#robotsautomation

Explore tagged Tumblr posts

Text

Technology Advancement in the Automotive Industry

August 30, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

Automobile manufacturers assemble vehicles such as cars, trucks, and motorcycles at vehicle build facilities. It is also known as a production plant or assembly factory for automobiles. To build a fully functional car, this process involves assembling many parts, such as the engine, chassis, body, and interior. Vehicle construction facilities are critical to mass production in the automobile industry.

The following are important components and stages frequently observed in the automotive industry:

Body Shop: This is the place where an automobile’s frame or chassis is assembled. Robotic welders and automated technologies are often used to connect the various components that comprise an automobile’s structure.

Paint Shop: After the body is built, it is brought to the paint shop. This is the stage where the vehicle undergoes numerous processes, including washing, priming, painting, and sealing. Sophisticated robotic technology is often used for precise painting.

Quality Control: Inspections for quality control are carried out at different points during the assembly process to ensure that each vehicle meets the required standards. This may involve the employment of both automated systems and human examination.

Testing: Some facilities perform a range of tests to ensure the vehicle’s safety and performance. This could include quality control inspections, road tests, and functionality tests.

Packaging and Shipping: After passing all tests and inspections, the finished cars are prepared for shipment. This covers the stages of packaging, loading into transport vehicles, and delivering to stores or warehouses.

Advantages of Technology Advancement in the Automotive Industry

An automotive assembly factory sometimes referred to as a vehicle build facility, can benefit the automotive industry, the economy, and society at large. Here are a few key benefits:

Economic Impact: Vehicle manufacturing facilities have a significant positive economic impact by creating jobs and promoting the economy. Many individuals work in the automobile industry, not just in assembly facilities but also in related fields including suppliers, logistics, and support services.

Efficiency of Mass manufacturing: Assembly plants enable mass manufacturing, which enables the inexpensive and efficient fabrication of a large number of cars. As a result of the ensuing economies of scale, consumer prices for cars have decreased.

Standardization and Quality Control: Automotive manufacturing facilities employ stringent quality control protocols in addition to standardized practices. This helps to maintain high standards for the manufactured cars and ensures consistency in the production process.

Integration of Innovation and Technology: Automotive assembly plants often employ cutting-edge innovations and technologies. To increase efficiency, precision, and the ability to add new features and materials to autos, automation, robots, and advanced production techniques are applied.

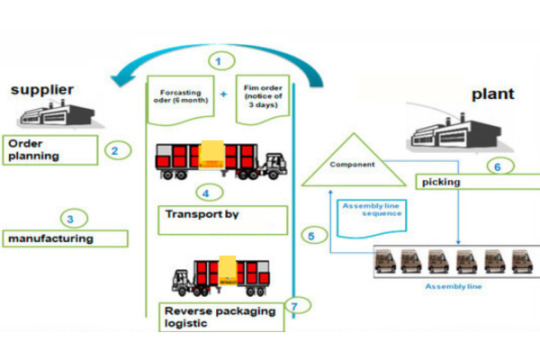

Integration of the Supply Chain: Manufacturers of auto parts and materials are part of a bigger supply chain that also includes auto assembly plants. This integration ensures a steady supply of parts and reduces lead times by better coordinating and optimizing the entire production process.

Local and International Trade: The capacity to manufacture cars in a particular region fosters both local and global trade. Completed cars can be exported to other countries, promoting global trade balances and economic interdependence.

Technological Advancements: Vehicle production facilities in the automotive industry often lead the way in terms of technological advancements. Research and development efforts at these institutions produce new technologies, safety features, and environmental advantages in cars.

Environmental Aspects: A few modern auto factories employ sustainable and environmentally friendly practices. Utilizing recycled materials, cutting waste, and employing energy-efficient processes can help the car industry become more ecologically friendly.

Consumer Access to Diverse Models: Through mass production in auto manufacturing facilities, a vast array of car models with different features, styles, and price points are made available to consumers. Customers with different demands and tastes are catered to by this variety.

Regional Development: The building of vehicle build facilities can support regional development by attracting related industries, creating a network of suppliers, and promoting the growth of ancillary services like retail, repair, and transportation.

Effects on the Technology Advancement in the Automotive Industry

Automobile manufacturing operations are not without issues and drawbacks, despite their many benefits. Here are a few potential drawbacks:

Environmental impact: The energy used, pollutants, and waste generated during the manufacturing of automobiles can have a significant impact on the environment. Even with initiatives to implement sustainable practices, the overall environmental effect of the car industry remains a problem.

Resource Intensity: The production of autos requires a substantial amount of raw materials, water, and energy. The extraction and processing of these materials could damage the environment and deplete natural resources.

High Initial Capital Expense: Establishing and maintaining a car manufacturing facility comes with a hefty upfront cost. Development of labor, infrastructure, land, and technology can be expensive.

Labor Issues: Labour-intensive industries like the auto industry may be threatened by strikes, disputes, and discontent among employees. There could be disruptions to production schedules and a decline in overall output.

Technological Obsolescence: Because of the rapid pace of Technology Advancement in the Automotive Industry, many production technologies may become antiquated. Research and development must be consistently supported to remain competitive and implement the most recent innovations.

Market Volatility: The Automotive Industry sector may be impacted by changes in legislation, consumer preferences, and the status of the economy. Changes in the demand for particular car models or economic downturns can have an impact on the production volume and profitability of automotive manufacturing plants.

Energy Consumption: Despite efforts to adopt more energy-efficient techniques, the production of automobiles is still very energy-intensive. The automotive industry’s use of non-renewable energy sources has an impact on its overall carbon footprint.

Waste Generation: A variety of wastes, including materials, chemicals, and by-products, are produced during the production process. Effective waste disposal and management are essential for minimizing the impact on the environment. Programs focused on minimizing trash and recycling might have challenges, though.

Land Use and Urbanization: The development of vehicular facilities typically requires large land parcels, which may lead to urbanization and the potential displacement of natural habitats. The local ecosystems and biodiversity may be impacted by this.

Conclusion:

To sum up, car manufacturing plants are essential to the automotive sector and have a major impact on commerce, economic expansion, and technological development. These factories’ capacity for mass production increases consumer access to automobiles and promotes a wide range of car models and features. Notwithstanding these benefits, there are still difficulties and disadvantages, from labor disputes and market volatility to resource intensity and environmental problems.

The automobile sector is emphasizing supply chain resilience, technological innovation, and sustainable practices to overcome these issues. Ongoing initiatives are to lessen the influence on the environment, increase energy efficiency, and use environmentally friendly production techniques. Furthermore, increased productivity, accuracy, and safety in the assembly line are brought about by advancements in robots and automation.

Maintaining a focus on worker welfare, appropriate resource management, and environmental sustainability will be crucial as the automotive industry develops. Car manufacturing facilities’ long-term viability and adaptability in a constantly shifting global environment depend on striking a balance between economic interests and environmental and social concerns. The future of car manufacturing will be shaped by the continuous dedication to research and development and the legal frameworks that support ethical behavior. This will guarantee a peaceful coexistence with the environment and society at large.

#autonomousvehicle#EVCharging#Advancedtechnology#robotsautomation#VCU#EVSoftwareservice#evCODE#ADASCode#VCUSupplier#VCUManufacturer

0 notes

Link

SummaryA new market study, titled “Global Agricultural Robots Market Analysis, Trends and Opportunities 2025” has been featured on WiseGuyReports. Agricultural robot is a robot deployed for agricultural purposes. The main area of application of robots in agriculture today is at the harvesting stage. Emerging applications of robots or drones in agriculture include weed control,[1][2][3] cloud seeding,[4] planting seeds, harvesting, environmental monitoring and soil analysis.Harvesting management is the most widely used application in agricultural robots as it plays a vital role in understanding the field variability and helps farmers in maximizing their yields. Increasing labor cost is motivating farm owners to adopt automated harvesting system. Automated harvesting management held the largest market share among all applications due to the high adoption rate among farmers and growers.The global Agricultural Robots market is valued at xx million US$ in 2018 is expected to reach xx million US$ by the end of 2025, growing at a CAGR of xx% during 2019-2025.This report focuses on Agricultural Robots volume and value at global level, regional level and company level. From a global perspective, this report represents overall Agricultural Robots market size by analyzing historical data and future prospect. Regionally, this report focuses on several key regions: North America, Europe, China and Japan.At company level, this report focuses on the production capacity, ex-factory price, revenue and market share for each manufacturer covered in this report. The following manufacturers are covered:Deere & CompanyTrimbleAgco CorporationAgjunctionDJIBoumatic Robotics, B.V.Lely HoldingAG Leader TechnologyTopcon Positioning Systems, Inc.AG Eagle LLCAgribotix LLCAutocopter CorpBlue River TechnologyAurorasGrowneticsAutonomous Tractor ALSO READ:https://industrytoday.co.uk/pr_and_marketing/global-agricultural-robot-market-2019--size--share--demand--trends--growth--consumption-and-2025-forecasts-explored-in-latest-research- Segment by RegionsNorth AmericaEuropeChinaJapanSegment by TypeUnmanned Aerial Vehicles (UAVs)/DronesMilking RobotsAutomated Harvesting SystemsDriverless TractorsOther Robots Segment by ApplicationHarvesting ManagementField MappingDairy Farm ManagementSoil ManagementIrrigation ManagementPruning ManagementWeather Tracking and ForecastingInventory ManagementOthers FOR MORE DETAILS:https://www.wiseguyreports.com/reports/3724093-global-agricultural-robots-market-research-report-2019 About Us:Wise Guy Reports is part of the Wise Guy Research Consultants Pvt. Ltd. and offers premium progressivestatistical surveying, market research reports, analysis & forecast data for industries and governmentsaround the globe. Contact Us:NORAH TRENT [email protected] Ph: +162-825-80070 (US) Ph: +44 203 500 2763 (UK)

0 notes