#soil testing machine suppliers

Explore tagged Tumblr posts

Text

The soil testing lab in India, which is outfitted with Heico soil testing equipment, delivers precise and trustworthy analysis, allowing farmers to understand the actual status of their soil and make educated decisions to improve crop productivity.

#soil testing lab#soil testing machine#soil testing lab in India#testing on soil#soil testing equipment#soil testing tools#soil testing machine price#soil testing equipment price#soil testing machine suppliers#soil testing equipment manufacturer

0 notes

Text

🏭 How Udhhyog Ensures Quality in Every Puddle Flange We Manufacture

When it comes to underground drainage, water tanks, STPs, and waterproof RCC structures, the reliability of a puddle flange is non-negotiable. A minor defect or inconsistency can lead to major water seepage, corrosion, and structural failure over time. That’s why at Udhhyog, we don’t just manufacture puddle flanges—we engineer them for 100% performance, precision, and durability.

In this article, we break down how Udhhyog ensures quality control across every stage of the puddle flange manufacturing process, making us one of India’s most trusted flange suppliers.

🔩 1. Material Selection: IS & ASTM-Compliant Raw Inputs

The foundation of a reliable puddle flange lies in the material itself. At Udhhyog, we source only certified mild steel (MS), galvanized iron (GI), and stainless steel (SS304, SS316) from verified vendors. Every batch is accompanied by mill test certificates to confirm composition, mechanical strength, and corrosion resistance.

✅ Standards Followed:

We match material type based on your project environment—whether that’s sewage, stormwater, marine, or chemical handling.

🧪 2. Precision Manufacturing with CNC Accuracy

Our production floor is equipped with CNC plasma cutting machines, MIG welding setups, and hydraulic presses, ensuring each puddle flange is cut and fabricated to the exact millimeter.

Every flange’s outer diameter (OD), inner diameter (ID), thickness, and web width are double-checked during production using calibrated tools.

💡 Udhhyog manufactures puddle flanges ranging from 50 mm to 1000 mm+, with thickness from 4 mm to 20 mm.

🔬 3. Multi-Stage Quality Inspection

We implement a 4-stage quality inspection system, which includes:

Raw Material Verification

In-Process Dimensional Checks

Weld Integrity Testing

Final Visual and Functional Inspection

Each unit is marked with a batch code, enabling full traceability.

🌧️ 4. Anti-Corrosion Coating & Surface Finish

Depending on the material and application, Udhhyog applies:

✅ Hot-dip galvanization (as per IS 4759) for MS puddle flanges

✅ Mirror or matte finish for SS304/SS316 flanges

✅ Custom epoxy coating for chemical resistance (on request)

These finishes protect the flange from moisture, soil chemicals, and oxidation, ensuring decades of service life.

🛠️ 5. Custom Engineering for Project-Specific Demands

Every civil project is different. That’s why Udhhyog offers fully customizable puddle flange designs, manufactured to meet:

Pipe type & OD

Concrete wall thickness

Fluid pressure rating

Environmental exposure (marine, chemical, soil, etc.)

Our in-house engineers create technical drawings for approval before mass production. You receive exactly what your site demands—no compromises.

📦 6. Packaging, Marking & Documentation

Each puddle flange is:

Carefully packed with rust protection and impact padding

Tagged with size, material, and batch number

Supplied with mill test reports, coating certificates, and installation guides

For government and industrial projects, we also provide compliance declarations and delivery inspection formats.

💬 Frequently Asked Questions (FAQs)

Q1: How does Udhhyog ensure uniform quality in large orders? A: We use CNC fabrication and quality batches with traceability, ensuring every flange—whether 5 or 500—meets the same exacting standards.

Q2: Are your flanges suitable for coastal or marine areas? A: Yes. Our SS316 puddle flanges are designed for high-salinity, high-corrosion environments like ports, desalination plants, and coastal foundations.

Q3: Can I request third-party inspection? A: Yes. We support third-party inspections from organizations like SGS, TUV, or your own QA teams before dispatch.

Q4: Do you offer installation support? A: Absolutely. We provide detailed technical sheets and guidance, and our team is available for virtual site consultations.

0 notes

Text

Laboratory Jaw Crusher

Introduction��

In the material testing and quality control industry, precision and reliability are everything. Laboratory jaw crushers are among the most vital tools used in laboratories and research facilities to break down hard materials into manageable sizes for further analysis. Choosing the right supplier is as crucial as choosing the right equipment. In India, K. S. Jandu & Sons has emerged as a trusted manufacturer and supplier of high-performance laboratory jaw crushers.

This blog explores the reasons why industry professionals consistently rely on K. S. Jandu & Sons for their laboratory crushing needs.

1. Proven Manufacturing Expertise

With over a decade of manufacturing excellence, K. S. Jandu & Sons brings precision engineering and deep industry understanding to the table. Their expertise ensures that each jaw crusher is designed for accuracy, durability, and consistent output, making them ideal for testing laboratories.

2. Precision-Focused Designs

K. S. Jandu & Sons crafts laboratory jaw crushers specifically to meet the needs of scientific and industrial testing. These machines deliver accurate size reduction of samples, helping engineers and researchers obtain reliable test results. Compact design and easy operation make them especially suited for lab environments.

3. Built with Quality Materials

Each jaw crusher is constructed using high-grade mild steel or stainless steel to ensure robustness, even when used with hard and abrasive materials. Components are built for longevity, with resistance to wear and minimal maintenance requirements.

4. Wide Range of Customization

Different labs have different needs. K. S. Jandu & Sons offers customizable jaw crushers based on size, feed capacity, discharge settings, and motor power. This flexibility ensures that customers receive a machine tailored to their specific application.

5. Competitive Pricing

Despite the high quality, K. S. Jandu & Sons keeps their pricing competitive. This makes their products accessible to both large industrial facilities and small testing labs without compromising on performance.

6. Excellent After-Sales Support

Their commitment doesn’t end at the point of sale. Customers benefit from responsive service, easy availability of spare parts, and regular maintenance support. This has helped build a loyal customer base over the years.

7. National and International Reach

Based in New Delhi, the company serves clients across India and exports to several countries. Their efficient logistics and support system ensure timely delivery and smooth installation, no matter where the customer is located.

8. Trusted by Leading Institutions

From construction companies and mining agencies to engineering colleges and government labs, many trusted organizations prefer K. S. Jandu & Sons for their reliable product performance and dependable service.

Conclusion

K. S. Jandu & Sons has established itself as a reliable supplier of laboratory jaw crushers in India through its commitment to quality, customization, and customer satisfaction. Whether you are testing soil, rock, or mineral samples, their crushers provide the durability and precision your lab needs.

If you’re in the market for a high-quality jaw crusher backed by expert support, K. S. Jandu & Sons is a name you can trust.

Contact them today to learn more or request a customized quote for your laboratory needs.

1 note

·

View note

Text

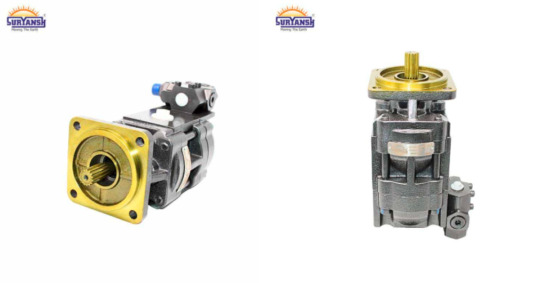

Hydraulic Gear Pump with Priority Valve for L&T Case 770 EX Backhoe Loader: A Complete Guide

In construction and excavation, machines like the L&T Case 770 EX Backhoe Loader need reliable components to handle tough jobs. One critical part is the hydraulic gear pump with a priority valve.

This pump ensures the machine’s hydraulic system works smoothly, powering tasks like digging, lifting, and steering. Let’s explore why this pump matters and how it boosts the L&T Case 770 EX’s performance.

What is a Hydraulic Gear Pump?

A hydraulic gear pump is a mechanical device that moves hydraulic fluid to power heavy machinery. It uses rotating gears to create fluid flow, generating pressure for functions like lifting buckets or steering. For the L&T Case 770 EX, this pump is paired with a priority valve to prioritize critical systems. For example, the valve ensures steering gets hydraulic power first for safety, even when other parts (like the loader) are active.

Key Features of the Hydraulic Gear Pump for L&T Case 770 EX

This pump is built to match the demands of the L&T Case 770 EX, a 74 HP machine weighing 7,780 kg. Here’s what makes it stand out:

Efficient Fluid DeliveryPrecision gears provide steady hydraulic flow for smooth operation of the loader, backhoe, and steering.

Priority Valve for SafetyDirects fluid to steering first, ensuring control during maneuvers.

Durable BuildMade from cast iron or aluminum alloy, it withstands dust, vibrations, and heavy loads.

High-Pressure PerformanceSupports heavy tasks like lifting up to 1,330 kg and digging through tough soil.

Low Noise DesignReduces operational noise, improving comfort for operators.

Easy MaintenanceSimple to inspect, repair, or replace, minimizing downtime.

How It Works in the L&T Case 770 EX

The pump draws hydraulic fluid from the machine’s reservoir. Gears pressurize the fluid, sending it to systems like the loader bucket or backhoe arm.

The priority valve ensures steering always gets fluid first. This setup keeps operators safe and in control, even when lifting heavy loads or working on uneven terrain.

Benefits for Operators

Safety First: Responsive steering reduces accident risks.

Higher Productivity: Smooth hydraulic flow speeds up digging and lifting.

Fuel Efficiency: Optimized fluid use lowers engine strain and fuel costs.

Long Lifespan: Tough materials cut maintenance needs and costs.

Where Is This Pump Used?

The L&T Case 770 EX relies on this pump for:

Construction: Digging foundations, moving earth.

Landscaping: Grading, trenching, and shaping land.

Excavation: Breaking through rocky soil.

Infrastructure: Road building, pipeline installation.

Why Choose This Pump?

This hydraulic gear pump meets or exceeds OEM standards. Brands like J.B. Industries (maker of Suryansh pumps) produce high-quality versions tested for durability. It’s a smart investment to keep your L&T Case 770 EX running efficiently for years.

Where to Buy

Look for this pump at:

Online platforms: eBay, CEParts.in, Global Lifters.

Heavy equipment suppliers: Check for warranties and certified refurbished options.

Manufacturers: Contact ISO-certified companies like J.B. Industries directly.

Always confirm compatibility with the L&T Case 770 EX before purchasing.

Final Thoughts

The hydraulic gear pump with a priority valve is the backbone of the L&T Case 770 EX’s hydraulic system. Its focus on safety, efficiency, and durability makes it essential for construction and excavation work.

Whether you’re a fleet manager or operator, this pump ensures your machine performs reliably in the toughest conditions.

Ready to upgrade? Check trusted suppliers today to keep your backhoe loader at peak performance!

0 notes

Text

From Quarry to Industry: Hydrated Lime Production by Top Manufacturers in Jodhpur

Introduction: Jodhpur’s Lime Legacy

Jodhpur, known for its architectural beauty and mineral wealth, is also a major hub for lime production. With vast limestone reserves and industrial expertise, the city houses some of the best Lime powder suppliers in Jodhpur, making it a cornerstone of India’s lime industry.

This blog will take you inside the complete production process of hydrated lime, revealing how raw material from quarries transforms into a refined product used across industries like steel, construction, water treatment, and chemicals. We also highlight how hydrated lime manufacturers in Jodhpur and quick lime manufacturers in India ensure top-quality outputs with cutting-edge technology.

1. What Is Hydrated Lime?

Hydrated lime, also called calcium hydroxide, is produced by adding water to quick lime (calcium oxide). This reaction, called "slaking," results in a white, dry powder used in multiple industries. Its purity, reactivity, and particle size determine its industrial value.

Before understanding hydrated lime's manufacturing, we must first understand how its precursor—quick lime—is produced.

2. Stage One: Quarrying of Limestone

The production journey begins at limestone quarries scattered across the Jodhpur region. Here, high-grade limestone, rich in calcium carbonate (CaCO₃), is extracted using advanced mining techniques.

Steps:

Drilling and blasting: Controlled explosions break the limestone into manageable sizes.

Crushing and sorting: The raw stone is crushed and segregated by size and purity.

Transport: Crushed limestone is transported to the calcination facility.

Jodhpur’s geological profile gives manufacturers access to superior raw material—one of the reasons why hydrated lime manufacturers in Jodhpur lead the national market.

3. Stage Two: Calcination—Creating Quick Lime

Once the limestone reaches the plant, it undergoes calcination—a high-temperature process in rotary or shaft kilns.

Process:

Heating at 900–1100°C: This drives off carbon dioxide, converting calcium carbonate into calcium oxide (quick lime). Reaction: CaCO₃ → CaO + CO₂↑

Quality checks: The resulting quick lime is tested for purity and reactivity.

Quick lime manufacturers in India, especially in Rajasthan, have invested heavily in modern kiln technologies, ensuring consistent and high-quality CaO production.

4. Stage Three: Hydration—Forming Hydrated Lime

The next step is slaking—where quicklime reacts with water to form hydrated lime.

Hydration Process:

Controlled addition of water to quick lime in a hydrator machine.

Exothermic reaction produces heat and results in fine calcium hydroxide powder. Reaction: CaO + H₂O → Ca(OH)₂ + Heat

Cooling and drying: The powder is cooled to ambient temperature.

Grinding and classification: Final product is ground and sieved to desired fineness.

The process requires precision, as both under-hydration and over-hydration can result in sub-standard product. That’s why the best Lime powder suppliers in Jodhpur use automated systems and real-time sensors.

5. Stage Four: Quality Control and Packaging

Once produced, the hydrated lime is subjected to rigorous quality checks:

Purity Tests

Moisture Content

Reactivity Index

Fineness and Particle Size Analysis

After approval, it is packed in moisture-proof bags (HDPE or paper) ranging from 25kg to 50kg or bulk bags for industrial buyers.

Leading hydrated lime manufacturers in Jodhpur comply with BIS (Bureau of Indian Standards) and international quality benchmarks to meet diverse client needs.

6. Applications Across Industries

Hydrated lime is not just a construction material—it plays a critical role across numerous sectors:

Industry

Application

Steel & Metallurgy

Flux for refining and removing impurities

Water Treatment

pH adjustment and removal of heavy metals

Construction

Soil stabilization, whitewash, and mortars

Chemicals

As a precursor for calcium-based compounds

Paper & Pulp

Bleaching and chemical recovery processes

Sugar Industry

Purification of sugarcane juice

This wide applicability keeps quick lime manufacturers in India and their hydrated lime divisions in continuous demand.

7. Why Jodhpur is the Ideal Manufacturing Base

Several factors make Jodhpur the preferred location for lime manufacturing:

Rich limestone reserves with high calcium content

Skilled labor force with generations of experience

Proximity to industrial hubs in Gujarat, Punjab, and Delhi

Government support and infrastructure for mineral processing

These advantages have led to the emergence of trusted names among the best Lime powder suppliers in Jodhpur, known for quality, service, and delivery efficiency.

8. Sustainability in Lime Production

Modern manufacturers in Jodhpur are adopting greener practices:

Use of alternative fuels like biomass in kilns

Waste heat recovery systems

Water recycling systems in the hydration process

Dust control and emission filtration technologies

These efforts are helping hydrated lime manufacturers in Jodhpur reduce environmental impact and meet ESG (Environmental, Social, Governance) goals.

9. Choosing the Right Manufacturer: Key Criteria

When selecting a lime supplier, consider the following:

Product purity and reactivity

Customization and particle size options

Delivery timelines and logistics

Certifications and client reviews

After-sales support

Reputed quick lime manufacturers in India often have in-house hydration units, ensuring consistency and traceability across the product line.

10. Conclusion: Precision from Stone to Solution

From the rugged quarries of Rajasthan to the precision-engineered plants of Jodhpur, the journey of hydrated lime is a remarkable transformation. The process reflects not only industrial prowess but also a commitment to quality, sustainability, and service.

Whether you're in construction, metallurgy, or water treatment, choosing one of the best Lime powder suppliers in Jodhpur ensures you're using a product that meets stringent industry standards and delivers performance.

#hydrated lime manufacturers in jodhpur#limestone suppliers in india#calcined lime powder manufacturers in india

1 note

·

View note

Text

Civil Engineering Test Instruments Suppliers From India Laboratory Instrument India is one of the leading Civil Engineering Test Instruments Suppliers from India, offering high-quality tools for accurate construction material testing. Their range includes compression testing machines, soil testing kits, and concrete mixers. Visit: https://www.laboratoryinstrumentindia.com/engineering-lab-equipment/civil-engineering-test-equipment

0 notes

Text

Hot Mix Plant Manufacturer in Delhi

When it comes to high-performance road construction machinery, S.K. Engineering stands out as the best static road roller supplier in India. With years of expertise in the road construction and heavy equipment industry, we provide top-quality static road rollers that ensure durability, efficiency, and superior compaction.

As a leading supplier of static road rollers in India, S.K. Engineering is dedicated to delivering heavy-duty road rollers that meet the demands of infrastructure projects, highway construction, and industrial roadworks.

Why Choose a Static Road Roller?

A static road roller is a crucial piece of road construction machinery used for compacting soil, gravel, asphalt, and other materials to create strong, durable surfaces. Unlike vibratory rollers, static rollers rely on heavy drum weight to achieve compaction.

Key Benefits of Static Road Rollers

Superior Compaction for Road Construction

Ideal for Smoothing Asphalt and Soil Layers

Heavy-Duty Performance for Long-Term Use

Cost-Effective and Low Maintenance

Ensures a Strong and Durable Road Surface

As the best static road roller supplier in India, S.K. Engineering ensures that every machine is built with precision engineering and high-quality materials, making it the most reliable choice for contractors and construction firms.

S.K. Engineering – Leading Static Road Roller Supplier in India

At S.K. Engineering, we are committed to delivering high-performance static road rollers that meet the highest industry standards. Our static road rollers are widely used in highway construction, airport runway development, dam projects, and industrial roadworks.

Why S.K. Engineering is the Best Static Road Roller Supplier in India?

Heavy-Duty Machines with Advanced Engineering

Affordable Prices for Bulk Orders

Custom-Built Road Rollers for Various Applications

Reliable After-Sales Support and Maintenance Services

Timely Delivery Across India

Energy-Efficient and Fuel-Saving Designs

Our high-quality static road rollers in India are designed for maximum efficiency, ensuring smooth and even compaction across different terrains.

Applications of Static Road Rollers in India

Highway and Expressway Construction – Ensuring smooth, durable roads.

Airport Runway Development – Compacting surfaces for safe aircraft landing.

Industrial and Commercial Road Projects – Reliable compaction for heavy vehicle usage.

Real Estate and Infrastructure Development – Used for site preparation and landscaping.

Railway Track Foundation Compaction – Strengthening rail line bases.

As the best supplier of static road rollers in India, S.K. Engineering provides customized solutions to meet the unique needs of each project.

Quality Standards and Certifications

We prioritize quality, durability, and compliance with industry standards at S.K. Engineering. Our static road rollers undergo rigorous testing to ensure:

ISO-Certified Manufacturing

High-Quality Steel and Drum Material

Fuel-Efficient and Low-Maintenance Machines

Environmental Safety Compliance

Our road rollers are built for long-term durability and heavy-duty performance, making us the top static road roller supplier in India.

Competitive Pricing & Bulk Orders for Static Road Rollers

Looking for the best static road rollers at competitive prices in India? S.K. Engineering offers affordable rates for both individual and bulk purchases.

Cost-Effective Road Rollers for Small and Large Projects

Fast and Reliable Delivery Across India

Custom Financing Options for Contractors and Companies

Whether you need one machine or multiple units, we ensure on-time delivery and the best pricing in the industry.

Conclusion

For the best static road rollers in India, trust S.K. Engineering – the leading supplier of heavy-duty road construction machinery. Our durable, fuel-efficient, and high-performance road rollers are designed to deliver superior compaction for highways, airports, and infrastructure projects.

With a commitment to quality, affordability, and customer satisfaction, we ensure fast delivery, bulk discounts, and customized solutions for all your road construction needs.

For bulk orders, price inquiries, and technical specifications, contact S.K. Engineering – the No.1 static road roller supplier in India today!

Frequently Asked Questions (FAQs)

1. Why is S.K. Engineering the best static road roller supplier in India?

S.K. Engineering is known for high-quality, durable, and fuel-efficient static road rollers that meet industry standards and provide superior compaction for road construction projects across India.

2. What types of static road rollers do you offer?

We offer single-drum, double-drum, tandem, and custom-built static road rollers to suit different road construction and infrastructure projects.

3. Do you provide bulk orders for static road rollers in India?

Yes! We offer bulk orders of static road rollers at competitive prices in India, ensuring fast delivery and wholesale discounts.

4. Are your static road rollers fuel-efficient?

Yes! Our static road rollers are designed for maximum fuel efficiency, reducing operational costs while maintaining high performance.

5. Can I customize a static road roller based on my project requirements?

Absolutely! We provide custom static road rollers in India, allowing clients to choose specifications like drum size, weight capacity, and design.

6. How long does it take for delivery?

We offer fast delivery across India, with most orders shipped within 7-10 working days, depending on availability and location.

0 notes

Text

Transforming Ukraine Industrial Sector with State-of-the-Art Lab Equipment

Himlaborreactiv stands as the leading supplier of laboratory equipment in Ukraine, specializing in a variety of critical industries. With a focus on sectors such as oil and gas, energy, mining and metallurgy, machine building, chemical industry, and construction, Himlaborreactiv provides state-of-the-art laboratory solutions that cater to the specific needs of these industries, ensuring both quality and precision in every operation.

Tailored Laboratory Solutions for Key Industries

1. Oil and Gas Sector: In the oil and gas industry, precise laboratory testing is essential for ensuring both the safety and performance of equipment and products. Himlaborreactiv delivers a range of specialized tools for the analysis of hydrocarbons, petroleum products, and gas components. These solutions help oil and gas companies maintain safety standards, optimize production processes, and adhere to environmental regulations.

2. Energy Sector: The energy industry demands efficient and accurate testing for the performance and reliability of its systems. Himlaborreactiv provides laboratory equipment designed to test energy materials, monitor equipment performance, and assess energy efficiency. These solutions support energy companies in maintaining high operational standards and meeting the increasing demand for sustainable energy production.

3. Mining and Metallurgy: In mining and metallurgy, the extraction and processing of raw materials require strict quality control. Himlaborreactiv offers specialized equipment for material testing, including the analysis of ores, metals, and alloys. By ensuring the integrity and quality of mined resources, our products help businesses optimize their operations and meet industry regulations, leading to increased productivity and reduced waste.

4. Machine Building: The machine building industry relies on laboratory equipment to test the durability, performance, and quality of components. Himlaborreactiv provides innovative solutions for material strength testing, component analysis, and precision measurements. These laboratory tools help manufacturers ensure that their machinery and parts meet the rigorous standards of the machine building sector.

5. Chemical Industry: The chemical industry demands constant innovation and accurate testing to maintain the safety and quality of its products. Himlaborreactiv supplies laboratory equipment used in chemical analysis, process control, and product testing. By using our cutting-edge equipment, chemical companies can ensure compliance with safety standards, improve production processes, and develop new and efficient products.

6. Construction Industry: In the construction sector, laboratory testing is crucial to guarantee the quality and safety of materials such as concrete, soil, and steel. Himlaborreactiv offers laboratory equipment for assessing the strength and durability of construction materials, enabling companies to build safe and reliable structures while meeting building regulations.

Why Himlaborreactiv?

Himlaborreactiv's leadership in the Ukrainian laboratory equipment market is attributed to its deep expertise across multiple industries, commitment to high-quality solutions, and focus on customer satisfaction. With tailored equipment, expert consultation, installation, and ongoing support, Himlaborreactiv provides a complete service for businesses aiming to improve performance, maintain safety, and ensure compliance with industry standards.

Whether for oil and gas, energy, mining, machine building, chemical, or construction industries, Himlaborreactiv remains the trusted partner for laboratory solutions in Ukraine.

0 notes

Text

Expert Concrete Contractors in Tamil Nadu for Quality Work

In the world of construction, concrete is more than just a building material — it is the foundation of structural strength, safety, and longevity. Whether it’s a residential building, commercial complex, or infrastructure project, the quality of concrete work directly influences the lifespan and performance of any structure. In Tamil Nadu, where construction needs are as diverse as its geography, working with expert concrete contractors is critical for delivering long-lasting, high-quality results.

Why Experience Matters Concrete work is not just about mixing cement, sand, and aggregates. It demands technical expertise, precision, and an understanding of site-specific conditions. Experienced contractors in Tamil Nadu bring deep knowledge of local soil behavior, climatic factors, and material compatibility. They know how to adapt mix designs to regional standards, comply with local construction codes, and handle complex site challenges with professionalism.

Contractors with years of hands-on experience are more likely to deliver work that meets not just structural standards but also aesthetic expectations, especially in projects that require architectural concrete finishes.

Quality Begins with Trusted Materials One of the key indicators of a reliable contractor is their choice of construction materials. In Tamil Nadu, Chettinad Cement is a preferred name for a reason — known for its strength, durability, and consistent performance. Expert contractors never compromise on material quality. They partner with trusted suppliers, conduct regular testing, and ensure every batch of concrete meets the required specifications.

This attention to quality at the material level reflects in the overall output — reducing cracks, increasing load-bearing capacity, and enhancing resistance to environmental wear and tear.

Professionalism and Process-Driven Work Expert concrete contractors operate with a well-defined workflow that includes site inspection, planning, material procurement, formwork setup, mixing, pouring, and curing. Every stage is monitored for precision and quality control. They maintain clear documentation, follow safety protocols, and commit to timely delivery — hallmarks of professional service.

Clients benefit not just from quality output but also from peace of mind, knowing the project is being handled with integrity and attention to detail.

Technology-Driven Efficiency Leading contractors in Tamil Nadu increasingly use advanced tools and equipment such as automated mixers, laser screeds, and curing machines to enhance accuracy and speed. Digital project management tools and quality monitoring apps help track progress in real-time, ensuring better accountability.

This technology-driven approach improves not just productivity but also the consistency of work across projects of any scale.

Long-Term Value and Structural Integrity When you work with expert concrete contractors, you’re not just paying for today’s job — you’re investing in the future. High-quality concrete work lowers maintenance costs, prevents premature failures, and adds value to the property over time. Whether you're building a home or a multi-storey structure, expert workmanship ensures the result stands strong for decades.

Conclusion In Tamil Nadu’s growing construction landscape, choosing the right concrete contractor can make all the difference. Look for a team that values quality, uses top-grade materials like Chettinad Cement, follows industry best practices, and brings experience to every project. With expert concrete contractors on your side, you're laying more than a foundation — you're building a legacy of strength and trust.

Website: https://www.chettinadcement.com/ Facebook: https://www.facebook.com/Chettinadcements Twitter: https://x.com/ChettinadCement Instagram: https://www.instagram.com/chettinadcements/ Threads: https://www.threads.net/@chettinadcements?hl=en Youtube: https://www.youtube.com/@ChettinadCementIndia E-mail: [email protected] Contact Number: 9659911155

#concrete contractors#concrete choice#concrete contractors in chennai#concrete contractors in Tamil Nadu

0 notes

Text

Choose Best Quality Dolomite Powder Online in India for Your Business

Select Dolomite Powder Best Quality Online in India for Business

With the rise of competitive industry nowadays, accessing better quality raw material is the most important action to establish a powerful and thriving business. Among all of them, dolomite powder is employed in construction fields, agriculture, paint, plastic, etc. As much as a business survival would rely on the mineral, buying the Best Quality Dolomite powder online in india out of the ones listed in India would need to be undertaken with sheer caution so one gets product quality in order and constant work procedure. What is Dolomite Powder and Why is It Important

Dolomite is a calcium magnesium carbonate mineral occurring naturally. If it is ground into powder form, it is a very useful material to be used for several industrial applications. Due to the fact that it is strong, smooth, and chemically resistant, it is the best to be used for different applications in different industries.

Dolomite powder is favored by industries as it enhances the quality of products. Be it being utilized in paint for texture, in agriculture to condition soil, or in plastic to make it tougher, it is an affordable but effective product. That's why companies are searching more and more for the Best Quality Dolomite powder in India online to meet their demands.

Major Industrial Applications of Dolomite Powder

Some of the prominent industries which utilize dolomite powder are listed below:

Paints and Coatings: Served as filler and pigment, white in nature and smoothens the surface.

Plastic and Rubber: Used to improve strength and flexibility of end products.

Construction: Assistance in the manufacture of cement and concrete-based materials.

Glass and Ceramics: Provides resistance and shine to glass products and ceramic tiles.

Agriculture: Serves as a conditioner for the soil, regulating pH and providing necessary nutrients.

All these industries require the Best Quality Dolomite powder online in India to maintain their production processes cost-effective and efficient.

Why You Should Buy Dolomite Powder Online

With the growth of digital technology in all fields, buying industrial minerals online is now easy and reliable. Rather than employing middlemen or local agents, companies can now easily get in contact with manufacturers who supply quality products.

The following are some reasonable reasons why it is a wise decision to buy Best Quality Dolomite powder online from India:

Saves effort and time

Provides a better selection of vendors

Facilitations bulk quantity purchase at favorable prices

Grant access to the product info and test reports for viewing

Encourages direct interactions with vendors and facilitates better communications

Through purchasing on the net, your business will be in a position to plan production better and spare wastages due to stock shortages.

Natural Minerals – Your Trusted Source

Natural Minerals is one of the most popular names when it comes to the supply of industrial minerals. Operating from India, the organization has the expertise of supplying superior quality dolomite powder to Indian industries. Natural Minerals does not supply services to any other country other than India, thus enabling the organization to give its undivided attention to industries within the country and catering to their expectations to the best.

We at Natural Minerals ensure every shipment of dolomite powder to be pure, highly processed, and free from any contaminants. Our experienced personnel employ advanced machines and quality check equipment to ensure consistent results. As one of the known names in business, we are well aware of the fact that businesses searching online in India to buy the Best Quality Dolomite powder require reliable suppliers who would make their deliveries on time, without fail.

We also provide customer support to assist you in choosing the product that will be best for your company. Whether you are involved in the paint, plastic, or agriculture industry, Natural Minerals is dedicated to assisting your growth with the best material.

Quality to Look Out for in Dolomite Powder

Before purchasing any dolomite powder, it is essential to ensure the quality. Any good supplier will provide all the information regarding the product. Some key points to look for:

Whiteness: The powder must be bright white in color.

Fineness: It should be smooth and fine, quick to mix with other products.

Purity: Must be devoid of moisture, dust, or any other type of harmful particles.

Balanced Minerals: Adequate calcium and magnesium provides better performance.

All these characteristics are always preserved in the Best Quality Dolomite powder available online in India, and businesses such as Natural Minerals make sure every product retains these details.

Read reviews of the supplier or customer testimonials

Request technical specifications and sample reports

Verify packaging and shipping alternatives

Know the terms of payment and the return policy

Stay in contact with the supplier for updates

By purchasing in this way, you will have a hassle-free and reliable buying process and get the Best Quality Dolomite powder online in India at your doorsteps.

Conclusion

Dolomite powder is a very helpful and widely used mineral in India. It is supporting many industries by enhancing strength, whiteness, and cost-effectiveness. To achieve best outcome in your production or cultivation process, it's advisable to purchase only high-quality powder from genuine sources.

By opting for the Best Quality Dolomite powder online in India, you are investing in improved quality of the product and cost-effectiveness in the long run. And when it comes to trust and quality, Natural Minerals is a trusted partner who is committed to Indian industries' growth.

0 notes

Text

Soil testing equipment plays a vital function in determining the composition and quality of soil. This makes it a necessary tool for many industries. It is impossible to overestimate the significance of employing soil testing techniques in environmental studies and building research. It is important for agricultural endeavors as well.

#Soil testing equipment#Quality soil testing manufacturers#Soil testing instruments#Soil testing device suppliers#Soil testing equipment manufacturer#Soil testing machine#Soil testing machine price#Soil testing machine manufacturer#Test on Soil#Soil Testing

0 notes

Text

Top Drone Trends in 2025: What B2B Buyers Need to Know? - Beyond SKY

The drone market is soaring higher than ever in 2025 — and it's not only for photography or video anymore. From logistics and agriculture to defence and inspections, drones are now a business necessity.

For B2B buyers, keeping up with the latest drone trends in 2025 is crucial to staying competitive. At Beyond SKY, the world's fastest-growing B2B Drone Marketplace, we’ve seen these trends evolve firsthand.

Here's what’s shaping the future of drones—and how your business can ride the wave.

1. BVLOS Operations Are Now a Reality

BVLOS (Beyond Visual Line of Sight) is not experimental anymore. With support from regulatory authorities DGCA and growing worldwide demand, long-distance drone applications are now viable and lucrative.

Require drones for BVLOS applications? Beyond SKY's online marketplace for drones provides ready-to-fly solutions from leading suppliers.

2. Drone Deliveries Are Shaping the Logistics of Tomorrow

Drone deliveries of medical supplies, groceries, and e-commerce shipments are becoming increasingly popular. The need for faster delivery, cost reduction, and less human labour is fuelling this change.

The commercial drone market for companies is evolving quickly—providing a broad range of business delivery drones and payload attachments for many different industries.

3. AI-Driven Drones Are Redefining Efficiency

Drones with integrated AI and machine learning are revolutionizing threat detection, mapping, and data collection. Agriculture, construction, and mining are all implementing these intelligent systems.

You can now Buy Drones Online those are pre-configured with smart features like object detection, real-time alerts, and pattern recognition—directly from Beyond SKY.

4. Agri-Drones Are Revolutionizing the Face of Indian Agriculture

Farmers are using Agricultural Drones to spray crops, analyze the soil, and inspect plant health precisely. The trend is booming throughout rural India due to the availability of cheap drone solutions and government subsidies.

At Beyond SKY, our website brings you in touch with authentic drone accessories suppliers who provide sprayers, multispectral cameras, and NDVI sensors.

5. Drone-as-a-Service (DaaS) Is Becoming a Preferred Model

Instead of buying and maintaining a drone fleet, many businesses now subscribe to Drone-as-a-Service. It offers flexibility, low upfront cost, and access to expert operators.

Whether you’re looking to provide or subscribe to services, Beyond SKY acts as the go-to drone marketplace for connecting businesses and providers.

6. Demand for Drone Testing Equipment is Surging

With drone usage scaling up, there’s more pressure on manufacturers to ensure safety and compliance. This means more investment in Drone Test Equipment, calibration tools, and simulation labs.

Through our Drone Marketplace, B2B buyers can now source the latest test benches, RF signal testers, and environmental chambers with ease.

What This Means for B2B Buyers

The drone industry is no longer niche — it’s mission-critical. Whether you need UAVs, accessories, compliance tools, or data-driven drone services, your business needs a reliable, scalable solution.

At Beyond SKY, we help you:

2025 marks a turning point in drone adoption across industries. World's first B2B marketplace for the global drone industry. Beyond Sky is on a mission to bring the global manufacturers and suppliers of the drone industry and its consumers onto a single platform.

Explore, connect, and scale with us today at https://beyondsky.xyz/—the ultimate drone marketplace for businesses.

#buydrone#Drone#dronesforagriculture#agriculturaluav#uavdroneagriculture#DroneCompanies#dronemanufacturers#droneelectricmotors

0 notes

Text

How Geo Bag Manufacturers Ensure Quality and Strength Standards

In civil engineering, environmental protection, and infrastructure development, geo bags play a critical role in preventing soil erosion, reinforcing riverbanks, and protecting coastal areas. These durable, high-performance bags are often used in highly sensitive and high-risk projects where failure is not an option. As a result, maintaining the highest standards of quality and strength is a top priority for every reputable Geo Bag Manufacturer.

In this article, we explore how geo bag manufacturers ensure that their products meet rigorous industry standards, perform in challenging environments, and deliver long-term results.

Understanding the Role of Geo Bags

Before diving into the quality aspect, it’s important to understand what geo bags are. These are specially engineered textile bags, typically made from woven or non-woven synthetic fabrics like polypropylene or polyester. Geo bags are filled with sand or other materials and used in erosion control, flood protection, land reclamation, and slope stabilization.

Given the environmental conditions they are exposed to—such as heavy rainfall, strong currents, UV radiation, and physical stress—it is crucial that every Geo Bag Manufacturer focuses on durability, strength, and reliability.

1. Material Selection and Sourcing

High-quality geo bags begin with high-quality raw materials. Manufacturers typically use UV-stabilized, high-tenacity synthetic fibers like polypropylene (PP) or polyester (PET). These materials are known for their resistance to chemicals, abrasion, and UV degradation.

A trustworthy Geo Bag Manufacturer will always source certified raw materials from reputable suppliers. The chosen material should have a high tensile strength, elongation capacity, and puncture resistance—qualities essential for field performance.

2. Precision in Weaving and Fabrication

The manufacturing process itself greatly affects the performance of geo bags. For woven geo bags, the weaving density and yarn quality are critical factors. For non-woven bags, the bonding process and fabric uniformity are essential.

Advanced manufacturing facilities use automated looms, heat cutters, and precision stitching machines to ensure consistent quality. Stitching techniques, such as double-lock or chain stitches, are employed to prevent seam failures under pressure. This level of precision ensures that every bag produced by the Geo Bag Manufacturer meets the required dimensional and mechanical standards.

3. In-House Testing and Quality Control

A top-tier Geo Bag Manufacturer will always have an in-house laboratory or tie-ups with accredited testing agencies to conduct rigorous quality checks. These tests include:

Tensile Strength Test: To assess the fabric’s ability to withstand pulling forces.

Puncture Resistance Test: To ensure the fabric resists sharp objects and tearing.

UV Resistance Test: To verify the fabric’s ability to withstand prolonged sun exposure without degradation.

Burst Strength Test: To evaluate the seam strength and bag integrity under pressure.

Water Permeability Test: Especially for applications where controlled drainage is required.

All results are benchmarked against global standards such as ASTM, ISO, or BIS, ensuring reliability and compliance.

4. Customization for Project-Specific Needs

Every project is unique, and so are its demands. Reputable geo bag manufacturers work closely with engineers, project managers, and procurement teams to understand load conditions, environmental factors, and application goals. Based on this input, manufacturers provide customized solutions in terms of size, weight capacity, coating, and seam design.

This tailored approach not only enhances performance but also ensures long-term durability in harsh field conditions.

5. Certifications and Compliance

Another key quality indicator is the set of certifications a Geo Bag Manufacturer holds. Compliance with ISO 9001 for quality management, ISO 14001 for environmental management, and industry-specific standards helps establish credibility. Many public and private sector projects also mandate third-party testing and documentation, further ensuring that the products meet international benchmarks.

Final Thoughts

In projects where the stakes are high—whether it’s preventing a landslide or protecting a coastline—there is no room for compromise. A reliable Geo Bag Manufacturer understands this and integrates quality at every stage, from material selection to final testing. By choosing a manufacturer committed to high standards, you ensure that your infrastructure or environmental project has the robust foundation it needs to withstand nature’s challenges and deliver long-term performance.

0 notes

Text

Choosing the Right Mini Intercultivator Machine Supplier for Your Farming Needs

In today’s fast-evolving agricultural landscape, efficiency and precision are crucial. Small and medium-scale farmers are constantly seeking modern tools that can increase productivity while reducing manual labor. One such essential tool is the mini intercultivator machine. However, finding the right mini intercultivator machine supplier is just as important as choosing the machine itself. The quality of your supplier can significantly affect your farming operations, machine performance, and long-term value.

In this blog, we’ll guide you through what a mini intercultivator machine is, its benefits, and how to choose a reliable supplier that aligns with your farming needs and budget.

What is a Mini Intercultivator Machine?

A mini intercultivator machine is a compact farming tool designed to perform inter-row cultivation. It helps loosen the soil, remove weeds, and prepare the land for sowing. This versatile tool is ideal for small plots, home gardens, and small to medium farms. Its lightweight structure makes it easy to operate, especially in tight spaces where larger equipment may not be practical.

Modern mini intercultivator machines often come with multi-functional attachments and fuel-efficient engines, making them an essential tool for mechanized farming.

Benefits of Using a Mini Intercultivator Machine

Investing in a mini intercultivator machine offers multiple benefits, especially for small-scale farmers:

Labor Saving: Reduces the need for manual weeding and tilling, saving both time and effort.

Increased Productivity: Enhances soil preparation and aeration, which can improve crop yield.

Cost-Effective: Lower initial investment compared to large tractors, with affordable maintenance.

Versatile: Suitable for various crops and soil types. Attachments can be customized based on usage.

Eco-Friendly Options: Some models come with fuel-efficient engines or even electric alternatives.

Why Choosing the Right Supplier Matters

With increasing demand, there are numerous suppliers in the market. However, not every mini intercultivator machine supplier offers the same level of quality, support, and value. The right supplier ensures that you get:

Quality Machines: Tested and certified equipment built to last.

Competitive Pricing: Value for money without compromising on quality.

After-Sales Support: Access to spare parts, servicing, and expert assistance.

Warranty and Guarantees: Added assurance and peace of mind.

Key Factors to Consider When Choosing a Mini Intercultivator Machine Supplier

To find the best supplier for your farming needs, consider the following points:

1. Experience and Reputation

Look for suppliers with a strong track record in the agricultural equipment industry. Check customer reviews, testimonials, and case studies. A well-established mini intercultivator machine supplier will have a history of satisfied clients and quality products.

2. Product Range

A reliable supplier should offer various models and attachments to meet different farming needs. Whether you’re working on paddy fields, vegetable gardens, or orchards, the right machine can make all the difference.

3. Technical Support and Training

Some farmers may be new to mechanized tools. Choose a supplier that offers product training, user manuals, and expert guidance. Technical support ensures smooth operation and maximum performance.

4. Availability of Spare Parts

Machines require regular maintenance. Ensure the supplier provides easy access to original spare parts and accessories to keep your machine in good condition.

5. Delivery and Logistics

Check if the supplier offers doorstep delivery and quick shipping options. Timely delivery can make a big impact, especially during the sowing or harvesting season.

Where to Find a Trusted Mini Intercultivator Machine Supplier

You can find suppliers through:

Online Marketplaces like IndiaMART, TradeIndia, Alibaba, or Amazon Business.

Local Agricultural Equipment Stores for in-person inspection and testing.

Exhibitions and Trade Shows where suppliers showcase their latest products and innovations.

Make sure to compare prices, warranty options, and user reviews before making your decision.

Final Thoughts

A mini intercultivator machine is a smart investment for any farmer looking to save time, increase yield, and modernize their farming practices. But the benefits of this powerful tool can only be realized when you choose a dependable and knowledgeable mini intercultivator machine supplier.

Do your research, ask the right questions, and don’t compromise on after-sales support. Whether you’re farming on a small plot or running a mid-sized agricultural operation, the right supplier can be your long-term partner in farming success.

Need help choosing the best mini intercultivator machine for your farm? Reach out to a trusted supplier today and take the first step toward smarter, more efficient farming.

0 notes

Text

The Southwest Florida Water Management District’s (District) Governing Board declared April Water Conservation Month at its March 25 meeting. April is historically one of the driest months of the year and typically marks the peak demand season for public water suppliers. With these 10 simple tips, you can lower your monthly water bill and do your part to save hundreds of gallons of water: INDOOR - Only run your washing machine and dishwasher when they are full. - Use the shortest clothes washing cycle for lightly soiled loads; normal and permanent-press wash cycles use more water. - Thaw frozen food in the refrigerator or microwave, not under running water. - Scrape, don’t rinse your dishes before loading in the dishwasher. - Install high-efficiency showerheads, faucets, and toilets. OUTDOOR - Check your home’s irrigation system for leaks. - Turn off your irrigation system and only water as needed. - Don’t leave sprinklers unattended. Use a kitchen timer to remind yourself to turn sprinklers off. - Use a hose with a shut-off nozzle when washing the car. - Consider installing a rain barrel with a drip irrigation system for watering your landscaping. Rainwater is free and better for your plants because it doesn’t contain hard minerals. How to Check for Leaks to Save Water Leaks are the biggest water waster, both inside and outside of your home. You can use your water meter to check for leaks. - Turn off all faucets and water-using appliances and make sure no one uses water during the testing period. - Wait for the hot water heater and ice cube makers to refill and for regeneration of water softeners. - Go to your water meter and record the current reading. - Wait 30 minutes. (Remember, no water should be used during this period.) Read the meter again. If the reading has changed, you have a leak. For more information about water conservation, please visit the District’s website at WaterMatters.org/Water101. Read the full article

0 notes

Text

PVC Pipes Factory in Bawana: A Manufacturing Powerhouse

Introduction

Bawana, an industrial area in Delhi, has become a prominent hub for PVC pipe factories. The demand for high-quality PVC pipes in sectors such as construction, agriculture, and plumbing has driven the rapid growth of factories in this region. With numerous manufacturers and suppliers, Bawana caters to both domestic and international markets. This blog explores the significance of PVC pipe factories in Bawana, their production processes, and why this location is ideal for PVC pipe manufacturing.

Understanding PVC Pipes

Polyvinyl Chloride (PVC) pipes are widely used due to their versatility, durability, and cost-effectiveness. These pipes, made from a plastic polymer, are utilized in various applications, including water supply, drainage, irrigation, and cable insulation. PVC pipes are lightweight, easy to install, resistant to corrosion, and have a long lifespan, making them an essential component in multiple industries.

The Growth of PVC Pipe Factories in Bawana

The increase in demand for PVC pipes has led to the establishment of numerous factories in Bawana. Several factors contribute to this industrial growth:

Cost-effectiveness: PVC pipe production is more affordable compared to metal pipes, reducing overall project costs.

Durability: PVC pipes have a long lifespan, resisting rust, corrosion, and chemical reactions.

Ease of Manufacturing: Modern extrusion and molding techniques have simplified the production process.

Eco-friendliness: Many PVC pipe factories focus on sustainable practices and recycling methods.

Why Bawana is the Ideal Location for PVC Pipe Factories

Bawana Industrial Area has evolved into a prime manufacturing location for PVC pipes due to several factors:

1. Availability of Raw Materials

Factories in Bawana benefit from a steady supply of high-quality polyvinyl chloride resins, additives, and stabilizers, which are essential for pipe production.

2. Well-Established Industrial Infrastructure

Bawana’s industrial ecosystem supports PVC pipe manufacturing through access to mold makers, extrusion machine suppliers, and testing facilities.

3. Skilled Workforce

Bawana has a large pool of skilled workers experienced in plastic manufacturing, ensuring the production of top-quality PVC pipes that meet industry standards.

4. Strategic Location and Market Reach

Bawana’s proximity to major cities like Delhi, Haryana, and Uttar Pradesh allows factories to efficiently distribute products, reducing logistics costs and delivery times.

5. Government Support and Incentives

The Delhi government provides various subsidies, tax benefits, and infrastructure improvements, making Bawana an attractive destination for PVC pipe manufacturing units.

Production Process in PVC Pipe Factories

PVC pipe factories in Bawana follow a systematic production process to ensure high-quality output. The key steps include:

Raw Material Preparation: Polyvinyl chloride resin is mixed with additives to enhance durability and flexibility.

Extrusion Process: The mixture is heated and passed through an extrusion machine to form pipe shapes.

Cooling and Sizing: The pipes are cooled using water or air to maintain proper dimensions and strength.

Cutting and Testing: Pipes are cut to required lengths and undergo quality testing for durability and performance.

Packaging and Distribution: Final products are packed and transported to suppliers and customers.

Types of PVC Pipes Manufactured in Bawana Factories

Factories in Bawana produce a wide variety of PVC pipes, including:

Rigid PVC Pipes: Used for plumbing, drainage, and irrigation.

Flexible PVC Pipes: Common in electrical conduit systems and gardening applications.

UPVC Pipes (Unplasticized PVC): Ideal for drinking water supply and sewer systems.

CPVC Pipes (Chlorinated PVC): Suitable for hot and cold water applications.

SWR Pipes (Soil, Waste, and Rainwater Pipes): Used in drainage and waste management systems.

Leading PVC Pipe Factories in Bawana

Bawana houses several well-known PVC pipe factories that adhere to international quality standards such as ISO, BIS, and ASTM. These manufacturers focus on innovation, ensuring their products meet diverse industrial needs efficiently.

How to Choose the Right PVC Pipe Factory in Bawana

If you’re looking for a PVC pipe factory in Bawana, consider the following:

Quality Certifications: Ensure the factory complies with industry regulations and certifications.

Product Range: Opt for a manufacturer that produces various types of PVC pipes to suit your needs.

Reputation and Experience: Select a factory with a strong track record of reliability and customer satisfaction.

Customer Reviews: Check testimonials and feedback to gauge product quality.

Pricing and Availability: Compare costs and confirm the factory can meet your demand efficiently.

Future of PVC Pipe Factories in Bawana

The future of PVC pipe factories in Bawana looks promising, with increasing infrastructure projects, urbanization, and government initiatives promoting sustainable construction. Technological advancements in production processes will further enhance quality and efficiency, making Bawana a key hub for PVC pipe manufacturing in India.

Conclusion

Bawana has positioned itself as a leading manufacturing hub for PVC pipes, offering high-quality and cost-effective products. With a strong industrial ecosystem, skilled workforce, and market reach, PVC pipe factories in Bawana continue to play a crucial role in India’s infrastructure development. Whether you are a contractor, builder, or industrial buyer, sourcing from Bawana ensures reliability and quality at competitive prices. As the industry grows, Bawana is set to become an even more vital center for PVC pipe production.

#pvcpipesfactoryinbawana#pvcpipesinbawana#pvcpipesmanufacturers#pvcpipesmanufacturersindelhi#pvcpipesmanufacturersinnarela#cantabilbathassets

0 notes