#winder machine manufacturer

Text

Magnetic and PCB Mounted Magnetic Components

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Toroid Hook Winders#Linear Traverse Winding Machines#Vacuum/Pressure Impregnation#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Text

Trim Winder Machine Manufacturers

Blueeye Machine, located in Ahmedabad, is specialised in the manufacture of trim winders, which are designed to meet the needs of the industries that require precise winding solutions for a variety of materials.

#trim winder machine#trim winder machine manufacturer#trim winder machine supplier#trim winder machine in india#trim winder machine manufacturer in Ahmedabad

0 notes

Text

Best Manufacturer & Supplier of Roller Winder in India

Manufacturer & supplier of Roller Winder in India. Aawadkrupa Plastomech Pvt. Ltd. with 25+ years of industry experience & 50+ countries worldwide exporter. ISO 9001: 2015 & 45001: 2018, CE & One Star Export House Certified

For More Information:

https://www.akiropes.com/fishing-winder.php

"Aawadkrupa" survey no-131-A,Navagam Bhavnagar-Rajkot highway Bhavnagar, Gujarat 364060

+91-951-018-6014,+91-987-961-5963

#high speed rope making machines exporter in india#high speed rope making machines manufacturer#high speed rope making machines supplier#high speed rope making machines exporter#monofilament extrusion plant manufacturer in india#high speed rope making machines supplier in india#monofilament plant#monofilament extrusion#high speed rope making machines#pp non-woven fabric machine manufacturer in india#Roller Winder manufacturer#Roller Winder supplier#Roller Winder exporter#Roller Winder#Roller Winder manufacturer in india#Roller Winder exporter in India#Roller Winder supplier in India#Roller Winder manufacturer in India

0 notes

Text

My uncle's friend asked if I wanted this machine that he has no use for, and yes I very much did want it, so now I have a beautiful crusty old friend to clean up!

I've never sewn on a White before, but from what I've read online they're very good. Quite a bit different from the Singers I'm used to though. The hand wheel moves in the opposite direction.

It was manufactured in the U.S. (more specifically - Cleveland, Ohio) sometime around the mid 1880s. I'm told it hasn't been used since about the 1970s, but that it used to belong to a woman who made her living by sewing on it for many years.

There's a lot of gunk and old dust to remove, and I need to shorten the drive belt and probably replace the rubber ring on the bobbin winder, but the moving parts are already spinning very smoothly and quietly so I'm hoping it won't be too much trouble.

2K notes

·

View notes

Link

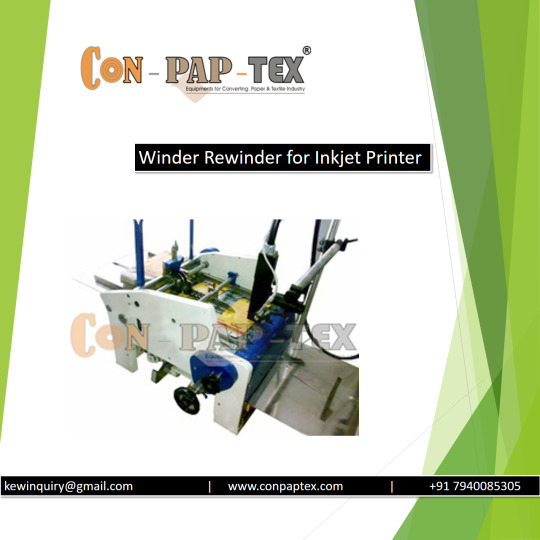

#Winder Rewinder for Inkjet Printer Manufacturer#Winder Rewinder for Inkjet Printer#Winder Rewinder for Inkjet#Winder Rewinder#Winder Rewinder Machine

0 notes

Link

#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder Machine

0 notes

Text

Current progress on medieval dress... the fur is on the collar, and I've moved to working on the belt (it is terribly done but whatever lol). After this, it'll be the hem, and then I get to move onto the escoffion hat. :)

in the meantime, I've been waxing my Singer, Doris, to see how she looks and she pretty much looks the same lol. Oh well. If I really want her to shimmer I guess I gotta put in the work of doing a french polish.

But her motor is together with new wires, and her little lamp works after many hours of struggling to take it apart and then put it back together. So once I get the lamp back from my dad (he helped lol), I can start wiring her all together and give her her first test run. The cabinet's in rough shape too, so there's pretty much nothing on this machine that doesn't need a revamp. That said, all the working bits were in decent shape outside of the wires, so I'm hoping she sews well.

Also, I currently have the only bid on this machine on the Goodwill auction site, because clearly I don't have enough projects on my hands:

This is called the "gingerbread motif" and was put on machines manufactured from 1900 to the 1930s. Judging by the modern bobbin winder, it's probably closer to the 1930s than 1900 (they didn't include a serial number in the pictures, so I can't check). I thought the motif looked to be in pretty good shape, and there are a MILLION of these Singer 15s around (unlike my current 101), so any replacement parts will be easy to come by. I'll probably resell it instead of keeping it. Not really gonna make a profit or anything considering all the hours of labor, but I do like the idea of taking a defunct, dirty, unloved machine and making it useful again. :)

5 notes

·

View notes

Text

Manufacturer of Exporter Metal Expander Roller Standard Quality at Best Price – CON-PAP-TEX

We are a “CON-PAP-TEX” manufacturer and exporter of metal Expander Roll Metal Expander Roller Manufacturer is most suitable in high-speed pulp & paper & Textile Applications it is also known as Wrinkle Removers, Bow Rollers & Banana Rollers. Metal expander roll has a hard Chrome surface which is suitable for high-speed and high-tension applications for paper industries, particularly for slitter re-winder, Calendars, Poop Reels, and M.G cylinders. On high-speed machines, it does not wear & tear so it is commonly used in place of Rubber Bow Roll. Metal Bow Roll with individual Rotating Segments. Carbon Steel Designed Bow Rollers. For more information:

Website: conpaptex.co.uk

Email id: [email protected]

Mobile No: +91-7940085305

#Metal Expander Roller Manufacturer#Metal Expander Roller#Metal Expander Rollers#Metal Expander Roll

2 notes

·

View notes

Text

Rajlaxmi Machine Tools offers HMP | Ramato | Roent Make Manual Hand Operated Motor Coil Winding Machine, Semi Automatic Coil Winding Machine, Fan Winding Machine, Counter Meter, Coil Winders Manufacturer From Rajkot Gujarat Bharat (INDIA).

#RajlaxmiMachineTools#HMPWindingMachine#RamatoWindingMachine#RoentWindingMachine#ManualCoilWindingMachine#HandOperatedCoilWindingMachine#SemiAutomaticCoilWindingMachine#FanWindingMachine#CoilWinders#CounterMeter#CoilWindersManufacturer#RajkotMachineManufacturer#GujaratMachineManufacturer#BharatMachineManufacturer#CoilWindingMachinesIndia#RajlaxmiCoilWinders#HMPManualCoilWinding#RamatoCoilWindingMachine#RoentManualCoilWinding#HandOperatedCoilWinders#SemiAutomaticWindingMachines#FanCoilWindingMachine#CoilWindingCounterMeter#RajkotCoilWinders#GujaratCoilWinders#BharatCoilWinders#RajlaxmiMachineToolsIndia#HMPWindingMachineIndia#RamatoWindingMachineIndia#RoentWindingMachineIndia

0 notes

Text

Leading Rotogravure Printing Machine Manufacturer Insights

Sai converting is leading rotogravure printing machine manufacturer. They well known for delivering high quality precision engineered solution. Sai Converting is providing a advance rotogravure printing machines designed to compete various needs of printing industry. Our machines are crafted using modern technology to make sure best quality and efficiency that make them first choice for business seeking reliable and durable printing solution.

Sai Converting first priority is customer satisfaction. Our experience team of expert worker closely work with client to understand their specific requirement and providing and improve productivity or performance. Sai Converting rotogravure printing machines are manufactured with high speed production capabilities or intricate print details to delivered superior result. Trust Sai Converting to elevate your printing operations with their cutting-edge technology and unparalleled expertise.

Our team is committed to customer satisfaction. We providing solution that enhance productivity. If you seeking high speed production or intricate print detail. Sai Converting has expertise to compete your needs. Visit our website saiconverting.com to discover how we can elevate your printing operations.

#high speed slitting machine#rotogravure printing machine manufacturers#rotogravure printing machine suppliers#rotogravure printing machine india#slitting machine in india#slitting machine in ahmedabad#rotogravure printing machine#lamination solvent base machine#slitting machine#high speed slitting machine in ahmedabad

0 notes

Text

Custom Slew Ring Bearing Fit for Your Demands

In the world of heavy-duty machinery, precision and reliability are paramount. Slew ring bearings, also known as turntable bearings or Slew ring Bearings, play a crucial role in ensuring smooth and controlled rotation in various industrial applications. Slew ring Bearing actions, or turntable addresses, are ball or comber- style behaviors composed of double-barreled concentric rings, either of which may include a gear. This feather of bearing enhances draft support and power transmission in all directions, and they’re commonly employed to support heavy loads for slow processes and large accoutrements alike as earth excavators and construction cranes. The exclusive power and elasticity of Slew ring bearing comportments have made them progressively valued in a wide collection of businesses, counting construction, manufacturing, robotics, machine tooling, and medical uses.

Slew Ring Bearing Usages:

Slew ring Bearing actions are again and again trusted upon to support loads in actually large, heavy- duty accoutrements. Their exceptional combination of weighty burden support and mobility improvement makes them useful in a variety of diligence and operations, including

Heavy- Duty Machinery. Slew ring Bearing conducts are current in heavy- duty outfit like cranes, excavators, and additional ministry that bear considerable cargo- bearing capacities and smooth pirouette. They offer the necessary strength and constancy to grip the extreme pressures and forces encountered throughout swinging, rotating, and lifting operations.

Wind Turbines. Wind turbines count on rotating nacelles to efficiently capture wind energy. Slew ring Bearing conducts support the nacelle and allow for smooth gyration, indeed under harsh thundershower conditions.

Mining Equipment. Slew ring Bearing behaviors are used in colored types of mining accoutrements, including conveyors, shovels, excavators, and mound declaimers.

Aerospace. Slewing comportments support movements in critical aerospace outfit, including satellite antennas, space delving ministry, and aircraft dock gear.

Crawlway- Borers. Slewing bearings are the main guard comportments in lair- borers and serve as the connective part of the knife head to insure that it rotates.

Water Treatment complexes. Slew ring Bearing conducts are normally used in wastewater treatment systems, suchlike as circuitous scraper purifiers.

Robotics Equipment. Robotic joints and arms depend on slewing actions to ease precise movement and positioning.

Medical Diagnostic Equipment. Slewing speeches are used in CT scanners and other advanced medical imaging accoutrements.

Other Applications of Slew Ring Bearing Actions Include

Pay- Off Reels

High- Speed Capstans

Large, Precision, and Index Turntables

Purities, Thickeners, and Rotary Distributors

float Buoys

Bottling Equipment

Fifth Wheels on campers and Farm Vehicles

Cranes & Excavators

Machining Tools

Radar Antennas

Log DE barkers

Coil Winders

Slew Ring Bearing Bearings from Kavistu Bearing

Kavitsu Slew ring Bearing comportments represent a technological caution in the fields of Mechanical power transmission systems. Kavitsu is a colonist in manufacturing and supplying of planetary gear systems and associated products for last 31 cycles. This field is a completely disparate field thank what Kavitsu was doing afore.We serve huge assiduousness requisite for construction ministry, palace cranes, truck mounted cranes, smash cranes, robotics and so on; the operations are endless. We’re proud to be one of India’s some Slew ring bearing manufacturers who have developed these products indigenously. We can guarantee that our Slew ring bearing comportments match global norms and are competitively priced.

Kavitsu Bearing is the best Slew ring bearing supplier, Manufacturer, Exporter, Dealer inABU DHABI, Algeria, Australia, Bhutan, Canada, Czech Republic, Egypt, Germany, Indonesia, Italy,Netherland, New Jersey, Saudi Arabia, Singapore, Spain, Thailand, Turkey, UAE, UK, USA, Vietnam,Port de Bejaia Algerie, Melbourne, Phuentsholing, Toronto, Ontario, Montreal, Joliette, Port ofPRAGUE, Cairo, HAMBURG, Eschweiler, SURABAYA, Milano, Genoa, Amsterdam, Rotterdam,Riyad,Dammam, Barcelona, Bangkok, Istanbul, Heathrow, Cleveland, Oklahoma, Houston,Pittsburgh, NEWYork, Hare Apt, Seattle, Minneapolis, HCMC Port.

Interested in learning other about our Slew ring Bearing comportments or other perfection- composed products? Request a citation or address us to speak with an expert directly for other information about kavistu bearing, appertain to kavistu bearing.

0 notes

Text

A manufacturer of textile machinery specializes in producing twister and winder machines.

As professional China weaving preparation equipment manufacturer and filament preparation equipment suppliers, Suzhou Sifang Technology Co., Ltd. has been committed to the research and development of domestic filament preparation equipment.It has world-class processing and metal cutting equipment, as well as excellent design and development personnel, and high-quality Staff team, and a strong quality management system.

1 note

·

View note

Text

Efficiency Unwrapped: How SunShine®'s Machines Boost Production

In a world that spins faster every day, manufacturers are constantly on the lookout for ways to boost their production efficiency. Enter SunShine®—a leader among coil winding machine manufacturers that's redefining what it means to be efficient in the manufacturing industry. Let's unpack how SunShine®'s innovative machines are not just winding coils but are also winding up industry standards for speed, precision, and productivity.

SunShine® and Their Machines

Have you ever wondered how electronic gadgets get their intricate internal wirings? SunShine® machines play a pivotal role in that process, proving that great things revolve around small coils.

What is a Coil Winding Machine?

Imagine a world-class chef expertly twirling spaghetti around a fork—that's similar to what a coil winding machine does with wires, but with even more precision and speed.

The Role of Coil Winding in Modern Manufacturing

From your car’s electric systems to the smartphone in your hand, coil winding is crucial in creating components that power our modern lives.

Key Innovations by SunShine®

SunShine® isn’t just following trends; they’re setting them with technologies that push the boundaries of what coil winding machines can do.

How Do SunShine® Machines Enhance Production?

These machines are like the Usain Bolt of manufacturing—setting record paces in production without breaking a sweat.

Benefits of Using SunShine® Coil Winders

Efficiency, reliability, and quality—SunShine® machines deliver these in spades, making them a favorite among manufacturers globally.

Types of Machines Offered by SunShine®

From desktop models for small projects to industrial giants for large-scale production, SunShine® has a machine for every need.

Industries Served by SunShine® Machines

Whether it’s automotive, electronics, or healthcare, SunShine® machines are winding their way into virtually every industry that uses electrical components.

Customer Success Stories

Hear from companies that have transformed their production lines and profits with SunShine® machines. Their stories are as compelling as they are inspiring.

Maintenance and Service Support

With SunShine® behind your machinery, downtime is significantly reduced thanks to their top-tier maintenance and service support.

Comparing SunShine® with Other Manufacturers

Stack SunShine® machines up against any competitor, and the difference in performance is clear. They’re not just in the game; they’re leading it.

The Cost-Benefit Analysis of Investing in Technology

While the upfront cost may seem daunting, the long-term savings and production gains make SunShine® machines a smart investment.

Sustainability and Environmental Impact

In an era where green manufacturing practices are crucial, SunShine® is proud to lead the charge towards more sustainable production methods.

Future Trends in Coil Winding Technology

As technology evolves, so too do the capabilities of coil winding machines. With SunShine® at the forefront, the future is looking more efficient and exciting than ever.

Conclusion: The Future Outlook for SunShine®

With a relentless drive for innovation and a commitment to quality, SunShine® is not just riding the wave of technological advancement—they’re making the waves. Whether you’re directly involved in manufacturing or simply curious about the future of production technologies, keeping an eye on SunShine® and their coil winding machines is watching the future take shape before our eyes.

0 notes

Text

Supplier of Monolayer Blown Film Machine in West Bengal

Adroit Extrusion is a Supplier of Monolayer Blown Film Machine in West Bengal.

We manufacture Monolayer Blown Film Machines in Ahmedabad, Gujarat, India.

Adroit Extrusion are Manufacturer, Supplier, and Exporter of Monolayer Blown Film, ABA and

AB Blown Film Machine and MultiLayer Blown Film Machine.

We design our monolayer blown film lines to accommodate a diverse range of resins, applications, and production levels.

This ensures customers receive top-quality film while optimizing resource use, facilitating quick startups and changeovers, minimizing waste, and achieving high productivity.

Our monolayer blown film lines process polymers such as LD, LLD, HM, and HDPE, offering outputs from 30 kg/hr to 200 kg/hr and lay-flat widths from 500 mm to 3000 mm.

Features include a motorized bubble cage surface winder with taper tension control, manual screen changer, oscillating haul-off, motorized bubble cooling system, barrier screw, gravimetric blending/dosing system, liquid PIB dosing system, and grooved feed section, ensuring advanced functionality and performance.

Specification:

Model Name: Monolayer Blown Film Plant

Material Used: LDPE, LLDPE, HDPE, CACO3, Virgin Raw Materials etc.

Output Range: 30 - 200 kg/hr

Screw Diameter: 35/45/55/65/75 (Customized)

Layflat Film Width: 500 - 3000 mm

Thickness Range: 20 microns to 150 microns

Application:

Carry Bag Film

Stretch Film

Shrink Film

Biodegradable Film

Shopping Bag Film

Garbage Film

Adroit Extrusion is a Supplier of Monolayer Blown Film Machine in West Bengal and includes locations like

Kolkata, Siliguri, Asansol, Durgapur, Howrah, Darjeeling, Malda, Kharagpur, Bardhaman, Krishnanagar, Jalpaiguri, Kalimpong, Kamarhati, Kanchrapara, Kharagpur, Malda, Midnapore, Murshidabad, Nabadwip, Palashi, Panihati, Purulia, Raiganj, Santipur, Shantiniketan, Shrirampur, Siliguri, Siuri, Tamluk, Titagarh.

For more information, we welcome you to engage in a professional conversation with our team.

View Product: Click Here

Read the full article

0 notes

Text

Innovate & Automate: Elevate Your Manufacturing with Transformer Coil Winders

In today’s rapidly evolving manufacturing landscape, staying competitive often means embracing innovation and automation. For industries reliant on electrical transformers, this is particularly true. Transformer coil winders, developed by leading coil winding machine manufacturers, are pivotal in revolutionizing manufacturing processes. These machines not only streamline production but also enhance the quality and consistency of the products. Let’s explore how integrating advanced coil winders can transform your manufacturing operations.

Revolutionizing Manufacturing

Imagine your manufacturing process as a well-oiled machine—smooth, efficient, and error-free. This isn't just an ideal; it's a reality made possible with the right technology, specifically transformer coil winders from top coil winding machine manufacturers.

What Are Transformer Coil Winders?

Transformer coil winders are sophisticated devices designed to produce coils used in transformers, which are crucial for energy distribution and regulation. These machines automate the winding process, ensuring precision and consistency.

The Benefits of Automation in Manufacturing

Automation introduces unparalleled efficiency and consistency to production lines. It reduces human error, speeds up production, and allows for real-time adjustments to improve output quality.

Core Features of Modern Coil Winders

Today’s coil winders come equipped with features such as programmable logic controllers, digital synchronization technology, and automatic wire tension control systems, all designed to maximize productivity and product quality.

How Automation Enhances Coil Winding

Automation in coil winding machines allows for precise control over the wire tension and winding speed, crucial factors in manufacturing high-quality coils. This leads to better performance and durability of the final product.

Precision Engineering with Coil Winders

Precision engineering ensures that every coil is exactly the same, which is vital for transformers to function efficiently. This precision extends the life of the product and enhances electrical efficiency.

The Impact on Production Speed and Efficiency

With automated coil winders, manufacturers can produce coils faster than ever before, significantly reducing the time from start to finish. This increased speed does not compromise quality, thanks to advanced monitoring and control technologies.

Reducing Waste with Advanced Technology

Advanced coil winders are designed to minimize waste by precisely calculating the exact amount of wire needed for each coil, reducing excess and cutting costs in materials.

Ensuring Quality with Innovative Features

Features like automatic fault detection and real-time adjustments during the winding process help ensure that each coil meets strict quality standards, reducing the need for rework and improving overall reliability.

Customization and Flexibility

Modern coil winders offer flexibility to handle various wire sizes and types, as well as different coil dimensions, making them suitable for a wide range of manufacturing needs.

Operational Cost Savings

While the initial investment in a high-quality coil winder may be significant, the long-term savings in labor, materials, and maintenance are substantial, providing a strong return on investment.

Training and Support

Leading coil winding machine manufacturers provide comprehensive training and ongoing support to ensure that your staff can maximize the benefits of the new technology and maintain optimal operational efficiency.

Future Trends in Coil Winding Technology

The future of coil winding technology looks promising, with trends leaning towards even greater automation, integration of AI for predictive maintenance, and more sustainable manufacturing practices.

Choosing the Right Coil Winder for Your Needs

Selecting the right coil winder involves considering your specific production requirements, including the type of coils you need, the volume of production, and the level of precision required.

Conclusion: Stepping Into the Future of Manufacturing

By adopting advanced transformer coil winders, manufacturers not only streamline their operations but also enhance the quality and consistency of their products. This move towards innovation and automation isn't just a step forward—it's a leap into the future of manufacturing. Embrace these technologies to stay competitive and lead in your industry.

0 notes

Text

Valmet to supply high-capacity winder to Wuzhou Special Paper in China

Valmet will supply an OptiWin Drum two-drum base winder to Wuzhou Special Paper’s paper machine PM 19 in China. The main target of the investment is to have one winder to handle the high quality and capacity targets of the high-speed paper machine. The winder includes Valmet Perforating Splicer, a new innovation to support the fast parent roll change. The start-up of the winder is scheduled for 2025.

The order is included in Valmet's orders received of the second quarter 2024. The value of the order will not be disclosed.

“Valmet winders are equipped with technologies necessary for high-speed printing paper machines. Also, the collaboration between Valmet and Wuzhou has been good in the past years: Valmet has actively participated in Wuzhou’s projects and always tried to respond to our needs. We are willing to take this opportunity to establish a long-term cooperation,” says Zhang Yanchen, deputy general manager, Wuzhou Special Paper.

“Wuzhou Special Paper was searching for a supplier capable of providing a single winder solution. Our OptiWin Drum two-drum base winder together with the new Valmet Perforating Splicer solution helps them reach their long-term investment targets,” says Ze Fan, vice-president, Capital Sales, China, Valmet.

Delivery’s technical information

Valmet’s delivery will include an OptiWin Drum two-drum base winder with automatic functions such as set change with core and tail gluing and slitter positioning. To meet the high-capacity targets reliably with only one winder, it is additionally equipped with Valmet Perforating Splicer which will improve capacity with fast parent roll change. The delivery will include spare parts packages and Valmet Industrial Internet solutions with connectivity.

The winder will handle parent rolls with a width of 8,210 mm at a design speed of 3,000 m/min and a daily design capacity of 830 tonnes. The PM 19 produces uncoated woodfree grades with a design basis weight from 55 to 100 g/m2.

Founded in 2008, Wuzhou Special Paper Group in Quzhou City, China, is mainly engaged in the R&D, production and sales of special paper. The offering includes food wrapping paper, glassine paper, tracing paper, transfer printing paper and special fine paper. The company is one of China’s largest manufacturers of glassine paper and tracing paper.

0 notes