#purlin brackets

Explore tagged Tumblr posts

Text

Purlin Brackets: An Essential Component for Your Structural Support Needs - EBolts

When it comes to construction, ensuring a stable and durable structure is paramount. One often-overlooked yet crucial component in building frameworks is the purlin bracket. These simple but vital components serve a key role in supporting roofing and cladding systems, ensuring that the entire structure remains sturdy and reliable over time. In this blog, we’ll explore what purlin brackets are, why they’re so important, and how they contribute to the overall integrity of a building.

What Are Purlin Brackets?

Purlin brackets are metal fixtures used to support purlins in the construction of roofs and other structures. Purlins are horizontal beams that run along the length of a roof, providing support for the roofing material. Purlin brackets are fixed to vertical columns or walls and hold the purlins in place. The bracket acts as a connection point, allowing for the proper distribution of weight and forces exerted on the roofing system.

Why Are Purlin Brackets Important?

Purlin brackets are indispensable for several reasons, including:

Structural Stability: They help distribute the weight of the roof and ensure that it is evenly supported. This helps prevent sagging or collapse over time, especially under the weight of snow or heavy rain.

Load Distribution: By connecting purlins to walls or columns, purlin brackets ensure that the load from the roof is properly transferred to the building's frame. This prevents any undue pressure on a single point, which could compromise the building's integrity.

Durability: Made from strong materials such as steel, purlin brackets are designed to withstand environmental stressors like high winds and heavy weather conditions. This makes them ideal for both residential and commercial structures.

Flexibility: Purlin brackets are available in various shapes and sizes to suit different types of purlin systems. Whether you're constructing a flat roof or a pitched one, purlin brackets can be customized to meet the specific needs of your project.

Types of Purlin Brackets

There are different types of purlin brackets, and the choice of which one to use depends on factors such as the size of the roof, the materials being used, and the overall design of the structure. Some common types include:

Z-Bar Brackets: These are commonly used when installing Z-shaped purlins, offering secure connections and strong load-bearing capabilities.

Angle Brackets: Often used for lighter purlin systems, angle brackets are versatile and easy to install. They provide strong support without being overly bulky.

Adjustable Brackets: These allow for fine-tuning the positioning of purlins, making them ideal for structures where slight adjustments may be needed during installation.

Fixed Brackets: These offer a rigid connection between purlins and columns, providing a strong, permanent hold.

Key Benefits of Using Purlin Brackets

Using the right purlin bracket can provide a number of advantages for your project:

Easy Installation: Purlin brackets are designed for straightforward installation, saving time and labor costs during construction.

Enhanced Safety: Properly installed purlin brackets reduce the risk of structural failure, ensuring the safety of both the building and its occupants.

Cost-Effective: While they are essential components, purlin brackets are a relatively low-cost investment that can help avoid costly structural repairs down the line.

Long-Lasting Performance: The durability of purlin brackets ensures that they will continue to provide reliable support for many years, even under harsh weather conditions.

Conclusion

Purlin brackets are a small but essential part of the construction process. Without them, roofing systems would lack the support necessary for maintaining stability and durability over time. By choosing the right type of purlin bracket and ensuring its proper installation, you can help create a safe, secure, and long-lasting structure. Whether you're building a commercial warehouse, a residential home, or a barn, purlin brackets should always be considered as part of your building’s framework for reliable support.

For More:

Contact: 61 3 9336 0155

Timings: Mon-Fri: 9am to 5pm

Visit Us: https://www.ebolts.com.au/

0 notes

Text

JUGMUG RollForming: Revolutionizing the Construction and Solar Industries with Advanced Roll Forming Machines

In the modern industrial landscape, precision engineering and efficiency are key to success. One of the most significant advancements in metal processing is roll forming technology. At the forefront of this innovation is JUGMUG RollForming, a leading name in the roll forming machine industry.

Whether you are in the construction business or part of the solar industry, JUGMUG RollForming provides high-quality solutions to meet your needs.

Understanding Roll Forming Machines

A roll forming machine is an essential piece of equipment used to shape metal sheets into specific profiles. This process involves passing metal through a series of rollers, gradually forming the desired shape with precision. Unlike other metal shaping methods, roll forming provides consistency, minimizes waste, and ensures structural integrity. JUGMUG RollForming specializes in designing and manufacturing roll forming machines that cater to diverse industry needs.

JUGMUG RollForming: The Pinnacle of Innovation

JUGMUG RollForming has established itself as a trusted supplier of roll forming machines for businesses worldwide. The company is committed to delivering advanced machinery that enhances productivity, ensures high precision, and reduces material wastage. With a focus on automation and customization, JUGMUG RollForming machines are designed to meet the unique requirements of different industries.

Why Choose JUGMUG RollForming?

Cutting-Edge Technology: The company utilizes the latest technological advancements to manufacture high-performance roll forming machines.

Customization Options: Every industry has different requirements, and JUGMUG RollForming offers tailored solutions.

Durability & Reliability: Their machines are built with high-quality materials to ensure longevity and consistent performance.

Cost-Effective Solutions: By reducing waste and increasing efficiency, JUGMUG RollForming machines help businesses optimize production costs.

Expert Support: The company provides excellent after-sales support, including maintenance, training, and technical assistance.

Roll Forming Machines for the Construction Business

The construction industry relies heavily on roll forming machines to produce various components such as:

Roofing sheets

Wall panels

Steel framing systems

Purlins and girts

JUGMUG RollForming manufactures state-of-the-art roll forming machines that help construction businesses achieve high precision and durability in their structural components. With the ability to handle different types of metals and produce complex profiles, these machines ensure that construction companies can meet the growing demands of modern infrastructure projects.

Benefits of JUGMUG RollForming Machines in Construction

Precision Engineering: Achieve exact measurements and superior quality in every batch.

High-Speed Production: Meet large-scale demands efficiently with automated processes.

Cost Savings: Reduce material waste and improve production efficiency.

Enhanced Strength: Ensure the durability of construction components with roll-formed metals.

Roll Forming Machines for the Solar Industry

The solar industry has witnessed tremendous growth in recent years, and roll forming technology plays a crucial role in manufacturing solar panel mounting structures. JUGMUG RollForming designs machines specifically for solar applications, ensuring the production of high-strength and corrosion-resistant components.

Key Applications in the Solar Sector

Solar panel mounting rails

Support brackets

Structural frames

Advantages of JUGMUG RollForming Machines in the Solar Industry

Sustainability: Roll forming minimizes waste, aligning with the green energy movement.

Weather-Resistant Components: Ensures long-lasting performance in outdoor conditions.

Lightweight & Strong: Ideal for supporting solar panels efficiently without adding excessive weight.

Automated Production: Reduces labor costs and speeds up production.

JUGMUG RollForming: Your Trusted Roll Forming Machine Supplier

JUGMUG RollForming has earned a reputation as a leading roll forming machine supplier by consistently delivering superior products and exceptional customer service. Their extensive range of roll forming machines caters to multiple industries, ensuring businesses get the best equipment for their specific needs.

Services Offered by JUGMUG RollForming

Custom Machine Design – Tailored solutions to meet unique production requirements.

Installation & Training – Comprehensive support to ensure smooth machine operation.

Maintenance & Spare Parts – Ensuring long-term reliability and efficiency.

Technical Consultation – Expert advice on optimizing roll forming processes.

Conclusion

JUGMUG RollForming is setting new standards in the roll forming industry by offering innovative and high-performance roll forming machines for the construction business and solar industry. Their commitment to quality, efficiency, and customer satisfaction makes them the go-to choice for businesses seeking reliable roll forming machine suppliers. Whether you need roofing sheets for a construction project or mounting structures for solar panels, JUGMUG RollForming has the perfect solution to meet your production needs.

If you’re looking to enhance your manufacturing capabilities with top-tier roll forming machines, contact JUGMUG RollForming today and take your business to the next level!

0 notes

Text

Harnessing the Sun: The Advantages of Photovoltaic Power Generation on Steel Warehouses | New Life Steel

Adopt photovoltaic power for your steel warehouses and revolutionize energy usage. Save on costs, reduce carbon emissions, and embrace a future-ready, sustainable solution. New Life Steel specializes in eco-friendly solar integration, making your business operations smarter and greener

Environmental protection, carbon neutrality, and energy efficiency have become urgent benchmarks of today’s world. While world organizations work hard in search of friendly energy options, photovoltaic electric power has come up as a major player in the green energy market. This method is achieved using solar panels that utilize solar energy to power machines this is environmentally friendly and renewable energy but has large coverage needs. Enter the steel warehouse: a solution that could not be more suitable for photovoltaic energy systems demand.

Warehouse steel structure solution

Steel warehouses have large roof surfaces and desired slopes to suit for installation of photovoltaic panels. Through the use of these structures, companies can harness underutilized spaces to achieve relatively large energy conservation and improvements to sustainability. The rows of solar panels installed on the steel building of a warehouse layout are successful in a clear focus on ecological safety and economic costs and hence offer synergy.

The Advantages of Photovoltaic Power Generation

Environmental Impact: Photovoltaic power generation is clean and pollution-free source of power which is produced without any emission. This power change leads to decreased emissions from the sun and therefore supports the goal of effective carbon neutrality among business organizations.

Energy Independence: Photovoltaic systems enable firms to produce their own electricity; this means a reduced dependence on local networks. Besides cutting operational expenses, it also insulates organizations from the likely supply interruptions of electrical power.

Low Maintenance and Longevity: When relating to maintenance, solar panels, especially those made from crystalline silicon, have service lives that range between 20 and 35 years. This reliability means that after the installation of the system, it will remain stable and efficient at producing energy for decades.

Flexible Installation: Large power plants would do well on the roofs and walls of steel warehouses and buildings in general particularly the roofs. They are relatively massive structures that can incorporate the weight and the load of solar installations and do not require complex mounting and integration.

Installation Insights

The installation of photovoltaic systems on steel warehouses requires careful consideration of the building’s structural integrity. Here are some key methods for installation:

Direct Connection to Roof Panels: When both steel frame and roof panels are designed in a way that the photovoltaic brackets can directly be connected to the roof panels, the load can be spread over the complete surface.

Using Purlins: When roof panels are flexible, brackets may be attached directly to purlins to provide stability and reduce stress on the roof.

Steel Frame Support: When roof panels are less rigid, connections can be made right to the steel frame or roof trusses, as they provide the support needed for the solar installation.

Waterproofing Considerations: All roof penetrating connections should have waterproof gaskets/sealing arrangements to avoid any water leakage in the warehouse.

Key Considerations for Design

Before proceeding with a solar installation, it is vital to:

– Understand the existing roof structure and its load-bearing capabilities.

– Assess the layout of photovoltaic modules to maximize sunlight exposure.

– Plan for site-specific construction conditions and select appropriate techniques to ensure safety and efficiency during installation.

The Future of Energy

There are countless benefits associated with incorporating photovoltaic systems within steel warehouses; some of these benefits include reduced expenses for energy, environmental benefits, and a consistent network for power. Stepping up the pressure of their efforts to cut costs and strengthen sustainable measures, businesses find a perfect fit in warehouse steel structure solutions with solar power.

Any steel construction venture manufacturing Peb steel structure that is on the fence about signing up for solar is encouraged to go ahead and do so because this is the best time. Using steel engineering complexity and great mastery in the photovoltaic array, now is the brilliant moment to tap into the power of the sun. Seize the moment for the future and call the team of professionals to talk about the prospects of your project right now!

0 notes

Text

Steel Market — Forecast(2024–2030)

Steel Market — Overview

Steel Market Report Coverage

For More

The report: “Steel Industry — Forecast (2024–2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Steel Market Report.

By Type: Carbon Steel, (Low Carbon Steel, Medium Carbon Steel, High Carbon Steel), Stainless Steel (Austenitic Stainless Steels, Ferritic Stainless Steels, Martensitic Stainless Steels, Precipitation Hardening Grade Stainless Steels, Duplex Stainless Steels), Alloy Steel (Chromium Molybdenum Steel, Nickel-Chromium-Molybdenum Steel, Chromium Vanadium Steel, HSLA -Nickel-Chromium-Molybdenum Steel), Tool Steel (Water-hardening tool steels, Shock-resisting tool steels, Cold-work tool steels, Hot-work steels, High-speed tool steels, Others), Others

By Form: Bar, Rod, Tube, Pipe, Plate, Sheet, Structural, Others

By Application: Transportation (Road, Bridges, Barriers, Rail, Tracks, Rail Cars), Construction (Cool Metal (infrared reflecting) Roofing, Purlins, Beams, Pipe, Recyclable steel framing (studs), Desks/Furniture), Packaging (Canes, Bottles, Others), Water Projects (Levees/Dams/Locks), Energy (Renewable, Nuclear, Bio-fuels, Fossil, Electric Grid), Others

By Industry: Construction (Steel Skeletons, Concrete Walls, Pillars, Nails, Bolts, Screws, Others), Machinery (Bulldozers, Backhoe Leaders, Pipelayers, Others), Automotive and Transportation (Exhaust, Trim/Decorative, Engine, Chassis, Fasteners, Tubing For Fuel Lines), Kitchenware and Domestic Appliances (Small Household Appliances, Black Home Appliances, White Home Appliances), Electrical and Electronics (Motor Mount Brackets, Adapter Plates, Electronic Frames and Chassis, Brackets, Others), Healthcare (Orthopaedic Implants, Artificial Heart Valves, Bone Fixation, Catheters, Others), Energy (Scrubbers, Heat Exchangers, Others)

By Region: North America, South America, Europe, Asia-Pacific and Rest of the World

Inquiry Before Buying

Key Takeaways

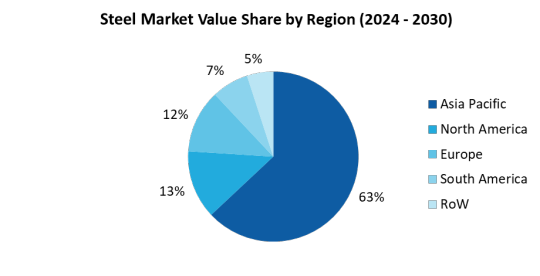

• The Asia-Pacific region, particularly China, has been a dominant force in the global steel market with a share of 63% in 2023, owing to China’s rapid industrialization and urbanization have driven substantial demand for steel in the construction, infrastructure, and manufacturing sectors.

• Government infrastructure spending, particularly in major economies, plays a significant role in driving steel demand. Large-scale infrastructure projects, such as bridges, railways, and urban development initiatives, can create substantial demand for steel products.

For More Details on This Report — Request for Sample

Steel Market Segment Analysis — By Type

In terms of type, the Steel Market is segmented into carbon steel, stainless steel, alloy steel, tool steel and others. In 2023, the Stainless-steel segment generated the greatest revenue of $361.94 billion and is projected to reach a revenue of $482.28 billion by 2030. Owing to the various benefits posed by stainless steel such as corrosion resistance, high and low temperature resistance, the ease of fabrication, strength, aesthetic appeal is one of the key factors for its adoption among various end-use industries, which in turn is boosting its market growth. The stainless-steel segment can be further classified as Austenitic stainless steels, Ferritic stainless steels, Martensitic stainless steels, Precipitation hardening grade stainless steel and Duplex stainless steels.

Steel Market Segment Analysis — By Form

By form, the steel market is segmented into bar, rod, tube, pipe, plate, sheet, structural and others. The bar segment accounted for the major market share in 2023, with a revenue of $554.58 billion, and is forecast to grow at a CAGR of 4.68% by 2030. The increasing demand for steel bar from various end-user industries such as building and construction, bridges, and many others, are driving the growth of the segment during the forecast period of 2024–2030.

Steel Market Segment Analysis — By Application

Steel Market is segmented by its application that includes transportation, construction, packaging, water projects, energy and others. The energy segment held the dominant market share, 31% of the whole market, in 2023, and is expected to maintain its dominance by 2030 with a CAGR of 4.69%. One of the major factors for the segment growth is the increasing awareness and focus towards renewable energy sources. Steel plays a crucial role in producing and distributing energy as well as improving energy efficiency. Renewable energy is further classified as Wind Towers and Foundation, Wind Turbines and Solar Parabolic Mirror Supports & Collectors.

Steel Market Segment Analysis — By Industry

The Steel finds its application across the industries such as construction, machinery, automotive and transportation, kitchenware and domestic appliance, electrical and electronics, healthcare, energy and others. Among them, the construction segment is the largest consumer of steel, as bearable structures can be manufactured easily at a low cost. The property of steel in its various forms and alloys makes it more flexible to cater the exclusive projects integrated with infrastructure. Moreover, the rapid industrialization and urbanization in various developing countries are fueling the segment growth in strengthening its dominant market position during the forecast period.

Buy Now

Steel Market Segment Analysis — By Geography/Country

The report comprises of the region wise study of the global market including North America, South America, Europe, Asia-Pacific and Rest of the World. Above all, Asia-Pacific region held the biggest share in 2023, up to 63% of the whole steel market owing to the rapidly expanding defense, machinery, automotive, and shipbuilding industries in the countries such as India, China, South Korea, and Japan. Foreign direct investment in energy and infrastructure is likely to provide opportunities for the market vendors. Coupled with favorable government regulations, growing infrastructure and construction activities in developing economies of the Asia-Pacific region are boosting the demand for the market.

Steel Market — Drivers

Growing Demand for Steel Across the Various Regions

Several factors have a significant impact on the overall development of the steel market. The major growth factor driving the Steel Market is the growing demand for steel across a variety of developing regions. For instance, Global crude steel production in January-November 2023 reached 1715.12 million metric tons, marking a marginal 0.5% year-on-year growth, per provisional data from the World Steel Association. November 2023 saw a production of 145.5 million metric tons, up by 3.3% from the previous year. China led the production with 952.14 million metric tons, followed by India and Japan, USA, Russia, South Korea, and Germany.

Construction and Infrastructure Development:

Construction activities, including residential, commercial, and infrastructure projects such as roads, bridges, and railways, are major drivers of steel demand. Urbanization and industrialization also contribute to the growth of the construction sector, thereby increasing the demand for steel products. For instance, as per Green Finance & Development Center, China Belt and Road Initiative (BRI) Investment Report 2023, engagement totalled about USD88.3 billion, with USD44.6 billion from investment and USD43.7 billion from construction contracts. Also, The US Department of Transportation allocates $3.2 billion in extra funding, alongside $4.3 billion from the Bipartisan Infrastructure Law for 2023. The Budget prioritizes $4.5 billion for the Capital Investment Grant program, aiming to bolster transit infrastructure for economic growth. As a result, the steel market is anticipated to thrive, propelled by heightened construction activities and the need for durable materials, reflecting a promising outlook for the industry.

Steel Market -Challenges

Environmental Regulations and Sustainability

The steel industry is facing mounting pressure to tackle environmental issues by cutting carbon emissions and enhancing sustainability efforts. Meeting stringent environmental regulations demands substantial investments in technology and infrastructure, presenting a formidable challenge for many companies. Despite the financial hurdles, embracing these changes can pave the way for a more sustainable and eco-friendly future for the industry.

Steel Market — Competitive Landscape

The companies referred in the study include Baosteel Co., Ltd., Posco Holding Inc, Nippon Steel Corporation, JFE Holdings, Tata Steel Limited, United States Steel Corporation, Anshan Iron and Steel Group Corporation, Hyundai Steel Co., Ltd., ThyssenKrupp AG, ArcelorMittal S.A., among others. Technology launches, acquisitions, and R&D activities are key strategies adopted by the key players in the Steel Market.

Steel Market — Recent Developments

November 2022, Tata Steel launched the fourth edition of MaterialNEXT, focusing on ‘Materials to Wonder.’ This open innovation event aims to gather ideas on emerging materials and their applications. The program spans five months across Idea Selection, Development, and Evaluation stages, fostering collaboration among scientists, researchers, and startups.

May 2022, Kobe Steel introduced ���Kobenable Steel,” Japan’s pioneering low CO2 blast furnace steel, aiming to curtail emissions during ironmaking. Utilizing innovative CO2 Reduction Solution technology, it plans to roll out the product this fiscal year, marking a milestone in sustainable steel production.

In June 2023, Nippon Steel introduces ZEXEED™ Checkered Sheet, a new addition to its high corrosion resistant coated steel series

0 notes

Text

Steel Market — Forecast (2024–2030)

Steel market is analyzed to be $1,746.35 billion in 2023 and is projected to reach $2,105 billion in 2030. The market is estimated to grow with a CAGR of 4.13% during 2024-2030. Steel is an alloy that is made up of iron ore or scrap steel and carbon. In general, steels have various unique properties including being non-corrosive, rust-resistant and heavier than other metals such as aluminum. Therefore, steel is extensively used in various end-use industry verticals, including the manufacturing various transportation and automobile components, medical equipment, metal surgical implants, structural components and more, which in turn is boosting its market growth. In recent years, the steel market has experienced fluctuations driven by several factors. One significant trend in the steel market is the impact of trade policies and tariffs. Trade tensions between major steel-producing nations, such as the United States, China, and the European Union, have led to shifts in supply chains and pricing dynamics. Tariffs imposed on steel imports have affected the competitiveness of domestic producers and influenced global trade patterns. Additionally, sustainability concerns and environmental regulations have influenced market dynamics. Increasing awareness of carbon emissions and the environmental footprint of steel production has led to a growing demand for greener steel products. This has prompted investments in cleaner production technologies such as electric arc furnaces and the development of recycled steel. Moreover, technological advancements and innovations in steel manufacturing processes have enhanced efficiency and product quality. As a result, the steel market is poised for sustained growth as global economic recovery accelerates, with innovations in technology and sustainability shaping future trends.

Steel Market Report Coverage

The report: “Steel Industry – Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Steel Market Report. By Type: Carbon Steel, (Low Carbon Steel, Medium Carbon Steel, High Carbon Steel), Stainless Steel (Austenitic Stainless Steels, Ferritic Stainless Steels, Martensitic Stainless Steels, Precipitation Hardening Grade Stainless Steels, Duplex Stainless Steels), Alloy Steel (Chromium Molybdenum Steel, Nickel-Chromium-Molybdenum Steel, Chromium Vanadium Steel, HSLA -Nickel-Chromium-Molybdenum Steel), Tool Steel (Water-hardening tool steels, Shock-resisting tool steels, Cold-work tool steels, Hot-work steels, High-speed tool steels, Others), Others By Form: Bar, Rod, Tube, Pipe, Plate, Sheet, Structural, Others By Application: Transportation (Road, Bridges, Barriers, Rail, Tracks, Rail Cars), Construction (Cool Metal (infrared reflecting) Roofing, Purlins, Beams, Pipe, Recyclable steel framing (studs), Desks/Furniture), Packaging (Canes, Bottles, Others), Water Projects (Levees/Dams/Locks), Energy (Renewable, Nuclear, Bio-fuels, Fossil, Electric Grid), Others By Industry: Construction (Steel Skeletons, Concrete Walls, Pillars, Nails, Bolts, Screws, Others), Machinery (Bulldozers, Backhoe Leaders, Pipelayers, Others), Automotive and Transportation (Exhaust, Trim/Decorative, Engine, Chassis, Fasteners, Tubing For Fuel Lines), Kitchenware and Domestic Appliances (Small Household Appliances, Black Home Appliances, White Home Appliances), Electrical and Electronics (Motor Mount Brackets, Adapter Plates, Electronic Frames and Chassis, Brackets, Others), Healthcare (Orthopaedic Implants, Artificial Heart Valves, Bone Fixation, Catheters, Others), Energy (Scrubbers, Heat Exchangers, Others) By Region: North America, South America, Europe, Asia-Pacific and Rest of the World

Request Sample

Key Takeaways

Steel Market Segment Analysis – By Type In terms of type, the Steel Market is segmented into carbon steel, stainless steel, alloy steel, tool steel and others. In 2023, the Stainless-steel segment generated the greatest revenue of $361.94 billion and is projected to reach a revenue of $482.28 billion by 2030. Owing to the various benefits posed by stainless steel such as corrosion resistance, high and low temperature resistance, the ease of fabrication, strength, aesthetic appeal is one of the key factors for its adoption among various end-use industries, which in turn is boosting its market growth. The stainless-steel segment can be further classified as Austenitic stainless steels, Ferritic stainless steels, Martensitic stainless steels, Precipitation hardening grade stainless steel and Duplex stainless steels.

Steel Market Segment Analysis – By Form By form, the steel market is segmented into bar, rod, tube, pipe, plate, sheet, structural and others. The bar segment accounted for the major market share in 2023, with a revenue of $554.58 billion, and is forecast to grow at a CAGR of 4.68% by 2030. The increasing demand for steel bar from various end-user industries such as building and construction, bridges, and many others, are driving the growth of the segment during the forecast period of 2024-2030.

Steel Market Segment Analysis – By Application Steel Market is segmented by its application that includes transportation, construction, packaging, water projects, energy and others. The energy segment held the dominant market share, 31% of the whole market, in 2023, and is expected to maintain its dominance by 2030 with a CAGR of 4.69%. One of the major factors for the segment growth is the increasing awareness and focus towards renewable energy sources. Steel plays a crucial role in producing and distributing energy as well as improving energy efficiency. Renewable energy is further classified as Wind Towers and Foundation, Wind Turbines and Solar Parabolic Mirror Supports & Collectors.

Steel Market Segment Analysis – By Industry The Steel finds its application across the industries such as construction, machinery, automotive and transportation, kitchenware and domestic appliance, electrical and electronics, healthcare, energy and others. Among them, the construction segment is the largest consumer of steel, as bearable structures can be manufactured easily at a low cost. The property of steel in its various forms and alloys makes it more flexible to cater the exclusive projects integrated with infrastructure. Moreover, the rapid industrialization and urbanization in various developing countries are fueling the segment growth in strengthening its dominant market position during the forecast period.

Buy Now

Steel Market Segment Analysis - By Geography/Country The report comprises of the region wise study of the global market including North America, South America, Europe, Asia-Pacific and Rest of the World. Above all, Asia-Pacific region held the biggest share in 2023, up to 63% of the whole steel market owing to the rapidly expanding defense, machinery, automotive, and shipbuilding industries in the countries such as India, China, South Korea, and Japan. Foreign direct investment in energy and infrastructure is likely to provide opportunities for the market vendors. Coupled with favorable government regulations, growing infrastructure and construction activities in developing economies of the Asia-Pacific region are boosting the demand for the market.

Steel Market - Drivers

Growing Demand for Steel Across the Various Regions Several factors have a significant impact on the overall development of the steel market. The major growth factor driving the Steel Market is the growing demand for steel across a variety of developing regions. For instance, Global crude steel production in January-November 2023 reached 1715.12 million metric tons, marking a marginal 0.5% year-on-year growth, per provisional data from the World Steel Association. November 2023 saw a production of 145.5 million metric tons, up by 3.3% from the previous year. China led the production with 952.14 million metric tons, followed by India and Japan, USA, Russia, South Korea, and Germany.

Construction and Infrastructure Development: Construction activities, including residential, commercial, and infrastructure projects such as roads, bridges, and railways, are major drivers of steel demand. Urbanization and industrialization also contribute to the growth of the construction sector, thereby increasing the demand for steel products. For instance, as per Green Finance & Development Center, China Belt and Road Initiative (BRI) Investment Report 2023, engagement totalled about USD88.3 billion, with USD44.6 billion from investment and USD43.7 billion from construction contracts. Also, The US Department of Transportation allocates $3.2 billion in extra funding, alongside $4.3 billion from the Bipartisan Infrastructure Law for 2023. The Budget prioritizes $4.5 billion for the Capital Investment Grant program, aiming to bolster transit infrastructure for economic growth. As a result, the steel market is anticipated to thrive, propelled by heightened construction activities and the need for durable materials, reflecting a promising outlook for the industry.

Steel Market -Challenges

Environmental Regulations and Sustainability The steel industry is facing mounting pressure to tackle environmental issues by cutting carbon emissions and enhancing sustainability efforts. Meeting stringent environmental regulations demands substantial investments in technology and infrastructure, presenting a formidable challenge for many companies. Despite the financial hurdles, embracing these changes can pave the way for a more sustainable and eco-friendly future for the industry.

Steel Market - Competitive Landscape The companies referred in the study include Baosteel Co., Ltd., Posco Holding Inc, Nippon Steel Corporation, JFE Holdings, Tata Steel Limited, United States Steel Corporation, Anshan Iron and Steel Group Corporation, Hyundai Steel Co., Ltd., ThyssenKrupp AG, ArcelorMittal S.A., among others. Technology launches, acquisitions, and R&D activities are key strategies adopted by the key players in the Steel Market.

0 notes

Text

Podrum Structure, southwest corner view

Atenica, Serbia

View of masonry walls and the interlocking plank joinery of the upper level and basic roof support system. The clay tile roofing is supported on purlins that extend beyond the primary roof frame. The wooden brackets and braces support the primary frame and allow for ventilation between the plank vaulted enclosure and the roof. The extended ends of members of the plank walls appear in early photographs to support poles to carry containers of other materials. (photo 1988)

11 notes

·

View notes

Video

youtube

Factory Galvanized Steel U Strut Channel Purlin profile post roll formin...

The U-shaped steel produced by this roll forming production line can be used for photovoltaic bracket bridges, lamp tube brackets, air-conditioning brackets, columns, etc. Applicable materials for steel production equipment: CR, HR Sheet; Galvanized Sheet, The production speed can reach 20m/min. Website: https://www.tfrollformer.com/tf-u-strut-roll-forming-line/ Email: [email protected] WhatsApp/Tel/Wechat: + 86-18834565182

#New Energy Industry#U-shaped steel#roller press#sheet metal processing#galvanized steel coil#Photovoltaic bracket

2 notes

·

View notes

Text

How to Put in a Skylight inside your Roof or Attic Conversion, Concerns and Strategies

optilight roof window

Skylights

We've found numerous means of introducing light-weight into our houses and homes. These range between finish conservatories made out of glass in a slim framework, via custom constructed, atrium roofing sections, to smaller fastened or opening windows fitted into an existing roof.

No matter just how much light you need indoors, it's critical to understand the way to go about it. Some skylights demand relatively economical and small-scale installation function; other individuals contain large-scale, tailored fabrication and style do the job. Even though planning authorization might not be required, the perform should comply with the developing restrictions, so speak to your neighborhood structures regulator.

A skylight is a great way to enable heat, light-weight and air right into a space. The addition of roofing lights can successfully turn a roof right into a grid managing among the squares of light.

Opening roof windows fix air flow and daylight difficulties involved with all the common setting up. Particularly within the circumstance of attic conversions where conventional windows will not be an option, a gap skylight turns a roof cavity into a practical and pleasurable place.

Constantly take into consideration ceiling geometry when you're considering skylights. Slender shapes functioning right down to the line in the eaves create the effect of slots of sunshine internally. When all the surfaces are plastered and painted, the skylight seems to be even more desirable.

Installing a skylight

A skylight is usually a fantastic way to let light and warmth into dreary rooms. Putting inside of a skylight, especially if the form of the ceiling mimics the slope of your roof, is undoubtedly not over and above the aptitude of your regular Do-it-yourself hobbyist.

Very first, make a decision how massive a skylight you need; two, a few or 4 more compact windows could possibly be a lot better than a significant one particular. Go over by way of your requirements with companies or suppliers. When it comes, meticulously read through the set up guidelines. Bear in mind that you are going to put a gap in your roof, which could let while in the rain when there is a delay mainly because you don't know exactly how the device should be equipped or there is some elements missing. Have tarpaulin and e ropes at hand, just in case.

Push a big nail into the ceiling the place the skylight would be to go. Donning footwear with good grip is vital. Climb onto the roof and find the specified position and remove the roof slates. The skylight have to not interfere using a ceiling hanger or possibly a purlin.

Slice the tiling battens and mark out the body sizing which will hold the skylight. Minimize the rafters and set in trimmers in compliance with all the manufacturer's instructions. Look out for almost any wiring or cables. Cut away the plaster having a noticed and take the skylight from its box and take away the flashings and trims.

Mark the place on the skylight on the ceiling and make sure that just one aspect of it fits upcoming to the ceiling joist. Generate a considerable nail by means of its center. Take away the tiles and maintain them within sight. Cut the battens by using a circular noticed or even a handsaw then slash the rafters until finally they are trimmed properly. Frame joints have to be perfectly nailed - make use of a minimum of four 90 mm nails in each case.

Before sawing the hole within the plasterboard, slash deeply in to the sheet from beneath by using a knife. This will lessen the likelihood of the lining paper tearing. If you have built the opening the right size, the brackets of the sides on the skylight should stand on the framing customers.

Stand the body while in the encouraged place and correct it for the rafters and trimmers employing brackets which really should be presented. It should be stage throughout the roof at the two finishes.

Match the underside flashing, bending it to adhere to the contours with the tiles. Fit the facet flashings, the best flashing and so forth. Refit the tiles round the skylight. You can use tile cutters or simply a carborundum wheel preset inside your circular observed for this. (In the event the latter is utilised, you should definitely wear goggles and extended protective clothes.) If you have adopted the measures effectively, the room underneath is not going to become drinking water harmed. Browse the manufacturer's suggestions cautiously, then placement the roof window and, after double examining it's right, quickly repair it to one on the rafters.

Make use of a spirit stage to check the skylight is flat. Whether it is not, pack it up on the lower aspect and after that, applying screws or nails, fasten it tightly into place.

The flashings are really essential, they are there to stop leaks and water hurt developing concerning the skylight along with the roof masking. They must be mounted the right way and devoid of injury. When you find yourself fitting the flashings to your roof slates, a wooden block can be employed for beating the metallic into posture. Do that right until it matches the contours with the slates just. When fitting the aspect and top rated flashings, commence very carefully. Test each and every step.

The final phase to the exterior should be to exchange the roof slates. This tends to require slicing. After the work is finished, be sure to crystal clear away the many particles that can block the downpipes. Evaluate the uncovered location in between the edge on the skylight as well as the ceiling and minimize the plasterboard to match. Nail the plasterboard in to put, using plasterboard nails. Steel corner angle joints bolster the join and provides a specific line to operate on if you find yourself plastering. Lower them using a hacksaw and nail them in position. Using a mortar trowel, apply the cement in separate layers, each having wider and wider. Make sure that you smooth each individual from the joints absent to practically nothing.

Plastering

Measure and mark the sections as required. Be certain the best facet (unmarked) faces outwards. By using a sharp knife, reduce deeply together the edge. Switch the board more than and, keeping 1 facet inside your hand, provide the sheet a thump with the fist. This should trigger the sheet to bend and break. Utilizing a sharp knife, minimize along the edge about the again in the sheet. This may make certain that the liner paper does not get ripped. Reduce and correct plasterboard round the skylight. Slice and correct the metal angles that fortify the corners. Plaster the corners. Sand, dry, primary and paint them.

Career carried out!

References Window https://en.wikipedia.org/wiki/Window

1 note

·

View note

Text

How you can Install a Skylight with your Roof or Attic Conversion, Factors and Suggestions

optilight roof window

Skylights

Now we have located a lot of means of introducing gentle into our homes and homes. These range from full conservatories produced from glass in a narrow framework, by way of customized created, atrium roofing sections, to smaller mounted or opening windows equipped into an existing roof.

Irrespective of the amount of light you wish indoors, it can be significant to grasp how you can go over it. Some skylights involve fairly affordable and small-scale installation function; other individuals require large-scale, tailored fabrication and structure operate. Whilst arranging permission is probably not needed, the work should comply with the setting up laws, so consult your community properties regulator.

A skylight is a wonderful method to enable heat, mild and air right into a place. The addition of roofing lights can correctly convert a roof into a grid working among the squares of sunshine.

Opening roof home windows address ventilation and daylight complications involved along with the ordinary making. Specially in the circumstance of attic conversions where by typical home windows usually are not a possibility, a gap skylight turns a roof cavity right into a helpful and pleasurable area.

Usually take into consideration ceiling geometry when you find yourself serious about skylights. Narrow designs running right down to the line in the eaves build the result of slots of light internally. When all the surfaces are plastered and painted, the skylight looks even more interesting.

Putting in a skylight

A skylight is actually a fantastic solution to let gentle and warmth into dreary rooms. Placing within a skylight, primarily if the form with the ceiling mimics the slope from the roof, is unquestionably not beyond the potential on the ordinary Diy hobbyist.

First, make a decision how massive a skylight you desire; two, three or 4 smaller sized windows may be much better than a substantial one particular. Talk about as a result of your requirements with manufacturers or suppliers. When it arrives, very carefully read the installation guidelines. Keep in mind that you're going to put a hole in your roof, which could allow in the rain if there is a hold up due to the fact you do not know exactly how the unit should really be equipped or you can find several sections lacking. Have tarpaulin and e ropes to hand, just in case.

Generate a considerable nail in to the ceiling in which the skylight would be to go. Carrying sneakers with fantastic grip is essential. Climb onto the roof and track down the specified placement and take away the roof slates. The skylight have to not interfere with a ceiling hanger or possibly a purlin.

Reduce the tiling battens and mark out the frame size that will hold the skylight. Cut the rafters and put in trimmers in compliance with all the manufacturer's directions. Watch out for just about any wiring or cables. Reduce absent the plaster by using a noticed and take the skylight from its box and take away the flashings and trims.

Mark the position from the skylight on the ceiling and ensure that just one aspect of it matches subsequent to some ceiling joist. Generate a significant nail by way of its center. Get rid of the tiles and maintain them within reach. Slash the battens by using a circular saw or possibly a handsaw and after that minimize the rafters till they are really trimmed the right way. Body joints has to be properly nailed - make use of a bare minimum of 4 ninety mm nails in each and every scenario.

Just before sawing the hole during the plasterboard, lower deeply to the sheet from beneath which has a knife. This could reduce the likelihood of your lining paper tearing. If you've got manufactured the opening the correct dimensions, the brackets with the sides of the skylight ought to stand over the framing associates.

Stand the body while in the proposed situation and take care of it to your rafters and trimmers applying brackets which really should be delivered. It needs to be level through the roof at both finishes.

In good shape the underside flashing, bending it to adhere to the contours from the tiles. Healthy the aspect flashings, the highest flashing etc. Refit the tiles within the skylight. You could use tile cutters or a carborundum wheel set inside your circular observed for this. (In case the latter is utilised, ensure that you don goggles and long protecting garments.) If you've followed the methods effectively, the home beneath will never develop into water weakened. Examine the manufacturer's pointers cautiously, then posture the roof window and, immediately after double examining it really is appropriate, quickly repair it to 1 with the rafters.

Make use of a spirit stage to check which the skylight is flat. Whether it is not, pack it up around the reduced side and after that, applying screws or nails, fasten it tightly into position.

The flashings are very critical, they can be there to halt leaks and h2o hurt building involving the skylight and also the roof covering. They must be put in accurately and without the need of destruction. If you find yourself fitting the flashings to your roof slates, a wood block can be used for beating the metal into place. Do this until finally it suits the contours of your slates specifically. When fitting the side and best flashings, commence very carefully. Look at just about every action.

The final step for the exterior would be to replace the roof slates. This can contain reducing. When the work is finished, be certain to apparent absent many of the particles that can block the downpipes. Evaluate the uncovered area involving the sting of your skylight and the ceiling and slash the plasterboard to go well with. Nail the plasterboard in to put, employing plasterboard nails. Metallic corner angle joints strengthen the sign up for and give a precise line to operate on when you are plastering. Slice them by using a hacksaw and nail them in position. Utilizing a mortar trowel, utilize the cement in independent levels, every one finding broader and wider. Guantee that you easy each with the joints away to very little.

Plastering

Evaluate and mark the sections as expected. Make sure the highest side (unmarked) faces outwards. Using a sharp knife, reduce deeply along the sting. Change the board in excess of and, holding one particular aspect inside your hand, give the sheet a thump with the fist. This should trigger the sheet to bend and crack. Employing a sharp knife, slash together the sting on the back in the sheet. This could make sure the lining paper will not get ripped. Reduce and fix plasterboard within the skylight. Reduce and correct the metallic angles that bolster the corners. Plaster the corners. Sand, dry, primary and paint them.

Occupation carried out!

References Window https://en.wikipedia.org/wiki/Window

1 note

·

View note

Text

An Architectural and Ornamental Glossary for Sekiro [Part 1]

Like my other ongoing series that concerns the Souls games and Bloodborne, my intention here is to bring some public awareness to the historicity surrounding the environments in Sekiro. My approach will be more direct than before, with each numbered or starred item resembling the entry in a dictionary.

I hope you enjoy these posts! I’ll try to abbreviate each one, as it appears on the feed, so that people who are still in the process of discovering the game for themselves are not exposed to sights from its later areas, if that is a concern.

Above: a residential interior within the Hirata Estate complex.

1. Tokonoma: An alcove having a raised floor, located in the most formal room of a traditional Japanese residence. Used to display a hanging, scroll, small objects, a flower arrangement, etc.

2. Chigai-dana: In the Shoin style of domestic Japanese architecture, shelves which are placed in a step-like arrangement in an alcove.

3. Fukuro-dana: A cupboard! Literally “pouch-shelf.”

4. Tokobashira: The visible nonstructural post which marks one of the front sides of a tokonoma.

Above: building details from the Senpou Temple and Fountainhead Palace.

Kumimono: A system of structural supports composed of weight-bearing blocks and bracket arms. Compare this to the Chinese tou kung method of construction, wherein tiers or clusters of brackets are used to carry rafters which support purlins far beyond the outermost columns of a building.

Above: a rooftop among many within the Fountainhead Palace.

Chigi: Originally, these were the projecting barge couples (rafters that support the part of a gable roof which projects beyond the gable wall) at the ends of the ridge in a roof in a Shintō shrine; now usually a pair of crossed timbers which are placed at each end of a ridge. Also, in English, called forked finials.

Above: close to what is likely most people’s first view of the Senpou Temple.

1. Shōrō: A small structure from which a bell is hung in a Japanese temple compound.

2. Bonshō: Large bells in Buddhist temples throughout Japan, used to summon monks to prayer and to demarcate periods of time. Bonshō are struck from the outside using a handheld mallet or a beam suspended on ropes (seen here).

Above: a shrine close to the Hirata Estate and a ridge atop Ashina Castle.

Shibi: In English what you might call a type of acroterion often in the shape of a shachihoko, an animal in Japanese folklore with the head of a tiger and the body of a carp. Placed at one or each end of a roof ridge in some Japanese temples and castles and believed to be a protection against fire.

Above: a distant view of a pagoda housing one of the temple monks’ texts.

1. Tō: A type of Japanese pagoda of two (tahō-tō), three (sanjū-no-tō), five (gojū-no-tō (the kind seen here)), or seven (nana-jū-no-tō) stories which enshrines Buddhist holy relics. These are usually square in form.

2. Sōrin: The crowning spire on a Japanese pagoda; usually made of bronze.

Above: a candlelit Ashina Castle interior.

Shōji: A very lightweight sliding partition used in Japanese architecture; consists of a wooden lattice covered on one side with translucent white rice paper. The lattice is most often composed of small horizontal rectangles, but narrow vertical rectangles or asymmetrical shapes also are used. The lower section is occasionally filled by a thin wooden panel.

You can support my writing projects on Patreon! And you can view the follow-up to this entry by clicking here.

188 notes

·

View notes

Text

Understanding Button Head Screws - EBolts

Button head screws are a versatile fastener choice, renowned for their distinct rounded heads and smooth contours. Typically made from materials such as stainless steel or alloy, these screws are designed to provide a clean, polished look while offering excellent strength and durability. Their unique shape allows for easy installation and removal, making them ideal for various applications in both industrial and residential settings.

The low-profile design of button head screws minimizes the risk of snagging or damage, making them a popular choice in environments where safety and aesthetics are paramount. These screws are commonly used in furniture assembly, automotive applications, and even electronics, where a flush finish is desired. Additionally, their compatibility with a range of tools ensures that they can be easily secured or loosened, making them a practical addition to any toolbox. Whether you're a DIY enthusiast or a professional, button head screws are a reliable option for your fastening needs.

For More:

Contact: 61 3 9336 0155

Timings: Mon-Fri: 9am to 5pm

Visit Us: https://www.ebolts.com.au/

0 notes

Link

SHENZHEN SUPERDA MACHINE CO., LTD.

Superda roll forming machine systems including

Construction material forming machine such as highway guardrail roll forming machine, roof panel roll forming machine, subway station panel roll forming machine, floor deck roll forming machine, drywall steel keel forming machine, stud and track profile roll forming machine, ceiling channel roll forming machine etc.

Metal frame roll forming machine for making rack shelf, solar bracket, logistic beam etc. If classified according to formed metal shape, there are C channel machine, CZ purlin machine, channel roll former, metal stud roll forming machine, door frame roll forming machine, rolling shutter door slat roll forming machine.

Electronic industry metal forming machine such as distribution enclosure forming machine, low voltage cabinet frame forming machine, box beam roll forming machine, cabinet frame upright roll forming machine, cable tray roll forming machine etc.

Metal sheet by cold roll forming process is most flexible and durable, it is more high efficiently than make through extrusion, bending, stamping. Superda roll forming machine systems using top quality material and perfect design, engineer’s experience and technological development are adapted to Europe market standard, excellent forming performance and machine lifespan reach 10-20 years. Timely shipment & Prompt after sale service.

Company has a powerful R&D team from the mechanical, electrical, software and technology professionals that most team members have over 10 years of experiences in the roll forming machine design and metal forming industry.

We always abide by the purpose that "Quality is permanent topic, user satisfaction is eternal center". Superda Roll Forming Machines are sold to over 30 countries, such as Western European, Middle East, Eastern and Southern Asia, and are highly praised and appreciated by metal process manufacturers.

#roll forming machine manufacturer#metal frame roll forming machine#metal sheet#electrical enclosure making machine#metal box roll forming machine#channel purlin machine#rack shelf production machine

4 notes

·

View notes

Text

Steel Market - Forecast(2024 - 2030)

Steel Market - Overview

The Steel market is analyzed to be $1,746.35 billion in 2023 and is projected to reach $2,105 billion in 2030. The market is estimated to grow with a CAGR of 4.13% during 2024-2030. Steel is an alloy that is made up of iron ore or scrap steel and carbon. In general, steels have various unique properties including being non-corrosive, rust-resistant and heavier than other metals such as aluminum. Therefore, steel is extensively used in various end-use industry verticals, including the manufacturing various transportation and automobile components, medical equipment, metal surgical implants, structural components and more, which in turn is boosting its market growth. In recent years, the steel market has experienced fluctuations driven by several factors. One significant trend in the steel market is the impact of trade policies and tariffs. Trade tensions between major steel-producing nations, such as the United States, China, and the European Union, have led to shifts in supply chains and pricing dynamics. Tariffs imposed on steel imports have affected the competitiveness of domestic producers and influenced global trade patterns. Additionally, sustainability concerns and environmental regulations have influenced market dynamics. Increasing awareness of carbon emissions and the environmental footprint of steel production has led to a growing demand for greener steel products. This has prompted investments in cleaner production technologies such as electric arc furnaces and the development of recycled steel. Moreover, technological advancements and innovations in steel manufacturing processes have enhanced efficiency and product quality. As a result, the steel market is poised for sustained growth as global economic recovery accelerates, with innovations in technology and sustainability shaping future trends.

Steel Market Report Coverage

The report: “Steel Industry – Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Steel Market Report.

By Type: Carbon Steel, (Low Carbon Steel, Medium Carbon Steel, High Carbon Steel), Stainless Steel (Austenitic Stainless Steels, Ferritic Stainless Steels, Martensitic Stainless Steels, Precipitation Hardening Grade Stainless Steels, Duplex Stainless Steels), Alloy Steel (Chromium Molybdenum Steel, Nickel-Chromium-Molybdenum Steel, Chromium Vanadium Steel, HSLA -Nickel-Chromium-Molybdenum Steel), Tool Steel (Water-hardening tool steels, Shock-resisting tool steels, Cold-work tool steels, Hot-work steels, High-speed tool steels, Others), Others

By Form: Bar, Rod, Tube, Pipe, Plate, Sheet, Structural, Others

By Application: Transportation (Road, Bridges, Barriers, Rail, Tracks, Rail Cars), Construction (Cool Metal (infrared reflecting) Roofing, Purlins, Beams, Pipe, Recyclable steel framing (studs), Desks/Furniture), Packaging (Canes, Bottles, Others), Water Projects (Levees/Dams/Locks), Energy (Renewable, Nuclear, Bio-fuels, Fossil, Electric Grid), Others

By Industry: Construction (Steel Skeletons, Concrete Walls, Pillars, Nails, Bolts, Screws, Others), Machinery (Bulldozers, Backhoe Leaders, Pipelayers, Others), Automotive and Transportation (Exhaust, Trim/Decorative, Engine, Chassis, Fasteners, Tubing For Fuel Lines), Kitchenware and Domestic Appliances (Small Household Appliances, Black Home Appliances, White Home Appliances), Electrical and Electronics (Motor Mount Brackets, Adapter Plates, Electronic Frames and Chassis, Brackets, Others), Healthcare (Orthopaedic Implants, Artificial Heart Valves, Bone Fixation, Catheters, Others), Energy (Scrubbers, Heat Exchangers, Others)

By Region: North America, South America, Europe, Asia-Pacific and Rest of the World

Request Sample

Key Takeaways

• The Asia-Pacific region, particularly China, has been a dominant force in the global steel market with a share of 63% in 2023, owing to China's rapid industrialization and urbanization have driven substantial demand for steel in the construction, infrastructure, and manufacturing sectors.

• Government infrastructure spending, particularly in major economies, plays a significant role in driving steel demand. Large-scale infrastructure projects, such as bridges, railways, and urban development initiatives, can create substantial demand for steel products.

• The automotive sector is a significant consumer of steel, particularly in the production of vehicles. Changes in consumer demand for automobiles, as well as shifts towards electric vehicles which may use different materials, can impact steel demand in this sector.

Steel Market Segment Analysis – By Type

In terms of type, the Steel Market is segmented into carbon steel, stainless steel, alloy steel, tool steel and others. In 2023, the Stainless-steel segment generated the greatest revenue of $361.94 billion and is projected to reach a revenue of $482.28 billion by 2030. Owing to the various benefits posed by stainless steel such as corrosion resistance, high and low temperature resistance, the ease of fabrication, strength, aesthetic appeal is one of the key factors for its adoption among various end-use industries, which in turn is boosting its market growth. The stainless-steel segment can be further classified as Austenitic stainless steels, Ferritic stainless steels, Martensitic stainless steels, Precipitation hardening grade stainless steel and Duplex stainless steels.

Inquiry Before Buying

Steel Market Segment Analysis – By Form

By form, the steel market is segmented into bar, rod, tube, pipe, plate, sheet, structural and others. The bar segment accounted for the major market share in 2023, with a revenue of $554.58 billion, and is forecast to grow at a CAGR of 4.68% by 2030. The increasing demand for steel bar from various end-user industries such as building and construction, bridges, and many others, are driving the growth of the segment during the forecast period of 2024-2030.

Steel Market Segment Analysis – By Application

Steel Market is segmented by its application that includes transportation, construction, packaging, water projects, energy and others. The energy segment held the dominant market share, 31% of the whole market, in 2023, and is expected to maintain its dominance by 2030 with a CAGR of 4.69%. One of the major factors for the segment growth is the increasing awareness and focus towards renewable energy sources. Steel plays a crucial role in producing and distributing energy as well as improving energy efficiency. Renewable energy is further classified as Wind Towers and Foundation, Wind Turbines and Solar Parabolic Mirror Supports & Collectors.

Steel Market Segment Analysis – By Industry

The Steel finds its application across the industries such as construction, machinery, automotive and transportation, kitchenware and domestic appliance, electrical and electronics, healthcare, energy and others. Among them, the construction segment is the largest consumer of steel, as bearable structures can be manufactured easily at a low cost. The property of steel in its various forms and alloys makes it more flexible to cater the exclusive projects integrated with infrastructure. Moreover, the rapid industrialization and urbanization in various developing countries are fueling the segment growth in strengthening its dominant market position during the forecast period.

Steel Market Segment Analysis - By Geography/Country

The report comprises of the region wise study of the global market including North America, South America, Europe, Asia-Pacific and Rest of the World. Above all, Asia-Pacific region held the biggest share in 2023, up to 63% of the whole steel market owing to the rapidly expanding defense, machinery, automotive, and shipbuilding industries in the countries such as India, China, South Korea, and Japan. Foreign direct investment in energy and infrastructure is likely to provide opportunities for the market vendors. Coupled with favorable government regulations, growing infrastructure and construction activities in developing economies of the Asia-Pacific region are boosting the demand for the market.

Schedule a Call

Steel Market - Drivers

Growing Demand for Steel Across the Various Regions

Several factors have a significant impact on the overall development of the steel market. The major growth factor driving the Steel Market is the growing demand for steel across a variety of developing regions. For instance, Global crude steel production in January-November 2023 reached 1715.12 million metric tons, marking a marginal 0.5% year-on-year growth, per provisional data from the World Steel Association. November 2023 saw a production of 145.5 million metric tons, up by 3.3% from the previous year. China led the production with 952.14 million metric tons, followed by India and Japan, USA, Russia, South Korea, and Germany.

Construction and Infrastructure Development:

Construction activities, including residential, commercial, and infrastructure projects such as roads, bridges, and railways, are major drivers of steel demand. Urbanization and industrialization also contribute to the growth of the construction sector, thereby increasing the demand for steel products. For instance, as per Green Finance & Development Center, China Belt and Road Initiative (BRI) Investment Report 2023, engagement totalled about USD88.3 billion, with USD44.6 billion from investment and USD43.7 billion from construction contracts. Also, The US Department of Transportation allocates $3.2 billion in extra funding, alongside $4.3 billion from the Bipartisan Infrastructure Law for 2023. The Budget prioritizes $4.5 billion for the Capital Investment Grant program, aiming to bolster transit infrastructure for economic growth. As a result, the steel market is anticipated to thrive, propelled by heightened construction activities and the need for durable materials, reflecting a promising outlook for the industry.

Steel Market -Challenges

Environmental Regulations and Sustainability

The steel industry is facing mounting pressure to tackle environmental issues by cutting carbon emissions and enhancing sustainability efforts. Meeting stringent environmental regulations demands substantial investments in technology and infrastructure, presenting a formidable challenge for many companies. Despite the financial hurdles, embracing these changes can pave the way for a more sustainable and eco-friendly future for the industry.

Buy Now

Steel Market - Competitive Landscape

The companies referred in the study include Baosteel Co., Ltd., Posco Holding Inc, Nippon Steel Corporation, JFE Holdings, Tata Steel Limited, United States Steel Corporation, Anshan Iron and Steel Group Corporation, Hyundai Steel Co., Ltd., ThyssenKrupp AG, ArcelorMittal S.A., among others. Technology launches, acquisitions, and R&D activities are key strategies adopted by the key players in the Steel Market.

Steel Market - Recent Developments

November 2022, Tata Steel launched the fourth edition of MaterialNEXT, focusing on 'Materials to Wonder.' This open innovation event aims to gather ideas on emerging materials and their applications. The program spans five months across Idea Selection, Development, and Evaluation stages, fostering collaboration among scientists, researchers, and startups.

May 2022, Kobe Steel introduced "Kobenable Steel," Japan's pioneering low CO2 blast furnace steel, aiming to curtail emissions during ironmaking. Utilizing innovative CO2 Reduction Solution technology, it plans to roll out the product this fiscal year, marking a milestone in sustainable steel production.

In June 2023, Nippon Steel introduces ZEXEED™ Checkered Sheet, a new addition to its high corrosion resistant coated steel series

#steel market#steel market size#steel market shape#steel market forecast#steel market analysis#steel market report#steel market growth

0 notes

Text

Stacked against Solar Mounting Systems Supplier installation of conventional platforms

Stacked Carport Mounting System against installation of conventional platforms, the Field-Fast racking can reduce costs per watt right from 35 to make sure you 50 percentage point. “With lesser parts and additionally installation simple steps, we pretty much can structure the install amount of time in half you might find, ” Goodwin tells. “On all the mechanical BoS area of an use, which certainly is the racking its own matters, we’re willing to show approximately 40 percentage point labor efficiency about the cost for watt, so this actual cooperate cost for watt just for mechanical is related to. 4 mere cents per watt, Solar Mounting Systems Supplier and that’s approximately 20 percent underneath we’re seeing looking to purchase racking. Relating to the panel install, those took labor costs all the down to. 2 mere Aluminum Solar Panel Roof Mounting System cents per watt. ” OMCO could perhaps handle all the purlins and additionally turnkey work services, but this approach isn’t just another tale about faster simply turn times and additionally reduced price ranges. Ordering factory-direct snips apart other potential uses for delays, that include last subsequently module transformations. “We may well adjust this roll-form program for just a size presented module [including the new First Solar Solar Mounting Bracket Accessories Series 6] just for Field-Fast, ” Goodwin tells. “We be aware of of campaigns where web template modules change go on second resulting from prices, and we’re willing to make many changes and alter to that. Which has been difficult any time you’re needing it created Roof Mounting System elsewhere. ”

1 note

·

View note

Text

What is Hurricane Strapping?

When Hurricane Irma arrived in a couple of islands a few years back, a lot of roofs stayed put, reason being they had been fastened with hurricane straps.

This should suffice to assure you that installing a hurricane strap in your house is the need of the hour and must not be delayed. Though it is not certain that your roof will successfully brace a Category 5 storm, a hurricane strap is nevertheless a useful and inexpensive addition to your house’s existing components that you just cannot overlook.

Based on where you reside, chances are these straps may already be comprising the building code. And if they don’t, new constructions may have to be done to install the straps and allow them to pass the inspection and meet the code requirements. The roofs of older houses in all probability will be lacking hurricane straps. For these, the straps can be retrofitted to further strengthen and safeguard the aging edifices.

In hurricane strapping, a connector is placed between a wooden roof and the house below to attach the two firmly. The most common hurricane straps are built with galvanized or stainless steel with the goal to safeguard physical structures from turbulent weather conditions such as storms and excessive rain. Properties lying in a coastal area in particular should not be devoid of them. Hurricane straps are known by other names too like hurricane ties, hurricane brackets, hurricane anchors, hurricane clips, and hurricane strips.

Hurricane strapping in Florida

Florida, a state situated adjacent to the sea in the southeast of the United States, is quite susceptible to storm devastation, the two recent hurricanes being a case in point. And post Hurricane Andrew in 1992, the building code of Florida was revised, necessitating all new constructions (even those made of timber and concrete) to feature hurricane ties. There is every possibility that houses built prior to this period may not be equipped with hurricane straps and the solution lies in retrofitting.

Because hurricane straps are required to meet the area’s building code and certain technical specifications, their installation becomes the prerogative of experts. And even if you move into a house that already has hurricane straps fitted in it, you will still have to get them inspected to ensure nothing is amiss.

Different types of hurricane straps

Do not have this notion that hurricane straps come in just one form. Hurricane straps have multiple variants designed for different sections including timber connectors, rafter connectors, multipurpose straps, rafter/purlin clips, mending plates, truss anchors, moment connectors, twist ties and purlin braces.

So while timber connectors help in connecting beams, purlins, wall plates, floor plates, rafters, and studs firmly to the main structure, rafter connectors assist in forming a stronger bond between rafters and ridge boards.

When your house has every required hurricane strap, only then can you think of continuing to have a roof over your head, come hell or high water.

However, if all the precautions taken by you fail to prevent your roof or house from sustaining damage on being pounded by a fierce storm, you will be required to file an insurance claim and for a faster settlement and a bigger reward, you can avail public adjusting services that have helped many a policyholder draw maximum benefits from their coverage.

0 notes

Text

Function of the Structure Steel Detailer

The role of the steelwork draughtsman or detailer examined more closely. When the contract is placed with a structure steel fabricator, and assuming that the steelwork detailer works for the fabricator, their duties can be categorised as follows.

The first function is to prepare a list of steel materials from the layout drawings provided by the consulting engineer, enabling the contractor to reserve the items from stock or to place orders with steel merchants or steel mills.

The detailers proceed with the preparation of the steel detailing drawings, providing an accurate representation of components of structures, namely, beams, girders, , columns, bracings, stairways, platforms, rails, brackets, girts, purlins etc., and where other structures such as bridges, towers, tanks etc., are involved, these will follow broadly the same pattern.

An experienced senior detailer must carefully supervise drawings and carefully scrutinise them as a checker. It is essential to correct the errors at this stage, as the correction of errors during fabrication in the shop or during erection on site will be infinitely more expensive. Draughtsmen should be critical of their own work, subconsciously acting as their own checker, to ensure that, to the best of their ability, their drawings are error-free.

The detail drawings are sent to the fabrication shop, where work is put in hand, drawing the material from stock, cutting it to exact length, drilling or punching the necessary holes and assembling the various parts by means of bolting or welding to make up the components or subassemblies ready for transport to site.

The drawing office, whether using a manual system or computer aided facilities, must now proceed with the preparation of erection drawings, showing steel framework in skeleton. These drawings should be checked by the senior detailer and endorsed by a qualified structural engineer. The steel detailing services erector will refer to these drawings for the assembly of the structure on site. The position of each component is identified by a distinguishing erection mark. In the fabrication shop, such erection marks are hand-marked, painted or tagged onto the steel components.

All drawings are updated to incorporate any revisions that have occurred during the progress of the job and a complete set of prints is handed to the engineer for filing. These serve as a record of the work and are useful for future reference

Undoubtedly, we have seen great change and growth over the past 20 years. I am very much confident about that the years ahead will be just as remarkable.

I thank D05 Design and engineering staff past and present for being part of the growing D05 family and for their efforts and their contributions

#structural steel detailing services#steel detailing companies in us#structural steel detailing companies in usa#top steel detailing companies in usa#structural steel detailing services in us#D05#stair steel detailing services#Steel Detailing company in us#structural steel detailers near me#steel detailing services in usa

0 notes