#possible package integrity failure

Explore tagged Tumblr posts

Text

Food Recall: Alehouse Clam and SeaBear Salmon Chowder:

#Alehouse Clam Chowder#FDA#possible Clostridium botulinum contamination#possible package integrity failure#Recalls Direct RIN: 19521-2025#Seabear Company#SeaBear Salmon Chowder#US FDA#US Food and Drug Administration#vegetables

0 notes

Text

Thailand Board of Investment

1. Institutional Framework and Historical Context

1.1 Legal Foundations

Established under the Investment Promotion Act B.E. 2520 (1977)

Amended by Act No. 4 B.E. 2560 (2017) to accommodate Industry 4.0

Operates under the Office of the Prime Minister with quasi-ministerial authority

1.2 Governance Structure

BOI Board: Chaired by the Prime Minister

Investment Committee: 12-member expert panel

Secretariat: Professional staff of 300+ specialists across 8 divisions

1.3 Historical Evolution

Phase 1 (1960-1990): Import substitution industrialization

Phase 2 (1991-2015): Export-oriented manufacturing

Phase 3 (2016-present): Technology-driven "Thailand 4.0" initiative

2. Investment Promotion Strategy

2.1 Geographic Prioritization

Eastern Economic Corridor (EEC): Enhanced incentives

Southern Border Provinces: Special security concessions

20 Provinces: Tiered incentive structures

3. Incentive Architecture

3.1 Tax Privileges

Corporate Income Tax (CIT) Holidays:

5-8 years exemption

50% reduction for 5 subsequent years

Import Duty Exemptions:

Machinery: 100% relief

Raw materials: Partial relief based on local content

3.2 Non-Tax Incentives

Land Ownership Rights: Foreign freehold permitted

Work Permit Facilitation: Fast-track processing (7 days)

Foreign Expert Visa: Multiple-entry 4-year SMART Visa

3.3 Special Incentive Packages

EEC+ Package:

15-year CIT exemption

Personal income tax cap at 17%

Digital Park Thailand:

10-year tax holiday

Data center infrastructure subsidies

4. Application and Approval Process

4.1 Pre-Application Phase

Eligibility Assessment (30-day diagnostic)

Project Feasibility Study requirements:

Minimum 3-year financial projections

Technology transfer plan

Environmental impact assessment (for Category 3 projects)

4.2 Formal Submission

Documentation Requirements:

Corporate structure diagrams

Shareholder background checks

Detailed investment timeline

Filing Channels:

Online BOI e-Service portal

In-person at BOI One Start One Stop center

5. Compliance and Operational Requirements

5.1 Investment Implementation

Capital Deployment Schedule:

25% within 12 months

100% within 36 months (extensions possible)

Employment Ratios:

Minimum 1 Thai employee per THB 1M investment

Technology transfer obligations

5.2 Reporting Obligations

Annual Progress Reports: Detailed project updates

Tax Privilege Utilization Statements: Certified by auditor

Foreign Expert Tracking: Monthly work permit updates

6. Sector-Specific Considerations

6.1 Manufacturing Sector

Local Content Requirements: 40-60% depending on sector

Environmental Standards: Tiered compliance levels

6.2 Digital Economy

Data Localization Rules: Conditional exemptions

IP Protection: Enhanced safeguards for BOI projects

6.3 Renewable Energy

Feed-in Tariff Eligibility: BOI+EGAT coordination

Carbon Credit Monetization: Special provisions

7. Dispute Resolution and Appeals

7.1 Privilege Revocation Process

Grounds for Cancellation:

Failure to meet investment timelines

Violation of environmental regulations

Fraudulent application information

Appeal Mechanism: 60-day window to petition

7.2 Arbitration Framework

THAC-administered proceedings

Expedited process for BOI disputes

8. Emerging Trends and Future Directions

9.1 Policy Developments

Draft Amendment Act (2025): Proposed R&D requirements

Green Industry Incentives: Carbon neutrality targets

9.2 Technological Integration

Blockchain Verification: For document authentication

AI-assisted Application Processing: Pilot program

9.3 Global Value Chain Positioning

ASEAN+3 Supply Chain Initiatives

EU-Thailand FTA Preparations

9. Strategic Implementation Guide

10.1 For Multinational Corporations

Regional HQ Strategy: Leverage RHQ privileges

Tiered Investment Approach: Phased capital deployment

10.2 For SMEs

Cluster Development: Co-location benefits

Technology Partner Matching: BOI-facilitated pairings

10.3 Risk Management

Compliance Calendar: Critical date tracking

Contingency Planning: Alternative incentive structures

Key Resources:

BOI Official Website: www.boi.go.th

Investment Privileges Database: privilege.boi.go.th

EEC Special Regulations: eeco.or.th

#thailand#thai#boi#boardofinvestment#thailandboardofinvestment#coporate#corporateinthailand#thaicorporate

2 notes

·

View notes

Text

i've been on a linux adventure recently —

one day i woke up and thought, "today is the day", and began working through the linux from scratch handbook. it turns out that most people do not in fact do this on bare metal because compiling everything yourself and just punting on package management does not provide for a workable system. at least, not as a daily driver. (this guy tried writing a debian from scratch where step 1 is getting apt going, but apparently it is not just outdated, but incorrect even at the version specified).

you're supposed to just do this in a virtual machine and treat it like a learning exercise. i did not do this, and spent twelve hours compiling all the packages and walking circular dependency trees basically trying to slowly divorce yourself from the host system's toolchain.

in the process it's very clear how "down in the dirt" linux as a whole is; nothing is made for each other, all the packages are just picked up from here and there, sometimes the maintainer doesn't update their domain and pkg-conf is just Gone so you have to dig it out of the gentoo repo. i kind of love it. it feels organic, it feels natural. of course this emerged. of course it all kinda works, of course it all fails easily.

it's a lot like the human body. that is, say you have a really nicely integrated distro. they probably have like fifty different upstreams, and teams that are making extensions or monkey patching the upstream as they go to slowly hone these disparate things into stuff that vaguely resembles each other. you introduce redundancies and reliability checks. you try to migrate to stuff that will enforce this (Ubuntu enforces Wayland by default; Fedora defaults you to btrfs; downstream distributions then in turn undo some of these like how Pop! OS goes back to X11).

you keep reinforcing against common failures with subsequent processes that can watch for those failures and prevent them, provide fallbacks, self-heal if possible.

and then in turn for everything else you isolate its ability to even impact the core system. ideally you're immutable — say, vanilla os, or some people use nix or fedora silverblue. but most of the time there's just a hybrid approach where we sandbox as much as we can. steam os completely replaces the OS every update and keeps the home folder. chromebooks do likewise. macos has been doing this since i think el capitan? and apfs is intended to have a less hacked-in way of providing for a core system partition that nothing else can touch.

that whole thing is really beautiful, i think — have BSDs replicated this? i don't know; i have never used one very seriously. it felt like they intended to start from scratch with a monolithic basis, but it feels like i'm in the early 2000s again when i try to debug a bsd system and look for documentation.

anyway, so after twelve hours i fumbled a very basic thing. that is, i assumed, why not? i will use UEFI, but i had already partitioned as if i was doing an MBR. so i tried to add a UEFI partition and inadvertently, in trying to unmount and safely perform this operation, rebooted into a system that was freaking out because there was no UEFI partition. it kept reboot cycling into a wifi recovery agent and occasionally realising there was a USB attached.

i moved to arch and performed the entire install in like less than an hour. but damn it, now i'm frustrated. i wanted to see this through. today i decided to move to fedora to better have an overarching experience for this specific hardware (the auto-rotation and on screen keyboard support is amazing on gnome 44) and then try to throw all this into a Box and do it again. but given so much of this was tedious, i would probably just ... automate it. but aren't we getting too close to just a distro?

4 notes

·

View notes

Text

Fix Insufficient Transport Layer Protection in Symfony

If your Symfony application still relies on HTTP or weak SSL/TLS configurations, you're at risk of exposing sensitive data. One of the most common vulnerabilities in modern web development is Insufficient Transport Layer Protection—and in Symfony, this mistake could compromise the integrity of your entire application.

In this blog post, we’ll show you:

What this vulnerability is

Real-world consequences

How to detect and fix it in Symfony

How our Free Website Security Scanner can help

Code examples to secure your Symfony app

Professional solutions via Pentest Testing Corp

📌 Bonus: We’ve included screenshots of a live vulnerability assessment using our tool and shared insights into our new services and blog!

🔍 What is Insufficient Transport Layer Protection?

"Insufficient Transport Layer Protection" refers to the failure to encrypt sensitive traffic using protocols like HTTPS, TLS, or SSL. In Symfony, this can happen when:

HTTP routes are left unsecured

SSL certificates are misconfigured or expired

The framework fails to enforce secure cookies or headers

Attackers can exploit this weakness through:

Man-in-the-Middle (MitM) attacks

Session hijacking

Data eavesdropping on unsecured networks

🖥️ Detect It with Our Free Website Vulnerability Scanner

Take a look at how our Website Vulnerability Scanner identifies transport layer issues automatically in just a few seconds.

📸 Screenshot of the Website Vulnerability Scanner homepage:

Screenshot of the free tools webpage where you can access security assessment tools.

📸 Screenshot of a sample report to check Website Vulnerability:

An Example of a vulnerability assessment report generated with our free tool, providing insights into possible vulnerabilities.

🧪 How to Fix It in Symfony

Let’s go step-by-step through code-level protection methods for Symfony.

✅ 1. Force HTTPS Redirect

Edit your Symfony routes or web server config to ensure all traffic is routed over HTTPS:

In config/packages/framework.yaml:

framework: http_method_override: true trusted_proxies: '%env(TRUSTED_PROXIES)%' trusted_headers: [ 'x-forwarded-for', 'x-forwarded-proto' ]

And enforce HTTPS in .htaccess or Nginx:

Apache:

RewriteEngine On RewriteCond %{HTTPS} off RewriteRule ^(.*)$ https://%{HTTP_HOST}%{REQUEST_URI} [L,R=301]

Nginx:

server { listen 80; server_name yourdomain.com; return 301 https://$host$request_uri; }

✅ 2. Configure Symfony for Secure Cookies

Edit your config/packages/framework.yaml:

framework: session: cookie_secure: auto cookie_samesite: strict

✅ 3. Enforce HSTS Headers

Set the Strict-Transport-Security header:

Apache:

Header always set Strict-Transport-Security "max-age=31536000; includeSubDomains; preload"

Symfony via EventSubscriber:

use Symfony\Component\HttpKernel\Event\ResponseEvent; public function onKernelResponse(ResponseEvent $event): void { $response = $event->getResponse(); $response->headers->set('Strict-Transport-Security', 'max- age=31536000; includeSubDomains; preload'); }

✅ 4. Update Your SSL Certificates

Use Let’s Encrypt or a valid commercial CA to ensure you’re using up-to-date certificates:

sudo certbot --apache -d yourdomain.com

Then configure auto-renewals:

0 12 * * * /usr/bin/certbot renew --quiet

🧪 Real Case: Fixing Symfony App Using Our Tool

A user recently scanned their Symfony app on https://free.pentesttesting.com and received a detailed vulnerability report that revealed:

Missing HSTS headers

Expired TLS certificate

Cookies set without secure flag

Using our recommendations, they patched their app in 1 hour and eliminated over 5 critical issues.

👉 Check out our blog for more examples: https://www.pentesttesting.com/blog/

💼 Need Help? Hire Experts to Secure Your Symfony App

Even if you apply the fixes above, deep vulnerabilities might still hide in your codebase. That’s why our Web Application Penetration Testing Service offers:

Manual pentests by certified experts

OWASP Top 10 Coverage

Detailed remediation support

📌 Affordable pricing starts at $25/hr.

💡 Want to Offer Cybersecurity Services to Your Clients?

Join our partner program! You can resell cybersecurity services under your brand and boost your revenue.

✅ White-label reports ✅ Custom pricing options ✅ Dedicated account manager

📰 Stay Updated – Subscribe to Our Cybersecurity Newsletter

Never miss a blog, update, or cybersecurity tip!

🔗 Subscribe on LinkedIn

🔗 Useful Links

🛠️ Website Vulnerability Scanner online free

📚 Our Blog on Cybersecurity

🔐 Web App Pentest Services

🤝 Offer Cybersecurity to Clients

📰 Cybersecurity Newsletter on LinkedIn

1 note

·

View note

Text

Smart Fire System Maintenance in Singapore – 2025 Guide to Safer Buildings

In a densely populated and highly regulated country like Singapore, fire protection is not an option—it's a requirement. From residential towers to large commercial complexes, ensuring that all fire protection systems function at peak levels is not just about compliance but the difference between saving lives and assets. That is where fire system maintenance in Singapore becomes imperative in 2025.

Why Fire System Maintenance Is Important in 2025

As more urban infrastructure and smart buildings develop, our approach to fire safety must evolve as well. Well-maintained fire systems in Singapore ensure that fire alarms, sprinkler systems, fire extinguishers, and emergency lighting all work flawlessly in case of an emergency. System maintenance leads to faster response times and less loss.

Forgetting your fire system maintenance in Singapore can have cataclysmic consequences. Beyond SCDF penalties, insurance claims shall be rejected if systems are found non-compliant or non-operational. Good operators like drakofire help cover this gap with comprehensive maintenance services.

Key questions of Fire System Maintenance

Full fire system maintenance in Singapore involves inspection, testing, servicing, and upgrading of varied components including:

Fire alarms and smoke detectors

Fire sprinkler systems

Fire extinquishers

Emergency exit lighting and signage

Fire hosereels

Hydrant systems

They all play a crucial role of signaling, confining, or putting out fire. Their maintenance is visual as well as functional. Proper maintenance can prove to be the turning point in decreasing the level of damage caused by unexpected instances of fires.

Significance of Fire Hosereel Maintenance

A vital part of every fire system is the fire hosereel. Maintenance of fire hosereels in Singapore ensures obstructions are removed from the reels, hoses are clean and free of blockages, and adequate water pressure is present. Faulty hosereels are the difference between a flame that is controlled and a fire that is out of control.In 2025, Singapore is giving more emphasis on fire hosereel maintenance due to its direct application in stage-one firefighting. Have your building reels serviced and marked according to SCDF specifications. A slight fault will lead to disaster when needed.

The Role of Technology in Modern Fire System Maintenance

As smart technology is on the rise, fire system maintenance in Singapore evolving. IoT-enabled fire alarm panels and sensor-based systems now make real-time monitoring and quicker diagnostics possible. These advancements facilitate fault detection by maintenance teams to occur earlier, reducing downtime and maximizing safety.

Companies such as drakofire have included such smart solutions in their maintenance processes, offering customers automated reports, predictive maintenance reminders, and cloud-based inspection logs. This makes compliance ease and transparency, especially with regards to SCDF audits.

How Often Should You Schedule Maintenance?

According to SCDF guidelines, fire system maintenance in Singapore required at least annually. Quarterly or even monthly inspections might nevertheless be needed for hazardous premises like factories, schools, and hospitals.

This includes regular fire hosereel servicing in Singapore, whereby experienced technicians check hose integrity, pressure, nozzle operation, and emergency access. Failure of a maintenance cycle can result in severe penalties and increased risk of fires.

For high-rise buildings with mixed uses, paying for an annual package of servicing for all the systems—alarms, sprinklers, extinguishers, and hosereels—means no essential piece of equipment is overlooked.

Finding the Right Maintenance Partner

Not every servicing company is the same. In choosing a company for your fire system servicing in Singapore, make sure they:

Are SCDF-approved

Offer full servicing including fire hosereel service in Singapore

Have clear pricing

Provide detailed service reports

Employ smart diagnostic and IoT technology

A well-known company in the sector, drakofire has enjoyed a long reputation for providing high-quality fire safety solutions that meet local and international regulations. Their professionals attend to all types of properties—residential complexes and large industrial plants not excluded.

Benefits of Ongoing Maintenance

Maintenance for your Singapore fire systems has many benefits:

Regulation Compliance: Obey SCDF and avoid paying fines.

Preparations for Usage: Your systems will do routine operations.

Cost Savings: Preventative maintenance will save you money in the long term.

Peace of Mind: You know your property and residents are protected.

Insurance Compliance: Many insurers require proof of regular fire system testing.

Reduced Downtime: Catch issues early to prevent equipment downtime.

Conclusion

Fire hazards are unpredictable, but your response to them does not have to be. With proactive Singapore fire system maintenance, you take the initiative on safety before disaster strikes.

Don't miss out on key services like fire hosereel servicing Singapore, and choose expert providers like drakofire who have experience coupled with innovation. Book your inspection today and begin 2025 with confidence, compliance, and maximum protection.

Because prevention is the most important thing when it comes to fire safety. Invest wisely, inspect frequently, and protect in advance.

0 notes

Text

Top 5 Things to Consider Before Buying Steel in Bulk in Pune

Buying steel in bulk is a critical decision for construction, fabrication, infrastructure, and industrial manufacturing businesses. The choice impacts not only your project's cost and timeline but also the overall structural integrity of your work. With several steel suppliers, stockists, and dealers in Pune, it's essential to know what to look for before placing a large order.

Whether you're based in Bhosari, Chakan, Rajgurunagar, Talegoan, Ranjangaon, Pirangut, Hadapsar, or Pimpri Chinchwad (PCMC), choosing the right steel provider can make all the difference.

Here's a comprehensive guide to help you make an informed decision, especially if you're looking to partner with a top steel supplier in Pune

✅ 1. Steel Grade & Quality Certification

The first and most important factor is the grade and quality of the steel. Different applications demand specific steel types - mild steel (MS) plates, TMT bars, or hot and cold rolled sheets. Using the wrong grade can lead to structural issues or failure in machinery.

Always confirm:

The grade matches your application needs

The supplier provides test certificates and quality assurance documents

Steel conforms to IS standards or other required compliance norms

At Anucool Industrial Aids, all products are sourced from verified manufacturers and delivered with proper documentation, ensuring you get what you pay.

✅ 2. Supplier Reputation and Industry Experience

Not all dealers offer the same reliability in Pune's competitive steel market. Reputation matters, especially when you're sourcing large quantities.

Look for:

A supplier with years of experience and market presence

Positive customer feedback

Consistency in delivery and service

Anucool Industrial Aids Pvt. Ltd., with its long-standing presence across Pune's industrial zones—including Chakan, Hadapsar, and Ranjangaon—is known for dependable service and transparent dealings.

✅ 3. Pricing and Bulk Order Flexibility

Steel prices can fluctuate, so working with a supplier who offers competitive rates and price transparency is essential. When buying in bulk, small differences in cost can significantly impact your budget.

Check for:

Bulk pricing options

Possibility of negotiated rates

Delivery charges and credit terms

Anucool offers fair pricing structures, with volume-based discounts and flexible payment options, for large clients in PCMC, Pirangut, and other nearby regions.

✅ 4. Logistics, Stock Availability & Delivery Timeline

Delays in material supply can hold up entire projects. Before finalising a bulk order, ensure the supplier has:

Adequate stock in hand

Logistics setup for your location (e.g., Bhosari MIDC or Talegoan)

Commitment to delivery timelines

Anucool maintains a well-stocked inventory and a strong logistics network to quickly and reliably supply steel products across Pune and its surrounding industrial clusters.

✅ 5. After-Sales Support and Customisation Options

Bulk orders often have unique requirements, such as cut-to-size sheets, custom lengths, or coated finishes. A professional supplier should be able to support post-order services and handle special requests.

Choose a steel provider or retailer who offers:

Material customisation

Packaging and handling support

Responsive customer service for queries or issues

Anucool ensures clients receive complete support before, during, and after purchase—whether at a fabrication shop in Rajgurunagar or a construction site in Pirangut.

🔚 Conclusion

Buying steel in bulk is more than just placing an order—it's a strategic business move. Evaluating the right factors, such as quality, reputation, pricing, logistics, and support services, ensures your project runs smoothly from start to finish.

For businesses across Pune, including Bhosari, Chakan, Talegoan, Hadapsar, and PCMC, Anucool Industrial Aids Pvt. Ltd. stands as a trusted partner in steel supply—providing quality materials, timely service, and honest pricing.

Explore bulk steel solutions now at https://anucool.co.in

Contact Anucool for expert assistance with your next project.

0 notes

Text

A Complete Guide to DevOps Consulting Services: Benefits, Process & Tools

Introduction

In this new digital marketplace with cut throat competition, enterprises are being pressured to produce, test and deliver software at the speed of light. Maintaining this velocity and still meeting an elevated bar for quality is probably the greatest challenge. This is the point where our DevOps Consulting Services come in.

Tools DevOps is more than tools, but tools are part of the equation. It’s a technical culture shift, a cultural convergence of development and operations. By investing in standardization processes, creating a culture of shared collaboration, and focusing on this data at every stage of the software development lifecycle, organizations that adopt a DevOps model will automate workflows, improve collaboration and ultimately deliver software faster, continuously and more reliably.

Whether you’re a new startup or an international corporation, understanding DevOps services and solutions is essential. This ultimate guide will introduce you to everything you need to know about DevOps consulting, including exactly what it is, why it’s important, how it works, what tools are used, and so much more with a specific focus on Azure DevOps Consulting Services.

What are DevOps Consulting Services.

These are hands-on, professional services delivered by seasoned DevOps practitioners to help an organization develop a customized strategy for adopting and scaling DevOps practices throughout the entire software development lifecycle.

Setting up DevOps processes and tools

Improving collaboration between development and operations teams

Automating software deployment pipelines

Enhancing monitoring, security, and testing workflows

A great DevOps consulting partner provides the custom solutions that best fit your larger enterprise objectives, current infrastructure and team skillsets.

Why DevOps Matters Today

At the same time I’m a developer out in the real world, creating code in an ecosystem where development is being forced to continue raising the bar on agility, code quality and delivery speed. Upon internal discovery it turned out that legacy development practices had developed silos between dev and ops teams resulting in longer releases and increased bugs.

At the heart of it, DevOps unifies development (Dev) and operations (Ops). Add enhanced discoverability and greater help in driving automation at scale, and you’ll find that DevOps speeds your organization’s path from planning to deploying much more quickly and efficiently

Benefits Of Receiving DevOps Consulting Services:

Faster Time to Market Automated CI/CD pipelines reduce development cycles.

Improved Product Quality Continuous testing and monitoring reduce bugs and system failures.

Enhanced Collaboration

Teams work together using shared goals, tools, and workflows.

Scalability and Flexibility Systems can easily scale with demand using cloud platforms like Azure.

Cost Savings Potential Automation makes it possible to go beyond reducing the burden of manual labor, moving so much more content through the pipeline, and at the speed and impact of real-time.

Key Features of DevOps Services and Solutions

A comprehensive DevOps services and solutions package typically includes:

Infrastructure automation at a huge scale through code.

Continuous Integration/Continuous Deployment (CI/CD): Automatically testing and releasing code changes..

Monitoring & Logging: Tracking system performance and errors in real time.

One-click, worry-free deployment to any cloud: public or private across Azure, AWS, or Google Cloud.

Security Integration (DevSecOps): Ensuring security checks are part of the development lifecycle.

Who Is DevOps Consulting Services For?

Continuous development, integration, delivery and deployment may have become big buzzwords among tech giants, but DevOps is not restricted to them. Any organization that develops or manages software is an ideal candidate for DevOps Consulting Services, such as:

Startups needing to deploy quickly with limited resources

Large enterprises managing complex systems and multiple teams

E-commerce platforms that need high uptime and frequent updates

Healthcare and finance sectors with strict compliance needs

Azure DevOps Consulting Services

Microsoft’s Azure DevOps is a cloud-based platform that offers a complete solution of integrated tools that allow teams to plan, develop, test and deliver software. From plan to code to build, test, and release, it supports the complete DevOps lifecycle.

Azure DevOps Consulting Services Unlock value.. These services typically include:

Setting up Azure Repos (version control)

Configuring Azure Pipelines (CI/CD automation)

Integrating Azure Test Plans (manual and automated testing)

Managing projects with Azure Boards (work tracking)

Monitoring with Azure Application Insights

Benefits of Azure DevOps Consulting:

Seamless Microsoft Ecosystem Integration Ideal for businesses already using Microsoft 365 or Azure Cloud.

Scalable for All Team Sizes Azure supports small teams to enterprise-scale DevOps operations.

Enhanced Security and Compliance In-built security controls ensure data protection.

Global Availability Azure’s global infrastructure supports multi-region deployment.

Step-by-Step DevOps Consulting Process

Here’s how a DevOps consulting company typically approaches a project:

1. Initial Assessment

Consultants analyze your current development processes, tools, and team structures.

2. Strategy Development

A roadmap is created to implement DevOps practices aligned with business goals.

3. Toolchain Selection

Consultants choose the best tools — often including Azure DevOps services and solutions — to match your infrastructure.

4. Implementation

Automation pipelines, cloud environments, and monitoring systems are set up.

5. Team Training

DevOps experts train your team on new processes and tools.

6. Monitoring and Optimizing

Ongoing support helps in closely analyzing the performance, scalability, and security of the project at hand.

Tools That Are Mostly Used: DevOps Consulting

Here are some commonly recommended tools by DevOps consultants:

Category

Tool Examples

Version Control

Git, GitHub, Azure Repos

CI/CD Pipelines

Jenkins, Azure Pipelines, GitLab CI/CD

Infrastructure

Terraform, Ansible, ARM Templates

Monitoring

Prometheus, Grafana, Azure Monitor

Containers

Docker, Kubernetes, Azure Kubernetes Service (AKS)

Testing

Selenium, Postman, Azure Test Plans

Challenges DevOps Consulting Services Help Overcome

Without expert help, businesses may face the following hurdles:

Poor collaboration between teams

Delayed deployments due to manual processes

Inconsistent environments across development and production

Security gaps in application lifecycle

Tool integration complexity

By letting an experienced and trustworthy DevOps consulting partner run your project, you can rest assured that all these challenges will be addressed efficiently and in a cost-effective manner.

Here’s why Azure is the smart choice

Relatedly connected to smart cities, smart roads and AVs Microsoft Azure is the global leader in commercial cloud computing service.. With Azure, DevOps becomes even more powerful thanks to:

High availability and scalability

Native integration with Azure DevOps tools

Enterprise-grade security and compliance

Flexibility to run hybrid cloud solutions

Azure DevOps Consulting Services are ideal for enterprises and their digital transformation efforts where the need for speed does not mean that they have to sacrifice governance and quality.

DevOps Best Practices for Beginners

Here are some best practices recommended by DevOps consultants:

Start Small and Scale Begin with one project and gradually expand DevOps across teams.

Automate Everything From code testing to deployment, automation is key.

Adopt Continuous Feedback Use monitoring tools to continuously improve the system.

Secure Early Incorporate security checks from the beginning (DevSecOps).

Promote a DevOps Culture Encourage transparency, communication, and shared responsibility.

Future of DevOps Consulting Services

The DevOps landscape is evolving rapidly with trends like:

AI and Machine Learning Integration

Edge Computing and IoT DevOps

Serverless Architectures

DevSecOps for Integrated Security

Platform Engineering as a Service

Early adoption of DevOps Services and Solutions will help Companies to evolve and take control of their markets

Conclusion

Whatever your position is within the sphere of DevOps, with aim to make the most out of any pipeline set, DevOps Consulting Services will be able to bestow a good deal of value. With the right tools, strategies, and assistance-aided by services like Azure DevOps Consulting Services- your business could secure faster releases, better software quality, and higher operational efficiency.

By partnering with a reputed DevOps consulting company you have guaranteed expert support deliberately designed and implemented to solve your problems. Solutions are provided that streamline operations and make up for shortfalls so your teams can continuously deliver value.

Call to Action

Ready to modernize your software delivery process? Explore our expert DevOps Consulting Services today and take the first step toward faster, smarter, and more secure software development.

Know More:- https://www.bloomcs.com/contact-us/

0 notes

Text

Fulfilment USA: Insider Tips to Avoid Shipping Disasters

Navigating fulfilment USA requires strategic precision, deep logistical awareness, and partnerships that scale with your business needs. With the ever-expanding eCommerce boom and rising consumer expectations, brands cannot afford missteps in shipping and delivery. Delays, misrouted packages, and inventory inaccuracies can crush customer trust and damage your bottom line.

Choose the Right Fulfilment Partner

The backbone of successful fulfilment is a reliable fulfilment partner. It’s not just about finding a warehouse; it’s about selecting a strategic logistics partner that understands your brand, customer expectations, and growth plans.

Key features to look for in a USA fulfilment partner:

Nationwide warehouse locations to reduce shipping zones and cut delivery times.

Real-time inventory management systems that integrate with your sales channels.

Transparent pricing with no hidden fees.

Scalability to accommodate seasonal spikes and business growth.

Returns processing and reverse logistics efficiency.

Optimize Inventory Management for Accuracy

Inaccurate inventory records lead to overselling, stockouts, and ultimately customer dissatisfaction. Proper inventory control is crucial for fulfilment success.

Best practices include:

Automated inventory tracking systems that sync with your online store.

ABC inventory analysis to prioritize high-value stock for frequent cycle counts.

Just-in-time (JIT) practices for products with predictable demand.

Dedicated fulfilment center zones for high-turnover items.

Use Distributed Warehousing to Reduce Shipping Times

Speed is non-negotiable. Distributed warehousing allows you to store inventory closer to your customers across multiple strategic locations, significantly cutting delivery time and shipping costs.

Benefits of distributed fulfilment:

Faster delivery windows (1-2 days in most regions).

Lower shipping costs due to fewer zones.

Improved customer satisfaction and retention.

Greater flexibility to serve diverse geographic markets.

Avoid Common Shipping Disasters

Shipping errors are often preventable. Understanding common pitfalls and proactively building safeguards into your logistics system is essential.

Common fulfilment failures and how to avoid them:

Incorrect packaging: Use the right box size, fillers, and labels. Automate packaging when possible.

Shipping wrong items: Implement barcode scanning during picking and packing.

Missed delivery deadlines: Work with carriers that guarantee delivery times and monitor carrier performance.

Inadequate return process: Provide clear instructions, pre-printed labels, and fast refunds.

Leverage Technology to Streamline Fulfilment

Modern fulfilment depends on tech-driven automation and real-time visibility.

Top fulfilment tech tools:

Order Management Systems (OMS): Centralize and streamline order processing.

Warehouse Management Systems (WMS): Automate inventory, picking, and shipping processes.

Shipping rate calculators: Dynamically choose the best carrier based on price and time.

Tracking and notification systems: Keep customers informed throughout the process.

Ensure Compliance with Shipping Regulations

Shipping within the USA still requires strict adherence to regulations, especially for specific product categories.

Key considerations include:

Hazardous materials regulations by the Department of Transportation (DOT).

State-specific tax compliance and nexus management.

Customs paperwork for cross-border shipments to Canada or Mexico.

Proper product labeling for perishables or age-restricted goods.

Prioritize Returns Management

The reality of eCommerce is that returns are inevitable. A smooth reverse logistics process can enhance brand loyalty and encourage repeat purchases.

Return best practices:

Pre-authorized return labels included in the shipment.

Clear return policy visible on product and checkout pages.

Fast refunds or store credit issuance.

Refurbishing or re-stocking workflow to minimize losses.

Partner with Third-Party Logistics (3PL) Providers for Growth

Scaling your eCommerce business often requires handing over operations to a 3PL provider that specializes in fulfilment.

What to expect from a quality 3PL:

Customized fulfilment workflows

Omnichannel order management

Fast onboarding and integration

Advanced reporting tools

Dedicated account managers

Outsourcing to the right 3PL can allow your brand to focus on marketing, product development, and customer engagement while leaving logistics to the experts.

Avoiding fulfilment disasters in the USA demands a strategic, tech-powered, and customer-focused approach. From choosing the right partners to leveraging automation, inventory planning, and performance monitoring—every decision can impact delivery speed, cost, and customer retention.

For original post visit: https://dailystorypro.com/fulfilment-usa-insider-tips-to-avoid-shipping-disasters/

0 notes

Text

Trusted Siemens Service Center in Dubai – Certified Technicians & Same-Day Repairs

If you’re searching for a reliable Siemens service center in Dubai, you’ve landed at the right place. At Siemens Service Center Dubai, we specialize in fast, professional repairs for all Siemens home appliances — including washing machines, refrigerators, dishwashers, ovens, cooking ranges, and washer-dryers.

Whether your Siemens appliance is making unusual noises, displaying an error, or not functioning at all, our certified technicians are just a call away. We bring you top-rated repair services with genuine parts, transparent pricing, and same-day availability across all areas of Dubai.

🔧 Learn more or book your repair service here: 👉 https://siemensservicecenter.co/siemens-service-center-dubai/

Why We’re Dubai’s Top Choice for Siemens Appliance Repair

Your Siemens appliances are a major investment — and they deserve expert care. Here's why thousands of Dubai residents trust us with their appliance repairs:

✅ Certified Siemens Technicians – Our team is trained and experienced in repairing all Siemens models. ✅ Original Spare Parts Only – We use only genuine Siemens components to ensure long-lasting performance. ✅ Same-Day Repair Service – We respond quickly and aim to complete most repairs in one visit. ✅ Honest Pricing – No hidden fees. You get a full quote before any work begins. ✅ All Dubai Areas Covered – From Downtown to Jumeirah, Dubai Marina to Deira, we come to you.

Our Siemens Repair Services in Dubai

We offer complete diagnostics and repairs for the following appliances:

���� Siemens Washing Machine Repair

From water leakage to spin failures, we fix all major and minor issues efficiently.

🧼 Siemens Dishwasher Repair

If your dishwasher is leaking, not cleaning properly, or won’t start — we’ll fix it on the spot.

❄️ Siemens Fridge & Freezer Repair

We handle cooling issues, strange noises, thermostat problems, and more for all refrigerator models.

🔥 Siemens Cooking Range & Oven Repair

Whether it’s a gas burner not igniting or an oven that won't heat, we repair it safely and fast.

👕 Siemens Washer Dryer Combo Repair

We troubleshoot dual-function units that stop drying, display error codes, or won’t complete cycles.

⚙️ Siemens Built-in Appliances Repair

We also service Siemens built-in hobs, extractor fans, and other integrated appliances.

Simple, Hassle-Free Repair Process

We’ve made our process as smooth and transparent as possible:

Book an Appointment – Schedule online or call us directly.

On-Site Visit – Our technician arrives promptly and diagnoses the issue.

Transparent Quotation – You receive a clear cost estimate before we start.

Instant Repairs – Most problems are fixed the same day using stocked parts.

Post-Repair Testing – We run full diagnostics to ensure everything works perfectly.

Service Areas Across Dubai

No matter where you live or work in Dubai, our team can reach you quickly:

Dubai Marina

Downtown Dubai

Jumeirah

Al Barsha

Business Bay

Mirdif

Deira

Silicon Oasis

Arabian Ranches …and all surrounding neighborhoods.

The Importance of Professional Siemens Appliance Repair

While DIY fixes or general technicians may seem cheaper, they often cause more damage and void warranties. Our authorized Siemens service technicians in Dubai ensure your appliance is repaired correctly and safely the first time.

We also offer maintenance advice and servicing packages to extend the life of your Siemens appliances and keep them running like new.

Book Your Siemens Repair in Dubai Today!

Ready to restore your Siemens appliance to full performance? Our trusted team at Siemens Service Center Dubai is ready to help with expert diagnostics, same-day service, and exceptional customer care.

🌐 Learn more or book a visit online: 👉 https://siemensservicecenter.co/siemens-service-center-dubai/

#SiemensServiceCenterDubai#SiemensRepairDubai#HomeApplianceRepairDubai#SiemensTechnicianUAE#ApplianceRepairExperts#SameDayRepairDubai

0 notes

Text

The Why and How of Seamless Integration of Packaging Artwork Automation with Existing Systems

Introduction

Integrating packaging artwork automation with existing systems is critical to enhancing operational efficiency, ensuring automatic data transfer between systems, and minimizing manual efforts and errors.

Robust integration ensures that all teams—such as marketing, compliance, and production—work with the most current and accurate version of packaging artwork, facilitating better collaboration and alignment. By streamlining complex workflows and ensuring a unified repository of artwork copy, organizations can ensure faster approvals and quicker time-to-market.

Introduction to the Importance of Integration

Integrating packaging artwork automation with existing systems is critical to enhancing collaboration, ensuring seamless data flow, and eliminating the need to key in data already available in other systems. With proper integration, organizations

Synchronize artwork-related data across departments and external partners in real-time, fostering better communication and collaboration and ensuring everyone works with the latest artwork copy.

Eliminate manual data entry across multiple systems, reducing the time (and costs) to design, approve, and release artwork and bringing high-quality products to the market.

Simplify data flow by creating seamless connections between design, production, and approval processes, eliminating data silos, and ensuring stakeholders are aligned and working with the same version of artwork.

Reduce errors and risks of using outdated or incorrect artwork by ensuring all systems and stakeholders work on approved artwork copies, thus minimizing delays, reworks, and recalls.

Understanding the Various Integrations

Understanding the Various Integrations

The packaging artwork lifecycle is long and complex, with several players and systems in the ecosystem. Unlocking excellence and going live faster requires organizations to stop operating in silos and start building a unified packaging artwork ecosystem. This is possible only when all the tools and systems within the businesses are properly and continuously integrated.

Let’s look at some of these integrations that are key to enabling better collaboration, driving efficiency, and helping you get to market faster.

Product codes: Integrating packaging artwork automation with the ERP system can help pull the relevant codes available within the ERP. Teams can reuse these codes within their packaging artwork automation system to track and manage products, maintain brand consistency, and ensure compliance.

Packaging and labeling inventory: Packaging designs are updated every 12-18 months in the CPG industry. Failure to check the inventory level of existing labels before ordering the print for the new artwork design often leads to discarded printed packaging material. Integrating artwork automation with packaging and labeling inventory can help provide much-needed insight into the current label inventory. This enables teams to make decisions related to launch date and existing inventory use, preventing wastage.

Vendor POs: When print vendor purchase orders are released from an ERP system, vendors must provide proofs and printed material. Integrating the ERP system with the artwork approval process guarantees that the final approved artwork reaches the vendor on time, minimizing delays and disruptions and alleviating stress for everyone involved.

PLM: When new products are introduced, the PLM system records crucial product information like ingredients, nutrition facts, allergens, etc. Robust integration can enable the packaging artwork automation system to pull this data from the PLM and reuse it. This can help centralize data, streamline workflows, and improve team collaboration, ensuring a single source of truth for artwork assets.

PIM: Once the pack copy is approved and artwork designed, PIM integration ensures vital copy information is transmitted to PIM systems. This enables online retailers and the broader company ecosystem to access accurate and up-to-date artwork, minimizing errors and the time spent on revisions. Additionally, PIM integration helps maintain compliance with branding guidelines and regulatory requirements by offering a complete view of all assets, ultimately enhancing the speed and effectiveness of product launches.

QMS: Quality is crucial in the packaging artwork lifecycle. Integrating with Quality Management Systems (QMS) allows artwork revisions initiated through QMS to automatically trigger a change process within the packaging artwork automation system. This integration facilitates the efficient sharing of change control numbers and other vital details between the systems. Additionally, it minimizes errors and accelerates the approval process, ultimately enhancing overall artwork quality, customer satisfaction, and brand loyalty.

eCommerce: By integrating packaging artwork automation with eCommerce systems, product updates can be automatically synchronized across all platforms, allowing for data export in any desired format. Such integration helps ensure that product data is accurate and up to date, leading to increased sales and reduced risk.

Streamlining Integration of Packaging Artwork Automation with Existing Systems

Integrating packaging artwork with existing Line of Business (LOB) applications is essential for achieving operational excellence. If you want to enable seamless integration across your PLM, ERP, QMS, and PIM systems and establish real-time, accurate data flows effortlessly, here are some tips to embrace:

Assess the current IT landscape to thoroughly understand the different systems within your business and how they will interface with the packaging artwork automation system.

Identify integration gaps and challenges early on and take necessary action to overcome hurdles, such as data silos, legacy systems, resource constraints, etc.

Define clear goals for automation while prioritizing objectives, defining success metrics, documenting processes, and communicating clearly.

Choose the right automation tools to streamline digital asset management and offer a single source of truth for all packaging-related decisions – thus getting to print faster.

Invest in APIs and add-ons to plug and play and extend the packaging artwork automation system to other tools and systems integrated into the ecosystem as business needs grow.

Ensure data quality and consistency across the packaging artwork lifecycle to deliver high-quality packaging and maintain brand reputation and compliance.

Enable change management and audit trails to track and ensure all changes made to packaging content and artwork review follow a structured approach, minimize resistance among employees, and ensure transparency and accountability.

Train users on how best to leverage the integrated ecosystem of multiple tools and address concerns as they arise.

Monitor the performance of integrated systems, track data flow, and identify bottlenecks in time to maintain high operational efficiency.

Transform Integration with ManageArtworks

ManageArtworks connects all stakeholders into an automated workflow, empowering them with modern proofing and approval tools. Integrating seamlessly with ERP, PIM, PLM, and QMS systems, ManageArtworks offers end-to-end visibility and transparency into the artwork management lifecycle. Additionally, real-time approval request tracking, audit trails, and dashboards allow companies to release error-free packaging artwork consistently with minimal effort.

Are you ready to transform packaging artwork management? Contact our experts to get started today!

0 notes

Text

From Code to Cloud: End-to-End Automation with CI/CD and IaC

Modern software development demands speed, reliability, and repeatability. Organizations aiming to fully leverage cloud computing must go beyond just migrating applications—they must automate the entire lifecycle, from writing code to deploying it in the cloud.

Two key practices make this possible: CI/CD (Continuous Integration and Continuous Deployment) and Infrastructure as Code (IaC). When combined, they provide an end-to-end automation framework that accelerates delivery while ensuring consistency and control.

In this post, we’ll explore how CI/CD and IaC work together to turn your development workflow into a streamlined, automated engine that takes your code seamlessly to the cloud.

Understanding CI/CD and IaC

What is CI/CD?

Continuous Integration is the practice of automatically integrating code changes into a shared repository, running tests to detect errors early. Continuous Deployment takes it further by automatically deploying tested code to production environments.

Benefits:

Faster and safer deployments

Reduced manual errors

Immediate feedback on code quality

Shorter time to market

What is Infrastructure as Code (IaC)?

Infrastructure as Code is the process of managing cloud infrastructure using code instead of manual provisioning. Tools like Terraform, AWS CloudFormation, and Pulumi allow teams to write, version, and deploy infrastructure configurations just like application code.

Benefits:

Environment consistency

Version control and change tracking

Faster provisioning and recovery

Improved collaboration between dev and ops

Why Combine CI/CD and IaC?

When CI/CD pipelines are integrated with Infrastructure as Code, the result is end-to-end automation—from code changes to infrastructure setup and deployment. This combination ensures:

Every environment is created exactly the same way

Code and infrastructure changes go through the same review and testing process

Deployments are consistent, secure, and repeatable

Real-World Example of Code-to-Cloud Automation

Let’s look at a typical workflow:

A developer pushes code and infrastructure configuration files to a Git repository.

A CI pipeline triggers:

Runs unit tests and static analysis

Lints and validates infrastructure templates

Packages the application

If tests pass, a CD pipeline triggers:

Applies infrastructure changes using Terraform

Deploys the new application build

Runs post-deployment tests

Sends notifications to the team

This approach means no manual steps are required—from writing the code to having it live in production.

Benefits of End-to-End Automation

1. Speed

CI/CD with IaC shortens the release cycle dramatically. Teams can deploy updates several times a day with minimal friction.

2. Scalability

IaC enables infrastructure to scale dynamically as needed. CI/CD ensures that changes scale alongside applications.

3. Security and Compliance

Automated pipelines can integrate security scans, secrets management, and compliance checks early in the lifecycle (a practice known as Shift Left Security).

4. Cost Efficiency

Resources are provisioned and deprovisioned automatically, reducing idle time and waste. Plus, errors are caught early, preventing costly downtime.

5. Resilience

Because infrastructure is version-controlled, it can be rebuilt quickly in case of failure. Teams can roll back to previous versions of both code and infrastructure with confidence.

How Salzen Cloud Delivers Code-to-Cloud Automation

At Salzen Cloud, we help businesses design, implement, and scale CI/CD + IaC workflows tailored to their cloud strategy. Our services include:

CI/CD pipeline setup using tools like GitHub Actions, GitLab CI, Jenkins

Infrastructure as Code with Terraform, AWS CDK, and more

Automated testing, monitoring, and security integration

Training teams on DevOps best practices

We recently worked with a SaaS company to rebuild their deployment process from scratch. The result? Deployment times reduced by 85%, infrastructure provisioning went from hours to minutes, and incident frequency dropped by half.

Best Practices to Get Started

Start with version control: Keep all code and infrastructure in Git

Use modular IaC: Create reusable and testable components

Integrate early testing: Catch issues before they reach production

Automate rollback: Always have a safe path back in case of failure

Monitor everything: Set up real-time alerts and dashboards

Final Thoughts

CI/CD and IaC are no longer optional—they’re the foundation of modern cloud-native operations. Together, they empower development teams to move fast, stay secure, and deliver value continuously.

If you’re ready to transform your development workflow and go from code to cloud seamlessly, reach out to Salzen Cloud. Our team can help architect a solution that scales with your business and accelerates innovation.

0 notes

Text

Debugging Full Stack Apps: Common Pitfalls and Fixes

If you’ve ever stared at your code wondering why nothing works—while everything looks fine—you’re not alone. Debugging Full Stack Apps: Common Pitfalls and Fixes is something every full stack developer becomes intimately familiar with, usually the hard way. Debugging can feel like detective work: sifting through clues, spotting red herrings, and slowly putting the pieces together.

Whether you’re knee-deep in React components or wrangling with PostgreSQL queries, bugs don’t discriminate. They can lurk in the front end, back end, or anywhere in between.

Here’s a look at common pitfalls when debugging full stack apps—and practical ways to fix them.

1. Miscommunication Between Front End and Back End

One of the most common issues arises from how the front end communicates with the back end. Sometimes, they seem to speak different languages.

Common Symptoms:

API calls returning unexpected results (or nothing at all)

Mismatched data formats (e.g., sending a string where the server expects a number)

CORS errors that mysteriously appear during deployment

Fixes:

Always double-check your request headers and response formats.

Use tools like Postman or Insomnia to simulate API requests separately from your front-end code.

Implement consistent API response structures across endpoints.

As a full stack developer, ensuring clean contracts between layers is essential. Don’t assume—it’s better to over-communicate between parts of your app than to be left scratching your head at 2 AM.

2. Version Mismatches and Package Conflicts

Let’s face it: dependency hell is real.

Common Symptoms:

Front-end not rendering after an npm install

Server crashing due to deprecated methods

Mysterious breaking changes after updating a package

Fixes:

Lock dependencies using a package-lock.json or yarn.lock file.

Regularly audit your packages with tools like npm audit or yarn audit.

Avoid updating all dependencies at once—do it incrementally and test thoroughly.

Even the most seasoned full stack developer gets tripped up here. Being methodical with updates and isolating changes can save you hours of frustration.

3. State Management Gone Wrong

If your app behaves inconsistently, the problem might be state management.

Common Symptoms:

UI doesn’t reflect expected changes

Data seems to "disappear" or update out of sync

Components re-render unnecessarily

Fixes:

Use debugging tools like Redux DevTools or Vuex Inspector to trace changes.

Store only essential data in global state—leave UI state local whenever possible.

Be cautious with asynchronous operations that update state (e.g., API calls).

Mastering state is part art, part science. As a full stack developer, understanding both front-end and back-end data flow is key to smooth state management.

4. Overlooking Server Logs and Console Errors

It’s easy to jump straight into the code—but logs often contain the breadcrumbs you need.

Common Symptoms:

500 errors with no clear origin

"Something went wrong" messages with no context

App crashing without traceable bugs

Fixes:

Always monitor the back-end logs (use console.log, but also tools like Winston or Log4js for structured logging).

Use browser developer tools to inspect network requests and console outputs.

Integrate error-tracking tools like Sentry or LogRocket.

A skilled full stack developer knows that logs are like black box recorders for your app—ignore them at your own peril.

5. Deployment-Specific Bugs

Your app runs perfectly locally—but breaks in production. Sound familiar?

Common Symptoms:

Missing environment variables

Static assets not loading

Database connection failures post-deployment

Fixes:

Use .env files carefully and securely manage environment-specific configs.

Ensure your build process includes all required assets.

Test your deployment process using staging environments before going live.

Every full stack developer eventually realizes: what works in dev doesn’t always work in prod. Always test in conditions that mimic your live environment.

Final Thoughts

Debugging Full Stack Apps: Common Pitfalls and Fixes isn’t just about technical skills—it’s about mindset. It’s easy to get overwhelmed when something breaks, but remember: every bug you squash teaches you something new.

Here are some golden rules to live by:

Reproduce the bug consistently before trying to fix it.

Break down the problem layer by layer.

Ask for a second pair of eyes—sometimes, fresh perspective is all it takes.

Being a full stack developer is like being a bridge-builder—you connect front end and back end, logic and interface, user and server. And in between, debugging is your glue.

So next time you hit a wall, take a breath, grab a coffee, and dig in. You’ve got this.

#FullStackDeveloper#FullStackDevelopment#FullStackCourse#TechnoBridgeFullStack#LearnFullStack#FullStackTraining#MERNStack#FrontendDevelopment#BackendDevelopment#CareerInTech#CodingBootcamp#SoftwareDevelopmentCourse#TopFullStackDeveloperCourse#PlacementAssistance#JobOrientedCourse#UpskillNow#ReactJS#ITTrainingIndia

0 notes

Text

How High-Quality Luer Caps Improve Infection Control and Device Integrity Worldwide

In the global medical device industry, safety, sterility, and performance are critical at every stage—from production to patient application. Among the many components that contribute to these standards, luer cap play a vital yet often overlooked role. Whether in disposable infusion sets, syringes, or hypodermic needle assemblies, the use of high-quality Luer caps significantly enhances both infection control and device integrity.

As a manufacturer and supplier of medical components such as drip chambers, Luer lock connectors, Y injection sites, roller clamps, and protective caps, understanding and delivering the best possible Luer cap design is key to standing out in competitive global markets.

What Are Luer Caps?

Luer caps are small, precisely engineered closures designed to fit onto Luer lock and Luer slip connectors. They are used to seal open ends of IV lines, syringes, and other disposable medical devices, protecting the internal pathway from contaminants and maintaining sterility until use.

There are typically two types of Luer caps:

Male Luer caps (seal female Luer connectors)

Female Luer caps (seal male Luer connectors)

These caps are made of medical-grade polypropylene or polyethylene, offering biocompatibility and compatibility with various sterilization methods.

The Crucial Role of Luer Caps in Infection Control

Infection control is a top priority in all healthcare environments. With the increasing threat of hospital-acquired infections (HAIs) and antibiotic-resistant bacteria, even the smallest component, such as a Luer cap, can be a front-line defense tool.

Here’s how high-quality Luer caps improve infection prevention:

1. Sealing Against Airborne Contaminants

Luer caps provide an airtight seal that prevents bacteria, viruses, and airborne particles from entering critical pathways such as IV lines and syringes. This protection is essential during storage, handling, and patient transport.

2. Prevention of Fluid Backflow and Leakage

Inferior caps can allow micro-leaks or backflow, which increases the risk of contamination. A precision-engineered Luer cap maintains a secure, leak-free seal, ensuring device sterility is preserved until the moment of use.

3. Single-Use, Sterile Packaging Options

High-quality Luer caps are often available in sterile, single-use packaging that complies with ISO 13485 and other international standards, further reducing the risk of cross-contamination between procedures or patients.

Device Integrity: Preserved and Protected

Maintaining the mechanical and functional integrity of medical devices is crucial for proper treatment outcomes and regulatory compliance. Luer caps support this by:

1. Preventing Physical Damage

Caps protect the delicate male or female Luer threads and tips from physical damage during transportation, storage, and handling. A deformed Luer connector can result in poor fits, leakage, or device failure.

2. Compatibility With Sterilization Processes

High-quality Luer caps are designed to withstand ETO gas, gamma radiation, or steam sterilization, ensuring that they maintain structural integrity without warping, cracking, or releasing harmful substances.

3. Extended Shelf Life

By sealing off exposure to moisture, dust, and other environmental hazards, these caps help medical products maintain their integrity and shelf life—especially critical for worldwide distribution across varying climates.

Global Impact and Regulatory Importance

For international distributors and healthcare providers, product quality and safety are not only clinical concerns but also regulatory requirements. Markets in the United States (FDA), Europe (CE marking), and Latin America (ANVISA, INVIMA, etc.) require strict adherence to manufacturing standards.

High-quality Luer caps:

Help meet ISO 80369 and ISO 13485 standards for small-bore connectors

Ensure tamper-evidence and traceability

Reduce product returns and enhance customer satisfaction

By integrating top-tier Luer caps into their product lines, global distributors can offer safer, more reliable devices that meet or exceed regulatory expectations.

Why Choose Our Luer Caps?

At [Your Company Name], we manufacture a comprehensive range of medical components, including precision-engineered Luer caps for male and female connectors. Our caps are:

Made with medical-grade materials

Compatible with all Luer lock and Luer slip systems

Available in sterile or bulk packaging

Customizable with color coding or branding

We serve global markets, ensuring every cap meets the highest standards for sterility, performance, and durability.

Conclusion

While often considered a minor component, the Luer cap is a critical asset in the fight against infection and in preserving the functionality of medical devices. For manufacturers, distributors, and healthcare professionals alike, investing in high-quality Luer caps is a cost-effective and practical way to enhance safety and performance.

If you're a global distributor seeking reliable, certified, and competitively priced medical components, contact [Your Company Name] today to learn more about how our Luer caps and other device components can support your goals in the medical device market.

0 notes

Text

What are the Top Examples, Use Cases, And Benefits of AI in Manufacturing

The rapid evolution of technology has ushered in a new era for industries worldwide, with artificial intelligence in manufacturing leading the charge. These revolutions are revolutionizing the methods of product development and delivery and go to unheard-of levels of automation, precision and added value. Manufacturers are now integrating AI to solve problems, to foresee a breakdown, and enhance workflows.

From advanced robots to predictive maintenance, artificial intelligence-powered solutions are transforming established procedures. Examining useful applications, prominent use cases, and the many advantages AI presents to firms negotiating a more competitive market, this article explores how this technology is changing the manufacturing sector.

How does AI enhance efficiency in manufacturing?

Organization and productivity have always been the key elements in the structure of manufacturing, and AI cannot be further helpful in the process. AI harnesses significant amounts of data from machine constructs, the production line and the marketplace to discover more efficient ways of functioning.

The global AI in manufacturing market size was valued at USD 8.14 billion in 2019 and is projected to reach USD 695.16 billion by 2032. One main area where the use of AI increases productivity is in the area of predictive maintenance.

Originally, the manufacturers used only a mechanical type of preventive or corrective maintenance, which means that they could only guess when their products were going to fail or could plan for periodic maintenance checks in a timetable that might be unconnected with the actual need.

AI-based systems, on the other hand, provide constant supervision through sensor and analytics and can predict when perhaps a part in the machinery might fail. This means that damages can be effected and sorted early enough without much time being lost to equipment breakdowns hence improving on its durability.

Automation by AI Robotics also adds to efficiency through removing hardworking and repetitive tasks. For example, robots that are incorporated with AI can either build, bond, or even package products with high efficiency and accuracy.

Collaborative robots, or cobots,are designed for joint operation with employees; the concept significantly applies human creativity with robotic precision. This synergy makes it possible for manufacturers to improve productivity by enhancing quality production.

What are real-world examples of AI in manufacturing?

AI is already showing positive returns within diverse manufacturing industries. Here are some noteworthy examples:

1. Predictive maintenance

Companies like GE and Siemens are pioneers in leveraging AI for predictive maintenance. In this way, with the help of data from sensors, their AI systems can predict device failures in advance, days or even weeks. It reduces incidences of a halt on production and allows what has been planned to go on as calendar and time dictate.

2. Quality control

Nowadays, firms like BMW have implemented the use of AI-based computer vision in the production processes. These systems use some form of image recognition to pick up on abnormalities such as scratches, dents, or seemingly off alignments in most instances within milliseconds. This not only improves the quality of the product but also does away with wastages and rework charges.

3. Demand forecasting

AI is useful in demand forecasts, the foundations of which are currently being set. For instance, Unilever recently revealed it uses Artificial Intelligence Algorithms to forecast customers’ demand of their products based on previous sales records, conditions and trends. This makes it possible to achieve the right stock, to accommodate the right stock without some vices such as overstock or out of stock problems.

4. Supply chain optimization

Amazon’s supply chain success is a testament to the power of AI. The mechanisms of algorithms based on machine learning allow the e-commerce giant to enhance the control over stock, storage facilities, and delivery. This level of optimization helps to minimize operational cost whilst at the same time ensuring short order turnaround.

5. Generative design

Many aerospace companies including Airbus are now using AI in generative design. Specific requirements, including weight, strength and necessity of materials, are entered by engineers and multiple design solutions are provided by an AI. Researchers defined that an AI-optimized design is much lighter yet stronger and cheaper as compared to original designs.

How does AI improve quality and precision?

AI’s assure high quality, and its precision makes the difference for the manufacturer. The previous tools used in quality control were based on the ability of the human eye to inspect the products, this was disadvantageous because the human eye may miss some defects due to tiredness or even carelessness.

AI however is superior when it comes to checking for discrepancies compared to human beings in this case. Within the manufacturing industry, most respondents (59 percent) state that quality control is the most important use case for artificial intelligence.

Examples of AI-driven quality enhancement:

Automotive industry: Tesla has implemented AI surveillance on welds and assemblies that need accuracy as small as micrometers. This gives both structural and product qualities and hence the company’s reputation.

Pharmaceutical manufacturing: It keeps necessary checks upon the medicine production and management of dosages of various medicines so there can be no compromise on the issues of safety and effectiveness.

Apart from the elimination of defective and, therefore, non-saleable products, AI contributes effectively to the achievement of sustainable objectives by cutting unnecessary use of raw materials and energy. For instance, AI control can allow a flexible management of material consumption, guaranteeing that every amount is used optimally without any compromise of quality.

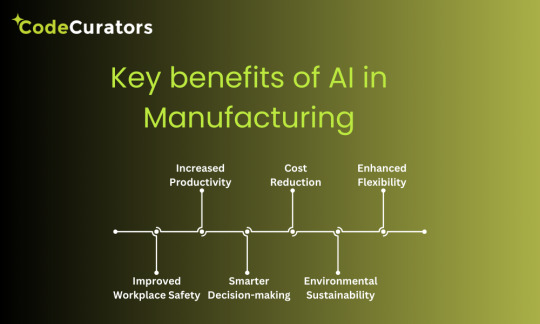

What are the key benefits of AI in manufacturing?

1. Increased productivity

AI automates repetitive procedures and thereby increases the manufacturing rate among the manufacturers. Through continuous functioning without being weary, the use of robots under the AI operations’ umbrella can help increase throughput.

2. Cost reduction

Predictive maintenance minimizes that time as well as the frequency of repairs. AI is projected to increase productivity by 40% or more in the manufacturing industry by 2035. Moreover, AI helps to save material consumption and energy as well these strategies also help in reducing expenses.

3. Enhanced flexibility

Production lines powered by artificial intelligence are incredibly flexible so the same line can produce different variations of a product and changes in market trends can easily be handled as well.

4. Improved workplace safety

AI relieves human workers of dangerous tasks that they used to perform. Hazardous work can be done by robots, and AI systems track the state of the workplace concerning safety in real-time.

5. Smarter decision-making

Real-time analytics and predictive insights let companies decide with knowledge. AI ensures optimal efficiency by helping to maximize everything from inventory levels to manufacturing schedules.

6. Environmental sustainability

Manufacturing sustainability goals are met because AI helps cut down on energy consumption and wastage. For example, skills can be used in the identification of chances of reclaiming raw materials or reducing energy use in the production process.

What challenges exist when implementing AI in manufacturing?

While the benefits are significant, implementing AI is not without challenges:

1. High initial costs

Both complex AI and the environments that support such systems are not inexpensive. The high initial cost is one of the chief concerns many manufacturing companies feel.

2. Data dependency

AI has more dependence on quality data and needs a significant quantity of data for the workspace. To provide the wrong recommendations or forecast, you need to feed the algorithm with inconsistent or inferior data quality.

3. Integration issues

Technologies based on AI can sometimes integrate with existing legacy systems with some level of difficulty and with much necessary reorganization.

4. Workforce adaptation

Workers may need retraining to collaborate with artificial intelligence systems, and change may face opposition.

To overcome these hurdles, manufacturers should consider phased AI implementation, invest in employee training, and prioritize data management.

What Is the Future of AI in Manufacturing?

The future of manufacturing will likely be defined by even deeper AI integration. Emerging trends include:

1. Collaborative robots (Cobots)

These robots will complement man in that they bring into the equation, the mechanical accuracy of a robot and the flexibility of man.

2. Edge AI

AI processing at the edges of networks will be a boon for decision making mechanisms because it will help in the localization of data processing.

3. Sustainability-Focused AI

AI will be responsible for further contributing to the right utilization of energy so as to minimize wastage in the manufacturing firms to meet environmental objectives.

4. Personalized manufacturing

AI will improve the production capacity of manufactures so as to meet the consumers’ demand for personalisation.As AI technologies evolve, their integration with other innovations like IoT, 5G, and blockchain will further revolutionize the manufacturing sector, making it more efficient, innovative, and sustainable.

Conclusion

Artificial intelligence in manufacturing has become instrumental in solving some of the oldest problems facing the industry while providing new opportunities for expansion. From improving speed and accuracy to transforming growth trajectories and enabling more sustainable practices, AI offers endless possibilities. However, despite barriers such as high costs and integration challenges, the advantages significantly outweigh the disadvantages.

The automotive sector, in particular, is gearing up to become smarter, more flexible, and better prepared for the global market as manufacturers increasingly adopt AI technology. For organizations aiming to remain at the forefront of the competitive landscape, leveraging AI in Manufacturing is no longer a luxury but an absolute necessity.

We can assist you if you are prepared to use AI to improve your manufacturing processes. For a consultation on how advanced AI technologies may boost your business’s operations, increase productivity, and promote long-term success, get in touch with us. Together, we can overcome obstacles, take advantage of fresh chances, and establish your company as a leader in the field. Are you prepared to welcome the AI-powered manufacturing of the future? Contact us right now, and together, let us make it happen.

#Evolution of technology#AI in manufacturing#AI powered solutions#benefits of AI in manufacturing#Future of AI in Manufacturing#manufacturer#software engineering

1 note

·

View note

Text

Mini Chainsaws Go Cordless: What’s New in Battery Tech