#thermal management market size

Text

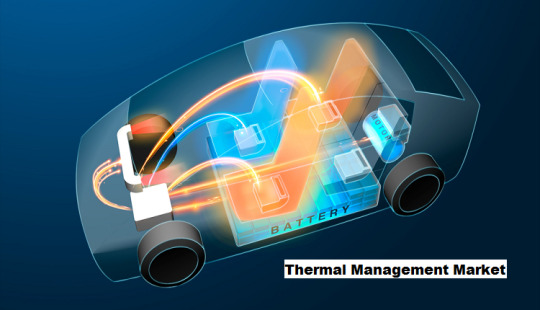

Thermal Management Market Witnessing Substantial Growth with Adhesive Materials Segment

The increasing global thermal management market is driven by rise of electric vehicles (EVs) and hybrid vehicles, expansion of data centers and cloud computing during the forecast period 2024-2028.

According to TechSci Research report, “Thermal Management Market - Global Industry Size, Share, Trends, Opportunity, and Forecast 2018-2028, The Global Thermal Management Market is experiencing a dynamic evolution driven by the escalating demand for advanced solutions to address heat dissipation challenges across various industries. In an era where electronic devices are becoming increasingly compact and powerful, the need for effective thermal management has become a critical aspect of product development. This demand is particularly pronounced in sectors such as automotive, consumer electronics, data centers, and aerospace, where efficient heat dissipation is paramount for maintaining optimal performance and preventing component failures.

The market is witnessing significant growth due to the global push towards sustainability and the increasing adoption of electric vehicles (EVs) and hybrid vehicles. The automotive industry, in particular, is undergoing a transformative shift, with thermal management solutions playing a crucial role in ensuring the longevity and efficiency of batteries and power electronics in EVs. Simultaneously, the rapid growth of data centers and the emergence of edge computing are driving the demand for thermal management solutions capable of handling the heat dissipation challenges associated with high-density computing environments.

Europe stands out as a dominant player in the Global Thermal Management Market, leveraging its commitment to technological innovation, stringent environmental regulations, and a diverse industrial landscape. The region's emphasis on sustainability aligns with the global trend towards eco-friendly technologies, positioning European companies at the forefront of providing thermal management solutions that adhere to both performance and environmental standards.

The integration of artificial intelligence (AI) in thermal management systems is another notable trend, allowing for predictive analysis and proactive thermal management strategies. Moreover, the market is grappling with challenges such as supply chain disruptions, rapid technological advancements, and cost constraints, necessitating continuous innovation and adaptability among market participants.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the "Global Thermal Management Market."

https://www.techsciresearch.com/report/thermal-management-market/22927.html

The global thermal management market is segmented into material, end user, and region. Based on material, the market is segmented into adhesive materials, non-adhesive materials. Based on end user, the market is segmented into automotive, aerospace, consumer electronics, servers & data centers, aerospace & defense, healthcare. Based on region, the market is further bifurcated into North America, Asia-Pacific, Europe, South America, Middle East & Africa. Based on end user, servers & data centers dominated in the global thermal management market in 2022.

Servers and data centers serve as the backbone of the digital infrastructure, facilitating the storage, processing, and dissemination of vast amounts of data. As these facilities continue to evolve, embracing higher computational capabilities and processing speeds, the associated heat generation has intensified exponentially. This has catapulted thermal management to the forefront of priorities for the server and data center industry, making it a pivotal driving force in the overall thermal management market.

The server and data centers segment's dominance can be attributed to several factors. First and foremost is the sheer scale of data processing within these facilities. The relentless demand for faster and more powerful servers to handle complex computations and data analytics has led to an escalation in heat dissipation challenges. Effective thermal management is imperative to prevent overheating, system failures, and downtime, which can have significant economic and operational repercussions.

Key market players in the global Thermal Management market are: -

Honeywell International Inc.

Parker Hannifin Corporation

Advanced Cooling Technologies Inc.

Gentherm Incorporated

Autoneum Holding AG

Vertiv Co

Delta Electronics, Inc.

Denso Corporation

Valeo

Mahle GmbH

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=22927

Customers can also request for 10% free customization on this report.

“The Global Thermal Management Market is driven by the increasing demand for efficient heat dissipation solutions across industries. With electronic devices becoming more powerful and compact, the market experiences a surge in demand, especially in automotive, consumer electronics, data centers, and aerospace. Europe plays a dominant role, emphasizing sustainability and innovation. The rise of electric vehicles, data centers, and the integration of AI in thermal management contribute to the market's growth.

Challenges include supply chain disruptions and rapid technological advancements, requiring continuous adaptation. In essence, the market reflects a dynamic landscape shaped by the need for sustainability and technological advancements.” said Mr. Karan Chechi, Research Director with TechSci Research, a research-based global management consulting firm.

“Thermal Management Market – Global Industry Size, Share, Trends, Opportunity, and Forecast, Segmented By Material (Adhesive Materials, Non-adhesive Materials), By End User (Automotive, Aerospace, Consumer Electronics, Servers & Data Centers, Aerospace & Defense, Healthcare), By Region, and By Competition, 2018-2028,” has evaluated the future growth potential of Global Thermal Management Marketand provides statistics & information on market size, structure, and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in Global Thermal Management Market.

Browse Related Research

Biomass Gasification Market

https://www.techsciresearch.com/report/biomass-gasification-market/14961.html

Distributed Generation Market

https://www.techsciresearch.com/report/global-distributed-generation-market/2491.html

Marine Gensets Market

https://www.techsciresearch.com/report/global-marine-gensets-market/2493.html

Contact

Techsci Research LLC

420 Lexington Avenue, Suite 300,

New York, United States- 10170

Tel: +13322586602

Email: [email protected]

Website: www.techsciresearch.com

#Thermal Management Market#Thermal Management Market Size#Thermal Management Market Share#Thermal Management Market Trends#Thermal Management Market Growth

0 notes

Link

#market research future#thermal management market#thermal management market size#thermal management#thermal management system

0 notes

Text

#Automotive Battery Thermal Management System Market Overview#Size#Share#Top Companies#Growth Will Expand at a CAGR of 16.35% by 2028 | 196 Pages#intellectualmarketinsights

0 notes

Text

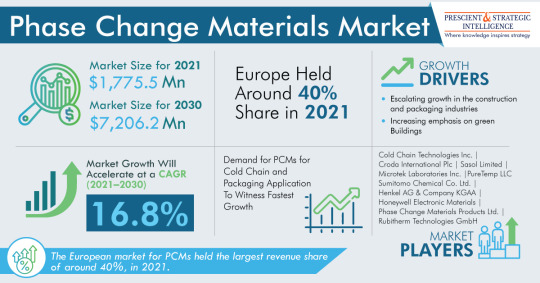

Transforming Industries: Phase Change Materials Market Insights

As stated by P&S Intelligence, the total revenue generated by the phase change materials market was USD 1,775.5 million in 2021, which will power at a rate of 16.8% by the end of this decade, to reach USD 7,206.2 million by 2030.

This has a lot to do with the increasing growth in the construction and packaging sectors and increasing importance on green buildings.

Cold chain and packaging category will grow at the highest rate, of above 17%, in the years to come. This can be mostly because of the surge in PCM requirement to sustain precise temperatures through the supply chain while lowering the emissions of carbon dioxide.

Using ACs and electric fans to stay cool contributes to approximately 20% of the total electricity employed in buildings globally. The increasing requirement for space cooling is straining quite a few countries' power infrastructure, along with bringing about increased emissions.

With the enormous increase in the requirement for energy-efficient ACs, the requirement for PCMs will soar, as the electrical consumption of modified ACs with PCMs could be brought down by 3.09 kWh every day.

Europe dominated the industry with a share, of about 40%, in the recent past. The predisposition toward the acceptance of eco-friendly materials will power the PCM industry in the region.

European regulatory associations, such as the SCANVAC, took more than a few initiatives for developing and promoting and effective building mechanical solutions and increase awareness pertaining to PCM applications.

The convenience of paraffin at a wide range of temperatures is a major reason for its appropriateness as an energy storage medium. Likewise, paraffin-based PCM is called a waxy solid paraffin, safe, dependable, noncorrosive, and economical material.

HVAC systems had the second-largest share, of about 30%, in phase change materials market in the recent past. This has a lot to do with the fact that PCM installation decreases fluctuations of temperature. HVAC with PCM supports in maintaining a steadier temperature and eliminating thermal uneasiness caused by alterations in temperature.

It is because of the emphasis on green buildings, the demand for phase change materials will continue to rise considerably in the years to come.

#Phase Change Material Market#Phase Change Material Market Size#Phase Change Material Market Share#Phase Change Material Market Growth#Phase change materials (PCMs)#Thermal energy storage#Energy efficiency solutions#Heat management technology#Sustainable materials#Building insulation#HVAC systems#Thermal regulation#Cold chain logistics#Renewable energy storage#Temperature-sensitive packaging

0 notes

Text

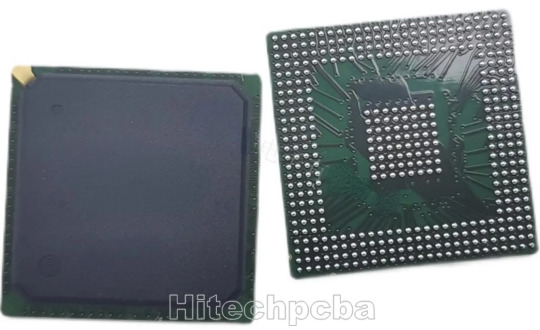

BGA PCB Assembly

What’s BGA PCB?

BGA PCB is Printed Circuit Boards with Ball Grid Array. We use various sophisticated techniques for making BGA PCBs. Such PCBs have a small size, low cost, and high packaging density. Hence, they are reliable for high-performance applications.

What’s BGA PCB Assembly?

Ball Grid Array (BGA) assembly technology is a surface mount packaging technology applied to integrated circuits, which is often used to permanently fix devices such as microprocessors. BGA assembly can accommodate more pins than other packages such as Dual in-line packages or Quad Flat Packages, and the entire bottom surface of the device can be used as pins , instead of only peripherals available, and also have a shorter average wire length than peripheral-limited package types for better high-speed performance.

Our BGA assembly services cover a wide range, including BGA prototype development, BGA PCB assembly, BGA component removal, BGA replacement, BGA rework and reballing, BGA PCB assembly inspection, and so on. Leveraging our full-coverage services, we can help customers streamline the supply network and accelerate product development time.

Benefits of BGA PCB Assembly

Efficient Use of Space – BGA PCB layout allows us to efficiently use the available space, so we can mount more components and manufacture lighter devices.

Better Thermal Performance – For BGA, the heat generated by the components is transferred directly through the ball. In addition, the large contact area improves heat dissipation, which prevents overheating of components and ensures long life.

Higher Electrical Conductivity – The path between the die and the circuit board is short, which results in better electrical conductivity. Moreover, there is no through-hole on the board, the whole circuit board is covered with solder balls and other components, so vacant spaces are reduced.

Easy to Assemble And Manage – Compared to other PCB assembly techniques, BGA is easier to assemble and manage as the solder balls are used directly to solder the package to the board.

Less Damage to Leads – We use solid solder balls for manufacturing BGA leads. Hence, there is a lesser risk that they will get damaged during the operation.

In a word, BGA PCB assembly, have these advantages, high density, better electrical conductivity, lower thermal resistance, easy to assembly & manage are some of the advantages of BGA PCB.

Stringent BGA PCB Assembly Testing Process

To achieve the highest quality standards for BGA assembly, we use a variety of inspection methods throughout the process including optical inspection, mechanical inspection, and X-ray inspection. Among them, the inspection of BGA solder joints must use X-rays. X-rays can pass through the components to inspect the solder joints below them, so as to check the solder joint position, solder joint radius, and solder joint thickness.

Inspection of BGA PCB

We mostly use X-ray inspection for analyzing the features of BGA PCBs. This technique is known as XRD in the industry and relies on X-rays for unveiling the hidden features of this PCB. This kind of inspection reveals.

* Solder Joint Position

* Solder Joint Radius

* Change in Circular shape

* Solder Joint Thickness

The Hitechpcba advantage lies in a whole range of aspects, beginning from the fact that we have the proven technology available at our disposal. With over 15 years of experience in a wide range of PCB Fabrication and Assembly techniques, what we also have is trained manpower and importantly, robust industry experience and best practices that you can benefit from.

Our unstinting devotion to quality and customer satisfaction means that once you partner with us, you can rest assured that you will get nothing but the best. The customer-oriented approach also shows up in your commitment to delivery times. With quick turnaround times, you can reap the benefit of quick time-to-market, which, in turn, can be a major source of competitive advantage.

Whether your requirement is BGA PCB design, BGA PCB, BGA PCB layout, BGA PCB Assembly or BGA rework, you can rest assured that you will get superior quality and performance, that will in turn, positively impact the performance of your final product.

With our efficient network of component suppliers and the many economies of scale that we enjoy, that you will get optimal costs, is a given.

Please feel free to contact us ([email protected]) if you have any other special request on the BGA pcb assembly.

3 notes

·

View notes

Text

The Point of Sale (POS) receipt printer Market has witnessed remarkable growth over the past few years, driven by the increasing adoption of POS systems across industries such as retail, hospitality, and healthcare. These printers, essential for issuing transaction receipts, play a critical role in ensuring smooth business operations, enhancing customer satisfaction, and maintaining transaction records. With advancements in technology and changing consumer expectations, the POS receipt printer market is evolving rapidly, presenting a plethora of growth opportunities.

Browse the full report at https://www.credenceresearch.com/report/point-of-sale-pos-receipt-printer-market

Market Overview

POS receipt printers are integral components of POS systems, which include hardware and software designed to facilitate and streamline business transactions. These printers are commonly used in retail stores, restaurants, hotels, and other service-oriented industries to print receipts, invoices, and bills. The global POS receipt printer market has been experiencing significant growth, supported by the proliferation of digital payment methods, increased demand for efficient transaction management, and the rise of cloud-based POS systems.

According to market research, the POS receipt printer market is projected to grow at a healthy compound annual growth rate (CAGR) over the coming years. In 2023, the market size was estimated at approximately USD 3 billion, and it is expected to expand further as businesses increasingly shift towards automated and paperless transaction systems.

Key Drivers of Market Growth

1. Digital Transformation in Retail and Hospitality

The widespread adoption of digital payment systems has led to an increased demand for POS receipt printers. Retailers and service providers are embracing technologies like contactless payments, mobile wallets, and online transactions, which necessitate modern POS systems that can quickly generate receipts for customers. These printers also support diverse printing needs, including QR codes, barcodes, and promotional content, thus enhancing the customer experience and facilitating faster checkout processes.

2. Growth of E-commerce and Omnichannel Retailing

The rise of e-commerce and omnichannel retail strategies is propelling the POS receipt printer market. As consumers increasingly expect seamless shopping experiences across multiple platforms (both online and offline), businesses are integrating POS systems that allow them to synchronize inventory, manage orders, and provide receipts regardless of the sales channel. Receipt printers, in this context, ensure transparency and accountability in both in-store and delivery-based transactions.

3. Increased Adoption in Emerging Markets

Emerging markets, particularly in Asia-Pacific and Latin America, are witnessing a surge in the adoption of POS systems due to the growth of the retail and hospitality sectors. As small and medium-sized enterprises (SMEs) modernize their operations, they are turning to POS systems equipped with receipt printers to manage payments more efficiently. Moreover, government initiatives promoting cashless transactions in these regions are further accelerating the demand for POS receipt printers.

Technological Advancements

Technological advancements have significantly influenced the POS receipt printer market. Over the years, traditional thermal and impact printers have evolved to offer more sophisticated solutions, including wireless and Bluetooth-enabled devices. Key innovations include:

1. Mobile and Wireless POS Printers

The growing popularity of mobile POS (mPOS) systems has led to the development of portable receipt printers. These wireless printers enable businesses to print receipts on the go, making them ideal for events, food trucks, and other mobile operations. Bluetooth and Wi-Fi-enabled POS printers also allow seamless integration with tablets and smartphones, further enhancing their convenience.

2. Cloud-Based Printing Solutions

Cloud-based POS systems are gaining traction, particularly among businesses looking to streamline operations and centralize data. POS receipt printers integrated with cloud technology enable businesses to store and retrieve transaction data remotely, offering greater flexibility and efficiency. Cloud-based solutions also allow for the management of multiple POS devices from a single location, making them ideal for chains and franchise businesses.

3. Eco-friendly Solutions

With growing concerns about sustainability, there has been a rising demand for eco-friendly POS receipt printers. Manufacturers are introducing energy-efficient printers that use less paper and consumables, aligning with businesses’ efforts to reduce their carbon footprint. Some advanced printers also offer the option to issue digital receipts, further minimizing paper waste.

Challenges

Despite its growth potential, the POS receipt printer market faces certain challenges. One significant hurdle is the shift towards paperless transactions, as consumers increasingly opt for digital receipts and businesses seek to reduce paper use. While digital receipts offer convenience and environmental benefits, they also pose a challenge for traditional receipt printer manufacturers who must innovate to remain relevant.

Additionally, market competition is intense, with numerous players offering a wide range of POS printers. Price sensitivity, particularly among SMEs, can also impact growth, as businesses may opt for lower-cost options without considering the long-term benefits of high-quality printers.

Future Outlook and Opportunities

The future of the POS receipt printer market looks promising, with continued growth expected due to technological advancements, the expansion of e-commerce, and increasing demand in emerging markets. The growing trend towards mPOS systems, cloud-based solutions, and eco-friendly printers offers lucrative opportunities for market players.

To stay competitive, manufacturers must focus on innovation, particularly in the areas of wireless connectivity, sustainability, and integration with modern POS systems. As businesses increasingly prioritize efficiency and customer experience, the demand for advanced POS receipt printers will continue to rise, solidifying their role as an essential component of transaction management systems.

Key Player Analysis:

Epson

Star Micronics

Bixolon

HP Inc.

Seiko Instruments

Zebra Technologies

CognitiveTPG

Citizen Systems

Toshiba TEC Corporation

Fujitsu

Segmentations:

By Type

Desktop Receipt Printer

Mobile Receipt Printer

By Technology

Thermal Printer

Impact/Dot Matrix

Inkjet

By End-use Industry

Hospitality

Healthcare

Retail

Warehouse/Distribution

Entertainment

Others

By Region

North America

The U.S

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/point-of-sale-pos-receipt-printer-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

The Role of Gaskets in High-Pressure Environments: What You Need to Know - Gasco Inc

Gasco Inc, a respected Indian company, is a prominent Gasket Manufacturers in India. As a trusted name in the industry, the company has established itself as a leading player in the Indian market for this component.

As a renowned Gasket Suppliers in India, we take pride in offering high-quality gaskets at affordable prices. Their superior gaskets are designed to maintain exceptional performance, making them crucial for the efficient and leak-proof operation of mechanical systems. Regular maintenance and replacement of gaskets is essential, and we are proud to provide a wide selection of excellent gaskets in various cities, including Gasket Manufacturer in Mumbai and Gasket Manufacturer in Pune.

Being a leading O rings Manufacturers in India and Seal Ring Manufacturers in India, we offers a diverse range of sizes to cater to the diverse needs of its customers. The company's unwavering dedication to upholding the highest standards is uncompromising, and it consistently supplies superior gaskets to clients across the globe. We never compromise on quality, and its customers can trust the company to deliver reliable and long-lasting products every time.

Gaskets are among the most significant components in most industrial installations, providing the much-needed seal solutions for equipment and pipes. Their role becomes even more crucial at times of high pressure. Severe leakage and possible damage to a machine due to gasket failure as well as serious safety issues are some of the reasons why the understanding of a gasket's importance in high-pressure conditions is also a desirable requisite in the industry as the efficiency and output increase. It then becomes very essential for the engineers, technicians, and managers to understand the role of a gasket.

1. What is a Gasket?

A gasket is a mechanical seal that fills the space between two or more mating surfaces, preventing leakage of fluids or gases under compression. Made from a variety of materials including rubber, silicone, metal, cork, and composite materials, gaskets are designed to withstand a range of environmental conditions, including temperature, pressure, and chemical exposure.

In high-pressure environments, gaskets must maintain their integrity despite significant forces acting upon them. Any deformation or failure could compromise the system, making gasket selection and installation critical to the safety and efficiency of the operation.

2. Challenges in High-Pressure Environments

High-pressure environments include oil and gas pipelines, power generation, chemical processing, and aerospace applications. Such conditions present extreme challenges for the parts used in such systems. Gaskets must withstand high pressure and often also high temperatures, aggressive chemicals, and mechanical vibrations.

Some of the key challenges for gaskets in such environments include:

Compression Forces: High pressures exert significant compressive forces on gaskets. These forces can cause materials to deform or extrude, leading to leaks. Choosing the right material and design is essential to avoid such issues.

Thermal Expansion: Changes in temperature can cause the materials around the gasket to expand and contract. If the gasket material does not have the right thermal characteristics, it may lose its ability to seal or deteriorate over time.

Chemical Compatibility: In sectors like chemical processing, gaskets face exposure to corrosive materials. Selecting gasket materials that are compatible with the specific chemicals present is crucial to prevent deterioration or malfunction.

Vibration and Movement: High-pressure systems often undergo mechanical oscillations or displacements. Gaskets must be able to adapt to these changes while still maintaining their ability to create a tight seal.

3. Types of Gaskets for High-Pressure Applications

Different types of gaskets are used in high-pressure applications, each with unique characteristics suited to specific environments. Here are some common gasket types that are widely used:

a) Metallic Gaskets

Metallic seals are frequently used in high-pressure settings because of their resilience and capacity to endure harsh conditions. These seals are commonly constructed from stainless steel, Inconel, or other high-strength metals. They are well-suited for applications involving extreme temperatures, high pressures, and corrosive surroundings.

Spiral Wound Gaskets: These sealing devices are made by combining metal and filler materials, such as graphite, which are then wound into a spiral shape. This construction enables the gasket to withstand high levels of pressure and temperature while still remaining flexible.

Ring-Type Joint Gaskets (RTJ): Metal RTJ gaskets are used in demanding settings with high pressure and heat, particularly in the oil and gas sectors. Crafted from solid metal, they fit into a grooved flange and create a tight seal when compressed, making them dependable for crucial applications.

b) Non-Metallic Gaskets

Soft and flexible non-metallic gaskets, commonly made from materials like rubber, PTFE, or graphite, are often used in situations where high pressure is not the sole consideration, but where there is a need for chemical resistance, flexibility, or electrical insulation as well.

PTFE Gaskets: PTFE is a chemically stable material that can endure a variety of chemicals, making it well-suited for chemical processing settings. Additionally, it provides low friction and high heat resistance.

Graphite Gaskets: Graphite seals provide strong resistance to high heat and pressure. They are commonly utilized in steam, gas, and chemical systems due to their capability to maintain sealing efficiency even when temperatures vary.

c) Composite Gaskets

Composite gaskets blend metallic and non-metallic components to leverage the strengths of each material. They are commonly used in situations requiring a mix of temperature tolerance, pressure resistance, and flexibility.

Kammprofile Gaskets: These gaskets have a metal center with a jagged shape, frequently covered with a softer, non-metal material like graphite. The metal center gives the gasket strength and resistance to pressure, while the softer material enhances the sealing ability.

We offer an array of sealing in diverse dimensions across the Indian subcontinent.

PTFE Sheet Gaskets Manufacturers in India

Expanded PTFE Sheet Gaskets Manufacturers In India

Ring Joint Gaskets Manufacturers In India

Metal Jacketed Gaskets Manufacturers In India

4. Gasket Material Selection for High-Pressure Environments

Selecting the right gasket material is crucial for ensuring reliability in high-pressure environments. Some key considerations include:

Pressure Rating: The gasket material needs to be able to handle the highest pressure the system will operate under without becoming misshapen or breaking.

Temperature Tolerance: Extreme heat can cause sealing materials to become soft or deteriorate. It is crucial to select materials with suitable thermal characteristics to guarantee consistent performance.

Chemical Compatibility: Chemicals can degrade certain gasket materials, leading to corrosion, swelling, or cracking. Verifying chemical compatibility is crucial, particularly in industries such as oil, gas, and chemical production.

Creep Resistance: Certain materials gradually change shape or deform when subjected to continuous pressure over time. In high-pressure settings, choosing a material with strong resistance to this deformation is crucial to ensure effective sealing performance.

5. Proper Installation and Maintenance

A well-made gasket can still malfunction if not installed correctly. In high-pressure systems, it's vital to make sure the gasket is uniformly compressed between the connecting parts. Tightening it too much can make the gasket distort, while not tightening it enough can cause it to leak.

Periodic examination and upkeep are also crucial for sustained effectiveness. In numerous cases, high-pressure systems undergo cyclic pressure and temperature fluctuations, which can lead to the gradual deterioration of gasket material over time. By inspecting and replacing gaskets as part of a regular maintenance routine, industries can prevent expensive and hazardous breakdowns.

6. The Future of Gasket Technology

As industries advance and push the boundaries of pressure and temperature in their operations, gasket technology must also progress. Innovative materials, including advanced composites and high-performance rubbers, are being created to meet the requirements of increasingly challenging applications.

Advancements in manufacturing, including 3D printing, are enabling the creation of customized gasket designs that can be tailored to meet specific needs. This degree of personalization allows for more accurate sealing solutions, which minimizes the likelihood of failure and enhances the overall reliability of the system.

Our shipping services are available in the countries listed below:

gasket manufacturers in the UAE

gasket manufacturers in South Africa

gasket manufacturers in Saudi Arabia

gasket manufacturers in Kuwait

To learn more, visit our website: gascogaskets.com

#GasketManufacturers#GasketManufacturersinIndia#GasketSuppliersinIndia#Gasket#GasketManufacturerinMumbai

0 notes

Text

Cryogenic Valves Market Size, Trends, Research Report - 2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Cryogenic Valves Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Cryogenic Valves Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Cryogenic Valves Market?

The global cryogenic valves market size reached US$ 3.8 billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 6.5 billion in 2032, exhibiting a growth rate (CAGR) of 6.2% during 2024-2032.

What are Cryogenic Valves?

Cryogenic valves are specifically designed to control the flow of extremely cold gases and liquids, typically at temperatures below -150°C (-238°F). They are crucial for managing cryogenic substances such as liquid nitrogen, helium, oxygen, and natural gas in industries like aerospace, energy, medical, and chemical processing. Built to maintain secure seals and provide effective insulation, these valves prevent leaks and reduce thermal loss even under extreme cold conditions. Their construction materials and design enable them to endure the expansion and contraction caused by low temperatures, ensuring safe and reliable performance in demanding applications.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1931

What are the growth prospects and trends in the Cryogenic Valves industry?

The cryogenic valves market growth is driven by various factors and trends. Cryogenic valves are designed to manage the flow of extremely cold liquids and gases, typically at temperatures below -150°C (-238°F), such as liquid nitrogen, helium, and oxygen. Essential for sectors like aerospace, energy, medical, and chemical processing, these valves ensure precise control and safe handling of cryogenic fluids. Built to endure the harsh conditions of low temperatures, cryogenic valves are constructed with materials and insulation methods that prevent leakage and reduce thermal loss. Their design accommodates the expansion and contraction of materials due to temperature changes, providing reliable and efficient performance in demanding environments. Hence, all these factors contribute to cryogenic valves market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Paper Type:

Matte Paper

Glossy Paper

Semi-gloss Paper

By Application:

Universal Files Copy Application

Advertisement Making Application

Graphic Design Application

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Emerson Electric Co.

Flowserve Corporation

Schlumberger Limited

Parker Hannifin Corporation

Velan Inc.

Herose GmbH

Chart Industries, Inc.

Cryogenic Limited

L&T Valves Limited

Bray International, Inc.

Powell Valves

Habonim Industrial Valves & Actuators

Valco Group

Samson AG

Valvesco AG

View Full Report: https://www.reportsandinsights.com/report/Cryogenic Valves-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

The Impact of Miniaturization on Electromechanical Assembly Design

Get seamless Electromechanical assemblies | Violin Technologies

The push toward miniaturization has become a significant trend in technology and manufacturing, especially in electromechanical assembly design. Miniaturization refers to the process of creating smaller components and systems while maintaining or even enhancing their functionality. This shift has brought about a host of challenges and opportunities for manufacturers, engineers, and designers in the electromechanical assembly sector.

Increased Demand for Smaller, Smarter Devices

The drive for smaller devices is most evident in industries like consumer electronics, medical devices, aerospace, and telecommunications. Smartphones, wearable technology, and medical implants are becoming increasingly compact, pushing the boundaries of what can be achieved in electromechanical assemblies. This trend isn’t just about shrinking size; these smaller devices are expected to perform at the same level—or better—than their larger predecessors.

Manufacturers must now focus on designing compact assemblies that integrate both electrical and mechanical components without sacrificing performance, efficiency, or durability. These new demands have led to innovations in material science, component design, and assembly techniques.

Challenges in Precision and Accuracy

As components shrink in size, precision becomes critical. Tolerances that were acceptable in larger assemblies no longer apply. Small deviations can lead to functionality issues or complete device failure. Engineers must now design with far more exacting standards, using high-precision tools and techniques such as micro-assembly and advanced soldering methods.

Additionally, traditional manufacturing methods often cannot meet the precision required for miniaturized components, necessitating the use of advanced technologies like laser machining, robotic assembly, and 3D printing.

The Role of Advanced Materials

Miniaturization requires the use of advanced materials that are not only smaller but also lighter and more durable. Materials like flexible printed circuit boards (PCBs), lightweight composites, and micro-electromechanical systems (MEMS) are becoming more commonplace. These materials are designed to support smaller and more complex assemblies while ensuring that they can withstand the mechanical and environmental stresses typical of real-world applications.

Furthermore, it is crucial to integrate heat management systems in miniaturized assemblies. Smaller devices are more prone to overheating, making thermal management a key factor in their design.

Increased Complexity in Assembly Processes

With miniaturization comes greater complexity in the assembly process. Fitting numerous components into a smaller footprint means that every millimetre of space must be utilized efficiently. Engineers need to consider how components interact, the flow of electricity, and the movement of mechanical parts within a confined space. This complexity often requires rethinking traditional assembly methods, utilizing modular designs, and finding innovative ways to fit components together.

The shift toward automation is also becoming more critical. Robotic assembly lines can offer the precision needed for these small-scale assemblies, reducing the risk of human error and improving efficiency.

Cost Implications

While miniaturization offers many benefits, it can also increase costs, especially in the initial design and prototyping stages. High-precision tools, advanced materials, and the need for specialized assembly techniques all contribute to higher costs. However, as demand for miniaturized components grows, economies of scale often come into play, eventually driving down the price of production.

Manufacturers need to balance these costs with the potential benefits, such as the ability to enter new markets, create innovative products, and meet the growing demand for smaller, more efficient devices.

The Future of Miniaturization in Electromechanical Assembly

The trend toward miniaturization is continuing. In fact, it’s likely to accelerate as industries like healthcare, telecommunications, and consumer electronics continue to push the limits of what’s possible. Emerging innovations, including nanotechnology and quantum computing, are likely to bring even more changes to electromechanical assembly design, making it essential for manufacturers to stay ahead of the curve.

As devices become smaller, the need for ultra-precise, efficient, and innovative assembly processes will continue to grow. Businesses that are able to adapt and innovate to address these challenges will be well-positioned to lead the way in the next generation of electromechanical devices.

Conclusion

Miniaturization has had a profound impact on electromechanical assembly design. While it presents challenges in terms of precision, material use, and cost, it also opens up exciting opportunities for innovation and growth. As industries continue to demand smaller, more efficient devices, manufacturers must embrace new technologies and assembly techniques to stay competitive. The future of electromechanical assembly lies in the ability to balance the demands of miniaturization with the need for performance, reliability, and cost-effectiveness.

#cable assembly#manufacturer#wires and cables#manufacturing#customsheetmetal#precisionstamping#qualitymatters#partnerwithus

0 notes

Text

Heat Exchangers Market 2024: Industry Analysis and Opportunity Assessment, Forecast to 2030

Heat Exchangers Industry Overview

The global heat exchangers market size was estimated at USD 18.19 billion in 2023 and is expected to expand at a compounded annual growth rate (CAGR) of 5.4% from 2024 to 2030.

Rising focus on efficient thermal management in various industries, including oil & gas, power generation, chemical & petrochemical, food & beverage, and HVAC & refrigeration, is expected to drive the demand for heat exchangers over the forecast period. Rising demand from chemical industry coupled with increasing technological advancements and a growing focus on improving efficiency standards is expected to drive heat exchangers market growth. Most processes in petrochemical facilities involve high pressure and temperature, thus, necessitating the optimization of heat transfer and enhancement of energy savings, which, in turn, is likely to boost the demand for energy-efficient heat exchangers.

Gather more insights about the market drivers, restrains and growth of the Heat Exchangers Market

U.S. dominated the North America heat exchanger market in 2023, owing to high electricity demand, industrialization, and investments in renewable power generation. Rising investments by oil & gas companies in exploration & production activities in the U.S. are expected to boost the demand for these products in oil & gas industry.

Significant power markets such as China, U.S., India, Russia, and Japan are restructuring their operating models to adopt the structure of renewable energy and efficient utilization of energy by installing heat exchangers and shifting from traditional energy use. This is expected to drive the demand for heat exchangers.

Technological advancements such as tube inserts in heat exchangers are expected to complement the market growth. Furthermore, ongoing technological improvements to improve energy efficiency, total life cycle cost, durability, and compactness of heat exchangers are expected to drive industry growth.

Manufacturers of these products face a long list of difficult supply chain challenges, including increasing demand variability, intense global competition, more environmental compliance regulations, increasing human- and nature-based risks, and inventory proliferation. COVID-19 pandemic has created new challenges, which are compelling manufacturers to innovate their supply chains at a faster speed.

Heat Exchangers Market Segmentation

Grand View Research has segmented the global heat exchangers market report based on product, end-use, material and region:

Product Outlook (Revenue, USD Billion, 2018 - 2030)

Plate & Frame Heat Exchanger

Brazed Plate & Frame Heat Exchanger

Gasketed Plate & Frame Heat Exchanger

Welded Plate & Frame Heat Exchanger

Others

Shell & Tube Heat Exchanger

Air-Cooled Heat Exchanger

Others

End-use Outlook (Revenue, USD Billion, 2018 - 2030)

Chemical & Petrochemical

Oil & Gas

HVAC & Refrigeration

Power GenerationFood & Beverage

Pulp & Paper

Others

Material Outlook (Revenue, USD Billion, 2018 - 2030)

Metals

Alloys

Others

Regional Outlook (Revenue, USD Billion, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Italy

Spain

UK

Asia Pacific

China

Japan

India

South Korea

Australia

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

South Africa

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The global wood plastic composites market size was estimated at USD 7.15 billion in 2023 and is expected to grow at a CAGR of 11.6% from 2024 to 2030.

The global industrial fasteners market size was estimated at USD 95.57 billion in 2023 and is expected to grow at a CAGR of 4.7% from 2024 to 2030.

Key Companies & Market Share Insights

Global heat exchangers industry is characterized by presence of multinational as well as regional players that are engaged in designing, manufacturing, and distributing these products. Product manufacturers strive to obtain a competitive edge over their competitors by increasing application scope of their products.

Strategies adopted by manufacturers include new product development, diversification, mergers & acquisitions, and geographical expansion. These strategies aid the companies in expanding their market penetration and catering to changing technological demand across various end-use industries.

Key Heat Exchangers Companies:

Alfa Laval

Danfoss

Kelvion Holding GmbH

Güntner Group GmbH

Xylem Inc

API Heat Transfer

Mersen

Hisaka Works, Ltd.

Chart Industries, Inc

Johnson Controls International

HRS Heat Exchangers

SPX FLOW, Inc.

Funke Wärmeaustauscher Apparantebau GmbH

Koch Heat Transfer Company

Southern Heat Exchanger Corporation

Recent Developments:

For instance, in April 2023, Kelvion launched dedicated air cooler series for natural refrigerants. The CDF & CDH ranges are dual discharge air coolers highlighting a similar proficient tube system.

In May 2023, Alfa Laval is enhancing its brazed plate heat exchanger capacity to bolster the global energy transition. The establishment of new facilities in Italy, China, Sweden, and the U.S. signifies significant progress in their initiative to advance manufacturing intelligence and efficiency throughout the entire supply chain.

In January 2021, Alfa Laval, opened a new facility for the production of brazed heat exchangers in San Bonifacio, Italy. The new facility will have more capacity to fulfill the increasing customer demand.

Order a free sample PDF of the Heat Exchanger Market Intelligence Study, published by Grand View Research.

0 notes

Text

Thyristor Market Revenue, Demand, Segment and Forecast by 2032

Thyristors are semiconductor devices used for high-power switching and control in electronic circuits. These devices are known for their ability to handle large amounts of current and voltage, making them suitable for power regulation and switching applications. Thyristors are commonly used in applications such as motor control, power supplies, and lighting systems. Their ability to remain in a conducting state once triggered makes them ideal for controlling power flow and managing electrical loads in various industrial and commercial systems.

The Thyristor Market size was valued at USD 1.6 billion in 2023 and is estimated to reach USD 2.31 billion by 2031 and grow at a CAGR of 4.21% over the forecast period of 2024-2031.

Future Scope

The future of thyristors is characterized by advancements in semiconductor technology and increasing demand for efficient power control solutions. Innovations in thyristor design and materials will enhance their performance, allowing for higher power ratings and better thermal management. The integration of thyristors with modern control systems and automation technologies will drive further advancements in power regulation and switching applications. Additionally, the growth of renewable energy systems and electric vehicles will create new opportunities for thyristor technology in managing power distribution and conversion.

Trends

Key trends in thyristor technology include the development of high-performance thyristors with improved switching capabilities and thermal management. The use of advanced semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), is gaining traction for their superior performance in high-power applications. There is also a growing emphasis on integrating thyristors with digital control systems to enable precise and efficient power management. Additionally, the trend towards energy efficiency and sustainability is driving innovations in thyristor technology to reduce energy losses and improve system performance.

Applications

Thyristors are used in a wide range of applications requiring high-power switching and control. In industrial automation, thyristors control motor drives and power supplies for machinery. In power electronics, they are used for voltage regulation and phase control in lighting systems. Thyristors are also employed in rectifiers and inverters for converting and managing electrical power in renewable energy systems and electric vehicles. Additionally, they play a role in welding and heating applications where precise control of high power is required.

Solutions and Services

Solutions for thyristors include the design and manufacture of high-performance thyristor modules and components tailored to specific applications. Providers offer integration services to incorporate thyristors into power control systems and automation technologies. Testing and validation services ensure that thyristors meet performance standards and reliability requirements. Additionally, consulting services are available to assist businesses in selecting and implementing thyristor solutions and optimizing power management strategies.

Key Points

Thyristors are semiconductor devices used for high-power switching and control.

Future developments include improved performance, advanced materials, and integration with modern control systems.

Trends include high-performance thyristors, use of SiC and GaN materials, and energy efficiency.

Applications span industrial automation, power electronics, renewable energy systems, and electric vehicles.

Solutions include custom design, integration, testing, and consulting services.

Read More Details: https://www.snsinsider.com/reports/thyristor-market-4208

Contact Us:

Akash Anand — Head of Business Development & Strategy

Email: [email protected]

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

Understanding FRP Square Tubes: Applications and Benefits

Fiber Reinforced Polymer (FRP) square tubes find extensive application across industries because of its desirable characteristics and benefits. These are materials that provide strong, lightweight structural performance as part of a polymer matrix reinforced with fibers such glass or carbon; they deliver engineering solutions for the replacement and design of traditional metals and plastics.

Benefits of FRP Square Tubes

Advantages of FRP square tubesLightweight: The most imposing benefit is the lightness nature of FRP square tube. FRP is so much lighter than steel or aluminum, that it can be handled and transported by one person. That ability is especially valuable in applications that require weight savings, such as the aerospace and automotive industries.

FRP materials are highly resistant to corrosion, which ensures that these can withstand in the toughest conditions. They do not corrode or deteriorate when they get wet, around chemicals and UV light. R e sista nce t o aging increases th e lifespan ofstructures,andsoa moredurable choice taxonomyistrates itsel f over time.

Lightweight, High Strength-to-Weight Ratio: While lightweight – often no more than 1/4 the weight of steel tubes and beams in industrial applications – FRP square tubes offer a high strength-to-weight ratio that allows them to support heavy loads without additional bulk. This single mold-ability makes it very important in construction and infrastructure projects where the durability of structures is a fundamental.

FRP Materials — FRP materials can be molded and designed in any shape &size here it is a greater flexibility to design. This versatility is especially important in architecture, since looks matter. The FTTH Box have FRP square tubes that are capable of customization for different designs and can provide both function as well as aesthetics.

Great Insulation — Unlike metals, FRP square tubes have superb thermal and electrical insulation. This is good in applications that need to shield heat or electricity such as electrical enclosures and thermal management systems.

FRP Square Tubes Applications

Following are where FRP square tubes can be used among a variety of Industries —

Applications: FRP Square tubes are widely used in construction for structural members, grating products and railings. Corrosion resistance means they can be used for bridges, piers and any other outdoor structures with high exposure to the harsh weather.

Automotive – The automotive industry incorporates FRP square tubes in vehicle structures and bodies to lighten the load while maintaining safety and fuel efficiency.

Aerospace: We know that in the field of aerospace, where every single ounce is expensive because you have to lift it off the ground Gravity weighs heavily as a factor with weight being such an important issue. Aircrafts: FRP materials are used in manufacturing various aircraft parts to improve the operational performance & Fuel awareness.

Marine: FRP is corrosion resistant which makes these tubes ideal for use in boat building and other applications that come into contact with saltwater.

Conclusion

The lightweight, robust, and corrosion-resistant characteristics of FRP square tubes are changing a variety of markets. As technology progresses and the need for materials that are more efficient, sustainable as well as aesthetic occurs, FRP will keep expanding its applications. Be it construction, automotive maritime or aerospace applications FRP square tubes have gained traction as a reliable and modern solution to meet contemporary engineering requirements.

0 notes

Text

Fiber-Reinforced Plastic (FRP) Recycling Market: Insights for 2024-2032

According to Triton Market Research, the global fiber-reinforced plastic (FRP) recycling market report is segmented into Product Type (Glass-Fiber Reinforced Plastic, Carbon-Fiber Reinforced Plastic), Recycling Technique (Thermal/Chemical Recycling, Incineration and Co-incineration), Mechanical Recycling [Size Reduction]), End-User (Industrial, Transportation, Building and Construction, Sports, Other End-Users), and Regional Outlook (Europe, Asia-Pacific, Middle East and Africa, North America, Latin America).

The report highlights the Market Summary, Industry Outlook, Impact Analysis, Porter’s Five Forces Analysis, Market Maturity Analysis, Supply Chain Analysis, Key Market Strategies, Market Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology and scope, Global Market Size, Forecasts & Analysis (2024-2032).

Triton Market Research report states that the global market for fiber-reinforced plastic (FRP) recycling is deemed to witness growth at a compound annual growth rate of 8.04% in revenue and 7.46% in volume during the forecast period 2024-2032.

Fiber-reinforced plastic (FRP) recycling involves collecting, sorting, and reprocessing waste materials made from composites of polymers reinforced with fibers like glass, carbon, or aramid. These materials commonly come from products such as boats, automotive parts, aerospace components, and construction materials.

Factors such as growth in products made from recycled fiber-reinforced plastics, innovations in composite recycling, and a rise in R&D efforts create opportunities for the FRP recycling market. Innovations in composite recycling are unlocking significant opportunities for the studied market by addressing long-standing challenges in processing these complex materials. Traditional FRP composites, which are widely used in industries like aerospace, automotive, and construction, have historically been difficult to recycle due to their reinforced fibers and durable resin matrix. However, advancements in technologies such as chemical recycling, thermal recovery, and mechanical processes allow for the efficient separation and recovery of valuable fibers, reducing waste and environmental impact.

On the contrary, limited recycling techniques for CFRP and the complex process of FRP recycling, coupled with a lack of awareness, hampers the expansion of the FRP recycling market.

Globally, North America is expected to become the fastest-growing region in the fiber-reinforced plastic recycling market. The region’s gradual growth is propelled by increasing environmental concerns and regulatory pressures to adopt sustainable waste management practices. Industries such as automotive, aerospace, and construction heavily utilize FRPs for their high strength-to-weight ratios, leading to a significant accumulation of composite waste. Advancements in recycling technologies—like mechanical grinding, pyrolysis, and chemical processes—are being explored to overcome these hurdles associated with FRP recycling.

The leading companies in the FRP recycling market are Global Fiberglass Solutions, Carbon Conversions, Aeron Composite Pvt Ltd, Conenor Ltd, Carbon Fiber Recycling, Gen 2 Carbon Limited, Carbon Fiber Recycle Industry Co Ltd, Mitsubishi Chemical Group Corporation, NeoComp GmbH, Vartega Inc, Toray Industries Inc, UComposites AS, and MCR Mixt Composites Recyclables.

The FRP recycling market presents moderate barriers for new entrants. While advanced mechanical and chemical recycling technologies can be costly, strict government regulations and growing environmental awareness fuel market expansion, making it appealing for newcomers. Achieving economies of scale is challenging, as higher capacity is often needed to ensure cost efficiency and profitability. Despite this, limited product differentiation makes it easier for new competitors to enter the market. As a result, the overall threat of new entrants remains moderate.

#fiberreinforcedplasticrecycling#frprecycling#chemicalsandmaterials#polymersandresins#marketresearchtrends#tritonmarketresearch

0 notes

Text

Fiber-Reinforced Plastic (FRP) Recycling Market: Insights for 2024-2032

According to Triton Market Research, the global fiber-reinforced plastic (FRP) recycling market report is segmented into Product Type (Glass-Fiber Reinforced Plastic, Carbon-Fiber Reinforced Plastic), Recycling Technique (Thermal/Chemical Recycling, Incineration and Co-incineration), Mechanical Recycling [Size Reduction]), End-User (Industrial, Transportation, Building and Construction, Sports, Other End-Users), and Regional Outlook (Europe, Asia-Pacific, Middle East and Africa, North America, Latin America).

The report highlights the Market Summary, Industry Outlook, Impact Analysis, Porter’s Five Forces Analysis, Market Maturity Analysis, Supply Chain Analysis, Key Market Strategies, Market Drivers, Challenges, Opportunities, Analyst Perspective, Competitive Landscape, Research Methodology and scope, Global Market Size, Forecasts & Analysis (2024-2032).

Triton Market Research report states that the global market for fiber-reinforced plastic (FRP) recycling is deemed to witness growth at a compound annual growth rate of 8.04% in revenue and 7.46% in volume during the forecast period 2024-2032.

Fiber-reinforced plastic (FRP) recycling involves collecting, sorting, and reprocessing waste materials made from composites of polymers reinforced with fibers like glass, carbon, or aramid. These materials commonly come from products such as boats, automotive parts, aerospace components, and construction materials.

Factors such as growth in products made from recycled fiber-reinforced plastics, innovations in composite recycling, and a rise in R&D efforts create opportunities for the FRP recycling market. Innovations in composite recycling are unlocking significant opportunities for the studied market by addressing long-standing challenges in processing these complex materials.

Traditional FRP composites, which are widely used in industries like aerospace, automotive, and construction, have historically been difficult to recycle due to their reinforced fibers and durable resin matrix. However, advancements in technologies such as chemical recycling, thermal recovery, and mechanical processes allow for the efficient separation and recovery of valuable fibers, reducing waste and environmental impact.

On the contrary, limited recycling techniques for CFRP and the complex process of FRP recycling, coupled with a lack of awareness, hampers the expansion of the FRP recycling market.

Globally, North America is expected to become the fastest-growing region in the fiber-reinforced plastic recycling market. The region’s gradual growth is propelled by increasing environmental concerns and regulatory pressures to adopt sustainable waste management practices. Industries such as automotive, aerospace, and construction heavily utilize FRPs for their high strength-to-weight ratios, leading to a significant accumulation of composite waste. Advancements in recycling technologies—like mechanical grinding, pyrolysis, and chemical processes—are being explored to overcome these hurdles associated with FRP recycling.

The leading companies in the FRP recycling market are Global Fiberglass Solutions, Carbon Conversions, Aeron Composite Pvt Ltd, Conenor Ltd, Carbon Fiber Recycling, Gen 2 Carbon Limited, Carbon Fiber Recycle Industry Co Ltd, Mitsubishi Chemical Group Corporation, NeoComp GmbH, Vartega Inc, Toray Industries Inc, UComposites AS, and MCR Mixt Composites Recyclables.

The FRP recycling market presents moderate barriers for new entrants. While advanced mechanical and chemical recycling technologies can be costly, strict government regulations and growing environmental awareness fuel market expansion, making it appealing for newcomers. Achieving economies of scale is challenging, as higher capacity is often needed to ensure cost efficiency and profitability. Despite this, limited product differentiation makes it easier for new competitors to enter the market. As a result, the overall threat of new entrants remains moderate.

#fiberreinforcedplasticrecycling#frprecycling#chemicals#materials#polymersandresins#tritonmarketresearch#marketresearchtrends

0 notes

Link

0 notes

Text

Inconel 625 Scrap Stockists in India

Inconel 625 is a high-performance nickel-chromium-molybdenum alloy renowned for its exceptional strength and resistance to oxidation, corrosion, and thermal fatigue. Widely used in demanding applications such as aerospace, chemical processing, and marine environments, the alloy’s unique properties also make it valuable in the recycling sector. This article delves into the characteristics of Inconel 625 scrap, its applications, and the processes involved in recycling this high-value material.

Properties of Inconel 625

Inconel 625 is characterized by its impressive mechanical properties and resistance to extreme conditions:

Composition: The alloy primarily consists of nickel (58-63%), chromium (20-23%), and molybdenum (8-10%). It also contains small amounts of niobium, tantalum, and titanium.

Corrosion Resistance: It excels in resisting oxidation, carburization, and nitridation, making it suitable for use in harsh chemical environments.

High-Temperature Strength: It maintains its mechanical properties at elevated temperatures, which is crucial for applications involving high heat.

Applications

Due to its robust properties, Inconel 625 is used in various high-stress environments:

Aerospace: Components such as jet engine parts, exhaust systems, and turbine blades.

Chemical Processing: Equipment like reactors, heat exchangers, and piping systems.

Marine: Parts for seawater systems, including pumps and valves.

Nuclear: Components in reactors and other nuclear applications due to its resistance to radiation-induced degradation.

Inconel 625 Scrap

Sources of Scrap

Inconel 625 scrap can originate from several sources:

Industrial Waste: Manufacturing processes often produce scrap materials, including cuttings, trimmings, and off-spec components.

Decommissioned Equipment: Outdated or replaced equipment containing Inconel 625.

End-of-Life Products: Products that have reached the end of their operational life but are still made from high-value materials.

Value and Recovery

The high cost of raw Inconel 625 makes its scrap valuable. The alloy’s price can fluctuate based on market demand and the cost of raw materials. Recycling Inconel 625 scrap helps recover a significant portion of the material’s value and reduces environmental impact.

Recycling Process

The recycling of Inconel 625 involves several steps:

Collection and Sorting: Scrap is collected from various sources and sorted to separate Inconel 625 from other materials.

Shredding and Size Reduction: The sorted scrap is shredded into smaller pieces to facilitate further processing.

Melting and Purification: The shredded scrap is melted in electric arc furnaces or induction furnaces. During this process, impurities are removed to produce high-purity Inconel 625.

Recasting: The purified molten alloy is then cast into molds to create new ingots or other forms suitable for manufacturing.

Challenges and Considerations

Contamination: Scrap must be carefully sorted and purified to avoid contamination with other metals, which can affect the quality of the recycled material.

Economic Factors: The cost of recycling can be influenced by fluctuations in energy prices and market demand for nickel and other alloying elements.

Conclusion

Inconel 625 scrap represents a significant opportunity for material recovery and recycling, contributing to both economic and environmental benefits. The alloy’s unique properties make it valuable across various high-performance applications, and its efficient recycling can help meet the growing demand for sustainable material management. As industries continue to seek cost-effective and environmentally friendly practices, the recycling of Inconel 625 scrap will play a crucial role in the circular economy of advanced materials.

0 notes