#siemens electric motors

Text

Comprehensive Guide to Siemens Motors by Popular Engineering

Popular Engineering Corporation is a leading supplier of Siemens motors, offering a wide range of high-quality, efficient, and reliable motor solutions. Their extensive catalog includes a variety of Siemens motors designed to meet the diverse needs of various industries. With over 48 years of experience in the industry, Popular Engineering has established itself as a trusted partner for businesses seeking top-notch motor solutions. In this blog, we will delve into the different types of Siemens motors available, their applications, and why Popular Engineering is the go-to source for these products.

Overview of Siemens Motors

Siemens is a global leader in the manufacturing of electric motors, known for their innovation, durability, and efficiency. Their motors are used in a myriad of applications, ranging from industrial machinery to commercial equipment. Siemens motors are designed to deliver optimal performance while minimizing energy consumption, making them an ideal choice for businesses looking to enhance productivity and reduce operational costs.

Types of Siemens Motors Offered by Popular Engineering

Popular Engineering offers a comprehensive selection of Siemens motors, each tailored to specific applications and industry requirements. Below, we explore the various types of Siemens motors available through Popular Engineering:

1. 1LA8 – 1PQ8 N – COMPACT Motors

These motors are known for their compact design, making them suitable for applications where space is limited. They offer high efficiency and reliability, ensuring consistent performance in demanding environments.

2. 1PQO Converter Duty Motors

Designed for use with variable frequency drives (VFDs), these motors are optimized for applications requiring precise speed control and energy efficiency. They are ideal for industries such as manufacturing and processing, where operational flexibility is crucial.

3. 1PTO – Textile Motors

Specifically engineered for the textile industry, these motors are built to handle the rigorous demands of textile machinery. They offer superior performance and longevity, even in harsh operating conditions.

4. Champion Frame Motors

These motors are designed for heavy-duty applications, offering robust construction and exceptional performance. They are suitable for industries such as mining, oil and gas, and construction.

5. Dual Speed Motors

Dual speed motors provide the versatility of operating at two different speeds, making them ideal for applications that require varying levels of power. They are commonly used in applications such as conveyor systems and pumps.

6. IE2 & IE3 Efficiency Motors

These motors meet the IE2 and IE3 energy efficiency standards, making them an excellent choice for businesses looking to reduce energy consumption and lower operational costs. They are suitable for a wide range of applications, from industrial machinery to HVAC systems.

Applications of Siemens Motors

Siemens motors in mumbai are versatile and can be used in a variety of applications across different industries. Some common applications include:

Industrial Machinery

Siemens motors are widely used in industrial machinery, providing the necessary power and efficiency for operations such as milling, drilling, and cutting.

Manufacturing and Processing

In the manufacturing and processing industries, Siemens motors are used in equipment such as conveyor systems, mixers, and extruders. Their reliability and efficiency help to optimize production processes.

Textile Industry

Textile machinery requires motors that can handle high loads and continuous operation. Siemens motor dealer in mumbai textile motors are designed to meet these demands, ensuring smooth and efficient operation.

Mining and Construction

Heavy-duty applications in mining and construction require robust and reliable motors. Siemens Champion Frame motors are built to withstand harsh conditions and deliver consistent performance.

HVAC Systems

Siemens motors are also used in heating, ventilation, and air conditioning (HVAC) systems, providing the necessary power for fans, pumps, and compressors.

Why Choose Popular Engineering for Siemens Motors

Popular Engineering Corporation stands out as a premier supplier of Siemens motors for several reasons:

1. Extensive Experience

With over 48 years of experience in the industry, Popular Engineering has a deep understanding of the market and the specific needs of their customers. Their expertise ensures that they can provide the best solutions for any application.

2. Comprehensive Product Range

Popular Engineering offers a wide range of Siemens motors, catering to various industries and applications. Their extensive catalog ensures that customers can find the perfect motor for their specific needs.

3. Quality Assurance

Quality is a top priority for Popular Engineering. They only supply Siemens motors dealer in mumbai, which are known for their reliability and durability. Customers can trust that they are receiving high-quality products that will perform consistently over time.

4. Customer Support

Popular Engineering is committed to providing excellent customer service. Their knowledgeable team is always available to assist with product selection, technical support, and any other inquiries. This dedication to customer satisfaction sets them apart from other suppliers.

5. Competitive Pricing

Despite offering top-notch products and services, Popular Engineering maintains competitive pricing. This ensures that customers receive the best value for their investment.

In-Depth Look at Siemens Motor Models

Let's take a closer look at some of the specific Siemens motor models offered by Popular Engineering:

1LA8 – 1PQ8 N – COMPACT Motors

The 1LA8 – 1PQ8 N – COMPACT motors are designed for applications where space is a constraint. Their compact design does not compromise on performance, making them suitable for a variety of industrial applications. These motors are known for their high efficiency, which helps to reduce energy consumption and operational costs. Additionally, they offer reliable performance even in demanding environments, ensuring minimal downtime and maintenance.

1PQO Converter Duty Motors

The 1PQO Converter Duty motors are optimized for use with variable frequency drives (VFDs). This makes them ideal for applications that require precise speed control and energy efficiency motor. Industries such as manufacturing and processing benefit greatly from these motors, as they offer the operational flexibility needed to adapt to varying demands. The 1PQO motors are also designed to handle the stress of frequent starts and stops, making them a reliable choice for dynamic applications.

1PTO – Textile Motors

Specifically designed for the textile industry, the 1PTO – Textile motors are built to withstand the rigorous demands of textile machinery. These motors offer superior performance and durability, ensuring smooth and efficient operation. They are capable of handling high loads and continuous operation, making them a reliable choice for textile manufacturers looking to maintain high productivity levels.

Champion Frame Motors

The Champion Frame motors are designed for heavy-duty applications, offering robust construction and exceptional performance. These motors are suitable for industries such as mining, oil and gas, and construction, where reliable and powerful motors are essential. The Champion Frame motors are built to withstand harsh conditions and deliver consistent performance, ensuring minimal downtime and maintenance.

Dual Speed Motors

Dual speed motors provide the versatility of operating at two different speeds, making them ideal for applications that require varying levels of power. Common applications for these motors include conveyor systems, pumps, and other equipment that needs to operate at different speeds. The dual speed functionality allows for greater flexibility and efficiency, optimizing the performance of the machinery.

IE2 & IE3 Efficiency Motors

The IE2 and IE3 efficiency motors meet international energy efficiency standards, making them an excellent choice for businesses looking to reduce energy consumption and operational costs. These motors are suitable for a wide range of applications, from industrial machinery to HVAC systems. By choosing IE2 and IE3 efficiency motors, businesses can achieve significant energy savings while maintaining high performance and reliability.

Conclusion

Siemens motors distributors, available through Popular Engineering Corporation, offer a wide range of high-quality, efficient, and reliable motor solutions for various industries. Whether you need a compact motor for a space-constrained application, a converter duty motor for precise speed control, or a heavy-duty motor for demanding environments, Popular Engineering has the perfect solution for you. With over 48 years of experience, a comprehensive product range, and a commitment to quality and customer satisfaction, Popular Engineering is the trusted partner for all your Siemens motor needs. Visit their website to explore their extensive catalog and find the ideal motor for your application.

#siemens electric motors#electric motor parts suppliers in india#electric motor dealer in india#electric motor dealer in mumbai#siemens gear motor distributor#siemens motors in mumbai#siemens motor supplier#siemens motor dealer in mumbai

0 notes

Text

Maximize Your Business Performance With Quality AC Drives And Motors

JS Electromec LTD is a leading provider of electrical solutions in Tanzania, offering a wide range of products and services for both industrial and commercial customers. We specialize in the distribution and installation of Siemens electric motors, UPS systems, and AC drives and motors.

JS Electromec LTD is proud to offer our customers the highest quality products and services. We source our Siemens electric motors from the Siemens 'MO-LINE' range which is known for its high energy efficiency and reliable performance. The range includes highly efficient motors to suit a wide range of applications, from fractional horsepower up to very large motors. The motors are also built to last, offering superior performance in even the harshest environments.

We are also the sole distributor of the best UPS systems in Tanzania – the Emerson UPS systems. These state-of-the-art units can provide power backup to ensure the uninterrupted functioning of critical operations and applications, even in the event of a power outage. The Emerson UPS systems are highly reliable and are designed to provide maximum protection for businesses, data centers, and government organizations.

Finally, JS Electromec LTD also offers AC Drives and AC Motors in Tanzania. We work with a variety of different motor and drive companies, including Hitachi, Lenze, ABB, and Omron, to provide our customers with the best AC Drive and Motor products. All our AC Drives and Motors are of superior quality and can be customized to suit any specific requirements.

At JS Electromec LTD, our goal is to provide our customers with the best electrical products and services in Tanzania. We use only the highest quality components and ensure that all products are built to last. We are committed to providing our customers with the best customer service and support.

Contact us today at +255 788 499111 and visit our website at https://www.jselectromec.co.tz/ to learn more about the variety of electrical products and services we offer.

#UPS Systems Tanzania#AC Drives#AC Motors Tanzania#Siemens Electric Motors#Electrical Control Panels#Control Panel Fabrication Tanzania

0 notes

Text

Get Cost-Effective Electrical Motor Control Center Panel at JS Electromec ltd

The Motor Control Center Panel in Tanzania is an essential piece of equipment for any business or organization that relies on motors to power their operations. This panel provides a centralized location for the control and monitoring of all motor-related activity, helping to keep your workplace running smoothly and efficiently. Featuring a variety of different features and functions, the JS Electromec ltd is the perfect solution for businesses of all sizes.

The Motor Control Center Panel is an essential part of the electrical infrastructure. It is responsible for the distribution of electricity to all parts of the country, and for the regulation of the electrical grid. The panel is located in the capital city of Dar as Salaam, and is operated by the Tanzania Electricity Supply Company (Transco). The Electrical Panel Boards is a specialized panel used to control the motors in a wide variety of applications.

It is manufactured by a team of experts with years of experience in the field, and it is designed to provide reliable and precise control over the motors in your system. This panel is an essential part of any motor control system, and it is available in a variety of sizes and configurations to suit your specific needs. AC/DC Disconnectors and Switches in Tanzania is designed to provide safe and reliable power distribution in a variety of applications. They are available in a variety of configurations to meet the specific needs of your application.

These products are used to Disconnectors and switch between various AC and DC power sources. They are available in a variety of sizes and configurations to suit the specific needs of the application. If you're looking for a trusted electrical online store that sells high-quality AC/DC Disconnectors and Switches in Tanzania at a reasonable price, look no further than JS Electromec Ltd. Contact us at +255 754 300348 today.

#Siemens Drive Systems#Siemens Drive Systems Tanzania#Siemens Electric Motors#UPS Systems Tanzania#AC Drives AC Motors Tanzania#Motor Control Center Panel Builder Tanzania#Siemens Control and Contactors#Electrical Panel Builders Tanzania#Electrical Distributors Tanzania

0 notes

Text

Alienskart.com is an online shopping site that enables you to explore different industrial & household electronics such as motors, ac drives, gearboxes, wires, leds, lubricants and many more. Our main brands consist of Havells, Hindustan, ABB, Castrol, Polycabs which are most trustful names in industries. Please visit us to get trustful and quality products. Thankyou for considering our site.

For more queries: 8818081001

#Alieskart#havells motors#high quality motors#wires & cables#ABB motors#hindustan motors#leds#lubricants#conveyor belts#Siemens motors#online shopping site#electronics & electricals site

0 notes

Text

Square D Magnetic Motor Starter

Are you looking for high-quality panel mount power switches? Denver breaker offers a wide range of inventory with brand new, obsolete, examined, and tested panel mounts power switches, square D magnetic motor starters, federal pacific replacement breakers, general electric circuits, high-quality electrical safety switches breakers, federal pacific replacement breakers, and many more at affordable prices. https://denverbreaker.com/

#square d magnetic motor starter#electrical safety switch#siemens electrical breakers#circuit breaker#general electric circuit breakers#panel mount power switch#electrical circuit breaker panel#federal pacific circuit breakers#used circuit breakers near me#federal pacific replacement breakers#reconditioned circuit breakers

0 notes

Text

Brand: Siemens Motors

Category: Electric AC Motor

Efficiency Class: IE2

FLP/Non FLP: Non FLP

Motor Phase: Three

Mounting: Foot

0 notes

Text

Top BBL Motor Dealers in India

Shri Rang Enterprise is one of the leading Bharat Bijlee – BBL motor dealers and manufacturers in India. We are proudly presents ourselves as top most BBL motor dealer and pumps which is a popular brand known for its best quality and persistence. As one of India's leading supplier, we have an experts who have excellent work quality with experienced who can help you choose the right motor for your particular requirements.

Bharat Bijlee motors are perfect for applications that require regular starting, stopping and reversing. They're used in a variety of industries including material handling, lifts, weirs and sluices and auxiliary motors. These motors are also used in cranes that need speed control for starting, stopping, or on and off functions.

Since 2005, Shri Rang Enterprise has been providing best quality products to their customers with a wide range of standard, gear, reduction gearboxes and many more other products. We offer a various kinds of products including servo motors, flame proof motors, electric motors, and cooling tower motors with their components and other parts.

We are committed to offering premium products with quality guaranteed by being one of India's top motor manufacturers and suppliers. We are able to offer different products such as BBL motor dealers, ABB motor dealers and suppliers, Siemens motor dealers and suppliers to provide to our all partners and clients as per their need.

Our reputation in the market is what has earned us the trust of both our suppliers and clients. We will keep working to provide the best possible service to those we already work with and those we have yet to do business with. For more information please visit our website or contact our representatives.

#BBL Motor Dealers#Brake Motors Manufacturers#Brake Motors Suppliers#Electric Motor Manufacturer#electric motor manufacturer#Electric Motor Suppliers#TEFC Motor Manufacturers#TEFC Motor Suppliers#Vibratory Motor Manufacturer#Vibratory Motors Suppliers#Induction Motor Dealers#Crompton Greaves Motor Dealers#Induction Motor suppliers#Electric Motor Dealers#AC Drives Suppliers#CG Motor Dealers#ABB Motor Dealers#ABB Motor Suppliers#Siemens Motor Dealers#Siemens Motor Suppliers#Flame Proof Motor Dealers#Flame Proof Motor Suppliers#Crane Duty Motor Dealers#Crane Duty Motor Suppliers

0 notes

Text

An alternative to Diesel: the Baureihe 563

More and more of these trains have appeared in the Offenburg area recently. Technically, I could be talking about both of the trains above because I'd never seen a Baureihe 218 locomotive (right) before, though over 400 were built in the 70s, but I am talking about the train on the left: the Baureihe 563.

5 is an unusual first digit for a German train type. Locomotives start with a 1 or a 2, for electric and Diesel power respectively, while passenger-carrying multiple units start with a 4 or a 6, again for electric and Diesel power respectively. Evidently, as seen above, these trains can run on non-electrified lines, but they are not Diesel multiple units - they are battery-electric multiple units.

Part of the Siemens Mireo family, the Mireo Plus B can run on electric power either from the overhead cable, or from the onboard batteries. The manufacturer states that the train can run between 80 and 120 km on battery power before needing a recharge from overhead cable, typically at a terminal station. This makes this train ideal for relatively short runs, such as those seen around Offenburg, the central station of the Ortenau area. As such, they are becoming more common, running local services for regional operator SWEG, indifferently on non-electrified lines like the one to Oberkirch, or electrified lines such as the picturesque Schwarzwaldbahn.

I know that Japan and the UK (link to Jago Hazzard's review of the GWR Class 230 and a quick overview of the BEMU topic) have also recently (re)introduced BEMUs. France hasn't really got on-board with this yet, as far as I know. Instead, they have built lots of bi-mode trains (mentioned at the end of the post), which have electric motors which can be powered by overhead cables or by an on-board Diesel engine.

#Germany#Deutschland#Ortenau#Offenburg#Oberkirch#Hornberg#Schwarzwaldbahn#SWEG#Siemens Mireo Plus B#BEMU#battery-electric#train#Baureihe 563#when I said the 'first digit' indicates the vehicle type I should really say 'third digit from the end'#for example the Baureihe 1440 and 1462 are EMUs as indicated by the 4#2024-07#2024-08

3 notes

·

View notes

Text

Choosing the Right Miniature Circuit Breaker for Your Electrical Needs

MCB Miniature Circuit Breaker is like a safety guard for electrical circuits. It turns off automatically when something goes wrong. For example, if too much electricity flowing through the circuit. This helps prevent damage to our electrical devices and keeps everyone safe. MCBs are used in homes, offices, and factories to protect circuits from problems like short circuits and overloads. These days, MCBs are now preferred over fuses in low-voltage electrical settings because they are more reliable. They quickly detect when there's too much electricity and cut off the circuit to prevent damage. So, it's a good idea to invest in an MCB switch and MCB box to keep our electrical appliances safe.

MCB, or Mini Circuit Breaker, is a safety device. It protect electrical circuits from failures caused by short circuits and over-currents. It's an important part of every electrical connection within a building. At Vashi Integrated Solutions, we offer high-end, affordable, and safe MCB switches to meet your specific needs.

How Does an MCB Work?

Thermal Mechanism: This component responds to prolonged overloads. It uses a bimetallic strip. It bends when heated by excessive current. This eventually trips the switch to disconnect the circuit.

Magnetic Mechanism: This responds to short circuits by using an electromagnet. A short circuit makes a strong magnetic force. It trips the switch almost instantly. This cuts off the current and protects the circuit.

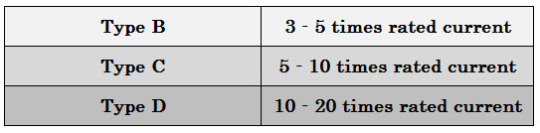

Types of MCBs

Type B: Trips between 3 to 5 times the rated current. Suitable for residential and light commercial applications where the likelihood of nuisance tripping is low.

Type C: Trips between 5 to 10 times the rated current. Ideal for commercial and industrial applications where there may be brief surges in current.

Type D: Trips between 10 to 20 times the rated current. Used for applications with high inrush currents, such as motors and transformers.

Type K and Z: Specialized types for specific applications, such as motor protection (Type K) or for sensitive equipment (Type Z).

Choosing the Right MCB

Determine the Load Requirements: Calculate the total load on the circuit. Then, select an MCB with a suitable current rating.

Consider the Type: Choose the MCB type (B, C, or D) based on the loads and inrush currents.

Check the Breaking Capacity: Ensure the MCB can handle the circuit's max fault current.

Verify Compatibility: Check that the MCB works with your electrical panel. It must meet local codes and standards.

Top Brands Offering MCBs

Siemens: Siemens provides a wide range of durable, technologically advanced MCBs. Their products meet high safety standards and suit various applications.

ABB: ABB is a global leader in electrical equipment, including MCBs. Their MCBs are known for their precision and reliability. They can handle high fault currents.

Legrand: Legrand provides a range of MCBs with advanced features and high performance. Their products protect circuits in homes and businesses. They're effective for both uses.

Conclusion

Miniature Circuit Breakers (MCBs) are crucial for modern electrical systems. They protect against overloads and short circuits. You can improve your electrical safety and efficiency. Just know how they work, their benefits, and how to choose them. This applies to both homes and industries. Investing in the right MCBs ensures reliable electrical protection.

2 notes

·

View notes

Text

Low-Carbon Propulsion Market: Key Technologies Driving Innovation

Introduction to Low-Carbon Propulsion Market

The Low-Carbon Propulsion Market is at the forefront of global efforts to reduce greenhouse gas emissions in transportation. As industries, governments, and consumers prioritize sustainability, this market is seeing rapid expansion driven by electric, hybrid, hydrogen, and alternative fuel technologies. Innovations in battery storage, electrification, and the infrastructure for sustainable energy sources are reshaping the future of transport. Increased government regulations and carbon reduction goals across various sectors further bolster market demand, positioning it as a key player in the green energy transition.

The Low-Carbon Propulsion Market is Valued USD XX billion in 2022 and projected to reach USD XX billion by 2030, growing at a CAGR of 21.4% During the Forecast period of 2024-2032. It encompasses technologies such as electric vehicles (EVs), hydrogen fuel cells, biofuels, and hybrid propulsion systems. Driven by global environmental policies, this market seeks to reduce the carbon footprint associated with conventional transportation methods, particularly in sectors like automotive, aviation, and maritime industries. Ongoing advancements in battery technology and fuel efficiency are central to the market's expansion.

Access Full Report :https://www.marketdigits.com/checkout/177?lic=s

Major Classifications are as follows:

Low-Carbon Propulsion Market, By Fuel Type

Compressed Natural Gas (CNG)

Liquefied Natural Gas (LNG)

Ethanol

Hydrogen

Electric

Low-Carbon Propulsion Market, By Mode

Rail

Road

Low-Carbon Propulsion Market, By Vehicle Type

Heavy-Duty

Light-Duty

Low-Carbon Propulsion Market, By Rail Application

Passenger

Freight

Low-Carbon Propulsion Market, By Electric Vehicle

Electric Passenger Car

Electric Bus

Electric Two-Wheeler

Electric Off-Highway

Key Region/Countries are Classified as Follows:

◘ North America (United States, Canada,)

◘ Latin America (Brazil, Mexico, Argentina,)

◘ Asia-Pacific (China, Japan, Korea, India, and Southeast Asia)

◘ Europe (UK,Germany,France,Italy,Spain,Russia,)

◘ The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, and South

Key Players of Black Alkaline Water Market

Tesla (US), BYD (China), Nissan (Japan), Yutong (China), Proterra (US), Alstom (France), Bombardier (Canada), BYD Auto Co. (China), Honda Motor Co., Ltd (Japan), Hyundai Motor Company (South Korea), MAN SE (Germany), Nissan Motor Company, Ltd (Japan), Siemens Energy (Germany), Toyota Motor Corporation (Japan) & others.

Market Drivers in Low-Carbon Propulsion Market

Government Regulations: Stringent carbon emission standards and the push for decarbonization across industries.

Technological Advancements: Breakthroughs in battery storage, electrification, and hydrogen propulsion technologies.

Rising Fuel Prices: The increasing costs of fossil fuels encourage the shift towards more efficient, low-carbon alternatives.

Market Challenges in Low-Carbon Propulsion Market

High Initial Costs: Upfront costs for low-carbon propulsion technologies, such as electric vehicles and hydrogen fuel cells, are still high.

Infrastructure Deficiencies: Insufficient charging and refueling stations for alternative fuel vehicles limit their adoption.

Technology Limitations: While improving, battery storage capacity, charging times, and range continue to pose challenges for electric vehicles.

Market Opportunities in Low-Carbon Propulsion Market

Innovation in Battery Technology: Advancements in solid-state batteries and fast-charging technologies can significantly enhance the market.

Expansion in Emerging Markets: Developing regions, especially in Asia and Africa, present vast untapped potential for low-carbon transportation.

Renewable Energy Integration: Combining low-carbon propulsion systems with renewable energy sources such as wind and solar can further reduce emissions.

Conclusion

The Low-Carbon Propulsion Market is poised for substantial growth as global efforts to combat climate change intensify. While challenges like infrastructure deficits and high upfront costs exist, technological advancements and policy support are driving the transition. The shift towards sustainable transportation is not only necessary for environmental protection but also offers considerable economic opportunities for industries willing to innovate. As consumer preferences evolve and government policies become more stringent, the market's expansion will continue to accelerate in the coming years.

0 notes

Text

Future Marine Automation and Emerging Technologies to Watch

Upcoming technology to anticipate in the field of Marine Automation and technologies to come

Automation is set to transform the maritime industry even further, meaning that the move towards greater levels of automation in the marine environment is almost inevitable. With the increasing trend in the movement of goods and commerce and ships worldwide, there is a need to develop better and safer marine Systems. RAM Automations is playing the leading role in this transformation, and we present the up-to-date marine automation products of the world's top brands to assist your business in leading the change. Here is what may happen to marine automation and which technologies will rise in 2024.

Autonomous Vessels: The shipping industry means the future of shipping. Whether a large industry or a small business organization, shipping is vital to its success.

One of the most significant topics in marine automation is that of fully autonomous vessels. These seaborne vessels are developed to travel independently with little or no interference from human beings, using devices such as sensors, navigation systems, and artificial intelligence.

Companies such as Rolls-Royce and Wärtsilä already use integrated automation systems that can command different functions of a vessel, including navigation and engine controls. These systems increase productivity and minimize human error, which is very beneficial in achieving safer and more reliable navigation in the sea.

• Rolls-Royce's Intelligent Awareness System: In this system, radar, LIDAR, infrared vision, and high-definition cameras capture 360-degree views of all surroundings of a vessel to enhance the safety of navigation, especially in restricted or adverse conditions.

• Wärtsilä's Smart Marine Ecosystem: Part of Wärtsilä's intelligent marine vision is the integration of autonomous vessels that will command and co-ordinate with other vessels and station-based control centers for efficient navigation and the fewest fuel requirements.

Artificial Intelligence and Machine Learning

Big data, Artificial intelligence, and machine learning are changing data usage in the maritime industry. These technologies allow the vessels to learn, improve performance, and even identify when some equipment would require maintenance, thus avoiding downtime.

ABB and Kongsberg are prime examples of companies leveraging Artificial Intelligence's power to optimize and safeguard marine operations.

• ABB's OCTOPUS Marine Software: This software uses artificial intelligence to determine the best performance of a vessel by taking data from sensors on the vessel. It helps save time on routes, fuel, and the lifespan of vehicles and other transport equipment.

• Kongsberg's AI-Powered Vessel Insight: Vessel Insight assists Kongsberg in its business by enabling data collection from various systems onboard that offers efficiency enhancement and operational costs. Vessel Insight is a centralized system that helps Kongsberg monitor all the data from the various systems onboard its vessels to reduce operational costs and enhance efficiency. The advanced functioning of this system makes it easier to predict when parts will need to be replaced, avoiding system faults.

Sustainable Technologies: The Green Revolution of Shipping

Over the years, environmental regulation has risen, and the maritime industry has had to incorporate sustainable technologies to minimize carbon emissions. Automation is instrumental in this green revolution because it helps in efficient energy consumption and thus cuts emissions.

Leading manufacturers such as Siemens and Schneider Electric are already launching automation systems that lower energy use to help adhere to set environmental laws for vessels.

• Siemens' BlueDrive PlusC System: This hybrid power train includes electric motor dynamics, batteries, and energy-efficient management for enhanced fuel economy and minimal emissions. The level of automation exhibited by the system enables a smooth change-over from one power source to the other for power efficiency.

• Schneider Electric's EcoStruxure for Marine: By implementing the EcoStruxure, the vessels can monitor and control consumption and emissions in real-time, branded by Schneider Electric. The system has an automation feature, guaranteeing that energy is consumed appropriately, leading to sustainable maritime transport.

Cybersecurity: As for the first security epistemology, protecting the connected vessel requires understanding security as both a process and an outcome.

Cybersecurity has become an essential issue in the shipping industry in the age of connected ships. Self-run systems have drawbacks because they can be hacked, leading to a safety breach and possible shutdown.

Today, cybersecurity solutions are being developed for the marine industry and proposed by brands like Cisco or Palo Alto Networks.

• Cisco's Cyber Vision: This cybersecurity platform is a system that helps protect industrial networks, including those on vessels. Another advantage is that it offers live traffic analysis on the network and pulls out suspicious activities that can potentially lead to harm before they are executed.

• Palo Alto Networks' Next-Generation Firewalls: These firewalls afford optimum safety to the vessels connected to other systems and safeguard the systems on board from cybersecurity threats.

Why Choose RAM Automations?

At RAM Automations, we fully commit to our clients to supply them with the best marine automation technology. Our catalog includes the best products from the world's acclaimed manufacturers, such as Rolls-Royce, Wärtsilä, ABB, Siemens, Kongsberg, etc, to guide you through the complex and ever-growing maritime market. It helps its clients find the right solutions to a business's issues with the help of a team of experts.

Conclusion

Marine automation has a very bright future, as the trends of new technologies state that they will significantly change how vessels are seagoing. Whether through robotic shipping, intelligent solutions, or environmentally friendly initiatives, the global sea transport sector is experiencing considerable changes. Thanks for visiting RAM Automations, your go-to solution provider.

0 notes

Text

The Importance of Quality Electric Motors in Industrial Applications

In the modern industrial landscape, electric motors are the workhorses that power a vast array of machinery and equipment. From manufacturing plants to processing facilities, these motors are integral to the efficient and effective operation of industrial systems. However, not all electric motors dealer are created equal. The quality of an electric motor can significantly impact performance, energy efficiency, reliability, and maintenance costs. In this blog, we will delve into the importance of quality electric motors in industrial applications, highlighting key factors to consider when selecting motors for your facility.

Understanding Electric Motors

Electric Components distributor convert electrical energy into mechanical energy. They are used in various applications, including pumps, fans, compressors, conveyors, and more. The basic principle behind electric motors involves the interaction of magnetic fields and electric currents to generate rotational force.

Types of Electric Motors

There are several types of electric motors, each suited for different industrial applications. The most common types include:

Induction Motors: These are widely used due to their robustness and simplicity. They are suitable for applications requiring constant speed.

Synchronous Motors: These motors are used in applications where precise speed and position control are necessary.

Servo Motors: Known for their high precision and rapid response, servo motors are used in automation and robotics.

DC Motors: These are used in applications requiring variable speed control.

Importance of Quality in Electric Motors

1. Performance and Efficiency

Quality electric motors are designed and manufactured to deliver optimal performance and efficiency. High-quality motors have better design, materials, and manufacturing processes that result in lower energy consumption and higher output. This efficiency translates to cost savings in the long run, as energy costs constitute a significant portion of operational expenses in industrial settings.

2. Reliability and Longevity

Industrial operations often run continuously, and any downtime can be costly. High-quality electric motors are built to withstand rigorous operating conditions, offering greater reliability and longer service life. They are less prone to failures and can operate efficiently under heavy loads and harsh environments. Investing in quality motors reduces the risk of unexpected breakdowns and costly repairs.

3. Reduced Maintenance Costs

Maintenance is a critical aspect of industrial operations. Quality electric motors require less frequent maintenance and are easier to service. They are designed with better components and materials that are resistant to wear and tear. This results in lower maintenance costs and less downtime for repairs, ensuring smoother and more efficient operations.

4. Enhanced Safety

Safety is paramount in industrial environments. High-quality electric motors adhere to stringent safety standards and regulations. They are designed with features that prevent overheating, electrical faults, and other hazards. Using quality motors reduces the risk of accidents, ensuring a safer workplace for employees.

Factors to Consider When Choosing Electric Motors

When selecting electric components manufacturing company for industrial applications, several factors should be taken into account to ensure optimal performance and longevity. These factors include:

1. Application Requirements

Understanding the specific requirements of the application is crucial. This includes the load type, speed, torque, and environmental conditions. Different applications have different demands, and selecting a motor that matches these requirements ensures efficient and reliable operation.

2. Energy Efficiency

Energy efficiency is a critical consideration, especially in industries with high energy consumption. Look for motors with high-efficiency ratings, such as those meeting the IE3 or IE4 standards. These motors consume less energy, leading to significant cost savings over time.

3. Quality and Reliability

Choose motors from reputable manufacturers known for their quality and reliability. Research the manufacturer's track record, customer reviews, and certifications. High-quality motors may have a higher upfront cost but offer better performance and longer service life, resulting in lower total cost of ownership.

4. Maintenance and Serviceability

Consider the ease of maintenance and availability of spare parts. Motors that are easy to service and have readily available spare parts reduce downtime and maintenance costs. Opt for designs that allow for easy access to components and straightforward servicing procedures.

5. Compliance with Standards

Ensure that the motors comply with relevant industry standards and regulations. This includes safety standards, energy efficiency ratings, and environmental regulations. Compliance ensures that the motors meet the required performance and safety benchmarks.

Popular Engineering’s Commitment to Quality

At Popular Engineering, we understand the critical role that quality electric motors play in industrial applications. Our commitment to quality is reflected in our extensive range of high-performance electric motors designed to meet the diverse needs of various industries. Here’s what sets our motors apart:

1. Advanced Engineering and Design

Our electric motors are engineered using advanced design techniques and state-of-the-art technology. We use high-quality materials and precision manufacturing processes to ensure that our motors deliver superior performance and efficiency.

2. Stringent Quality Control

Quality control is an integral part of our manufacturing process. Each motor undergoes rigorous testing and inspection to ensure that it meets our high standards for performance, reliability, and safety. Our quality control procedures are designed to identify and address any potential issues before the motors leave our facility.

3. Customer-Centric Approach

We believe in building long-term relationships with our customers. Our customer-centric approach involves understanding the unique needs of each client and providing tailored solutions. Our team of experts is always available to offer technical support and guidance, ensuring that our customers get the most out of our products.

4. Sustainable Practices

Sustainability is a key focus at Popular Engineering. We are committed to reducing our environmental footprint by implementing eco-friendly practices in our manufacturing processes. Our energy-efficient motors not only help our customers save on energy costs but also contribute to a greener environment.

Popular Engineering as Your Trusted Electrical Components Manufacturing Company

Popular Engineering is not just about electric motors; we are a comprehensive electrical components manufacturing company. We offer a wide range of products that cater to various industrial needs. Our expertise extends to being a leading electronic components dealer and electrical component distributor, providing high-quality components that meet the highest standards of performance and reliability.

Case Studies: Success Stories with Popular Engineering Motors

Case Study 1: Manufacturing Plant Efficiency Boost

A large manufacturing plant was experiencing high energy costs and frequent motor failures, leading to significant downtime. After consulting with Popular Engineering, they replaced their existing motors with our high-efficiency induction motors. The result was a 15% reduction in energy consumption and a 30% decrease in downtime due to motor failures. The improved reliability and efficiency of our motors significantly enhanced the plant’s productivity and profitability.

Case Study 2: Reliable Performance in Harsh Conditions

A mining operation required motors that could withstand harsh environmental conditions, including high temperatures and heavy dust. Popular Engineering provided specially designed motors with enhanced cooling systems and protective coatings. These motors performed reliably under the demanding conditions, reducing maintenance costs and improving operational efficiency.

The Future of Electric Motors in Industrial Applications

The future of electric motors in industrial applications looks promising, with ongoing advancements in technology and design. Here are some trends to watch for:

1. Smart Motors

The integration of smart technology in electric motors is revolutionizing industrial applications. Smart motors equipped with sensors and IoT capabilities provide real-time monitoring and data analysis. This enables predictive maintenance, reducing downtime and optimizing performance.

2. Energy Efficiency Innovations

Advancements in materials and design are leading to even more energy-efficient electric motors. Future motors will continue to reduce energy consumption, helping industries lower their operational costs and carbon footprint.

3. Sustainability Focus

The push for sustainability is driving the development of eco-friendly electric motors. Manufacturers are focusing on using recyclable materials and reducing waste in the production process. Energy-efficient motors will play a crucial role in achieving sustainability goals.

4. Customization and Flexibility

As industries become more specialized, the demand for customized electric motors is increasing. Manufacturers like Popular Engineering are offering flexible solutions tailored to specific applications. This customization ensures optimal performance and efficiency for unique industrial needs.

Conclusion

Quality electric motors are essential components in industrial applications, impacting performance, efficiency, reliability, and safety. Investing in high-quality motors from reputable manufacturers like Popular Engineering ensures that your industrial operations run smoothly and efficiently. By considering factors such as application requirements, energy efficiency, and maintenance needs, you can select the right motors for your facility.

At Popular Engineering, our commitment to quality, advanced engineering, and customer satisfaction sets us apart. Our extensive range of electric motors is designed to meet the diverse needs of various industries, delivering superior performance and reliability. As we look to the future, we remain dedicated to innovation and sustainability, helping our customers achieve their goals while contributing to a greener environment.

For more information on our products and services, Visit Popular Engineering and discover how our high-quality electric motors and electrical components can enhance your industrial applications.

#siemens electric motors#electric motor dealer in india#siemens motors#gearbox#electric motor parts suppliers in india#electric motor dealer in mumbai#motors#electric motors#electric motor#gearbox supplier#electrical components manufacturing company#electronic components dealer#electrical component distributors

0 notes

Text

Industrial Rectifiers Market Trends and Industry Research, Regional by 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Industrial Rectifiers Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Industrial Rectifiers Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Industrial Rectifiers Market?

The global industrial rectifiers market size reached US$ 694.5 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,105.5 million in 2032, exhibiting a growth rate (CAGR) of 5.3% during 2024-2032.

What are Industrial Rectifiers?

Industrial rectifiers are devices that convert alternating current (AC) into direct current (DC) for a range of industrial uses. They are vital for processes that require a stable and controlled DC power supply, such as in electroplating, battery charging, and driving DC motors. Featuring components like diodes or thyristors, these rectifiers efficiently handle the conversion, ensuring dependable performance with minimal energy loss. By providing a consistent DC output, industrial rectifiers enable accurate control and operation of equipment and processes in various industrial and manufacturing settings.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1921

What are the growth prospects and trends in the Industrial Rectifiers industry?

The industrial rectifiers market growth is driven by various factors and trends. The industrial rectifiers market is growing steadily, driven by the increasing need for reliable and efficient power conversion across various industrial sectors. Industries such as manufacturing, automotive, and energy require stable direct current (DC) power for processes like electroplating, battery charging, and operating DC motors, fueling demand for high-performance rectifiers. Market growth is supported by advancements in rectifier technology, a focus on energy efficiency, and expanding industrial activities globally. Hence, all these factors contribute to industrial rectifiers market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type:

Silicon Rectifiers

Selenium Rectifiers

Schottky Rectifiers

Fast Recovery Rectifiers

Ultrafast Rectifiers

Other Rectifiers

By Application:

Power Supplies

Motor Drives

Welding Equipment

Battery Charging Units

Electrochemical Processes

Others

By End-Use Industry:

Automotive

Manufacturing

Energy & Power

Telecommunications

Aerospace & Defense

Consumer Electronics

Others

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

ABB Ltd.

General Electric Company

Siemens AG

Schneider Electric SE

Mitsubishi Electric Corporation

Eaton Corporation PLC

Rockwell Automation, Inc.

Delta Electronics, Inc.

Infineon Technologies AG

Fuji Electric Co., Ltd.

Toshiba Corporation

Emerson Electric Co.

View Full Report: https://www.reportsandinsights.com/report/Industrial Rectifiers-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Industrial Rectifiers Market share#Industrial Rectifiers Market size#Industrial Rectifiers Market trends

0 notes

Text

Fenaflex Tyre Plus Couplings, Fenner, Distributor, India

Fenaflex Tyre Plus Couplings, Power Transmission Accessories, Fenner, Authorized Distributor, Supplier, Dealer, Mumbai, Maharashtra, India.

Fenaflex Tyre Plus Couplings, Geared Motor, Geared Motors, Motor, Motors, Gear, Gears, Standard Motor, Standard Motors, High Efficiency Motor, High Efficiency Motors, Standard Motors High Efficiency, High Efficiency Standard Motor, High Efficiency Standard Motors, Energy Efficient Motor, Energy Efficient Motors, Cooling Tower Motor, Cooling Tower Motors, Flameproof Motor, Flameproof Motors, Flame Proof Motor, Flame Proof Motors, Brake Motor, Brake Motors, Crane Duty Motor, Crane Duty Motors, Textile Motor, Textile Motors, Variable Drive Motor, Variable Drive Motors, Two Speed Motor, Two Speed Motors, Torque Motor, Torque Motors, Special Motor, Special Motors, Standard TEFC Motor, Standard TEFC Motors, Standard SPDP Motor, Standard SPDP Motors, Non Sparking Motor, Non Sparking Motors, Increased Safety Motor, Increased Safety Motors, Variable Frequency Drive Motor, Variable Frequency Drive Motors, TEFC Motor, TEFC Motors, SPDP Motor, SPDP Motors, Safety Motor, Safety Motors, Sparking Motor, Sparking Motors, AS - Series In Line Helical Geared Motor, AS - Series In Line Helical Geared Motors, In Line Helical Geared Motor, In Line Helical Geared Motors, Helical Geared Motor, Helical Geared Motors, Geared Motor, Geared Motors, In Line Helical Gear Motor, In Line Helical Gear Motors, Electric Motor, Electric Motors, AS-Series Bevel Helical Gear Motor, AS-Series Bevel Helical Gear Motors, Bevel Helical Gear Motor, Bevel Helical Gear Motors, Helical Gear Motor, Helical Gear Motors, Gear Motor, Gear Motors, VF - W Series Worm Gear Motor, VF - W Series Worm Gear Motors, Worm Gear Motor, Worm Gear Motors, VFR - WR Heliworm Gear Motor, VFR - WR Heliworm Gear Motors, Heliworm Gear Motor, Heliworm Gear Motors, Heli Worm Gear Motor, Heli Worm Gear Motors, 300 Series Planetary Gear Motor, 300 Series Planetary Gear Motors, Planetary Gear Motor, Planetary Gear Motors, BN Series Motor, BN Series Motors, F Series Parallel Helical Gear Motor, F Series Parallel Helical Gear Motors, Parallel Helical Gear Motor, Parallel Helical Gear Motors, Siemens Geared Motor, Siemens Geared Motors, Siemens Gearbox, Siemens Gearboxes, Bonfiglioli Gearbox, Bonfiglioli Gearboxes, Bonfiglioli Geared Motor, Bonfiglioli Geared Motors, Gearbox Dealer Nashik, Gearboxes Dealer Nashik, Motor Dealer Nashik, Motors Dealer Nashik, Gearbox Dealer Aurangabad, Gearboxes Dealer Aurangabad, Motor Dealer Aurangabad, Motors Dealer Aurangabad, Bonfiglioli Assembly Partner, Bonfiglioli Best Partner, Gearbox Dealer Indore, Gearboxes Dealer Indore, Motor Dealer Indore, Motors Dealer Indore, Switchgear Dealer, Switchgears Dealer, Eaton Switchgear Dealer, Eaton Switchgears Dealer, Fenner Coupling Dealer, Fenner Couplings Dealer, Fenner Pulley Dealer, Fenner Pulleys Dealer, Klockner & Moeller, Klockner Switch, Klockner Switches, Moeller MCB, Moeller Miniature Circuit Breaker, Moeller Miniature Circuit Breakers, Moeller Contactor, Moeller Contactors, Moeller Contactor Relay, Moeller Contactor Relays, Moeller MCCB, Moeller Molded Case Circuit Breaker, Moeller Molded Case Circuit Breakers, Moeller MPCB, Moeller Motor Protection Circuit Breaker, Moeller Motor Protection Circuit Breakers, Moeller Indication Lamp, Moeller Indication Lamps, Moeller Push Button, Moeller Push Buttons, Moeller Pilot Device, Moeller Pilot Devices, Moeller Over Load Relay, Moeller Over Load Relays, Moeller OLR, Moeller Dealers Mumbai, Moeller Dealers Pune, EATON MCB, EATON Miniature Circuit Breaker, EATON Miniature Circuit Breakers, EATON Contactor, EATON Contactors, EATON Contactor Relay, EATON Contactor Relays, EATON MCCB, EATON Molded Case Circuit Breaker, EATON Molded Case Circuit Breakers, EATON MPCB, EATON Motor Protection Circuit Breaker, EATON Indication Lamp, EATON Indication Lamps, EATON Push Button, EATON Push Buttons, EATON Pilot Device, EATON Pilot Devices, EATON Over Load Relay, EATON Over Load Relays, EATON OLR, EATON Dealer Mumbai, EATON Dealer Pune, Dealer, Distributor, Supplier, Mumbai, Maharashtra, India.

#Fenaflex Tyre Plus Couplings#Geared Motor#Geared Motors#Motor#Motors#Gear#Gears#Standard Motor#Standard Motors

0 notes

Text

https://www.timessquarereporter.com/technology/siemens-motor-starting-devices--a-comprehensive-overview

In industrial and commercial operations, motors are the driving force behind many processes and systems. The efficiency, protection, and control of motors are critical to ensuring that operations run smoothly and safely. Siemens, a global leader in electrical and automation technology, offers a broad range of motor starting devices designed to meet the demanding needs of modern industries.

0 notes

Text

Bharat Bijlee Motors

Shri Rang Energy Efficient is are the leading Bharat Bijlee motor dealer and distributor in India. We offer the best brands of Siemens, Crompton, Havells and Bharat Bijlee motors that meet our clients' requirements. Shri Rang Energy Efficient is one of the leading Bharat Bijlee motor dealers in Ahmedabad. We offer a wide range of high-quality Bharat Bijlee products. All of our products are certified to meet its standards. We have a team of experienced sales engineers who can help you choose the right product for your needs.

BBL Motor Dealers

At our company, we pride ourselves on being able to provide customized solutions to our customers while maintaining a cost-effective product range as BBL motor dealers. Our strong customer focus approach allows us to constantly strive for top-quality service and products, which in turn has helped us maintain our leadership position in the market.

Key Features of our Bharat Bijlee Motors are listed below:

High performance

Longer assistance life

Prominent Quality

Sensible Cost

Low Maintenance

Exact Usefulness

Ready Stock

Well educated staff

Fast inquiry full fill approaching process

Salient features of Energy Efficient Motors:

Near uniform efficiency from 50% to 100% of full load.

Insulation class F. Temperature rise limited to 70°Cover ambient of 50°C.

Voltage variation: ±10%

Frequency variation: ±5%

Combined variation: ± 10%

Enclosure: IP55.

A brief information of our different electric motors range is given below:

Low Voltage Motors

Motors for Safe Area application in the efficiency series of IE2 and IE3, ranging from 0.12 to 355 kW. Higher kW can be offered upon request.

The SynchroVERT® Series presents a variety of motors that are ideal for safe areas, with output power ranging from 2.2 kW to 45 kW. These 1500 RPM low-speed PMSM motors boast IE4 efficiency, meaning they're some of the most efficient models on the market.

Hazardous Area Motors are classified into two types: Flame Proof (FLP) Ex‘d’ motors and increased Safety Ex ec motors.

FLP motors are available in standard, IE2 and IE3 efficiency series and have a power rating of up to 200 kW. On the other hand, increased Safety Ex ec motors are available in IE2 and IE3 efficiency series and have a power rating of up to 355 kW.

We offer a range of crane duty motors up to 400 kW and brake motors up to 22kW. We also have special application motors like cane unloader motors, textile motors and railway auxiliary motors.

Medium Voltage Motors

We offer a variety of Medium Voltage Motors ranging from 120 kW to 1000 kW, 11kV in both Totally Enclosed Fan Cooled (TEFC) and Closed Air Circuit Air Cooled (CACA) arrangements. With such a wide range of options available, we're sure to have the perfect motor for your needs!

Our electric motors are designed to meet the specific needs of our clients and are suitable for use in a variety of industries.Our electric motors are available in a wide range of power ratings and sizes to suit your specific requirements. We also offer customization options to ensure that our products meet your unique needs. If you are looking for an electric motor that is reliable, efficient, and durable, then Bharat Bijlee motors is the right choice for you. Contact us today to learn more about our products and services.

Get in touch

Contact : 9099959998

Email : [email protected]

Visit site

#dc motor manufacturers#tefc motors#flame proof motor supplier#artists on tumblr#across the spiderverse#ac motors manufacturers in india#barbie#electric motors#dc motor manufacturers in india#asexual

0 notes