#stainless steel chemical anchor

Video

youtube

FIXDEX & GOODFIX technical department explains new energy technology

#youtube#Wedge anchor bolts#threaded rods#din975#self drilling screws#chemical anchor#drop in anchor#foundation bolt#hex nut#flat washer#hex bolt#Photovoltaic Bracket#angle brackets#Stainless steel bracket#Bracket Clamp

3 notes

·

View notes

Text

Connecting the dots the essential role of industrial cable gland connectors

Introduction

Industrial Cable Gland Connectors are vital components in electrical and mechanical systems, designed to securely fasten, seal, and protect cables as they enter electrical enclosures or machinery. These connectors are widely used across a variety of industries, including manufacturing, oil and gas, telecommunications, automation, and construction, where they provide critical protection for cables in harsh environments.

In this blog post, we’ll explore the purpose, types, and benefits of industrial cable gland connectors and why they are essential to the safety and performance of electrical systems.

What Are Industrial Cable Gland Connectors?

Industrial cable gland connectors are mechanical devices that attach and secure electrical cables to equipment, junction boxes, and panels. They provide strain relief to prevent damage to cables, while also protecting against environmental factors such as dust, moisture, and chemicals. Cable glands are typically made from materials like brass, stainless steel, nylon, or plastic, depending on the specific application and environment.

Key Functions of Industrial Cable Gland Connectors

Strain Relief

One of the primary functions of cable gland connectors is to provide strain relief, preventing cables from being pulled out of place or damaged due to mechanical stress, tension, or vibrations. This is critical in industrial settings where machinery and equipment are constantly in motion.

Environmental Protection

Industrial cable glands create a seal that protects cables from environmental factors such as water, dust, and chemicals. This ensures that electrical systems remain safe and operational, even in harsh or hazardous conditions. In industries like oil and gas or mining, this protection is essential for maintaining the integrity of electrical systems.

Cable Sealing

Cable glands provide a watertight and airtight seal around the cable entry points, preventing moisture and contaminants from entering electrical enclosures. This feature is crucial for preventing short circuits, equipment failure, and safety hazards.

Electrical Safety

By securely anchoring and sealing cables, industrial cable glands contribute to the overall safety of electrical systems, reducing the risk of fire, electric shock, and equipment malfunctions.

Types of Industrial Cable Gland Connectors

Single Compression Cable Glands

These are commonly used for general-purpose industrial applications. They provide effective sealing for standard cables but are typically used in less harsh environments.

Double Compression Cable Glands

Designed for more demanding applications, double compression cable glands offer enhanced protection against dust, moisture, and extreme temperatures. They are often used in hazardous areas, such as oil rigs and chemical plants.

EMC Cable Glands

These cable glands are designed to prevent electromagnetic interference (EMI), making them ideal for sensitive electrical and communication systems where signal integrity is crucial.

Explosion-Proof Cable Glands

Explosion-proof or flameproof cable glands are used in hazardous environments where flammable gases, vapors, or dust are present. These glands prevent sparks or flames from traveling through the cable entry points, ensuring safety in areas prone to explosions.

Benefits of Using Industrial Cable Gland Connectors

Improved System Longevity

By protecting cables from environmental damage and strain, cable glands help extend the life of electrical systems and reduce the need for maintenance or replacements.

Enhanced Safety

Cable glands reduce the risk of accidents, electrical failures, and fires by providing secure connections and protecting cables from external hazards.

Cost-Effective

Investing in high-quality cable glands helps reduce downtime and maintenance costs by protecting electrical systems from damage and wear.

Choosing the Right Cable Gland Connectors for Your Application

When selecting industrial cable gland connectors, consider factors such as the type of cable, environmental conditions, material requirements, and safety regulations. For hazardous environments, it's essential to choose cable glands that are certified for explosion-proof or flameproof applications. Additionally, ensure that the gland material—whether brass, stainless steel, or plastic—matches the demands of the environment to prevent corrosion or degradation over time.

Conclusion

Industrial cable gland connectors are indispensable components in maintaining the safety, efficiency, and longevity of electrical systems in demanding environments. Whether you are working in manufacturing, oil and gas, or construction, the right cable gland ensures that your electrical systems remain protected and perform optimally under challenging conditions. Choosing the right type of cable gland for your specific application is a critical step in ensuring the safety and reliability of your entire setup.

0 notes

Text

Enhancing Hose Safety with Whipcheks: A Comprehensive Overview

Introduction: In industries where high-pressure hoses are prevalent, ensuring safety during operations is paramount. Whipcheks emerge as crucial safety devices designed to prevent hose whip accidents and protect personnel and equipment from potential hazards. In this blog post, we'll explore the importance of whipcheks, their functionality, and their role in promoting workplace safety.

Understanding Whipcheks: Whipcheks, also known as hose whip restraints, are specialized safety devices designed to prevent hose whip by securely anchoring high-pressure hoses to fixed points. These devices consist of strong steel cables encased in a flexible nylon sleeve, providing robust reinforcement and protection against hose failure.

Functionality: Whipcheks function by securely anchoring the hose to a fixed object, such as a hose fitting or pipe, using a stainless-steel loop and a high-strength nylon strap. In the event of a hose failure or separation, the whipchek prevents the hose from flailing uncontrollably, minimizing the risk of injury or property damage.

Key Features and Benefits:

Enhanced Safety: Whipcheks provide an additional layer of safety by preventing hose whip accidents and minimizing the risk of injury to personnel and equipment.

Durability: Constructed from high-quality materials, including stainless steel cables and rugged nylon sleeves, whipcheks offer exceptional strength and durability.

Easy Installation: Whipcheks are easy to install and can be quickly attached to hose assemblies using simple tools, ensuring minimal downtime during installation.

Versatility: Available in various sizes and configurations, whipcheks can accommodate different hose diameters and applications, making them suitable for a wide range of industries and environments.

Compliance: Utilizing whipcheks demonstrates a commitment to workplace safety and regulatory compliance, helping organizations meet industry standards and requirements.

Applications: Whipcheks find application in industries such as construction, mining, oil and gas, manufacturing, and agriculture, where high-pressure hoses are used in hydraulic systems, pneumatic systems, water blasting operations, and chemical transfer processes.

Conclusion: Whipcheks are essential safety devices that play a crucial role in preventing hose whip accidents and safeguarding personnel and equipment in high-pressure hose applications. By investing in quality whipcheks and incorporating them into safety protocols, organizations can create safer work environments and mitigate the risks associated with hose failure. Prioritizing hose safety not only protects personnel and equipment but also enhances operational efficiency and regulatory compliance.

0 notes

Text

From Factories to Frontlines: Exploring India's Premier Bolt Manufacturers

Introduction

The overlooked leaders of industrial applications are bolts, holding together everything from massive structures to tiny gadgets. In India, the bolt manufacturing industry has grown significantly, providing high-quality products for both domestic and international markets. This article delves into the intricacies of bolt manufacturing in India, highlighting its history, types, materials, top manufacturers, and future prospects.

History of Bolt Manufacturing in India

The journey of bolt manufacturing in India began in the early 20th century with small-scale operations. Over the decades, the industry evolved, driven by increasing industrialization and technological advancements. Today, India is a prominent player in the global bolt manufacturing sector.

Types of Bolts Manufactured in India

Indian manufacturers produce a wide range of bolts to meet diverse industrial needs. Here are some of the key types:

Hex Bolts: Known for their hexagonal heads, these bolts are commonly used in construction and machinery.

Carriage Bolts: Featuring a rounded head and square neck, these bolts are used in wood and metal applications.

Anchor Bolts: Essential for securing structures to concrete, these bolts are crucial in construction.

Eye Bolts: With a looped end, these bolts are used for lifting and securing cables.

Other Specialized Bolts: Customized bolts for specific applications in various industries.

Key Materials Used in Bolt Manufacturing

The choice of material is crucial for bolt performance. Indian manufacturers use a variety of materials:

Stainless Steel: Known for its corrosion resistance and strength.

Carbon Steel: Commonly used due to its affordability and versatility.

Alloy Steel: Offers enhanced mechanical properties for high-stress applications.

Non-Ferrous Metals: Used for specialized bolts requiring unique properties.

Manufacturing Process of Bolts

Bolt manufacturing is a meticulous process involving several stages:

Raw Material Selection: High-quality materials are chosen based on the bolt's intended use.

Forging and Shaping: The material is heated and forged into the desired shape.

Heat Treatment: Bolts undergo heat treatment to enhance strength and durability.

Threading: Threads are cut or rolled onto the bolt shaft.

Finishing: The bolts are coated or plated for protection against corrosion.

Quality Standards and Certifications

Ensuring quality is paramount in bolt manufacturing. Indian manufacturers adhere to various standards:

ISO Certifications: International standards ensuring consistent quality.

ISI Mark: Indian standard mark for product quality.

International Quality Standards: Compliance with global benchmarks.

Superior High-Quality Bolt Manufacturer In India

One of the largest bolt manufacturer in India is Bhansali Fasteners. Bolts are an excellent choice for fluid transfer in a variety of sectors, including construction, culinary, chemical, oil and gas, and pharmaceuticals. They also provide sustainability advantages and cheap maintenance. They offer dependability and security.

We provide low-cost, high-quality bolts that promote efficient and successful work. Our bolts meet numerous standards, including ASTM, ASME, ANSI, UNS, and DIN. Our collection, which includes various sizes, thicknesses, bars, and grades, meets a wide variety of demands. In addition, we are one of leading screw manufacturer in India.

Bhansali Fasteners is one of the leading Bolt Manufacturers in India. Bolts are polished to the specifications provided by the customer, including wall thickness and size. For more demanding applications, heat treatment is also available. At the lowest possible price, we manufacture, provide, and stock a wide variety of bolts in all sizes. Check the bolt weight chart as well.

We are also a Bolt Manufacturers in UAE, Bolt Manufacturer in Bangladesh.

The bolt manufacturing industry in India is a dynamic and growing sector, contributing significantly to various industrial applications. With advancements in technology, government support, and a focus on quality and sustainability, Indian bolt manufacturers are well-positioned for future success.

For More Detail

Website: bhansalibolt.com

Product: SS Bolt Manufacturer

Other Product: Fasteners Manufacturers In Saudi Arabia.

#Bolt Manufacturers In India#Bolt Manufacturers#SS Bolt Manufacturer#Bolt Suppliers#Fasteners Manufacturers In Saudi Arabia

0 notes

Text

The Essential Guide to Bolts: Types, Uses, and Selection Tips

Jinnox Bolt is a leading Bolt Manufacturer in India, known for quality, innovation, and customer satisfaction. Since it started, we have been catering top-quality fasteners to industries such as automobile, construction, aerospace etc. Bolts are a fundamental component in construction and manufacturing, serving as the backbone for various structures and machinery. Understanding the different types of bolts, their applications, and how to select the right one is crucial for ensuring the stability and safety of any project. In this article, we'll explore the world of bolts in detail, providing you with the knowledge needed to make informed decisions.

Introduction to Bolts

Bolts are threaded fasteners that are typically used in conjunction with nuts to hold objects together. They come in various shapes, sizes, and materials, each designed for specific applications. Unlike screws, bolts are not self-tapping and require a nut or a pre-tapped hole for installation.

Types of Bolts

Hex Bolts

Hex bolts are one of the most common types, characterized by their hexagonal heads. They are used in various applications, from construction to machinery, due to their strong grip and ease of installation.

Carriage Bolts

Carriage bolts have a round head with a square neck that prevents the bolt from turning when the nut is tightened. They are often used in wood connections and applications where a smooth, finished appearance is desired.

Eye Bolts

Eye bolts have a looped head and are used for attaching ropes, chains, or cables. They are commonly used in lifting and rigging applications.

Anchor Bolts

Anchor bolts are designed to attach structures to concrete. They come in various designs, including L-shaped, J-shaped, and wedge anchors, each serving specific purposes.

Materials Used in Bolts

Bolts are made from a variety of materials, each offering different levels of strength, corrosion resistance, and suitability for specific environments.

Steel Bolts

Steel bolts are the most common and come in different grades, such as low-carbon steel, medium-carbon steel, and alloy steel. They are known for their strength and versatility.

Stainless Steel Bolts

Stainless steel bolts offer excellent corrosion resistance, making them ideal for use in environments exposed to moisture and chemicals.

Brass Bolts

Brass bolts are known for their resistance to corrosion and electrical conductivity. They are often used in plumbing and electrical applications.

Titanium Bolts

Titanium bolts are lightweight and highly resistant to corrosion, making them suitable for aerospace and marine applications.

How to Select the Right Bolt

Choosing the right bolt for your application involves considering several factors:

Load Requirements

Determine the load that the bolt will need to support. This includes both static and dynamic loads.

Environmental Conditions

Consider the environment in which the bolt will be used. Corrosive environments require bolts made from materials like stainless steel or titanium.

Bolt Size and Length

Select the appropriate bolt size and length to ensure a secure fit. This involves measuring the thickness of the materials being joined.

Thread Type

Choose the right thread type for your application. Coarse threads are suitable for quick assembly, while fine threads offer better-holding power.

Common Applications of Bolts

Bolts are used in a wide range of applications across various industries:

Construction

Bolts are essential in construction for joining structural elements, securing beams, and assembling scaffolding.

Automotive

In the automotive industry, bolts are used to assemble engines, transmissions, and other critical components.

Machinery

Bolts are used in machinery to hold parts together, ensuring the smooth operation of equipment.

Furniture

In furniture making, bolts provide strong and durable connections, especially in flat-pack furniture.

Countries Where We Supply Our Bolts:

Bolt Manufacturers in UK

Bolt Manufacturers in Australia

Bolt Manufacturers in South Africa

Bolt Manufacturers in USA

Bolt Manufacturer in UAE

Bolt Manufacturer in Kenya

Bolt Manufacturer in Qatar

Jinnox Bolt is a top Bolt Manufacturers in India. We focus on providing the most premium Bolts that are made with the help of the latest technology and the best quality Bolt materials. Our Fasteners are used in diverse industries across the board ranging from petroleum, transportation and construction.

For more details:

Product: Bolt Supplier in India

Website: jinnoxbolt.com

0 notes

Text

Ananka

1: Introduction to Eye Bolt Fasteners Manufacturing

Introduction

Eye bolt fasteners are versatile components used across various industries, including construction, maritime, and manufacturing. They provide a secure attachment point for lifting, rigging, and anchoring applications. This series will delve into the manufacturing process of eye bolt fasteners, exploring each stage from material selection to quality control.

Overview of the Manufacturing Process

The manufacturing process for eye bolt fasteners includes several critical steps:

1. Material Selection

2. Forming the Shank and Eye

3. Threading

4. Heat Treatment

5. Surface Finishing

6. Quality Control

Each of these steps is vital in ensuring the final product meets the required standards for strength, durability, and performance.

Conclusion

Understanding the manufacturing process of eye bolt fasteners is essential for appreciating the complexity and precision involved in creating these crucial components. Each step contributes to the overall quality and functionality of the fasteners. The next will focus on the first stage: material selection.

Eye bolt fasteners manufacturer in india

2: Material Selection for Eye Bolt Fasteners

Introduction

Material selection is a critical step in manufacturing eye bolt fasteners, as the chosen material directly impacts the fastener's performance, durability, and suitability for various applications. This explores the importance of selecting the right materials and the common materials used in manufacturing eye bolts.

Material Properties

Eye bolts are typically made from materials that offer high tensile strength, excellent corrosion resistance, and good fatigue resistance. The most commonly used materials include:

- Carbon Steel: Known for its strength and affordability, carbon steel is often used for eye bolts intended for general-purpose applications.

- Stainless Steel: Valued for its superior corrosion resistance, stainless steel is ideal for environments exposed to moisture, chemicals, or extreme temperatures. Grades 304 and 316 are commonly used.

- Alloys: Specialized alloys, such as titanium or aluminum, may be used for specific applications requiring unique properties like high strength-to-weight ratios or resistance to particular environmental factors.

Conclusion

Choosing the right material is fundamental in eye bolt fastener manufacturing. The selected material must meet the specific requirements of the intended application to ensure the fastener's reliability and longevity. The next will delve into the forming process, where the raw material is shaped into the basic form of the eye bolt.

Eye bolt supplier

3: Forming the Shank and Eye of Eye Bolt Fasteners

Introduction

Forming is a pivotal stage in the manufacturing of eye bolt fasteners, where the raw material is shaped into the basic form of the fastener. This explores the forging and machining processes used to create eye bolts and explains their importance in achieving the desired strength and precision.

Forging Process

Forging is a common method for forming the shank and eye of eye bolts. It involves heating the material and then shaping it under high pressure. This process enhances the metal's grain structure, resulting in stronger and more durable fasteners.

Steps in Forging:

1. Heating: The raw material is heated to a high temperature to make it malleable.

2. Forming: The heated material is placed in a die and subjected to high-pressure deformation to create the shank and eye shape.

3. Cooling: The formed fasteners are cooled at a controlled rate to maintain their mechanical properties.

Machining Process

For applications requiring high precision, machining is used to form the shank and eye. This method involves cutting away excess material using various tools and techniques to achieve the desired shape and dimensions.

CNC Machining

Computer Numerical Control (CNC) machining is often employed for its precision and consistency. It allows for complex shapes and tight tolerances, ensuring that each eye bolt meets exact specifications.

Conclusion

The forming process is crucial in manufacturing eye bolt fasteners, as it sets the foundation for the fastener's strength and durability. Forging and machining, combined with precise control of temperature and pressure, contribute to creating high-quality fasteners. The next will explore the threading process, which ensures the fasteners' compatibility with nuts and other components.

Eye bolt manufacturer in Mumbai

4: Threading Eye Bolt Fasteners

Introduction

Threading is a vital step in eye bolt fasteners manufacturing, where the fasteners are machined to create the screw threads. This explores the various threading methods and their importance in ensuring high precision and compatibility with nuts and other fasteners.

Thread Rolling

Thread rolling is a popular method for creating threads on eye bolts. It involves pressing the fastener shank between two dies to form the threads through a cold-forming process. Thread rolling displaces material rather than cutting it, resulting in stronger threads with improved fatigue resistance.

Thread Cutting

Thread cutting involves removing material from the fastener shank to create the threads. This can be done using taps or thread-cutting machines. While this method is suitable for producing precise threads, it is less common for eye bolts due to the higher material waste and potential for reduced thread strength.

Quality Control

Ensuring the threads meet exact specifications is crucial for the fastener's performance and compatibility. This involves inspecting the thread pitch, diameter, and profile using precision measuring tools. Any deviations can result in poor fit and compromised joint integrity.

Thread Lubrication

During the threading process, lubrication is often applied to reduce friction and heat, ensuring a smooth and precise operation. This also helps extend the life of the threading dies and cutting tools.

Conclusion

Threading is a critical part of eye bolt fasteners manufacturing, ensuring the fasteners can securely fasten components together. Thread rolling and cutting are two common methods, each with its advantages. Ensuring high precision and quality control during threading is essential for producing reliable fasteners. The next will discuss the heat treatment process, which enhances the fasteners' mechanical properties.

Eye bolt fasteners

5: Heat Treatment for Eye Bolt Fasteners

Introduction

Heat treatment is a crucial step in eye bolt fasteners manufacturing that enhances the mechanical properties of the fasteners, such as hardness, strength, and resistance to wear. This explores the heat treatment process, its various stages, and its importance in producing high-quality fasteners.

Purpose of Heat Treatment

Heat treatment involves heating and cooling the fasteners to alter their physical and mechanical properties. The primary goals are to increase hardness, improve strength, and enhance resistance to wear and fatigue.

Stages of Heat Treatment

The heat treatment process typically involves three stages: annealing, quenching, and tempering.

Annealing

Annealing involves heating the fasteners to a high temperature and then cooling them slowly. This process softens the material, making it more workable and relieving internal stresses.

Quenching

After annealing, the fasteners are rapidly cooled, or quenched, to lock the microstructure in place. This process increases the hardness and strength of the fasteners but can also make them brittle, so it is often followed by tempering.

Tempering

Tempering involves reheating the fasteners to a lower temperature and then cooling them slowly. This process reduces brittleness while maintaining the increased hardness and strength from quenching, resulting in a balanced combination of strength and toughness.

Conclusion

Heat treatment is essential for producing eye bolt fasteners with the desired mechanical properties. The annealing, quenching, and tempering stages work together to enhance the fastener's hardness, strength, and durability. The next will focus on surface finishing, the final step in the manufacturing process.

Eye bolt stockist

6: Surface Finishing for Eye Bolt Fasteners

Introduction

Surface finishing is the final step in eye bolt fasteners manufacturing, providing additional protection against corrosion and improving the fastener's appearance. This examines the various surface finishing techniques used to produce high-quality eye bolts.

Purpose of Surface Finishing

Surface finishing enhances the fastener's resistance to environmental factors, such as moisture, chemicals, and heat. It also improves the fastener's aesthetic appeal and can provide additional functional benefits, such as reduced friction.

Common Surface Finishing Techniques

Several surface finishing techniques are used for eye bolt fasteners, each offering unique benefits:

Passivation

Passivation involves treating the surface of the fasteners with a mild acid solution to remove contaminants and enhance the formation of a protective oxide layer. This process improves the fastener's corrosion resistance.

Electropolishing

Electropolishing is an electrochemical process that removes a thin layer of material from the fastener's surface, producing a smooth, shiny finish. It also enhances corrosion resistance by eliminating surface imperfections.

Coating

Various coatings can be applied to eye bolt fasteners, including zinc plating, nickel plating, and other protective coatings. These coatings provide an additional barrier against corrosion and wear.

Quality Control

After surface finishing, the fasteners undergo rigorous quality control checks to ensure they meet the required specifications. This includes visual inspections, thickness measurements of coatings, and corrosion resistance tests.

Conclusion

Surface finishing is a crucial step in the manufacturing of eye bolt fasteners, enhancing their corrosion resistance and appearance. Techniques such as passivation, electropolishing, and coating are commonly used to achieve the desired surface properties. Ensuring high-quality surface finishing is essential for producing durable and reliable fasteners. This concludes our series on the manufacturing process of eye bolt fasteners, providing a comprehensive overview of each step involved in creating these vital components.

Eye bolt Exporter

0 notes

Text

Key Advice for Choosing the Right Bolt Fasteners for Your Project | Akbarali Enterprises

Akbarali Enterprises, a leading bolt manufacturer in India, provides experienced advice on how to choose the right bolts for your needs. Choosing the appropriate bolt fasteners for your project is critical to ensuring the structural integrity and endurance of your structure. Bolts are essential components in a variety of applications, including machinery, automobiles, structures, and bridges. Choosing the right type and quality will help you avoid potential failures and pricey repairs.

Understand the Types of Bolts

The first step in selecting the proper bolt is to understand the many varieties available. Common types include:

Hex Bolts: They are known for their six-sided heads and are employed in a variety of applications due to their adaptability and strength.

Carriage Bolts: These have a rounded head and a square neck and are typically used for wood connections.

Lag Bolts: Also called as lag screws, these are great for anchoring heavy wood or metal.

Machine Bolts: Used in precision applications that demand exceptional strength and durability.

Anchor Bolts: Designed to attach structural elements to concrete.

Each type has a distinct function, and understanding their applications will help you make an informed decision.

Consider the Material

Bolts are made of a variety of materials, each with its own set of qualities.

Steel Bolts: The most common material, offering a good balance of strength and affordability.

Stainless Steel Bolts: These provide excellent corrosion resistance, making them ideal for outdoor and marine applications.

Brass Bolts: Known for their corrosion resistance and aesthetic appeal, often used in electrical and decorative applications.

Titanium Bolts: Lightweight and strong, suitable for high-stress environments.

Choosing the proper material is determined by the ambient conditions and your project's specific requirements.

Evaluate the Strength

Bolts are graded according to their strength, which is critical for assuring the safety and dependability of your project. The grading system differs by country; nevertheless, common grades include:

Grade 2: Low or medium-carbon steel is ideal for non-critical applications.

Grade 5: Medium carbon steel, quenched and tempered, provides greater strength.

Grade 8: High carbon alloy steel quenched and tempered for maximum strength.

It's essential to match the bolt strength to the demands of your project to avoid failures.

Check the Bolt Manufacturer's Certification

When sourcing bolts, it is critical to select a trustworthy bolt manufacturer. Akbarali Enterprises, India's leading bolt manufacturer, ensures high-quality goods through rigorous quality control and testing. Check that the producer follows industry standards and certifications to ensure you receive dependable and long-lasting fasteners.

Check for Proper Coatings

Coatings can greatly improve the performance and longevity of bolts. Common coatings include:

Zinc Plating: Offers basic corrosion resistance and is cost-effective.

Hot-Dip Galvanizing: Provides superior corrosion resistance, ideal for outdoor applications.

Black Oxide: Enhances appearance and provides mild corrosion resistance.

Consider the Application Environment

The environment in which the bolts will be used plays a significant role in your selection process. Factors to consider include:

Exposure to Moisture: Requires corrosion-resistant materials and coatings.

Temperature Extremes: Needs bolts that can withstand thermal expansion and contraction.

Chemical Exposure: Necessitates materials resistant to specific chemicals.

Understanding the environmental conditions ensures you choose bolts that will perform reliably over time.

Consult with Experts

Finally, speaking with professionals can provide helpful insights and ideas based on your project's specific requirements. Akbarali Enterprises, a prominent bolts supplier in India, provides expert advice to help you pick the best decision for your application.

Conclusion

Choosing the right bolt fasteners is a critical aspect of any project, impacting both safety and longevity. By understanding the types, materials, strengths, threads, and coatings, and by consulting with reputable bolts suppliers like Akbarali Enterprises, you can ensure your project's success. As a leading bolt manufacturer and supplier in India, Akbarali Enterprises is committed to providing high-quality, reliable fasteners for a wide range of applications.

Website: akbarfasteners.com

0 notes

Text

The Role of Fasteners in Construction

Fasteners are the unsung heroes of the construction industry, playing a crucial role in the integrity, safety, and longevity of buildings and structures. Ananka Group is the Prominent Fasteners Manufacturers in India. We supply high-quality fasteners to a wide range of businesses globally. Fasteners come in many sizes, shapes, and dimensions. Many things can be linked or fastened using fasteners. They are vital parts of many sectors, such as building, manufacturing, transportation, and household goods. We are the best Fasteners Manufacturer.

Types of Fasteners Used in Construction

Fasteners come in various shapes, sizes, and materials, each designed to meet specific requirements. The most common types of fasteners used in construction include:

Nails: Typically used in wood construction, nails are hammered into materials to hold them together. They come in various lengths and thicknesses, designed for different applications.

Screws: Offering more holding power than nails, screws are used in both wood and metal construction. They provide a tighter fit and are easier to remove and replace.

Bolts and Nuts: Essential for heavy-duty applications, bolts and nuts provide a strong, reliable connection. They are commonly used in steel construction and for securing heavy components.

Anchors: Used to attach objects to concrete or masonry, anchors come in several types, including wedge anchors, sleeve anchors, and drop-in anchors.

Washers: Often used in conjunction with bolts and screws, washers distribute the load of the fastener, preventing damage to the material and ensuring a secure fit.

Applications of Fasteners in Construction

Fasteners are used in nearly every aspect of construction, from framing and roofing to finishing and furnishing. Some key applications include:

Framing: Nails and screws are extensively used in framing walls, floors, and roofs. The choice between nails and screws depends on the specific requirements of the structure and the materials being used.

Structural Connections: Bolts and nuts are critical in connecting steel beams and columns, ensuring the structural integrity of the building. These fasteners must be chosen based on their strength and durability to withstand loads and stresses.

Drywall Installation: Screws are the preferred fasteners for attaching drywall to wooden or metal studs. They provide a secure hold and are less likely to pop out over time compared to nails.

Concrete and Masonry: Anchors are used to secure fixtures and fittings to concrete and masonry surfaces. They must be selected based on the type of load they will bear and the material they will be embedded in.

Importance of Choosing the Right Fasteners

Selecting the appropriate fasteners for a construction project is crucial for several reasons:

Structural Integrity: The wrong fastener can compromise the strength and stability of a structure. For example, using nails instead of screws in certain applications may result in a weaker connection that can fail under stress.

Durability: Fasteners must be able to withstand environmental conditions such as moisture, temperature changes, and exposure to chemicals. Corrosion-resistant materials like stainless steel or galvanized fasteners are essential for outdoor or humid environments.

Safety: Using the correct fasteners ensures the safety of the structure and its occupants. Inadequate or improper fastening can lead to structural failures, causing accidents and injuries.

Efficiency: The right fasteners can simplify the construction process, making it faster and more efficient. For instance, self-tapping screws reduce the need for pre-drilling, saving time and effort.

Best Practices for Fastener Selection and Installation

To ensure the optimal performance of fasteners in construction, it is essential to follow best practices in selection and installation:

Consult Standards and Guidelines: Refer to building codes and industry standards to determine the appropriate fasteners for specific applications.

Consider Material Compatibility: Choose fasteners that are compatible with the materials being joined to prevent galvanic corrosion and other issues.

Use Proper Tools: Ensure that the right tools are used for installing fasteners to achieve a secure and accurate fit.

Inspect and Maintain: Regularly inspect fasteners for signs of wear or damage and replace them as needed to maintain the integrity of the structure.

We now provide our excellent fasteners and rapid shipping to all major Indian cities. We are the most reliable Stainless Steel Fasteners Manufacturer in India. We provide our clients with the greatest prices available on global stainless steel fasteners. These are also used for delicate applications in harsh settings.

0 notes

Text

Ball Valve in Gujarat

Meghmani Metal Industries is a Manufaturer and Supplier of Ball Valve in Gujarat, India.

Established in 2011, Meghmani Metal Industries has consistently prioritized customer satisfaction and environmental responsibility in every aspect of its operations.

We provide a wide range of stainless steel products such as plates, coils, bars, pipes, tubes, flanges, valves, fittings, fasteners, channels, and flats, meticulously crafted to fulfill diverse industrial requirements.

A Ball Valve is a fundamental component in fluid control systems, prized for its efficiency and reliability. This valve uses a spherical closure element to regulate the flow of liquids or gases through a pipeline.

Ball valves consist of a hollow, perforated sphere (the ball) that pivots to control the flow through it. When the valve handle aligns with the pipe.

Floating Ball Valve floats downstream for tight sealing at low pressure. Mechanical anchoring secures the Trunnion Ball Valve for high-pressure applications. Three-way Valve diverts or mixes flows.

Ball valves offer fast, quarter-turn operation, making them ideal for applications requiring rapid shut-off. Their robust construction and choice of materials ensure longevity and reliability in demanding environments.

Our ball valve is available in a wide range of sizes and materials, ball valves are suitable for various industries, from residential plumbing to industrial applications.

Ball valves are used in residential plumbing, industrial settings for gases and liquids, oil and gas pipelines, and chemical industries for corrosive materials.

Meghmani Metal Industries is a Manufaturer and Supplier of Ball Valve in Gujarat and places like Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Junagadh, Gandhinagar, Nadiad, Anand, Morbi, Surendranagar, Bharuch, Vapi, Navsari, Veraval, Porbandar, Godhra, Bhuj, Ankleshwar.

Please feel free to contact us with any questions or for additional information.

Read the full article

0 notes

Text

A Complete Guide to Carbon Fibre Solutions Concrete for Strengthening

With its carbon fibre concrete strengthening, remarkable chemical resistance, extensive temperature tolerance, and minimal thermal expansion, carbon fibre provides great adaptability. Studies on the subject of service life indicate that carbon fibre-reinforced polymers are more promising than agamid and glass fibres due to their high temperature tolerance, low thermal expansion, and corrosion resistance.

The Industrial concreting in Melbourne has an unlimited number of uses since it can be shaped into infinite forms and sizes and created at different densities. It may be formed into a variety of composite parts and components and is frequently moulded into tubes, cloth, and fabric. Due to these features, carbon fibre is becoming a more well-liked and popular substitute for aluminium and stainless steel in the avionics, automotive and construction sectors.

Constructing the Land Below the Local Influence

Not only is concrete a worldwide phenomenon, but it also plays a major role in forming Australia's infrastructure. Imagine packing over to get a sense of this! Due of its rapid hardening period, it must be made close to the location of application. Additionally, the gravel and sand that go into its makeup are usually obtained locally. This supports local jobs and initiatives, in addition to minimising transportation expenses.

Numerous qualities characterise concrete, including strength, resilience, pliability, energy economy, and affordability. Due of these characteristics, it is the preferred material for a wide range of constructions, including large bridges, hospitals, and stores. The possibilities for architecture and infrastructure are endless when working with concrete.

Concrete Structures That Strengthen the Fibres

Requirements for strengthening include structures that have undergone usage changes, are experiencing deterioration, or have construction or design flaws. Carbon fibre components are also becoming more common for externally reinforcing concrete buildings. They might serve as the columns' exterior reinforcement. This strengthening method lessens the requirement for further installation and anchoring work, which may be an expensive and time-consuming task.

This removes the requirement to tear down and rebuild existing constructions, including suspended slabs, structural columns, and concrete beams. When a building has to support heavier loads or when the design is inadequate, this kind of structural reinforcement is incredibly economical.

Source

0 notes

Video

youtube

FIXDEX GOODFIX industrial cologne exhibition in germany

#youtube#Cologne Germany#FASTENER EXPO 2024#FIXDEX GOODFIX#Wedge Anchor Fastener#M8 Threaded Rod#M12 Threaded Rod#Chemical Bolt M16#Toggle Bolts#M16 Drop In Anchor#U Foundation Bolt#Spring U Bolts#square nuts#din 928#slotted steel#c channel#slotted c channel#concrete fixings#stainless steel concrete screws#concrete anchors bolts#concrete bolt

0 notes

Text

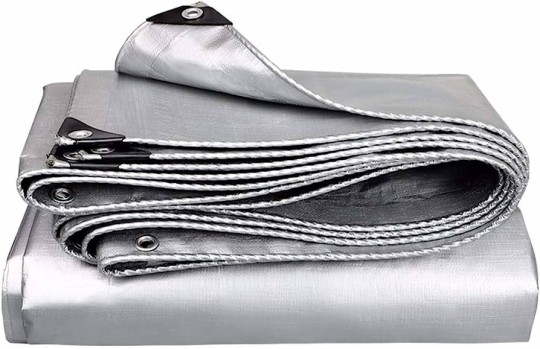

Heavy Duty Tarps: Indispensable for Protection and Durability

Heavy duty tarps are a crucial tool across various industries, known for their robustness, versatility, and ability to withstand extreme conditions. From shielding construction sites to protecting agricultural assets, these tarps are designed to provide reliable coverage and protection. The resilience and adaptability of heavy duty tarps make them an essential component in many operational settings.

Primary Uses and Applications

Tarps are employed in an array of settings due to their strength and durability. In construction, they serve multiple purposes, such as covering unfinished buildings to shield them from adverse weather, protecting construction materials from moisture, and creating temporary shelters for equipment and personnel. The use od heavy duty tarps in this industry is vital for maintaining the integrity of construction projects and ensuring work continues uninterrupted.

In agriculture, heavy duty tarps protect crops, livestock, and equipment. Farmers use these tarps to cover hay bales, silos, and machinery, preventing damage from rain, snow, and UV rays. These tarps also serve as windbreaks or ground covers to control soil erosion and weed growth. Their durability ensures that they can withstand harsh agricultural environments, providing long-term protection and cost savings.

The transportation industry relies heavily on these tarps for securing loads on trucks and trailers. Heavy duty tarps safeguard cargo from environmental elements and road debris during transit. This is especially crucial for transporting sensitive or perishable goods, where even minor exposure to moisture or contaminants can result in significant losses.

Materials and Design Features

Heavy duty tarps are typically made from materials such as polyethylene (PE), polyvinyl chloride (PVC), and canvas, each offering distinct advantages. Polyethylene tarps are popular for their lightweight, waterproof, and UV-resistant properties. They are often reinforced with a mesh fabric for added strength and tear resistance. PVC tarps are known for their superior durability and resistance to chemicals, making them ideal for industrial applications. Canvas tarps, though heavier, provide excellent breathability and abrasion resistance, suitable for covering machinery and equipment that require ventilation.

The design of heavy duty tarps includes several key features to enhance their functionality. These tarps are available in various thicknesses, commonly measured in mils (thousandths of an inch). Thicker tarps, ranging from 10 to 20 mils, offer greater strength and longevity. Reinforced edges, often double-stitched or heat-sealed, prevent fraying and add to the tarp's durability. Grommets, typically made of rust-resistant metals like brass or stainless steel, are spaced along the edges to facilitate secure tie-downs and anchoring.

Environmental and Economic Considerations

The production and use of heavy duty tarps have both positive and negative environmental impacts. On the positive side, their durability and reusability mean they can serve their purpose for extended periods, reducing the need for frequent replacements and minimizing waste. Many heavy duty tarps are also designed to be recyclable, contributing to sustainability efforts.

However, the production of materials like polyethylene and PVC involves significant energy consumption and the use of non-renewable resources. The disposal of these materials poses environmental challenges, as they can take hundreds of years to decompose. To mitigate these issues, manufacturers are increasingly focusing on developing eco-friendly tarps made from recycled materials or biodegradable alternatives.

Economically, heavy duty tarps offer substantial savings over time. Their initial cost is offset by their long lifespan and the protection they provide, reducing potential losses from damaged goods or delayed projects. The versatility of these tarps also means they can be repurposed for different tasks, adding to their value.

Industry Standards and Best Practices

When selecting tarps, it's essential to consider industry standards and best practices to ensure optimal performance and safety. One critical factor is the tarp's material and thickness, which should match the specific application requirements. For example, thicker tarps are necessary for heavy-duty applications like covering machinery or construction sites, while lighter tarps may suffice for temporary or less demanding uses.

Proper installation and maintenance are also crucial. Ensuring that tarps are securely fastened and regularly inspected for wear and tear can prevent accidents and extend their lifespan. In industrial settings, following OSHA guidelines for using tarps can help maintain workplace safety and compliance.

Historical Context and Evolution

The use of tarps dates back centuries, with early versions made from materials like canvas and animal hides. The development of synthetic materials in the 20th century, such as polyethylene and PVC, revolutionized the tarp industry by offering stronger, more durable, and versatile options. These advancements have expanded the applications of heavy duty tarps and improved their performance in various environments.

Today's heavy duty tarps are the result of continuous innovation and improvement. Manufacturers have developed new weaving techniques, coatings, and reinforcements to enhance the durability and functionality of tarps. The incorporation of UV inhibitors, fire retardants, and anti-mildew treatments has further extended the range of uses and environments where heavy duty tarps can be effectively deployed.

Case Studies and Real-World Applications

Several real-world applications highlight the critical role of heavy duty tarps. In disaster relief efforts, these tarps are used to create temporary shelters and protect supplies, providing immediate and effective solutions in crisis situations. For instance, following natural disasters like hurricanes and earthquakes, heavy duty tarps are often among the first supplies distributed to affected areas.

In the construction of large-scale infrastructure projects, heavy duty tarps are used to cover scaffolding and work areas, protecting them from weather-related delays and ensuring worker safety. These tarps also play a vital role in environmental protection projects, such as lining landfills or covering soil stockpiles to prevent erosion and contamination.

Conclusion

Heavy duty tarps are an essential tool across numerous industries, providing reliable protection and versatility. Their robust construction, availability in various materials and sizes, and design features make them suitable for a wide range of applications. While environmental concerns associated with their production and disposal remain, ongoing innovations and the development of eco-friendly alternatives offer promising solutions. As these tarps continue to evolve, they will undoubtedly maintain their status as indispensable assets for protecting and preserving valuable resources and operations worldwide.

0 notes

Text

SS304 Reaction Vessel Manufacturer: Hexamide Agro Tech Inc., Mumbai

Hexamide Agro Tech Inc., located in Mumbai, is a leading manufacturer of SS304 Reaction Vessels. With over 25 years of expertise, Hexamide Agro Tech has established itself as a pioneer in designing, engineering, and fabricating high-quality reaction vessels. Our SS304 reaction vessels are highly sought after in various industries, including pharmaceuticals, chemicals, petrochemicals, and food processing, due to their exceptional durability, corrosion resistance, and superior performance.

Product Overview

SS304 Reaction Vessels

Hexamide Agro Tech’s SS304 Reaction Vessels are meticulously engineered to handle a wide range of chemical processes. These vessels are designed for applications that demand robust construction, reliability, and efficient performance under various conditions.

Key Features and Benefits

High-Quality Material:

Constructed from premium-grade stainless steel SS304, known for its excellent corrosion resistance, durability, and ability to withstand moderate to high temperatures and pressures.

Advanced Design:

Precision-engineered designs to ensure optimal mixing, heating, and cooling. Available in various configurations, including jacketed, limpet coil, and pressure vessels, tailored to specific process requirements.

Customizable Options:

Offering bespoke solutions to meet unique client specifications, including different sizes, shapes, and additional features such as heating or cooling jackets, insulation, and sophisticated control systems.

Superior Mixing Efficiency:

Equipped with advanced agitation systems to ensure thorough and uniform mixing, preventing sedimentation and phase separation.

Ease of Operation and Maintenance:

Designed for user-friendly operation, easy cleaning, and maintenance, thus reducing downtime and operational costs.

Compliance and Safety:

Manufactured in compliance with stringent industry standards and safety regulations, ensuring safe and reliable operation in various industrial environments.

Technical Specifications

Material: High-quality stainless steel SS304

Capacity: Available in various sizes to accommodate different batch volumes

Agitator Types: Paddle, turbine, anchor, helical ribbon, and more, depending on specific mixing requirements

Pressure Ratings: Designed to handle a wide range of pressure conditions, including vacuum and moderate to high-pressure applications

Temperature Control: Optional heating or cooling jackets for precise temperature regulation

Control Systems: Advanced control systems for monitoring and adjusting process parameters

Applications

Hexamide Agro Tech’s SS304 Reaction Vessels are ideal for a variety of industrial applications, including:

Pharmaceuticals: For the synthesis of active pharmaceutical ingredients (APIs) and other chemical reactions requiring high purity and sterility.

Chemicals: For the production and processing of various chemicals, ensuring corrosion resistance and operational safety.

Petrochemicals: For processing hydrocarbons and other petrochemical products, requiring robust and reliable vessels.

Food and Beverage: For applications where hygiene and corrosion resistance are critical, such as in the preparation of sauces, syrups, and dairy products.

Cosmetics: For the mixing and reaction processes involved in the production of lotions, creams, and other personal care products.

Manufacturing Excellence

Hexamide Agro Tech’s manufacturing facility in Mumbai is equipped with advanced machinery and technology. Our team of experienced engineers and technicians is dedicated to producing SS304 reaction vessels that meet the highest standards of quality and performance. Through rigorous quality control processes and continuous improvement practices, we ensure that every vessel delivered to our clients is reliable, efficient, and durable.

Conclusion

Hexamide Agro Tech Inc. is a leading manufacturer of SS304 Reaction Vessels in Mumbai, providing high-performance solutions tailored to meet the diverse needs of various industries. By combining advanced engineering with superior materials, Hexamide Agro Tech delivers reaction vessels that ensure exceptional performance, reliability, and efficiency. Whether for pharmaceuticals, chemicals, petrochemicals, food processing, or cosmetics, Hexamide Agro Tech’s SS304 Reaction Vessels are designed to meet the most demanding operational requirements, ensuring consistent and optimal results in every application.

#limpet coil reactor#limpet reactor#jacketed reactor#reactor#reaction vessel#liquid blending tank#liquid mixing tank

0 notes

Text

Fastener Manufacturer, fastener supplier

Fasteners are vital components used to join or regular or more objects together. From simple screws and bolts to specialized rivets and anchors, fasteners are available in severa sorts and sizes, each designed for precise packages. In this blog publish, Fasteners LLP will help you discover the tremendous kinds of fasteners, their uses, and provide recommendations on a way to pick out the right one to your desires.

Types of Fasteners:

1. Screws: Screws are threaded fasteners with a helical ridge that allows them to be pushed into substances which includes wooden, metal, or plastic. They are to be had in numerous head sorts, such as flat head, spherical head, pan head, and countersunk head, each appropriate for extremely good packages.

2. Bolts: Bolts are much like screws however are usually used with a nut to lock or more elements collectively. They are to be had in one-of-a-kind lengths, diameters, and thread pitches, and are to be had in a vast sort of materials, which incorporates steel, stainless steel, and brass.

3. Nuts: Nuts are internally threaded fasteners which can be used collectively with bolts to secure gadgets together. They are available in various sorts, which includes hex nuts, lock nuts, wing nuts, and acorn nuts, every designed for particular packages and environments.

4. Washers: Washers are skinny, flat discs with a hole inside the middle which might be placed some of the top of a bolt or screw and the surface of the material being fixed. They distribute the burden and prevent damage to the material, in addition to offer an easy bearing surface for the fastener.

5. Rivets: Rivets are permanent fasteners used to enroll in or greater substances collectively. They include a cylindrical shaft with a head on one give up and are hooked up thru deforming the shaft to form a 2d head, growing a sturdy and constant connection.

Uses of Fasteners:

Fasteners by Fasteners LLP are used in an extensive sort of industries and applications, together with advent, automotive, aerospace, electronics, and manufacturing. Some not unusual uses of fasteners embody:

- Joining structural components in buildings and bridges.

- Assembling fixtures and cabinetry.

- Securing electric and plumbing furniture.

- Mounting hardware and system.

- Repairing device and device.

- Installing car components and add-ons.

- Fabricating sheet metal assemblies.

- Constructing and repairing fences, gates, and railings.

How to Choose the Right Fastener:

Choosing the right fastener on your application is based upon on numerous elements, along side:

1. Material Compatibility: Consider the material of the gadgets being joined and select fasteners made from compatible substances to save you corrosion and make certain long-time period durability.

2. Strength Requirements: Determine the load and stress necessities of the utility and pick out fasteners with the right electricity score to face up to the forces they may be subjected to.

3. Environmental Conditions: Consider the running environment, collectively with factors together with temperature, humidity, exposure to chemical substances, and corrosion, and select fasteners with appropriate coatings or substances that may withstand the ones conditions.

4. Size and Dimensions: Ensure that the dimensions, diameter, length, and thread pitch of the fastener are well suited with the substances being joined and the layout specifications of the software.

5. Head Type: Choose the first-rate head kind for the software, thinking about elements together with accessibility, look, and the want for flush or countersunk set up.

6. Installation Method: Consider the method of set up, whether or not guide or automated, and pick fasteners which are probably well suited with the installation equipment and techniques to be had.

Conclusion:

Fasteners are crucial components applied in a large form of programs to enroll in or stable devices together. By recording the special types of fasteners they make use of, and the manner to select the proper one for your wishes, you can ensure strong, steady, and reliable connections to your tasks. Whether you're building a shape, assembling fixtures, or repairing equipment, deciding on the right fastener is crucial for accomplishing maximum beneficial general overall performance and sturdiness.

0 notes

Text

Top 6 Bolts You Can Get from Bolt Suppliers - Jinnox Bolt

Jinnox Bolt is a leading Bolt Manufacturers in India, known for quality, innovation and customer satisfaction. Since it started, we have been catering top-quality fasteners to various industries such as automobile, construction, aerospace etc. We have modernized and well-equipped manufacturing facilities, with the latest equipment to manufacture high-quality bolts as per international standards.

Hex Bolts

Hex Bolt Manufacturer in India, our regular Hex Bolts are designed for optimum grip strength, making them perfect for applications that require a strong fastener. These bolts provide unrivalled dependability, ensuring that your constructions stay firmly connected even under the most difficult situations.

Description: Hexagonal heads for easy wrenching.

Uses: Common in construction, machinery, and automotive applications.

Materials: Available in stainless steel, carbon steel, and alloy steel.

Carriage Bolts

As a leading Carriage Bolt Manufacturer in India, we supply our products in the proper amount and with all personalised options to fulfil the demands of various industrial sectors. Various metals contribute to these Carriage Bolt's great strength, superb quality, and long life. We provide formable and high-strength steels, as well as weather-demanding steels.

Description: Round head with a square neck.

Uses: Ideal for wood connections, preventing bolt rotation.

Materials: Typically made from zinc-plated steel or stainless steel.

U-Bolts

U Bolt Manufacturer in India, we take great satisfaction in manufacturing high-quality U Bolt that fulfils the different demands of our clients as a top U Bolt Supplier. Our U Bolt is perfect for situations requiring maximum grip strength, whilst our half U Bolt provides a mix of grip strength and flexibility.

Description: U-shaped bolts with threads on both ends.

Uses: Commonly used to attach pipes or tubes to a surface.

Materials: Available in stainless steel, galvanized steel, and plain steel.

Eye Bolts

Eye Bolt Manufacturer in India, we provide high-quality Eye Bolt in a variety of sizes and forms to satisfy our client's individual needs. Eye Bolts are the most prevalent pipe system fittings. They provide a secure connecting point for numerous applications. They have a round or oval-shaped “eye” at one end that permits ropes, cables, hooks, or other gear to be attached.

Description: Bolts with a looped head.

Uses: Used for lifting or securing cables, ropes, and chains.

Materials: Made from stainless steel, carbon steel, and galvanized steel.

Anchor Bolts

Anchor Bolt Manufacturer in India, our firm specializes in producing premium Anchor Bolt that satisfies the demanding requirements of several sectors, including chemical processing, oil and gas, and the petroleum industry. To manufacture Anchor Bolt, we only employ the highest quality materials which also made us a top Anchor Bolt Supplier.

Description: Bolts with various heads designed to attach structures to concrete.

Uses: Essential for securing structural elements to concrete foundations.

Materials: Typically constructed from galvanized or stainless steel.

Square Head Bolts

Square Head Bolt Manufacturer in India, The Square Bolt has been rigorously constructed by national and international industry standards, utilizing premium raw materials and cutting-edge technology. Before being packed, our high-grade Square Bolt and other products are subjected to stringent quality inspections

Description: Bolts with a square-shaped head.

Often used in vintage machinery or for a rustic aesthetic in woodworking.

Materials: Usually made from carbon steel or stainless steel.

By understanding the different types of bolts and their specific uses, you can make informed decisions that enhance the quality, safety, and durability of your projects. Happy building!

0 notes

Text

SS Heat Exchanger Tube Manufacturer

SS Heat Exchanger Tube Manufacturer

KRYSTAL GLOBAL ENGINEERING LIMITED, formerly known as Krystal Steel Manufacturing Private Limited, stands as a premier stainless steel company with a clear mission: to emerge as the leading force in Stainless and Nickel Alloy Tubes originating from India, anchored on the pillars of Operational Excellence and Exceptional Services.

Our commitment revolves around empowering our clientele with a competitive edge through an extensive array of offerings, including Tubes, Pipes, U Tubes, and Coil Formed Tubes.

At KRYSTAL, we boast state-of-the-art facilities, continuously honed to perfection, aimed at elevating both our products and services to cater to the diverse needs of customers worldwide.

Our clientele spans across various sectors, encompassing Power Plants, Oil & Gas, Chemical Plants, Fertilizers, Pharmaceuticals, Textiles, Railways, Defense, Automobiles, Desalination, and more. Our range of products finds application in critical Engineering sectors such as Pressure Vessels, Heat Exchangers, Condensers, Heat Recovery Systems, and beyond. The assurance of quality, reliability, and global applicability underscores every facet of our Products, Technology, and Services.

With a dedicated workforce exceeding 315 individuals, comprising highly qualified management, seasoned technocrats, engineers, supervisors, and skilled workers, we are steadfastly committed to creating enduring Core Values that resonate across the industry.

Tap here to know about: https://krystalgeltd.com

#BrightAnnealedTubes#BuySeamlessTubesandPipes#SSCapillaryTubes#HeatExchangerTubesManufacturer#Inconelalloy#InstrumentationTube#SeamlessTubeSuppliers#SeamlessHeatExchangerTube#HydraulicTubesManufacturer#ManufacturerofInstrumentationTubes#ManufacturerofSeamlesstubes&Pipes#ManufacturerHeatExchangerTubes#ManufacturerofStainlessSteelPipe#ManufacturerofStainlessSteelTubeandPipe#ManufacturerofStainlessSteelTubes#MonelAlloy#NickelAlloyTubes#SeamlessPipeManufacturer#StainlessSteelBrightAnnealedTubesManufacturers#StainlessSteelManufacturerinIndia#StainlessSteelPipeManufacturersinIndia#StainlessSteelPipeManufacturingCompanyInVadodara#StainlessSteelSeamlessPipes#StainlessSteelSeamlessTubes

0 notes