#rotary union suppliers

Text

0 notes

Text

Boost Your Industrial Process with Efficient Rotary Union Water Systems

In today's industrial landscape, efficiency is key to maintaining a competitive edge. One crucial aspect of improving efficiency in various industrial processes is the utilization of efficient rotary union water systems. These systems play a vital role in ensuring the smooth operation of machinery by facilitating the seamless transfer of fluids, specifically water, in rotating equipment. This article will explore the benefits, working principles, and considerations for implementing rotary union water systems in industrial applications.

Industrial processes often involve the use of rotating machinery, such as turbines, compressors, and machinery in the printing industry. These machines generate heat and require cooling mechanisms to prevent overheating. Rotary union water systems provide a reliable solution for efficiently transferring water to these rotating equipment, ensuring optimal performance and extended equipment lifespan.

Understanding Rotary Union Water Systems

Rotary union water systems are specialized devices that enable the transfer of fluids, primarily water, between a stationary and rotating part of a machine. They are designed to accommodate rotational movement while maintaining a leak-free seal. These systems consist of various components, including housing, seals, bearings, and connections, all working together to facilitate the controlled flow of water.

Key Benefits of Rotary Union Water Systems

Implementing efficient rotary union water systems in industrial processes offers several advantages:

Enhanced Equipment Performance

By effectively dissipating heat, rotary union water systems prevent machinery from overheating, thereby optimizing equipment performance. Improved cooling capabilities result in increased productivity, reduced downtime, and enhanced overall operational efficiency.

Extended Equipment Lifespan

Overheating can significantly impact the lifespan of rotating equipment. Rotary union water systems efficiently regulate temperature, reducing the wear and tear caused by excessive heat. This extends the lifespan of machinery and minimizes the need for costly repairs or replacements.

Versatile Applications

Rotary union water systems find applications in diverse industries, including manufacturing, energy generation, chemical processing, and printing. They can be customized to meet specific requirements, accommodating different flow rates, pressure levels, and water quality parameters.

Working Principles of Rotary Union Water Systems

Rotary union water systems operate on the principle of a rotating seal. As the equipment rotates, water is transferred through the system via internal passages, while the seals prevent leakage. The design and construction of these systems ensure a reliable and continuous flow of water to the rotating machinery.

Factors to Consider for Implementing Rotary Union Water Systems. Before implementing a rotary union water system, several factors should be taken into consideration:

Operating Conditions

Understanding the operating conditions, such as temperature, pressure, and rotational speed, is crucial for selecting an appropriate rotary union water system. The system must be able to withstand and operate efficiently under the specified conditions.

Compatibility with Fluid and Material

The compatibility between the fluid being transferred and the materials used in the rotary union water system is essential. It is vital to consider factors such as chemical compatibility, resistance to corrosion, and suitability for hygienic applications, depending on the specific industry requirements.

Flow Rate and Pressure

Determining the required flow rate and pressure of the water is crucial for selecting the appropriate size and specifications of the rotary union water system. Adequate flow and pressure ensure optimal cooling and performance of the rotating machinery.

Maintenance and Troubleshooting of Rotary Union Water Systems

To ensure the longevity and efficiency of rotary union water systems, regular maintenance is necessary. Proper maintenance includes periodic inspection, cleaning, and lubrication of the system components. Additionally, troubleshooting techniques should be employed to identify and resolve any issues that may arise, such as leaks or blockages.

Case Studies: Successful Integration of Rotary Union Water Systems

Several industrial applications have successfully integrated rotary union water systems, leading to improved operational efficiency and cost savings. Case studies highlighting the successful implementation of these systems in industries such as automotive manufacturing, power generation, and paper printing provide valuable insights into their benefits and potential applications.

Future Trends and Innovations in Rotary Union Water Systems

The field of rotary union water systems is continuously evolving. Future trends and innovations include advancements in materials and seal technologies, integration of smart sensors for real-time monitoring, and the development of more compact and energy-efficient systems. These advancements aim to further enhance the performance, reliability, and ease of maintenance of rotary union water systems.

Conclusion

Efficient rotary union water systems play a pivotal role in optimizing industrial processes by providing effective cooling and heat dissipation for rotating machinery. The benefits of implementing these systems include enhanced equipment performance, extended equipment lifespan, and versatile applications across various industries. Understanding the working principles, considering critical factors, and performing regular maintenance are crucial for successful integration and long-term reliability of rotary union water systems.

0 notes

Text

#Rotary Unions#Rotary Joints#Rotary Swivels#Steam Joints#Machine tool coolant Unions#Water Unions#Hydraulic Rotary Unions#Air Rotary Unions#Hot Oil Rotary Unions#High Speed Coolant Unions#Rotating Unions for Coolants#What is a Rotary Union?#Food Rotary Joint

0 notes

Text

Efficient OEM Pumps Replacement Mechanical Seals: Optimal Functionality

Exploring Mechanical Seals, OEM Pumps, and Online Steam Joints

In the world of industrial machinery, reliability and efficiency are paramount. Whether you're involved in manufacturing, chemical processing, or any industry that relies on fluid handling equipment, the importance of mechanical seals, OEM pumps, and steam joints cannot be overstated. These components play a vital role in ensuring the seamless operation of various machines and systems. In this article, we'll delve into the world of mechanical seal manufacturer, OEM pump manufacturers, the best online steam joints, and the various types of gland packing seals, with a specific focus on multi-spring mechanical seals.

Mechanical Seal Manufacturers:

Mechanical seals are critical components in preventing the leakage of fluids from pumps, agitators, and other rotary equipment. They provide a dynamic seal between a rotating shaft and a stationary part, effectively sealing off the process fluid and ensuring the integrity of the equipment. Mechanical seal manufacturers are responsible for designing, producing, and supplying these seals to various industries.

Choosing a reliable mechanical seal manufacturer is essential for ensuring the longevity and efficiency of your machinery. These manufacturers utilize advanced materials, designs, and manufacturing processes to create seals that can withstand the harsh conditions of industrial applications. They often offer a range of mechanical seal types, such as single spring, double spring, and multi-spring seals, to meet the specific needs of different industries and applications.

OEM Pumps Manufacturer:

Original Equipment Manufacturer (OEM) pumps play a crucial role in various industries, providing customized solutions for specific applications. These manufacturers design and produce pumps that are integrated into larger systems and equipment, tailored to the unique requirements of their customers. OEM pumps are known for their reliability, performance, and efficiency.

Working with an OEM pumps manufacturer allows businesses to acquire pumps that are specifically engineered to meet their exact needs. These pumps can be designed to handle different fluids, pressures, and flow rates, ensuring that the machinery they're incorporated into operates optimally. OEM pump manufacturers often provide maintenance and support services, making it easier for businesses to maintain and service their equipment.

Best Online Steam Joints:

Steam joints, also known as rotary unions, are essential components in a wide range of industries, including paper mills, food processing, and manufacturing. They are responsible for transferring steam or other media from a stationary source to a rotating component, such as a drum or roll. Finding the best online steam joints is essential for ensuring a leak-free and efficient transfer of steam or other fluids.

The best online steam joints are those that are not only reliable but also designed to meet the specific requirements of your application. They should be capable of handling high temperatures, pressures, and speeds, while also minimizing maintenance requirements. Online suppliers of steam joints often provide a variety of options, allowing customers to select the appropriate size, configuration, and material to match their needs.

Gland Packing Seal Types:

Gland packing, also known as packing or mechanical packing, is a traditional sealing method used in applications where mechanical seals may not be suitable or cost-effective. Gland packing consists of braided or twisted materials, such as graphite, PTFE, or asbestos, which are inserted around a shaft or valve stem to prevent leakage.

There are various types of gland packing seal materials and styles available to suit different applications. These include:

Die-Formed Gland Packing: This type of packing is manufactured with specific shapes and dimensions to fit into sealing spaces efficiently.

Graphite Gland Packing: Graphite packing is widely used in high-temperature and high-pressure applications. It offers excellent thermal conductivity and lubrication properties.

PTFE Gland Packing: PTFE packing is highly resistant to chemicals and is often used in applications involving corrosive fluids.

Aramid Fiber Gland Packing: Aramid fiber packing is known for its strength and is suitable for applications where abrasion resistance is essential.

Multi-Spring Mechanical Seal:

Multi-spring mechanical seals are a type of mechanical seal that utilizes multiple springs to provide the necessary axial movement to maintain the seal's integrity. These seals are designed to handle a wide range of applications, including those with high pressures and speeds. The multiple springs ensure even distribution of force and allow for self-adjustment, which can enhance the longevity of the seal.

In conclusion, the choice of mechanical seal manufacturers, OEM pump manufacturers, steam joints, and gland packing seal types can significantly impact the efficiency and reliability of industrial machinery. Understanding the specific requirements of your application and working with trusted suppliers is crucial to ensure that your equipment operates seamlessly, with minimal downtime and maintenance. Whether you opt for advanced multi-spring mechanical seals or traditional gland packing, selecting the right components is essential for the success of your operations.

0 notes

Text

#High Pressure Water Rotary Joints#High Pressure Water Rotary Unions#Rotary Joints For High Pressure Water#Rotary Unions For High Pressure Water#High Pressure Air Rotary Joints#High Pressure Air Rotary Unions#Rotary Joints For High Pressure Air#Rotary Unions For High Pressure Air#High Pressure Hydraulic Oil Rotary Joints#High Pressure Hydraulic Oil Rotary Unions#Rotary Joints For High Pressure Hydraulic Oil#Rotary Unions For High Pressure Hydraulic Oil

0 notes

Text

Rotary Unions for Semiconductor Market Size, Emerging Trends, Technological Advancements, and Business Strategies 2023-2029

The global Rotary Unions for Semiconductor market was valued at US$ 193.5 million in 2022 and is projected to reach US$ 418.1 million by 2029, at a CAGR of 11.6% during the forecast period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes.

Get Full Report @ https://semiconductorinsight.com/report/rotary-unions-for-semiconductor-market/

A rotary union or swivel joint is a mechanism used to transfer fluid (under pressure or vacuum) from a stationary inlet to a rotating outlet, preserving and isolating the fluid connection. Also referred to as rotary joints, rotary couplings, fluid swivels or swivel joints; rotary unions are engineered to endure a large range of temperatures, pressures and speeds for a variety of conditions and environments. Rotary unions typically function by connecting to an input and securing onto another mechanism while allowing a moving connection to be preserved.

Rotary unions are an important component used in the semiconductor industry for various applications, including wafer processing, cooling systems, and vacuum applications. The rotary unions help to transfer fluids or gases from a stationary supply pipe to a rotating component, without causing any leakage or contamination.

The market for rotary unions in the semiconductor industry is expected to grow significantly in the coming years due to the increasing demand for semiconductors and the need for advanced processing techniques. The growing demand for smartphones, tablets, and other electronic devices is driving the demand for semiconductors, which in turn is boosting the demand for rotary unions.

This report aims to provide a comprehensive presentation of the global market for Rotary Unions for Semiconductor, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Rotary Unions for Semiconductor.

This report contains market size and forecasts of Rotary Unions for Semiconductor in global, including the following market information:

Global Rotary Unions for Semiconductor Market Revenue, 2018-2023, 2024-2029, ($ millions)

Global Rotary Unions for Semiconductor Market Sales, 2018-2023, 2024-2029, (K Units)

Global top five Rotary Unions for Semiconductor companies in 2022 (%)

Global key players of rotary unions for semiconductor include Deublin, Eagle Industry, DSTI, etc. Global top three manufacturers hold a share over 10%. North America is the largest producer of rotary unions for semiconductor, holds a share about 50%, followed by Asia-Pacific, and Europe. In terms of product, multi-channel rotary union is the largest segment, with a share about 90%. And in terms of application, the largest segment is chemical mechanical polishing (CMP) and grinding, followed by chemical vapor deposition (CVD) and physical vapor deposition (PVD).

We surveyed the Rotary Unions for Semiconductor manufacturers, suppliers, distributors and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks.

Asia Pacific is expected to hold the largest market share for rotary unions in the semiconductor industry, due to the increasing demand for semiconductors in the region.

The wafer processing segment is expected to hold the largest share of the market, driven by the increasing demand for advanced processing techniques in the semiconductor industry.

The vacuum applications segment is expected to witness the highest growth during the forecast period, due to the increasing use of vacuum technology in the semiconductor industry.

The demand for multi-channel rotary unions is expected to grow at a faster pace than single-channel rotary unions, due to their ability to transfer multiple fluids or gases simultaneously.

Key trends in the market include the increasing demand for smart devices and the development of new materials and manufacturing techniques to drive innovation in the rotary unions market.

Total Market by Segment:

Global Rotary Unions for Semiconductor Market, by Type, 2018-2023, 2024-2029 ($ Millions) & (K Units)

Global Rotary Unions for Semiconductor Market Segment Percentages, by Type, 2022 (%)

Single Channel Rotary Union

Multi-Channel Rotary Union

Global Rotary Unions for Semiconductor Market, by Application, 2018-2023, 2024-2029 ($ Millions) & (K Units)

Global Rotary Unions for Semiconductor Market Segment Percentages, by Application, 2022 (%)

Chemical Mechanical Polishing (CMP) and Grinding

Wafer Handling Robots

Chemical Vapor Deposition (CVD)

Physical Vapor Deposition (PVD)

Vacuum Coating Systems

Further, the report presents profiles of competitors in the market, key players include:

Deublin

Eagle Industry

DSTI

Moog GAT

Rotary Systems

Sealink Corp

Kadant

Dynamic Sealing Technologies Inc.

Parker Hannifin

MOFLON

Advanced Motion & Controls Ltd.

Uniflow Control Systems Inc.

KADIMI TOOL MFG. CO., LTD.

Global Rotary Unions for Semiconductor Market, By Region and Country, 2018-2023, 2024-2029 ($ Millions) & (K Units)

In North America, the demand for rotary unions is expected to increase, with a forecasted market size of USD 128 million by 2028. The growth in this region is attributed to the rising demand for electronics and technological advancements in the semiconductor industry.

In Europe, the market for rotary unions is projected to witness steady growth, with a forecasted value of USD 90 million by 2028. This growth can be attributed to the increasing investments in the semiconductor industry and the demand for advanced electronic devices.

The Asia Pacific region is expected to dominate the rotary unions market, with a forecasted value of USD 256 million by 2028. The growth in this region is attributed to the increasing demand for electronics, rising industrialization, and the presence of major semiconductor manufacturing companies.

Global Rotary Unions for Semiconductor Market Segment Percentages, By Region and Country, 2022 (%)

North America

U.S.

Canada

Europe

U.K.

Germany

France

Spain

Rest of Europe

Asia-Pacific

India

Japan

China

Australia

South Korea

Rest of Asia-Pacific

Latin America

Brazil

Mexico

Rest of Latin America

The Middle East & Africa

South Africa

GCC Countries

Rest of the Middle East & Africa (ME&A)

The market for rotary unions in the semiconductor industry is driven by several factors, including:

Growing demand for semiconductors: The increasing demand for smartphones, tablets, and other electronic devices is driving the demand for semiconductors, which in turn is boosting the demand for rotary unions.

Need for advanced processing techniques: The semiconductor industry is constantly evolving, and there is a need for advanced processing techniques to meet the demand for faster and more efficient electronic devices. Rotary unions are an essential component in many of these advanced processing techniques.

Increasing use of vacuum technology: The semiconductor industry uses vacuum technology extensively in various processes, and rotary unions play a crucial role in the transfer of fluids and gases in vacuum systems.

However, the market for rotary unions in the semiconductor industry also faces some challenges, including:

Intense competition: The market for rotary unions in the semiconductor industry is highly competitive, with a large number of manufacturers operating in the market. This can lead to pricing pressures and margin erosion.

High cost: Rotary unions for the semiconductor industry are often custom-designed and manufactured to meet specific application requirements. This customization can result in higher costs for the end-users.

Despite these challenges, there are also several opportunities in the market for rotary unions in the semiconductor industry, including:

Growing demand for smart devices: The growing demand for smart devices such as smartphones, tablets, and wearables is expected to drive the demand for semiconductors and, in turn, the demand for rotary unions.

Technological advancements: The development of new materials and manufacturing techniques is expected to drive innovation in the rotary unions market and provide new opportunities for growth.

Get Full Report @ https://semiconductorinsight.com/report/rotary-unions-for-semiconductor-market/

0 notes

Text

Rotary Joints, Rotary Union, Roto Seal Coupling Manufacturer, Supplier & Dealer in Kolkata

Rotary Joints Manufacturers - We offer Rotary Joints which is also known as Rotary Union & Roto Seal Coupling in Kolkata. Airmax Pneumatic Technology is a Manufacturer & Supplier of Rotary Joint.

0 notes

Text

Rotary Joints, Rotary Union, Roto Seal Coupling Manufacturer, Supplier & Dealer in Surat

We offer Rotary Joints which is also known as Rotary Union & Roto Seal Coupling in Surat. Airmax Pneumatic Technology is a Manufacturer & Supplier of Rotary Joint.

#Rotary Joints Manufacturer in Surat#Rotary Union Supplier in Surat#Roto Seal Coupling Dealer in Surat

0 notes

Text

Rotary Joints, Rotary Union, Roto Seal Coupling Manufacturer, Supplier & Dealer in Silvassa

We offer Rotary Joints which is also known as Rotary Union & Roto Seal Coupling in Silvassa. Airmax Pneumatic Technology is a Manufacturer & Supplier of Rotary Joint.

#Rotary Joints Manufacturer in Silvassa#Rotary Union Supplier in Silvassa#Roto Seal Coupling Dealer in Silvassa

0 notes

Text

0 notes

Text

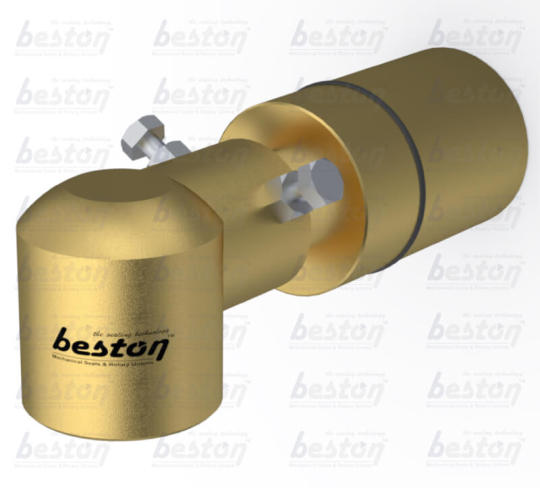

How The Rotary Union Works: A Technical Breakdown

A rotary union is a critical piece of machinery in many industries. It allows for smooth, continuous shaft rotation while sealing and lubricating the joint. In this blog post, we'll take a closer look at how rotary unions work, the different components that make them up, and the benefits and applications of rotary unions.

What is a Rotary Union?

A rotary union is a device that transfers fluids or gasses from one point to another while rotating. The most common type of rotary union is used in hydraulics and pneumatics, but unions are also for other fluids and gasses such as water, steam, air, and coolant. Rotary unions can be either male- or female-threaded, and are available in various sizes and materials.

Rotary unions are used in various applications, from tiny medical devices to large industrial machines. In many cases, they are essential components that enable smooth operation and prevent damage to equipment. For example, a rotary union might transfer hydraulic fluid from a stationary pump to a rotating arm on a machine. Without a rotary union, the liquid would leak out at the connection point, potentially causing equipment failure or injury.

There are two main types of rotary unions: fixed and swivel. Set blocks are permanently attached to one of the two surfaces they connect, while swivel unions can rotate freely on their axis. Swivel unions are often used in applications where there is movement between the two surfaces that need to be connected, such as in robotic arms or conveyor belts.

Rotary unions come in various sizes and configurations to suit different applications. They can be single- or multi-ported, meaning they have one or more fluid or gas flow channels. Some rotary unions also have features such as built-in check valves or filters.

How Does a Rotary Union Work?

A rotary union is a device that allows for relative motion between two parts while simultaneously transferring fluid or other materials between them. Rotary unions are often used in applications where it is necessary to rotate an object, such as a wheel or shaft while supplying it with fluids or other materials.

Many types of rotary unions are designed for a specific application. In general, however, all rotary unions work in the same fundamental way. Fluid or material enters the league through an inlet port and is then transferred to the outlet port as the two parts of the union rotate relative to each other.

Rotary unions can transfer various fluids or materials, including air, water, oil, hydraulic fluid, coolant, and even electricity. They are commonly used in machine tooling, robotics, and manufacturing equipment applications.

The Components of a Rotary Union

A rotary union consists of three main components: the body, the rotor, and the seals. The body of the association is typically made from metal and houses the inlet and outlet ports. The rotor is located inside the body and is connected to one of the two moving parts relative to each other. The seals are located between the body and the rotor and prevent fluid or material from leaking out of the union as it is transferred.

The Benefits of a Rotary Union

There are many benefits to using a rotary union in an application. One of the most important benefits is that it allows for high accuracy and repeatability in the transfer of fluid or material. Rotary unions can also transfer very viscous fluids or materials and operate at high pressures and temperatures. Another benefit of rotary unions is that they are relatively low maintenance and do not require frequent replacement like other fluid-transfer devices.

The Applications of a Rotary Union

There are many different applications for rotary unions. One common application is machine tooling, which is used to transfer coolant or cutting fluid to the cutting tool. This helps to keep the cutting tool cool and prevents it from overheating. Rotary unions are also commonly used in robotics, where they transfer hydraulic fluid or lubricating oil to the robot's moving parts. This helps to keep the robot moving smoothly and prevents wear and tear on the robot's components. Rotary unions can also be used in manufacturing equipment, such as conveyor belts or assembly lines, where they are used to transfer materials between different parts of the equipment.

The Future of Rotary Unions

The future of rotary unions looks very promising. With the ever-growing popularity of robotics and other automated machines, the demand for rotary unions will only continue to increase. Rotary unions are essential for keeping these machines running smoothly and efficiently, and as technology continues to advance, the capabilities of rotary unions will continue to increase as well. In addition to their use in robotics and automation, rotary unions can also be used in various other applications, such as medical equipment, food processing machinery, and textile machinery. As the world increasingly relies on technology, the demand for rotary unions will surely rise.

0 notes

Text

#Rotary Unions#Rotary Joints#Rotary Swivels#Steam Joints#Machine tool coolant Unions#Water Unions#Hydraulic Rotary Unions#Air Rotary Unions#Hot Oil Rotary Unions#High Speed Coolant Unions#Rotating Unions for Coolants#What is a Rotary Union?#Food Rotary Joint

0 notes

Text

Rotary Joints, Rotary Union, Roto Seal Coupling Manufacturer, Supplier & Dealer in Rajkot

We offer Rotary Joints which is also known as Rotary Union & Roto Seal Coupling in Rajkot. Airmax Pneumatic Technology is a Manufacturer & Supplier of Rotary Joint.

#Rotary Joints Manufacturer in Rajkot#Rotary Union Supplier in Rajkot#Roto Seal Coupling Dealer in Rajkot

0 notes

Text

#air & hydraulic oil service Rotary Joints#air & hydraulic oil service Rotary Unions#Rotary Joints For air & hydraulic oil service#Rotary Unions For air & hydraulic oil service

0 notes

Text

Rotary Joints, Rotary Union, Roto Seal Coupling Manufacturer, Supplier & Dealer in Pune

We offer Rotary Joints which is also known as Rotary Union & Roto Seal Coupling in Pune. Airmax Pneumatic Technology is a Manufacturer & Supplier of Rotary Joint.

0 notes

Text

Rotary Joints, Rotary Union, Roto Seal Coupling Manufacturer, Supplier & Dealer in Ankleshwar

We offer Rotary Joints which is also known as Rotary Union & Roto Seal Coupling in Ankleshwar. Airmax Pneumatic Technology is a Manufacturer & Supplier of Rotary Joint.

#Rotary Joints Manufacturer in Ankleshwar#Rotary Union Supplier in Ankleshwar#Roto Seal Coupling Dealer in Ankleshwar

0 notes