#servo motor

Explore tagged Tumblr posts

Text

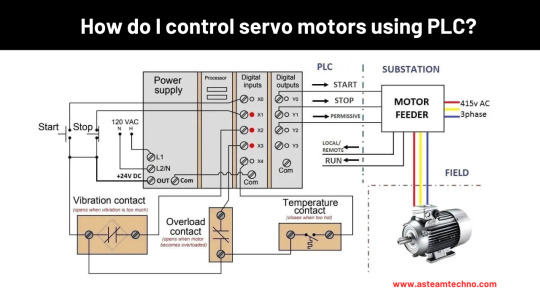

How do I control servo motors using PLC?

Select the appropriate PLC and Servo Drive

Connect the hardware

Program the PLC

Configure Servo Drive Parameters

Implement Motion Control Commands

Testing and Debugging

Safety Considerations

Documentation

🌐Website :- https://asteamtechno.com

👉Contact us :- +91 95372 40404

📧Email :- [email protected]

#automation#trending#tumblr trends#viral#viralpost#trendingnow#bestdeals#allen bradley#rockwell automation#plc#servo motor#today on tumblr

2 notes

·

View notes

Text

The Siemens 1FK6083-6AZ21-9ZZ9-Z S01 Servo Motor is a high-performance motor designed for precision control in industrial automation. Ideal for applications requiring accurate speed and position, this compact servo motor delivers reliable power and smooth operation. It is built for long-lasting performance, even in demanding environments. With Siemens’ trusted engineering, it ensures optimal efficiency and integration with drive systems. This motor is commonly used in CNC machines, robotics, and factory automation setups. At Auto2mation, we offer genuine Siemens servo motors to keep your systems running at peak performance. Upgrade your automation setup with trusted Siemens quality and performance.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Siemens#Servo Motor

0 notes

Text

A Comprehensible Guide to Servo Motor Sizing

Discover the importance of proper servo motor sizing for optimal motion control performance. Learn how to calculate torque, inertia, and select the right motor to reduce energy costs, improve efficiency, and prevent oversizing.

#servo motor#stepper motor#sizing#torque#inertia#performance profile#speed profile#selection#motion control#motion controller

0 notes

Text

Servo Motors in Industrial Automation: Precision, Control, and Efficiency

Servo motors are part of the high-speed industrial automation world, producing precise, controlled, and efficient motion for various applications. Whether it is robotics, conveyor systems, CNC machines, or packaging lines, servo motors make sure that industrial processes are run smoothly with maximum accuracy. In this blog, we will discuss what servo motors are, how they work, their advantages in automation, and why they are indispensable in modern industrial settings.

What is a Servo Motor?

A servo motor is a type of electric motor designed to provide precise control over angular position, speed, and acceleration. Rather than a standard motor, which runs at a fixed speed, a servo motor can vary its speed of rotation and change its position based on input signals. This makes it very useful for applications that need accuracy, such as robotics, automation machines, and CNC machines.

Servo motors consist of a motor (often a DC or AC motor), a feedback device (such as an encoder or resolver), and a controller that processes the feedback signals to adjust motor operations. The feedback mechanism ensures that the motor operates with high accuracy and precision, making it perfect for applications that require consistent and repeatable motion.

Servo motors are integral parts of industrial automation in the modern scene and are essential for obtaining precision in speed, position, and acceleration. A high-quality servo motor ensures exceptional performance; thus, it avails superior accuracy, fast response times, and high efficiency, highly crucial in applications such as robotics, CNC machines, and material handling systems. It enables industries to obtain optimal performance with reduced consumption of energy and minimal downtime by using high-quality servo motors. Advanced materials and sophisticated feedback mechanisms ensure enhanced resilience and reliability, even in challenging environments. Whether it is a matter of precision manufacturing, automated assembly lines, or advanced robotics, high-quality servo motors ensure a high level of operational efficiency, reduced maintenance costs, and consistent, high-precision results.

Types of Servo Motors:

AC Servo Motors: AC servo motors use AC to produce rotary motion, with much higher efficiency and superior speed and torque control. They are thus suited for high power applications.

DC Servo Motors: DC servo motors use direct current and provide accurate speed and position control. They are simpler to control but lack in efficiency at higher powers as opposed to AC motors.

Brushless DC Servo Motors (BLDC): These motors use electronic commutator technology instead of brushes; they are therefore more efficient and longer-lived than DC motors, with less maintenance cost.

Stepper Motors: Stepper motors give exact step-by-step control and thus are known for proper application for positioning without necessarily having a feedback system, usually in low to moderate load applications.

Permanent Magnet Synchronous Motors (PMSM): PMSMs use permanent magnets to create a magnetic field and are noted for their high efficiency, high torque output, and low maintenance, commonly being used in high-performance automation systems.

Applications of Servo Motors in Industrial Automation:

Robotics: In robotics, servo motors are widely applied for accurate positioning, arm movement, and fine control. The motors allow robots to be precise while performing complicated tasks like assembly, material handling, and packaging.

CNC Machines: Computer Numerical Control machines rely on servo motors in performing cutting, milling, or drilling operations. These motors are highly important to accurately move the tool in multiple axes.

Conveyor Systems: Servo motors in automated conveyor systems control the speed and position of conveyor belts. This contributes to the efficiency of handling and packaging materials in industries such as food processing, logistics, and manufacturing.

Packaging Machinery: Servo motors help align and seal packaging materials with high accuracy in packaging machines, improving efficiency and reducing waste.

Injection Molding Machines: The use of servo motors enables precision and efficiency in the control of injection molding, leading to consistently high-quality products with less cycle time.

Servo motors are integral in the industrial automation field, as they have supplied accuracy, speed, and efficiency in a broad range of applications. Efficiency and precision with low energy consumption make servo motors perfect for modern high-performance automation systems. Servo motors enhance the capability of automation systems in all service areas, like robotics, CNC machining, material handling, and reduced downtime, better productivity, and high-quality output. As industries are pushing for more automation and innovation, servo motors will continue to be at the heart of this advancement, changing the future of manufacturing, processing, and assembling.

0 notes

Text

Essential Guide: How to Drive a Servo Motor Like a Pro

Servo motors have become vital across various industries, from robotics and CNC machinery to automation. Their precision and control make them ideal for applications requiring specific movement or positioning. For those new to the world of servo motors or anyone seeking to sharpen their skills, understanding how to drive a servo motor effectively is key to harnessing its full potential. This guide will walk you through everything you need to know to drive a servo motor like a pro, covering basics, technical tips, and best practices.

What Is a Servo Motor?

A servo motor is a specialized rotary actuator designed for precise control of angular or linear position, velocity, and acceleration. Unlike traditional motors, which typically run at a constant speed, servo motors respond to specific instructions to move to set positions with a high degree of accuracy. They are commonly used in robotics, conveyor systems, camera focus mechanisms, and beyond.

Key Components of a Servo Motor System

To operate a servo motor effectively, it's essential to understand its components:

Motor – The main driver of motion, either DC or AC, that generates rotational movement.

Controller – Sends specific signals to the motor to reach a target position or speed.

Feedback Device – Typically an encoder or potentiometer, providing feedback on the motor's position to ensure accuracy.

Drive Circuit – Interfaces the controller with the motor, enabling controlled power and precise motion.

Step 1: Choose the Right Servo Motor for Your Application

Choosing the right motor type depends on your application's power, speed, and control requirements. Generally, servo motors fall into two main categories:

DC Servo Motors – Better suited for applications requiring lower power and precise control.

AC Servo Motors – More powerful and suitable for higher-speed applications, often used in industrial automation.

Consider the torque, speed, and voltage ratings as you assess which servo motor fits your needs.

Step 2: Understand Control Signals

Servo motors require control signals to determine movement. There are three main types:

Pulse Width Modulation (PWM) – Common in hobbyist and small-scale applications, it involves sending pulses to control motor position.

Analog Signals – Often used in industrial settings, where a specific voltage range controls motor speed or position.

Digital Signals – A more advanced option that communicates precise instructions for accurate control in complex systems.

Step 3: Master the Basics of Servo Motor Controllers

To drive a servo motor effectively, you’ll need a servo controller, the brain behind the operation. It’s responsible for interpreting the commands and converting them into movements. There are two primary control modes:

Position Control – This mode commands the servo to move to a specified position and is highly accurate.

Speed Control – Here, the controller maintains a steady speed, ideal for applications like conveyor belts.

Selecting the right controller based on your application can make all the difference in achieving optimal performance.

Step 4: Set Up Your Servo Drive

The servo drive is an essential component, bridging the motor and controller. Here’s a basic setup guide:

Power Supply – Connect a power source that matches the servo motor’s voltage and current requirements.

Signal Wires – Connect the control signals from your controller to the servo motor input.

Feedback Mechanism – Ensure the encoder or potentiometer is connected to relay accurate positioning data.

Check Connections – Verify all wiring and connections are correct, ensuring stable performance and avoiding overheating or short circuits.

Step 5: Programming Your Servo Motor

Servo motors can be controlled manually or programmed via a microcontroller or PLC (Programmable Logic Controller) for automation. Start by writing basic commands to rotate the motor to specific angles, then proceed to more complex programs for movement sequences. Popular platforms like Arduino and Raspberry Pi are ideal for beginner programmers.

Step 6: Fine-Tuning Performance

To drive a servo motor like a pro, fine-tuning is necessary. Here are some techniques:

PID Tuning – PID (Proportional-Integral-Derivative) controllers are commonly used to fine-tune servo motors, helping achieve smoother and more precise control.

Frequency Response Tuning – Adjusting frequency parameters can prevent oscillations and improve stability.

Gain Adjustment – Increasing or decreasing gain settings affects responsiveness and precision.

Step 7: Troubleshoot Common Servo Motor Issues

When driving a servo motor, issues may arise. Here’s how to troubleshoot:

Inconsistent Positioning – Verify the feedback device is correctly calibrated and connected.

Overheating – Check that the motor isn’t overloaded and that the drive circuit isn’t providing excessive current.

Unexpected Stopping – Inspect connections, power supply, and control signal integrity.

Noise and Vibration – Adjust gain settings or consider a damper if high-frequency noise affects performance.

Step 8: Regular Maintenance

Regular maintenance ensures optimal servo motor performance and extends lifespan. Here are some maintenance tips:

Check Wiring and Connections – Loose connections can cause erratic movements.

Lubricate Bearings – Especially in industrial environments, to prevent wear and tear.

Inspect Feedback Devices – Clean encoders or potentiometers for accurate data.

Why Learn to Drive a Servo Motor Like a Pro?

Mastering servo motor operation enhances productivity, precision, and cost efficiency. Industries benefit from improved control and accuracy in applications ranging from robotics to medical devices, where precise movement can make a crucial difference.

Conclusion

Driving a servo motor may seem complex initially, but with this guide and hands-on practice, you'll be able to control it confidently. Whether you’re aiming for exact positioning or consistent speed, mastering servo motors will open up opportunities for innovation and efficiency.

0 notes

Text

Financial Benefits of Repairing & Refurbishing Critical Spare Parts

Discover the financial benefits of repairing and refurbishing critical spare parts in industrial settings. This blog explores how strategic critical spare parts management and industrial repair management can optimize maintenance budgets and reduce downtime. Learn how repairing components like gearboxes and servo motors, and purchasing refurbished parts, can extend equipment life while cutting costs. Emphasizing the importance of maintaining a critical spare parts inventory, we reveal how these practices ensure operational efficiency and sustainability, providing a cost-effective alternative to purchasing new equipment.

#Critical spare parts management#Critical spare parts#Industrial repair management#Gearbox#Servo motor

1 note

·

View note

Text

1 note

·

View note

Text

AC Motor Çeşitleri

AC motor çeşitleri, farklı uygulama ihtiyaçlarına göre geniş bir yelpazede sunulur. Bu motorlar, alternatif akım (AC) ile çalışan cihazlardır ve genellikle endüstriyel tesislerden ev aletlerine kadar birçok alanda kullanılır. AC motorlar, genellikle senkron motorlar, asenkron motorlar ve servo motorlar olarak sınıflandırılır. Senkron motorlar, rotor ve stator arasındaki manyetik alanın senkronize olması sayesinde belirli bir hızda çalışarak sabit hız kontrolü sağlar. Asenkron motorlar ise rotor hızının stator hızından biraz farklı olduğu durumlarda çalışır ve bu tür motorlar daha yaygın olarak kullanılır. Servo motorlar ise hassas hareket kontrolü ve geri besleme özellikleri sunar, bu da onları yüksek hassasiyet gerektiren uygulamalar için ideal kılar. Her AC motor türü, özel avantajları ve kullanım alanları ile farklı ihtiyaçlara hitap eder.

Alternatif Akımlı Motor

Alternatif akımla çalışan motorlar, elektrik enerjisini mekanik enerjiye dönüştüren motorlardır ve geniş bir kullanım alanına sahiptirler. Bu motorlar, genellikle düşük maliyetleri, bakım gerektirmemeleri ve dayanıklılıkları nedeniyle tercih edilir. Alternatif akımlı motorlar, genellikle senkron ve asenkron olarak iki ana kategoriye ayrılır. Senkron motorlar, rotor ve stator arasındaki manyetik alanın senkronize olması sayesinde sabit bir hızda çalışır, asenkron motorlar ise rotor hızının stator hızından farklı olduğu durumlarda kullanılır. Bu motorlar, farklı uygulamalar için uygun çözümler sunar ve genellikle düşük enerji tüketimi ile uzun ömür avantajı sağlar.

Alternatif Akımlı Servo Motor

Alternatif akımlı servo motorlar, yüksek performans ve hassasiyet gerektiren uygulamalar için özel olarak tasarlanmış AC motorlardır. Bu motorlar, özellikle otomasyon sistemleri ve robotik uygulamalarda yaygın olarak kullanılır. Yüksek hızda ve yüksek torkta çalışabilen alternatif akımlı servo motorlar, geri besleme sistemleri sayesinde pozisyon, hız ve tork kontrolünü son derece hassas bir şekilde gerçekleştirir. Genellikle encoders ve kontrol sistemleri ile donatılmış olan bu motorlar, hareketlerin anlık olarak izlenmesini ve kontrol edilmesini sağlar. Yüksek verimlilikleri ve performansları ile endüstriyel uygulamalarda önemli bir rol oynar.

AC Servo Motor

AC servo motorlar, alternatif akımla çalışan ve yüksek hassasiyet gerektiren uygulamalarda kullanılan motor türleridir. Bu motorlar, robotik sistemler, CNC makineleri ve otomasyon uygulamaları gibi alanlarda tercih edilir. AC servo motorlar, yüksek tork ve hassas hız kontrolü sunar, aynı zamanda düşük gürültü seviyeleri ile çalışır. Rotor ve stator arasındaki manyetik alanların hassas bir şekilde kontrol edilmesi sayesinde mükemmel hareket kontrolü sağlanır. Ayrıca, bu motorlar geri besleme sistemleri ile donatılmış olup, motor hareketlerini ve pozisyonunu sürekli olarak izleyebilir, bu da onları güvenilir bir kontrol çözümü haline getirir.

AC Servo Motor Fiyatları

AC servo motor fiyatları, motorun gücü, özellikleri, markası ve kullanım alanına bağlı olarak geniş bir fiyat aralığında değişiklik gösterebilir. Motorun tork kapasitesi, hız aralığı, geri besleme sistemi ve kontrol ünitesi gibi unsurlar fiyatları etkileyen önemli faktörlerdir. Genel olarak, yüksek performans ve hassasiyet sunan AC servo motorlar daha yüksek maliyetlerle gelir. Ancak, uzun ömürleri ve düşük bakım gereksinimleri sayesinde toplam sahip olma maliyeti daha ekonomik olabilir. AC servo motor satın alırken, uygulamanızın gereksinimlerini ve bütçenizi göz önünde bulundurarak en uygun seçeneği belirlemek önemlidir. Fiyat karşılaştırmaları ve ürün incelemeleri, doğru motoru seçmenizde size yardımcı olabilir.

#servo motor fiyatları#servomotor#servo motor#servo motor ayarları#turkey#türkiye#istanbul#teknoloji#technology#tech

0 notes

Text

https://www.servodrivemotorrepair.com/ac-dc-servo-motor-repairing-services-in-pune.html

0 notes

Text

The ABB 3HAC17343-1/01 Servo Motor SGMAS-07ARB-AB11 is a high-performance motor designed for precision motion control in industrial automation. Operating at 200V with a current rating of 7.4A, this servo motor ensures reliable and efficient performance. Ideal for robotics, CNC machines, and automated systems, it offers accurate speed and torque control. The compact and durable design makes it suitable for demanding environments. Compatible with ABB robotic systems, it delivers smooth and consistent operation. Choose the ABB SGMAS-07ARB-AB11 Servo Motor from Auto2mation for dependable automation solutions that enhance productivity and system accuracy.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Abb#Servo motor

0 notes

Text

The Powerflex 753 AC drive's motor control modes

A flexible range of motor control modes designed to satisfy various industrial demands is provided by the PowerFlex 753 AC drive. The fundamental speed regulation it provides, appropriate for simple applications, comes from the V/Hz Control, which modifies both voltage and frequency simultaneously. The Sensorless Vector Control mode improves torque management and dynamic response while boosting performance without requiring external feedback devices.

#automation#trending#viral#tumblr trends#viralpost#trendingnow#bestdeals#allen bradley#rockwell automation#acdrive#servo motor

1 note

·

View note

Text

Schneider Electric Bangladesh Supplier

Schneider Electric Bangladesh Supplier in Bangladesh to empower everyone to make the most of your strengths and resources, bridging progress and creating sustainability for all. They call it “Life is On”. They aim to be your digital partner for sustainability and efficiency. They drive digital transformation by integrating world-leading process and energy technologies, cloud-connected products,…

View On WordPress

#AC Conductor#DC Conductor#Electrical Conductor#Life is On#Power Conductor#Schneider AC Conductor#Schneider DC Conductor#Schneider Electric#Schneider Electric Bangladesh#Schneider Electric Product Supplier#Schneider Electrical Conductor#Schneider Power Conductor#Schneider Servo Drive#Schneider Servo Motor#Schneider Stepper Motor#Servo Drive#Servo Motor#Stepper Motor

0 notes

Text

Manufacturer of Servo Voltage Stabilizer in India

Hindustan Power Control System is a professionally well managed company since 1999 which is successfully serving the global market through its wide range of products with the brand name HPCS. We are the leading manufacturer & Supplier of Servo Voltage Stabilizers, Electrical Panels, Isolation Transformers, Constant Voltage Transformers (CVTs) as per IS standards. We are having manufacturing plant at Lucknow, Uttar Pradesh, India.

#servostabilizer#servo motor#electricalengineering#isolationtransformer#electrical panel upgrades#electrical panel replacement

1 note

·

View note

Text

Servo Motor Market Report (2024-2030)

HTF MI recently introduced Global Servo Motor Market study with in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status (2024-2030). The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence and some of the key players from the complete study are Yaskawa (Japan), FANUC…

View On WordPress

0 notes