#tool demagnetizer

Explore tagged Tumblr posts

Text

What About Mom?

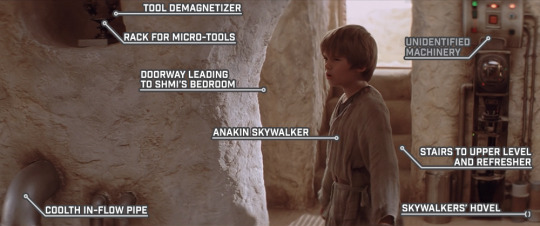

STAR WARS EPISODE I: The Phantom Menace 01:13:08

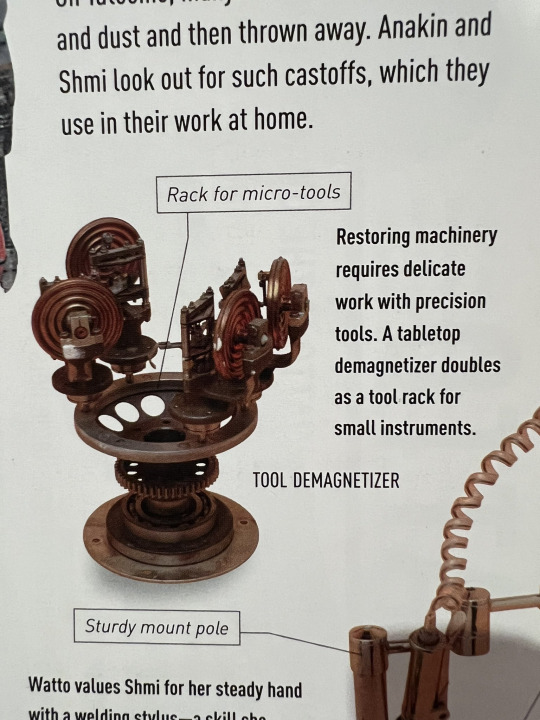

The tool demagnetizer on the shelf in the top left corner was identified on page 79 of the Episode I Expanded Visual Dictionary by Jason Fry.

#Star Wars#Episode I#The Phantom Menace#Tatooine#Mos Espa#Slave Quarters Row#Skywalkers' hovel#tool demagnetizer#rack for micro-tools#Shmi's bedroom#Anakin Skywalker#coolth in-flow pipe#unidentified machinery#refresher

6 notes

·

View notes

Text

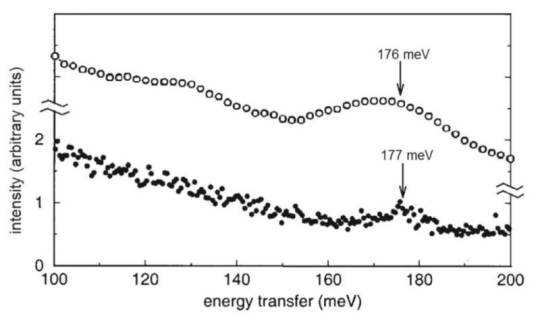

Study offers correction for better calculations for the magnetic properties of neodymium compounds

High-energy neutron scattering is a powerful tool in spectroscopy, allowing researchers to probe the physical and chemical properties of many different materials. It is especially well suited for studying the dense and complex structures of lanthanide-iron intermetallic compounds, such as the celebrated Nd2Fe14B. So far, however, researchers still haven't figured out how to probe the material's valuable magnetic properties using neutron scattering. In a new study published in The European Physical Journal Plus, Michael Kuz'min at Aix-Marseille University, together with Manuel Richter at Leibniz IFW Dresden, present a correction to the technique which could be used to determine the 'exchange field' of Nd: an important indicator of its magnetic properties. The duo's approach could help researchers to better understand the origins of neodymium compounds' high resistance to demagnetization, which is crucial for their use as permanent magnets, which are indispensable for wind turbines, electric cars, and robots.

Read more.

6 notes

·

View notes

Text

Infinity Prelude Magnetic Failure – Expert Repair Available Only at LoudspeakerRepair.com

Are you experiencing distortion or rubbing sounds in your Infinity Prelude speakers? You're not alone. This model suffers from a known manufacturing defect: the magnet material begins to flake off and disintegrate, falling into the narrow magnetic gap of the voice coil. The result? Severe distortion, mechanical noise, and in many cases, complete driver failure.

This issue cannot be resolved by conventional speaker repair shops. The process requires complete demagnetization, gap cleaning under microscope, and re-alignment with micrometer accuracy. Most importantly, the magnet needs to be stabilized to prevent further shedding.

At LoudspeakerRepair.com, we are the only specialized workshop with the tools, experience, and custom procedures to carry out this highly technical repair.

Recently, we restored a set of Infinity Prelude speakers for a customer in Australia, dealing precisely with this issue. After stabilization, voice coil realignment, and fresh ferrofluid application, the speakers returned to perfect condition — no more distortion, no more debris.

🌍 We offer worldwide speaker repair with secure shipping and insured return.

🔧 Services include: – Magnetic gap debris removal – Voice coil inspection and realignment – Magnet stabilization – Surround edge replacement – Ferrofluid refill – Crossover capacitor updates

🎯 Trusted by audiophiles worldwide.

📩 Contact: [email protected] 🌐 www.loudspeakerrepair.com 📱 WhatsApp: +32 476 945 785

#InfinityPrelude #SpeakerRepair #MagnetFailure #AudioRestoration #InfinityFix #WorldwideSpeakerService #BelgiumToAustralia #HighEndAudioRepair

0 notes

Text

Ferrite Permanent Magnet Market Trends, Size, Segment and Growth by Forecast to (2021-2031)

The global ferrite permanent magnet market, a crucial part of the magnet industry, is projected to decrease from US$14,877.96 million in 2024 to US$7,986.42 million by 2031, with a compound annual growth rate (CAGR) of -9.8% from 2025 to 2031. 📚Download Full PDF Sample Copy of Market Report @ https://wwcw.businessmarketinsights.com/sample/BMIPUB00031697

Ferrite permanent magnets, made from iron oxide and ceramic materials like barium or strontium, are highly valued for their cost-effectiveness, reliability, high electrical resistance, corrosion resistance, and stable magnetic properties. These qualities make them essential in a wide range of applications, including consumer electronics, automotive components, industrial machinery, renewable energy systems, and medical technologies.

Despite the projected market size decrease, the market continues to see demand driven by the expanding consumer electronics sector, the growing adoption of electric vehicles (EVs), and global initiatives for renewable energy. Advancements in technology have enhanced magnetic performance and manufacturing efficiency, broadening the applications for ferrite magnets in both established and new markets. The Asia-Pacific region is a major force in this market, fueled by strong industrial activity, extensive electronics manufacturing, and significant investments in EV and renewable energy infrastructure. Even with competition from rare-earth magnets, ferrite magnets are often preferred for many uses due to their affordability and dependability.

Ferrite Permanent Magnet Market: A Comprehensive Analysis

The global ferrite permanent magnet market is experiencing robust growth, driven by key factors such as the burgeoning consumer electronics industry and expanding applications in emerging markets. This analysis delves into the market's segmentation, key drivers, opportunities, and leading segments.

Market Segmentation

The ferrite permanent magnet market is primarily segmented by:

Type: Sintered and Bonded.

Product Type: Strontium Ferrite Permanent Magnet and Barium Ferrite Permanent Magnet.

End-User: Automotive, Consumer Electronics, Power Tools, and Others.

Geography: North America, Europe, Asia-Pacific, Middle East & Africa, and South & Central America.

2024 Market Dominance Highlights

Several segments demonstrated significant market dominance in 2024:

Sintered ferrite magnets held the largest market share by type, primarily due to their superior magnetic strength and temperature resistance (up to 250°C), making them ideal for demanding applications like electric motors and automotive systems.

Strontium ferrite magnets dominated the market by product type, preferred for their higher coercivity and better temperature stability. Their robust performance is crucial in automotive (especially EVs), electronics, and renewable energy sectors.

The consumer electronics segment was the leading end-user, propelled by the widespread use of ferrite magnets in a vast array of devices such as smartphones, tablets, and home appliances. Their balance of magnetic strength, compact size, and cost-effectiveness makes them ideal for miniaturized electronic products.

The Asia-Pacific region emerged as the dominant geographical segment.

Market Drivers

Rising Demand for Consumer Electronics: The proliferation of consumer electronics, including smartphones, tablets, wearables, and home appliances, is a primary driver. Ferrite magnets are crucial for miniaturization and functionality, offering reliable magnetic performance in compact and lightweight designs. Their cost-effectiveness and resistance to demagnetization make them a preferred choice for manufacturers balancing performance with affordability.

Opportunities

Expansion into Emerging Markets and New Applications: Significant growth opportunities exist in emerging economies undergoing rapid industrialization and digital transformation. New applications in healthcare, smart technologies, and infrastructure development also present promising avenues for market expansion. Manufacturers can capitalize on these trends by developing tailored solutions and exploring innovative uses in sectors like medical devices, security systems, and renewable energy infrastructure.

Market leaders and key company profiles Proterial, Ltd

TDK Corporation

Shin-Etsu Chemical Co., Ltd

Ningbo Yunsheng Co., Ltd.

Beijing Zhong Ke San Huan High-Tech Co., Ltd.

Hangzhou Permanent Magnet Group., Ltd.

FE Ferrite Co., Ltd.

Anhui Long Magnetic Technology Co., Ltd.

Guangdong LingYI Co., Ltd. Ferrite Permanent Magnet Market Report Coverage and Deliverables

The "Ferrite permanent magnet market Outlook (2021–2031)" report provides a detailed analysis of the market covering below areas:

Ferrite permanent magnet market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

Ferrite permanent magnet market trends, as well as market dynamics such as drivers, restraints, and key opportunities

Detailed Porter's Five Forces and SWOT analysis

Ferrite permanent magnet market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the Ferrite permanent magnet market

Detailed company profiles

The Ferrite permanent magnet market is segmented geographically into North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America. The Asia-Pacific region dominates this market, driven by its extensive manufacturing base for electronics, automotive components, and industrial equipment. Countries like China, Japan, and South Korea benefit from established supply chains, significant investments in production technology, and an export-oriented manufacturing focus, leading to high output and market penetration of ferrite magnets.

Rapid industrialization and urbanization in Asia-Pacific further boost demand for consumer electronics, household appliances, and automotive products. Additionally, governmental policies and incentives in the region promote the adoption of ferrite magnet-reliant technologies such as electric vehicles and renewable energy systems, further stimulating market growth. China is a key leader within Asia-Pacific, owing to its vast production capacity, abundant raw materials, and concentration of major magnet manufacturers. The country's large electronics and automotive sectors create a synergistic effect, maintaining high demand for ferrite magnets. Asia-Pacific's cost-effective manufacturing capabilities and ability to scale production to meet both domestic and international demand have solidified its dominant position in the market.

Ferrite Permanent Magnet Market Research Report Guidance:

The research report provides both qualitative and quantitative data, segmented by drive type, propulsion, sales channel, and geography.

Chapter 2 (Key Takeaways): Highlights key trends and the market outlook.

Chapter 3: Details the research methodology.

Chapter 4: Includes ecosystem and Porter's analysis.

Chapter 5: Discusses major industry dynamics, including market drivers, deterrents, opportunities, and future trends, along with their impact analysis.

Chapter 6: Presents historical market revenues and forecasts up to 2031.

Chapters 7-9: Cover market segments by type, product type, end-use, and geography (North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America), including revenue forecasts and driving factors.

Chapter 10: Provides competitive analysis and heat map analysis of key players.

Chapter 11: Describes the industry landscape, including market initiatives, new developments, mergers, joint ventures, and the competitive landscape.

Chapter 12: Features detailed profiles of major companies, including key facts, business descriptions, products and services, financial overview, SWOT analysis, and key developments.

Chapter 13 (Appendix): Contains a brief company overview, list of abbreviations, and disclaimer.

Ferrite Permanent Magnet Market News and Key Development:

The market is evaluated using qualitative and quantitative data from primary and secondary research, including corporate publications, association data, and databases. A significant recent development occurred in March 2025:

PREMO S.L. (Spain) and Delta Manufacturing Ltd. (India) Joint Venture: This strategic partnership aims to enhance the production and innovation of soft ferrite components for various industries, including automotive, telecommunications, smart grids, and IoT. The joint venture plans to establish a new manufacturing facility with advanced technologies, leveraging PREMO's expertise in inductive components and RFID technology and DML's manufacturing capabilities. This collaboration is expected to foster innovation, improve operational efficiencies, and expand product offerings for both domestic and global markets.

About Us: Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Défense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications Author's Bio Akshay Senior Market Research Expert at Business Market Insights

0 notes

Text

How to Select a Magnetic Chuck That Matches Your Machining Needs

Introduction: Why Choosing the Right Magnetic Chuck Matters

In precision machining, workholding is just as critical as the cutting tools you use. Magnetic chucks devices used to hold ferrous metal workpieces can significantly enhance productivity, reduce setup time, and ensure accuracy. But not all magnetic chucks are created equal. Whether you're grinding, milling, or turning, choosing the right magnetic chuck tailored to your specific machining application can make all the difference.

This guide walks you through the key factors to consider when selecting a magnetic chuck so you can ensure optimal performance and longevity for your machining operations.

🔍 Types of Magnetic Chucks

Understanding the different types of magnetic chucks is your first step:

1. Permanent Magnetic Chucks

No external power needed.

Reliable and safe especially in case of power failure.

Ideal for grinding and light-duty milling.

2. Electromagnetic Chucks

Require a continuous electric current.

Offer adjustable holding force.

Best suited for heavy-duty machining, milling, and turning operations.

3. Electro-Permanent Magnetic Chucks

Combine the benefits of both types.

Require power only during activation/deactivation.

Provide strong, stable holding force for a wide range of applications.

⚙️ Key Considerations When Selecting a Magnetic Chuck

✅ 1. Machining Application

Choose a chuck based on your operation type:

Grinding: Permanent magnetic chucks are often sufficient.

Heavy Milling or Turning: Opt for an electromagnetic or electro-permanent chuck.

✅ 2. Workpiece Size & Shape

Flat and uniform surfaces are easier to hold magnetically.

For irregular shapes or smaller parts, a chuck with fine pole spacing may be required.

✅ 3. Holding Force

Look at the rated holding force (kg/cm² or N/cm²). Larger, heavier workpieces or aggressive machining operations require stronger holding forces.

✅ 4. Pole Design

Fine pole chucks: Ideal for securely holding small, thin, or delicate workpieces with minimal surface area.

Standard/longitudinal poles: Suitable for general use.

Transverse poles: Good for large surface areas.

✅ 5. Size and Mounting Options

Ensure the chuck fits your machine bed and allows for easy installation. Opt for circular chucks when using rotary grinders, and choose rectangular chucks for surface grinding applications.

✅ 6. Control Unit Compatibility

For electromagnetic and electro-permanent chucks, ensure the control unit is compatible and has the necessary features (such as variable control or demagnetization cycles).

🧼 Maintenance and Durability

Selecting a quality magnetic chuck from a trusted manufacturer ensures minimal maintenance. However, regular cleaning and surface checks are essential to prolong life and maintain magnetic performance.

❓ Q&A: Frequently Asked Questions

Q1: Are electro-permanent magnetic chucks safe during a power failure? A: Yes, they retain their magnetic hold even if power is lost, offering both safety and stability.

Q2: What happens if I machine across the magnetic poles? A: Machining across the poles can reduce holding force and affect finish quality. Always align the workpiece with the magnetic lines for best results.

📞 Ready to Find Your Perfect Fit?

Choosing the right magnetic chuck can boost your shop’s efficiency, safety, and precision. 🛠️ Need expert advice? Contact Us today for customized recommendations and exclusive deals.

0 notes

Text

Demagnetizer Metal Testing Machine - Magkraftndt

This demagnetizer quickly removes magnetism from metal tools, ensuring accurate work and preventing damage. Easy to operate and portable, it’s perfect for workshops, helping tools stay in top condition longer.

#magkraftndt#mpimachine#demagnetizermachine#stationarytypedemagnetizer#chutetypedemagnetizermachine#trollytypedemagnetzermachine#magneticparticletestingmachine#mpimachinemanufacturer

0 notes

Text

Screwdriver Magnetizer / Demagnetizer Tool (Kaisi)

Magnetize by sliding the tool through the plus opening. Demagnetize by sliding the tool through the ( – ) opening. Step design permits greater control of magnetization.

0 notes

Text

How Pot Magnets Work: The Science Behind Their Strong Magnetic Hold | Permag

Discover how neodymium pot magnets and alnico pot magnets create a strong magnetic hold through advanced magnetic circuit design. Learn their applications, benefits, and why they are essential for industrial use.

How Pot Magnets Work: The Science Behind Their Strong Magnetic Hold

Pot magnets are powerful and versatile magnetic assemblies designed for industrial and commercial applications. They provide exceptional holding force, thanks to their unique structure and combination of strong magnetic materials like neodymium pot magnets and alnico pot magnets. In this article, we will explore the working mechanism of pot magnets and why they are widely used in different industries.

What Are Pot Magnets?

Pot magnets, also known as cup magnets, are composed of a strong magnet enclosed in a steel casing. This casing enhances the magnetic field, directing it toward the active face, significantly increasing the holding force. Neodymium pot magnets and alnico pot magnets are among the most commonly used types, each offering distinct advantages.

The Science Behind Pot Magnets

Pot magnets work on the principle of magnetic circuit design. Unlike standard magnets that emit their magnetic field in all directions, the steel casing in a pot magnet focuses and amplifies the magnetic force on one side. This enhances its holding capacity while protecting the magnet from damage.

Magnetic Field Enhancement: The steel casing acts as a return path for the magnetic flux, strengthening the magnetic pull on the exposed surface.

Reduced Magnetic Loss: Unlike bare magnets, pot magnets minimize demagnetization by concentrating their force on a single area.

Increased Durability: The casing protects the internal magnet from wear and impact, making it suitable for industrial use.

Types of Pot Magnets

1. Neodymium Pot Magnets

Neodymium pot magnets are made from NdFeB (Neodymium-Iron-Boron), the strongest type of permanent magnet available. They provide an extremely high holding force in a compact size, making them ideal for applications where space is limited but high magnetic strength is required.

Applications:

Industrial lifting and holding

Magnetic clamping in machinery

Securing signage and displays

Mounting tools and fixtures

2. Alnico Pot Magnets

Alnico pot magnets are composed of Aluminum, Nickel, and Cobalt, offering excellent temperature stability and corrosion resistance. While they are not as strong as neodymium magnets, they are ideal for high-heat environments and applications requiring long-term stability.

Applications:

Temperature-sensitive environments

Aerospace and automotive industries

Measuring and sensing devices

Holding and retrieval applications

Advantages of Using Pot Magnets

High Holding Force: Pot magnets provide stronger holding power than conventional magnets of similar size.

Durability: The protective casing shields the magnet from physical and environmental damage.

Versatility: Available in different materials and sizes, pot magnets suit a wide range of industrial and commercial applications.

Ease of Installation: Many pot magnets come with threaded holes, countersunk designs, or hooks for easy mounting.

Pot magnets, whether neodymium pot magnets or alnico pot magnets, offer an efficient way to generate a strong magnetic force in a controlled manner. Their unique design enhances durability and performance, making them an essential component in industrial, automotive, and engineering applications. Whether you need high-strength holding or stability under extreme conditions, selecting the right type of pot magnet can significantly enhance efficiency in your operations.

0 notes

Text

Unlocking Powerful Solutions with Mainrichmagnets.com

In today's fast-paced world, industries require reliable and powerful magnetic solutions to meet evolving needs. Mainrichmagnets.com stands out as a trusted name offering products that are both effective and innovative. Whether it's for industrial machinery, crafting, or technology, strong neodymium disc magnets have become an essential tool for various applications. Many businesses across the United States are turning to providers that offer Customized Magnet Solutions USA to get the exact specifications they need for their projects.

Choosing the right magnets can make all the difference in performance. Strong neodymium disc magnets are known for their exceptional strength compared to other types of magnets available on the market. Their compact size combined with an impressive magnetic pull makes them perfect for a wide range of uses. From holding heavy objects in place to assisting in complex engineering processes, these magnets offer reliability that is hard to beat. The demand for Customized Magnet Solutions USA has grown significantly, allowing businesses to adapt standard designs to their unique requirements without sacrificing quality or performance.

Mainrichmagnets.com understands that every client has different needs. This is why they provide a diverse range of customizable magnetic products designed to offer maximum value. Tailored solutions ensure that companies can integrate magnets seamlessly into their products and workflows. For industries like renewable energy, automotive manufacturing, and advanced electronics, the right magnetic configuration is crucial for success. It’s not just about having a strong magnet; it’s about having the right magnet engineered for a specific purpose.

Innovation is key in today's competitive landscape, and Mainrichmagnets.com consistently proves its commitment to excellence by providing cutting-edge magnetic technology. The ability to source Customized Magnet Solutions USA enables businesses to improve efficiency and product performance while also reducing costs in the long run. It’s a win-win for companies that prioritize both quality and customization.

In addition to strength and customization, durability plays an important role when choosing magnetic products. Strong neodymium disc magnets are highly resistant to demagnetization, meaning they maintain their holding power for years even under tough conditions. This longevity makes them a wise investment across various sectors, ensuring minimal maintenance and high operational reliability. It is this resilience and dependability that have made neodymium magnets the preferred choice for many industry leaders.

Furthermore, working with an experienced supplier is crucial when designing custom magnetic solutions. Mainrichmagnets.com brings years of expertise and a deep understanding of magnetic materials, ensuring that every project they touch meets high standards of performance and safety. Their commitment to customer satisfaction and technological advancement ensures that their clients receive top-tier service at every stage of their project.

As industries continue to evolve and demand higher performance standards, the role of magnets becomes even more significant. Companies that seek to stay ahead in the market are increasingly opting for tailor-made solutions that offer both flexibility and strength. Thanks to providers who specialize in Customized Magnet Solutions USA, businesses no longer have to settle for one-size-fits-all options. They can now achieve precise, high-quality results that directly contribute to their growth and success.

In conclusion, whether you are in need of reliable strong neodymium disc magnets or exploring custom solutions to fit specialized applications, working with a trusted brand like Mainrichmagnets.com can help you meet your goals effectively. By combining powerful products with personalized service, they ensure that your magnetic needs are not only met but exceeded.

0 notes

Text

Caring for Your Timepiece: Tips from the Experts at Nikki Fine

Whether you’re sporting a Rolex Daytona, an elegant Cartier Tank, or a vintage Omega, a luxury timepiece is more than just a way to tell time — it’s a statement, an investment, and often, a treasured heirloom. At Nikki Fine Jewelers, we understand the craftsmanship behind every watch and the care it deserves. That’s why our in-house horology experts have put together this essential guide to help you protect and preserve your timepiece for generations.

1. Regular Winding Is Key

If your watch is mechanical or automatic, it’s important to keep it running regularly. Mechanical watches should be wound daily at the same time, while automatic watches benefit from being worn often. If you rotate between watches, consider using a watch winder to maintain their functionality.

Pro Tip: Always wind your watch slowly and stop when you feel resistance — overwinding can damage the movement.

2. Keep It Clean — The Right Way

Dirt, oils, and sweat can build up over time, affecting both the look and performance of your watch. For a gentle clean:

Use a soft microfiber cloth to wipe the case and bracelet.

For metal bands, a toothbrush and mild soapy water can be used occasionally.

Avoid submerging vintage or leather-banded watches.

Important: Never clean your watch under running water unless it’s rated for water resistance — and even then, caution is key.

3. Know Your Watch’s Water Resistance

“Water-resistant” doesn’t mean “waterproof.” Be aware of your watch’s rating:

30m: Splash resistant only.

50m–100m: Safe for showering or light swimming.

200m+ (Diver’s): Good for serious water exposure.

At Nikki Fine: We offer water resistance testing to ensure your seals are intact — especially recommended before summer or travel season.

4. Avoid Magnetic Fields

Magnetic fields — from phones, speakers, even handbags with magnetic closures — can affect the accuracy of your timepiece. If your watch begins running fast or erratically, it might need demagnetization, a quick fix in our service center.

5. Service Every 3–5 Years

Just like a luxury car, watches need scheduled maintenance. Lubricants dry out, gaskets wear down, and calibration can drift. A full service includes:

Cleaning and oiling the movement

Polishing the case and bracelet

Testing for accuracy and water resistance

Nikki Fine Tip: We recommend servicing mechanical watches every 3–5 years — especially if it’s a high-value or vintage piece.

6. Store Smartly

When not wearing your watch:

Store it in a dry, cool place

Use a padded watch box or travel roll

Keep it away from direct sunlight and humidity

Bonus: If you own multiple timepieces, consider a display case that not only protects but showcases your collection.

Trust the Timepiece Experts at Nikki Fine Jewelers

Luxury watches deserve expert care. At Nikki Fine Jewelers, our certified watch technicians are trained to service brands like Rolex, Cartier, Breitling, and more — using genuine parts and industry-leading tools.

Whether your timepiece needs a tune-up or a full overhaul, we’re here to help. Visit our San Diego showroom today.

0 notes

Text

Handheld Demagnetizer 100 Volt KANETEC KMDH-5A

CV Adara Bintang Caraka supply Japan Tools KANETEC. Silakan hubungi WA 0819 3831 0824

Steel Plate Separator Floater Thin Type KANETEC

Handheld Demagnetizer 100 Volt KANETEC KMDH-5A

V Groove Block Type KYA Type KANETEC

Magnetic Holder KANETEC

#kanetec #japantools #japanbrand #separatorfloater #adara

0 notes

Text

Still Using Outdated ID Cards? Here’s Why It’s Time for an Upgrade!

In modern business operations, identity verification is no longer just about letting employees in and out of the office building. Do you often encounter any of the following situations?

“Does the access control system frequently fail when employees are entering or exiting the building?”

“Do hotel room cards easily get demagnetized, causing customers to repeatedly request resets at the front desk?”

“Are you aware that modern ID cards not only provide identity verification but can also help businesses enhance operational efficiency?”

These seemingly trivial technical issues actually hide greater potential risks: if your business is still using outdated ID cards, it can affect not only employee productivity but also the overall experience for your customers.

Traditional magnetic stripes or simple plastic ID cards have been phased out, and smart ID cards and RFID technology are gradually becoming mainstream. Is your business keeping up with this trend?

If your answer is no, then it’s time to consider upgrading your ID card system. By adopting modern identity verification technology, you can not only improve security but also provide both employees and customers with a smoother and more convenient service experience.

1. Basic Concept of ID Cards: The Core Tool for Identity Verification

With the demands of enterprise management, security control, and efficient operations, ID cards have become an indispensable tool. Whether for employee attendance, access control, or customer identification, ID cards play a crucial role. But do you really understand their function?

✅ What is an ID Card? In simple terms, an ID card (Identification Card) is used to verify the identity of the cardholder. These cards typically incorporate a magnetic stripe, barcode, or RFID chip, allowing interaction with access control systems, payment terminals, attendance systems, and more, thus providing secure and efficient identity authentication.

The form and technology of ID cards may vary across different industries. For example:

In businesses, ID cards are used for employee access control, attendance tracking, and visitor management.

In hotels, room keys are a special type of ID card that can unlock doors and facilitate payments.

In the healthcare sector, ID cards are used for patient identification, ensuring accurate medical records.

✅ Why Do Businesses Need ID Cards? For enterprises, ID cards are not just identity markers; they are vital tools for enhancing operational efficiency and security management.

Access Control: Ensures that only authorized employees or visitors can enter specific areas, preventing unauthorized access.

Attendance Systems: Records employee attendance through card swipes, replacing traditional paper sign-ins, enhancing efficiency, and reducing human error.

Payments and Transactions: Many corporate campuses, schools, and even hotels use ID cards for internal payments, eliminating cash transactions and enhancing convenience.

Data Management and Tracking: Businesses can analyze employee activity through the ID card system, optimizing office spaces and resource utilization.

As enterprises grow, traditional keys and paper attendance methods cannot meet security and efficiency demands. Thus, ID cards become a smarter and safer solution.

2. The Evolution of ID Cards: From Traditional Magnetic Stripes to Smart Chips

The development of ID cards has gone through several stages, advancing from simple magnetic stripe cards to today’s smart chip cards, continuously evolving to meet increasingly complex security demands.

Magnetic Stripe ID Cards (Previously Common but Easily Damaged): These cards rely on magnetic stripes to store data, allowing information to be read by swiping the card. However, magnetic stripes are susceptible to wear, demagnetization, and have relatively low security.

RFID ID Cards (Current Mainstream Choice): Using radio frequency technology, RFID cards support contactless reading and are widely used in enterprises, hotels, and campus settings. Compared to magnetic stripe cards, RFID cards offer enhanced data security and longer lifespans.

NFC Smart ID Cards: Based on Near Field Communication (NFC) technology, these cards not only serve for identity verification but also allow direct interaction with smartphones, payment terminals, and other devices, further enhancing convenience.

In the past, many businesses primarily relied on magnetic stripe ID cards. However, these cards are easily duplicated and damaged, posing security risks and usability challenges. Today, RFID ID cards, with their higher security and durability, are gradually replacing traditional magnetic stripe cards and have become the preferred choice in the enterprise and hospitality sectors.

3. How to Choose the Right ID Card for Your Business?

Selecting the appropriate ID card is not only crucial for enterprise security but also directly affects daily operational efficiency and user experience. Different businesses have varying needs, so it’s important to consider the following key factors when making your decision.

Focus on Security: Prevent Duplication and Fraud

The security of your ID cards is paramount, especially in contexts involving access control, identity verification, or payment functionalities. Traditional magnetic stripe cards are easily duplicated, while RFID or smart chip ID cards come equipped with advanced encryption technologies that effectively prevent unauthorized access and data breaches. For instance, businesses can opt for RFID ID cards with AES encryption, such as MIFARE DESFire® EV1/EV2/EV3, to ensure robust security measures in their access control systems.

Focus on Durability: Long-Term Use Without Damage

Enterprise ID cards are frequently used, especially for attendance, access control, or hotel room keys, and the durability of the cards directly impacts operational costs. Traditional plastic magnetic stripe cards tend to get demagnetized due to friction when used in card slots. In contrast, RFID ID cards utilize contactless technology, reducing wear and tear, thus extending their lifespan. If businesses want to further enhance card longevity, they may opt for durable materials such as PVC, which is the mainstream choice, ensuring stable performance across various environments.

Consider Applicable Scenarios: Different Industries Have Different Needs

When selecting ID cards, businesses should consider their specific operational requirements. For example:

Hotels: It’s advisable to use high-security, environmentally-friendly RFID ID cards that can function as room keys while also supporting in-hotel payments and access control for communal facilities, enhancing security while reducing the hotel's sustainability burden.

Enterprise Access Control: Basic encryption RFID or NFC ID cards are suitable for ensuring security in office areas and can be integrated with attendance systems, allowing for dynamic tracking of employee attendance across the organization.

Healthcare Industry: Hospitals can utilize smart chip RFID ID cards for quick identity verification, integrating seamlessly with electronic health record systems.

Campuses: Colleges can deploy RFID chip ID cards that support flexible features like access control, cafeteria payments, and library borrowing, enabling comprehensive management with a single card.

Emphasize Personalization: Enhance Brand Recognition

Your business’s ID cards serve not only as identification tools but also as part of your brand image. Today, companies can customize:

✔ Company Logos to boost brand visibility.

✔ QR Codes or Barcodes to facilitate visitor management and attendance tracking.

✔ Different Colors, Transparent Designs, or Metal Edging to enhance visual recognition.

✔ Smart Chip Integration allowing ID cards to feature additional functionalities.

Ensure Compatibility with Your Card Printer

If your business intends to print its own ID cards, it’s essential to ensure that the chosen card materials are compatible with your card printer. Companies focused on sustainability can select BioPolyTM Vinyl eco-friendly PVC materials, which offer the same durability as regular PVC ID cards but decompose completely within three years in landfills, aligning with sustainable development principles. Furthermore, this eco-friendly material remains compatible with most card printers, allowing businesses to maintain their brand image while fulfilling environmental responsibilities.

4. Future Trends: The Next Step for Smart ID Cards

As businesses navigate the wave of digital transformation, the demand for identity verification and security management continues to evolve, leading to rapid advancements in ID card technology. Here are some key trends that are driving industry change:

Contactless Smart ID Cards Become Mainstream

Traditional magnetic stripe cards and contact chip cards are gradually being phased out, while contactless ID cards based on RFID technology are becoming the preferred choice for businesses and organizations. This contactless technology not only enhances the convenience of use but also reduces wear and tear from physical contact, making the cards more durable.

Increasing Application of High-Security Encryption Chips

As the importance of data security rises, high-security ID cards featuring AES encryption, two-factor authentication (2FA), and biometric integrations are becoming more prevalent. For example, high-security RFID cards like MIFARE DESFire® EV3 and HID Seos have emerged as ideal options for business access control and payment authentication.

Why Your Business Needs to Upgrade Its ID Cards

If your business is still using traditional ID cards, you may be facing the following issues:

Low Security: Magnetic stripe cards can easily be duplicated, and traditional ID cards struggle to meet the security demands of modern enterprises.

Complex Management: Physical cards are difficult to track if lost, and the cost of reissuing them can be high.

Lack of Scalability: Traditional ID cards offer limited functionality and cannot accommodate the multi-functional demands for identity verification, payments, and access control that modern businesses require.

Act Now: Upgrade Your ID Card Solutions!

Looking for a more secure and intelligent ID card solution? Now is the time to transition to RFID ID cards to provide your business with enhanced security and convenience. Contact us for customized ID card solutions that will align your enterprise with the future!

0 notes

Text

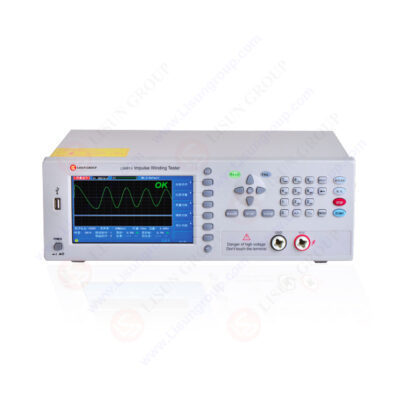

Principle and Applications of Impulse Coil Testers

Introduction to Impulse Coils Tester Impulse coil testers, also known as digital interturn insulation testers, are devices used for non-destructive electrical testing of coil-wound components. The operating principle involves applying the same pulse voltage to both a standard coil winding and the coil under test, then comparing their transient waveforms to evaluate the quality of the tested coil. Transient waveforms, or damped oscillation waveforms occurring within the coil, can be used to assess the inductance, quality factor, number of turns, and interturn short circuits of the winding. Additionally, in the presence of a core, the material differences can also be determined. The occurrence of corona discharge under high voltage pulses can be used to evaluate insulation deficiencies. LISUN LS8815 Series Impulse Coils Tester The LS8815 series impulse coil testers employ advanced, high-stability high-voltage impulse power sources, significantly improving testing accuracy. The instrument quantifies various waveform parameters using microcomputer technology, displaying and judging them through intuitive waveforms. This makes the device easy to operate, providing accurate judgments with a high degree of automation. LS8815 Impulse Winding Tester Working Principle The LS8815 series testers utilize a high-voltage charged small capacitor (low testing energy) to form an RLC parallel resonance with the coil under test. By analyzing the damped oscillation waveforms using precise sampling and processing technology up to 100Msps (customizable to 200Msps), the testers can detect insulation issues within the coil (such as interturn short circuits, layer-to-layer short circuits, and reduced insulation performance). This enables manufacturers and users to more effectively control product quality. Applications The LS8815 series impulse coil testers are characterized by fast measurement speed and good waveform repeatability, making them widely applicable in the following fields: • Motors: Assess the quality of motor windings to ensure reliable operation. • Power Frequency Transformers: Test the interturn insulation of transformer windings. • Relays: Evaluate the quality factor and insulation performance of relay coils. • Switching Power Transformers: Inspect the winding quality of switching power transformers. • Demagnetization Coils: Ensure good interturn insulation of demagnetization coils. • Automation Testing Systems: The LS8815 series instruments can also be integrated into automated testing systems to significantly enhance testing efficiency. Conclusion Impulse coil testers, particularly the LS8815 series, utilize high-stability high-voltage impulse power sources and advanced sampling and analysis technology to quickly and accurately assess the quality and insulation performance of coil windings. They have broad application prospects in fields such as motors, transformers, and relays. Their efficient, accurate, and automated features make them an indispensable tool in modern electronic and electrical testing. Read the full article

0 notes

Text

Choose the Best Custom Countersunk Magnets with these Tips

If you're a DIY-er or a construction expert or are simply interested in magnets. In that case, this article will give you all the details you require to be able to comprehend and use countersunk magnets effectively. Many folks want to choose Custom Countersunk Magnets for a variety of purposes. If you want to get details about what these magnets are and know about their cool features and benefits, read this post. Also, you will learn the important factors to look at when selecting these magnets.

What Are Countersunk Magnets?

Countersunk magnets are magnets that are designed with an elongated shape and holes in the middle. This permits them to be connected to surfaces with screws. The countersunk hole helps the magnet fit flush to the surface, giving an elegant and solid fitting. The magnets are typically constructed from neodymium, which is among the strongest permanent magnets available. There is a wide variety of countersunk magnets available. For example, customers can choose from Custom SmCo Magnets, Custom AINiCo magnets, etc.

Key Features and Benefits:

Strong Magnetic Force

Countersunk magnets made of Neodymium are incredibly powerful, with a strong magnetic pull for their dimensions. This makes them ideal for a variety of situations where a stronghold is essential.

2. Easy Installation

The countersunk hole permits an easy installation using conventional screws. The conical design ensures that the head of the screw lies right in the middle of the magnet's surface, resulting in an appearance of a professional and neat look.

3. Versatile Applications

They are flexible and can be utilized in a variety of applications, including industrial use and household projects. They are ideal for fixing things to metallic surfaces, constructing magnetic closures, and even building customized tools.

4. Durability

Neodymium magnets are well-known for their long-lasting properties. They keep their magnetic strength throughout time and are impervious to corrosion and demagnetization, especially when they are coated with protective layers, such as epoxy or nickel.

Choosing the Right Countersunk Magnet

When choosing a countersunk magnet, you must look into diverse factors at the first place.

Size and Shape

The dimension of the magnet determines its capacity to hold, so it's crucial to choose one that is appropriate to the needs of your application. Larger magnets typically provide more grip.

2. Material

Neodymium is the most popular material used in countersunk magnets because of its strength. But it's equally important to think about the coating that the magnet is coated with. Common coatings include nickel, epoxy, and zinc, each of which provides various levels of protection against wear and corrosion.

3. Pull Force

The force that pulls magnets is an indication of the weight it can support. When choosing a magnet, be aware of the weight of the object to which you are planning to attach it, and select a magnet that has the right pull force. Manufacturers typically offer this information, so make sure to read the specifications.

4. Temperature Resistance

If you are working with high temperatures, you should look for magnets with higher temperatures to ensure they will remain strong under these conditions.

Magnetstek provides you with a wide variety of Custom Neodymium Magnets. We are a popular dealer of a variety of custom magnets that can help our customers to avail the best results. No matter whether they are DIY magnet lovers or belong to a construction business. Our brand gives them an ultimate satisfaction level.

0 notes

Text

Magnetic Chuck Safety Tips: Best Practices for Operators

Magnetic chucks are essential tools in machining and metalworking, providing a secure and efficient workholding solution. However, improper handling can lead to safety risks and equipment damage. By following best practices, operators can ensure safe and efficient use of magnetic chuck. Here are key safety tips to consider.

Inspect the Magnetic Chuck Before Use

Before starting any machining process, inspect the magnetic chuck for signs of wear, damage, or contamination. Ensure that the surface is clean and free of debris, as dirt, metal shavings, or rust can reduce its holding power and lead to workpiece slippage.

Verify Proper Magnetization

Confirm that the chuck is fully magnetized before beginning operations. If using an electromagnetic or electro-permanent magnetic chuck, check the power supply and connections to ensure the magnet is activated correctly. Partial magnetization can cause weak clamping and lead to accidents.

Ensure Proper Workpiece Positioning

Align and position the workpiece correctly before activating the magnet. Uneven placement or gaps between the workpiece and chuck surface can reduce magnetic force and compromise workholding stability. For irregularly shaped materials, consider using magnetic parallels or pole extensions for better grip.

Use the Right Magnetic Chuck for the Job

Different applications require different types of magnetic chucks, such as permanent, electromagnetic, or electro-permanent chucks. Choose the appropriate chuck based on workpiece material, size, and machining requirements. Using an unsuitable chuck can result in insufficient holding force and increase the risk of movement during machining.

Check the Weight and Load Capacity

Every magnetic chuck has a rated holding capacity. Exceeding this capacity can lead to reduced magnetic force and potential workpiece detachment. Always check the manufacturer’s specifications to ensure the chuck can safely hold the workpiece weight and dimensions.

Keep the Work Area Clean and Dry

Moisture, oil, and coolant buildup on the chuck surface can reduce magnetic adhesion and create a slippery work environment. Regularly clean the chuck surface and surrounding area to maintain optimal working conditions.

Use Safety Stops and Backup Clamping When Necessary

For high-speed machining, heavy-duty cutting, or unstable workpieces, consider using additional mechanical clamps or safety stops. These provide extra security in case of accidental demagnetization or loss of holding force.

Follow Proper Demagnetization Procedures

When removing a workpiece from an electromagnetic chuck, always follow the correct demagnetization sequence to prevent residual magnetism. Residual magnetism can cause material handling difficulties or lead to unintended workpiece attraction to other metal surfaces.

Train Operators on Safe Usage

Proper training ensures that all operators understand how to safely use, inspect, and maintain magnetic chucks. Regular safety drills and refresher courses help reinforce best practices and reduce workplace accidents.

Perform Regular Maintenance

Routine maintenance, including checking for wear, tightening loose components, and inspecting electrical connections, prolongs the chuck’s lifespan and ensures consistent performance. Schedule periodic servicing to detect potential issues early.

Conclusion

By following these safety tips, operators can maximize the effectiveness of magnetic chuck while minimizing risks. Regular inspections, proper workpiece positioning, and adherence to best practices contribute to a safer and more efficient machining environment. Prioritizing safety not only protects workers but also enhances productivity and equipment longevity.

0 notes

Text

NDT Demagnetizer Machine

Demagnetizer Machine effectively removes residual magnetism from metal parts, ensuring precise non-destructive testing. It's a reliable tool for improving accuracy and performance in various industrial applications.

#magkraftndt#mpimachine#demagnetizermachine#stationarytypedemagnetizer#chutetypedemagnetizermachine#trollytypedemagnetzermachine#magneticparticletestingmachine#mpimachinemanufacturer

0 notes