#selfloadingmixer

Explore tagged Tumblr posts

Text

Which Concrete Solution Fits UAE Projects Better: Self Loading Mixer or Mobile Concrete Plant?

The UAE's construction landscape presents unique challenges that demand innovative concrete solutions. With projects ranging from towering skyscrapers to sprawling infrastructure developments, contractors face critical decisions about their concrete production methods. Two technologies have emerged as frontrunners in this demanding environment: self loading mixer and mobile concrete plants. Each offers distinct advantages tailored to different project requirements, but choosing the right one can make or break a project's efficiency and profitability.

Understanding which solution fits better requires examining several factors unique to the UAE context. The region's extreme temperatures, dust conditions, and ambitious construction timelines create special considerations for concrete production. Additionally, labor availability, transportation logistics, and project scales vary dramatically across different emirates. This analysis will help you navigate these complexities to select the optimal concrete solution for your specific needs in this dynamic market.

Operational Flexibility in UAE's Diverse Project Sites

Mobility and Space Constraints

Self-loading mixers shine in confined urban job sites common in Dubai and Abu Dhabi. Their compact footprint allows operation in spaces as tight as 6-meter wide lots, perfect for high-rise construction in dense city centers. The ability to load, mix, and pour concrete from a single machine eliminates the need for separate batching plants and transit mixers.

Temperature Adaptability

UAE's scorching climate demands special considerations. Modern self-loading concrete mixers in UAE incorporate thermal management systems that maintain optimal mixing temperatures even in 50°C heat. Their enclosed mixing drums protect materials from direct sunlight and dust contamination, crucial for maintaining concrete quality in desert conditions.

Production Capacity and Project Scale Considerations

Meeting High-Volume Demands

Mobile concrete plants dominate when large-scale production is required. For mega-projects like Expo City developments or major highway constructions, their 60-120 m³/hour output capacity proves indispensable. These systems can be scaled up with additional mixing units to match project growth, a critical feature for the UAE's rapidly evolving construction timelines.

Material Consistency Across Batches

Centralized batching in mobile batching plants ensures uniform quality control across thousands of cubic meters. This becomes particularly important for specialized concrete mixes used in UAE's iconic architectural projects, where precise strength and finish requirements must be maintained consistently.

Economic and Logistical Factors

Labor Optimization Strategies

Self-loading mixers require just 1-2 operators, a significant advantage in the UAE's tight labor market. Their automated systems reduce dependency on skilled workers while maintaining production quality. This operational simplicity translates to lower training costs and reduced visa-related overheads.

Transportation and Setup Economics

Mobile concrete plants offer better economies of scale for long-duration projects. While requiring more initial setup time, their per-unit production costs drop dramatically at higher volumes. For remote projects in emirates like Ras Al Khaimah, they eliminate the need for lengthy concrete hauls from centralized batching plants.

The choice between these technologies ultimately depends on your specific project parameters in the UAE context. Self-loading mixers offer unparalleled flexibility for urban projects with space constraints and variable daily requirements. Mobile concrete plants deliver superior efficiency for large-scale, long-duration projects where consistent high-volume output is critical. Smart contractors often employ both, using self-loaders for finishing work while relying on mobile plants for structural elements, creating an optimized hybrid approach tailored to the UAE's unique construction challenges.

0 notes

Text

Boost Your Concrete Game with Apollo Carmix 4TT!

This infographic shows how Electronic Weighing Systems with Load Cells in the Self-Loading Concrete Mixer 4TT ensure 100% concrete quality—every time. Get precise material measurement, reduce wastage, and enjoy automated tracking with built-in printers.

Designed for efficiency, accuracy, and seamless integration, it’s the smart choice for compact, cost-effective concrete production.

👉 Visit www.apollocarmix.com

#ApolloCarmix#ConcreteMixer#SelfLoadingMixer#ConstructionInnovation#SmartConstruction#ConcreteTechnology

0 notes

Video

youtube

New Mini track self loading mobile concrete mixer #selfloadingmixer #con...

1 note

·

View note

Video

youtube

How to Operate HM2.0 Self Loaind Mixer

0 notes

Video

youtube

Is it Easy to Use a Self Loading Mixer?

Self loading mixer is a "magical" machine to supply concrete for small projects in mountainous and rural areas.

Roads to these projects are narrow - the self loading mixer is compact, less than 3 meters in width.

Roads are rugged and non-paved - the mixer is 4-wheel driven and its tires are off-road type.

There is a shortage of workers - one self loading mixer replaces 6 workers in the production of concrete.

There is a tight schedule- the mixer is productive. It produces up to 200 cubic meters of concrete daily.

The self loading mixer seems to be complicated, will it be easy to use?

Yes, it is.

The mixer is highly automated. It has 2 hydraulic systems. One for moving, the other for mixing concrete. All the movements are controlled by the operator moving joysticks in the cabin. With the joysticks, the operator can make the mixer move forward, backward and make turns. This is the moving system working. By moving other joysticks, the mixer can raise or lower the loading arm to load materials, rotate the drum to mix or discharge concrete, and swing the drum in different directions.

#selfloadingmixer #concretemixer #mixermachine #mountains #ruralareas #ruggedroad #operation #hydraulicsystem #constructionprojects #swingdrum

0 notes

Text

Why Electronic Weighing Systems in Self-Loading Concrete Mixer 4TT Make a Difference in Concrete Production

The Apollo Carmix 4TT Self-Loading Concrete Mixer revolutionizes concrete production with its electronic weighing system, ensuring accuracy, efficiency, and quality in every batch!

🔹 Why It Makes a Difference:

✅ Precise Material Measurement – Ensures the right mix ratios for consistent concrete quality ✅ Reduces Wastage & Costs – Avoids overuse of cement and aggregates ✅ Real-Time Monitoring – Provides accurate weight data for better control ✅ Enhanced Productivity – Speeds up the mixing process with automated calculations ✅ Improved Construction Quality – Delivers uniform and high-strength concrete With Apollo Carmix 4TT, you get the perfect blend of efficiency, accuracy, and durability, making it the ideal choice for construction professionals! 🔗 Learn more: https://www.apollocarmix.com/products/apollo-carmix-4tt

0 notes

Text

Self-Loading Transit Mixers: Key Community Projects That Benefit from Their Use

In the realm of construction and infrastructure development, the advent of advanced machinery has revolutionized traditional practices. Among these innovations, the self loading transit mixer stands out for its efficiency and versatility. This remarkable piece of equipment not only streamlines the process of concrete mixing and transportation but also adapts seamlessly to various project types. Understanding the specific community projects that leverage this technology can provide insights into its growing significance in modern construction methodologies.

The self-loading transit mixer is particularly advantageous for its ability to combine the functions of concrete batching, mixing, and transportation into a single operation. This capability reduces labor costs and minimizes the time required to complete projects. As a result, municipalities and local organizations increasingly recognize the utility of self-loading transit mixers for a range of community-oriented projects.

1. Road Construction and Rehabilitation

1.1. Urban Infrastructure Development

Urban infrastructure projects, such as road construction and rehabilitation, frequently utilize self loading concrete mixer in Kenya. These mixers facilitate the rapid application of concrete, essential for creating durable road surfaces. The ability to mix concrete on-site ensures that the material remains fresh and workable, which is crucial for achieving optimal performance.

1.2. Pavement Repairs and Maintenance

Self-loading transit mixers are also invaluable for pavement repairs and maintenance tasks. With their capacity to deliver precise amounts of mixed concrete directly to the work zone, these machines expedite repair processes. This efficiency translates into reduced downtime for roads, benefiting both commuters and local economies.

2. Community Infrastructure Projects

2.1. Sidewalk and Pathway Construction

In community-focused projects, the construction of sidewalks and pathways is a common application for self-loading transit mixers. These mixers enable the quick and effective pouring of concrete, which is essential for creating safe and accessible pedestrian routes. The flexibility of the mixer allows for various designs and specifications, making it a favored choice among local authorities.

2.2. Park and Recreational Area Development

Self-loading transit mixers also play a critical role in the development of parks and recreational areas. From constructing benches to building playground foundations, the versatility of these mixers facilitates a wide array of concrete applications. By enhancing the aesthetic and functional aspects of community spaces, they contribute significantly to local quality of life.

3. Residential Construction Projects

3.1. Home Foundations and Structural Elements

Residential construction frequently employs self-loading transit mixers for home foundations and other structural components. The precision and speed of concrete delivery ensure that construction timelines are met without compromising quality. Moreover, the ability to mix concrete on-site minimizes the risk of material waste, contributing to more sustainable building practices. Check its applications from AIMIX Group website.

3.2. Driveways and Garages

Another prominent application is the construction of driveways and garages. Self-loading transit mixers enable homeowners and contractors to achieve high-quality finishes with minimal effort. This efficiency not only enhances the aesthetic appeal of properties but also increases their market value.

In conclusion, the versatility and efficiency of self-loading transit mixers make them indispensable in various community projects. From road construction to residential developments, these machines enhance productivity while ensuring quality outcomes. As communities continue to evolve, the reliance on such innovative equipment is likely to increase, shaping the future of construction methodologies.

0 notes

Text

Why Self-Loading Concrete Mixers Are Revolutionizing Small to Medium Construction Projects

Introduction

The Changing Landscape of Construction

In recent years, the construction industry has undergone a significant transformation. The focus has shifted towards efficiency, cost-effectiveness, and sustainability. Amidst these changes, self loader concrete mixer have emerged as a revolutionary solution for small to medium construction projects. These ingenious machines have quickly gained popularity, and for good reason.

Introduction to Self-Loading Concrete Mixers

Self-loading concrete mixers are a marvel of modern engineering. Combining the functions of a concrete mixer and a concrete transporter, these machines allow for the seamless mixing and delivery of concrete on-site. They are compact, versatile, and incredibly user-friendly, making them an essential tool for contemporary construction projects.

Key Advantages of Self-Loading Concrete Mixers

Efficiency and Time Savings

One of the standout benefits of self-loading concrete mixers is their efficiency. These mixers are designed to handle every aspect of the concrete mixing process, from loading raw materials to delivering the final mix. This all-in-one capability drastically reduces the time and labor required, allowing construction crews to complete projects faster. In an industry where time is money, this efficiency is invaluable.

Cost-Effective Operations

Beyond saving time, self-loading concrete mixers are also cost-effective. Traditional concrete mixing often involves multiple pieces of equipment and a larger workforce. Self-loading mixers, on the other hand, streamline the process and reduce the need for additional machinery and labor. This reduction in operational costs can have a significant impact on the overall budget of a construction project, making it more feasible for smaller firms and independent contractors.

Versatility on Diverse Job Sites

Another major advantage of self-loading concrete mixers is their versatility. These machines are designed to operate in a variety of environments, from urban settings to remote locations. Their compact size allows them to navigate tight spaces and challenging terrains, making them ideal for a wide range of projects. Whether it's a small residential build or a medium-sized commercial development, self-loading concrete mixers can handle the job with ease. Check its wide applications here: https://concretemixerwithpump.com/self-loading-transit-concrete-mixer/.

Real-World Applications and Success Stories

Small Residential Projects

Self-loading concrete mixers are particularly beneficial for small residential projects. Homebuilders can use these mixers to efficiently handle concrete needs for foundations, driveways, and other structural elements. The ability to mix and pour concrete on-site ensures that the material is fresh and of the highest quality, leading to better construction outcomes.

Medium-Sized Commercial Developments

For medium-sized commercial developments, self-loading concrete mixers offer a practical solution to managing concrete supply. These projects often require a steady flow of concrete to maintain progress. Self-loading mixers provide the flexibility and reliability needed to keep the project on track, reducing the risk of delays and cost overruns.

Infrastructure and Public Works

In infrastructure and public works projects, self-loading concrete mixers have proven to be invaluable. These projects often occur in remote or hard-to-reach areas where traditional concrete delivery methods are impractical. The mobility and self-sufficiency of self-loading mixers make them perfect for such applications, ensuring that infrastructure projects are completed efficiently and effectively.

Future Prospects and Innovations

Emerging Technologies

The future of self-loading concrete mixers is bright, with numerous emerging technologies set to enhance their capabilities. Innovations such as automated controls, GPS tracking, and real-time data analytics are becoming increasingly integrated into these machines. These advancements will further improve efficiency, accuracy, and ease of use, making self-loading mixers even more indispensable in the construction industry.

Sustainability and Environmental Impact

As sustainability becomes a priority in construction, self-loading concrete mixers are also evolving to meet these demands. Newer models are designed to be more fuel-efficient and produce less emissions, aligning with global efforts to reduce the environmental impact of construction activities. Additionally, the ability to mix concrete on-site reduces waste, contributing to more sustainable building practices.

Anticipated Trends in Construction

Looking ahead, we can anticipate several trends that will shape the use of self-loading concrete mixers. The integration of artificial intelligence and machine learning will likely play a significant role, enabling these machines to operate with greater autonomy and precision. Moreover, the shift towards modular and prefabricated construction methods will create new opportunities for self loading concrete mixer for sale in ghana, as their flexibility and efficiency make them well-suited for these innovative building techniques.

In conclusion, self-loading concrete mixers are revolutionizing small to medium construction projects by offering unparalleled efficiency, cost savings, and versatility. As technology continues to advance, these machines will only become more integral to the construction process, driving the industry towards a more efficient and sustainable future.

0 notes

Text

NEW AGE OF CEMENT MIXER – UNDERSTANDING THE PROCESS

We can call it a new age of cement mixer or concrete mixer. Different types of cement mixers are available in the market and all of them have distinct functionalities with several usage. You can get complex but advanced version of this machine as well as some simple ones. It ultimately depends on the pattern and requirement of the construction that which type of mixer will be more effective for you. The main task of this material is preparing an aggregated mixture of water and sand to create robust concrete. This type of cement becomes durable too. Before you get the mixer to have the cement, make sure you are aware of the process that is followed to prepare the same.

Knowing the Basic Component

When you see an average machine then you can find that it has some basic components like a revolving drum. This is the main place where the blending of water and sand is happened. As a result of that blending you can get the mixture after a certain time. However, if you need concrete in a larger amount then you should look for advanced machines that can produce more mixture within the shortest possible time. Such types of machines are required for construction businesses where larger amount of cement is required every day.

Know about Self Loading Cement Mixer visit: https://www.apollocarmix.com/all-about-self-loading-concrete-mixers/

Follow us on

Facebook - https://www.facebook.com/apollocarmix

Twitter - https://twitter.com/apollocarmix

Pinterest - https://www.pinterest.com/apollocarmix/

0 notes

Text

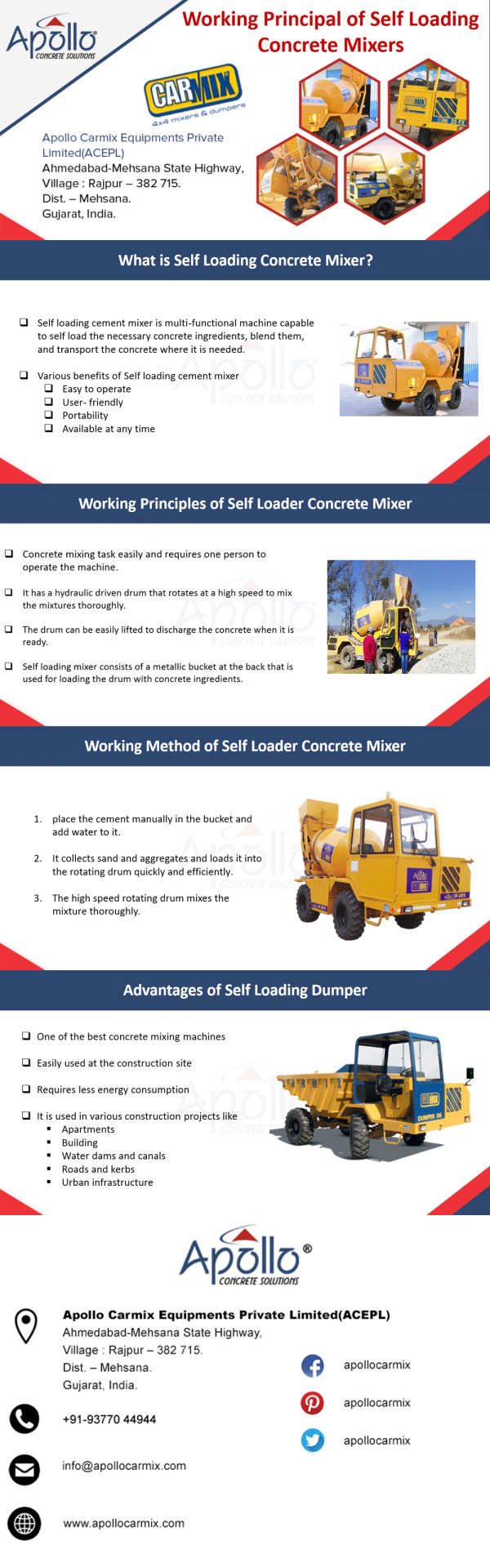

Working Principal of Self Loading Concrete Mixers

For few decades construction industries was struggling with cementing, mixing and transporting of the raw materials to the worksite on time. The construction industry at any time requires fresh and quality concrete, but their requirement was not fulfilled and they found difficulty in working. There was only one way to bridge this gap was the invention of the advanced technology-based machine. So, self loading concrete mixers were invented that made life bit easier. In this article, we will learn about how this machine works?

Various model and types of concrete mixing machines are available in the market either small portable mixer or large concrete trucks. Every model comes with unique features along with advantages and disadvantages, specifications and configurations. But, the requirement of the construction industry is bit different. They require a powerful machine to mix heavy quantity of cement and aggregates and at the same time it should be time and cost effective.

What is self loading concrete mixer?

Self loading cement mixer is multi-functional machine capable to self load the necessary concrete ingredients, blend them, and transport the concrete where it is needed. It comes with various benefits such as easy to operate because of its self loading design, user- friendly, portability, and available at any time. The machine reduces the time consumption in making the concrete and provides the desired proportion that is small to medium volume of mixture for the construction purpose. Also, it avoids unnecessary wastage. It has become popular amongst the construction industry today as the concrete machine is equipped with an effective engine and four wheel drive system that extends its utility in any terrain and conditions.

Know about Self Loading Cement Mixer visit: https://www.apollocarmix.com/all-about-self-loading-concrete-mixers/

0 notes

Video

youtube

Golden Tandems for Mini Construction Projects

The various types of mini construction projects share the same pains.

For example, when you are building villas in the mountains;

When you are making a road in the mountains;

When you are paving the front and back yards;

When you are digging drainage;

When you are doing side ditches for the main road;

Either the construction site or the connecting road is too small for the massive machinery. And it is time-consuming for manual work.

Compact machines are introduced to release pains for such projects. These machines are small in volume but can do the same job as the big ones.

The mini excavators can dig the foundation pits and side ditches, level the ground, or dismantle old buildings.

The self loading mixers can produce concrete automatically and discharge it in different directions to be more efficient.

The trailer pumps can deliver concrete to a higher or further location that the mixer cannot access.

The 3 machines together can finish most of the work on the job site.

#miniprojects #compactmachines #selfloadingmixer #miniexcavator #trailerpump #telescopicloader #minidigger #minibreaker #concretemixer #minimixertruck

0 notes