#t5 fluorescent fixtures

Text

Hykolity 6 Pack LED Shop Light 4FT, T5 Integrated Single Fixture, 40W, 4000lm, 6500K Super Bright White, Aluminum Linkable Ceiling and Under Cabinet Light, Corded Electric with ON/Off Switch

Price: (as of – Details)

https://amzn.to/3PRUe37

Product Description

We are committed to providing the most COST-EFFECTIVE lighting products to our customer.

The T5 LED integrated fixture is well suited for 100W traditional fluorescent tube replacement by using only 40W, which helps to save you energy cost up to 75%. The 4000lm brightness and 6500K color temperature provides a super bright…

View On WordPress

#lighting board#lighting decoration#lighting shoes#lighting shop near me#lighting technologies#lighting the lamp

0 notes

Text

Differences Between T5 and T8 Lights

When it comes to choosing lighting fixtures for commercial or residential spaces, it’s important to consider various factors such as energy efficiency, brightness, and cost-effectiveness. Two popular options that often come up in discussions are T5 and T8 lights. These fluorescent lights offer distinct characteristics that are worth exploring before making a decision. In this article, we will delve into the key differences between T5 and T8 lights, helping you make an informed choice for your lighting needs.

1. Size and Lamp Design

The first noticeable difference between T5 and T8 lights lies in their size and lamp design. T5 lights have a narrower diameter of 5⁄8 inch, whereas T8 lights have a larger diameter of 1 inch. This size variance impacts the overall lighting output and usage.

T5 lights, with their smaller diameter, are more compact and can fit into tight spaces where T8 lights may be too large.

T8 lights, being larger, provide a broader coverage area and are ideal for lighting up larger spaces such as offices, warehouses, and commercial buildings.

The different lamp designs also affect the ease of installation, with T5 lights being more flexible due to their smaller size.

2. Energy Efficiency

Energy efficiency is a crucial aspect to consider while selecting lighting fixtures. T5 lights are known for their superior energy efficiency compared to T8 lights. Due to their smaller size and advanced technology, T5 lights require less power to produce the same amount of light as T8 lights. This translates to lower energy consumption and reduced electricity costs.

T5 lights use approximately 10-15% less energy than T8 lights, making them a more sustainable and cost-effective option in the long run.

The advanced technology of T5 lights allows them to produce more lumens per watt, providing higher efficiency in converting electrical energy into visible light.

Lower energy consumption also contributes to a reduced carbon footprint and helps in achieving environmental sustainability goals.

3. Brightness Levels

Brightness is often a top priority when it comes to lighting choices. T5 and T8 lights differ in their brightness levels. T8 lights typically offer a slightly higher lumen output compared to T5 lights. However, advancements in T5 technology have made it possible for them to deliver comparable brightness. Additionally, T5 lights emit a more uniform and even light distribution, making them suitable for applications where consistent illumination is desired.

T8 lights provide a higher lumen output, which is beneficial in areas that require brighter lighting, such as warehouses or large workspaces.

T5 lights, despite having slightly lower lumen output, can achieve comparable brightness levels due to their improved technology and superior light distribution.

The more uniform light distribution of T5 lights eliminates dark spots and shadows, creating a visually pleasing and well-lit environment.

4. Lifespan

Another important factor to consider is the lifespan of the lighting fixtures. T5 lights tend to have a longer lifespan compared to T8 lights. On average, T5 lights can last up to 25,000 to 30,000 hours, whereas T8 lights have a lifespan ranging from 20,000 to 25,000 hours. This longevity makes T5 lights a cost-effective option in the long run, as they require fewer replacements and maintenance.

The longer lifespan of T5 lights reduces the frequency of bulb replacements, resulting in lower maintenance costs and less downtime.

T8 lights, although having a slightly shorter lifespan, still offer a reasonable duration of usage before requiring replacement.

It is important to consider the expected usage and maintenance requirements when selecting between T5 and T8 lights to optimize cost-effectiveness.

5. Application Suitability

The application or intended use of the lighting fixtures also plays a significant role in the decision-making process. T5 lights are oft

en preferred for applications where space is limited, such as under-cabinet lighting, cove lighting, or accent lighting. Their smaller size allows for more flexibility in installation. On the other hand, T8 lights are commonly used in larger spaces such as offices, warehouses, and commercial buildings, where higher brightness levels are required.

T5 lights are ideal for compact spaces where a narrower fixture is required, such as display cabinets, retail shelves, or decorative lighting installations.

The smaller size of T5 lights also makes them suitable for applications that demand more precise and focused lighting, like task lighting in kitchens or workstations.

T8 lights, with their larger size and higher lumen output, are well-suited for general lighting purposes in larger areas like offices, warehouses, or retail stores.

6. Compatibility

When considering the switch from T5 to T8 lights or vice versa, compatibility should be taken into account. T5 and T8 fixtures are not interchangeable due to their size differences. If you plan to upgrade your lighting system, it is essential to match the fixtures with the appropriate lamps. Upgrading from T8 to T5 lights may require changing the existing fixtures, which can add to the overall cost.

T5 and T8 lamps have different pin configurations and require specific sockets or ballasts designed for their respective sizes.

Switching from T5 to T8 lights or vice versa may involve rewiring or replacing the existing fixtures to accommodate the different sizes and lamp designs.

It is important to consult with a lighting professional or electrician to ensure compatibility and avoid any potential issues during the installation process.

7. Environmental Impact

In today’s eco-conscious world, it’s crucial to consider the environmental impact of lighting choices. Both T5 and T8 lights are more environmentally friendly compared to traditional incandescent bulbs. However, T5 lights have the edge in terms of lower energy consumption and longer lifespan, resulting in a reduced carbon footprint. Additionally, T5 lights typically contain less mercury than T8 lights, making them a greener choice.

The reduced energy consumption of T5 lights helps in conserving natural resources and reducing greenhouse gas emissions.

The longer lifespan of T5 lights contributes to fewer bulbs being disposed of in landfills, reducing waste generation.

T5 lights containing less mercury not only have a lower environmental impact but also pose less risk during disposal or accidental breakage.

Conclusion

In conclusion, T5 and T8 lights offer distinct differences that should be considered when selecting lighting fixtures for your space. T5 lights are smaller, more energy-efficient, and suitable for applications where space is limited. On the other hand, T8 lights offer higher brightness levels and are commonly used in larger areas. Factors such as energy efficiency, brightness, lifespan, application suitability, compatibility, and environmental impact should guide your decision-making process. By understanding the differences between T5 and T8 lights, you can make an informed choice that best meets your specific lighting needs.

FAQ

Q: What is the difference in size and lamp design between T5 and T8 lights?

A: T5 lights have a narrower diameter of 5⁄8 inch, while T8 lights have a larger diameter of 1 inch.

Q: Which type of lights are more energy efficient, T5 or T8?

A: T5 lights are known for their superior energy efficiency compared to T8 lights.

Q: How do T5 and T8 lights differ in terms of brightness levels?

A: T8 lights typically offer a slightly higher lumen output compared to T5 lights, but advancements in T5 technology have made them comparable in brightness. T5 lights also emit a more uniform and even light distribution.

Q: Which type of lights has a longer lifespan, T5 or T8?

A: T5 lights tend to have a longer lifespan compared to T8 lights. On average, T5 lights can last up to 25,000 to 30,000 hours, while T8 lights have a lifespan rangin

g from 20,000 to 25,000 hours.

0 notes

Text

What are LED canopy lights?

LED canopy lights are a type of outdoor lighting fixture designed for illuminating areas with overhead coverage, such as canopies, awnings, and building overhangs. These lights are commonly used in various commercial and industrial settings, including gas stations, parking garages, loading docks, building entrances, and outdoor walkways. LED canopy lights offer several advantages over traditional lighting technologies like incandescent or fluorescent bulbs. Here are some key features and benefits of LED canopy lights:

Energy Efficiency: LED canopy lights are highly energy-efficient, consuming significantly less electricity compared to traditional lighting sources. This translates into cost savings on energy bills over time.

Longevity: LED canopy lights have a much longer lifespan than traditional lights, often lasting up to 50,000 hours or more. This reduces maintenance costs and the need for frequent bulb replacements.

Bright and Uniform Lighting: LEDs produce bright, white light that provides excellent visibility and security in outdoor areas. Many LED canopy lights are designed to distribute light evenly, minimizing shadows and dark spots.

Instant On/Off: LEDs do not require warm-up time, so they provide instant illumination when switched on. This can be important for safety and security in outdoor environments.

Durability: LED canopy lights are built to withstand harsh weather conditions, including rain, snow, and extreme temperatures. They are also resistant to vibrations and shocks, making them ideal for outdoor use.

Reduced Light Pollution: LED technology allows for precise directional lighting, which can help reduce light pollution by minimizing light spillage into unwanted areas.

Dimming Capabilities: Many LED canopy lights are dimmable, allowing for flexible control over the level of illumination based on specific needs and times of day.

Environmental Benefits: LEDs are environmentally friendly because they contain no hazardous materials like mercury and are fully recyclable. Their energy efficiency also helps reduce carbon emissions.

Various Mounting Options: LED canopy lights come in various styles and mounting options to suit different installation requirements, including surface-mounted, recessed, and pendant-mounted fixtures.

Cost Savings: While LED canopy lights may have a higher upfront cost than traditional lighting, their energy efficiency, long lifespan, and reduced maintenance expenses often result in significant cost savings over the long run.

LED canopy lights have become increasingly popular in outdoor lighting applications due to their numerous advantages. They not only provide improved lighting quality and energy efficiency but also contribute to enhanced safety and security in outdoor areas.

What kind of lights are used in canopy lighting?

Canopy lighting typically involves the use of specific types of lights designed to provide illumination in outdoor or covered areas such as gas station canopies, parking garages, building entrances, and walkways. The choice of lights for canopy lighting is important to ensure safety, visibility, and energy efficiency. Here are some common types of lights used in canopy lighting:

LED (Light Emitting Diode) Lights: LED lights are increasingly popular for canopy lighting due to their energy efficiency, long lifespan, and brightness. They come in various forms, including LED canopy lights, LED wall packs, and LED floodlights. LEDs provide uniform illumination and are often chosen for their low maintenance and energy-saving capabilities.

Fluorescent Lights: Fluorescent canopy lights, such as T8 or T5 fixtures, were once commonly used but have become less popular due to their lower energy efficiency and shorter lifespan compared to LEDs. However, some older installations may still use fluorescent lighting.

Metal Halide Lights: Metal halide lamps were once commonly used for canopy lighting, but they are being phased out in favor of more energy-efficient options like LEDs. Metal halide lights provide high-intensity illumination but consume more energy and have a shorter lifespan compared to LEDs.

High-Pressure Sodium (HPS) Lights: HPS lights were also used in the past for canopy lighting but are now less common due to their lower color rendering index (CRI) and lower energy efficiency compared to LEDs. They emit a yellowish-orange light that may not be as visually appealing as LED lighting.

Induction Lights: Induction lighting is a technology that falls between fluorescent and LED lighting in terms of efficiency and lifespan. It is more efficient and longer-lasting than fluorescent lights but not as energy-efficient as LEDs.

Solar-Powered Lights: In remote or off-grid locations, solar-powered canopy lights may be used. These lights rely on solar panels to generate electricity during the day and store it in batteries for nighttime illumination. They are environmentally friendly and reduce energy costs.

Gas Station Canopy Lights: Gas station canopies often have specialized canopy lights designed for this specific application. These lights are typically high-output LED fixtures that provide bright and uniform illumination to ensure safety and visibility for customers and employees.

The choice of canopy lighting will depend on factors such as energy efficiency goals, maintenance considerations, light quality, and budget constraints. LED lighting has become the preferred choice for many canopy lighting applications due to its overall advantages in terms of energy savings, longevity, and performance.

How do you put lights in a canopy?

Adding lights to a canopy can enhance its aesthetics and functionality. The process of installing lights in a canopy depends on the type of canopy, the lighting fixtures you want to use, and the power source available. Here are general steps to guide you through the process:

Materials and Tools You'll Need:

Lighting fixtures (e.g., LED strips, pendant lights, or string lights)

Mounting brackets or hooks

Extension cords (if needed)

Screws, anchors, and a screwdriver

Wire connectors and electrical wiring (if needed)

Electrical tape

A power source (outlet or electrical wiring)

A ladder or step stool (if the canopy is high)

Steps to Put Lights in a Canopy:

Plan Your Lighting Design: Determine where you want to place the lights in the canopy and what type of fixtures you want to use. Consider the purpose of the lights, such as ambient, task, or accent lighting.

Prepare the Canopy: Make sure the canopy is clean and free of any debris. If your canopy has a fabric cover, ensure it's securely attached, and consider whether you need to make any adjustments to accommodate the lighting fixtures.

Choose a Power Source: Decide how you will provide power to your lights. You can either use an existing outdoor electrical outlet or run electrical wiring to the canopy if it's not already equipped with power. If you're running new wiring, consult a professional electrician for safety and compliance with local electrical codes.

Mounting the Fixtures:

For pendant lights or chandeliers, use mounting brackets or hooks to secure them to the canopy's frame or ceiling.

For LED strips or string lights, you can attach them directly to the canopy using adhesive or clips. Ensure the adhesive is appropriate for outdoor use.

Make sure the fixtures are evenly spaced and aligned according to your lighting design.

Wiring (if applicable):

If your lights require electrical wiring, follow the manufacturer's instructions for installation.

Securely connect the wires, matching the color-coded or labeled wires. Use wire connectors and electrical tape to insulate the connections.

Run the wiring to the power source, either through conduit or discreetly along the canopy's structure.

Connect to Power:

Plug in the lights to an outdoor electrical outlet if you're using plug-and-play fixtures.

If you've run electrical wiring, connect it to the power source, following proper electrical safety procedures.

Test the Lights: Before completing the installation, test the lights to ensure they are functioning correctly. This is also a good time to adjust the placement or alignment if needed.

Secure and Hide Wiring (if applicable): If you ran electrical wiring, make sure it is safely secured and concealed to prevent tripping hazards and exposure to the elements.

Finish and Enjoy: Once you're satisfied with the installation, complete any final adjustments, secure all fixtures, and enjoy your beautifully lit canopy.

Remember that safety is essential when working with electricity. If you're not comfortable with electrical work or if it involves complex wiring, it's advisable to hire a qualified electrician to ensure a safe and compliant installation.

Read the full article

0 notes

Text

A Guide to Commercial Electrical Load Calculations

Commercial electrical load calculations are important to determine the electricity needs of a building. As such, you can reduce energy consumption hence reducing electricity bills. This article provides a guide on how to calculate the electrical load of your building.

What Is an Electric Load?

An electric load is a device that consumes electrical energy, converting it into another form of energy, such as heat, light or motion. Some examples of electric loads include light bulbs, electric motors, and office equipment such as computers and printers.

Electric loads are an important factor in electrical engineering and power systems, as they determine the amount of power that must be generated and distributed to meet the electricity demand.

To determine how much power can support the energy needs of your building, you need commercial electrical load calculations. Tercero is a leading commercial electrical contractor who can help determine your needed power. If you need these services, feel free to contact us.

Types of Commercial Electric Loads

There are many types of commercial electric loads, which can vary depending on the specific needs of the commercial building. Some common types of commercial electric loads include:

Lighting:Commercial buildings typically have many light fixtures, which consume significant electricity. It is one of the main electric loads in commercial buildings. The most common light fixtures are tubular fluorescent, compact fluorescent, T5 fluorescent, and LED lights, each with specific energy needs.

HVAC (heating, ventilation, and air conditioning):Commercial buildings often have complex HVAC systems that use electricity to heat, cool, and ventilate the building. Ideally, they keep humidity between 40% and 60%, temperatures in the range of 72 degrees, and C02 levels below 1000PPM.

Office equipment:Commercial buildings often have different electrical equipment, such as computers, telephone systems, and printers, that consume a significant amount of electricity. It is also a significant electric load in commercial buildings.

Appliances:Commercial buildings also have kitchen appliances like refrigerators, ovens, dishwashers, washers and dryers. As you’d expect, they affect the electrical load of a commercial building. As such, it is crucial to include them in your calculations.

Motors:There are a variety of motors in a commercial building, such as those used in elevators, escalators, and other machinery. Like appliances and lighting, they affect the final electric load of your building.

There are many different types of commercial electric loads, which can vary depending on the specific needs of the building. Understanding these electric loads and their characteristics is important for managing and maintaining the electrical system in a commercial building.

Tercero can help you identify the various electric loads in your building. We ensure to include every load in our calculation so we can accurately estimate how much energy you’ll need.

Calculating Commercial Electric Load

The formula for calculating the commercial electric load is relatively simple. It is based on the basic power formula, P = VI (where P is power, V is voltage, and I is current).

To calculate the commercial electric load, you would need to measure the current and voltage of each electric load in the commercial building and then use the formula P = VI to calculate the power consumption of each load.

Once you have the power consumption of each electric load, you can simply add them up to get the total commercial electric load.

For example, let’s say you have three electric loads in a commercial building with the following current and voltage measurements:

Electric load 1: 5 amps at 120 volts

Electric load 2: 2 amps at 240 volts

Electric load 3: 1 amp at 120 volts

To calculate the commercial electric load, you would first use the formula P = VI to calculate the power consumption of each electric load. For electric load 1, the power consumption would be 5 amps * 120 volts = 600 watts.

For electric load 2, the power consumption would be 2 amps * 240 volts = 480 watts. And for electric load 3, the power consumption would be 1 amp * 120 volts = 120 watts.

Next, you would simply add up the power consumption of each electric load to get the total commercial electric load. In this case, the total commercial electric load would be 600 watts + 480 watts + 120 watts = 1,200 watts. This is the total amount of electricity that the commercial building consumes.

Benefits of Calculating a Commercial Building’s Electrical Load

There are several benefits to calculating the commercial electric load, including the following:

It helps to ensure that the electrical system in the commercial building is capable of meeting the electricity demand. Knowing the total electric load, you can ensure that the power supply and distribution systems are properly sized and configured to handle the load.

You can identify areas where energy efficiency can be improved. Calculating the commercial electric load lets you see which devices and systems consume the most power.

As such, you can take steps to reduce their energy consumption. For example, you might replace old, inefficient appliances with newer, more efficient models or install energy-saving lighting systems.

It can help to reduce the cost of electricity. Load calculations can help you identify ways to reduce the amount of power used, leading to lower electricity bills.

For example, you might be able to negotiate a lower rate with your electricity provider if you can demonstrate that you have implemented energy-saving measures.

It helps to prevent power outages and other electrical problems. It helps identify potential problems before they occur, such as overloaded circuits or inadequate power supply. It can help avoid power outages and other electrical issues that disrupt your business operations.

Why Do You Need an Electrician To Calculate Commercial Electric Load?

While it is theoretically possible for someone who is not an electrician to calculate the commercial electric load, it is generally recommended that an electrician be hired to perform this task. There are several reasons for this, including the following:

Electricians have the knowledge and expertise to accurately measure the current and voltage of each electric load in a commercial building. Itis an important part of calculating the commercial electric load, and it requires an electrician’s specialized knowledge and skills.

Electricians have the tools and equipment to safely and accurately measure the current and voltage of each electric load. It can be a complex and potentially dangerous task, requiring specialized tools and equipment that an electrician has.

Electricians can provide valuable insight and advice on reducing commercial electric load. Once the electrician has calculated the commercial electric load, they can provide recommendations on how to reduce the electricity consumption of the building, such as by upgrading to more energy-efficient appliances or installing energy-saving lighting systems.

It is generally best to hire an electrician to calculate the commercial electric load, as they have the knowledge, expertise, and tools to safely and accurately perform this task.

Tools for Calculating the Commercial Electrical Load

Microsoft Excel

Microsoft Excel allows you to input all the necessary information, such as the type and number of electrical devices and appliances in a building. You’ll then use pre-determined formulas to calculate the total load. It is the most basic form of calculating the electric load of a commercial building. The software can help you calculate the following:

The voltage difference between phases.

Load in each phase and the outgoing feeders.

Starting, full load, continuous, and non-continuous load.

Unbalanced load in the neutral wire.

Specialized Software

Another option is to use specialized electrical load calculation software. This type of software is specifically designed for calculating electrical loads and often includes features such as pre-populated electrical equipment databases and the ability to input and edit data easily.

Some of the key benefits of using specialized software include the following:

Comprehensive: Many commercial electrical load calculation software comes with common electrical equipment databases. As such, it helps you ensure that all vital details are included in the calculations.

Accuracy: This is arguably the chief benefit of using specialized software. As you’d expect, this software is specifically designed for this task. As such, it will provide more accurate results than using general-purpose software such as MS Excel.

Efficiency: Generally, it is easier to use load calculation software than a general-purpose spreadsheet. It allows you to input and edit data quickly and easily. You can save time and effort using it.

Customization: Some electrical load calculation software programs allow you to customize the calculations to take into account specific factors, such as the layout of the building or local building codes.

In short, specialized software for commercial electrical load calculations can help ensure that the calculations are comprehensive, efficient, and accurate. It can enable you to ensure the electrical system meets the power demands of your commercial building.

Conclusion

Calculating commercial electrical load is as easy as following the above formula. The best part? There is specialized software for this, and you can consult a professional electrician. If you need commercial electrical load calculations, Tercero is a perfect choice. Call us to book a consultation.

Original Source:

https://terceroinc.com/a-guide-to-commercial-electrical-load-calculations/

0 notes

Text

Hemp Buds Health Tips

When growing hemp, optimizing plant health for maximum yield is essential. It means getting the right tools, understanding your growing system, and maximizing environmental conditions. Managing plant health is an art form that requires a careful balance between genetics and environmental conditions, and crop management. While some of these factors are beyond your control, a few tips can go a long way.

Hemp plants grow taller and thin compared to marijuana plants.

One of the most noticeable differences between marijuana plants and hemp plants is the height and slenderness of hemp plants. While marijuana plants are generally shorter and broader, hemp plants grow tall and thin. This characteristic is attributed to its plant structure, with leaves containing slender, serrated fingers. The leaves on hemp plants consist of five to seven leaflets. The leaflets join together at the rachis, which connects the leaf to the branch. Therefore, higher leaves have more brochures than lower leaves.

Marijuana and hemp are both species of cannabis, but they are very different plants. Marijuana is a flowering plant with high levels of THC, while hemp contains little or no THC. Despite these differences, both types are used for food, fiber, and clothing. Industrial hemp plants grow taller and thinner than marijuana plants and are more complex and challenging. They can be raised more widely than marijuana and can produce more fiber.

Hemp plants can handle a wide range of soil conditions, from very wet soil to compacted soil. They also have roots that can draw nutrients from deep soils and absorb toxic heavy metals. It makes them an excellent crop for decontaminating, reinforcing, and reclaiming ground.

Cannabinoids in hemp flowers are activated only when exposed to heat.

Heat is an essential trigger for the activation of cannabinoids in hemp flowers. The plant's metabolism increases the amount of CBD and other metabolites when exposed to heat. This effect is known as phenotypic plasticity. Heat activates a variety of metabolites, including cannabidiol, which is responsible for the effects of CBD.

Cannabis plants undergo a series of stressful conditions during the growing process, including heat and drought. Drought is the most significant field stress, causing a decrease in THC and CBD and an increase in CBG. As a result, they are used in food additives, flavorings, and biopharmaceuticals.

Hemp buds need the right tools to grow.

If you're growing hemp buds, you'll need the tools to grow them successfully. A good pair of pruning scissors is essential for cutting stems, leaves, and whole buds. They should be strong enough to cut plants up to one inch in diameter. They can also use to remove any imperfections, such as sprouts and weeds, that are present.

Regardless of your growing method, it's essential to maintain consistent moisture for your seedlings. Hemp seedlings perform best in temperatures between 68 and 77 degrees F. A heat mat can help keep the temperature constant for seedlings. Keeping the humidity level around 65-70% is also essential. You can also use high-output LEDs or T5 fluorescent grow lamps to deliver adequate light. Some hemp grows kits even include an adjustable high-output LED fixture.

Another essential tool is a harvester, which is specific to hemp. This tool gently cuts hemp plants without damaging the plants' delicate flowers. On the other hand, traditional harvesters can damage delicate hemp flowers, which contain the bulk of the CBD, terpenes, and resins. In addition, traditional harvesters require labor to hand cut the buds, so you'll need to hire workers to harvest them.

0 notes

Text

How Many LED Grow Lights Do I Need?

The number of LED grow lights you need depends on a few factors. First, how many plants are you growing? You can see our chart above for a general recommendation of how much wattage is required per plant.

Second, are you planning on cloning or growing from seed? Baby weed plants have different light requirements, so you may wish to buy a separate grow light for this purpose. Many growers prefer to use T5 fluorescent lights for seedlings and clones. You can also use smaller, less expensive LED grow lights -- like LED grow lights under $500.

Finally, do you need supplemental lighting for dark areas of your grow room? You can maximize coverage by using enclosed grow tents or by installing reflective mylar sheeting in your grow room. Still, if you have a very large grow room you may end up with some corners that are not fully lit by horizontal LED grow lights. In this case, purchasing a few extra supplemental lights to hang vertically can make a big difference.

ECO Farm ECOD Samsung UV+ IR 480W Dimmable LED Grow Light

This fixture provides you with total control over everything. With onboard dimming function, growers can set the ideal intensity at any stage of plant growth for optimal photosynthesis activation.

Different plug outlet options (USA, EU, AU, UK etc) and Voltage options for different countries (120v-240v) We will base it on the country of origin unless specified.

ECO Farm DBL5000 Full Spectrum LED Grow Light 480W

Unique designed 6-LED bars provide more even canopy coverage, especially to the outer edges of cultivation areas. With 1296 pcs SAMSUNG LM281B diodes, DBL5000 Led grow lights draw 480 watts achieving an impressive PPE of 2.5 umol/J, coverage for 4'x4′ of high-yielding full-cycle growth.

If you are interested in the led grow lights, welcome to visit our official website: growpackage.com

Buy now has a discount, you can take this led grow light home at a better price.

0 notes

Note

Hi!! I have one more question. I recently got my ball python and everything is good so far. I got her a UV light and I have heard that much of it will get filtered if I put it above the mesh, but it's also safer to keep it outside. Would it be OK to mount it within her vivarium, or would that be a bad idea because my python could get burned if she touched it directly?

Hey friend!

My timing sucks but this is not an April Fool's Day joke, I promise!

Soooooooo the answer here kinda depends on what kind of UV light source you're using.

T5 fluorescent fixtures don't get super duper hot. At worst they can become uncomfortably warm to touch and they won't cause a burn unless your snake is camped out on them with direct contact for a bit. You can safely mount them inside of your enclosure on the ceiling in most cases. You can also protect them in a tubular housing of aviary wire mesh or hardware cloth (around the entire fixture) if you're concerned about your buddy trying to touch them directly, or worse: poop on them. You definitely do not want that.

T8 fixtures are even cooler than T5s but they generally have lower UV output so be mindful of that. Same as before, make sure your snake can't climb on or camp out over top of it.

Halogen type UV bulbs get VERY HOT and you absolutely do not want a ball python coming into contact with a halogen fixture. These lights should absolutely be kept outside of your enclosure. I've seen halogens used with a metal light-cage that keeps reptiles from being able to touch the bulb, but the metal cage gets pretty dang hot, too, and I do not recommend this setup for snakes. It's great for terrestrial lizards who are not likely to try to climb on the light cage, though.

One last potential option to maximize safety while ensuring UV penetration is to swap out your fine mesh screen for a wider-gauge mesh like the aforementioned aviary wire or hardware cloth. This requires some handyperson skills, though, and not all of us are super handy.

I recommend that you err on the side of safety versus UV exposure. Ball pythons are crepuscular anyway and they're probably not going to be spending a ton of time basking directly in the light.

I hope this helps!

#snake#snakes#reptile#reptiles#reptiblr#snake behavior#snake keeping#snake husbandry#snake care#snake enclosure#snake enclosures

23 notes

·

View notes

Text

Hydroponics Supplies Online | T5 Fluorescent Grow Light Fixture

Looking for Hydroponics Supplies Online? The Manufacture of hydroponic equipment, grow lights and ventilation products from China. Order Online! Call +86 18502139019 for more queries.

0 notes

Text

Submited:

Oh wow. I’m so envious. I don’t have a lot of light in my house or in my garage. We actually toured a house with a sunroom while house shopping, but it was out of our price range and needed tons of fix-ups. I regret that decision every winter. I love the cart and lettuce ideas. I’m going to brainstorm with those. I bought a little Ikea cart for my daughter, and it’s already full of plants she bought this summer.

I definitely realize how lucky I am : ) . We live on a farm and recently built a new house, so there is more space than most people have (esp when I used to live in a city apartment!) and I took my plants into account when we were planning. FWIW, we thought we were going to build a new house within 5 years of getting married, and it took 20. And then it took us four years to complete (we did it ourselves).

Our old house wasn’t very good for plants at all. No windowsills, the windows were small and high up, and only one window faced east.

The light cart I’m talking about is like this. It wasn’t cheap even in the early 90s (shades of Meg!) when I bought mine,

https://www.leevalley.com/en-us/shop/garden/planting/grow-lights/102173-floralight-t5-led-full-spectrum-multi-tier-grow-light-stands?item=PK452

https://growerssupplycompany.com/product/flora-cart-ba3p4-aluminum/

but mine is still going strong after almost 30 years. I just had to update the light fixtures and fluorescent tubes the other year. I have a feeling it was probably possible to buy them secondhand pretty inexpensively *before* the pandemic, sigh. Depending on what you’re growing and their light needs, you can use either 2 or 4 light tubes per shelf.

_______________________________________________________________________

Thank you so much. This is great!

21 notes

·

View notes

Text

HOW TO CHOOSE THE RIGHT LED SHOEBOX LIGHTS FOR YOUR PARKING LOT

If you are considering upgrading your lights to LED, the parking lot lights should always be the first one to take into consideration, because of the large service area of parking lot and the high energy consumption of traditional metal halide parking lot light.

It’s not easy to research dozens of websites to put all the pieces of the puzzle together and answer all of your questions about what is the right LED shoe box light Fixture for your needs. For this reason, we prepared some tips about shoebox light, Parking Lot and Area Lighting in this article.

Here are several things you need to know before converting your facility:

1. Type of facility: Is the site retail, warehouse or other commercial use?

2. Type of fixture or lamp: Wall Packs, Shoeboxes, Flood Lamp

3. Wattage of existing lamps: This gives your LED manufacture insight to the LED equivalent needed.

4. Line voltage: LED products are voltage specific, and the LED installer will need to know this detail.

5. Needs from the changes: To increase/decrease the lighting output, address a specific problem or area, meet a specific specification or code

6. The best color of light: The sun is 5778k, and in the LED industry, 5000k is considered to be the closest to natural sunlight. Outdoor lighting is often oriented to a 5000k color.

7. Quality of LED products: Quality means you trust you will not have any warranty issues, service means if you do have any issues, the integrity of service will be tasked to work its magic.

What is high bay lighting, and what applications benefit from it?

Whenever a large indoor space needs to be illuminated, high bay lighting is usually appropriate. Consider spaces like manufacturing facilities, gymnasiums, warehouses, large department stores, factories, and more; these facilities are typically vast and cover a lot of vertical as well as horizontal space. This requires powerful lighting to provide the appropriate foot-candle levels to adequately illuminate. High bay lighting fixtures typically hang from the ceiling via hooks, chains, or pendants, or they may be fixed to the ceiling directly (similar to troffer lights). The image above features high bay lighting in action.

Various industries and facilities require high bay lighting. Some of the most common are:

Warehouses

Industrial facilities (read more about Industrial LED lighting here)

Manufacturing facilities

School and university gymnasiums

Municipal facilities like community centers or recreation centers

Commercial applications like department stores

Why choose LED high bay lights instead of metal halide, fluorescent, or other conventional high bay lights?

Historically, various lighting technologies were (and still are) used in warehouse and industrial settings when high bay lights were required. Some of the most common include metal halide (MH), high pressure sodium (HPS), and fluorescent. While each of these bulbs have their merits, industrial LED lighting outperforms its conventional counterparts in important ways. Let’s take a look at some of the various considerations when deciding whether an LED retrofit is appropriate for your warehouse or industrial space.

Industrial LED lighting vs metal halide high bay light: If you’ve ever been to a ballgame, you've likely seen metal halide illuminating the field. MH lamps are common in sporting and warehouse/industrial uses (as well as any setting where large, high spaces need to be illuminated). Benefits of MH lights include decent color rendering and comparatively adequate foot-candle levels (as opposed to other types of conventional bulbs). Some of their major drawbacks are a long time to warm up (sometimes 15-30 minutes) and a high cost to maintain, and their failure characteristics include flickering on and off. This is in addition to the fact that much of the energy they produce is wasted as heat. Read more about LED versus Metal Halide Lights.

Linear LED high bay light vs high pressure sodium (HPS) lights: HPS lights are often used in warehouse, industrial, business, and recreational facilities where high bay lighting is appropriate. Their benefits include cheap selling price, high energy efficiency (low operating costs), and a relatively long lifespan. HPS lighting technology retains these advantages over most conventional bulbs, but they lose on all three counts to LED high bay lighting. The downsides of HPS bulbs include the worst color rendering on the market and a warm up period. Read more about LED versus High Pressure and Low Pressure Sodium Lights.

Industrial LED lighting vs fluorescent lighting: Though somewhat less common, fluorescent lighting is sometimes utilized in warehouse or industrial applications (primarily T12, T8, and T5 lights). The benefits of fluorescent lights include cheaper initial costs and relatively high efficiency (especially when compared to other conventional bulbs). Downsides include the presence of toxic mercury (which requires certain waste disposal procedures), decreased lifetime if switched on and off, and requiring a ballast to stabilize the light. Read more about LED versus Fluorescent Lighting.

It’s no secret that LED lighting technology has surpassed the capabilities of conventional lighting in important ways. In addition to the considerations discussed above, there are three general benefits of LED lighting that apply to all lighting applications.

Decreased maintenance requirements. As discussed above, LED lights have a lifespan that is four to forty times longer than many conventional bulbs. This means fewer replacements for bulbs that wear out. LED lighting technology also generates light differently than typical fuel and filament lighting by using a diode (learn more in this blog). This means that there are fewer moving pieces to break, and consequently, fewer repairs or replacements. Maintenance is an especially important consideration when it comes to industrial lighting or warehouse lighting. By definition, high bay lights have higher mounting heights, which means that changing a bulb requires some specialized equipment or creativity. Scaffolding, catwalks, and hydraulic lifts are generally used to swap or replace bulbs, and each of these can result in additional maintenance or equipment costs. Again, the lifespan of industrial LED lighting means that fixtures need to be changed much less often, which means savings for your bottom line.

Improved lighting quality. Industrial LED lighting and high bay lights will typically score better in a head-to-head comparisons against most other bulbs when it comes to color rendering index (CRI), correlated color temperature (CCT), and foot candles. CRI is a measurement of a light’s ability to reveal the actual color of objects as compared to an ideal light source (natural light). In non-technical terms, CCT generally describes the “glow” given off by a bulb - is it warm (reddish), or cold (bluish white)? Foot candles compare the amount of light coming from a source and the amount of light hitting the desired surface; they’re basically a measure of efficiency. On all three fronts, LED lights perform very well. (Read more about CRI, CCT, and foot candles here.)

Increased energy efficiency. Not only do LED lights generate light differently, they also distribute light differently than conventional lighting solutions, which results in less energy required to provide the same output. How does that work? First, many conventional lights waste a lot of the energy they produce by emitting it as heat (this is especially the case with metal halide lighting). Second, most conventional lights are omnidirectional, which means that they output light in 360 degrees. So, a lot of light is wasted pointing at a ceiling, or being diluted because it has to be redirected through the use of fixtures. Industrial LED lighting for applications that require high bay lights eliminates these two problems of wasted energy (through heat loss and omnidirectional emission).

Indoor Plant Lighting

Indoor plant lighting gives plants most of the energy they need to grow, thrive, even to stay alive.

The proper type of indoor plant light is more than just a matter of giving a plant the brightness it needs. There are three lighting factors that control growth of a plant:

Amount of light: number of hours of daylight on your plants

Intensity of light: levels of light from full sun to full shade

Spectrum: warm and cool colors

Gas Station Lights

Every location has its own unique lighting needs. When it comes to gas station lights, there are a few fixtures that are exceptionally well suited to this location. Let's take a look at a few of the most common solutions for gas station lighting.

LED

When looking at fixture options, you should first determine the right lamping solution to narrow down the choices. LED is the best choice for this unique location. LED offers a higher lumen output for a brighter fixture while operating on a lower wattage which saves on energy for utility costs. LED is also a no heat solution which means the life of the fixture will be protected from heat damage. Another benefit of LED is that the lamps last a long time to save on replacement costs and maintenance spent on maintaining fixtures. Best of all, LED is available in the most commonly used gas station lighting solutions.

Canopy Lights

When looking at gas station lighting, the most obvious area is the canopy. This is where the majority of the business happens since customers pump gas under the canopy. It is also important to make sure this area is well-lit, so customers can see it clearly from the road at night. A well-lit canopy also gives a feeling of safety and security when pumping gas at night that most customers expect. In fact, most customer will pass up a poorly lit gas canopy in favor of a brighter one, so this area directly impacts your business. This is where canopy lights come in and save the day! Canopy lights are made specifically for this type of environment, so they offer such features as vandal proof options, wet rated listings, durable polycarbonate lenses, and bright, powerful illumination where you need it most. Canopy lights come in choices of thin profile to save on space and low profile for lower canopies in terms of height.

Parking Lot Lights

While the canopy lights are the main draw on the exterior, you will still need additional parking lot lighting. Parking lot lighting is necessary for any surrounding parking spaces not covered by the canopy. They can also be used to add visibility to roads leading to the parking lot or behind the building for added safety and security. When choosing parking lot lights, you can go with either cobra head or floodlights. Floodlights are ideal if you have a larger lot whereas cobra head is ideal for smaller lots.

Interior Lights

While the outside lighting is important, the inside is just as crucial to a successful lighting plan. For interior gas station lighting, there are several great options to consider. A few of the most common are recessed troffer-style and surface mounted fixtures. Both options offer an easy to install and maintain solution to meet the needs of this location. In this type of location, you want to avoid suspended or chain fixtures since they can create more shadows and detract from the clean, bright atmosphere your customers appreciate.

1 note

·

View note

Text

2 Pack LED Shop Light 4FT, T5 Integrated Single Fixture, 22W, 2200lm, 6500K Super Bright White, Linkable Shop Light, Utility Shop Lights, Corded Electric with Built-in ON/Off Switch

Price: (as of – Details)

https://amzn.to/3PRUe37

Product Description

We are committed to providing the most COST-EFFECTIVE lighting products to our customer.

The T5 LED integrated fixture is well suited for 40W traditional fluorescent tube replacement by using only 22W, which helps to save you energy cost up to 65%. The 2200lm brightness and 6500K color temperature provides a super bright…

View On WordPress

#lighting board#lighting decoration#lighting shoes#lighting shop near me#lighting technologies#lighting the lamp

0 notes

Text

How much power can a fluorescent light fixture handle?

The power-handling capacity of a fluorescent light fixture can vary depending on several factors, including the type of fixture, the number and wattage of the fluorescent tubes it's designed to accommodate, and the electrical rating of the fixture's components. Here are some general guidelines:

Type of Fixture: There are different types of fluorescent light fixtures, including single-tube fixtures, double-tube fixtures, and more complex configurations. Each type will have a different power-handling capacity.

Number and Wattage of Tubes: The power consumption of fluorescent tubes is typically measured in watts. Common sizes are T8, T12, and T5 tubes. The wattage of the tubes multiplied by the number of tubes in the fixture will give you the total power consumption of the fixture.

Ballast: Fluorescent fixtures use ballasts to regulate the electrical current flowing through the tubes. The ballast's capacity will determine the overall power that the fixture can handle. Different types of ballasts (magnetic or electronic) have different power ratings.

Voltage: Fluorescent fixtures are designed to operate at specific voltage levels (e.g., 120V or 240V). Using a fixture with the appropriate voltage rating is essential for safe operation.

Circuit Wiring: The wiring of the electrical circuit that the fixture is connected to should also be considered. It needs to be able to handle the total power draw of the fixture.

Environmental Factors: If the fixture is installed in a location with high temperatures or other adverse conditions, its power-handling capacity might be affected. Some fixtures are designed for specific environments, such as damp or wet locations.

It's important to consult the manufacturer's specifications and guidelines for your specific fluorescent light fixture model to determine its maximum power-handling capacity. Exceeding the fixture's rated capacity could lead to electrical hazards, reduced lifespan of components, and decreased efficiency.

Read the full article

0 notes

Text

A Classification Method for LED Lighting Products

This article tells the way to classify the varied LED lighting systems within the market, to form them more straightforward and acceptable. And that we would make the tactic practical to hide hottest products like LED bulbs, spotlights, par cans, fluorescent tubes, ceiling lights, floodlights, etc.

This classification is simple for many consumers to know easily, and it is also complied by many manufacturers unconsciously or intentionally. During our retail sales, we discover out that the majority people wouldn't attempt to probe detailed performance characteristics of the LED lights, like electrical, thermal, or optical performance. Instead, they might like better to know whether the item is compatible with their traditional lighting sources. Generally, we might wish to define LED systems into four categories. They're LED lamps, LED Fixtures, LED Portable, and LED accessories.

LED Lamps are those systems which will be mounted into standardized socket or sockets, among which the foremost popular are E26/E27, G5.3, GU10, T5 or T8. In traditional lighting sources, they include incandescent bulbs, MR16(or Multifaceted-Reflector halogen), PAR (or Parabolic aluminized reflector light), fluorescent tubes. They will be subdivided with their socket base for many cases. for instance, there could also be BULB-E27, MR16-E27, or PAR-E27 for bulbs, and for MR16, there could also be MR16-G5.3, or MR16-GU10.

LED Fixtures are those products that require to be installed with external wiring or plugging. They will be differentiated easily by checking whether or not they have an exerted wire. LED fixtures got to be mounted with extra fittings on predefined areas, like opening on the ceiling or cabinet. LED ceiling lights, floodlights, wall lights, linear bars, flexible strips fall under this category. additionally, typical LED street lights and tunnel lights belong to the fixture category, too.

LED Portable are those finished portable products independent of external power. These products are often held in your hand or worn on your head. LED flashlights, headlights, or key chains are among this category.

youtube

The last part isn't direct for lighting but essential for LED systems. LED Accessories include these things to support the stable operation. For several cases, the facility adapter is a crucial factor to ensure the lifespan and performance of LEDs. The dimmer control unit makes damnability possible in LED lighting. There could also be other specially designed independent components to facilitate the merchandise in heat sinking or beam distribution.

#portable LED light#LED Light Bar Driving Lights#perception lighting#LED Driving Lights#Light Bars#Camp Lighting#solar blankets

1 note

·

View note

Text

Bringing Plants In For the Winter For Newbies

- Hello! I have some more plants to add, and some to raise closer to the lights, but this is pretty much my winter set-up!

I decided to write a helpful guide since this was my first time having an indoor plant set-up for the winter. The process was frustrating as I couldn't find a comprehensive guide of what would be needed. Between unknowledgeable store employees, and my lack of full comprehension, trying to choose and pair the right lights with compatible light fixtures was difficult. Now I know what is needed in terms of lightning, and also understand light and fixture compatibility. I ended up doing a lot of research on various websites, gained advice from this Facebook page, and even spoke with GE (General Electric Company), who was quite helpful! I'm hoping this helps others that are in the same situation I was!

Lighting (bulbs) - Do yourself a favor and go with LED (light emitting diodes). Fluorescent lighting is being phased out along with their fixtures, as per the General Electric and hardware stores I spoke with. Everything is now going towards the more efficient, more environmentally friendly, easier to dispose of LED lights and fixtures. It may cost a bit more now, but it's going to save you money in energy bills and hassle in the future. People will talk about T5 lights. T5 is just the diameter size of the bulb or covering that covers the LEDs that are inside. So, pretty much the only difference between T5, T8, and T12, are the diameter. Most of the fixtures I saw were compatible with the T8 sized LED bulbs. For cacti and succulents choose 6500k (k = Kelvin) bulbs. Kelvins refer to the "color" of the light. "Daylight color" is considered 5000k and up. The lumens matter as well. The higher the lumen, the brighter the light. I found GE brand, 6500k, 2300 lumen, T8 "bulbs" in a pack of 10 at Lowe's. They are compatible with my fixture (I called GE to find out).

They cost $89 for the 10 pack. Here is the link: https://www.lowes.com/pd/GE-32-Watt-EQ-Daylight-Light-Bulbs-10-Pack/1000437645

Light fixtures - In order to hang lights from the bottom of your shelves you will need lighting that will plug in to the wall (as opposed to being hard-wired). Alot of places call this "Shop Lighting". Being able to plug one fixture into another is also nice. This is called daisy-chaining. The lights that come with a chain to hang are going to be better than the lights that use stiff wires to hang, as you will be able to get the lights with the chain closer to the bottom of the shelf that you will be hanging it from. This allows for taller plants to be placed underneath it. Remember your plants should be about 5 inches from the bulbs. If you can find it, you will want a fixture that holds 4 bulbs. I found however, that most of the LED fixtures have only two bulbs. Many also come with the LEDs (but if not, you can purchase them separately, see specifications below under 'Lighting'). You can use 2, two-bulb fixtures per shelf hung side-by-side. I also found 8 bulb fixtures. As long as those fit the length and width of your shelves, go for it.

The only 4 bulb, plug-in fixtures I was able to find were fluorescent fixtures by Lithonia Lighting. I got them from Home Depot. If you call Lithonia Lighting they will tell you that even putting "fluorescent compatible" LEDs in the fixture will void the warranty as the fixture is only designed to be used with fluorescent bulbs. (That said, I'm not quite sure how they will know what kind of lights you put in them though if it comes down to having to use the warranty.) I called GE and they had actually tested that exact fixture with their "fluorescent compatible" LEDs! They said that using their fluorescent compatible LEDs will not affect the performance or quality of the lights or the fixture. The fixtures I chose cost $49 each.

Here is the link: https://www.homedepot.com/p/Lithonia-Lighting-4-Light-Grey-Fluorescent-Heavy-Duty-Shop-Light-1284GRD-RE/202968125

Shelving - this was the easy part. I simply went to Lowe's (don't forget that they have a 10% military discount, so be sure to sign up to save some money), and picked out a good quality stainless steel shelving unit. Make sure the one you choose has adjustable shelves. Remember, the lights have to hang 5 inches from the top of your plants, and plants grow! I wanted one that was more sturdy and would last, so I got one that holds 600 pounds per shelf. Plastic shelving will just not cut it for the weight of pots filled with soil and the weight of the lights, so just don't bother or you will end up with shelves that sag in the middle and are not level. The unit I chose was 72" high, 48" wide and 18" deep. Since it's going to be in my home as opposed to a garage or shed, I wanted a shelving unit that looked decent. Wire shelving allows you to hang lighting from the shelves.

My shelving unit cost $99. Here is the link: https://m.lowes.com/pd/Style-Selections-72-in-H-x-47-7-in-W-x-18-in-D-6-Shelf-Steel-NSF-Certified-Freestanding-Shelving-Unit/999990412

Trays/Shelf liner - Since you don't want water to short out your fixtures, and to keep dirt etc. from falling from shelf to shelf, using trays is helpful. I found large sized, cafeteria style lunch trays on Amazon. I wanted them to be all one neutral color for aesthetics. They fit perfectly on the shelving unit I bought. I have four on each of the upper shelves.

They were only $2.87 each! Here is the link: https://www.amazon.com/dp/B00BM8GX0A?ref=yo_pop_ma_swf

On the bottom shelf I have Plexiglass which I had from Lowe's. They will cut it to size for you. It is expensive. If I hadn't already purchased it I would have just gone with the trays on the bottom shelf as well.

Light Reflector (optional) - If you will not have your shelving unit in front of a window that gets sun, you may choose to purchase something that reflex the light from your bulbs back towards the plants. Mylar survival blankets do this well. One side is silver and shiny, much like tin foil. I chose one that was advertised as 'heavy duty,' as mylar is thin and rips easily.

I got it from Amazon for $14. Here is the link: https://www.amazon.com/dp/B07CJ9BH2M?ref=yo_pop_ma_swf

Fan - air circulation is important to keep plants healthy and keep bugs at bay. A ceiling fan in a small room run on medium, or a larger room run on high should work. If you have no ceiling fan, a simple plug-in fan will do! You may want to consider an adjustable hight, oscillating fan.

I hope this helps!

I just found this on a Facebook group for plants I am a part of and thought it might help you guys as well, it surely helped me! Above are photos of the poster's plants and the poster's name (so that she is credited)

357 notes

·

View notes

Text

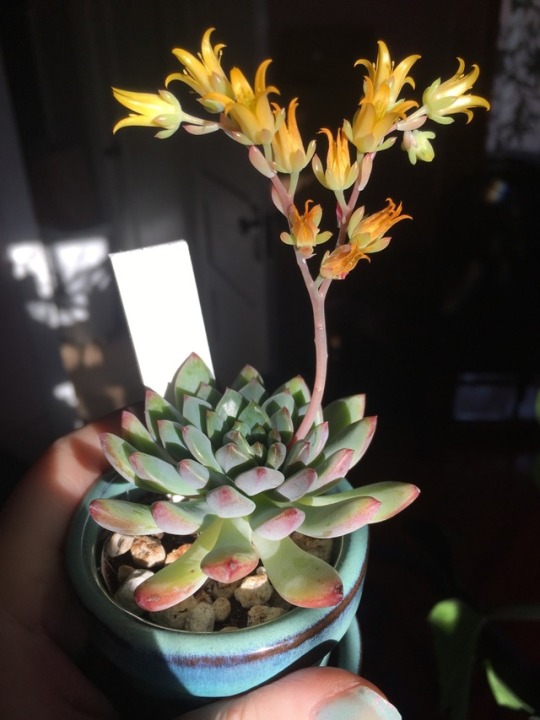

I’m trying to stay upbeat. My biggest light fixture (4 tubes, 4 feet long, T5 fluorescent) just blew unexpectedly. Thankfully I have an awesome friend who shares my plant fixation and he lent me some bulbs! It’s still not as bright as the dead fixture, but I can lower these bulbs some more, and am doing the best I can. Hopefully product support will get in touch with me so I can either fix this fixture myself, or get a replacement.

My sedeveria “blue elf” has cute yellow flowers, and the mammillaria (pringleii? Rhodantha?) has started her flower crown, much to my dismay. Also, hey look! Aeoniums!

Also was proud of myself for cleaning up the windows/trims/glass in this room finally, it was hella dusty.

The pot count for this room is currently 54. It’s crowded, but 90% of the plants are little, so hey!

#houseplants#plant hoarder#succulents#echeverias#aeoniums#cacti#mammillaria#my jade looks so much happier these days#spot the ficus!#i love them all so much but i cant get more until i get support on the t5#if i were a reasonable person i would hold off until spring#but there are so many plants on my wish list still!

211 notes

·

View notes

Text

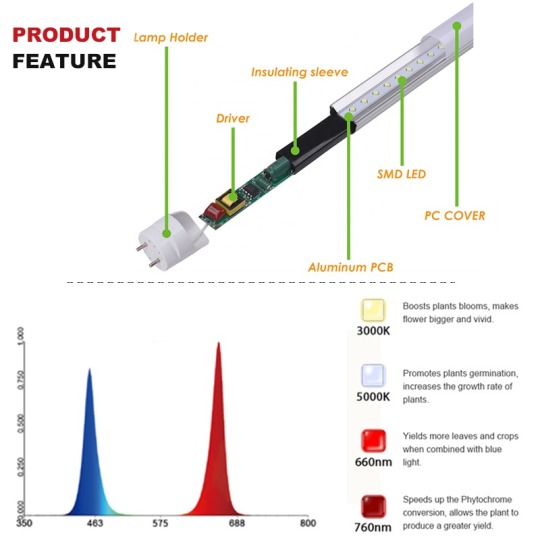

LED Tube Light

4ft LED Fluorescent Tube Light Fixtures is endurable with the life span that it can keep working about 50,000 hours that it can be used over and over again. With the scientific design, it is convenient to use with simple operation which is able to maintain the lighting steadily. The product is a kind of the 4ft led fluorescent tube light fixtures which adopts the latest LED technology, which is able to convert the electricity into light with less energy consumption that it is quite cost effective. Magnetic ballast tube is easily fitted, which is able to take place of the traditional fluorescent tube lamps. Adopting the latest LED technology, it is energy-saving which can greatly reduce the cost of electricity. It is economical for the home and the office. 4 Foot LED T8 Tube Light Fixture for Home Use is engineered to light instantly when the switch is flipped that you don't need to wait for the old fluorescent tubes to warm up, which is able to provide the stable light with no flashing, good to your eyes. 20W T8 LED Fluorescent Tube Light is waterproof, light in weight with small size which is quite easy to carry and move. Adopting the premium materials, it has the strong frame to support the normal operation, which is resistant to rust, dust and oxygen, prolonging its service time. 40W 120v 4 Foot LED Fluorescent Tubes is able to work silently with no noise, which can provide the quiet working environment. And it is energy-saving which can contribute to save money, and time. 4ft LED Tube Light Fixture is the tube light with the new LED technology which is specialized in its low energy consumption that it can directly convert the electricity into light, reducing the waste of power and improving the working efficiency. Dimmable T8 LED Tube Light Fixtures are the kind of professional luminaire made by high quality materials, aluminum and PC, which is designed with the resistance to water, dust and corrosion, for the purpose of ensuring the safe working environment. 4ft LED Fluorescent Lights is green, safe and healthy with no harmful substances, which is able to protect the nature and do no harm to the human body. We also have Direct Wire LED T8 Tubes Outdoor and 4ft LED T5 Tube Lights for Under Cabinet. 5ft LED Tube Light Fittings adopt end or rear cable entry for maximum potential energy savings, which is a suitable alternate and a perfect replacement for Traditional T8 tubes which saves your energy cost by consuming less power. We also have Outdoor LED Tube Light for Building Façade, High Brightness Meeting Room LED Tube Lights, T8 LED Tube Light for Living Room and IP65 High Quality Indoor Aluminum LED Tube Light.

https://www.toppolighting.com/led-tube-light/t8-led-tube-light/

1 note

·

View note