#titanium sheets

Explore tagged Tumblr posts

Text

Why Titanium Is the Metal of Choice for Aerospace & Medical Industries

Introduction

Titanium has become a preferred metal across aerospace and medical industries due to its high strength-to-weight ratio, corrosion resistance, and biocompatibility. As industries demand lighter, stronger, and more durable materials, titanium continues to dominate in aircraft components and medical implants. But what makes titanium materials superior to traditional metals like stainless steel or aluminum? Let's explore.

Why Titanium in Aerospace?

The aerospace industry requires materials that can withstand extreme temperatures, high stress, and corrosion. Titanium meets these demands with:

✅ Lightweight Strength – Titanium is 45% lighter than steel but just as strong, reducing overall aircraft weight and improving fuel efficiency. ✅ Corrosion Resistance – Titanium withstands saltwater, chemicals, and extreme atmospheric conditions, making it ideal for aircraft exteriors. ✅ High Heat Resistance – With a melting point of 1,668°C (3,034°F), titanium maintains its integrity under extreme heat. ✅ Durability – Unlike aluminum, titanium is more resistant to fatigue and wear, reducing long-term maintenance costs.

🔹 Common Aerospace Applications of Titanium:

Jet engine components (compressor blades, turbine disks)

Aircraft structural parts (landing gear, wing frames)

Spacecraft components

Why Titanium in Medical Applications?

Titanium is widely used in medical implants and surgical instruments due to its biocompatibility and strength. Key advantages include:

✅ Non-Toxic & Biocompatible – Titanium is inert inside the human body, meaning it won’t cause allergic reactions or rejection. ✅ Corrosion Resistance – Unlike other metals, titanium does not degrade from exposure to bodily fluids. ✅ Long-Term Durability – Titanium implants can last a lifetime without breaking down. ✅ Bone Fusion Compatibility – Titanium integrates naturally with human bones in a process called osseointegration, making it ideal for hip replacements, dental implants, and spinal fusion devices.

🔹 Common Medical Applications of Titanium:

Orthopedic implants (hip and knee replacements)

Dental implants

Surgical tools and pacemakers

Why Choose Accromet’s Titanium Materials?

At Accromet, we supply high-quality titanium sheets, bars, and plates that meet the strict demands of aerospace and medical industries. Our materials offer:

✔ Precision Engineering – Manufactured to exact specifications ✔ Industry-Grade Durability – Tested for strength and corrosion resistance ✔ Reliable Supply Chain – Ensuring you get premium titanium materials when you need them

FAQs About Titanium for Aerospace & Medical Use

1. Is titanium stronger than stainless steel? Yes, titanium has a higher strength-to-weight ratio than stainless steel, making it stronger for its weight while being much lighter.

2. Why is titanium preferred over aluminum in aerospace? Titanium is more heat-resistant, corrosion-resistant, and durable than aluminum, making it better suited for high-performance aircraft.

3. Can titanium rust? No, titanium is highly corrosion-resistant and does not rust, even in extreme conditions.

4. Is titanium safe for the human body? Yes, titanium is 100% biocompatible, making it ideal for medical implants and surgical tools.

5. Where can I buy high-quality titanium materials? Accromet provides top-tier titanium sheets, plates, and bars for industrial, aerospace, and medical applications.

Call to Action (CTA)

Looking for high-quality titanium materials for aerospace or medical applications? Accromet offers premium titanium sheets, bars, and plates with superior strength, corrosion resistance, and reliability.

🔹 Contact us today to get a quote or discuss your specific requirements!

📞 Call: 800-543-4755 🌐 Visit: https://www.accromet.com/

#Titanium materials#Titanium for aerospace#Titanium for medical use#Titanium sheets#bars#and plates#Titanium strength-to-weight ratio

0 notes

Text

Titanium sheets and plates are essential materials in various industries due to their remarkable properties, including high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. They are widely used in aerospace, medical, chemical processing, and marine applications. Titanium is a lightweight metal that offers superior performance compared to other materials like steel and aluminum, making it an ideal choice for applications where weight and durability are critical.

Grade 2 Titanium

Grade 2 titanium (UNS R50400) is a commercially pure titanium with a minimum titanium content of 99%. It is known for its excellent weldability, ductility, and corrosion resistance. The material's high strength and light weight make it suitable for a variety of applications, including:

Aerospace Components: Used in airframes, engine components, and fasteners due to its high strength-to-weight ratio.

Chemical Processing: Employed in chemical reactors, heat exchangers, and piping systems where resistance to corrosive environments is crucial.

Medical Devices: Ideal for surgical implants and instruments because of its biocompatibility and resistance to body fluids.

Grade 2H Titanium

Grade 2H titanium is a variant of Grade 2, offering enhanced strength through a specific heat treatment process. It retains similar properties to Grade 2 but features a higher strength and slightly lower ductility. This makes Grade 2H suitable for applications requiring a balance between strength and corrosion resistance, such as:

Aerospace Fasteners: Used in applications where high strength is necessary without compromising weight.

Marine Applications: Commonly utilized in offshore structures and vessels due to its excellent resistance to seawater and marine environments.

Industrial Applications: Employed in machinery and equipment exposed to harsh chemicals and elevated temperatures.

Summary

Both Grade 2 and Grade 2H titanium sheets and plates provide excellent performance in demanding environments. While Grade 2 is favored for its ductility and weldability, Grade 2H is selected for applications needing enhanced strength. These materials are available in various thicknesses and dimensions, catering to diverse industrial needs.

0 notes

Text

4 Years 278 Days! More Duchess souls!

6 notes

·

View notes

Text

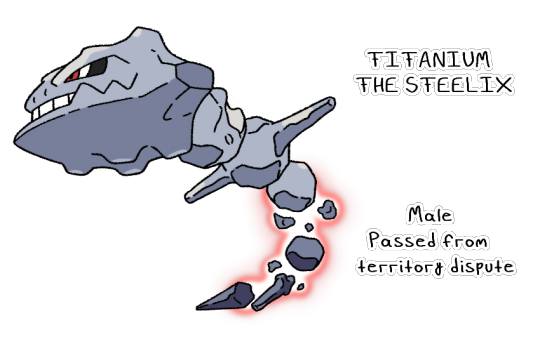

Stupid Silly Design for Titanium for my

Metals AU based off SU..

Heres the doc if anyone's interested in basically Steven Universe gems but guys and yoai

Steven Universe where like gems, theres Metals, and they're all men

https://docs.google.com/document/d/15G7Wd4KRpHx3JQ7Rvu7sFhuNPYdDNbKjHq9wFakfLfI/edit?usp=drivesdk

#steven universe#steven unvierse au#steven universe oc#metal#periodic table of elements#yaoi#titanium#digital art#digital drawing#reference#species sheet

4 notes

·

View notes

Text

Me and Mojo go on dates to Home Depot 💖💖💖💖💖💖💖💖💖💖💖

#giant evil rayguns take more than illegal chemicals and sheets upon sheets of titanium. sometimes a man (ape) just needs screws in bulk#and when it comes to ME??? ohohohoho if my ass was set loose in a home depot with unlimited cash well#idk when i would come out of there but imma say no less than three hours#i would let him infodump to me abt what he's used certain tools and pieces we see for#we might even come up with some project ideas there based on just what we see >w<#either way it would be fun heehee!!! 💖💖💖💖💖💖💖💖#ruby rambles#💜: loving you's a felony

4 notes

·

View notes

Text

Aesteiron Steels is a leading stockist and supplier of Titanium Sheet in Mumbai, Maharashtra, India. We export Titanium Sheet with best price.

#Titanium Sheet#Alloy Strips & Coil#Titanium Sheet Cost Per Kg In India#List Of CP Titanium sheet Types#Titanium Plate Composition Chart#Titanium Sheet Sizes#Titanium Alloy Coils Equivalent Material#Aesteiron Steels

2 notes

·

View notes

Text

Ref sheets for the twin-chillas of Star Village (not actual twins, but call themselves that, its complicated lol)

2 notes

·

View notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

Why You Should Use Titanium Plates for Superior Engagement Results

Looking for long-lasting, high-performance materials? Let us talk about titanium plates the powerhouse solution making waves in industries where reliability is non-negotiable. Whether you are in aerospace, automotive, medical, or marine sectors, using the right material can make or break your project. That is where titanium plates step in.

It is no wonder manufacturers and engineers are making the switch.

🏭 Why Titanium Beats the Rest

The buzz around titanium sheet and plates is not just hype. It is real engineering value.

Here is what sets titanium plates apart:

✔️ Lightweight Yet Strong – You get the muscle without the bulk.

✔️ Superior Corrosion Resistance - Ideal for chemical and marine applications.

✔️ High Temperature Tolerance – Performs under extreme heat like a champ.

✔️ Biocompatibility – Safe and reliable for medical devices and implants.

✔️ Long-Term Cost Efficiency – Higher upfront cost, but major long-term savings.

Now, compare this to a bronze plate which may offer decent strength but lacks the lightweight advantages. Or an aluminum plate light, yes, but far less durable under stress or heat.

📦 Industries That Depend on Titanium Plates

If you are wondering where all this material ends up, here is a quick list:

✈️ Aerospace: Aircraft frames, turbine engines

🚢 Marine: Submersibles, naval vessels, offshore rigs

🏥 Medical: Surgical tools, implants, prosthetics

🏎 Automotive: High-performance sports cars, exhaust systems

🏗 Construction: Infrastructure needing longevity and strength

And the best part? Businesses in Monroe, NC are now benefiting from local access to these game-changing materials thanks to regional distributors offering fast, reliable service.

✅ Why Distributors Choose Titanium Plates for Engagement Projects

When it comes to delivering reliable results, material choice is everything. Distributors do not just pick titanium for fun it is a strategic move.

What distributors love about titanium plates:

✔️ Fast machining and forming

✔️ Available in a wide range of thicknesses

✔️ Reliable global supply chain

✔️ Compatible with metals like aluminum and bronze

✔️ Ideal for scaling up without quality compromise

It is all about building trust. And trust begins with durable, efficient materials like titanium.

📢 Conclusion: It is Time to Upgrade to Titanium

If you are still sticking with old-school materials like aluminum plates or bronze plate, it is time to rethink your strategy. Titanium plates offer a powerful combination of lightweight strength, corrosion resistance, and high performance—qualities that make a massive difference in engagement-driven industries.

From Monroe, NC to global markets, reliable suppliers and distributors are ensuring that you have access to the best. Whether you are building rockets or medical devices, it pays to invest in the best.

🧠 FAQs

1. What are titanium plates used for?

Titanium plates are used in aerospace, medical implants, marine construction, automotive parts, and any application requiring high strength and corrosion resistance.

2. Are titanium plates better than aluminum plates?

Yes. While aluminum is lighter, titanium offers better strength, corrosion resistance, and high-temperature tolerance.

3. How do titanium plates compare to bronze plate materials?

Bronze is good for specific uses like bearings and electrical connectors, but titanium offers superior mechanical performance for structural applications.

4. Where can I find titanium plates in Monroe, NC?

Many distributors in Monroe, NC stock titanium plates, providing quick access and support for local businesses and industries.

🚀 Ready to Upgrade Your Materials Game? Let reliability and performance be your standard not the exception. Contact your trusted supplier today!

#titanium plates#titanium sheet#aluminum plate#bronze plate#DurabilityMatters#RetailDisplayUpgrade#RetailFixtures#USAmanufacturing

0 notes

Text

Top-Tier Titanium Sheets – Quality You Can Trust

As one of the leading Titanium Sheet Manufacturers in India, Timex Metal ensures every sheet meets international quality standards. We offer a wide range of sizes and grades to suit your specific project requirements, all backed by years of industry expertise and precision engineering.

Trusted by clients across various sectors, we’ve built our reputation as reliable Titanium Sheet suppliers in India. Whether you need small quantities or bulk orders, we deliver with consistency, speed, and a commitment to quality.

Choose Timex Metal for your next project and experience the unmatched performance of our Titanium Sheet solutions. Contact us today for quotes or inquiries – let’s build stronger, together.

For More Details :

Website: timexmetals.com

Product Source: Titanium Sheet Manufacturer in India

Other Product Source: Fin Tube Manufacturer in India

0 notes

Text

Choosing the Right Metal Sheet for Your Industry

When selecting a metal sheet for your project, choosing the right material is crucial for performance, durability, and cost-efficiency. Different industries, such as aerospace, marine, and industrial manufacturing, require specific metals to meet unique demands. This guide will help you compare stainless steel, titanium, aluminum, and exotic alloys to determine the best fit for your needs.

Stainless Steel Sheets: Strength and Corrosion Resistance

Best for: Food processing, medical, architecture, and marine applications.

High corrosion resistance, ideal for environments with moisture exposure.

Strong and durable, making it perfect for heavy-duty applications.

Available in various grades, including 304 and 316 stainless steel sheets for enhanced resistance.

Titanium Sheets: Lightweight and High-Strength

Best for: Aerospace, medical implants, and high-performance industrial equipment.

Exceptional strength-to-weight ratio, reducing overall structural weight.

Excellent heat and corrosion resistance, even in extreme environments.

Preferred for aerospace metal sheets due to its durability and efficiency.

Aluminum Sheets: Lightweight and Cost-Effective

Best for: Automotive, construction, packaging, and electrical applications.

Lightweight yet strong, making it easy to work with.

High conductivity, ideal for electrical and heat transfer applications.

Aircraft aluminum sheets are widely used in aviation for fuel efficiency.

Exotic Alloys: Extreme Durability for Harsh Environments

Best for: Chemical processing, power plants, and marine engineering.

Includes materials like Inconel, Hastelloy, and Monel, known for superior performance.

High resistance to oxidation, extreme temperatures, and chemical corrosion.

Used in specialized applications where standard metals fail.

FAQs About Choosing the Right Metal Sheet

Q1: What is the most corrosion-resistant metal sheet? A: Stainless steel and titanium offer the highest corrosion resistance, with 316 stainless steel being the best choice for marine applications.

Q2: Which metal sheet is the most lightweight? A: Aluminum sheets are the lightest among commonly used metals, making them ideal for transportation and aerospace applications.

Q3: Are exotic metal sheets worth the investment? A: If your industry requires extreme temperature and corrosion resistance, exotic alloys provide long-term cost savings and durability.

Q4: How do I choose the right thickness for my metal sheet? A: The required gauge thickness depends on your industry and application. Consult with Accromet for expert guidance.

Find the Perfect Metal Sheet for Your Application

At Accromet, we specialize in high-quality stainless steel, titanium, aluminum, and exotic metal sheets tailored to your industry’s needs. Contact us today to get expert recommendations and competitive pricing.

0 notes

Text

titanium and titanium alloys suppliers in India.

0 notes

Text

Titanium Sheet

Located in Xi’an, Shaanxi Province High-tech Zone East, specializing in titanium materials and research and development and production of titanium materials and products. Our main products are titanium materials, medical titanium, titanium pipe and fittings, which are widely used in scientific research, chemical, pharmaceutical, environmental protection, marine and other fields.

Titanium Sheet

0 notes

Text

Titanium Gr 2, Gr 5, and Gr 7 Sheet/Plates/Coils Manufacturers in Kuwait | Bhagya Laxmi Industrial

When it consists of sourcing Titanium Gr 2 Sheet/Plates/Coils, Titanium Gr 5 Sheet/Plates/Coils, or Titanium Gr 7 Sheet/Plates/Coils, Bhagyalaxmi Industrial is a relied-on name in Kuwait. With years of records, we offer first-rate titanium products for numerous industries, which consist of aerospace, chemical, and marine sectors. In this weblog, we’ll look at the precise features and programs of numerous titanium grades to help you choose the right product for your dreams.

What Is Titanium?

Titanium is a flexible, sturdy, and moderate-weight steel for its corrosion resistance, making it terrific for disturbing environments. It is extensively carried out in aerospace, chemical processing, medical, and marine industries because of its functionality to upwardly push up to excessive temperatures, harsh chemical materials, and mechanical stresses.

Titanium Gr 2 Sheet/Plates/Coils: Versatile and Reliable

Use: Titanium Gr 2 is the purest form of titanium with fantastic corrosion resistance.

Titanium Gr 2 sheets/plates/coils are famous in industries in which excessive corrosion resistance is crucial, which incorporates chemical processing and marine programs. Due to its extraordinary weldability and formability, Titanium Gr 2 is proper for manufacturing warmth exchangers, pressure vessels, and pharmaceutical tools.

Titanium Gr 2 is usually applied in:

Marine Hardware

Power generation

Heat exchangers

Pharmaceutical device

We ensure our Titanium Gr 2 products meet stringent enterprise requirements, providing you with long-lasting and dependable solutions.

Titanium Gr 5 Sheet/Plates/Coils: Strength and Lightweight Properties

Use: Titanium Gr five (Ti-6Al-4V) is the most substantially used titanium alloy, imparting immoderate strength and corrosion resistance.

Titanium Gr 5 sheets/plates/coils are top-notch for applications that require energy and weight reduction. This alloy, which incorporates aluminium and vanadium, is substantially more potent than Titanium Gr 2 without sacrificing corrosion resistance. It is used in aerospace, cars, and clinical industries.

Titanium Gr 5 gives:

Excellent fatigue resistance

High electricity-to-weight ratio

Resistance to oxidation and corrosion

Applications encompass:

Aircraft additives

Medical implants

Power plants

Structural applications

Whether you need titanium Gr 5 sheets, plates, or coils for aerospace or clinical programs, we offer tremendous products that meet specific specs.

Titanium Gr 7 Sheet/Plates/Coils: Superior Corrosion Resistance

Use: Titanium Gr 7 is an alloy that includes small quantities of palladium to enhance corrosion resistance.

Titanium Gr 7 sheets/plates/coils are extremely good for environments that contain aggressive chemical substances, acids, or chlorides. Its superior corrosion resistance makes it a first-rate desire for programs in chemical processing, marine environments, and energy generation.

Titanium Gr 7 is believed to be:

Exceptional resistance to acids and chlorides

Superior weldability and formability

Increased resistance to corrosion in the assessment of natural titanium

Applications encompass:

Chemical processing device

Marine applications

Heat exchangers and condensers

For industries requiring brilliant levels of corrosion resistance, Titanium Gr 7 is the proper product. We offers one's products in several sizes and finishes to meet your needs.

Why Choose Bhagyalaxmi Industrial?

We prioritize turning out very first-rate satisfactory titanium products to our clients in Kuwait. Our titanium sheets, plates, and coils undergo strict, fantastic control strategies to ensure they meet the demands of industries like aerospace, clinical, and chemical processing.

Advantages of strolling with us include:

High-brilliant titanium products

A large shape of grades and sizes

Customization alternatives for unique requirements

Reliable shipping and excellent customer service

We are a relied-on partner for industries that require titanium solutions, and we make certain that every product meets or exceeds your expectations.

Conclusion

Finally, deciding on the right titanium product is crucial to the achievement of your demands. Whether you require Titanium Gr 2 Sheet/Plates/Coils for corrosion resistance, Titanium Gr 5 Sheet/Plates/Coils for power, or Titanium Gr 7 Sheet/Plates/Coils for advanced corrosion resistance, Bhagyalaxmi Industrial in Kuwait has the right solutions for you. Contact us in recent times to talk about your titanium needs and permit us to offer you brilliant products on your programs.

#Titanium Gr 2 Sheet/Plates/Coils#Titanium Gr 5 Sheet/Plates/Coils#Titanium Gr 7 Sheet/Plates/Coils#Bhagya Laxmi Industrial

0 notes

Text

UNDERSTANDING THE GLOBAL MARKET TRENDS FOR TITANIUM SHEETS

Titanium is renowned for its unique properties, making it a preferred material across various industries, from aerospace to medical and chemical applications. As a leader in metal supply, SMM Industries takes pride in being a trusted manufacturer and supplier of high-quality Titanium Sheets Manufacturers & Suppliers. Our expertise, commitment to quality, and advanced manufacturing capabilities have positioned us as one of the top names in the titanium industry. In this blog, we will explore the key global market trends shaping the future of titanium sheets and what industries and investors need to consider.

1. Increasing Demand from Aerospace and Defense

The aerospace industry remains the largest consumer of titanium sheets, accounting for a substantial share of the market. With growing air traffic, the demand for lightweight yet durable materials like titanium is surging, particularly for aircraft manufacturing. Titanium’s ability to withstand extreme temperatures while reducing weight makes it ideal for critical aerospace applications such as airframes and jet engines.

The defense sector also continues to rely heavily on Titanium Sheets Manufacturers & Suppliers for the production of military vehicles and armor, further driving market growth. As governments worldwide increase defense budgets, this segment is expected to fuel demand for titanium sheets in the coming years.

2. Expanding Applications in Medical and Healthcare

Titanium’s biocompatibility, which means it does not react negatively with the human body, makes it essential in medical applications such as implants, prosthetics, and surgical tools. With the rise in healthcare investments and advancements in medical technologies, titanium sheets are becoming increasingly popular for these applications. The growing elderly population and the prevalence of chronic conditions also contribute to this sector’s rising demand for titanium.

3. Growth of the Electric Vehicle (EV) Market

With the growing popularity of electric vehicles (EVs), the demand for lightweight materials to improve vehicle efficiency and performance is on the rise. Titanium sheets are playing a crucial role in the development of EVs, as automakers seek ways to reduce weight and improve battery performance without compromising on safety or strength. As governments worldwide push for greener transportation solutions, the EV industry will likely become a significant driver of titanium sheet demand.

4. Increasing Investments in Sustainable Energy

As the world shifts towards renewable energy sources, the use of titanium sheets in wind and solar energy applications is gaining traction. Titanium’s corrosion resistance makes it ideal for use in harsh environmental conditions, which are common in energy projects like offshore wind turbines. The transition to cleaner energy sources is creating new opportunities for Titanium Sheets Manufacturers & Suppliers, particularly in regions pushing aggressive renewable energy targets.

5. Technological Advancements in Manufacturing

Innovations in manufacturing techniques, such as 3D printing and advanced forging methods, have enhanced the production of Titanium Sheets Manufacturers & Suppliers, reducing waste and improving efficiency. The integration of AI and automation into the manufacturing process is helping producers streamline operations, reducing costs, and improving product quality. These technological advancements are expected to play a crucial role in shaping the future of the titanium sheet market.

Our Commitment to Sustainability

At SMM Industries, we understand the importance of sustainability in today’s world. We are committed to environmentally friendly manufacturing processes, reducing waste, and using energy-efficient technologies to minimize our carbon footprint. Our Titanium Sheets Manufacturers & Suppliers are recyclable, contributing to greener and more sustainable practices across industries.

Conclusion

If you’re looking for high-quality, reliable titanium sheets for your next project, SMM Industries is your trusted partner. Our commitment to quality, customization, and timely delivery ensures that we exceed customer expectations every time.

Contact us today to learn more about how we can support your titanium sheet requirements!

To Know More https://www.smmindustriesllp.com/understanding-the-global-market-trends-for-titanium-sheets/

0 notes