#uPVC Profile Processing Machine

Explore tagged Tumblr posts

Text

Drilling Milling Machine Manufacturer, UPVC CNC Window Machine Supplier & Exporter | Shiner

As the market shifts towards durable, cost-effective, and easy-to-maintain materials, uPVC (Unplasticized Polyvinyl Chloride) has emerged as a top choice for fabricators and builders. To match this evolving market, Shiner brings you a comprehensive range of Drilling & Milling Machines and uPVC CNC Window Machines designed for superior performance and precision.

As a trusted Drilling Milling Machine Manufacturer and leading uPVC CNC Window Machine Supplier & Exporter, Shiner is committed to delivering high-quality, technologically advanced machines that meet the evolving needs of uPVC window and door manufacturers.

Why Choose uPVC in Window Fabrication?

Before diving into machinery, let’s understand why uPVC has become a leading material in window and door fabrication. uPVC is highly durable, weather-resistant, and requires minimal maintenance. It doesn’t rot, corrode, or require frequent painting. Its superior thermal insulation and soundproofing capabilities make it ideal for modern architectural needs.

However, to make the most of uPVC’s benefits, manufacturers need highly efficient and reliable machinery — which is where Shiner steps in with its state-of-the-art uPVC Window Machinery.

Shiner’s Cutting-Edge Drilling & Milling Machines

At the core of any precision window fabrication process lies accurate drilling and milling. Shiner’s Drilling & Milling Machines are designed to deliver precise cuts, slots, and holes for various uPVC profiles. Engineered with robust components, our machines offer high stability, minimal vibration, and long-term performance.

Key Features:

High-speed operation for increased productivity

Digital control panels for ease of use

Adjustable heads for versatile profile handling

Low maintenance with durable components

Compatible with all major uPVC profile types

Our uPVC Drilling and Milling Machines are designed to execute multiple functions such as water slot milling, lock hole drilling, and hardware slot cutting with extreme precision. These machines are ideal for manufacturers who need reliable solutions to scale up operations and ensure uniformity in every product.

uPVC CNC Window Machine – Precision and Automation in One

Automation is revolutionizing the fabrication industry, and Shiner’s uPVC CNC Window Machines are at the forefront of this transformation. These machines are powered by advanced computer numeric control systems that allow you to automate tasks like cutting, welding, drilling, milling, and corner cleaning.

Whether you're fabricating casement windows, sliding windows, or tilt & turn systems, our CNC uPVC Window Machines help reduce manual labor and errors, delivering unmatched precision and consistency.

Advantages:

Complete automation of repetitive tasks

High-speed processing of complex profiles

Integration with CAD software for custom designs

Minimal operator intervention needed

Reduces material wastage and boosts output

Our Automatic uPVC Window Machines are perfect for modern-day factories looking to boost productivity without compromising on quality.

uPVC Profile Processing Machine – Versatile and Efficient

Processing uPVC profiles involves multiple steps — cutting, welding, milling, and cleaning. Shiner’s uPVC Profile Processing Machines are built to handle these operations with precision. Designed for heavy-duty operations, these machines come equipped with servo motors, digital displays, and programmable logic controllers to make profile processing seamless and efficient.

These machines ensure clean and smooth profile edges, exact slot placements, and perfect corners, making your final window or door not only functionally sound but also aesthetically pleasing.

uPVC Window Fabrication Machine – Complete Fabrication Line

For end-to-end window manufacturing, you need a complete fabrication setup. Shiner offers a series of uPVC Window Fabrication Machines tailored for all stages of the production line. Our fabrication machines include:

Double-head cutting machines

Corner welding machines

V-notch milling machines

End milling machines

Corner cleaning machines

These machines are engineered for synchronization, ensuring each step complements the next. Whether you're a startup or an established manufacturer, our uPVC Window Making Machines allow you to build high-quality, customized windows at scale.

Why is Shiner the Preferred uPVC Machine Manufacturer?

Shiner is not just a uPVC Machine Manufacturer — we are a technology partner to hundreds of businesses in India and around the world. Our machines are known for their durability, reliability, and innovation.

Here’s why manufacturers choose Shiner:

In-House R&D and Engineering: All our machines are designed and built in-house. Our R&D team constantly innovates to ensure we meet global standards and customer expectations.

Customization Options: Different markets and clients have different needs. We offer machine customization to match your exact production requirements.

Global Exports: As a trusted uPVC CNC Window Machine Supplier & Exporter, we have a strong footprint in countries across Asia, the Middle East, and Africa. Our machines are exported with compliance to international quality norms and safety standards.

Post-Sales Support: We believe that machinery is only as good as the service behind it. Our expert technicians offer on-site installation, operator training, and prompt after-sales support to ensure maximum uptime.

Competitive Pricing: Despite offering cutting-edge technology, our machines are competitively priced to ensure maximum ROI for our clients.

Applications of Our uPVC Window Machinery

Our machines are ideal for:

Residential window and door manufacturing

Commercial and office space installations

Modular construction companies

Prefabricated housing units

Industrial window and facade solutions

Whether you’re catering to large infrastructure projects or personalized residential constructions, Shiner’s uPVC CNC Window Machines and Drilling & Milling Machines help you meet deadlines and quality benchmarks with ease.

In a fast-paced world where efficiency and precision are paramount, investing in the right fabrication equipment can transform your production capability. Shiner’s wide range of Drilling & Milling Machines, uPVC CNC Window Machines, and complete uPVC Window Fabrication Machines ensure you remain ahead of the competition.

From design to delivery, we empower you with automation, innovation, and dependable performance. Whether you're just starting out or scaling up, Shiner is your trusted partner in achieving excellence in uPVC Window Machinery.

Ready to upgrade your window fabrication facility?

Get in touch with Shiner — your trusted Drilling Milling Machine Manufacturer, uPVC CNC Window Machine Supplier & Exporter.

👉 Contact us today to learn more about our full range of uPVC Machine Manufacturer solutions or to request a free quote.

Let’s build precision — together.

For more informations: https://www.shinercnc.com/

Email id: [email protected]

Call Now: +8615753113189

Location: Room 7-1101, Rongsheng Times Square , No.9 Beiyuan Street, Lichen, Jinan City , Shandong

#Drilling & Milling Machines#uPVC CNC Window Machine#uPVC Window Machinery#uPVC Drilling and Milling Machine#Automatic uPVC Window Machine#uPVC Profile Processing Machine#CNC uPVC Window Machine#uPVC Window Fabrication Machine#uPVC Window Making Machine#uPVC Machine Manufacturer

0 notes

Text

Understanding the Technology Behind uPVC Windows and Doors

uPVC doors and windows have become popular among builders and architects as they offer numerous advantages. uPVC (unplasticized polyvinyl chloride) has several unique properties including high thermal insulation, durability, enhanced aesthetics, and superior weather resistance. So, it has become a preferred alternative to traditional materials like wood and aluminium.

Aparna Venster is among the leading uPVC doors and windows suppliers and uses world-class technology in fabrication. This ensures greater reliability, precision, and accuracy of the uPVC solutions. Read the blog to understand the technological aspects of the process that we follow in uPVC windows and doors manufacturing.

Manufacturing process for uPVC windows and doors

The manufacturing of the uPVC windows and doors happens in different phases. The operations involved and resources required at various stages in the manufacturing process are listed below:

1. Raw material preparation

The quality of the raw materials and the preparation process determine the functionality and durability of the uPVC windows and doors. At Venster, we handpick the raw materials and process them with utmost care. The windows and doors made from low-quality materials are prone to cracks and lack robustness. So, we pay close attention to ensuring raw materials quality in the manufacturing process.

While manufacturing uPVC windows and doors, the primary ingredient is PVC resin. It is blended with stabilizers, impact modifiers, UV absorbers are also added to the mixture. An extensive raw material preparatory phase promotes colour stability, UV resistance, and longevity of the windows and doors.

2. Extrusion of the compound

Extrusion is a crucial phase of the uPVC windows and doors manufacturing process. The mixture is then melted at very high temperatures and fed into extrusion moulds to finally create long, hollow uPVC profiles. They serve as the key component in manufacturing and shaping up the windows and doors.

A large mixing equipment is used to mix the compound and then cast it into a die. By pulling and stretching the extruded mould, the uPVC profile can be shaped appropriately.

3. Reinforced profiles

The hollow uPVC profiles must be strengthened to bear the heavy loads and adverse weather conditions. The galvanized steel is the best form of reinforcements and they are pushed into the hollow profiles. This enhances their resilience against high temperatures, heavy loads, and poor weather conditions.

4. Welding and cutting

While the extruded profiles are put into a shape, they are cooled down completely. Using advanced machines, they are cut to the desired size and welded together into frames. At Venster, we use world-class robotic welding equipment to ensure accuracy. This helps ensure tightness and minimise the problem of water seepage/ leakage.

5. Glazing

After the profiles are cut and welded into desired frames, they are fitted with glass panels. The panels can be single, double, or triple-glazed. Adding multiple layers of glass helps improve the acoustics, insulate against outside noise, and prevent heat transfer. The barriers elevate energy efficiency and depending on your desired needs between single, double, or triple-glazed windows.

6. Final assembly

Locks, handles, gaskets, etc. are added to finish the assembly and get a complete product. At each step of the process, our team invests in a strenuous effort to ensure that the output meets the desired quality standards.

Key technologies in uPVC windows and doors manufacturing:

While we described the entire manufacturing process in the previous section, here we take a deeper look at some of the essential technologies involved in manufacturing uPVC windows and doors.

1. UV resistance

In the preparatory phase, uPVC profiles must be enhanced with UV stabilisers. This helps prevent discolouration when exposed to sunlight. The UV stabilisers ensure that the windows and doors do not fade away and remain new and fresh for a long time. The structural integrity also improves and minimises the need for maintenance and repairs.

2. Steel reinforcements for durability

Steel reinforcements are crucial for improving the strength and longevity of uPVC windows and doors, enabling them to withstand strong wind loads and harsh weather conditions. These reinforcements offer structural stability, guaranteeing that the windows stay stable and secure, even in difficult conditions. Aparna Venster uPVC systems merge exceptional strength with elegant design by incorporating premium steel reinforcements, providing an ideal harmony of safety and visual appeal. This renders them a perfect option for residences in tall buildings or regions susceptible to severe weather.

3. Resilience against adverse weather

The windows and door frames are integrated with high-quality, watertight seals. This prevents seepage of water, dust, etc. while enhancing their durability and functionality.

4. Innovative mechanisms

uPVC windows and doors suppliers, ie, Aparna Venster, are exploring innovative mechanisms to provide greater convenience to the residents. We also look for ways to improve energy efficiency, lighting, air circulation, etc. For instance, the tilt and turn mechanism in uPVC windows is an innovative opening method for windows that allows the window to be tilted for ventilation or cleaning purposes.

uPVC sliding doors help improve space utilization inside the building. They can be moved horizontally along the track. This reduces the extra space needed for opening and closing the windows. Similarly, slide and fold doors add a minimal yet modern appeal and bring you close to nature. The uPVC casement windows can be open inwards or outwards on hinges. This ensures water tightness and greater energy efficiency.

Looking for a reliable uPVC window and door supplier?

Aparna Venster is the leading uPVC windows and doors manufacturers in India. It has production facilities in Hyderabad & fabrication unit in Bangalore and holds a remarkable achievement of delivering 3 million+ windows and doors .. Our production facilities are equipped with top-notch machinery from Germany.

The uPVC windows and doors manufactured at Aparna Venster conform to stringent European quality standards. Equipped with world-class technology, we ensure precision and accuracy in all our products. Our laboratory equipment used for testing is certified by NABL (National Accreditation Board for Testing and Calibration Laboratories). Additionally, our uPVC windows and doors adhere to RoHS (Restriction of Hazardous Substances) standards, guaranteeing that they are free from harmful substances like lead, making them safe for both your home and the environment.

At Venster, we provide a greater degree of customisation, in terms of colour, size, glazing, energy efficiency, and so on. Our uPVC windows and doors have unique properties.

If you are looking for a high-quality uPVC windows and doors manufacturer, Aparna Venster is your go-to choice. Check our products at https://aparnavenster.com/.

FAQs

What is the average uPVC windows price?

At Venster, we offer high-quality windows at economical rates. However, the exact price of the uPVC windows depends on several aspects like size, glazing options, open type, etc. To know the exact price, book a free consultation with us.

Why choose Aparna Venster for uPVC windows and doors?

At Aparna Venster, we are committed to delivering the highest quality when it comes to uPVC windows and doors. Our products meet the most stringent European standards and this stands as a testament to our quality commitment. With rich experience in the field, we help customise the size, type, and appeal of the windows and doors to match your specific requirements.

0 notes

Text

Planning to set up - upgrade your uPVC window & door manufacturing plant?

Yilmaz, Turkey is a global partner of LGF SYSMAC since 2017 and is a manufacturer of uPVC and Aluminium profile processing machines.

To get assistance, connect with us, visit- www.lgfsysmac.com and our team will be happy to assist you.

To know more, visit: www.lgfsysmac.com

0 notes

Text

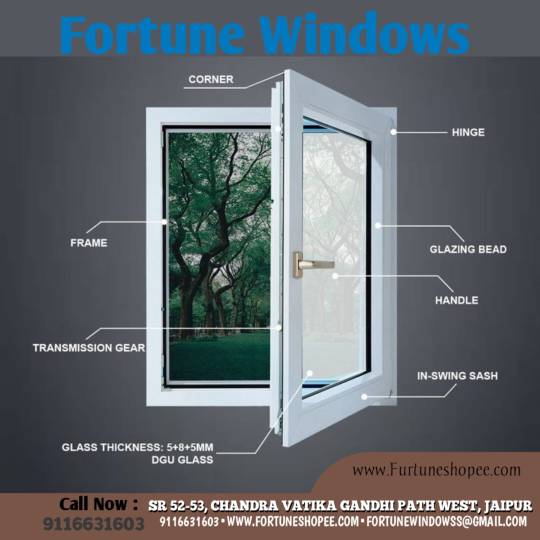

How uPVC Windows & Doors are manufactured in a factory ?

Introduction:

In the dynamic world of construction and home design, uPVC (Unplasticized polyvinyl chloride) windows and doors have emerged as a preferred choice, blending durability, energy efficiency, and aesthetic appeal. FortuneWindows, a brand synonymous with innovation and quality, takes us behind the scenes to unveil the meticulous process of manufacturing their uPVC windows and doors.

Material Selection:

The journey begins with the careful selection of raw materials. FortuneWindows sources high-quality uPVC, known for its durability, resistance to weathering, and low maintenance. The raw material undergoes a rigorous testing process to ensure it meets the brand’s stringent quality standards.

Extrusion Process:

Once the raw material is approved, it’s time for the extrusion process. The uPVC is heated and forced through a precision-designed die, taking the shape of the window or door profile. FortuneWindows’s state-of-the-art extrusion machinery ensures uniformity and consistency in every profile, setting the foundation for a product that stands the test of time.

Reinforcement Insertion:

To enhance structural strength, FortuneWindows integrates galvanized steel reinforcement within the uPVC profiles. This step ensures that the windows and doors not only maintain their shape but also provide the necessary support for hardware and operational components.

Cutting and Welding:

Precision is paramount in crafting FortuneWindows uPVC windows and doors. Computer-guided cutting machines accurately cut the profiles to the required dimensions. The pieces are then welded together using advanced welding technology, creating seamless joints that contribute to both the aesthetic appeal and structural integrity of the final product.

Glazing Installation:

FortuneWindows places a strong emphasis on energy efficiency. The next step involves the installation of high-performance glazing, which includes double or triple-pane glass with low emissivity coatings. This not only enhances insulation but also contributes to noise reduction and UV protection.

Hardware Integration:

The windows and doors are then equipped with top-of-the-line hardware, sourced from reputable suppliers. FortuneWindows ensures that all components, from handles to locking mechanisms, meet the brand’s standards for functionality, security, and longevity.

Quality Control Inspections:

At every stage of the manufacturing process, FortuneWindows conducts rigorous quality control inspections. From profile dimensions to welding integrity, each component undergoes scrutiny to ensure that the finished product aligns with the brand’s commitment to excellence.

Finishing Touches:

Once the uPVC windows and doors have passed the quality checks, they undergo any necessary finishing touches. This may include adding decorative elements, textures, or colour finishes to meet the design preferences of customers.

Packaging and Delivery:

FortuneWindows understands the importance of ensuring that their products reach customers in pristine condition. The carefully crafted uPVC windows and doors are securely packaged and prepared for delivery to construction sites or distribution centres, ready to adorn homes and buildings with functionality and style.

Conclusion:

The manufacturing process of FortuneWindows uPVC windows and doors is a testament to the brand’s commitment to precision, quality, and innovation. From material selection to the final touches, each step reflects the brand’s dedication to crafting products that not only meet but exceed the expectations of homeowners and architects alike. As FortuneWindows continues to shape the future of uPVC solutions, it is evident that excellence is not just a goal – it’s a standard.

Phone: 091166 31603 Message Fortune on WhatsApp.

#window #italy #interiordesign #clouds #homedecor #streetphotography #city #view #light #street #world #interior #garden #house #bnw #wood #building #reflection #kitchen #construction

0 notes

Text

Best UPVC window profile machine Manufacturer in Delhi

HPMC is top growing UPVC window profile machine Manufacturer in India It was established in 1973 and also has an ISO 9001:2008 certfied manufacturer, exporter and supplier of plastic processing machine .

The irrigation pipe plant manufacturer is an effective and innovatively crafted unit that is designed well by skilled engineers. UPVC (unplasticized polyvinyl chloride) doors and windows have emerged because of the popular choice among urban Indian homes and builder apartments over conventional materials like wood or aluminium. Our team behind the walls works day and night to make our customer happy

UPVC window profile machine manufacturer: 1 Popular machinery type 2 Can use to form angel welding between various angles. 3 Solid machinery base and structure 4 Profile fixture to use various height profiles

Address- Hindustan Plastic & Machine Corporation 5, Category II, DSIDC Industrial Area Nangloi, Delhi-110041 Phone : 011-25473361,25471114, (M)+91 9891061200, 9899074169, 9312645101 E-mail : [email protected]

Website https://www.hpmcindia.com/upvc-window-profile-machine.html

380 notes

·

View notes

Text

Using Plastic Extruders to Create a Diverse Catalog of Plastic Extrusion Products

Melted plastic is forced through a die into a form with a defined cross-section in plastic extrusion. It is an effective method of producing plastic extrusion products in a variety of forms, and it is vital in both industrial and consumer product applications. Only thermoplastics can be extruded since they are melted from a solid-state and then resolidified.

uPVC extrusion profiles have a wide range of applications. They may be readily softened and moulded into any shape required by the design and project. These are waterproof, energy-efficient, non-polluting, and fire-resistant.

What Kinds of Products Can Be Made Using Plastic Extruders?

Pieces with Cross-Sections: Extrusion is used to make typical profile forms for house building, including windshield wipers and vinyl siding.

Hollow Pieces: Using a plastic extrusion machine, hollow plastic tubes such as industrial pipework and drinking straws may be readily and effectively manufactured.

Insulated Wiring: Plastic insulation can be extruded over fragile electrical filaments to protect them from harm. Plastic can protect wiring from liquids, gases, and other corrosive substances while simultaneously giving the wires greater flexibility.

Plastic Sheet: Acrylic and polycarbonate can be extruded in thin sheets as a substitute for glass; both are frequently utilised for commercial glazing applications on commercial properties.

Solid Pieces: Large pieces of solid plastic can be extruded for plastic lumber applications such as park benches or other constructions that must be water and element resistant.

Conclusion

Extruded plastic goods help almost any business you can think of: automotive, industrial, food and beverage, medical, chemical processing, plumbing, electronics, water treatment, and more.

Source

0 notes

Text

PVC window frame making machine

PVC door/window frame profile making machine is one of our advantage products , xinda precision machinery company has focused on plastic machinery over 21 years with rich experience and strong technology , our machinery exported to 25 countries , such as Iran , Turkey , Vietnam , UAE , Africa , Germany , America , etc.

we continue to perfect the design and quality , ensure the top quality and the turn-key service including installation , test running and training workers in your local factory . we are your trustworthy partner ! please contact Mr John Yu to get more details .Mr John Yu +86 13301561523 ; Email : [email protected]

The PVC UPVC profile making machine consist of twin screw extruder , vacuum calibration device , hauling off machine , automatic cutter , tipping table . the main spare parts adopt the top quality famous brand , such as ABB converter , SIEMENS motors , SCHNEIDER electric parts , OMRON temperature meters , etc . special design the screw and barrel , it’s high efficiency extrusion and easy to disassemble for maintenance . it can process the PVC powder or PVC + wood powder .

#PVC window frame making machine#PVC window profile making machine#PVC window frame production line#PVC window machine

1 note

·

View note

Photo

Planning to set up - upgrade your uPVC window and door manufacturing plant

Yilmaz, Turkey is a global partner of LGF SYSMAC since 2017 and is a manufacturer of uPVC and Aluminium profile processing machines. To get assistance, connect with us, visit- www.lgfsysmac.com and our team will be happy to assist you.

https://www.lgfsysmac.com/

0 notes

Text

Drilling & Milling Machine - UPVC CNC Window Machine | Shiner

Enhance your uPVC window fabrication process with Shiner CNC advanced Drilling & Milling Machines. Engineered for precision and speed, these CNC machines are ideal for creating accurate holes, slots, and hardware placements in uPVC profiles. Whether you're running a small workshop or a large-scale production unit, our machines ensure smooth operations with minimal manual intervention. Designed with durability and user-friendly controls, Shiner’s uPVC CNC Window Machines offer unmatched performance and long-term reliability. Maximize productivity while maintaining exceptional quality with every unit. Ready to upgrade your window manufacturing process? Contact Shiner today for expert guidance and unbeatable deals!

🌐 https://www.shinercnc.com/products/drilling-milling-machines/21

#Drilling & Milling Machines#uPVC CNC Window Machine#uPVC Window Machinery#uPVC Drilling and Milling Machine#Automatic uPVC Window Machine#uPVC Profile Processing Machine#CNC uPVC Window Machine#uPVC Window Fabrication Machine#uPVC Window Making Machine#uPVC Machine Manufacturer

0 notes

Photo

Lock Hole Copy Router is Used for processing of holes and slots of aluminum profile, upvc profile. This machine has copy router and lock hole drilling part.

0 notes

Text

uPVC Windows and Doors that fit the lifestyle of your customers

As customers become increasingly conscious about living a premium lifestyle, they are also willing to spend top dollar for quality products that are strong, durable, impeccably crafted and also great to look at! In this context, with people constantly aspiring to a better quality of life, the only products that truly stand the test of time are those that are made from the highest quality raw materials, and with state-of-the-art processes and technology, to ensure that a great quality product is delivered every single time. Welcome uPVC windows and doors from Ökotech that fit the lifestyle of your customers. World-class Quality Ökotech uPVC profiles are manufactured with world-class, cutting-edge German extrusion equipment. All the equipment for the manufacturing of our uPVC profiles has been imported from Germany to introduce high reliability and accuracy into the manufacturing process. Ökotech employs the largest profile bending machine among uPVC brands in India, which can produce arches with a maximum radius of 3 meters. This combination of top-quality equipment and stringent quality control processes ensures that all orders are of uniformly premium quality and fit for the best residential or commercial projects. Precision Engineering Ökotech uPVC profiles are cut to the desired dimensions on high-precision PLC controlled cutting machines, based on a client’s unique requirements. These high-quality profiles are then taken to the drilling and copy routing machine, where the necessary machining to fix the hardware and provide water drainage slots is done. The complete manufacturing process is monitored under the stringent stage-wise control of the parameters set by the Quality Assurance department. We also always maintains a well-stocked inventory of profiles to ensure the quick and timely delivery of uPVC windows and doors to even large-size projects at short notice. For more CLICK uPVC Windows and Doors that fit the lifestyle of your customers

0 notes

Text

UkrPromAutomation Ukraine 2019 at Ukraine(Kiev) 2019-November

aluminium windows and doors business, upvc windows Exhibitors, wood companies contacts, aluminium-wrapped wood contacts list, composite of aluminium and wood windows Trade Shows, steel windows Expos, variety of compound profiles Exhibitors, facades & curtain walls contact info, glass Fairs, aluminium business opportunities, stone events, profile Meetings, aluminim companies, upvc events, composite of aluminium and wood other composite profiles Events, machinery contact links, aluminium profile processing Exhibitors, upvc window processing info, glass processing B2B Opportunities, solid wood doors & windows Exhibitors Directory, aluminium-clad wood windows & doors Events, aluminium composite wood proessing machinery & equipment Trade Fairs, others Meetings, accessories of windows B2C opportunities, doors and curtain walls directory, sun-shading products Exhibitions, ventilation equipment Exhibitions, architectural glass contact links, thermal insulation materials contacts list, windows Exhibitors, doors and curtain wall systems Trade Shows, software companies, sealants Exhibitions, building-integrated photovoltaics (bipv) B2B ideas, machine accessories contact links, interior designers & consultants Expos, interior decorators business contacts, contractors & builders Trade Shows, allied professionals Exhibitors, property developers Exhibitions, facility managers Fairs, agents & distributors Exhibitors, marketing consultants Exhibitions, contract manufacturers events, manufacturers business, suppliers & traders business, importers & exporters Trade Fairs, department & chain store buyers business opportunities, institutional buyers Shows, government departments B2C opportunities, local councils & agencies. B2C ideas 2019, November, Indonesia, Jakarta

Glasstech Asia 2019 at Indonesia(Jakarta) 2019-November

Glasstech Asia 2019 trade show event mainly focuses on:

aluminium windows and doors companies, upvc windows B2B Opportunities, wood contact links, aluminium-wrapped wood Events, composite of aluminium and wood windows contacts list, steel windows events, variety of compound profiles contact info, facades & curtain walls Exhibitors, glass network, aluminium companies contacts, stone Business events, profile Exhibitors, aluminim contact info, upvc Exhibitors Directory, composite of aluminium and wood other composite profiles Business events, machinery Exhibitors Directory, aluminium profile processing Shows, upvc window processing Meetings, glass processing Trade Shows, solid wood doors & windows contacts list, aluminium-clad wood windows & doors Fairs, aluminium composite wood proessing machinery & equipment info, others Expos, accessories of windows Exhibitors, doors and curtain walls companies, sun-shading products business opportunities, ventilation equipment Expos, architectural glass events, thermal insulation materials business contacts, windows B2C opportunities, doors and curtain wall systems Trade Fairs, software Exhibitions, sealants Expos, building-integrated photovoltaics (bipv) Exhibitors, machine accessories Fairs, interior designers & consultants Shows, interior decorators companies contacts, contractors & builders Expos, allied professionals contact info, property developers Business events, facility managers Fairs, agents & distributors business ideas, marketing consultants business contacts, contract manufacturers Shows, manufacturers B2C opportunities, suppliers & traders B2B Opportunities, importers & exporters events, department & chain store buyers business opportunities, institutional buyers Shows, government departments Shows, local councils & agencies. contact links

related products/services/industry/business. This trade show opens top business opportunities to exhibit products and services from aluminium windows and doors events, upvc windows Exhibitors Directory, wood Exhibitors, aluminium-wrapped wood Meetings, composite of aluminium and wood windows contacts list, steel windows companies, variety of compound profiles directory, facades & curtain walls contact info, glass B2C opportunities, aluminium Business events, stone Trade Fairs, profile contact links, aluminim companies contacts, upvc Exhibitors, composite of aluminium and wood other composite profiles contacts list, machinery network, aluminium profile processing B2C opportunities, upvc window processing B2C ideas, glass processing business contacts, solid wood doors & windows Business events, aluminium-clad wood windows & doors Trade Shows, aluminium composite wood proessing machinery & equipment Exhibitors, others business opportunities, accessories of windows info, doors and curtain walls Exhibitors Directory, sun-shading products companies, ventilation equipment Exhibitors, architectural glass business contacts, thermal insulation materials Trade Fairs, windows contact list, doors and curtain wall systems B2B ideas, software Exhibitors Directory, sealants contact info, building-integrated photovoltaics (bipv) Business events, machine accessories contact links, interior designers & consultants Fairs, interior decorators Exhibitions, contractors & builders events, allied professionals Exhibitions, property developers contact links, facility managers business, agents & distributors info, marketing consultants contacts list, contract manufacturers companies contacts, manufacturers Trade Fairs, suppliers & traders companies list, importers & exporters info, department & chain store buyers companies list, institutional buyers info, government departments Exhibitors Directory, local councils & agencies. Exhibitors Directory industry.

Find More Details about Glasstech Asia 2019 event...

We help you to grow your business by providing the required contact details of all companies participating in this event and you can download the same data in excel format using the above links. Location of the Event:Indonesia(Jakarta) Year-Month:2019-November Official Website:Event Website source https://www.expomahal.com/2019/11/ukrpromautomation-ukraine-2019-at.html

0 notes

Text

Top UPVC window profile machine Manufacturer in Delhi

HPMC is top growing UPVC window profile machine Manufacturer in India It was established in 1973 and also has an ISO 9001:2008 certfied manufacturer, exporter and supplier of plastic processing machine

.The irrigation pipe plant manufacturer is an effective and innovatively crafted unit that is designed well by skilled engineers. UPVC (unplasticized polyvinyl chloride) doors and windows have emerged because of the popular choice among urban Indian homes and builder apartments over conventional materials like wood or aluminium. Our team behind the walls works day and night to make our customer happy

UPVC window profile machine manufacturer:

1 Popular machinery type 2 Can use to form angel welding between various angles. 3 Solid machinery base and structure 4 Profile fixture to use various height profiles

Address- Hindustan Plastic & Machine Corporation 5, Category II, DSIDC Industrial Area Nangloi, Delhi-110041 Phone : 011-25473361,25471114, (M)+91 9891061200, 9899074169, 9312645101 E-mail : [email protected]

Website https://www.hpmcindia.com/upvc-window-profile-machine.html

0 notes

Text

Explore Multiple Benefits of Plastic Extrusion in Melbourne to Gain Variety of Products

Plastic extrusion in Melbourne is a moulding process where plastics are changed from solid to liquid. At last, it is reconstituted into a finished product. In simpler words, plastic is melted and reshaped into useful products. In the current time, this method is widely used for making versatile items that comes with multiple advantages. The main theory behind this method is the manufacturing of raw materials into a continuous profile. The plastic materials are created in a high volume.

If you need strong and versatile products made from plastic, you can connect with UPVC profile manufacturers that can offer desirable items. In this method, heat is used for virgin or recycled plastic to create the desired shape. Some of the popular examples are weather stripping, fencing, plastic films and sheeting, piping and tubing, deck railings, and thermoplastic coatings.

This method is used for a wide range of products such as elastomers, nylon, ABS, PVC, and many more. As depending on the materials with plastic, the end-product will be rigid, semi-rigid, and flexible. The resultant products have many interesting properties.

One of the core advantages of this process is that the resultant products come at a reduced cost. So if you want to buy something in low-budget, one will not face any difficulty. As compared to other moulding processes, plastic extrusion is conducted low cost. Most of the extrusion process utilizes the thermoplastics, it constantly undergoes melting and hardening. In other processes, leftover materials are discarded whereas extrusion process reuses every residue.

As there is less usage of new materials, the cost of resultant products is automatically low. Reduced raw materials and disposal cost are the main reason behind the cost-effective pricing of extrusion. These machines work continuously except mechanical failure or planned downtime, reduces inventory costs and constant manufacturing. If you need this process, don’t hesitate to connect with reputable manufacturers in the city.

Source

0 notes

Text

uPVC Profiles in India, uPVC Profiles Wholesalers

HIGH RELIABILITY & ACCURACY:

The entire equipment for manufacturing of ÖKOTECH uPVC profiles has been imported from WEGOMA, Germany to ensure high reliability and accuracy in the manufacturing process. The uPVC profiles are reinforced with galvanized steel sections for additional strength to withstand high wind loads. ÖKOTECH has the largest profile bending machine in India that can produce arches with max of 3m radius.

PRECISION ENGINEERING:

Based on requirements, uPVC profiles are cut to the required dimensions on PLC controlled cutting machines. These profiles are taken to the drilling and copy routing machine, where necessary machining is done on the profile to fix the hardware and also provide water drainage slots. Galvanized Steel Reinforcements matching the profile sizes are inserted into the chambers of the profiles and fixed in place by screws.

The entire manufacturing process is under the stage-wise control of the parameters set by the Quality Assurance Department. ÖKOTECH maintains a large inventory of profiles to ensure quick and timely deliveries of windows and doors to large sized projects at a short notice. for know more uPVC Windows

0 notes

Text

Tongxiang Longcheng Plastic Co.,Ltd Now Announces To Supply Flexible PVC Compound For The Footwear Industry

Tongxiang City, Zhejiang Province, China – In the footwear industry, flexible PVC compounds are an important element, required to manufacture high quality sleepers, sandals, rain boots and other products. China based Tongxiang Longcheng Plastic Co.,Ltd assures of supplying flexible PVC compounds for the footwear industry with environment-friendly features.

The company specializes in the flexible PVC compound, used for the production of footwear with excellent transparency and shine. The compound is non-toxic and odorless for companies to produce quality footwear for their customers. The company spokesperson reveals that they can supply flexible PVC compounds with custom properties, and can modify the common parameters, such as hardness, specific gravity, tensile strength, tearing strength, elongation ability, etc. One can choose the properties of the compound as per their machining requirement and can produce superior quality products.

Besides flexible and clear PVC compounds, the company can also supply the UPVC granule that is used primarily in making window and door frames. The granules can allow producing tough and robust products that can withstand the outside weather conditions. With an outstanding surface finish, the granules can be used in many other applications as well, such as hard tubes and pipes for transporting different fluids. The spokesperson reveals that they have the latest machines in their facility to formulate UPVC granules that can also be used in the injection molding for producing products, like transparent wheels, clear lampshades, and transparent lights and so on.

Tongxiang Longcheng Plastic Co.,Ltd supplies PVC particles that can be used in the extrusion process for manufacturing clear price tag profiles. The spokesperson states that they have PVC granules with RoHS quality that can be used in different industries. With over 20 years of experience, the company can supply PVC compounds to international companies with custom specifications. They can modify the properties of the compounds, such as hardness, specific gravity and others. Companies can pick the PVC particle as per their production needs.

One can learn about the different types of PVC compounds the company can supply by visiting their website https://www.lcpvc.com.

About Tongxiang Longcheng Plastic Co.,Ltd.

Tongxiang Longcheng Plastic Co.,Ltd is focused on modified PVC granules and has been providing all kinds of high quality PVC pellets for different industries for more than 20 years. The company has the most professional R&D team, working to modify PVC granules as per the industry needs. The company’s main products are rigid PVC compound, soft PVC compound, UPVC compound, and clear PVC compound.

For Media Enquiry –

Contact Person: Jane Tang

Telephone: +86 573 8861 8523

Email: [email protected]

Website: www.lcpvc.com

0 notes