#ripening chamber manufacturer

Text

Ripening chamber manufacturers in India

With our cutting-edge ripening chambers you can maximize the potential of your food! We provide specialized solutions for the ripening of bananas, mangoes, and other fruits as top manufacturers in India.

Our Ripening chambers in India are built to be effective, long-lasting, and precisely controlled, guaranteeing consistently flawless ripening.

Contact us today for a consultation and a quote!

Phone: +918866230337

Email: [email protected]

Website: https://www.blueiceindia.com/

#banana ripening chamber project cost#ripening chamber exporter#ripenning chamber supplier#ripening chamber manufacturer#ripening#ripening chamber manufacturer in India#ripening chamber manufacturer ahmedabad

0 notes

Text

Discover How Future Freshness Will Be Changed by Our Ripening Chambers!

Are you a retailer, exporter, or distributor of fruit seeking to improve the quality and longevity of your produce? Look nowhere else! For the best ripening chamber solutions in Gujarat, Blue Ice India

What Makes Our Ripening Chambers the Best?

Modern Technology: To produce the optimal atmosphere for controlled ripening, our chambers are outfitted with cutting-edge technology.

Customized Solutions: We are aware that every fruit has a different ripening schedule. Our specialists design chambers specifically for your goods, providing the best results each and every time.

Energy Efficient: We built our chambers to be as energy efficient as possible, lowering operating expenses while boosting performance. Without sacrificing quality, be green!

Expert Support: From installation to maintenance, our motivated crew offers thorough support. To ensure smooth operations, we are by your side at every stage.

Proudly Local: As a company located in Gujarat, we take pride in helping to advance the local food and agriculture sectors. By choosing us, you're promoting a locally owned company.

To find out more about how our fruit ripening chambers can change your fruit business, get in touch with us right now. Let's work together to give your consumers produce that is more flavorful, fresher, and more durable. We're developing a healthy future together!

#ripening chamber manufacturer#ripening chamber supplier#ripening chamber manufacturer in India#top ripening chamber manufacturer in India

0 notes

Link

The biggest role a cold warehouse by cold storage manufacturers plays is that it keeps your products at a defined low temperature. As a result, the products remain fresh and last longer than normal.

#cold storage manufacturers#cold room manufacturers#cold chamber manufacturers bangalore#Ripening Chamber

0 notes

Text

How Ripening Chambers and Cold Rooms Ensure Banana Freshness

The integration of ripening chambers and cold rooms is crucial in maintaining the quality and taste of bananas from harvest to consumption. This seamless transition between ripening and storage not only boosts supply chain efficiency but also significantly reduces food waste and fulfils consumer demands for high-quality produce.

Banana Ripening and Storage

Ripening chambers play a vital role in accelerating the ripening process by controlling temperature, humidity and ethylene levels while preserving the fruit’s quality. Cold rooms, on the other hand, are essential for extending the shelf life of bananas and preventing premature spoilage.

Bananas are ideal for long-term storage due to their ethylene gas emissions, which speed up maturation. When stored while still green, bananas can last for 6-7 weeks. However, they cannot be directly marketed from storage. To achieve the desired yellow colour, bananas are treated with ethylene in controlled environments, which converts chlorophyll to a yellow pigment in 6-8 days, depending on the temperature.

In a ripening room, bananas typically transition from green to yellow in 4-6 days, gaining sweetness and flavour.

Challenges in Banana Storage

Bananas are susceptible to various diseases and injuries during storage, including Anthracnose, Blackrot, Chilling Injury, Fruit Spot and Rhizopus Rot. Both green and ripe bananas can bruise easily, so careful handling at each stage is crucial to minimise damage and maintain market value.

Temperature and Humidity

Temperature and humidity are pivotal in the ripening process. The ideal temperature for ripening bananas is between 18-25°C, with humidity levels maintained at 85-95%. These conditions facilitate the enzyme activity that converts starches into sugars, enhancing the bananas' sweetness and flavour.

Proper ventilation and air circulation are essential in ripening chambers and cold rooms to ensure even ripening and storage conditions. Adequate airflow helps distribute ethylene evenly in ripening chambers and maintains consistent temperature and humidity levels in cold rooms, thereby optimising fruit quality and freshness.

Impact of Cold Rooms on Nutritional Value

Cold rooms use refrigeration systems to maintain a stable temperature, preventing spoilage due to temperature fluctuations. When well-maintained, cold rooms do not significantly impact the nutritional value of bananas. Instead, they help retain essential nutrients by preserving fruit freshness.

Benefits of Ripening Chamber

Ripening chambers can be customised to meet the specific ripening requirements and storage preferences of different banana varieties, optimising the quality and process for each type. Modern ripening and cold storage facilities often feature energy-efficient designs that reduce overall energy consumption and environmental impact.

Key Benefits include:

Enhanced control over the ripening process, providing flexibility in timing.

Uniform ripening, resulting in a more consistent product.

Faster ripening, saving time and reducing costs.

Mechair’s Banana Cold Rooms As a client-centric organisation, Mechair specialises in manufacturing and exporting high-quality banana ripening machines. These machines are crafted using tested materials and adhere to industry standards, ensuring precise functionality. Highly demanded for their accuracy, Mechair’s banana ripening machines come in various specifications to meet client needs. For more information, visit our website: https://mechair.in/

0 notes

Text

Ethylene: From Cracking Open the Basics to Shaping Our World

From the plastic bottles you use every day to the antifreeze in your car and even the soft fabric of your pajamas, a surprising common thread exists: Ethylene. This essential molecule, with the chemical formula C2H4, forms the backbone of countless products we use every day. In this blog, we'll uncover the secrets of Ethylene, how it's made, and its surprising impact on our modern world. We'll even explore some of the exciting ways it might be used in the future. Get ready to dive into the world of the most significant industrial organic compound around!

Introduction

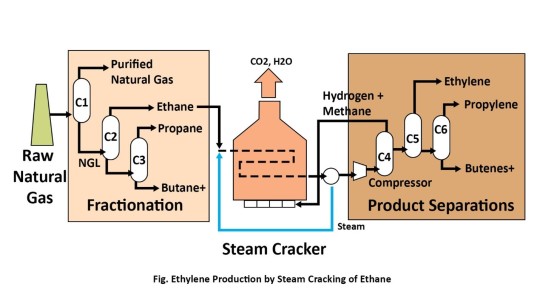

Ethylene, a colorless gas with a hint of fruitiness, is a major player in the industrial world. Through a process called steam cracking, manufacturers turn ethane and naphtha (petroleum liquids) into valuable chemicals, including ethylene. This process involves intense heat (around 750°C) to break down the hydrocarbons. Ethylene itself is flammable, but it's the foundation for numerous essential chemicals. From polyethylene (the plastic in many everyday items) to ethylene oxide (used in antifreeze) and even ingredients for PVC and polystyrene, ethylene is a versatile building block. Interestingly, this same gas also helps speed up fruit ripening in large-scale agriculture. Polyethylene production currently dominates ethylene use, but its applications extend to refrigeration and even fuel gas for industrial cutting and welding.

Manufacturing Processes

Ethylene, a very common organic compound, is essential for the petrochemical industry. Made from various oil-based materials in factories that use high-temperature steam, it serves as the starting point for many other important chemicals.

Cracking and quenching

Cracking and quenching are fundamental processes in ethylene production. Initially, an ethane-propane blend undergoes high-temperature cracking in furnaces, yielding ethylene, propylene, and additional byproducts. To halt undesirable reactions and byproduct formation, the resultant stream is swiftly cooled in a water-based quench. Downstream, a decanter removes heavies, condensed dilution steam, tar, and coke, ensuring product purity. The cracked gas is then guided to compression and separation stages, enabling the isolation of ethylene and propylene for further refinement and utilization. These sequential steps are integral to the efficient production of ethylene, a cornerstone chemical in numerous industrial applications.

Compression and drying

Compression and drying are crucial stages in gas processing. The cracked gas undergoes compression across five stages, ensuring optimal pressure levels for subsequent processing. Following the third compression stage, caustic soda and water washes in a caustic scrubber effectively eliminate carbon dioxide and sulfur impurities from the cracked gas stream. Subsequently, the compressed gas is cooled and subjected to molecular sieves for drying, effectively removing residual water content. This meticulous drying process ensures the purity and quality of the gas, preparing it for further refinement and utilization in various industrial applications.

Separation

• After drying, the cracked gas goes through a special chamber (cold box) to remove hydrogen and other small, light hydrocarbons. This process is designed to take out these unwanted elements without losing much of the valuable ethylene.

• At this stage, the condensed substances from the cooling process are directed into a sequence of separation columns. Initially, in the first column known as the demethanizer, methane is separated at the top and utilized further within the cold box, while the lower portion is directed into a second column, the deethanizer.

• The upper portion of the deethanizer, primarily containing ethylene and ethane, is sent through an acetylene converter before undergoing fractionation in the C2-splitter. Within this column, lighter components are removed from the overheads and returned to the compression system, while ethylene suitable for polymer-grade applications is extracted as a side stream. Ethane from the bottom of the C2-splitter is recycled back to the cracking furnaces.

• The lower portion of the deethanizer is channeled into a depropanizer, which separates out C3 (propylene fractionation tower/distillation tower) components in the overheads. This overhead stream is subjected to catalytic hydrotreatment to remove methyl acetylene and propadiene before being directed to the C3-splitter. Within this column, lighter components are extracted from the overheads and recycled to the compressors, while propylene suitable for polymer-grade applications is extracted as a side stream. Propane from the bottom of the C3-splitter is recycled back to the cracking furnaces, while a C4+ stream is obtained from the bottom of the depropanizer.

Technologies used by Major Players

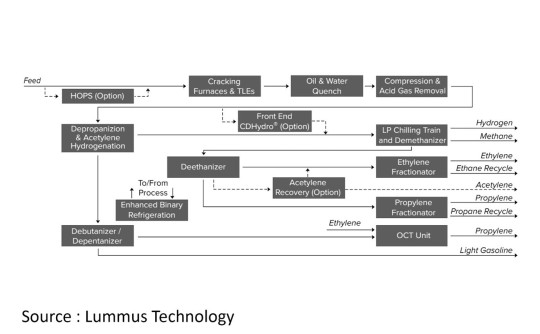

Lummus Technology

• The raw materials utilized in the production of ethylene by Lummus Technologies encompass a variety of hydrocarbons, such as ethane, propane, butane, naphtha, kerosene, diesel, gasoils, or hydrocracked vacuum gasoils.

• Initially, a mixture of fresh feed and recycled ethane and propane undergoes thermal cracking with steam in pyrolysis furnaces. The resulting gas is progressively cooled through steam generation and direct contact with oil and/or water.

• Subsequently, the effluent undergoes compression in a three-stage centrifugal compressor, followed by the removal of acid gases using amine solution and/or caustic soda. Dehydration of the gases is achieved using a molecular sieve. Product recovery is carried out under cryogenic conditions in refrigerated fractionation systems.

• Acetylene compounds undergo hydrogenation in catalyst systems, and hydrogen is purified through Pressure Swing Adsorption (PSA) or methanation.

• Polymer-grade ethylene and propylene are obtained via highly integrated super-fractionation towers aimed at minimizing energy consumption. Simultaneously, mixed C4 products and pyrolysis gasoline are coproduced and recovered. The C4s can serve as feed for an OCT or CPT unit, facilitating the production of propylene, butene-1, or hexene-1. A unified mixed refrigeration system fulfills all refrigeration needs. Essential utilities like steam, cooling water, and fuel are fully integrated to optimize overall efficiency.

• An additional feature involves potentially integrating a gas turbine generator with the pyrolysis furnaces to generate electrical power and extra super-high-pressure steam. The hot exhaust gases from the turbine are directed back to the furnaces to provide hot combustion air.

Applications of Ethylene

Ethylene, a crucial building block in chemical manufacturing, plays a pivotal role in the production of various essential compounds. One prominent application is in the synthesis of Polyethylene, a versatile plastic widely used in packaging, construction, and other industries. Additionally, Ethylene Oxide, valued for its role as a sterilizing agent and in the manufacture of ethylene glycol, finds extensive use in the medical and automotive sectors. Ethylene Dichloride serves as a precursor in the production of vinyl chloride, a key ingredient in the manufacturing of PVC pipes and other products. Ethylene Benzene is utilized in the synthesis of styrene, employed in the production of plastics, rubber, and resins. These and other derivatives highlight the diverse applications of ethylene across various industrial sectors.

1. Polyethylene

Polyethylene, a ubiquitous plastic, finds extensive application in diverse industries. Its versatility makes it a preferred choice for food packaging, ensuring the preservation and safety of food products. Additionally, it is utilized in the production of bottles, providing lightweight and durable containers for beverages, household products, and personal care items. Polyethylene's flexibility and strength make it ideal for manufacturing bags, facilitating storage, transportation, and disposal of goods. Its widespread use in these applications underscores its importance in modern society, contributing to convenience, efficiency, and safety in various aspects of daily life.

2. Ethylene dichloride (EDC)

Ethylene dichloride (EDC), recognized for its lead scavenging properties, is a common additive in leaded fuels, effectively reducing engine knocking and enhancing combustion efficiency. Beyond its role in fuel formulations, EDC has found diverse industrial applications. It served as an extraction solvent, facilitating the separation of desired compounds in various processes. Moreover, its solvency properties made it suitable for textile cleaning and metal degreasing applications. EDC's inclusion in certain adhesives contributed to their adhesive strength and durability.

3. Ethylene Benzene

Ethylbenzene serves as a fundamental precursor in the synthesis of styrene and synthetic polymers, playing a pivotal role in various industrial processes. Widely recognized as a solvent, it facilitates the dissolution of substances in applications ranging from paints and inks to carpet glues and varnishes. Additionally, ethylbenzene finds utility as a constituent of asphalt and naphtha, contributing to their formulation and performance characteristics. Its presence in synthetic rubber and fuels underscores its versatility across multiple sectors. Moreover, ethylbenzene is incorporated into tobacco products and insecticides, adding to its diverse range of applications. It also serves as a component in automotive and aviation fuels, enhancing their combustion properties.

4. Food & Beverages

Ethylene provided in cylinders are employed to regulate the ripening of fruits, particularly bananas, with a concentration of a few ppm being utilized in warehouse atmospheres.

Market Outlook

The driving force behind the global Ethylene market is its use in making Polyethylene plastic. No wonder it's everywhere, from food packaging and grocery bags to toys, cable insulation, and even household items like squeeze bottles. There are different types of Polyethylene, with two major players being LDPE (Low-Density) and HDPE (High-Density). Interestingly, HDPE goes a step further – it's also used to create other plastics like PET (Polyethylene Terephthalate), commonly found in water bottles, food containers, and packaging. But Ethylene's uses extend beyond plastics. It's also a key ingredient in producing Ethylene Oxide, a precursor for chemicals like ethanol amines and monoethylene glycol, further boosting the demand for Ethylene.

Ethylene Major Global Players

Significant players in the Global Ethylene market are Sinopec, LyondellBasell, DowDupont, Exxon Mobil Corporation, INEOS, Chevron Phillips, Braskem, Zhejiang Petrochemical, PTT Global Chemical, Formosa Plastics Group (Formosa Petrochemical Corp.), PetroChina, Arabian Petrochemical Company, Yeochun NCC Co. Ltd., Royal Dutch Shell, Kavian Petrochemical, and Others.

Conclusion:

Ethylene is a colorless gas with a distinctive fruity odor. Widely utilized in agriculture, ethylene expedites the ripening of fruits such as tomatoes, bananas, and mangoes. Moreover, ethylene serves as a vital precursor in chemical synthesis, contributing to the production of Polyethylene, Ethylene Oxide, Ethylene Dichloride, and Ethylene Benzene. Additionally, it finds application as a refrigerant in petrochemical industries and as a fuel gas for welding and cutting processes. The global ethylene market is forecasted to witness substantial growth, primarily driven by increasing demand for ethylene as a feedstock in chemical manufacturing, particularly for Polyethylene, renowned for its durability, flexibility, and lightweight nature, essential for food and beverage packaging and various other industries. This anticipated market expansion reflects the continuous evolution of ethylene-based products and their pivotal role in meeting diverse industrial needs, paving the way for innovation and growth opportunities in the chemical sector.

0 notes

Text

Food Grade Gases Market Potential Growth, Share, Demand and Analysis of Key Players, Research Forecasts By 2032

The food-grade gases market is expected to be worth USD 7.1 billion in 2032 and grow at a CAGR of 6.2% over the course of the forecast period to reach USD 13.0 billion. According to recently released market analysis data from Future Market Insights, the demand for food grade gases worldwide is expected to increase by 3.5% Y-o-Y in 2022.

In numerous industries, including agriculture, food processing, aquaculture, and the production of fruits and vegetables, there is a need to boost food production due to the rapid development of the human population. The usage of technologies related to food production has increased as a result. This method is demonstrated by the employment of gases during the many stages of food preparation, processing, preservation, and ripening.

It includes in-depth insights into the food grade gases market. Some of these are:

The estimated value of the market was at US$ 5.3 Bn in 2022. Through the course of the report’s forecast period, the market is likely to exhibit to a steady pace of growth.

North America accounted for the largest market in the global food grade industrial gases market owing to higher demand for processed food.

Europe is emerging as the second largest market for food grade industrial gases. However, it is considered as established markets.

Asia Pacific is growing at a faster rate to grab major market in this region.

To Get a Sample @https://www.futuremarketinsights.com/reports/sample/rep-gb-11255

“The increasing use of gases such as carbon dioxide, nitrogen, etc., in carbonated drinks has resulted in a positive impact on the food grade gases market,” said a lead analyst at FMI.

Nationwide Lockdown due to Coronavirus has stunted the Market Growth

The raising prices of raw materials needed to produce are hampering demand development. Worsening situation is disruptions in the supply chain caused by the recent COVID-19 impact. With manufacturers facing difficulties in obtaining available raw materials and fewer labourers, the production might be hampered. Reduced transport due to lockdowns imposed across different nations is also limiting the growth of the sector. If COVID-19 continues to spread around the world, it is unlikely that prevailing economic problems will abate quickly at any time. Unprecedented events occur with the illness passing through one horrid phase after another.

Who is Winning?

Global Food-Grade Industrial Gases Market is a highly competitive market which a major share taken by the active player such as Linde plc, Linde plc, Air Liquide S.A. and others. Mergers and acquisitions and product innovations are the next strategies preferred by companies to strengthen their market dominance. This strategy helps companies to expand their presence in the market across the globe. For instance, Linde plc acquired Praxair which is America’s one of the largest industrial gas companies to capitalize theirs in the American market. Also, the key players are focusing on expanding their network of innovation centers, which enable them to collaborate with customers on new product development and reformulations and make investments.

Get Valuable Insights into Food Grade Gases Market

Gas Type

Nitrogen

Carbon dioxide

Oxygen

Others

Product Type

Dairy and frozen products

Beverages

Fruits & vegetables

Meat

Fish & seafood

Bakery and confectionery

Others

Application

Freezing and chilling

Packaging

Carbonation

Others

Region

North America

Latin America

Europe

East Asia

South Asia

Oceania

MEA

View Complete Report@ https://www.futuremarketinsights.com/reports/food-grade-gases-market

About Future Market Insights (FMI)

Future Market Insights, Inc. is an ESOMAR-certified business consulting & market research firm, a member of the Greater New York Chamber of Commerce and is headquartered in Delaware, USA. A recipient of Clutch Leaders Award 2022 on account of high client score (4.9/5), we have been collaborating with global enterprises in their business transformation journey and helping them deliver on their business ambitions. 80% of the largest Forbes 1000 enterprises are our clients. We serve global clients across all leading & niche market segments across all major industries.

0 notes

Text

Cold storage companies in India

Blue Ice India is a leading cold storage manufacturer company in Ahmedabad, India, we are able to provide sustainable solutions and services for your business and requirements.

Visit site

#Ripening chamber manufacturer#Controlled Atmosphere Chamber Suppliers#Cold Storage & room manufacturers in india#Ripening chamber manufacturers in india#Ripening chamber manufacturers in nepal#Banana ripening chamber manufacturer#Fruit Ripening Chamber manufacturer#Controlled Atmosphere Chamber#Controlled Atmosphere System#Manufacturer of Controlled Atmosphere Chamber

0 notes

Text

An Italian Cheese Odyssey: Discovering the Artisanal Cheesemaking of Italy

Italy has actually gone to the forefront of artisanal cheesemaking for centuries. Consequently, the country is home to a few of the world's most renowned and also precious cheeses, including Parmigiano Reggiano, Pecorino Romano, as well as Gorgonzola. However what is it regarding cheese making in Italy that makes it so special? Let's take a journey with Italy to explore its distinct cheesemaking customs.

The Perfect Cheese Begins with Perfect Milk

Italian cheeses are renowned for their quality and taste. The secret lies in the milk that enters into making them. All Italian cheeses start with raw milk from cows, lamb, goats, or buffalo elevated on local farms within 24 hours of milking. This ensures freshness and also a premium item whenever. The milk is then thoroughly sterilized using low temperatures to preserve its initial tastes as well as fragrances, tuscany olive oil tour .

Next comes the ripening procedure, which calls for specific temperature and moisture control relying on the kind of cheese being created. Throughout this phase, germs are added to produce lactic acid, which helps give each cheese its distinct flavor profile. Once more, this process can take anywhere from two days to numerous weeks, depending upon celebrity being made.

Finally comes shaping and maturation-- throughout this phase, cheesemakers utilize typical tools like wood molds to form each wheel prior to they are placed into maturing chambers for anywhere from one month to one year, depending upon what type of cheese is being made. Here, they create their trademark tastes via a combination of enzymes as well as bacteria action and also oxygen direct exposure throughout aging.

Regional Variations

Cheese production differs extensively from region to region in Italy. Southern areas like Sicily are known for their sheep's milk cheeses like Pecorino as well as Ricotta. On the other hand, north regions are accountable for tough cow's milk cheeses such as Grana Padano as well as Parmigiano Reggiano. Different climates lend themselves to different kinds of cheese manufacturing-- the warmer south produces more soft-ripened cheeses while the north specializes in longer aging ones. Each area has its distinct design of cheese that shows its history as well as culture.

Cheese Manufacturing Techniques

The procedures used to make Italian cheese are additionally quite diverse. In many cases, conventional techniques have actually been given over generations; in others, modern-day innovation has actually influenced the method cheese is produced today. From small farms generating raw milk cheese by hand making use of conventional techniques to larger operations making use of sophisticated innovation and also sterilized milk, there is a vast array of strategies used in Italy's many cheesemaking areas, olive oil tours tuscany .

The Society Of Cheese Making

Cheesemaking in Italy is not almost production-- it's additionally about society as well as tradition. Lots of rural towns throughout the nation still practice conventional dishes created centuries back, commonly with just slight variations depending on regional personalizeds or ingredients available at the time. In addition, cheesemakers usually participate in events where they share their understanding with others or team up with various other artisans to create unique items for sale or intake at regional restaurants or markets. This culture of sharing aids keep these traditions alive and makes certain that these one-of-a-kind tastes stay part of the cooking landscape for generations ahead.

Cheesemaking in Italy is an art form that has been perfected over centuries by masterful chefs as well as craftsmens that have actually devoted their lives to improving their craft. It takes careful attention to information at every step of manufacturing-- from selecting only premier raw milk to maturing each wheel-- to make sure that each Italian cheese offers an unique flavor profile like nothing else worldwide! Whether you're a fan of Parmigiano Reggiano or Gorgonzola Dolce, you can be certain that every bite will certainly transport your preference buds back centuries earlier when these scrumptious cheeses were first produced!

1 note

·

View note

Text

Why do horticulturists require fruit ripening room?

Horticulturists, farmers, and companies in fruit cultivation look for affordable and reliable means to safely store and carry out the ripening process of their harvest. Post-harvest fruit ripening requires a sophisticated process and strategy. Ripening rooms are tailor-made for the ripening of raw fruits.

9 notes

·

View notes

Text

Agricultural Commodities that can be stored in Cold Storage

Agricultural Commodities such as potato, cucumber, onion, mushrooms, leafy materials, apple, mango, orange, grapes, cabbage, carrot, radish, pumpkins, melons etc. can be stored in cold storage. Storing commodities requires looking at the value chain of the commodity, temperature, humidity and seasonality.

Among all other commodities in the world, potato storage in India is the highest. The temperature of cold storage units is -25 degree Celsius. Keeping the agricultural commodities in a multi-commodity cold storage helps in keeping the vegetables fresh.

Most fruits produce a hormone called ethylene, which ultimately affects the surrounding produce. This hormone changes the texture, colour and flavour of the produce and speeds up the ripening process considerably. If fruits are stored alongside vegetables, the risk will result in food wastage.

Distributors should know the history of fruits and vegetables to make the best decision regarding cold storage and transportation arrangements. This includes product maturity, prior goods preparation, quality inspections and produce grading.

Besides that if cold units have no proper arrangement for Co2, they will become responsible for product rotting. Opening the door can increase the temperature directly to a higher rate because more electricity would be required to maintain the temperature.

The investments and risks are high in grain crops and have kept the farmers moving. The crops require refrigeration and cultivating of fruits and vegetables. Therefore, cold storage facilities are important to ensure a better ROI. More and more multi-purpose storages are in demand to provide end-to-end services. Even pharmaceuticals require a cold chain as these products are susceptible to time constraints and temperature.

The cold chain industry is rapidly growing in India and has received a major boost from the government. The sector has a bright future and includes built-to-suit assets with diversity in cold storage offerings.

Mechair’s multi-commodity cold storage is a great place to store fruits and vegetables, prolong their life and prevent spoilage of foods. This makes cold storage rooms and cooler room refrigerations a great place for storing perishable items.

Our cold storage is designed for precise monitoring of temperature conditions required for cold storage of fruits, vegetables, flowers, dairy products, pharmaceuticals, RTE foods, etc. These are made by erecting PUF panels and manufactured as per GMP norms, provided with a refrigeration system, including an optional standby refrigeration system for uninterrupted functioning and a control panel. It offers several advantages like maintaining precise temperature for long-term cold storage. It works as a complete solution for the simulation of desired uniform temperature throughout the chamber and is an eco-friendly CFC refrigeration system. To get more details about our offerings, visit our website https://mechair.in/

0 notes

Link

We are one of the trusted Banana Ripening Chambers Manufacturer in Agra. With expertise across the full spectrum of fruit Banana ripening chambers, Pre-cooling chambers, cold storage construction & refrigeration system, Singhsons Refrigeration provides focused solutions namely conceptualizing, designing, manufacturing and implementation of cold infrastructure requirements to cater to the needs of diverse industries.

0 notes

Link

Sai Cool Point provides Fruits and Vegetable ripening chamber in Bhubaneswar with customized ripening chamber design and affordable price. We are one of the most well-distinguished companies in the market that are into offering Fruit Ripening Chamber.

#Ripening chamber manufacturing company in Bhubaneswar#Mango Ripening Chamber manufacturer in Bhubaneswar#Best ripening chamber manufactures in Bhubaneswar#Banana Ripening Chamber manufacturer in Bhubaneswar#Papaya Ripening Chamber manufacturer in Bhubaneswar

0 notes

Text

Tobacco

TOBACCO

The tobacco plant is a coarse, large-leaved perennial, usually cultivated as an annual, grown from seed in cold frames or hotbeds and then transplanted to the field. Tobacco requires a warm climate and rich, well-drained soil. Tobacco is initially grown in outdoor frames called seedbeds. In warm regions, the frames are covered with mulch or a cotton top sheet; in cooler regions, glass or plastic shields are installed to protect the plants. After 8-10 weeks, when the seedlings are almost 10 inches (25 cm) tall, they are transplanted to the fields. Although transplanting machines are available, the vast majority of the world's tobacco plants are still planted manually. As the plants grow, the heads are broken off by hand so the leaves will grow fuller, a process called topping. The plants stay in the field 90-120 days before they are harvested.

HARVESTING

Tobacco plants are harvested by one of two methods, priming or stalk-cutting. In the priming method, the leaves are gathered and brought to a curing bam as they ripen. In the stalk-cutting method, the entire plant is cut and the plants are allowed to wilt in the field before being taken to the curing barn.

CURING THE LEAF

Next, the leaves are carefully, gradually dried in a specially constructed barn by air curing, flue curing, or fire curing. Air curing uses natural weather conditions to dry tobacco. Stalks are hung in a barn with ventilators that can be opened and closed to control temperature and humidity. Artificial heat is used only during cold or excessively humid weather. The stalks are hung for four to eight weeks.

Flue curing is done in small, tightly constructed barns that are artificially heated. The heat comes from flues (metal pipes) that are attached to furnaces. Open oil and gas burners are sometimes used, but this method is problematic because smoke can-not come in direct contact with the tobacco. Flue curing takes about four to six days.

Fire curing dries tobacco with low-burning wood fires whose smoke comes in direct contact with the leaves, thus producing a smoky flavor and aroma. The tobacco is allowed to dry naturally in the barn for three to five days before it is fire-dried for 3-40 days.

MOISTENING AND STRIPPING

Unless humid weather conditions eliminate the need, the brittle, cured tobacco leaves must be conditioned in moistening chambers so they do not break when they are handled. After moistening, the tobacco is stripped. During this process, the leaves are sprayed with additional moisture as a precaution against cracking or breaking.

SORTING AND AUCTIONING

After the leaves are moistened and stripped, they are sorted into grades based on size, color, and quality, and tied in bundles for shipment. The farmers then bring the tobacco to warehouses, where it is placed in baskets, weighed, graded once again by a government inspector and, finally, auctioned to cigarette manufacturers.

CONDITIONING, AGING, AND BLENDING

After they have purchased and transported the material to their factories, manufacturers treat and age the tobacco to enhance its flavor. First, the manufacturer

redries the tobacco. This involves completely drying the leaves by air and then adding a uniform amount of moisture. Packed into barrels called hogsheads, the tobacco is then aged for one to three years, during which period it develops its flavor and aroma. After it is aged, the tobacco leaves are again moistened and the stalks and other wastes removed. Leaves from different types of tobacco are mixed to create a particular flavor.

MAKING THE CIGARETTES

After blending, the tobacco leaves are pressed into cakes and mechanically shredded. Materials such as fruit juices or menthol are added to give additional flavor. The final shredded tobacco is then dispersed over a continuous roll of cigarette paper. A machine rolls the shredded tobacco into the paper and cuts it to the desired length. A device then grabs each cigarette and fastens a filter in one end. Modern cigarette machines can produce 25-30 cigarettes a second.

PACKAGING

The final stage of cigarette manufacture is packaging. The completed cigarettes are packed 20 to a package. The hard or soft packs are mechanically sealed in cellophane and hand-placed in cartons.

TYPES

1. Aromatic fire-cured is cured by smoke from open fires. In the United States, it is grown in northern middle Tennessee, central Kentucky and in Virginia. Fire-cured tobacco grown in Kentucky and Tennessee are used in some chewing tobaccos, moist snuff, some cigarettes, and as a condiment in pipe tobacco blends. Another fire-cured tobacco is Latakia, which is produced from oriental varieties of N. tabacum. The leaves are cured and smoked over smoldering fires of local hardwoods and aromatic shrubs in Cyprus and Syria.

2. Burley tobacco is an air-cured tobacco used primarily for cigarette production. In the U.S., burley tobacco plants are started from palletized seeds placed in polystyrene trays floated on a bed of fertilized water in March or April.

3. Cavendish is more a process of curing and a method of cutting tobacco than a type. The processing and the cut are used to bring out the natural sweet taste in the tobacco. Cavendish can be produced from any tobacco type, but is usually one of, or a blend of Kentucky, Virginia, and burley, and is most commonly used for pipe tobacco and cigars.

4. Turkish tobacco is a sun-cured, highly aromatic, small-leafed variety that is grown in Turkey, Greece, Bulgaria, and Macedonia. Originally grown in regions historically part of the Ottoman Empire, it is also known as "oriental".

5. Perique At one time, the freshly moist Perique was also chewed, but none is now sold for this purpose. It is typically blended with pure Virginia to lend spice, strength, and coolness to the blend.

CIGARS

Cigar is tightly rolled bundles of dried and fermented tobacco, which is ignited so its smoke may be drawn into the smoker's mouth.

Cigarettes are a product consumed through inhalation of smoke and manufactured from cured and finely cut tobacco leaves and reconstituted tobacco, often combined with other additives, then rolled or stuffed into a paper cylinder.

Pipe tobacco typically consists of a small chamber (the bowl) for the combustion of the tobacco to be smoked and a thin stem (shank) that ends in a mouthpiece (the bit). Shredded pieces of tobacco are placed into the chamber and ignited.

HISTORY OF CIGARS

The Indians in South and Central America did not smoke cigars as we know them today. The natives smoked tobacco wrapped in maize, palm or other native vegetation. The Spanish created the cigar industry, and are given credit for creating the modern cigar. The first modern observation of the cigar occurred with the arrival of Christopher Columbus in the New World. On October 28, 1492 Columbus noted in his log reports that the natives of San Salvador burned and inhaled the leaves of a local plant. The Origin of the word cigar comes from the native language of the ancient Mayans. The Mayans called the cigar a "Ciq-Sigan" which the Spanish word "Cigarro" is derived from. The New English Dictionary of 1735 called the cigar a "seegar", and was later adapted into the modern word "cigar".

COMPOSITION

Filler- inner core gives body and shape to the cigar. The leaves of tobacco at the core of the cigar that provide a significant portion of its taste.

Binder- a leaf wrapping the filler. The portion of a tobacco leaf that is rolled around the filler to hold it together.

Wrapper- ribbon like leaf rolled around the bunch. Filler and binder together is called bunch a high-quality tobacco leaf wrapped around the finished bunch and binder. It is very elastic and, at its best, unblemished

MANUFACTURING

Once the tobacco is harvested the leaves are sent to "tobacco barns" where the tobacco is dried. Leaves are tied in pairs and hung for the curing process... The tobacco is kept in the barn for approximately 2 months while the leaves change color from green to yellow to brown. After the leaves are dried, they are carefully laid into large piles for fermentation, where they are kept for several months. The piles are moistened and covered in cloth. The fermentation reduces natural resins, ammonia and nicotine present in the tobacco leaves. The fermented tobacco is taken to warehouses, stored in large bales and allowed to slowly mature. The aging process can last from several months to many years depending on the quality desired.

Once the aged tobacco reaches the factory, the leaves are graded according to size, color, and quality. Leaves that are torn or have holes are set aside and used primarily as filler. Finally the leaves are de-veined by removing the center vein from the leaf. Handmade cigars are composed of filler tobacco bunched together with a binder leave and finally covered with the wrapper leaf. The binder holds the bunch together and is enclosed with the wrapper leaf in an aesthetically pleasing manner. Machine made cigars are generally produced using short filler. A processed tobacco binder which resembles brown paper is used as the binder, and in most cases a natural wrapper is used to complete the cigar. Tragacanth is a viscous, odorless, tasteless, water-soluble mixture of polysaccharides obtained from sap which is drained from the root of the plant and dried. It has traditionally been used as an adhesive in the cigar-rolling process used to secure the cap or "flag" leaf to the finished cigar body.

COLOUR CLASSIFICATION

CCC – CLARO (LIGHT BROWN) A pale-green to light-brown wrapper, usually shade-grown.

CC – COLORADO CLARO (MID BROWN)

C – COLORADO (DARK BROWN)

CM – COLORADO MADURO (VERY DARK BROWN)

M – MADURO (EXCEPTIONALLY DARK BROWN) A wrapper shade from a very dark reddish-brown to almost black. The word means ripe in Spanish. The color can be achieved by sun exposure, a cooking process or a prolonged fermentation.

OSCURO A black shade of wrapper, darker than maduro, most often Brazilian or Mexican in origin.

JUDGING THE CIGAR

CONSTRUCTION - How well is the cigar made? How does it feel to the touch? With a firm, but soft grip feel it from end to end. Does it feel consistent all the way through? Are there any hard or soft spots? A cigar that is too hard, too soft, or inconsistent will not draw properly.

CONDITION - Cigars should be well conditioned before smoking. Cigars should be aged for several months to several years at the proper humidity (70% RH) and temperature (70° F). A dry cigar will burn hot, fast and can taste harsh. A damp cigar will be hard to light and can be hard to draw.

CAUSALITY (CAUSE AND EFFECT) - How does the cigar taste? How does the cigar make you feel? Does the cigar build in taste, flavor and complexity as it burns? Or is it the same all the way through? Do you feel relaxed and calm after finishing it?

TYPES OF CIGAR CUTTERS

The "Guillotine" or "Traditional" Cut: This cutter takes a straight slice across the cigars cap line. It is the best cut to create an easy, well circulated draw; however residue and tar from the burning tobacco will come in direct contact with the smoker's mouth.

THE "BULLET" OR "PUNCH" CUT: A bullet cutter pierces a small hole into the cigars cap. Depending on the diameter of the cutter, air circulation may be restricted and the smokes tar and residue can accumulate around the opening.

THE "V" CUT: The V cutter creates a wedge shaped notice in the cigars cap. This cut allows proper air circulation to occur. The smokes tar and residue accumulate on the sides of the wedge keeping the bitter taste away from the smoker's mouth. It can be difficult to keep a V cutter sharp because of its unique shape.

HOW TO LIGHT THE CIGAR

Tobacco will absorb any aroma or fragrance that it comes in contact with. Paper and sulfur based matches or the use of a fluid based lighter can leave the cigar with an unpleasant taste. The preferred method to light a cigar is the use of butane based lighter. A lit wooden match can be used once it has burned off the chemicals used in the ignition process. Once the cigar is cut hold the open end of the cigar over your flame and slowly rotate it. This will "Toast" the cigar and prime it for lighting. While it is still warm, place the cigar in your mouth and hold it at a 45° angle over the flame. Slowly puff and rotate the cigar while maintaining slight contact with the flame. A Good cigar will light easy and burn evenly.

Cigars are lit with the help of either a wooden match or cedar strip called “spill”.

SIZE AND SHAPE

n CORONA – 5 ½ INCHES The most familiar size and shape for premium cigars: generally straight-sided with an open foot and a closed, rounded head, traditionally measuring approximately 5½ x 43.

n PETIT CORONA - 5 INCHES

n TRES PETIT CORONA – 4½ INCHES

n LONSDALE – 6 ½ INCHES A long cigar; generally 6 to 6 3/4 inches by a 42 to 44 ring gauge, but there are many variations.

n IDEALES – (TORPEDO SHAPED) 6 ½” Torpedo) A cigar shape that features a closed foot, a pointed head and sometimes a bulge in the middle.

n LONDRES-4 ¾ INCHES

n PANATELA-5 INCHES OPEN AT BOTH ENDS.

n A CHEROOT- THIN CIGAR OPEN AT BOTH ENDS.

n RING GAUGE: Definition: The ring gauge of a cigar is a measurement of its diameter expressed in 64ths of an inch. For example, a cigar with a ring gauge of 42 means that it is 42/64 inches thick.

SERVICE OF CIGARS

a. Cigars should be offered in their own boxes.

b. Guest chooses the cigars.

c. Steward should offer to remove the band.

d. Cigar is cut using the cigar cutter.

e. Steward should offer to light the cigar.

STORAGE OF CIGARS

a. Cigar can be stored in cedar wood boxes or in glass case with humidifier.

b. Ideal temperature is 16 – 18˚ c.

c. Relative humidity required is 65 – 70 %.

HUMIDOR

An entire room, or a box, that's designed to preserve and promote the proper storing of fragile cigars. An optimum humidity and temperature level in a humidor is 70/70, or 70 percent humidity and 70 degrees Fahrenheit (21 degrees Celsius).

BRANDS OF CIGARS

i. Macanudo

ii. H. Upmann

iii. Partagas

iv. Cohiba

v. Montecristo

vi. Romeo y Julieta

vii. Habana 2000

viii. Churchill

3 notes

·

View notes

Photo

Sandwich Puff Sheets Manufacturers in Bangalore - Delta Infrastructures

Delta Infrastructures provides one stop solutions for all types of Sandwich Panel for Roof, Wall & Ceiling insulation requirements. It includes Porta Cabin, Prefab Porta cabin, Prefab Site office, Workers Accommodation, Solar Inverter Room, Multi Storey Building, Clean Room, Cold Storage, Ripening Chambers, Railway Shelters, Prefabricated Pulpits, Acoustic Enclosure, Security cabin, Prefabricated toilet, Industrial for Residential and Commercial Buildings Project.

We do provide maintenance & repair solutions for existing project too..

Contact us for any requirement at affordable rates.

Delta Infrastructures

Contact - 080-48662435,

Call and WhatsApp - +91 9741782011 and +91 9741357011

For more information visit our company website - www.deltainfrastructures.com

#Puffsheets #Puffpanels #sandwichpanel #ordernow #callnow #booknow #addtocart #sales #festivaloffer #bestoffers #puffpanelssale #deltaoffers #factory #supplier #performance #order #fastestdelivery #quality #weatherproof #deltaproductbasedcompany #deltaservicebasedcompany #bangalore #india

#Sandwich Puff Sheets Manufacturers in Bangalore#delta infrastructures#BANGALORE#INDIA#PUFF PANELS MANUFACTURERS

0 notes