in the laboratory gas generators market

Key Players:

Hannifin Corporation (US), PeakGas (UK), Linde plc (Ireland), Nel ASA (Norway), PerkinElmer Inc. (US), VICI DBS (US), Angstrom Advanced Inc. (US), Dürr Group (Germany), ErreDue spa (Italy), F-DGSi (France), LabTech S.r.l. (Italy), CLAIND S.r.l. (Italy).

Frequently Asked Questions (FAQ):

What is the projected market revenue value of the global laboratory gas generators market?

The global laboratory gas generators market boasts a total revenue value of $686 million by 2026.

What is the estimated growth rate (CAGR) of the global laboratory gas generators market?

The global laboratory gas generators market has an estimated compound annual growth rate (CAGR) of 14.2% and a revenue size in the region of $353 million in 2021.

#Laboratory Gas Generators Market#Nitrogen Gas Generators Industry Size#Hydrogen Gas Generators Industry Share#Laboratory Gas Generators Market Growth

0 notes

Text

nitrogen bottles

High-Quality n2 cylinders, nitrogen gas bottles

ISO9809 Standard 80L N2 Gas Cylinder, Seamless Steel 84.7KG Weight Nitrogen gas tanks

Nitrogen gas is widely used in Chemicals, Pharmaceuticals, Food and Beverage, Glass, Cement and Lime, Healthcare, Laboratories & analysis, Electronics, Electronics, Automotive & transportation, and Other industries.

Categories: Nitrogen Gas, GasesTags: 80L Nitrogen gas cylinder, N2 Gas Cylinder, nitrogen gas cylinders

Description

portable nitrogen cylinder suppliers-n2 storage & transportation solution

DSW provides nitrogen in high-pressure nitrogen gas cylinders as well as liquid nitrogen dewars. These are available in different sizes and can be used to meet any low-volume requirements.

DSW offers liquid and compressed nitrogen in different grades, each suited to a specific application.

• A coolant for concrete work

• An assist gas for laser cutting

• A pressurizing agent in pipelines

• A cryogenic for preserving biological material

• A welding gas in automotive manufacturing

Nitrogen Gas Bottles

N2 80L Nitrogen cylinders with special fire suppression valve and cap.

– Volume: 80Litre

– Color: Red,

– Diameter:267mm,

– Height:1710mm

– Thickness: 6.3mm

– Weight:76kg.

– Working pressure:200bar

– Test pressure:300bar

What are the sizes of nitrogen cylinders?

Nitrogen gas bottles come in G2 and E2 sizes, from 2L to 80L. Nitrogen gas is inert to virtually all substances at ambient temperatures and conditions, rendering it safe for storage for many applications.

Nitrogen is used in the food and chemical industry for blanketing, purging, and sparging.

It can also be found in modified atmosphere packaging of foodstuffs.

Liquid nitrogen can also be used to shock-freeze food or biological materials for storage.

Its power is also helpful for cryosurgery and cryogenically grinding rubber and plastics.

N2 is used extensively in the semiconductor industry as a purge gas and carrier gas.

It also serves as a zero and balancing gas in laboratory analyses.

Nitrogen is also used in heat treatment, ammonia production, fire suppression, tire filling, shrink fitting, and cold traps.

Nitrogen Cylinders Supply

Nitrogen and gas cylinders supplied by DSW are available in a range of cylinder sizes, purity requirements, and on-site solutions to meet your nitrogen gas needs.

Supply Modes

Cylinders & Liquid Containers

We have nitrogen available in liquid nitrogen dewars, high-pressure gas bottles, and cylinders.

MicroBulk

DSW MicroBulk is a safe, clean, and efficient solution for users who need to store nitrogen in large quantities but don’t have the space.

Bulk Delivery

The bulk liquid and gas delivery of nitrogen and a wide range of purities are available.

Buy N2 Cylinders

From filling to the point of use, our compressed gas cylinders protect the compressed gas quality and ensure stability.

Ask DSW International for more information on available certifications.

0 notes

Text

Liquid Nitrogen Supplier in Jaipur

Leading Manufacturer of acetylene gas, dissolved acetylene gas, xenon gases, sulphur dioxide gas, neon gas and compressed gases from Jaipur.

In the heart of Jaipur, amidst the bustling industrial landscape, stands a beacon of reliability and excellence — Salasar Carbonics Private Limited. Renowned as the leading manufacturer and supplier of a diverse range of industrial gases, Salasar Carbonics has been serving the region with unwavering commitment and top-notch quality for years.

Founded with a vision to cater to the burgeoning demands of various industries, Salasar Carbonics takes pride in its extensive product line, which includes acetylene gas, dissolved acetylene gas, xenon gases, sulphur dioxide gas, neon gas, compressed gases, liquid nitrogen, dry ice, CO2 cylinders, oxygen gas, carbon dioxide gas, and calibration gases. Whether you are in need of specialty gases for scientific research or industrial gases for manufacturing processes, Salasar Carbonics has got you covered.

Purity 99.99%

Boiling Point 195.8 deg C

Working Pressure 200 bar

Test Pressure 300 bar

Volume 20–30 L

Packing Type Cylinder

One of the hallmark offerings of Salasar Carbonics is its comprehensive range of gases, tailored to meet the diverse needs of industries ranging from healthcare to manufacturing. As a trusted liquid nitrogen supplier in Jaipur, the company ensures the highest quality and purity standards, crucial for critical applications such as cryogenic freezing and preservation.

Moreover, Salasar Carbonics takes pride in being a premier dry ice manufacturer in jaipur, providing businesses with a reliable source of dry ice for various applications, including shipping perishable goods, preserving medical samples, and creating special effects in the entertainment industry.

In addition to liquid nitrogen and dry ice, Salasar Carbonics is also a trusted CO2 cylinder supplier in Jaipur, offering a wide range of cylinders suitable for different industrial purposes, from beverage carbonation to welding applications. With a commitment to excellence and safety, the company ensures that its CO2 cylinders meet stringent quality standards, providing customers with peace of mind.

Furthermore, as an oxygen gas supplier in Jaipur, Salasar Carbonics plays a crucial role in supporting industries such as healthcare, metal fabrication, and aerospace, where oxygen is a vital component of various processes. With a focus on reliability and prompt delivery, the company ensures that customers have access to high-quality oxygen gas whenever they need it.

Salasar Carbonics is not just an industrial gas supplier in Jaipur; it is a partner in progress for businesses across sectors. Whether you require carbon dioxide gas for beverage carbonation, calibration gases for analytical purposes, or specialized gases for niche applications, Salasar Carbonics is your one-stop destination.

With a commitment to excellence, reliability, and customer satisfaction, Salasar Carbonics Private Limited continues to set the benchmark for industrial gas supply in Jaipur and beyond. As industries evolve and technology advances, Salasar Carbonics remains at the forefront, continuously innovating and expanding its product offerings to meet the dynamic needs of its customers.

In conclusion, whether you are a small-scale enterprise or a large industrial conglomerate, if you are in need of top-quality industrial gases in Jaipur, look no further than Salasar Carbonics Private Limited. With an unmatched reputation for quality, reliability, and customer service, Salasar Carbonics is poised to be your trusted partner in success.

#liquid nitrogen supplier in jaipur#dry ice manufacturer in jaipur#co2 cylinder supplier in jaipur#oxygen gas supplier in jaipur#Industrial gas supplier in jaipur#carbon dioxide gas supplier in jaipur#All Types Of Gases supplier in jaipur#co2 gas manufacturer in jaipur#Calibration Gassupplier in jaipur

0 notes

Text

Store and handle the oxygen cylinders with great care:-

All of us know what the importance of the oxygen cylinder for the health industry is. The oxygen cylinders are required in the hospitals and medical facilities. In many homes, if there is a presence of sick people who are under some medical treatment, the oxygen cylinders are required. To read more: https://gasontrade.com/blogs/store-and-handle-the-oxygen-cylinders-with-great-care/

0 notes

Text

Detailed Report on Multiple Element Gas Container Market | BIS Research

Multiple Element Gas Container is a type of pressure vessel designed to transport and store multiple gaseous substances. It typically consists of a framework or structure that houses several gas cylinders, each capable of holding a different type of gas or the same gas under different conditions.

According to BIS the Multiple Element Gas Container Market, was valued at $164.8 Million in 2023, and it is expected to grow with a CAGR of 8.19% during the forecast period 2023-2033 to reach $361.9 Million by 2033.

Multiple Element Gas Container Overview

A Multiple Element Gas Container (MEGC) is a specialized equipment designed for the safe storage and transportation of gasses in bulk quantities.These containers can store a variety of gasses, including industrial gasses like hydrogen, helium, nitrogen, and natural gas, under high pressure

Download the Report Click Here !

Multiple-element gas containers mark a significant step forward in gas storage and transportation, signaling a transition away from traditional single-element systems. These revolutionary containers are designed to hold many types of gasses at once,at varied pressure and temperature settings, in separate portions, or using advanced molecular separation processes.

Multiple-element gas containers marked a huge technological breakthrough in gas transportation safety and efficiency.

Have a look at our sample page here !

Applications for Multiple Element Gas Containers

Industrial Gas Transport

Energy Sector

Chemical Industry

Medical Gas Distribution

Food and Beverage Industry

Multiple Element Gas Containers have transformed the economics of gas transportation. These containers' modular design enables modification based on unique transport requirements, maximizing space usage and lowering shipping costs.

Furthermore, the use of new materials and technology in MEGC manufacture has resulted in lighter but stronger containers, boosting fuel economy and lowering transportation's carbon impact.

Key Players In the Multiple Element Gas Container Market

ASML

Zeiss Group

TOPPAN Holdings Inc.

NTT Advanced Technology Corporation

KLA Corporation

Ushio Inc

SÜSS MicroTec SE

AGC Inc.

Lasertec Corporation

Market Segmentation

By Application : Natural Gas Segment to Dominate the Global Multiple-Element Gas Container Market

The multiple-element gas container market is led by the natural gas segment, with an 82.79% share in 2022 in terms of revenue.

By Type : 20 Ft Segment to Witness the Highest Growth between 2023 and 2033

The 20 Ft segment dominated the global multiple-element gas container market,with an 80.78% share in terms of revenue due to the need to be integrated into various platforms to carry out the tasks.

By Region

Europe's multiple-element gas container market was the highest-growing market among all the regions, registering a CAGR of 9.11%. North America is anticipated to gain traction in terms of multiple-element gas container adoption owing to the technological advancements in material sciences in the region.

Benefits for Multiple Element Gas Container

High Capacity and Efficiency: Store large volumes of gas, making them ideal for bulk transportation. This high capacity reduces the number of trips needed, saving time and resources.

Versatility: They can carry different types of gasses in separate cylinders, allowing for the transportation of a variety of gasses within a single container

Safety : Designed to meet stringent international safety standards, ensuring the secure containment of gasses under high pressure.

Cost Effectiveness :By consolidating multiple gas cylinders into one unit, MEGCs reduce handling costs and logistics complexity.

Durability and Reliability:Built with robust materials and designed for harsh conditions, MEGCs are highly durable.

Reduced Environmental Impact : By optimizing the transportation and storage of gasses, MEGCs can help reduce the carbon footprint associated with multiple shipments.

Ease of Handling: The modular design of MEGCs allows for easy loading, unloading, and stacking, simplifying logistics operations.

Market Drivers

Growing demand for Industrial Gases

Expansion of Infrastructure

Economic Growth

Demand for Safety and Compliance

Visit our Next Generation Fuel Energy Storage Vertical Page here!

Recent Developments

In September 2023, Luxfer Gas Cylinders' European hub in Nottingham received a more than $1.24 million (£1 million) investment, establishing a new production facility to enable 'virtual' gas pipes capable of distributing hydrogen throughout the U.K. and Europe.

In January 2023, Arkema, a multinational specialty materials manufacturer, awarded FIBA Technologies a contract to deliver 16 multi-element gas containers (MEGCs) for the transportation of boron trifluoride (BF3) across Europe. FIBA started supplying the 12-tube, 20-foot MEGCs to Arkema in early July.

Key Questions

Q What are the main factors driving the demand for the multiple-element gas container market?

Q How does the supply chain function in the multiple-element gas container market?

Q Which application and product type are expected to lead the market during the forecast period 2023-2033?

Q Who are the players that are catering to the demand within the multiple-element gas container market?

Q What is the competitive landscape in the multiple-element gas container market?

Conclusion

In conclusion, Multiple Element Gas Containers play a vital role in the safe and efficient transport and storage of various gasses across multiple industries. As industries continue to demand versatile and efficient gas storage and transport solutions, MEGCs stand out as a critical technology, supporting various applications and promoting safety and efficiency in gas handling.

0 notes

Text

Why On Site Gas Solutions Are Essential for Modern Industries

**Oxygen Generation Solutions: Enhancing Efficiency and Accessibility**

In today’s world, access to oxygen is crucial for various applications, from medical emergencies to industrial processes. Oxygen generation solutions play a significant role in ensuring a reliable supply of oxygen for diverse needs. This article explores what oxygen generation solutions are, their types, and their applications.

### What Are Oxygen Generation Solutions?

Oxygen generation solutions refer to technologies and systems designed to produce oxygen on-site rather than relying on external supply sources. These solutions are essential in sectors where a continuous and reliable supply of oxygen is necessary. They offer a range of benefits, including increased efficiency, cost savings, and enhanced safety.

### Types of Oxygen Generation Solutions

Pressure Swing Adsorption (PSA) systems are commonly used for generating oxygen by separating it from nitrogen in the air. These systems use adsorbent materials to selectively remove nitrogen, producing high-purity oxygen. They are widely used in medical facilities and industrial applications due to their reliability and efficiency.

Membrane systems use selective permeable membranes to separate oxygen from other gases in the air. These systems are compact and efficient, making them suitable for applications where space is limited, such as in smaller medical facilities or remote locations.

Electrolytic generators produce oxygen through the electrolysis of water. This method splits water into hydrogen and oxygen, providing a high-purity oxygen supply. These generators are used in various settings, including space exploration and advanced industrial processes.

### Applications of Oxygen Generation Solutions

In the medical field, oxygen generation solutions are vital for hospitals, clinics, and home care settings. They provide a steady supply of oxygen for patients with respiratory conditions or during medical procedures.

Industries such as steel manufacturing, chemical production, and wastewater treatment use oxygen generation solutions to enhance efficiency and productivity. Oxygen is used to accelerate chemical reactions and improve the quality of products.

In emergencies, such as natural disasters or industrial accidents, having on-site oxygen generation solutions ensures that there is no delay in providing critical oxygen supplies. This capability is essential for disaster response teams and first responders.

### Benefits of Using Oxygen Generation Solutions

Producing oxygen on-site can be more cost-effective than relying on external suppliers. It eliminates the need for transportation and storage of oxygen cylinders or tanks, reducing overall expenses. Additionally, on-site generation ensures a continuous and reliable supply, which is crucial for operations that depend on uninterrupted oxygen availability. Moreover, these solutions enhance safety by minimizing the risks associated with handling and transporting high-pressure oxygen cylinders.

In summary, oxygen generation solutions are vital for various sectors, offering efficiency, cost savings, and enhanced safety. By understanding the different types and applications of these solutions, industries and medical facilities can better meet their oxygen needs and ensure a reliable supply.

0 notes