#panel rockwool

Text

các loại panel cách nhiệt https://www.baodanang.vn/can-biet/202304/cac-loai-panel-cach-nhiet-tot-nhat-3942276/

0 notes

Text

Innovations in Cold Room Door Technology: What's New in the Industry

In the ever-evolving world of refrigeration, cold room door technology has seen significant advancements, driven by the need for greater energy efficiency, enhanced security, improved hygiene, and user-friendly designs. As Cold Room Doors Manufacturers continue to innovate, the industry is witnessing new products and technologies that cater to diverse needs across sectors like food storage, pharmaceuticals, and logistics. In this blog, we will explore the latest cold room door technology innovations and how they are revolutionizing the industry.

Smart Door Systems

Integrating smart systems is one of the most significant trends in cold room door technology. These systems leverage IoT (Internet of Things) for real-time monitoring and control. Smart cold room doors can now be equipped with sensors that monitor temperature, humidity, and door status. These sensors can alert operators to anomalies, ensuring that the cold room's environment remains optimal and preventing spoilage or damage to stored goods.

Moreover, smart systems can automate door operations, reducing the need for manual intervention. For instance, motion sensors can detect when someone approaches and automatically open the door, ensuring that it remains closed as much as possible to maintain temperature stability.

Energy-Efficient Solutions

Energy efficiency remains a top priority for Cold Room Doors Manufacturers. Innovations in insulation materials and door sealing technologies have significantly reduced energy consumption. High-performance insulating materials such as vacuum-insulated panels (VIPs) and advanced polyurethane foams provide superior thermal resistance, helping to maintain the desired internal temperature with minimal energy expenditure.

Developing advanced sealing mechanisms, including magnetic gaskets and multi-point locking systems, has also improved the airtightness of cold room doors. These features minimize air leakage, crucial for maintaining energy efficiency and reducing operational costs.

Hygienic Designs

Maintaining hygiene is paramount in industries such as food processing and pharmaceuticals. Recent innovations in cold room door technology have focused on creating designs that are easy to clean and resistant to microbial contamination. Stainless steel surfaces, antimicrobial coatings, and smooth, seamless door designs help prevent the accumulation of dirt and bacteria.

Furthermore, automated door operation reduces the need for physical contact, lowering the contamination risk. Hands-free operation, achieved through foot pedals or motion sensors, ensures that cold room environments remain hygienic and safe for sensitive products.

Enhanced Security Features

Security is critical for cold storage facilities, particularly those storing valuable or sensitive items. Cold room door technology innovations now include advanced security features such as biometric access control, RFID (Radio-Frequency Identification) systems, and remote monitoring capabilities.

Biometric systems, which use fingerprint or facial recognition, ensure that only authorized personnel can access the cold room. RFID systems can track who enters and exits, providing detailed logs and enhancing traceability. Remote monitoring allows managers to oversee multiple cold rooms from a central location, ensuring that security protocols are always maintained.

Improved Durability and Longevity

Durability is a key consideration for cold room doors, as they must withstand frequent use and harsh conditions. Cold Room Doors Manufacturers are now using more robust materials and construction techniques to enhance the longevity of their products. High-grade stainless steel, corrosion-resistant coatings, and reinforced door frames contribute to doors that can endure the rigours of industrial use without compromising performance.

Additionally, some manufacturers incorporate impact-resistant features to protect doors from accidental damage caused by forklifts or other machinery. These innovations not only extend the lifespan of the doors but also reduce maintenance costs and downtime.

Customizable Solutions

Every cold storage facility has unique requirements, and customizable solutions are becoming increasingly popular. Cold Room Doors Manufacturers now offer a wide range of customization options to meet specific needs. These options include size, insulation thickness, door type (hinged or sliding), and additional features like windows or pass-throughs.

Customization ensures that the cold room doors fit perfectly within the existing infrastructure and meet the facility's operational needs. It also allows businesses to optimize their storage environments for maximum efficiency and productivity.

Rapid Roll-Up Doors

Rapid roll-up doors are a game-changer for high-traffic cold storage areas. These doors are designed to open and close quickly, minimizing the time the door remains open and thus reducing temperature fluctuations. Rapid roll-up doors are ideal for facilities requiring frequent access, such as loading docks and processing areas.

These doors' fast operation is often complemented by advanced safety features, including soft-edge technology and automatic reversing mechanisms, which prevent accidents and injuries. Using durable, insulated curtain materials also ensures that energy efficiency is maintained even with the high frequency of use.

Integration with Building Management Systems (BMS)

Modern cold room doors can be integrated with Building Management Systems (BMS) for centralized control and monitoring. This integration allows for seamless temperature, humidity, and access control management across the entire facility. BMS integration provides valuable data insights, helping facility managers optimize operations, identify inefficiencies, and implement preventative maintenance strategies.

By integrating cold room doors with BMS, businesses can achieve greater operational efficiency, reduce energy consumption, and ensure compliance with regulatory standards. This holistic approach to facility management is becoming increasingly essential in the competitive landscape of cold storage.

Noise Reduction Features

Noise pollution is common in busy cold storage facilities, particularly in urban areas. Cold room door technology innovations now include noise reduction features to create a quieter working environment. Soundproofing materials and design enhancements help minimize the noise generated during door operation.

These noise reduction features are particularly beneficial in facilities where maintaining a quiet environment is crucial, such as pharmaceutical labs or food processing plants. Businesses can improve workplace conditions and enhance overall productivity by reducing noise levels.

Sustainability and Eco-Friendly Materials

Sustainability is a growing concern across all industries, and cold room door technology is no exception. Cold Room Door Manufacturers are increasingly focusing on eco-friendly materials and sustainable manufacturing practices. To reduce their environmental impact, they are adopting recyclable materials, low-VOC (volatile organic compounds) coatings, and energy-efficient production processes.

Additionally, some manufacturers are exploring using renewable energy sources for production and integrating sustainable practices throughout the supply chain. These efforts contribute to environmental conservation and align with the growing demand for sustainable products from consumers and businesses alike.

Conclusion

The cold room door industry is undergoing a significant transformation, driven by technological advancements and the evolving needs of various sectors. Innovations in smart systems, energy efficiency, hygiene, security, durability, customization, rapid roll-up doors, BMS integration, noise reduction, and sustainability are shaping the future of cold storage solutions.

As Cold Room Doors Manufacturers continue to innovate, businesses can expect more efficient, secure, and sustainable cold room environments. These advancements not only improve operational efficiency and reduce costs but also ensure the safety and quality of stored products. By staying abreast of the latest trends and technologies, businesses can make informed decisions and invest in cold room doors that meet their specific needs and future-proof their operations.

Whether you are in the food industry, pharmaceuticals, logistics, or any sector requiring reliable cold storage, the latest innovations in cold room door technology offer a range of benefits that can enhance your operations. Embracing these advancements will ensure that your cold storage facilities remain at the forefront of efficiency, safety, and sustainability.

#Clean Room Doors Manufacturers#Cold Room Panels Manufacturers#Rockwool Sandwich Panels Manufacturers

0 notes

Text

Innovations in Rockwool Sandwich Panel Technology

The demand for efficient, durable, and eco-friendly materials has never been higher in the construction and insulation industry. Among the most innovative solutions available today are Rockwool sandwich panels. As one of the leading Rockwool sandwich panels manufacturers, Isoflex is at the forefront of this technological revolution. This blog explores the latest advancements in Rockwool sandwich panel technology and highlights why Isoflex is the go-to choice for high-quality cold room doors and insulation solutions.

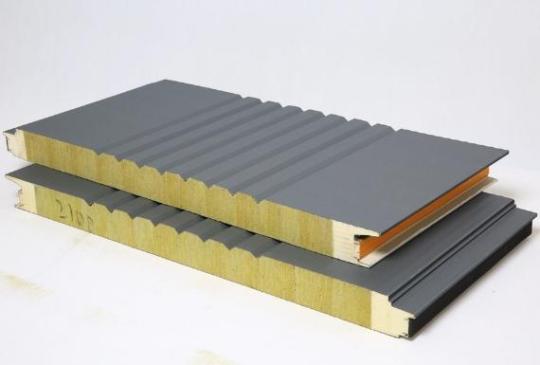

What are Rockwool Sandwich Panels?

Rockwool sandwich panels are composite materials made of two layers of metal sheeting with a core of Rockwool insulation. This unique combination offers exceptional thermal and acoustic insulation, fire resistance, and structural integrity, making them ideal for various applications, from industrial buildings to residential projects.

Innovations in Rockwool Sandwich Panel Technology

Enhanced Fire Resistance

One of the standout features of Rockwool is its inherent fire resistance. Recent innovations have further improved this aspect, with advanced manufacturing techniques allowing for even higher levels of fire protection. Modern Rockwool sandwich panels can withstand extreme temperatures, providing crucial time for evacuation and firefighting in case of a fire. This makes them particularly valuable in applications where safety is paramount, such as in the construction of cold rooms, warehouses, and commercial buildings.

Improved Thermal Performance

Energy efficiency is a key consideration in today's building design, and Rockwool sandwich panels excel in this area. Innovations in the density and composition of the Rockwool core have led to panels with superior thermal insulation properties. These improvements help maintain optimal temperatures in cold rooms and other controlled environments, reducing energy consumption and operational costs.

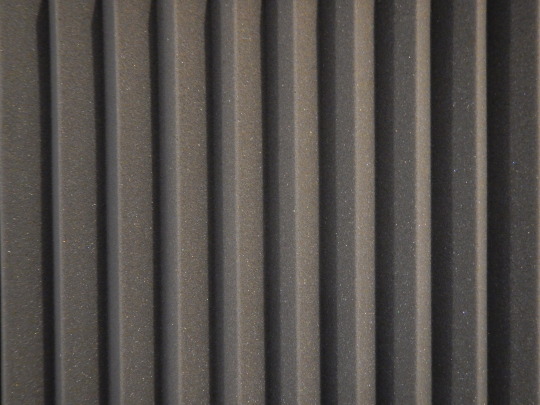

Acoustic Insulation

Noise pollution is a growing concern in both urban and industrial settings. Rockwool sandwich panels offer excellent acoustic insulation thanks to the fibrous structure of the Rockwool core. Recent advancements have enhanced these properties, making them ideal for use in environments where noise reduction is essential, such as recording studios, industrial facilities, and residential buildings close to busy roads.

Sustainability and Eco-Friendliness

Rockwool sandwich panels have emerged as a green building solution as the construction industry moves towards more sustainable practices. Rockwool is made from natural stone and recycled materials, making it an environmentally friendly choice. Innovations in the production process have reduced the carbon footprint of these panels, aligning with global efforts to reduce greenhouse gas emissions. Isoflex, as a responsible manufacturer, ensures that our Rockwool panels are produced with minimal environmental impact.

Structural Strength and Durability

Recent advancements have also focused on enhancing the structural integrity of Rockwool sandwich panels. By optimizing the bonding process between the Rockwool core and the metal facings, manufacturers have created panels that are not only strong but also lightweight. This balance of strength and weight makes them easier to handle and install, reducing labour costs and construction time.

Why Choose Isoflex?

Isoflex has established itself as a reputable manufacturer in the Rockwool sandwich panels industry. Our commitment to quality, innovation, and customer satisfaction sets us apart from the competition. Here are some reasons why investing in Rockwool sandwich panels and cold room doors from Isoflex is a smart choice:

Quality Assurance

At Isoflex, quality is paramount. We adhere to stringent quality control measures throughout manufacturing to ensure that our Rockwool sandwich panels meet the highest industry standards. Our products undergo rigorous testing for fire resistance, thermal performance, and structural integrity, guaranteeing reliability and safety.

Customization Options

We understand that every project has unique requirements. Isoflex offers a range of customization options, including different panel thicknesses, facings, and finishes. Whether you need panels for a large industrial facility or a small residential project, we can tailor our products to meet your needs.

Expertise and Experience

With years of experience in the industry, Isoflex has developed deep expertise in Rockwool sandwich panel technology. Our skilled professionals are dedicated to staying abreast of the latest advancements and incorporating them into our product offerings. This ensures that our customers benefit from cutting-edge solutions that deliver superior performance and value.

Comprehensive Support

From initial consultation to after-sales service, Isoflex provides comprehensive support to our clients. Our experts are available to assist with design, installation, and maintenance, ensuring a seamless experience from start to finish. We are committed to building long-term relationships with our clients based on trust and satisfaction.

The Importance of Investing in Cold Room Doors

Cold room doors are a critical component of any cold storage facility. They play a vital role in maintaining the internal temperature, preventing energy loss, and ensuring the safety of stored goods. Here's why you should invest in cold room doors from Isoflex:

Superior Insulation

Isoflex cold room doors are designed with the same high-quality Rockwool insulation used in our sandwich panels. This ensures excellent thermal performance, helping to maintain consistent temperatures within the cold room and reducing energy consumption.

Durability and Reliability

Our cold room doors are built to withstand the demanding conditions of cold storage environments. They are constructed from robust materials that resist wear and tear, ensuring long-lasting performance. Whether for food storage, pharmaceuticals, or other temperature-sensitive goods, Isoflex doors provide reliable protection.

Custom Design

We offer a range of cold room door designs to suit different applications. Whether you need hinged doors, sliding doors, or automated solutions, Isoflex can provide a customized door that meets your requirements. Our doors are designed for easy installation and maintenance, minimizing downtime and operational disruptions.

Enhanced Safety Features

Safety is a top priority in cold storage facilities. Isoflex cold room doors have advanced safety features, including emergency release mechanisms, robust seals, and smooth operation systems. These features not only protect your goods but also ensure the safety of your personnel.

Conclusion

Rockwool sandwich panel technology advancements have made them an indispensable solution for modern construction and insulation needs. As one of the leading Rockwool sandwich panels manufacturers, Isoflex is proud to offer innovative products that deliver exceptional performance, safety, and sustainability. Our Rockwool sandwich panels and cold room doors are designed to meet the highest standards, providing our customers with reliable and efficient solutions for their projects.

Investing in Isoflex products means investing in quality, innovation, and long-term value. Whether you are constructing a new building, upgrading an existing facility, or setting up a cold storage unit, Isoflex has the expertise and the products to meet your needs. Contact us today to learn more about our Rockwool sandwich panels and cold room doors and how we can help you achieve your project goals.

#Rockwool Sandwich Panels Manufacturers#Cold Room Panels Manufacturers#Clean Room Doors Manufacturers

0 notes

Text

Telp Kami - 08.22.18.95.79.12 | Peredam Karaoke di Kota Bonto Somba,Tompobulu,Maros,Sulawesi Selatan

Mengenal Busa Telur untuk Peredam Suara, Ini Keunggulan dan Kekurangannya

Telp Kami – 08.22.18.95.79.12 |

Peredam Karaoke di Kota Bonto Somba,Tompobulu,Maros,Sulawesi Selatan,Hello warga Makassar dan sekitarnya. Makassar dengan ibu kota provinsi Sulawesi Selatan, Indonesia.

Kota Makassar (Lontara Makassar: ᨀᨚᨈ ᨆᨀᨔᨑ, transliterasi: Kota Mangkasara’ , Lontara Makassar: ᨀᨚᨈ ᨍᨘᨄᨉ, transliterasi: Kota…

View On WordPress

#ahli peredam Suara Ruangan#anggaran biaya#aplikator peredam suara#Auditorium dan Rumah Ibadah.†ruangan bebas suara#auditorium hall#bali#bekasi#bioskop#bogor#busa peredam suara#depok#distributor peredam suara#home theater#instalasi sistem peredaman#jabodetabek#jasa kontraktor#Jasa kontraktor kedap suara#jasa pasang kedap suara ruangan#jasa pemasangan peredam rockwool#Jasa Pemasangan Peredam Suara Ruangan#Jasa Pembuatan Ruang Kedap Suara#jasa penyedia panel akustik#jasa peredam suara ruangan atau soundproofing#jual busa peredam suara#kamar apartemen#kamar tidur#kedap suara#kontraktor peredam suara ruangan dan harga jasa peredam untuk di ruang genset#makassar#memproduksi pintu partisi geser peredam suara.metode peredam suara ruangan

0 notes

Text

Clean room wall panels are specialized building components designed to maintain strict environmental conditions. Used in industries like pharmaceuticals, biotechnology, and electronics, these panels offer superior contamination control, durability, and easy sanitation. Made from non-porous materials with sealed joints, they resist microbial growth and can endure frequent cleaning. With their sleek appearance and precision engineering, clean room wall panels ensure a hygienic and controlled environment, essential for high-stakes applications.

#Clean Room Wall Panels#clean room panels#modular clean room panels#luckydeep#rockwool panels#clean room doors#modular clean room panel#clean room manufacturers in india#modular clean room

0 notes

Text

High-Quality Rockwool Insulation Panels: Enhance Your Property's Energy Efficiency!

Boost your property's energy efficiency with premium Rockwool insulation panels from HIKOM International LLP! Crafted with top-quality materials, our panels provide exceptional thermal performance, reducing heat loss and lowering utility bills. Perfect for residential and commercial applications, these panels offer superior fire resistance and sound absorption properties. Trust HIKOM International LLP for reliable solutions that enhance comfort and sustainability in any building. Invest in Rockwool insulation panels today for lasting benefits and a greener tomorrow!

1 note

·

View note

Text

Advantages of Rockwool Sandwich Panels in Building Insulation

In modern construction, insulation is a crucial element for ensuring comfort, energy efficiency, and sustainability within buildings. Among the myriad options available, Rockwool Sandwich Panels emerge as a top contender, offering many advantages that cater to the diverse needs of builders, architects, and occupants alike. This comprehensive guide delves into the remarkable benefits of picking the top Rockwool Sandwich Panels Manufacturers, & shedding light on why they have become the preferred choice for building insulation.

Rockwool Sandwich Panels, or mineral wool sandwich panels, comprise a dense layer of Rockwool insulation core sandwiched between two layers of rigid-facing materials, typically steel or aluminium. The Rockwool insulation core is derived from natural volcanic rock, which undergoes a sophisticated manufacturing process to produce high-quality insulation material.

One of its main benefits is the outstanding thermal insulation qualities of Rockwool Sandwich Panels. The unique composition of Rockwool insulation ensures high thermal resistance, effectively minimizing heat transfer through walls, roofs, and floors. This results in significant energy savings by reducing the need for heating and cooling systems, thereby enhancing the overall energy efficiency of buildings.

Any construction project must prioritize safety, and Rockwool Sandwich Panels perform exceptionally well in this area. Thanks to the inherent fire-resistant properties of Rockwool insulation, buildings insulated with these panels demonstrate superior fire performance. Rockwool insulation inhibits the spread of flames in the case of a fire, giving residents plenty of time to safely evacuate and lowering the possibility of property damage. Rockwool Sandwich Panels is an ideal choice for applications where fire safety is a top priority, such as commercial buildings, industrial facilities, and residential complexes.

In addition to thermal insulation, Rockwool Sandwich Panels offer excellent acoustic properties, making them an effective solution for soundproofing applications. The dense structure of Rockwool insulation effectively absorbs sound waves, reducing noise transmission between rooms and minimizing external noise pollution. This is particularly beneficial in environments where noise control is essential, such as offices, schools, hospitals, and recording studios. By creating a quieter and more comfortable indoor environment, Rockwool Sandwich Panels contribute to enhanced productivity, concentration, and overall well-being.

Durability is a hallmark of Rockwool Sandwich Panels, ensuring long-term performance and reliability. The robust construction of these panels, combined with the inherent strength of Rockwool insulation, results in a highly resilient building envelope that can withstand various environmental stresses, including extreme temperatures, moisture, and mechanical impact. Unlike traditional insulation materials, Rockwool does not degrade over time or lose its insulating properties, ensuring consistent performance throughout the lifespan of the building. This longevity translates to cost savings and reduced maintenance requirements, making Rockwool Sandwich Panels a sound investment for any construction project.

In a time when environmental consciousness is growing, sustainability is becoming a crucial factor in building methods. Rockwool Sandwich Panels offer numerous environmental benefits that align with green building principles. The raw materials used in Rockwool insulation, namely volcanic rock and recycled steel or aluminum, are abundant and readily available, minimizing the environmental impact of production. Additionally, Rockwool insulation is non-toxic and fully recyclable, contributing to resource conservation and waste reduction. Builders can reduce their carbon footprint by choosing Rockwool Sandwich Panels and contribute to a more sustainable built environment.

Rockwool Sandwich Panels offer unparalleled versatility and design flexibility, allowing architects and builders to realize their creative vision without compromising performance. These panels are available in various thicknesses, sizes, and facing materials, enabling customization to suit specific project requirements. Whether used in walls, roofs, or floors, they can be seamlessly integrated into various architectural styles and construction techniques. Moreover, their lightweight design makes carrying and installation easier, reducing labour expenses and construction time.

In conclusion, Rockwool Sandwich Panels stand out as a superior choice for building insulation, offering many advantages encompassing thermal performance, fire safety, acoustic insulation, durability, sustainability, and design flexibility. As trusted Rockwool Sandwich Panels Manufacturers, Isoflex is committed to delivering high-quality insulation solutions that meet the evolving needs of the construction industry. By harnessing the power of Rockwool insulation, builders can create healthier, safer, and more energy-efficient buildings that enrich the lives of occupants and contribute to a sustainable future. Incorporating Rockwool Sandwich Panels into your next construction project is not just a wise investment—it's a step towards building a better world for future generations. Choose Isoflex for premium-quality insulation solutions that elevate your building's performance and redefine the standards of excellence in construction.

#Rockwool Sandwich Panels Manufacturers#Rockwool Sandwich Panels Manufacturer#Rockwool Panels Manufacturers

0 notes

Text

What Makes Rockwool Sandwich Panels a Sustainable Choice for Construction

Construction is no exception in an era where sustainability is at the forefront of every industry. The demand for eco-friendly building materials is rapidly increasing as individuals and businesses strive to minimize their environmental footprint. Among the many options available, Rockwool Sandwich Panels Manufacturers emerge as a standout choice for sustainable construction practices.

Rockwool sandwich panels, also known as mineral wool sandwich panels, are composed of two outer layers of material (typically metal) with a core insulation layer made from stone wool. This composition offers a myriad of benefits, making it an ideal choice for environmentally-conscious builders and architects. Let's delve deeper into what makes Rockwool sandwich panels a sustainable solution for construction projects.

One of the primary advantages of Rockwool sandwich panels is their exceptional thermal performance. The stone wool core provides excellent insulation properties, effectively regulating indoor temperatures and reducing the need for excessive heating or cooling. By minimizing energy consumption for climate control, buildings constructed with Rockwool sandwich panels contribute to lower greenhouse gas emissions and decreased reliance on fossil fuels.

Rockwool sandwich panels are renowned for their durability and longevity. Rock wool panels resist moisture, mould, and fire, unlike traditional insulation materials, such as fibreglass. This inherent resilience ensures that buildings constructed with Rockwool sandwich panels maintain their structural integrity over time, reducing the frequency of repairs and replacements. Consequently, more resources are needed to maintain and renovate structures, aligning with sustainable construction principles.

Another notable aspect of Rockwool sandwich panels is their recyclability. At the end of a building's life cycle, these panels can be recycled and repurposed, minimizing waste and reducing the burden on landfills. The stone wool core is entirely recyclable and can manufacture new insulation products or other materials, contributing to a closed-loop system that conserves resources and reduces environmental impact.

In addition to thermal insulation, Rockwool sandwich panels offer excellent sound insulation properties. The dense composition of stone wool effectively absorbs and dampens sound waves, creating a quieter and more comfortable indoor environment. Buildings equipped with Rockwool panels experience reduced noise pollution, enhancing occupant well-being and productivity. This acoustic performance is particularly beneficial in urban areas or buildings where noise control is a priority.

Safety is paramount in construction, and Rockwool sandwich panels excel. The non-combustible nature of stone wool provides inherent fire resistance, significantly reducing the spread of flames in the event of a fire. As a result, buildings constructed with Rockwool panels offer enhanced fire protection, potentially saving lives and minimizing property damage. This feature is especially critical in high-risk environments or buildings with stringent fire safety regulations.

Compared to alternative insulation materials, Rockwool production requires fewer resources and generates a lower environmental impact. Rockwool sandwich panels manufacturers employ sustainable practices, including the use of recycled materials and energy-efficient manufacturing processes. Additionally, the longevity and recyclability of Rockwool panels further mitigate their environmental footprint, making them a preferred choice for environmentally responsible construction projects.

In conclusion, Rockwool sandwich panels are a sustainable choice for modern construction projects. From energy efficiency and durability to recyclability and fire resistance, these panels offer many benefits that align with sustainable construction principles. As the demand for eco-friendly building materials continues to grow, Rockwool sandwich panels manufacturers play a crucial role in providing innovative solutions that prioritize both environmental stewardship and building performance. By incorporating Rockwool panels into construction projects, builders and architects can create structures that are not only sustainable but also resilient, safe, and comfortable for occupants.

For sustainable construction solutions backed by quality Rockwool sandwich panels, trust the expertise of leading manufacturers committed to environmental responsibility. Choose Rockwool for a greener, more sustainable future in construction.

0 notes

Text

Rockwool panel suppliers and dealers in Chennai – Maruthi Engineering solutions is one of the strong and growing presence in Chennai circular includes manufacturing rockwool materials and supplying the wide range of product with high quality.

0 notes

Text

Understanding the Different Types of Sandwich Panels and Their Applications in Construction!

https://www.alfapebltd.com/

Sandwich panels are composite materials that consist of a core material, which is usually lightweight, and two outer layers that provide structural support and protection. Sandwich panels are widely used in construction due to their excellent thermal insulation, fire resistance, and durability. Here are some of the different types of sandwich panels.

Sandwich Puf Panels: Sandwich PUF panels, also known as polyurethane foam sandwich panels, are a type of insulated panel used in construction. These panels consist of three layers: two outer metal sheets (usually made of steel or aluminium) and a middle layer of polyurethane foam. They are widely used in Roofing and Cladding, Cold Storage Rooms, Clean Rooms, Prefabricated Buildings etc.

Fireproof Rockwool Sandwich Panels: Rockwool sandwich panels consist of a core material made of Rockwool that is sandwiched between two outer layers made of metal or other materials. They offer excellent fire resistance, thermal insulation, and sound absorption properties.

EPS Sandwich Panels: EPS sandwich panels consist of a core material made of expanded polystyrene foam that is sandwiched between two outer layers made of metal or other materials. They are widely used in roofing, wall cladding, and cold storage applications.

PIR Sandwich Panels: PIR (polyisocyanurate) sandwich panels consist of a core material made of rigid polyurethane foam that is sandwiched between two outer layers made of metal or other materials. They offer excellent thermal insulation, fire resistance, and sound absorption properties.

Honeycomb Sandwich Panels: Honeycomb sandwich panels consist of a core material made of a honeycomb structure, usually made of aluminium or other materials, that is sandwiched between two outer layers made of metal or other materials. They offer an excellent strength-to-weight ratio, making them ideal for applications that require lightweight but strong materials.

In conclusion, sandwich panels come in various types, each with unique properties and advantages that make them suitable for different construction applications. The selection of the right sandwich panel depends on factors such as the application, the required level of insulation, fire resistance, and strength.

Sandwich panels are widely used in the construction industry due to their high strength, thermal insulation, and aesthetic appeal. Here are some of the most common applications of sandwich panels in construction:

Roofing and wall cladding: Sandwich panels are frequently used for roofing and wall cladding in industrial and commercial buildings. They provide excellent insulation and are quick and easy to install, making them a popular choice for large-scale construction projects.

Cold storage facilities: Sandwich panels are ideal for use in cold storage facilities, as they provide superior insulation properties that help to maintain a consistent temperature and prevent the loss of energy.

Cleanrooms: Sandwich panels are frequently used in the construction of cleanrooms, where a controlled environment is required. The panels offer excellent air-tightness and can be designed to meet specific cleanliness and hygiene requirements.

Residential construction: Sandwich panels are becoming increasingly popular in residential construction, particularly for prefabricated homes. They offer excellent insulation and are easy to install, making them an attractive option for builders and homeowners alike.

Agricultural buildings: Sandwich panels are often used in the construction of agricultural buildings, such as barns and sheds. They offer excellent insulation properties and can be designed to withstand harsh weather conditions.

Commercial/Industrial buildings: Sandwich panels are commonly used in the construction of industrial buildings such as factories, warehouses, and distribution centers, where they provide excellent insulation and fire resistance.

Modular buildings: Sandwich panels are often used in the construction of modular buildings such as prefabricated houses, offices, and classrooms. They can be easily transported and assembled on-site, offering a fast and cost-effective construction solution.

Partition walls: Sandwich panels can be used as partition walls to divide large spaces into smaller rooms. They are easy to install, lightweight, and can be designed to meet specific fire resistance requirements.

Prefabricated buildings: Sandwich panels are a popular material for prefabricated buildings as they are lightweight, easy to assemble, and offer excellent insulation properties.

Overall, sandwich panels are a versatile and popular building material that can be used in a wide range of construction applications.

For More Information Visit :- https://www.alfapebltd.com/

0 notes

Text

We are one of the best rockwool sandwich panels manufacturers

Isoflex is a leader in the design and production of a variety of intelligent and environmentally friendly Rockwool Sandwich Panels using Rockwool insulation materials. Isoflex rose to prominence as a leading manufacturer of rockwool sandwich panels as a result of the expanding market demand. Moreover, Isoflex's rockwool sandwich panels manufacturers are environmentally beneficial because they are constructed from natural basalt.

0 notes

Text

Panel Rockwool làm công trình xây dựng

https://panelviet.vn/panel-rockwool-lam-cong-trinh-xay-dung

0 notes

Text

Rockwool Sandwich Panel Manufacturers in India

As per as Cactus Profiles Pvt Ltd is the top Rockwool sandwich panel manufacturer within India. We are expanding our supply of prefabricated building material with many years of experience and expertise in the construction industry. We ensure safe and secure buildings.

The rockwool sandwich panels are known as a kind of thermal insulation that is made of minerals and rocks. It's also known as mineral wool. The rockwool sandwich panels are employed to improve the acoustic efficiency of the structure in which it is used in both old and new structures.

Click here to get more details@ https://www.cactusprofiles.com/rockwool-sandwich-panel/

Contact Us

B-12, Sector 81,

Noida – 201306, UP (NCR) India

Website: cactusprofiles.com

Gmail: [email protected]

Phone: +91-120-4251011/12/13

+91 - 82873 85024

0 notes

Link

We offer a solution for Industrial acoustic sound insulation using Rockwool Doors Manufacturers. Isoflex system has successfully designed, maintained, and executed numerous projects comprising Rockwool Sandwich Panels Manufacturers.

1 note

·

View note

Text

Telp Kami - 0822-189-57912 | Ruangan Peredam Suara di Kota Bulumpare'e,Awangpone,Bone,Sulawesi Selatan

Mengenal Busa Telur untuk Peredam Suara, Ini Keunggulan dan Kekurangannya

Telp Kami – 0822-189-57912 |

Ruangan Peredam Suara di Kota Bulumpare’e,Awangpone,Bone,Sulawesi Selatan,Hello warga Makassar dan sekitarnya. Makassar dengan ibu kota provinsi Sulawesi Selatan, Indonesia.

Kota Makassar (Lontara Makassar: ᨀᨚᨈ ᨆᨀᨔᨑ, transliterasi: Kota Mangkasara’ , Lontara Makassar: ᨀᨚᨈ ᨍᨘᨄᨉ, transliterasi:…

View On WordPress

#ahli peredam Suara Ruangan#anggaran biaya#aplikator peredam suara#Auditorium dan Rumah Ibadah.†ruangan bebas suara#auditorium hall#bali#bekasi#bioskop#bogor#busa peredam suara#depok#distributor peredam suara#home theater#instalasi sistem peredaman#jabodetabek#jasa kontraktor#Jasa kontraktor kedap suara#jasa pasang kedap suara ruangan#jasa pemasangan peredam rockwool#Jasa Pemasangan Peredam Suara Ruangan#Jasa Pembuatan Ruang Kedap Suara#jasa penyedia panel akustik#jasa peredam suara ruangan atau soundproofing#jual busa peredam suara#kamar apartemen#kamar tidur#kedap suara#kontraktor peredam suara ruangan dan harga jasa peredam untuk di ruang genset#makassar#memproduksi pintu partisi geser peredam suara.metode peredam suara ruangan

0 notes

Text

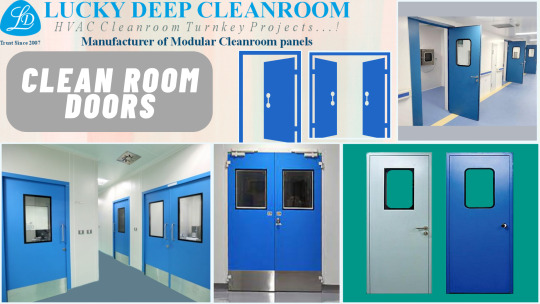

Clean room doors are crucial for places like labs, pharmaceutical factories, and semiconductor plants, where controlling contamination is a must. These doors help keep the air clean, limit who can enter, and block pollutants from getting in. They have airtight seals, smooth surfaces for easy cleaning, and systems to ensure only one door opens at a time. When picking clean room doors, you should look for durability, compliance with industry rules, and easy connections to air filtration systems.

#clean room doors#clean room panels#modular clean room panels#luckydeep#rockwool panels#modular clean room panel#clean room manufacturers in india#clean room wall panels#modular clean room

0 notes