#power socket

Explore tagged Tumblr posts

Text

The Critical Role of Low Contact Resistance in Power Socket Design

Introduction

In modern power socket design, ensuring long-term electrical performance and safety is essential. One often-overlooked but technically vital factor is contact resistance—the resistance encountered where conductive surfaces meet, such as between socket terminals and inserted plugs. High contact resistance can lead to localized heating, power loss, arc discharge, and even fire hazards. This article explores how to achieve low contact resistance through proper material selection, structural design, and manufacturing quality control, with a particular focus on terminal plating materials such as silver and gold.

1. What is Contact Resistance and Why Does It Matter?

Contact resistance refers to the resistance that occurs at the interface of two conductive materials in contact. While this resistance is usually small, it becomes critical in power sockets, especially under high current or long-term load.

Consequences of high contact resistance:

Heat generation at the contact point

Oxidation and corrosion of contact surfaces

Accelerated material degradation

Increased energy loss

Risk of socket failure or fire

2. Impact of Terminal Plating Materials

Terminal materials and their surface treatments play a decisive role in determining contact resistance. Below are common plating options and their characteristics:

2.1 Silver Plating

Advantages: Extremely low contact resistance High electrical conductivity Good thermal conductivity

Disadvantages: Susceptible to surface tarnishing (silver sulfide) Not ideal for corrosive or polluted environments

Application Example: Silver-plated terminals are commonly used in industrial-grade sockets where low resistance and high conductivity are prioritized over corrosion resistance.

2.2 Gold Plating

Advantages: Excellent corrosion resistance Stable contact resistance over time High reliability in low-voltage circuits

Disadvantages: Much higher cost Slightly higher resistance compared to silver

Application Example: Gold-plated terminals are used in medical devices and precision instruments, where contact reliability and long-term oxidation resistance are critical.

2.3 Tin Plating

Advantages: Cost-effective Acceptable performance in moderate conditions

Disadvantages: Higher contact resistance Vulnerable to fretting corrosion under vibration

Application Example: Tin plating is used in consumer-grade power sockets and low-cost applications where cost outweighs performance.

3. Structural and Mechanical Design Factors

Achieving low contact resistance is not only about materials. Mechanical design directly impacts how the contact force is distributed, which in turn affects resistance.

3.1 Contact Pressure

Higher contact pressure helps:

Break through oxide layers

Increase true contact area

Reduce micro-gap resistance

However, excessive pressure may lead to:

Mechanical fatigue

Plug insertion difficulty

Material deformation

Optimization Tip: Use spring-loaded or elastic contact structures to maintain consistent pressure without deformation.

3.2 Contact Surface Area

Larger surface area = lower resistance, assuming good contact. However:

Must be carefully balanced with size constraints

Too large may increase insertion force or reduce structural strength

3.3 Insertion-Extraction Cycle Design

Wear and oxidation occur over time. A well-designed socket:

Maintains low resistance after 5000–10000 plug-in cycles

Uses self-cleaning contact surfaces to remove oxide layers

4. Environmental Resistance and Surface Treatments

Environmental factors like humidity, dust, and chemical pollutants impact contact performance.

Protective strategies include:

Applying corrosion-resistant coatings

Using sealing structures to block contaminants

Designing moisture-drainage channels in sockets used outdoors or in humid areas

Example: Outdoor-grade sockets often use silver-nickel composite plating and sealed terminal chambers to combat corrosion and moisture.

5. Manufacturing and Quality Control

Even with ideal materials and design, manufacturing consistency is key to low contact resistance.

Critical quality control steps:

Surface roughness control of contact parts

Plating thickness inspection (e.g., silver ≥ 5μm)

Conductivity and resistance measurement in mass production

High-current cycle simulation test

Oxidation/aging test under elevated temperature and humidity

Best Practice: Implement automated optical inspection (AOI) and four-point resistance measurement systems in production lines to catch variations early.

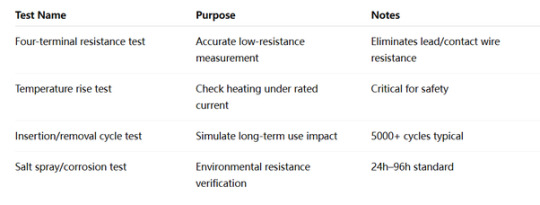

6. Testing and Verification Methods

To ensure actual contact resistance meets design expectations, standard tests include:

Conclusion

Low contact resistance is not merely a technical detail—it is a core performance and safety indicator in power socket design. Through intelligent selection of plating materials (silver, gold, etc.), sound mechanical design (optimal contact force, wear-resistant structures), and rigorous quality control, manufacturers can significantly improve product lifespan, safety, and user satisfaction. In high-performance applications, investment in low contact resistance pays off in both product reliability and brand reputation.

en.dghongju.com

0 notes

Text

Have you considered that your nose kind of looks like a socket? That or an alien.

0 notes

Text

Power sockets with protective covers. Black and white photo.

#power sockets#electricity#energy#power#power socket#protective covers#covers#photography#photo#photos#picture#pictures#image#images#a photo#a picture#an image#photograph#photographs#a photograph#black and white#black and white photo#black and white photos#black and white photograph#black and white photographs#black and white picture#black and white pictures#black and white image#black and white images#blackandwhite

1 note

·

View note

Text

Nice to meet you

What can I do?

0 notes

Text

pre-encounter snack

#i hate rhulk's shitty little lamps i'm unplugging them all and putting the power sockets to proper use#acquisition more like acquire some fucking queso you weird greasy hydraulic press looking bastard and maybe youll calm down#destiny#destiny 2#damascus-12#kullen art#(deathclaugust will resume im just stuck doing other stuff rn)

544 notes

·

View notes

Text

Idk why I thought of this but its killing me

#juno didn't miss this time damn#also think this is the first time my mind redesign is posted on here#the one with the glass torso at least#also first time in awhile that i feel happy with how i drew heart#also i don't know if those things have different names#electric outlet. power outlet. electrical socket i have no idea#but you know what i mean#chonny jash#chonnys charming chaos compendium#cj mind#cj heart#-atlas art-#ive said also like 5 times in this post lol

300 notes

·

View notes

Text

When Perceptor finally sends a rebuttal to the rebuttal to the rebuttal to the rebuttal to the rebuttal of one of Brainstorm's most recent papers. Brainstorm is getting ready to write another rebuttal.

I am not a complicated person. I see @tiesthatbind-tf post a Brainstorm design here , and I am struck by the urge to draw an incredibly handsome insufferable genius.

also i didn't draw the desk that way but Brainstorm reads as the type of person to me who, if given the option, would have one of those desks that converts between being a sitting desk and a standing desk. <- The type of riveting headcanons my brain can cook up while I am trying to tie down the details.6

#tinman doodles#ttb au#i fully admit i traced that perceptor altmode microscope next to him i was NOT up for trying to freehand that right now#i was also going to try and shade this but i realized i dont really know how to shade or highlight yet#so this will be a fun piece to revisit in a bit once i improve but for now it is flats#i also have to be at work in like 5 hours so that will be fun#i also should have been packing my house more tonight but this drawing idea wouldnt leave#also if you read to the end of my tag ramble the plane on his laptop is based on a c-wing spitfire#also another fun fact the power socket on the wall is the type used in south korea#and i remembered what to put because someone just went and told me about needing an adapter

29 notes

·

View notes

Text

#clemart#macthinker#ttcc#toontown corporate clash#im out of captions. what do i even say to this. im really embarrassed with this one#which means absolutely nothing because im embarrassed over EVERY piece but i digress.#wisdom tooth socket ache is no match for the power of macthinker withdrawl no drawing 6 days no nothing#alone in a wet cardboard box with no art .. but im free now#actually the aching isnt that bad sorry guys i lied. after the 1st day i was fine i was just tired#this was supposed to be a warmup but i got carried away#ive also done that grabbing pose like 3 times now i need to get creative

101 notes

·

View notes

Text

Not awake enough to really cohesively explain this but I think the reason Annatar looked so fucking malicious and soulless and unsettling in s2 as opposed to how he looked in S1 in so many shots was actually due to a noticeable lack of catch lights when paired next to characters in the same scene & I think that has to be a deliberate set lighting choice send tweet

#the rings of power#annatar#this occurred to me while browsing some gif sets bc it’s been bothering me for a while#it’s such a subtle thing but it’s definitely there#but it’s like 2:30am so I don’t have the brain to do a writeup#don’t get me wrong he definitely does have some catch light but it seems v muted comparatively#either that or the catch light is ALL that we see which is a different kind of unsettling#makes his eyes look like they’re glinting in the sockets#idk idk let me cook#like yes girl give us nothingggg

15 notes

·

View notes

Text

Global Certification Systems for Power Sockets: Key Differences and Testing Focus

Introduction

In today’s globalized market, power sockets are used in a wide variety of applications ranging from household appliances to industrial equipment. In order to ensure product safety, compliance, and market access, manufacturers must obtain relevant certifications in different countries and regions. However, certification requirements, testing standards, and regulatory focus vary widely between systems such as UL (USA), VDE and TUV (Germany), CCC (China), PSE (Japan), and KC (South Korea). Understanding the differences among these certification systems is critical for product development, export planning, and ensuring long-term reliability and safety.

1. UL Certification (United States)

Overview: UL (Underwriters Laboratories) is one of the most authoritative safety certification bodies in North America. UL certification focuses on electrical safety, fire prevention, and mechanical hazard prevention.

Testing Focus:

Dielectric strength test

Grounding resistance test

Temperature rise test under load

Flammability test of plastic components

Abnormal operation test

Example: For a household power socket with surge protection, UL requires that the internal metal parts withstand prolonged heating under overload conditions without degradation or safety risk.

2. VDE and TUV Certifications (Germany/Europe)

Overview: Both VDE and TUV certifications are recognized in Germany and throughout the EU. They are based on harmonized European standards (EN standards) and emphasize both electrical and mechanical safety.

Testing Focus:

Contact clearance and creepage distances

Endurance testing (e.g., 10,000 insertion/removal cycles)

Material insulation resistance

Heat resistance of housings

EMC (Electromagnetic Compatibility) in some product types

Example: A German-standard wall-mounted power socket must pass a 100N plug-in force test to ensure mechanical strength during repetitive use.

3. CCC Certification (China)

Overview: China Compulsory Certification (CCC) is a mandatory product certification system. CCC emphasizes safety, EMC compliance, and consistent product quality.

Testing Focus:

Grounding continuity and resistance

High voltage withstand

Fire resistance of enclosure materials

Electrical strength

Marking and user instructions

Example: A power socket for office use must pass a 2000V high-voltage test between live parts and ground to confirm dielectric strength.

4. PSE Certification (Japan)

Overview: PSE (Product Safety of Electrical Appliance & Materials) is regulated by Japan’s METI. Products are divided into “specified” and “non-specified” categories, each with different testing intensities.

Testing Focus:

Insulation resistance

Power cord flexibility and strength

Internal component flame retardancy

Leakage current test

Temperature cycling test

Example: For a multi-socket power strip with USB charging, PSE testing will validate USB output voltage stability and temperature rise under simultaneous full-load operation.

5. KC Certification (South Korea)

Overview: KC (Korea Certification) is managed by the Korean Agency for Technology and Standards (KATS). It integrates safety and EMC requirements for consumer and industrial electrical products.

Testing Focus:

Dielectric strength

Heat resistance and fire testing of plastic components

Stability testing

Grounding resistance

Labeling and instruction compliance

Example: A Korean-certified industrial power socket needs to demonstrate structural stability and enclosure flame resistance even under prolonged high-load conditions.

6. Key Certification Differences Summary

7. Additional Considerations for Global Certification

Plug types and standards: Different regions use different plug and socket types (e.g., Type A in the US, Type C/E/F in Europe). Certification includes verifying compatibility.

Voltage and frequency standards: 100V in Japan vs. 230V in Europe. Testing must reflect real-use scenarios.

Materials and environmental testing: Some certifications now include RoHS (restriction of hazardous substances), especially in Europe and Korea.

Product labeling and documentation: Proper markings, warning labels, and usage instructions are part of the test process.

Conclusion

Power socket manufacturers targeting global markets must understand and comply with the unique certification requirements of each region. UL focuses on fire and electrical safety; VDE and TUV emphasize mechanical and long-term reliability; CCC ensures consistency and safety; PSE requires thermal and insulation checks; KC demands comprehensive safety validation. By understanding these differences, companies can reduce certification costs, avoid compliance delays, and enhance product competitiveness.

en.dghongju.com

0 notes

Text

I recovered, but my laptop's power supply died))))) I hate sockets

#this fucking socket melted the plug#I nahren scared of this sockets#I won't get the new power supply until Saturday#and it’s not a fact that it will suit my laptop#:“”“”“”“”“”“”^)

10 notes

·

View notes

Text

I love watching this man's fish filleting videos but this section from when he's redoing a room fundamentally changed me. Look at my power socket, boy

#masaru#masaru youtube#@masaru.9268#honestly i think about this whenever i make anything#LOOK AT MY POWER SOCKET!!!#I WORKED SO HARD ON IT#i installed a lamp last year and i was like this every second of the way

29 notes

·

View notes

Text

A black and white photo of a power socket with a protective cover.

#power socket#cover#protective cover#electronics#electricity#power#energy#photography#photo#photos#picture#pictures#image#images#a photo#a picture#an image#photograph#photographs#a photograph#black and white#black and white photo#black and white photos#black and white photograph#black and white photographs#black and white picture#black and white pictures#black and white image#black and white images#blackandwhite

2 notes

·

View notes