#understanding the lockout/tagout process

Explore tagged Tumblr posts

Text

A key aspect of industrial safety is understanding the lockout/tagout process, which safeguards workers during maintenance by isolating energy sources. This procedure prevents accidental equipment startup, ensuring compliance with safety standards and reducing workplace injuries.

#understanding the lockout/tagout process#workplace safety protocols#lockout/tagout compliance#energy isolation procedures#reducing workplace hazards#industrial maintenance safety#preventing accidental machinery startups

0 notes

Text

Understanding NFPA 70B: A Comprehensive Guide to Electrical Maintenance

Electrical systems are integral to the smooth operation of any facility, and maintaining them is crucial for safety and efficiency. In this context, NFPA 70B PDF provides essential guidelines for the maintenance of electrical equipment to prevent failures and hazards. Understanding these guidelines is key for building owners, electrical contractors, and safety professionals alike.

The Importance of Electrical Maintenance

Maintaining electrical systems is not just about preventing downtime; it’s about ensuring the safety of the individuals who operate, maintain, and interact with these systems. Without proper maintenance, electrical equipment can malfunction, leading to fires, electrical shocks, or even loss of life. The National Fire Protection Association 70B PDF outlines a comprehensive strategy for the upkeep of electrical systems, recommending periodic inspections, testing, and proper procedures for repairs.

The document provides specific recommendations for various types of equipment, ranging from motors and transformers to distribution panels and circuit breakers. It stresses the importance of creating a maintenance schedule tailored to the specific needs of a facility and its equipment.

Key Elements in the NFPA 70B Guidelines

Inspection and Testing: Regular inspections help identify potential issues before they cause damage. The National Fire Protection Association 70B PDF provides detailed procedures for testing electrical systems to assess their condition, ensuring they meet the necessary operational standards.

Preventive Maintenance: One of the primary focuses of the National Fire Protection Association 70B is preventive maintenance. By performing routine checks, electrical systems can be kept in optimal condition, reducing the likelihood of unexpected breakdowns and expensive repairs.

Condition-Based Monitoring: In addition to routine maintenance, the document emphasizes the importance of condition-based monitoring. This involves using advanced techniques such as thermal imaging and vibration analysis to assess the health of equipment in real-time, allowing for more precise maintenance planning.

Safety Protocols: The safety of workers and building occupants is paramount. NFPA 70B provides guidelines on the safe handling of electrical systems during maintenance, ensuring that workers are protected from electrical hazards. Personal protective equipment (PPE) and lockout/tagout procedures are essential components of these guidelines.

Record Keeping: Proper documentation is a critical part of the maintenance process. The guidelines stress the importance of keeping detailed records of inspections, tests, repairs, and replacements. These records not only help with compliance but also offer insights into the long-term performance of the system.

Integrating NFPA 70B Into Your Maintenance Plan

Creating an effective electrical maintenance plan based on the NFPA 70B guidelines involves several key steps. First, it is essential to assess the current state of your electrical systems. This means reviewing the age, condition, and previous maintenance history of the equipment. Once this assessment is complete, a detailed maintenance schedule should be created, taking into account the specific needs of each piece of equipment.

Next, ongoing monitoring should be incorporated into the plan. This ensures that any changes in the condition of the equipment are promptly identified and addressed. Regular training for maintenance personnel is also necessary to keep them updated on best practices and safety protocols outlined in the guidelines.

The Role of Compliance and Regulations

Compliance with the National Fire Protection Association 70B is not just a recommendation but, in many cases, a requirement. Local and national electrical codes often reference these guidelines, and non-compliance can lead to legal consequences or increased risk. For example, if an electrical failure occurs and it is discovered that proper maintenance protocols were not followed, the responsible parties could face fines or liability for damages.

Building owners and managers should be proactive about ensuring that their electrical systems adhere to the latest standards outlined in the NFPA 70B PDF. This includes staying updated on revisions to the document, which are typically released every few years to address emerging technologies and new safety challenges.

Training and Education

To implement the guidelines effectively, it is crucial to provide training for all personnel involved in electrical system maintenance. Workers need to be familiar with the standards outlined in the National Fire Protection Association 70B PDF to understand what is required for compliance and how to perform maintenance tasks safely and efficiently. Regular training sessions should focus on the latest techniques, tools, and safety protocols.

Benefits of Following NFPA 70B Guidelines

Enhanced Safety: The primary benefit of following the National Fire Protection Association 70B guidelines is improved safety. Proper maintenance minimizes the risk of electrical failures, which could result in fires, electrocution, or other hazards.

Reduced Downtime: A well-maintained electrical system is less likely to experience unexpected breakdowns, leading to reduced downtime and increased productivity.

Cost Savings: Regular inspections and maintenance can extend the life of equipment, preventing costly emergency repairs or replacements. Additionally, by identifying issues early, you can avoid expensive damage to your systems.

Regulatory Compliance: Adhering to the National Fire Protection Association ensures that you remain compliant with local, state, and federal electrical safety regulations, avoiding potential legal issues. For more info Click here

By following the guidelines laid out in the National Fire Protection Association 70B PDF, facilities can ensure the longevity, safety, and efficiency of their electrical systems. Regular maintenance and adherence to safety protocols not only protect workers but also save costs in the long run by preventing costly repairs and legal issues. Understanding and integrating these best practices into your facility’s maintenance plan is key to maintaining a safe and functional electrical system.

2 notes

·

View notes

Text

Exploring the World of Electromechanical Systems: A Fusion of Electronics and Mechanics

Introduction:

In the realm of facility management, the effective operation and maintenance of electromechanical systems play a vital role in ensuring the smooth functioning of buildings and infrastructure. The fusion of electronics and mechanics has given rise to sophisticated systems that require skilled professionals to handle their operations and maintenance.

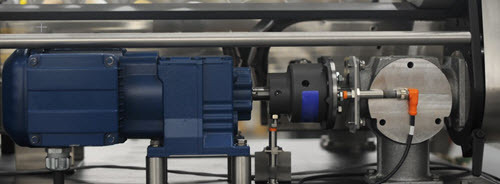

Electromechanical systems are a fascinating field that combines the principles of electronics and mechanics. These systems involve the integration of electrical components and mechanical structures to create devices capable of performing a wide range of tasks. From simple household appliances to complex industrial machinery, electromechanical systems are an integral part of our daily lives.

Understanding Electromechanical Systems:

Electromechanical systems are integral to the functioning of modern facilities. These systems combine electrical and mechanical components, utilizing electronic controls to enhance efficiency and automation. Examples include HVAC (Heating, Ventilation, and Air Conditioning) systems, elevators, escalators, fire protection systems, security systems, and energy management systems.

Workforce Requirements:

To ensure the optimal performance of electromechanical systems, facility management teams require a diverse range of professionals with specialized skill sets. Key roles may include:

a. Engineers: Electrical and mechanical engineers are crucial for system design, installation, and troubleshooting. They possess the technical knowledge to handle complex electromechanical systems.

b. Technicians: Skilled technicians play a vital role in maintaining, inspecting, and repairing electromechanical systems. They are responsible for regular maintenance, diagnosing issues, and performing necessary repairs or replacements.

c. Operators: Operators are responsible for monitoring and controlling electromechanical systems, ensuring their proper functioning and responding to alarms or emergencies.

d. Facility Managers: These professionals oversee the operations and maintenance of electromechanical systems, ensuring compliance with regulations, managing budgets, and coordinating the work of the entire facility management team.

Recruitment Strategies:

To build a competent team for operations and maintenance in facility management, consider the following recruitment strategies:

a. Job Portals: Utilize online job portals that cater to the facility management industry to reach potential candidates with the desired skill sets.

b. Industry Networks: Engage with industry-specific networks, associations, and professional forums to connect with qualified professionals in the field of electromechanical systems.

c. Collaboration with Technical Institutes: Partner with technical institutes and vocational schools to tap into fresh talent. Establish internship programs or participate in job fairs to attract entry-level candidates.

d. Skill Assessment: Conduct thorough skill assessments during the recruitment process to evaluate candidates' proficiency in handling electromechanical systems and their related components.

Training and Professional Development:

Given the complexity and evolving nature of electromechanical systems, investing in training and professional development is crucial. Provide regular training sessions to enhance the skills of your workforce, keeping them up-to-date with the latest technologies and maintenance practices. Encourage employees to attend industry conferences, workshops, and certifications to expand their knowledge base.

Safety and Compliance:

Operations and Maintenance in Facility Management must prioritize safety and compliance. Ensure that all staff members are well-versed in safety protocols, including electrical safety, lockout/tagout procedures, and handling hazardous materials. Familiarize your team with relevant regulations and standards, such as building codes, fire safety regulations, and environmental guidelines.

Team Collaboration and Communication:

Effective collaboration and communication within the facility management team are vital for seamless operations and maintenance. Foster a culture of teamwork, encourage knowledge sharing, and promote open lines of communication between different departments and roles. This collaborative approach can lead to efficient problem-solving and improved system performance.

Conclusion:

Electromechanical systems form the backbone of facility management, and staffing considerations for operations and maintenance are crucial to ensure their reliable and efficient functioning. By understanding the workforce requirements, implementing effective recruitment strategies, prioritizing training and professional development.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Best Electromechanical Systems#Integrated Electronics and Mechanics

2 notes

·

View notes

Text

Essential Features to Look for in a Busbar Trunking System for Your Business

In today’s fast-paced industrial landscape, choosing the right busbar trunking system can make a significant difference in operational efficiency and safety. With a variety of options on the market, businesses must weigh performance, cost, scalability, and ease of maintenance before making a decision. Manikaran Enterprises understands these challenges and offers expert guidance to help you navigate this complex process. Whether you’re retrofitting an existing facility or designing a new installation, understanding the nuances of different busbar trunking systems is crucial for long-term success.

Understanding Busbar Trunking Systems

Busbar trunking systems are prefabricated electrical distribution assemblies designed to carry large currents in industrial and commercial settings. Unlike traditional cable systems, trunking systems offer higher current-carrying capacity, easier installation, and improved heat dissipation. Key components typically include conductors enclosed in protective housing, connection modules, and accessories such as bends, tees, and tap-off units. By eliminating complex cable routes, these systems simplify project timelines and reduce labor costs.

Types of Busbar Trunking Systems

There are two primary categories of busbar trunking systems: insulated and uninsulated. Insulated systems feature conductors separated by solid insulation materials, offering superior protection against accidental contact and short circuits. Uninsulated systems, on the other hand, rely on air gaps and plastic barriers to maintain clearance. While uninsulated trunking can be more cost-effective, insulated versions are often preferred in environments where safety and minimal downtime are paramount.

Key Selection Criteria

When comparing busbar trunking systems, consider the following factors:

Current Rating: Ensure the system can handle your facility’s peak current demands without overheating.

Voltage Level: Match the system’s rated voltage with your supply network, typically ranging from 400 V to 1,000 V.

Short-Circuit Withstand: Verify that the trunking can withstand short-circuit forces to prevent catastrophic failures.

Environmental Conditions: For outdoor or corrosive settings, choose trunking with appropriate protection levels (e.g., IP54 or higher).

Expansion Capability: Look for modular designs that allow easy addition of tap-off units and extensions.

Comparing Performance and Efficiency

Performance comparisons often focus on thermal ratings and power loss. Insulated systems tend to exhibit lower heat generation due to superior dielectric materials, which translates into less energy loss over time. Additionally, the solid insulation prevents oxidation of the conductors, ensuring consistent performance and minimizing maintenance needs. Uninsulated designs, while initially cheaper, may incur higher lifecycle costs due to more frequent inspections and potential corrosion issues.

Installation Considerations

The ease of installation can greatly affect project timelines and labor costs. Prefabricated busbar trunking sections come in standardized lengths and fittings, allowing rapid on-site assembly. However, ensuring precise alignment and secure connections is critical to avoid performance degradation. Partnering with a specialized provider—such as Busbar Trunking System Installation Service in India—ensures professional installation, testing, and commissioning, reducing the risk of installation errors and post-deployment failures.

Maintenance and Safety

Routine maintenance of busbar trunking systems involves visual inspections, thermal imaging checks, and mechanical torque verification of bolted joints. Because insulated systems reduce the likelihood of accidental contact, safety protocols can be streamlined. Nevertheless, it’s essential to adhere to industry standards (e.g., IEC 61439) and implement lockout/tagout procedures during maintenance. Properly trained technicians from a reputable provider can significantly decrease downtime and extend the lifespan of your electrical distribution network.

Cost Analysis and ROI

While initial investment in high-quality trunking may seem substantial, the long-term benefits often justify the cost. Reduced installation time, lower energy losses, and fewer maintenance interventions contribute to a faster return on investment. Conduct a total cost of ownership (TCO) analysis that factors in equipment, installation labor, maintenance expenses, and energy consumption. Businesses that opt for fully insulated systems typically report lower TCO due to minimized operational disruptions.

Why Expertise Matters

Selecting and installing the right busbar trunking solution requires in-depth technical knowledge and hands-on experience. As a Top Electrical Solution Company in Rajasthan Manikaran Enterprises combines engineering expertise with industry best practices to deliver customized solutions tailored to your specific needs. From initial site survey to final commissioning, our team ensures compliance with safety regulations and optimizes system performance for years to come.

Conclusion

Choosing the optimal busbar trunking system for your business involves balancing performance, safety, cost, and scalability. By understanding the differences between insulated and uninsulated systems, evaluating key selection criteria, and leveraging professional installation services, you can achieve a reliable electrical distribution network that supports your operations. Trust Manikaran Enterprises to guide you through every step, ensuring your investment delivers maximum efficiency and minimal downtime.

0 notes

Text

Top Safety Tips for Power Pole Transformer Installation

At Tristar Electrical, we understand the critical role a power pole transformer plays in ensuring reliable energy distribution across communities. However, installation must be handled with the utmost care and precision to avoid risks to both personnel and equipment. With years of experience in the electrical industry, we’ve compiled our top safety tips to guide you through a successful and secure installation process.

1. Conduct a Site Assessment First

Before any work begins, it’s essential to perform a thorough site inspection. This allows us to identify potential hazards, evaluate the terrain, and ensure the area is clear of obstructions. Checking for existing underground utilities or overhead lines can prevent accidents and unnecessary delays.

2. Use Proper Personal Protective Equipment (PPE)

No installation should begin without the correct safety gear. Our team ensures every technician is equipped with insulated gloves, helmets, eye protection, and high-visibility clothing. PPE acts as the first line of defense against electric shock, falling debris, and other onsite dangers.

3. Follow Load and Rating Guidelines

One of the most important safety measures is to confirm the transformer’s load capacity and voltage rating match the area’s energy demands. Installing a power pole transformer without this verification can lead to overheating, failure, or even fire. We always double-check specs to ensure a proper fit.

4. Secure the Pole and Transformer Properly

Pole stability is crucial. We ensure the pole is embedded at the recommended depth and is structurally sound to support the transformer’s weight. Mounting hardware must be durable and corrosion-resistant to handle environmental stresses over time.

5. De-energize Lines During Installation

Working with live lines is extremely hazardous. We always de-energize the system before beginning installation or maintenance. Lockout/tagout procedures are strictly followed to eliminate any accidental energization during the process.

6. Train and Supervise Technicians

All our installers are trained professionals with hands-on experience. Additionally, each project is supervised by a qualified team leader who ensures that safety protocols are followed from start to finish.

Conclusion

Safety is not just a guideline—it’s a commitment. When installing a power pole transformer, every step should be planned and executed with care. At Tristar Electrical, we take pride in providing not only quality products but also safe and efficient installations. Your power infrastructure is in good hands with us.

0 notes

Text

How Animated Safety Videos Can Reduce Workplace Accidents

June 18, 2025 How Animated Safety Videos Can Reduce Workplace Accidents Workplace safety is a top priority for any business, especially in industries where hazards are part of the job. Whether you’re operating in construction, manufacturing, logistics, or engineering, maintaining high safety standards is essential to protect employees, avoid downtime, and remain compliant with regulations. While traditional training methods like manuals and presentations have their place, businesses are increasingly turning to animated safety videos as a more effective, engaging, and impactful way to reduce workplace accidents. Here’s how animation can play a pivotal role in transforming safety culture and protecting your workforce. 1. Visual Learning Improves Retention It’s no secret that people tend to remember what they see more than what they read. Studies show that visual information is processed 60,000 times faster than text, and viewers retain up to 95% of a message when delivered via video compared to just 10% through text alone. Animated safety videos leverage this by turning key messages into visual stories. Whether it’s demonstrating how to use PPE, showing proper machinery procedures, or highlighting emergency exit protocols, animation makes the content easier to understand and remember. Result: A workforce that not only completes safety training, but actually retains it. 2. Simplifies Complex Safety Procedures Some workplace safety topics involve technical detail or complex processes that are difficult to explain with still images or written descriptions. Animation can simplify these concepts through motion graphics, diagrams, and 3D visualisations, showing step-by-step processes in a clear and digestible format. For example, an animated sequence can walk employees through the correct lockout/tagout procedure or show how gases behave in confined spaces, all without needing to film in a real, risky environment. Benefit: Clear, simplified safety messaging without any real-life hazard. 3. Engages Employees of All Levels and Languages One major challenge in safety training is reaching a diverse workforce. From apprentices to senior staff and across multilingual teams, training must be accessible and engaging to everyone. Animated videos can include universal visual cues and multilingual voiceovers or subtitles, making it easier for non-native speakers to understand. Additionally, the style and tone of animation can be tailored to resonate with different demographics, helping to keep engagement levels high across your team. Inclusive and adaptable, animation makes training accessible to all. 4. Safer Than Live Demonstrations Filming live action safety videos on-site comes with challenges, from operational disruption to real-life risks. Animated videos, on the other hand, allow you to recreate dangerous scenarios in a safe, controlled way. Whether it’s illustrating a fall from height or a chemical spill, you can show consequences without ever putting anyone at risk. Plus, animations are evergreen content. You can reuse them across departments, locations, and even years, with updates made easily as procedures change. No real-life risk, no reshoots, and no costly interruptions to operations. 5. Encourages a Stronger Safety Culture Safety is more than compliance, it’s a mindset. When your business invests in high-quality, engaging safety training, it sends a clear message: your people come first. Animated safety videos reflect that commitment. They’re a modern, proactive training tool that encourages staff to take safety seriously and become active participants in a culture of care and awareness. Outcome: Fewer accidents, stronger morale, and improved productivity. Animated safety videos are more than just a modern alternative to printed manuals, they’re a powerful tool that can reduce workplace accidents, improve training outcomes, and strengthen company-wide commitment to safety. By investing in animated video, businesses can deliver consistent, engaging, and accessible safety training that actually sticks. Whether it’s 2D explainer animations , 3D visualisations of hazardous processes , or interactive training modules, the potential to make a real impact is huge. At Shot Blast Media, we specialise in creating high-impact animated safety content that helps businesses protect their people while enhancing communication and compliance. If you’re ready to bring your safety training to life, let’s start the conversation: +44 (0)113 288 3245 | [email protected] Your Industrial Story Starts Here Press The Button. Make The Call. Transform Your Media. Contact Us Your Name * Your Email * Phone * What service are you interested in? Please Select An Option Below 2D Animated Video Production 3D Animated Video Production Video Production Drone Videography E Learning Video Production Health & Safety Video Production Interactive Video Production Video Training Virtual Reality Video Production Podcast Production Message * YOUR PRIVACY * Please tick here to confirm you have read our privacy notice which gives information on how we collect and process your personal data. SUBMIT If you are human, leave this field blank. +44(0)113 2883245 [email protected] 3 Fusion Court, Garforth, Leeds, LS25 2GH

0 notes

Text

Beyond Compliance: How Group Lock Boxes Foster Teamwork and Accountability

Workplace safety is more than just following regulations - it’s about creating a culture where every team member is actively involved in ensuring hazard-free operations. While Lockout Tagout procedures are essential for preventing accidents, group lock boxes take safety a step further by reinforcing teamwork and accountability in industrial environments.

The Role of Group Lock Boxes in Workplace Safety

A group lock box is a simple yet powerful device designed to streamline LOTO protocols in situations involving multiple workers. Instead of each employee securing their own padlock on a piece of equipment, all keys from individual locks are placed inside a group lock box. This box is then secured with multiple padlocks - each belonging to a different worker - ensuring that machinery remains inoperable until every individual has removed their lock.

This group lockout procedure fosters a collective sense of responsibility, making safety a shared goal rather than an individual task. When workers know their colleagues are relying on them to follow proper procedures, adherence to safety standards becomes second nature.

Teamwork in Lockout Tagout Procedures

Safety in the workplace is most effective when employees collaborate seamlessly. Group lock boxes eliminate confusion and ensure that everyone involved in a task understands when equipment is safe to operate and when it is strictly off-limits.

Here’s how group lock boxes promote teamwork:

Clear Communication: Workers can easily see who is involved in the lockout, preventing misunderstandings about equipment status.

Streamlined Process: Instead of managing multiple locks on machinery, a single box consolidates all keys, making the process more efficient.

Mutual Accountability: Each team member is responsible for removing their lock once the job is complete, ensuring no one bypasses critical safety checks.

Building a Culture of Accountability

The presence of group lock boxes does more than enhance compliance - it instills accountability at every level. Supervisors and workers alike become conscious of their role in upholding safety measures. Employees feel empowered to take ownership of their actions, reinforcing the idea that safety isn’t just about regulations - it’s a fundamental part of their daily responsibilities.

By integrating group lock boxes into LOTO programs, organizations demonstrate their commitment to workplace safety, fostering a culture where employees proactively prevent hazards rather than react to incidents.

Conclusion

Group lock boxes go beyond compliance - they create an environment where safety is shared, structured, and reinforced through teamwork and accountability. E-Square Alliance continues to advocate for effective safety solutions, ensuring that workplaces worldwide remain secure, efficient, and compliant.

0 notes

Text

Lockout Tagout Training: Key Steps for Workplace Safety

Workplace safety is crucial. Many workplaces use machines that can be dangerous if not handled properly. Lockout tagout (LOTO) is a safety process used to prevent accidents when machines are being serviced or maintained. The training helps protect workers from unexpected machine start-ups or energy releases. LOTO training teaches workers how to safely turn off machines, lock them, and tag them to warn others. This prevents injuries and can even save lives. In this blog, take a look at the key steps of lockout tagout training and why this training is an essential skill to add.

What is lockout tagout? Lockout tagout is a procedure that ensures machines are completely turned off before maintenance. It also prevents them from being turned on accidentally. Lockout means placing a lock on the machine’s power source to prevent activation. Tagout means placing a warning tag on the machine to inform others that it is under maintenance.

LOTO is required in workplaces where machines use electrical, hydraulic, pneumatic, or other energy sources. The Occupational Safety and Health Administration (OSHA) has strict rules for lockout and tagout training to protect workers.

Why is LOTO training important? Machines can cause cuts, burns, shocks, or even fatalities if not correctly turned off. It is the employer’s responsibility to ensure that workers understand and follow LOTO procedures. LOTO training is essential because it helps prevent such serious injuries. The training teaches you the following skills:

Identifying hazardous energy sources Properly shutting down machines Locking and tagging machines to prevent accidents Following correct procedures when restarting machines

Key steps for lockout tagout training Lockout tagout training follows a structured process. These key steps ensure that you are safe when working with machines.

Identifying hazardous energy sources: Each type of energy needs to be adequately controlled to ensure safety. You should know how to recognize these hazards in your workplace. The first step is to identify all energy sources connected to the machine. Some of the energy sources include: Electrical energy (power supply, wiring) Mechanical energy (moving parts) Hydraulic energy (pressurized fluids) Pneumatic energy (compressed air) Thermal energy (heat sources)

Shutting down the machine properly: Before starting maintenance, the machine must be turned off completely. A proper shutdown procedure ensures that no part of the machine remains active. You will learn to press the stop button, turn off switches, and close valves or disconnect power sources.

Isolating the energy source: Simply turning off the machine is not enough. The energy source must be completely isolated to prevent accidental activation. You should confirm that all energy sources are safely disconnected before proceeding. This means unplugging electrical machines, shutting off the fuel or gas supply, and draining pressure from hydraulic or pneumatic systems.

Applying the lockout device: A lockout device is a physical lock that prevents the machine from being turned on. It should be placed on the power switch, breaker, or valve to block access. This ensures that no one else can remove it while the work is in progress. The training helps you learn how to lock the machinery and keep the key secure.

Attaching a tagout warning label: Along with the lock, a tag is placed on the machine. The tag provides essential information about the worker’s name, the date and time of maintenance and a warning not to turn on the machine. Tags alone do not prevent the machine from being turned on, but they serve as a clear warning to others.

Releasing stored energy: Some machines may still have stored energy even after being turned off. Moreover, there could be residual electricity in circuits or pressure in hydraulic or pneumatic systems. You must learn different procedures in LOTO training to release all stored energy safely. This may involve bleeding air, draining fluids, or grounding electrical charges.

Verifying that the machine is safe: Before starting maintenance, you must check that the machine is fully de-energized. This step confirms that the lockout process is complete and safe. You can do so by keeping the following steps in mind: Pressing the start button to see if the machine turns on. Using a voltage tester to check electrical circuits. Ensuring there is no movement in the machine.

Performing the maintenance work: Once the machine is safe, you can perform the necessary repairs or maintenance by following all safety guidelines and using the proper tools. If maintenance takes a long time, you should regularly check that the lock and tag are still in place.

Removing lockout tagout devices safely: After maintenance is complete, make sure all tools are removed from the machine. Inform others that the maintenance is finished. Lastly, remove tags and unlock the machine. Only the person who placed the lock and tag should remove them. This prevents accidental restarts.

Restarting the machine to resume work: Once everything is checked, the machine can be restarted. You should turn on the power source carefully. Observe the machine to ensure it runs properly, and then inform other workers that the machine is operational. Restarting should only be done after all safety checks are completed. Common mistakes in LOTO and how to avoid them Even with lockout tagout training, mistakes can happen. Here are some common errors and ways to prevent them: Common mistakes in LOTO Why it happens Potential risk How to avoid Forgetting to identify all energy sources You may overlook hidden energy sources like hydraulic, pneumatic, or residual electricity. Unexpected energy release can cause severe injuries or even fatalities. Always check for all types of energy before starting work. Use an energy control checklist to ensure nothing is missed. Using only a tag without a lock You may think a tag alone is enough to warn others. Tags do not physically prevent the machine from being turned on, increasing the risk of accidental activation. Always use both a lock and a tag. The lock physically prevents the machine from starting, while the tag warns others. Allowing unauthorized workers to remove locks Lack of training or poor enforcement of LOTO rules. Unauthorized removal of a lock can result in the machine starting unexpectedly while maintenance is in progress. Only the person who placed the lock should remove it. Employers must ensure strict compliance with this rule.

Conclusion Lockout tagout training is essential for workplace safety. It ensures that machines are properly turned off before maintenance. The key steps include identifying energy sources, shutting down machines, isolating power, applying locks and tags, releasing stored energy, verifying safety and carefully restarting the machines. You can prevent serious accidents and injuries by following lockout tagout training procedures. Moreover, employers must provide proper training and enforce safety rules to create a safe working environment.

0 notes

Text

Lockout Tagout - Energy Isolation and Notification of Employee

Section (c) states that the process of Lockout Tagout shall be performed only by the authorized employees who are servicing. This is so because, an authorised employee is especially trained for the particular isolation, which any other employee might not be able to perform efficiently.

Lockout Tagout requires technical understanding, which cannot be done by any unskilled professional. Therefore, an authorised employee is assigned by the supervisor.

Notification of Affected Employees.

Lack of information regarding the status of equipment could endanger the employees who re-energize, operate or work around the machines. Whenever LOTO control might directly affect another employee’s work activities, paragraph (c) (9) requires the employer or authorized employee to notify the affected employees prior to applying, and after removing the Lockout Tagout device.

Such notification informs affected employees of the impending interruption of the normal production operation and reinforces the importance of the restrictions imposed.

After removing a LOTO device, notifying employees, alerts them that the equipment is capable of being started-up. Else, employees might mistakenly believe that a system is safe to continue working around the machine, leading to heinous accidents.

Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#LockotuTagout#OSHA#EnergyIsolation#EnergyIsolationDevices#Safety#OSHAGuidelines#LOTO#OSHAStandard#SafetyTips#LOTOProgram#OSHARegulations#OSHALockoutTagout#AffectedEmployee#LockoutTagoutDevice#LOTODevices#ESquare

0 notes

Text

Industrial burner repair are vital components in various industries, providing the necessary heat for processes such as power generation, heating, and sterilization. Regular maintenance and timely repairs are essential to ensure their efficiency, safety, and longevity.

Understanding Industrial Burners

Industrial burners are devices that mix fuel and air to produce a controlled flame for heating applications. They are commonly used in boilers, furnaces, kilns, and other industrial equipment. The performance of these burners directly impacts energy consumption, operational costs, and environmental emissions.

Common Issues and Their Causes

Several factors can lead to burner malfunctions:

Fuel Supply Problems: Inconsistent or contaminated fuel can disrupt combustion.

Air Supply Issues: Insufficient or obstructed air intake affects combustion efficiency.

Ignition Failures: Faulty ignition systems can prevent the burner from starting.

Control System Malfunctions: Defective sensors or controllers can lead to improper burner operation.

Maintenance Practices

Regular maintenance is crucial for optimal burner performance:

Daily Inspections: Check for leaks, unusual noises, and ensure proper flame appearance.

Weekly Checks: Inspect air and fuel filters, clean combustion chambers, and verify control settings.

Monthly Maintenance: Examine burner components for wear, calibrate controls, and test safety devices.

Repair Procedures

When issues arise, follow these steps:

Diagnosis: Identify the root cause through inspections and testing.

Component Replacement: Replace faulty parts such as igniters, sensors, or valves.

System Calibration: Adjust settings to manufacturer specifications to restore optimal performance.

Testing: Conduct thorough testing to ensure the burner operates correctly before returning it to service.

Safety Considerations

Always adhere to safety protocols during maintenance and repairs:

Lockout/Tagout: Ensure all power sources are disconnected before servicing.

Personal Protective Equipment (PPE): Wear appropriate gear, including gloves and safety glasses.

Ventilation: Work in well-ventilated areas to prevent the accumulation of hazardous gases.

#weishaupt burner#industrial gas burner#combustion burners manufacturer#duel fuel weishaupt burner#burner spare parts#industrial burner

0 notes

Text

How to Implement an Effective NFPA 70B Electrical Maintenance Program?

Developing a structured approach to electrical system upkeep begins with knowing what standards are in place. The NFPA 70B Electrical Maintenance Program offers comprehensive guidelines that help minimize downtime, reduce risks, and extend the life of critical assets. In the second line of its framework, this guideline emphasizes consistency, documentation, and periodic review to maintain compliance and safety in industrial and commercial electrical systems.

To implement a program effectively, it’s essential to go beyond minimal compliance. This involves strategic planning, team engagement, asset prioritization, and ongoing evaluation. The goal is to prevent failures before they happen, thus ensuring productivity and protecting both people and property.

Step 1: Conduct a Full Electrical System Assessment

Start by assessing all electrical infrastructure, including switchgear, transformers, panelboards, circuit breakers, motors, and cables. Understanding the condition of each component allows for better decision-making when establishing maintenance schedules. Documenting age, manufacturer specs, maintenance history, and known performance issues is crucial.

Additionally, identify any past incidents of unplanned downtime, overheating, or short circuits. These findings help in prioritizing components based on their risk and criticality.

Step 2: Establish a Maintenance Strategy

Once the evaluation is complete, decide on the types of maintenance to implement: preventive, predictive, or condition-based. Preventive maintenance involves routine servicing at fixed intervals, while predictive methods rely on monitoring tools and analytics to identify potential issues. Condition-based maintenance uses real-time data such as thermal imaging and vibration analysis to trigger maintenance actions.

An optimal strategy often includes a blend of all three, customized for specific equipment categories. For example, preventive practices might be used for lighting panels, while condition-based techniques apply to high-voltage transformers.

Step 3: Develop Written Procedures and Schedules

A written plan ensures everyone follows the same steps, reducing variability in how equipment is serviced. This documentation should include:

Inspection checklists for each equipment type

Safety procedures, including lockout/tagout (LOTO)

Calibration and testing methods

Frequency of inspections

Acceptable operating parameters

Automated maintenance scheduling tools can help teams keep track of tasks and ensure accountability. Maintenance logs should be maintained and reviewed regularly to identify patterns and opportunities for process improvements.

Step 4: Train and Certify Your Team

Training is a vital part of executing any Electrical Maintenance Program effectively. Your team must be familiar with current standards, safety procedures, and diagnostic tools. Even experienced electricians need periodic refreshers, especially as new technologies or methods are introduced.

Certification programs help validate that your maintenance personnel understand the requirements outlined in the National Fire Protection Association 70B and are prepared to act according to them.

Step 5: Invest in Modern Testing Tools

Technology plays a major role in improving maintenance outcomes. Infrared thermography helps detect overheating connections, ultrasonic testing can locate air leaks or corona discharge, and motor circuit analyzers offer insight into motor winding health.

Advanced diagnostic tools enable condition-based approaches that are often more cost-effective and less intrusive than fixed-interval maintenance. Incorporating these tools into your protocol can also reduce the need for emergency repairs.

Step 6: Prioritize Based on Risk and Criticality

Not all assets require the same level of attention. Use risk-based analysis to determine how frequently each asset should be maintained. Factors to consider include:

The asset’s role in core operations

Consequences of failure (safety, financial, operational)

Historical performance and reliability

Availability of replacement parts

High-priority assets, such as main distribution panels or emergency generators, will likely require more frequent inspections and detailed procedures.

Step 7: Perform Regular Audits and Reviews

To ensure long-term success, your program should include periodic audits. These evaluations verify that maintenance is performed according to schedule and that the outcomes meet operational goals.

Audits should also check documentation quality, calibration records, and compliance with the National Fire Protection Association 70B. If any issues are found, corrective actions must be taken quickly to maintain system integrity.

Reviews can also assess whether the current strategy is still effective. As equipment ages, business operations change, or better technologies become available, your program may need to adapt.

Step 8: Leverage Data and Analytics

As part of a modern Maintenance strategy, data-driven decision-making can significantly enhance program effectiveness. Collect data on maintenance tasks, equipment failures, energy use, and system performance. Use this data to identify trends, forecast potential failures, and optimize service schedules.

Predictive analytics can help minimize unnecessary maintenance while catching hidden problems before they escalate. This not only improves reliability but also reduces operational costs over time.

Step 9: Ensure Safety Compliance and Risk Mitigation

At every step, safety must be the core priority. Follow all regulatory guidelines related to electrical work, arc flash protection, personal protective equipment (PPE), and emergency response. Update safety protocols regularly and ensure they are part of every maintenance activity.

NFPA 70B helps minimize hazards, but it's your team's responsibility to implement these principles in the field. Clear communication, safety drills, and proper signage reinforce a culture of safety.

Step 10: Foster a Culture of Continuous Improvement

An effective National Fire Protection Association 70B strategy is never truly complete—it should evolve. Encourage team members to provide feedback, report inconsistencies, and suggest improvements. Hold regular meetings to review program performance and recognize areas of success or concern. For more info, click here

Over time, this mindset will help uncover inefficiencies, improve system reliability, and support a proactive approach to electrical infrastructure management.

0 notes

Text

What Is Electrical Installation?

Electrical installation Newcastle is a complex process that involves the creation of electric circuits and wiring. It can be done in factories, offices, or homes. Electrical installers install new wires, fixtures, and outlets according to blueprints and codes. They also inspect and repair existing wiring.

It is now a legal requirement for landlords to get their fixed electrical installations tested and certified with an EICR report. This is an essential task for ensuring safety in your property.

Qualifications

A person seeking to become an electrician will need a certain set of qualifications. These include technical knowledge and the ability to solve problems. They must be able to read blueprints and understand electrical circuits and codes. Other requirements include physical stamina and attention to detail. Electricians are responsible for installing, maintaining and repairing electrical systems. They are also required to follow local, state and national electrical safety standards.

The Level 3 NVQ Electrotech Apprenticeship qualification is the most common and recognised route to becoming a fully qualified electrician. It requires a level 2 qualification and the completion of the City and Guilds 18th Edition Course, which is a pre-requisite for those who are not already JIB approved electricians.

The City and Guilds 2393-10 Part P Domestic Electrical Qualification is a popular choice for practising electricians, trainee electricians, and other trade professionals, including handypersons, gas engineers, plumbers, landscapers, kitchen fitters, and builders. This qualification is designed to showcase your comprehension of the latest industry regulations on wiring in dwellings and can improve your career prospects.

Experience

Electrical work requires extensive knowledge of the BS 7671 (IET Wiring Regulations) and Part P of the Building Regulations, which govern electrical safety in homes. It is also important to understand the risks involved in working with electricity and have access to appropriate protective gear, such as insulated gloves and safety goggles.

Experienced electricians can perform routine maintenance tasks and help prevent potential issues before they become a problem. This includes conducting planned maintenance, responding to breakdowns, and testing equipment to ensure compliance with health and safety regulations.

Domestic electrical installation begins with planning the layout of outlets, switches, and lighting fixtures. This involves assessing the size of your property, determining how many outlets are needed, and identifying any special requirements like dedicated circuits for high-usage appliances. You should also consider future needs, such as the addition of smart home technology. Taking the time to plan your wiring system can reduce installation costs and ensure compliance with the code.

Safety

Keeping safety measures in mind is critical when working on electrical projects. It’s important to use proper safety equipment, including hard hats, gloves, and eye protection. It’s also a good idea to keep all non-essential devices off of shared circuits to minimise the risk of overloading. Unplugging unnecessary appliances and switches before leaving a workspace can also help to minimise fire risks.

An ECIR report is essential for residential and commercial properties, as it highlights any potential electrical safety issues. It can help you avoid costly repair bills and ensure that your property is in compliance with electrical safety regulations.

Lockout/tagout procedures are designed to prevent workers from accidentally coming into contact with energised equipment while servicing or repairing it. These procedures involve locking or tagging out equipment that’s being serviced or repaired to prevent it from accidentally being re-energised while it’s unattended. They’re essential to preventing accidents, injuries, and downtime. Having an experienced electrician by your side can help you implement these procedures effectively and safely.

Cost

Electrical wiring is a complex and potentially dangerous task that should be left to professional electricians. Although DIYers may be tempted to save money by doing the work themselves, this could cost more in the long run due to mistakes and repairs. A qualified electrician will provide a comprehensive quote itemizing all expenses, which can help homeowners to understand what they are getting for their money.

The price of a residential electrical installation is dependent on a variety of factors, including location and energy efficiency upgrades. For example, installing a smart home system requires specialised equipment and labour. However, the increased convenience and energy savings offered by these upgrades make them worth the upfront investment.

Regional differences also impact costs, as some areas may require additional permits and inspections. In addition, urban regions typically see higher prices, owing to higher demand for electricians and the higher cost of materials. This can lead to significant price variations, and homeowners should always obtain a comprehensive quote before committing to a project.

0 notes

Text

A Beginner’s Guide to Operating a Centrifuge Separator

Centrifuge separators are a crucial component in various industries, including wastewater treatment, oil and gas, mining, and food processing. These machines use centrifugal force to separate solids from liquids, enabling the efficient removal of contaminants and pollutants from wastewater. Operating a centrifuge separator requires a good understanding of its components, principles, and procedures. In this article, we will provide a beginner's guide to operating a centrifuge separator, covering the essential steps and considerations for safe and effective operation.

Pre-Operational Checks

Before starting the centrifuge separator, it is essential to perform pre-operational checks to ensure that the machine is in good working condition. This includes checking the power supply, lubrication system, and cooling system. The operator should also inspect the centrifuge separator's components, such as the rotor, bearings, and seals, for any signs of wear or damage. Additionally, the operator should review the operating manual and manufacturer's instructions to understand the specific requirements and procedures for the particular centrifuge separator model.

Start-Up Procedure

The start-up procedure for a centrifuge separator involves several steps. First, the operator should ensure that the machine is properly installed and levelled. Next, the operator should connect the power supply and turn on the machine. The centrifuge separator will then begin to rotate, and the operator should monitor the machine's performance, checking for any unusual vibrations or noises. Once the machine has reached its operating speed, the operator can start feeding the wastewater or liquid into the centrifuge separator.

Operating Parameters

To ensure optimal performance, the operator should monitor and adjust the operating parameters of the centrifuge separator. This includes the rotational speed, flow rate, and pressure. The rotational speed should be adjusted to achieve the desired separation efficiency, while the flow rate should be adjusted to match the capacity of the centrifuge separator. The pressure should be monitored to ensure that it is within the recommended range, as excessive pressure can damage the machine.

Maintenance and Troubleshooting

Regular maintenance is essential to ensure the longevity and performance of the centrifuge separator. The operator should perform routine checks and maintenance tasks, such as cleaning the machine, replacing worn-out parts, and lubricating the bearings. Additionally, the operator should be able to troubleshoot common issues, such as vibration, noise, or reduced separation efficiency. The operator should consult the operating manual and manufacturer's instructions for guidance on maintenance and troubleshooting procedures.

Safety Considerations

Operating a centrifuge separator can be hazardous if proper safety precautions are not taken. The operator should wear personal protective equipment, such as gloves, safety glasses, and a face mask, to protect against potential hazards. The operator should also ensure that the machine is properly installed and levelled to prevent accidents. Additionally, the operator should follow proper lockout/tagout procedures when performing maintenance or repairs to prevent accidental start-up.

Shut-Down Procedure

The shut-down procedure for a centrifuge separator involves several steps. First, the operator should stop feeding the wastewater or liquid into the machine. Next, the operator should reduce the rotational speed and allow the machine to come to a complete stop. The operator should then disconnect the power supply and perform a final inspection of the machine to ensure that it is in good working condition.

Conclusion

In conclusion, operating a centrifuge separator requires a good understanding of its components, principles, and procedures. By following the pre-operational checks, start-up procedure, operating parameters, maintenance and troubleshooting, safety considerations, and shut-down procedure, operators can ensure safe and effective operation of the centrifuge separator. Remember to always consult the operating manual and manufacturer's instructions for specific guidance on operating and maintaining your centrifuge separator.

0 notes

Text

Key Safety Standards in Substation Installation and Construction

Introduction

Substation installation and construction are critical processes that require strict adherence to safety standards. Ensuring the safety of personnel, equipment, and the surrounding environment is paramount. In this blog, we’ll discuss the key safety standards that govern substation projects and the best practices for compliance.

1. Understanding Electrical Safety Regulations

Electrical safety regulations are designed to protect workers and the public from electrical hazards. Key standards to be aware of include:

National Electrical Safety Code (NESC): Provides guidelines for the safe installation, operation, and maintenance of electric supply and communication lines.

Occupational Safety and Health Administration (OSHA) Standards: Mandates safe work practices and identifies hazards in the workplace, including electrical safety protocols.

2. Personal Protective Equipment (PPE)

Personal Protective Equipment is essential for protecting workers during substation installation and construction. Essential PPE includes:

Insulated Gloves: Protect against electrical shock during equipment handling.

Hard Hats: Shield against falling objects and electrical hazards.

Flame-Resistant Clothing: Reduces the risk of burns in the event of an electrical arc.

3. Site Safety Assessment

Before beginning construction, conducting a thorough site safety assessment is crucial. This involves:

Hazard Identification: Recognizing potential risks such as overhead power lines, underground utilities, and environmental hazards.

Access Control: Ensuring that only authorized personnel are allowed on-site to prevent accidents and injuries.

4. Safe Equipment Handling and Operation

Proper handling and operation of equipment are vital for ensuring safety during installation. Key practices include:

Training and Certification: All personnel should be trained and certified to operate heavy machinery and electrical equipment.

Equipment Inspection: Regularly inspect tools and equipment to ensure they are in good working condition and safe to use.

5. Implementing Lockout/Tagout Procedures

Lockout/Tagout (LOTO) procedures are essential for ensuring that machinery is properly shut off and not accidentally started during maintenance or installation. This includes:

Locking Out Energy Sources: Physically locking and tagging equipment to prevent accidental activation.

Training Workers: Educating all personnel on LOTO procedures and the importance of compliance.

6. Emergency Preparedness and Response

Having a plan in place for emergencies is crucial for maintaining safety during substation projects. Key components include:

Emergency Action Plans (EAP): Develop and communicate plans for various emergency scenarios, including electrical accidents and fires.

First Aid Training: Ensure that personnel are trained in first aid and CPR to respond to medical emergencies on-site.

7. Regular Safety Audits and Reviews

Continuous monitoring and improvement of safety practices are essential for compliance and risk reduction. Regular safety audits should include:

Safety Inspections: Conduct periodic inspections to identify and rectify potential safety hazards.

Feedback Mechanism: Establish a system for workers to report safety concerns and suggest improvements.

Adhering to key safety standards in substation installation and construction is vital for protecting workers and ensuring project success. By understanding and implementing these safety measures, companies can minimize risks and create a safer working environment.

If you need assistance with safety compliance in your substation projects, contact ATSPower today! Our team of experts is here to help you navigate safety standards and ensure the success of your projects.

Call to Action

For more information about our services, visit atspower.com.bd or call us at +8801724-826148.

0 notes

Text

Lockout Tagout - Training and Communication

Training is one of the most important steps in the process of Lockout Tagout, needed to provide employees with knowledge, skills and motivation to effectively implement a successful Lockout Tagout program. OSHA instructs in Standard 1910.147 with respect to employees training states that - Training must ensure that the purpose and function of the energy control program are understood by employees.

As a basic requirement, all employees should be trained in the basis of Lockout Tagout. Through this training, all employees should understand the purpose, function, and restrictions of the Energy Control Program. The training needed by each employee should be provided initially upon assignment. For the purpose of the standard, three types of employees that require training are recognized - Authorized, Affected, and Other. Under section (c)(7)(i)(A) Each authorized employee must be trained enough to recognize the applicable Hazardous Energy sources, the type & magnitude of the energy available in the workplace, the methods & means necessary for energy isolation & control. Under section (c)(7)(i)(B) Affected employees must be instructed in the purpose and use of the energy control procedure. Employees who exclusively perform functions related to normal production operations and who perform servicing and/or maintenance under the protection of normal machine safeguarding need only be trained as affected employees even if tagout procedures are used.

Under section (c)(7(i)(C) This group consists of anyone else who works in an area where LOTO procedures are used. All of these employees must be instructed about the procedure, and trained not to start locked or tagged equipment, and not to remove or ignore lockout tagout devices. Check OSHA Guidelines - https://www.safetylock.net/learn-lockout-tagout/osha-29-cfr-1910-147-standard/

#OSHA#LockoutTagoutTraining#LOTOTraining#Communication#Safety#WorkplaceSafety#LockoutTagout#OSHALockoutTagout#OSHAGuidelines#LOTO#OSHAStandard#OSHARegulations#ESquare

0 notes

Text

Industrial burners are the unsung heroes of manufacturing, providing the heat that powers countless processes. But like any workhorse, they require regular maintenance and occasional repair to keep running smoothly. This guide is your one-stop resource for understanding the ins and outs of industrial burner repair.

Prevention is Key:

The best way to avoid costly repairs is to implement a robust preventative maintenance program. Regular inspections, cleaning, and component replacement can significantly extend the life of your burner and prevent unexpected breakdowns.

Troubleshooting Common Issues:

Even with diligent maintenance, problems can arise. Here are some common issues and their potential causes:

Poor combustion: This can be caused by a variety of factors, including dirty nozzles, faulty igniters, or incorrect air-fuel ratios.

Flame instability: This may be due to issues with the fuel supply, air flow, or burner controls.

Overheating: This can be a sign of blocked flues, insufficient cooling, or problems with the burner's safety controls.

Repair Procedures:

When a burner requires repair, it's crucial to have a qualified technician perform the work. Attempting DIY repairs can be dangerous and may void warranties. Common repair procedures include:

Nozzle replacement: Worn or damaged nozzles can affect combustion efficiency and fuel consumption.

Igniter replacement: Faulty igniters can prevent the burner from starting.

Control system repair: Issues with the burner's control system can lead to a variety of problems, including flame instability and overheating.

Safety First:

Safety is paramount when working with industrial burners. Always follow proper lockout/tagout procedures before performing any maintenance or repair work. Ensure that the area around the burner is well-ventilated and free from flammable materials.

#industrial burner repair#industrial gas burner#weishaupt burner#combustion burners manufacturer#duel fuel weishaupt burner#monarch weishaupt burner#weishaupt burners#weishaupt parts#dual fuel burners price#duel fuel weishaupt burner

0 notes