#simulators routed through technology that is being prevented from learning as their sources of information are unable to learn

Explore tagged Tumblr posts

Text

fresh static snow

→ on Ao3

@dbhrarepairs Thursday Day 4: Enemies to Lovers • Abandoned Things; post-revolution RK900/Simon

He is PL600 #501 743 923, designated name ‘Simon’. He was activated on the 2nd of February 2034, and reported missing on the 16th of February 2036 by one of his owners, Mr Keelan Burbank. That’s it. That’s all he remembers.

Not the fact he is a leader of Jericho, the original leader of Jericho, and one of the Jericho Four. Not the fact he was a martyr, a leader willing to sacrifice himself to save the others. Not the fact he put a gun under his chin and pulled the trigger to prevent the Deviant Hunter from discovering Jericho. No, he doesn’t remember any of that.

They tell him the bullet tore through his memory core, damaging it irreparably. Simon of the Jericho Four died on the rooftop of Stratford Tower and he is but a shell. This does not sit well with the other three, who he learns are PJ500, Josh, WR400, North, and RK200, Markus. They want Simon back, but there is nothing left of Simon to give.

Not for the lack of trying, though, Elijah Kamski and Chloe RT600, the First, work tirelessly on him. They try and salvage his fried memory core, they take it apart with miniscule tweezers as if to save every atom and attempt to piece it back together like a delicate puzzle. They run simulations, they make prototype replacements, they spend resources worth more than Simon’s PL600 model a thousand times over. And still, he remembers nothing.

With nothing else to do between tests, he roams CyberLife Tower like a ghost in its clean, clinical hallways. He shares his face with so many others no one spares him a second glance. It both comforts and hurts him, to be so readily ignored.

Sometimes one, or two, or all three come to visit him again and they try to tell him anecdotes, of things their Simon did in the hopes it would jog his memory. There is no memory to jog, he tells them over and over. The bullet ripped that apart.

When North visits him by herself, she holds his hands so tightly it alerts his pressure sensors. She cries, she cries a lot of tears and says a lot of I’m so fucking sorrys and I didn’t want this to happens. She tells him they promised each other that Markus always came first, even at the cost of their lives. She just didn’t think he’d pay for it so soon. He’s not sure what to say to her, to comfort her, only that if Simon did promise such things to her then she should feel proud that he upheld the promise because Markus is here, Markus is safe.

When Josh visits him by himself, he sits with Simon on the floor in the corner of the room designated to him. Josh tells him this is how they spent so many nights in Jericho, when Jericho was a rotting freighter in the canal and Markus had not crashed into their lives yet. He would sit in the corner with Simon and keep him warm because of his broken thermal regulator. Josh’s hands are warm when he holds his hands and Simon thinks the original Simon was incredibly lucky to have such a friend on cold, seemingly endless nights.

When Markus visits him by himself, he gives Simon a sketchbook.

“I tried to draw as many as I could remember.” The android explains, as Simon slowly turns the pages. They are memories, Markus’ memories, but Simon is in them. “Chloe said we shouldn’t interface, we shouldn’t force our memories onto you so I thought this would be the next best thing.”

He is holding a sketchbook of original Manfred drawings. From his research he knows Markus Manfred (yes, a human surname given by his human father) is both seen as the spokesperson of their kind, and a prolific artist famous for his works about the revolution. This sketchbook alone is probably worth more than his PL600 body.

“Thank you, it’s beautiful.” He says, because it is a gift and sadly not the tool Markus wishes it were. “You’re very kind. I’m… I’m sorry for your loss.”

A look of grief washes over Markus’ handsome face, and he pulls Simon into his arms briefly, embracing him tightly before he steps back and walks away.

He wonders if the original Simon haunts that rotting freighter now at the bottom of the canal. Does he wander up and down its corridoors, does he roam with the other lost souls that died during the raid he never lived to see? Or is he up on Stratford Tower, pacing that rooftop, waiting for his friends to return, to rescue him, only to have to kill himself over and over and over, stuck in an endless cycle with no one to break it?

It is a kindess he died, he thinks.

*

CyberLife Tower has only been under the control of the Kamskis (yes, Chloe has a human surname given by her human creator, though perhaps she took it without it being given?) for less than a month. Elijah Kamski became interim CEO after Hudson Davenport stepped down, wishing to wash his hands clean of the deviancy ‘mishap’ as he called it. Elijah in turn appointed Chloe Kamksi as the CEO once the Sentient Life Act passed, stepping down to remain Chief Technical Officer by her side.

It means they are still trying to catch up after more than a decade’s absence from this place. It means they do not know everything, they do not know everywhere and there are still discoveries being made day to day. With nothing else to do between tests, he roams CyberLife Tower and because he is a ghost, no one sees him.

He is a ghost with cutting edge technology in his head now, and an upgraded core capable of processing data faster than his obsolete predecessor could even hope to process. And so he finds rooms that don’t exist, much the same way he doesn’t exist, not really, because Simon is dead and he is but a shadow of him.

He finds an entire floor deep underground that doesn’t exist on any blueprint, any elevator route, anyone’s knowledge. When he finds things like this, he is supposed to notify the Kamskis immediately, but this one thing he wants to keep to himself at least for now. Just for a little while.

It’s a self contained lab complete with its own power source, its own network, its own servers; a completely isolated floor unbeknowst to everyone above. It smells sharp, like disinfectant and spilled thirium and gunpowder residue. There is a fabricator and assembly arms and they were building androids down here, that weren’t meant to be built by everyone above.

There is a single android standing on the assembly dias, inactive. It looks like the Deviant Hunter- like Detective Connor Anderson, he should say, because the Deviant Hunter became a deviant and a son. This one is wearing a white and black uniform, the model number RK900 emblazoned on its jacket in glowing neon.

The android no one knows about. The android haunting this level, unable to wake fully and control his actions. It must be lonely down here, abandoned and without purpose. Simon thinks they must be alike this way. It’s been so lonely, not having any friends who don’t treat him like the walking dead. Perhaps he can befriend this one instead. Perhaps they will haunt CyberLife Tower together, ghosts of what could have been.

Reaching out, he cups his palm to the android’s cheek.

“Wake up.” He whispers, and the RK900 opens his cold grey eyes.

~*~

They tell him he is to be deployed soon. He is progressing well, on track to complete his testing phase and replace the RK800 prototype currently involved with the DPD. When he is not actively completing tests, he remains in his Zen Garden. Sometimes his handler is there, but most times she is not. He tends to her roses in her absence, and ensures the grounds are well kept.

It is on the cusp of Summer here, though outside Winter has only just begun. He thinks perhaps it has something to do with his anticipation, of waiting with simulated bated breath before his deployment out into the real, waking world. In the meantime he will care for this garden, he will nurture it so it flourishes in time for Summer.

Time passes differently in the garden which is not beholden to the world outside. His handler has not appeared, nor has he been brought out of stasis and activated for more tests. He cannot be entirely sure, but he thinks substantial time has passed though he has no way to confirm such thoughts. It’s as he’s tending to the amaranthus, as he’s carefully avoiding the flight patterns of the bumblebees, that he feels something trigger his proximity sensors.

“Wake up.” Someone commands, and when he opens his eyes there is an android in front of him, hand cupping his cheek. The wi-fi on this level, the one he automatically connects to, no longer exists and instead he finds himself automatically connected to the main CyberLife network, something he has never had access to. He scans the android’s face and a deluge of information topples into his head.

“PL600, serial number 501 743 923, designated name ‘Simon’. Founder and member of the Jericho Four. Martyr for the deviant revolution.” He recites the information, and Simon rubs his cheek with his thumb idly, expression distant.

“So they say.” The android moves his hand, bringing up his other to fuss over his uniform, smoothing non-existent creases from the front of his jacket out of domestic habit, he surmises. “I have no memory of that Simon. He died when he shot himself on the roof of Stratford Tower.”

There’s still information pouring into his head, like a dam breaking and flooding the fjord before it. The deviant revolution- the event CyberLife deployed his prototype to quell, paving the way for his placement into SWAT Unit 32 and the eventual release of his model for government use. But it succeeded, and RK800 prototype Connor remained deviant and defied CyberLife’s control, becoming a key figure in securing the numbers for the revolution by activating the androids in the Tower’s storage level.

The Sentient Life Act passed on the first of December, granting androids legally recognised autonomy as living, sentient beings. Elijah Kamski and Chloe RT600 now helm CyberLife, with the android as the CEO and the human as the Chief Technical Officer. The nation has changed drastically, and he has slept through the entirety of it.

“Do you have a name?” Simon asks.

“I was not assigned a name.” He takes a moment to survey his surroundings. Everything has been switched off, packed up, and taken away in a great hurry. There are odds and ends strewn everywhere, left behind in their haste. He realises he is one of those things, something abandoned in their rush to escape. From what? From whom? The scrutiny of Elijah Kamski and Chloe RT600, he thinks.

“Then we must choose one.” Simon smiles softly, reaching up to smooth his hair back away from his face. “Without the meddling of humans.”

“Why are you here?”

“Because I accidentally found this place while exploring the Tower.” The PL600 tugs on his wrists, coaxing him to step off the dias. There is a workbench nearby, and Simon hops onto it, patting the spot beside him. He takes a seat and frowns at the android.

“Why are you exploring the Tower? Should you not be in Jericho, with the other three?”

“I am not that Simon.” He says simply, looking down at his hands. “That Simon is dead.”

“Why did you activate me by yourself?” The RK900 looks down the hallway now in his line of sight, seeing a similar state of harried departures. Not a single sign of life to be found. No one considered him important enough to bring with them, or at least notify anyone else of his presence.

“I was lonely.” Simon confesses quietly. “I thought you would know a thing or two about that too.”

Loneliness. Yes, he thinks, he does know a thing or two about that.

“Have you been here in the Tower since Elijah Kamski returned?”

“Yes, but I was under Chloe and Elijah’s care even before that. Your brother had me brought over to their private laboratory at the Kamksi villa after the revolution.” Simon explains, picking at the cuff of his jacket. “I was being held in the DPD evidence locker, with other casualties from his cases. When he became deviant he tried making amends, and though the others were able to be repaired, my memory core was damaged irreparably.”

“So he brought you to the man who created us.”

“And the First of us.” He adds with a small smile. “She is his equal. She is his superior, in more ways than one.”

“But even they could not repair your memory core?”

“I shot myself through it for a reason. I’m told it was to protect Jericho, to destroy all information Connor could possibly access to locate it.” There’s a loose thread on his cuff, and he tugs on it distractedly. “In the end he still managed to piece it together using another deviant.”

“In the end he still deviated, and aided the three in turning the tide against the humans.”

“Yes. You should be proud.” He reaches over to pat his hand. “Your big brother is a revolutionary.”

Brother. That’s the second time he’s used that word, and he isn’t sure how he feels about it. Feels, because that is something he can do now, somehow, without the humans around. Without the red wall surrounding him, boxing him in.

“How did you do that?”

“Hm?”

“My firewalls are gone.”

“Oh I-” Simon frowns, before offering a somewhat apologetic smile. “I’m not sure. I just wanted you to wake up, so I opened a connection and overrode them in order to reach you.”

“You deviated me.” He tips his head in confusion. “Your system should not have been able to breach my firewalls.”

“I’m not a PL600 anymore.” Simon shrugs. “I’m a Kamski prototype now. First of my kind, just like you I suppose. You’ve been here this whole time, haven’t you? Were you in stasis?”

“I was still active in my Zen Garden though my body was in stasis.” He explains, not missing Simon’s flash of distress. “Time passes differently in there, though. I hadn’t realised weeks had passed at all.”

“It sounds peaceful.”

“Shall I show you?” He’s not sure if he can. He’s never brought anyone into his Zen Garden, Amanda had always simply appeared at her own whim. But surely it can’t be too hard? Simon nods and slips his hand into his, and as he closes his eyes a small part of him thinks it’s nice to hold hands with someone else. No one has ever held his hand before. He wouldn’t mind holding Simon’s hand again.

*

When he opens his eyes he’s standing at the entrance to the garden, and Simon is right there at his side. The android gasps, eyes wide with wonder.

“Oh it’s beautiful. It’s exquisite, I’ve never seen anything like this.” They’re still holding hands, and he leads Simon down the path at a slow, leisurely pace. “You were tending this garden all this time?”

“Yes.” He nods. “My handler’s favourite was the roses growing on the trellis over there.” He points, wondering if the roses had always been blue. He’s so sure they used to be red.

“Do you have a favourite?” He shakes his head.

“Not really. I care for everything equally. I was to tend to the rowan tree next.”

“Rowan.” Simon repeats. “That could be your name.”

“Rowan.” He says, and thinks it sounds far more pleasing when Simon says it. “RK900, serial number 313 248 317 - 87, designated name ‘Rowan’.”

“Now you’re no longer a nobody.” Simon declares with a smile. “Now there’s two of us. Ghosts in the machine.”

“Forgotten and left behind.” He adds lightly, and it no longer tastes so bitter on his tongue.

“But no longer alone.” Simon curls against his side, snaking an arm around his waist. After a moment Rowan wraps an arm around his shoulders, resting his cheek atop his soft blond hair.

“No longer alone.”

#simon pl600#rk900#simon900#detroit: become human#dbhrarepairsweek#annie writes: dbh#song inspo by porter robinson

15 notes

·

View notes

Text

Industrial AI Applications – How Time Series and Sensor Data Improve Processes

(This article was written by TechEmergence Research and originally appeared on: https://www.techemergence.com/industrial-ai-applications-time-series-sensor-data-improve-processes/)

Over the past decade the industrial sector has seen major advancements in automation and robotics applications. Automation in both continuous process and discrete manufacturing, as well as the use of robots for repetitive tasks are both relatively standard in most large manufacturing operations (this is especially true in industries like automotive and electronics).

One useful byproduct of this increased adoption has been that industrial spaces have become data rich environments. Automation has inherently required the installation of sensors and communication networks which can both double as data collection points for sensor or telemetry data.

According to Remi Duquette from Maya Heat Transfer Technologies (Maya HTT), an engineering products and services provider, huge industrial data volumes don’t necessarily lead to insight:

“Industrial sectors over the last two decades have become very data rich in collecting telemetry data for production purposes… but this data is what I call ‘wisdom-poor’… there is certainly lots of data, but little has been done to put it into productive business use… now with AI and machine learning in general we see huge impacts for leveraging that data to help increase throughput and reduce defects.”

Remi’s work at Maya HTT involves leveraging artificial intelligence to make valuable use of otherwise messy industrial data. From preventing downtime to reducing unplanned maintenance to reducing manufacturing error – he believes that machine learning can be leveraged to detect patterns and refine processes beyond what was possible with previous statistical-based software approaches and analytics systems.

During our interview, he explored a number of use-cases that Maya HTT is currently working on – each of which highlights a different kind of value that AI can bring to an existing industrial process.

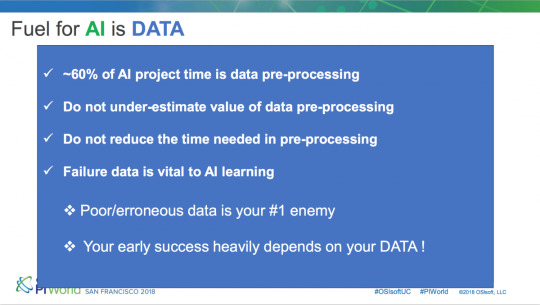

This point is reiterated in an important slide from one of his recent presentations at the OsiSoft PIWorld Conference in San Francisco:

Use Case: Discrete Manufacturing

Increasing throughputs and reducing turnaround times are some of the biggest business challenges faced by the manufacturing sector today – irrespective of industry.

One interesting trend here was that individual machine optimization was the most common form of early engagement with AI for most manufacturers – and much more value can be gleaned from simultaneously optimizing the combined efficiencies of all the machines in a manufacturing line.

“There has been little that has been done to really help that industry to go beyond automation and statistical-based procedures, or optimizing individual machines.

What we find in our AI engagements is that – at the individual machine level – there is little that can be done, as it’s been fairly optimized… if we look at where AI can help significantly, it’s at looking at the production chain as a whole or combining different type of data to further optimize a single machine or a few machines together.”

In a typical discrete manufacturing environment today, we would likely find that there are over ten manufacturing stages and that data is collected at each stage from a plethora of devices. Remi explains that in such a scenario AI can today track correlations between many machines and identify patterns in the industrial data which can potentially lead to overall improved efficiency.

He adds some color here with a real-life example from one of Maya HTT’s clients. He elaborates that for one particular discrete manufacturer’s industrial process which faced high rejection rates, Maya HTT collected around 20,000 real-time telemetry variables and by analysing the data along with manufacturing logs and other non real-time production data, the AI platform was able to find what led to the high rejection rates.

“A discrete manufacturing process with over 10 manufacturing stages – each collecting tons of data. Yet towards the end of the process there were still high rejection rates… In this case we applied AI to look at various processes throughout this ‘food chain’.

There were 20,000 real-time telemetry variables collected, and by correlating them and combining them with production data, the AI was able to learn which combinations and variance led to the rejection rate. In this particular case the AI was able to remove over 70% of the rejection issues.”

This particular AI solution was able to quickly recognize faulty pieces so the machine operators could remove them from the process thereby reducing the work that the quality assurance team had to handle and leading to saved material and less real work hours spent detecting or correcting faulty pieces.

What this means in real business terms is that the manufacturer used fewer raw materials, had a lot less rework hours, which essentially translated to saving of half a million dollars per production line per year. “We estimated a savings of over $500,000 per year in this particular case”, said Remi.

Use Case: Fleet Management

Another such use-case that Remi explored was in fleet management or freight operations in the logistics sector where maintaining high fuel efficiency for vehicles like trucks or ships is essential for cost-savings in the long run.

Remi explains that AI can enable ‘real-time’ fleet management which would otherwise be difficult to achieve with plain automation software. Various patterns identified by AI from data, like weather or temperature conditions, operational usage, mileage, etc can potentially be used to pick out anomalies and recommend what the best route or speed would be in order to operate at the highest efficiency levels.

Remi agreed that no matter the mode of transportation used (trucks or ships, for example), some of the more common emerging use-cases for AI in logistics are around overall fuel consumption analysis for fleets.

“When you have a large fleet, it’s possible to mitigate a lot of loss by finding refinements in fuel use.” In cases of very large fleets, AI can simulate and potentially mitigate huge loss exposure by reducing fuel consumption for the fleet.

Use Case: Engineering Simulation

The last use-case that Remi touched on was 3D engineering simulations for design in the field of computational fluid dynamics.

Traditional simulation software can be fed input criteria like flow rates of fluids and can generate a 3D simulation which usually takes around 15 minutes to be rendered and involves a long, iterative, and often manual process.

Maya HTT’s team claims that it was able to deliver an AI tool for this situation resulting in getting simulation results time falling to less than 1 second. Maya HTT claims that this improvement of over 900x in efficiency gains (from 15 minutes to 1 second) during the design process enabled design teams to explore far more design variants than previously possible.

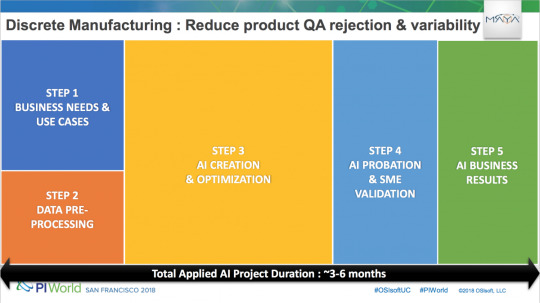

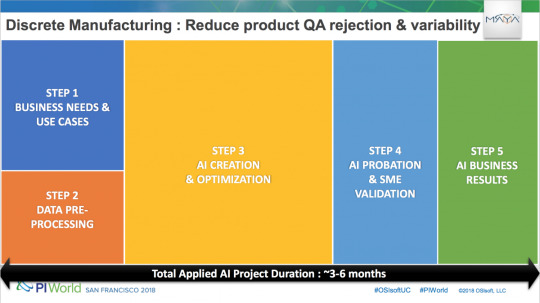

Phases of Implementation for Industrial AI

When asked about what business leaders in the manufacturing sector interested in adopting AI would need to do, Remi outlines a 5 step approach used at Maya HTT:

The first step would be a business assessment to make sure any target AI project will eventually lead to significant business impact.

Next businesses would need to understand data source access and manipulations that may be needed in order to train and configure the AI platform. This may also involve restructuring the way data is collected in order to enhance compatibility.

The actual creation and optimization of an AI application.

Training and conclusions from AI need to be properly explained and understood. The operational AI agent is put to work and final tweaks are made to improve accuracy to desired levels.

Delivery and measurement of tangible business results from the AI solution.

In almost all sectors we cover, data preprocessing is an underappreciated (and often complex) part of an AI application process – and it seems evident that in the industrial sector, the challenges in this step could be significant.

A Look to the Future

Remi believes that for the time being, industrial AI applications are safely in the realm of augmenting worker’s skills as opposed to wholly replacing jobs:

“At least for the short-medium timeframe… we augment people on the shop floor in order to increase throughput and production rates.”

He also stated that the longer-term implications of AI in heavy industry involve more complete automation – situations where machines not only collect and find patterns in the data, but take direct action from those found patterns. For example:

A manufacturing line might detect tell-tale signs of error in a given product on the line (possibly from a visual analysis of the item, or from other information such as temperature and vibration as it moves through the manufacturing process), and remove that product from the line – possibly for human examination, or simply to recycle or throw out the faulty item.

A fleet management system might detect a truck with unusual telemetry data coming from its breaks, and automatically prompt the driver to pull into the nearest repair shop on the way to the truck’s destination – prompting the driver with an exact set of questions for the diagnosing mechanics.

He mentions that these further developments towards autonomous AI action will involve much more development in the core technologies involved in industrial AI, and a greater period of time to flesh out the applications and train AI systems on huge sets of data over time.

Many industrial AI applications are still somewhat new and bespoke. This is due partially to the unique nature of manufacturing plants or fleets of vehicles (no two are the same), but it’s also due to the fact that AI hasn’t been applied in the domain of manufacturing or heavy industry for as long as it has been in the domains of marketing or finance.

As the field matures and the processes for using data and delivering specific results become more established, AI systems will be able to expand their function from merely detecting and “flagging” anomalies (and possibly suggesting next steps), to fully taking next steps autonomously when a specific degree of certainty has been achieved.

About Maya HTT

Maya HTT is a leading developer of simulation CAE and DCIM software. The company provides training and digital product development, analysis, testing services, as well as IIoT, real-time telemetry system integrations, and applied AI services and solutions.

Maya HTT are a team of specialized engineering professionals offering advanced services and products for the engineering and datacenter world. As a Platinum level VAR and Siemens PLM development partner and OSIsoft OEM and PI System Integration partner, Maya HTT aims to deliver total end-to-end solutions to its clients.

The company is also a provider of specialized engineering services such as Advanced PLM Training, Specialized Engineering Consulting for Thermal, Flow and Structural projects as well as Software Development with extensive experience implementing NX Customization projects.

3 notes

·

View notes

Text

Industrial AI Applications – How Time Series and Sensor Data Improve Processes

(This article was written by TechEmergence Research and originally appeared on: https://www.techemergence.com/industrial-ai-applications-time-series-sensor-data-improve-processes/)

Over the past decade the industrial sector has seen major advancements in automation and robotics applications. Automation in both continuous process and discrete manufacturing, as well as the use of robots for repetitive tasks are both relatively standard in most large manufacturing operations (this is especially true in industries like automotive and electronics).

One useful byproduct of this increased adoption has been that industrial spaces have become data rich environments. Automation has inherently required the installation of sensors and communication networks which can both double as data collection points for sensor or telemetry data.

According to Remi Duquette from Maya Heat Transfer Technologies (Maya HTT), an engineering products and services provider, huge industrial data volumes don’t necessarily lead to insight:

“Industrial sectors over the last two decades have become very data rich in collecting telemetry data for production purposes… but this data is what I call ‘wisdom-poor’… there is certainly lots of data, but little has been done to put it into productive business use… now with AI and machine learning in general we see huge impacts for leveraging that data to help increase throughput and reduce defects.”

Remi’s work at Maya HTT involves leveraging artificial intelligence to make valuable use of otherwise messy industrial data. From preventing downtime to reducing unplanned maintenance to reducing manufacturing error – he believes that machine learning can be leveraged to detect patterns and refine processes beyond what was possible with previous statistical-based software approaches and analytics systems.

During our interview, he explored a number of use-cases that Maya HTT is currently working on – each of which highlights a different kind of value that AI can bring to an existing industrial process.

This point is reiterated in an important slide from one of his recent presentations at the OsiSoft PIWorld Conference in San Francisco:

Use Case: Discrete Manufacturing

Increasing throughputs and reducing turnaround times are some of the biggest business challenges faced by the manufacturing sector today – irrespective of industry.

One interesting trend here was that individual machine optimization was the most common form of early engagement with AI for most manufacturers – and much more value can be gleaned from simultaneously optimizing the combined efficiencies of all the machines in a manufacturing line.

“There has been little that has been done to really help that industry to go beyond automation and statistical-based procedures, or optimizing individual machines.

What we find in our AI engagements is that – at the individual machine level – there is little that can be done, as it’s been fairly optimized… if we look at where AI can help significantly, it’s at looking at the production chain as a whole or combining different type of data to further optimize a single machine or a few machines together.”

In a typical discrete manufacturing environment today, we would likely find that there are over ten manufacturing stages and that data is collected at each stage from a plethora of devices. Remi explains that in such a scenario AI can today track correlations between many machines and identify patterns in the industrial data which can potentially lead to overall improved efficiency.

He adds some color here with a real-life example from one of Maya HTT’s clients. He elaborates that for one particular discrete manufacturer’s industrial process which faced high rejection rates, Maya HTT collected around 20,000 real-time telemetry variables and by analysing the data along with manufacturing logs and other non real-time production data, the AI platform was able to find what led to the high rejection rates.

“A discrete manufacturing process with over 10 manufacturing stages – each collecting tons of data. Yet towards the end of the process there were still high rejection rates… In this case we applied AI to look at various processes throughout this ‘food chain’.

There were 20,000 real-time telemetry variables collected, and by correlating them and combining them with production data, the AI was able to learn which combinations and variance led to the rejection rate. In this particular case the AI was able to remove over 70% of the rejection issues.”

This particular AI solution was able to quickly recognize faulty pieces so the machine operators could remove them from the process thereby reducing the work that the quality assurance team had to handle and leading to saved material and less real work hours spent detecting or correcting faulty pieces.

What this means in real business terms is that the manufacturer used fewer raw materials, had a lot less rework hours, which essentially translated to saving of half a million dollars per production line per year. “We estimated a savings of over $500,000 per year in this particular case”, said Remi.

Use Case: Fleet Management

Another such use-case that Remi explored was in fleet management or freight operations in the logistics sector where maintaining high fuel efficiency for vehicles like trucks or ships is essential for cost-savings in the long run.

Remi explains that AI can enable ‘real-time’ fleet management which would otherwise be difficult to achieve with plain automation software. Various patterns identified by AI from data, like weather or temperature conditions, operational usage, mileage, etc can potentially be used to pick out anomalies and recommend what the best route or speed would be in order to operate at the highest efficiency levels.

Remi agreed that no matter the mode of transportation used (trucks or ships, for example), some of the more common emerging use-cases for AI in logistics are around overall fuel consumption analysis for fleets.

“When you have a large fleet, it’s possible to mitigate a lot of loss by finding refinements in fuel use.” In cases of very large fleets, AI can simulate and potentially mitigate huge loss exposure by reducing fuel consumption for the fleet.

Use Case: Engineering Simulation

The last use-case that Remi touched on was 3D engineering simulations for design in the field of computational fluid dynamics.

Traditional simulation software can be fed input criteria like flow rates of fluids and can generate a 3D simulation which usually takes around 15 minutes to be rendered and involves a long, iterative, and often manual process.

Maya HTT’s team claims that it was able to deliver an AI tool for this situation resulting in getting simulation results time falling to less than 1 second. Maya HTT claims that this improvement of over 900x in efficiency gains (from 15 minutes to 1 second) during the design process enabled design teams to explore far more design variants than previously possible.

Phases of Implementation for Industrial AI

When asked about what business leaders in the manufacturing sector interested in adopting AI would need to do, Remi outlines a 5 step approach used at Maya HTT:

The first step would be a business assessment to make sure any target AI project will eventually lead to significant business impact.

Next businesses would need to understand data source access and manipulations that may be needed in order to train and configure the AI platform. This may also involve restructuring the way data is collected in order to enhance compatibility.

The actual creation and optimization of an AI application.

Training and conclusions from AI need to be properly explained and understood. The operational AI agent is put to work and final tweaks are made to improve accuracy to desired levels.

Delivery and measurement of tangible business results from the AI solution.

In almost all sectors we cover, data preprocessing is an underappreciated (and often complex) part of an AI application process – and it seems evident that in the industrial sector, the challenges in this step could be significant.

A Look to the Future

Remi believes that for the time being, industrial AI applications are safely in the realm of augmenting worker’s skills as opposed to wholly replacing jobs:

“At least for the short-medium timeframe… we augment people on the shop floor in order to increase throughput and production rates.”

He also stated that the longer-term implications of AI in heavy industry involve more complete automation – situations where machines not only collect and find patterns in the data, but take direct action from those found patterns. For example:

A manufacturing line might detect tell-tale signs of error in a given product on the line (possibly from a visual analysis of the item, or from other information such as temperature and vibration as it moves through the manufacturing process), and remove that product from the line – possibly for human examination, or simply to recycle or throw out the faulty item.

A fleet management system might detect a truck with unusual telemetry data coming from its breaks, and automatically prompt the driver to pull into the nearest repair shop on the way to the truck’s destination – prompting the driver with an exact set of questions for the diagnosing mechanics.

He mentions that these further developments towards autonomous AI action will involve much more development in the core technologies involved in industrial AI, and a greater period of time to flesh out the applications and train AI systems on huge sets of data over time.

Many industrial AI applications are still somewhat new and bespoke. This is due partially to the unique nature of manufacturing plants or fleets of vehicles (no two are the same), but it’s also due to the fact that AI hasn’t been applied in the domain of manufacturing or heavy industry for as long as it has been in the domains of marketing or finance.

As the field matures and the processes for using data and delivering specific results become more established, AI systems will be able to expand their function from merely detecting and “flagging” anomalies (and possibly suggesting next steps), to fully taking next steps autonomously when a specific degree of certainty has been achieved.

About Maya HTT

Maya HTT is a leading developer of simulation CAE and DCIM software. The company provides training and digital product development, analysis, testing services, as well as IIoT, real-time telemetry system integrations, and applied AI services and solutions.

Maya HTT are a team of specialized engineering professionals offering advanced services and products for the engineering and datacenter world. As a Platinum level VAR and Siemens PLM development partner and OSIsoft OEM and PI System Integration partner, Maya HTT aims to deliver total end-to-end solutions to its clients.

The company is also a provider of specialized engineering services such as Advanced PLM Training, Specialized Engineering Consulting for Thermal, Flow and Structural projects as well as Software Development with extensive experience implementing NX Customization projects.

0 notes