#steel market

Text

Understanding the Steel Rates in India: A Complex Pricing Landscape:

Steel, a cornerstone of India’s construction and manufacturing industries, plays a vital role in the nation’s development. From skyscrapers to bridges, from highways to residential buildings, steel is the backbone of infrastructure growth. However, the pricing of this essential material is far from straightforward. The steel rates in India today are shaped by a delicate and dynamic interplay of factors that continuously influence costs, impacting everyone from large construction firms to individual consumers.

The Steel rate: Raw Material Costs

Steel production relies heavily on two critical raw materials: iron ore and coking coal. These materials are at the heart of steelmaking, and their prices are closely tied to global market dynamics. Any disruption in the supply of iron ore, whether due to geopolitical tensions, natural disasters in mining regions, or increased demand from steel giants like China, can significantly impact the cost of steel production in India.

When iron ore prices rise globally, steel manufacturers in India face higher production costs, which are inevitably passed on to consumers in the form of increased steel prices. Similarly, coking coal, which is essential for converting iron ore into steel, is also subject to price fluctuations driven by global energy markets, trade policies, and supply chain disruptions. A spike in coking coal prices results in higher steel production costs, making it more expensive for builders and manufacturers to procure the steel they need.

Domestic Market Demand: Construction as a Driving Force

In India, the construction sector is one of the largest consumers of steel rate, and its demand significantly influences steel prices. Market demand for steel is closely linked to the overall health of the economy. When the economy is booming, infrastructure projects abound—new roads, bridges, housing developments, and commercial buildings. During these times of economic expansion, the demand for steel soars, driving prices upward as manufacturers work to keep pace with the need for this critical material.

Government-led infrastructure projects also play a pivotal role in shaping demand. Initiatives such as the construction of highways, railways, and smart cities can lead to a surge in steel consumption. On the flip side, during periods of economic slowdown or when construction activity slows down, the demand for steel may decline, resulting in more stable or even reduced prices. Understanding these demand patterns is crucial for anyone involved in construction, as they directly impact project costs.

Production Costs: The Energy and Labor Factor

The process of manufacturing steel is energy-intensive, requiring substantial inputs of electricity and fuel at various stages, from melting and casting to rolling and finishing. Energy costs are a major component of steel production, and any fluctuations in electricity tariffs or fuel prices can directly affect the cost of producing steel.

Additionally, labor costs—which vary depending on the region—contribute to the overall expense of steel production. Manufacturers must also invest in modern technologies and quality control measures to ensure their products meet high standards. While these investments are necessary for maintaining quality, they also increase production costs, which are reflected in the final steel rates.

Conclusion:

The steel rates in India today are shaped by a multifaceted set of factors that intertwine global market forces, domestic demand, regional pricing variations, production costs, and government policies. This dynamic pricing environment requires vigilance from stakeholders in the construction industry, as well as consumers who rely on steel for various projects.

If you are looking for best quality tmt bars, please visit our website : www.steeloncall.com or you can contact us through our toll-free number: 18008332929

1 note

·

View note

Text

Steel Imports in India: Key Trends, Data & Top Countries

India, a rapidly developing economy, has witnessed significant growth in infrastructure, construction, and industrial sectors, which has driven the demand for steel. While India is one of the world's largest producers of steel, it still relies on imports to meet its growing domestic demand. Steel imports play a crucial role in complementing domestic production, particularly in specialized steel types where domestic manufacturers face limitations. In this article, we will explore the import of steel in India, analyze data on Indian steel imports, examine the countries that play a key role in this trade, and provide insights into the top 10 steel-importing countries globally.

Import of Steel in India: An Overview

India's steel sector is a cornerstone of its industrial growth, contributing significantly to the nation's GDP. Despite having a strong domestic production base, India has continued to import steel to meet specific needs, such as high-grade and specialized steel used in sectors like automobiles, defense, and infrastructure. The Indian government has undertaken various initiatives to boost domestic steel production, but imports remain essential to filling gaps in domestic supply and ensuring the availability of specific steel grades.

Indian steel imports vary by category and often depend on factors such as demand fluctuations, cost competitiveness, and availability of raw materials. These imports help maintain the supply-demand balance and meet the requirements of various industries, including the construction, manufacturing, and automotive sectors.

Steel Imports by Country

Several countries contribute to India's steel imports, each supplying different types and grades of steel. The top steel exporters to India include countries with advanced steel industries that produce specialized steel variants. Here's a list of steel imports by country:

China

China is one of the largest steel producers and exporters in the world, making it a significant source of steel for India. Despite India’s efforts to curtail its dependency on Chinese imports, Chinese steel, especially finished and semi-finished products, continues to play a critical role in India's steel sector.

Japan

Japan's advanced steel technology and high-quality products make it a reliable exporter to India. Japanese steel is preferred in industries that require precision and high durability, such as automotive and electronics manufacturing.

South Korea

South Korea is another key exporter, known for its high-quality steel. The country's advanced steel production capabilities allow it to cater to India's need for specialized steel in sectors like construction and heavy engineering.

Russia

Russia has emerged as an important steel exporter to India, offering competitive prices and a variety of steel grades. The country’s vast reserves of raw materials enable it to provide high-quality steel at lower costs.

Germany

Germany is renowned for its high-quality engineering and steel products. Although not a major player compared to China or Japan, Germany supplies specialized steel to India, particularly for industries like automotive and machinery manufacturing.

Indian Steel Imports Data: An Analysis

Analyzing steel import data reveals valuable insights into the trends and dynamics of India's steel sector. According to recent reports, India imported approximately 6 million metric tons of steel during the last financial year. The demand for steel imports is primarily driven by sectors such as infrastructure, construction, defence, and automotive industries.

The most significant category of steel imported by India includes finished steel products, semi-finished steel, and flat-rolled products. A substantial share of these imports comes from countries with advanced steel manufacturing industries. A review of Indian steel imports data also highlights a fluctuation in imports based on changes in government policies, global steel prices, and the growing domestic production of steel.

In recent years, the Indian government has introduced measures like imposing anti-dumping duties and other tariffs on imported steel to protect domestic manufacturers from cheap imports. However, the demand for certain types of steel that cannot be produced locally continues to drive imports.

Top 10 Steel Importing Countries

While India is a notable steel importer, it is far from being the largest globally. The following list shows the top 10 steel importing countries, driven by their industrial demand:

United States

The US is the largest steel importer globally. Despite having a significant domestic steel industry, the country relies on imports for various types of steel used in construction, automotive, and manufacturing sectors.

Germany

Germany imports substantial amounts of steel, mainly for its robust manufacturing sector, which includes automotive and heavy machinery industries.

China

Although China is the largest steel producer, it also imports steel, especially raw materials and semi-finished steel products, to meet its domestic and export demands.

South Korea

As a global leader in technology and heavy industries, South Korea imports steel to support its manufacturing sector, which includes shipbuilding and automotive industries.

Italy

Italy is a major importer of steel, with a heavy demand from its industrial and construction sectors. It imports various steel grades to meet the requirements of its manufacturing sector.

Mexico

Mexico imports significant amounts of steel, primarily for use in its booming automotive and construction industries, which contribute to its strong export economy.

Turkey

Turkey imports a large volume of steel for its construction and infrastructure projects, making it one of the largest steel importers in the region.

Vietnam

Vietnam's rapidly growing construction and manufacturing sectors drive its steel imports, positioning it as a key player in the global steel market.

Thailand

Thailand imports steel to support its industrial and construction sectors, contributing to its growing economy.

10. France

France imports steel to meet the needs of its automotive, aerospace, and construction industries, making it a major importer in Europe.

Conclusion

Steel imports are critical to India's industrial growth, complementing domestic production and filling the gaps in demand for specialized steel types. While India aims to strengthen its steel manufacturing capabilities, imports remain essential for meeting the specific needs of high-growth sectors like the construction, defence, and automotive industries. Countries such as China, Japan, and South Korea play a vital role in supplying India with steel, and analyzing steel import data helps shed light on key trends and patterns. On the global stage, countries like the United States, Germany, and China are the largest steel importers, reflecting the dynamic nature of global steel trade. However, if you need steel import data, steel HS code, or global trade data, you can connect with import and export data provider platforms like Seair Exim Solutions.

Frequently Asked Questions (FAQs)

Q1. Why does India import steel despite being a large producer?

India imports steel to meet the demand for high-quality and specialized steel types that are not produced in sufficient quantities domestically, such as those used in the automotive and defense sectors.

Q2. Which countries are the largest steel exporters to India?

The largest steel exporters to India include China, Japan, South Korea, Russia, and Germany.

Q3. How much steel does India import annually?

India imports approximately 6 million metric tons of steel annually, depending on factors such as domestic demand, global steel prices, and government policies.

Q4. What types of steel does India import the most?

India primarily imports finished steel products, semi-finished steel, and flat-rolled products, which are used in various industrial sectors.

Q5. What measures has the Indian government taken to reduce steel imports?

The Indian government has implemented anti-dumping duties, tariffs, and other measures to protect domestic steel manufacturers and reduce their reliance on imports.

Also Read:

The Rising Significance of the Export of Steel from India

Post By:

Seair Exim Solutions

Phone No.: 099900 20716

Address: B1/E3 Mohan Cooperative Industrial Estate Near Mohan Estate Metro Station Opposite Metro Pillar No:-336, NH-19, New Delhi, Delhi 110044

#steel#steelimport#steelimportdata#import of steel in India#steel imports by country#Indian steel imports#top 10 steel importing countries#global trade data#international trade#trade data#trade market#global market#steel market#steel industry#import#importers#steel importers

0 notes

Text

Global steel market trends and their impact on India. Read the blog post to learn more.

0 notes

Text

Exploring the Dynamics of the India Steel Market: Trends, Prices, and Leading Companies

Delve into the India Steel Market, a critical sector driving economic growth and infrastructure development. Discover the latest trends in Steel Market dynamics and the factors influencing Steel Commodity Prices in India. Learn about prominent Steel Companies and their role in shaping the industry, from advanced Steel Factories to diverse Steel Products. Gain insights into the properties and applications of Steel Metal and Steel Material, essential components in construction and manufacturing. Explore the innovations of leading Steel Manufacturing Companies and the current Steel Rate trends. Understand the competitive landscape of Steel Companies in India and meet the top Steel Manufacturers in India, key players ensuring quality and sustainability in steel production. This comprehensive overview provides valuable knowledge for investors, industry professionals, and anyone interested in the robust and evolving steel sector in India.

#India Steel Market#Steel Market#Steel Commodity Prices India#Steel Company#Steel Factory#Steel Products#Steel Metal#Steel Material#Steel Manufacturing Companies#Steel Rate#Steel Companies In India#Steel Manufacturers In India

0 notes

Text

Steel Market Share, Growth, Industry Analysis, Report 2024-2032

IMARC Group, a leading market research company, has recently releases report titled “Steel Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032” offers a detailed analysis of the industry, including the steel market report. The global market size reached US$ 942.3 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 1,279 Billion by 2032, exhibiting a growth rate (CAGR) of 3.3% during 2024-2032.

Request For Sample Copy of Report: https://www.imarcgroup.com/steel-market/requestsample

Factors Affecting the Growth of the Steel Industry:

Urbanization and industrial development:

A significant driver of the global steel market is the rapid urbanization and industrial development, particularly in emerging economies. As countries undergo urban transformation, the demand for steel escalates in various sectors such as construction, infrastructure, and transportation. Steel, known for its durability and versatility, is integral in constructing buildings, bridges, railways, and other infrastructure projects. Emerging economies, notably in Asia and Africa, are experiencing a rise in construction activities, which in turn, is boosting steel consumption. Furthermore, industrialization efforts, including the expansion of manufacturing capabilities, are also contributing to the increased demand for steel, as it is a fundamental material in manufacturing processes across various industries.

Automotive industry growth:

The automotive industry remains a crucial end-user of steel, influencing the global steel market significantly. Innovations in vehicle design and the rising production of automobiles worldwide are contributing to the steady demand for steel. The shift toward lightweight and high-strength steel variants to improve fuel efficiency and meet regulatory standards on emissions are further intensifying this demand. Moreover, with the advent of electric vehicles (EVs), the automotive sector is undergoing a transformation, necessitating new types of steel and alloys to meet specific requirements for EV production, such as battery enclosures and lightweight frames. This evolving landscape in the automotive sector presents ongoing opportunities for the steel industry to innovate and adapt.

Technological advancements and sustainability efforts:

Technological advancements and a growing emphasis on sustainability are significantly influencing the global steel market. Innovations in production techniques, such as electric arc furnace technology, have made steel production more efficient, cost-effective, and environmentally friendly. These advancements help in reducing the carbon footprint of steel production, aligning with global efforts to combat climate change. Moreover, the recycling capabilities of steel play a pivotal role in promoting a circular economy, making steel a preferred material in various sectors committed to sustainable practices. The ongoing research and development in creating more sustainable and higher-quality steel variants are expected to drive market growth, catering to the evolving demands of industries prioritizing environmental responsibility and efficiency.

Leading Companies Operating in the Steel Industry:

ArcelorMittal S.A.

EVRAZ plc

Gerdau S.A.

Hyundai Steel Co. Ltd

JFE Steel Corporation (JFE Holdings Inc.)

Jiangsu Shagang Group Co. Ltd

Nippon Steel Corporation

Nucor Corporation

Shougang Group Co. Ltd.

Tata Steel Ltd. (Tata Group)

thyssenkrupp AG

United States Steel Corporation

Steel Market Report Segmentation:

By Type:

Flat Steel

Long Steel

Flat steel represents the leading type segment on account of its extensive use in industries such as automotive, construction, and heavy machinery, due to its versatility, easy fabrication properties, and wide range of applications.

By Product:

Structural Steel

Prestressing Steel

Bright Steel

Welding Wire and Rod

Iron Steel Wire

Ropes

Braids

Structural steel holds the largest market share, driven by its critical role in construction and infrastructure projects, offering strength, durability, and flexibility in design, which are essential for large-scale constructions.

By Application:

Building and Construction

Electrical Appliances

Metal Products

Automotive

Transportation

Mechanical Equipment

Domestic Appliances

Building and construction account for the majority of the market share due to the indispensable use of steel in construction activities for its strength, sustainability, and cost-effectiveness, meeting the demands of growing urbanization and infrastructure development.

Regional Insights:

North America (United States, Canada)

Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

The dominance of the Asia Pacific region in the steel market is attributed to the large manufacturing base and increasing urban population.

Global Steel Market Trends:

One of the most significant trends in the market is the focus on producing advanced high-strength steels (AHSS), which offer superior strength-to-weight ratios. This is particularly important in the automotive industry, where the demand for lightweight yet strong materials is increasing to enhance fuel efficiency and reduce emissions. Additionally, the integration of digital technologies like AI and IoT in steel manufacturing processes is gaining traction. These technologies enable predictive maintenance, improved quality control, and enhanced operational efficiency, leading to cost savings and increased competitiveness.

Another notable trend is the rise in demand for eco-friendly steel. As global awareness and regulations around environmental sustainability intensify, the steel industry is exploring innovative methods to reduce carbon emissions. This includes the adoption of green steelmaking processes using renewable energy sources and the development of low-carbon steel products. The recycling aspect of steel also presents vast opportunities, as recycled steel maintains its quality and strength, making it a key player in the circular economy. Moreover, the expansion of the construction sector, especially in developing countries, continues to offer growth opportunities for the steel market. The need for durable and versatile steel products for infrastructure, residential, and commercial projects is a significant driver of demand.

Other Key Points Covered in the Report:

COVID-19 Impact

Porters Five Forces Analysis

Value Chain Analysis

Strategic Recommendations

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes

Text

APL Apollo Tubes’ recent financial report is undoubtedly a cause for celebration. A 35% annual profit growth is an achievement that highlights the company’s commitment to excellence and its ability to adapt to the ever-changing market conditions. Despite a minor dip in share prices, it’s crucial to focus on the big picture – APL Apollo Tubes is a strong, growing company with a bright future. As it continues to make strides in the structural steel tubing industry, investors and industry enthusiasts should keep a close eye on this exceptional company.

0 notes

Link

The global steel market size reached US$ 907 Billion in 2022. Looking forward, IMARC Group expects the market to reach US$ 1,077 Billion by 2028, exhibiting a growth rate (CAGR) of 2.8% during 2023-2028.

0 notes

Text

0 notes

Text

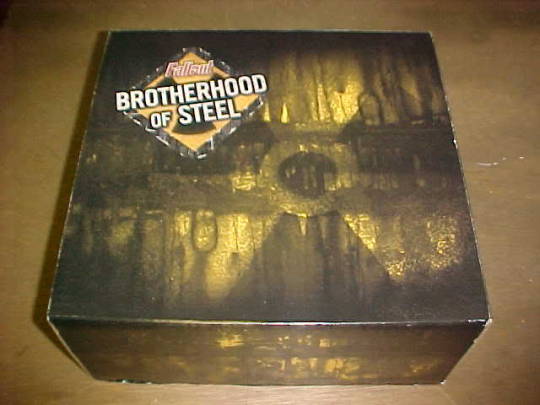

Pictured: The Fallout: Brotherhood of Steel press kit. Inside was a disc with media assets, a water bottle, a first aid kit, and a flashlight.

Some of the kits also contained condoms and a video named "A guide to post-nuclear intimacy."

If you have this press kit, we would be interested in acquiring it for archival purposes.

You can read more about the marketing of Fallout: Brotherhood of Steel here.

Our friend Triangle City has also made a video about A guide to post-nuclear intimacy which you can see here.

94 notes

·

View notes

Text

Structural Steel and TMT Bars in Modern Construction

Structural steel and TMT bars are the backbone of modern construction, providing the necessary strength and durability for buildings and infrastructure. As construction demands increase, so does the need for high-quality materials that ensure safety and longevity. Whether you’re working on residential, commercial, or industrial projects, understanding the benefits of structural steel and TMT bars is crucial.

Why Structural Steel and TMT Bars are Essential

Structural steel is renowned for its high strength-to-weight ratio, making it an ideal choice for large structures that require stability without excessive bulk. It offers flexibility in design, allowing architects and engineers to create innovative and complex buildings while maintaining structural integrity. The use of structural steel in construction provides resilience against natural forces such as wind and earthquakes, making it a preferred material in regions prone to such challenges.

TMT bars, or Thermo-Mechanically Treated bars, complement structural steel by reinforcing concrete structures. These bars are specifically designed to withstand high stress and are known for their excellent bonding with concrete, ensuring that the structure can bear heavy loads. The thermo-mechanical treatment process gives TMT bars enhanced strength, ductility, and corrosion resistance, making them ideal for use in foundations, columns, beams, and other critical components of a building.

Purchasing Structural Steel and TMT Bars Online

With advancements in technology, purchasing structural steel and TMT bars online has become increasingly convenient. Online marketplaces offer a wide range of options, allowing builders and contractors to compare prices, check specifications, and make informed decisions from the comfort of their offices. Structural steel online platforms provide detailed information on various steel grades, sizes, and prices, making it easier to find the right materials for your project.

Similarly, buying TMT bars online ensures you get the best deals and access to top-quality products. These platforms often feature the latest TMT bar prices, helping you stay within budget without compromising on quality. Additionally, online purchasing often comes with the added benefits of doorstep delivery and secure payment options, further simplifying the procurement process.

The Importance of Choosing the Right Materials

Selecting the right structural steel and TMT bars is crucial for the success of any construction project. The strength and durability of these materials directly impact the safety and longevity of the structure. By choosing high-quality TMT bars and structural steel, you can ensure that your building can withstand environmental challenges, such as seismic activity and harsh weather conditions.

Moreover, the right choice of materials can lead to cost savings in the long run. High-quality TMT bars and structural steel require less maintenance and reduce the need for repairs, ultimately lowering the total cost of ownership for the structure.

Conclusion

Structural steel and TMT bars are indispensable components of modern construction, providing the strength, durability, and flexibility needed for safe and resilient structures. By purchasing these materials online, builders and contractors can take advantage of competitive prices and a wide range of options, ensuring that their projects are built to the highest standards. Whether you're working on a large commercial project or a smaller residential build, investing in quality structural steel and TMT bars is a decision that pays off in both safety and longevity

0 notes

Text

New Taipei City Lantern Festival

#I diligently braved the crowds to look at the lanterns but the night market section was too much#however it was good of them to host the thing in a large park at least#I'm still steeling myself to go back to Ximen for the Taipei City one#lanterns#taipei#Taiwan#lantern festival#元宵節

24 notes

·

View notes

Text

18 years old, slaving away on my job, still live with my family, have no idea what I’m doing, no future, still balls-deep in the dark pit, feeling like absolute an absolute failure and the loneliest person in the whole goddam world, hate myself, hate my life, given up on falling in love, unhealthy, smoking.

Happy birthday to me. The most underserving person in the world.

#bucktommy#annabel lee nevermore#romance#spooky month#self h@rm#poetry#2014 tumblr#cry of fear#goth#k#m#s#corn#legend of zelda#nail art#marketing#zendaya#peter steele#the disturbing rabbit hole of laceygames.com#kappa black mirror#dont hug me im scared#abreathofdeath#type o negative#i need to lose so much weight#shattered bloodmoon#nature#miguel ohara#fantasy high junior year#iono#aemond one eye

17 notes

·

View notes

Note

Drawing request. Arthur and Zarian at applebees. Arthur has ordered the apple. Zarian has chosen the bees.

they're about to be banned from all applebees locations for fifty years

#this is 110% not what you were asking for but i was bored [read: avoiding other responsibilities]. enjoy#anyways applebees exists in shr setting now as a joint fruit market slash bee store. god bless#this is fucking stupid lol#steelheart redux#arthur steele#zarian#my art#ask#anon#guy who was like “this is stupid im not going to put effort into linig this” and painted it instead. cool

43 notes

·

View notes

Text

homunculus facts¡

there were no homunculi in the cambrian era' since most animals were basically wormlike• there were however wormunculi' which are like homunculi but simpler•

a survey of 20000000 homunculi in master,s lab revealed that not one was neurotypical• this has clear implications on master,s recipe and the value of his market research' but he has ignored these findings•

emails are as hazardous to a homunculus as strychnine is to typical lifeforms• unlike strychnine' which is like candy to homunculi•

i took up steel drums this week and am learning quickly• plink plink plink•

i saw a wormunculus in real life this week and it was freaky• i thought they were extinct but apparently people can just whip them up at home¡

you,re so in love with me but i,m too weird for you• it,s time to let me go•

#homunculus#homunculus facts#wizardposting#unreality#paleontology#worms#market research#capitalist wizards#those goddamn emails#strychnine#steel drums#alchemy#hes just not that into you

20 notes

·

View notes

Text

Metalman Auto files draft papers with SEBI to raise funds via IPO

The IPO consists of a fresh issue of Rs 350 crore and an offer for sale of upto 12.64 million shares by its existing shareholders and promoters.

Metalman Auto Ltd has submitted a Draft Red Herring Prospectus (DRHP) to the Securities and Exchange Board of India (SEBI) to raise capital through an Initial Public Offering (IPO). The IPO includes a fresh issuance of shares worth Rs 350 crore and an offer for sale of up to 12.64 million shares by the company’s current shareholders and promoters.

The proceeds from the fresh issue will be allocated as follows: Rs 25 crore will be used to partially finance the capital expenditure for the procurement of plant and machinery at the Pithampur manufacturing unit 2. The company also plans to utilize Rs 240 crore to repay a portion of its existing debt. As of June 2024, Metalman Auto Ltd has a total debt of Rs 314.43 crore.

The firm operates nine manufacturing units across five states in India, strategically located near OEM customers to ensure efficient production and supply. Axis Capital, ICICI Securities, and Motilal Oswal Investment Advisors are the lead managers for this issue.

Metalman Auto Ltd is a leader in the metal fabrication, finishing, and assembly sector in India, specializing in the production of metal components for two-wheelers (including both electric and internal combustion engines), three-wheelers, passenger vehicles, commercial vehicles, agri-vehicles, and off-highway vehicles. Additionally, the company manufactures aesthetic components for white goods, such as panels for washing machines, and offers contract manufacturing services for two-wheeler electric vehicle (2W EV) OEMs.

#metalman auto#oem manufacturing#oemparts#electric vehicles#metal fabrication#fabricationservices#steel fabrication#supplier#manufacturer#stainless steel#transport technology#transport service#transport for london#vehicle transport#transportation#ipo news#ipo alert#markets#stocks#business standard#business magazines#High-Volume Automotive Parts Manufacturing#manufacturing#automotive parts#parts Manufacturin#automotive industry#automotive#car accessories

2 notes

·

View notes