#electronic manufacturing services

Text

Clean Energy Design and Manufacturing

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#best Ems companies in India#EMS#industry#cleanenergy#manufacturing#quality#renewableenergy#technology

2 notes

·

View notes

Text

Texan’s Top Notch EMS and PCB Services

Dallas, Texas, is known for its thriving technological and manufacturing sectors, making it a hub for innovation and electronic production. Electronic Manufacturing Services and PCB Prototype Dallas Texas development are key components of this ecosystem, supporting a wide range of industries such as telecommunications, healthcare, automotive, and consumer electronics. This article explores the benefits of Electronic Manufacturing Services and PCB Prototype Dallas Texas, highlighting the advantages of working with them.

Electronic Manufacturing Services offer comprehensive solutions for businesses seeking assistance in electronic product development, production, and assembly. Here are some key aspects of Electronic Manufacturing Services:

End-to-End Services: Electronic Manufacturing Services provide end-to-end services that cover the entire product lifecycle. From design and prototyping to assembly, testing, and supply chain management, these providers offer comprehensive support to bring electronic products to market.

Advanced Technologies: Electronic Manufacturing Services leverage state-of-the-art technologies and automated manufacturing equipment to produce high-quality electronic products efficiently. This commitment to innovation ensures that clients receive reliable and advanced products.

Quality Assurance: Electronic Manufacturing Services adhere to strict quality control standards throughout the manufacturing process. They conduct inspections, testing, and verification to ensure products meet performance and safety requirements.

Customization and Flexibility: Electronic Manufacturing Services offer customized solutions tailored to the specific needs of their clients. Whether it's small-batch production or large-scale manufacturing, they can adjust their services to meet unique project requirements.

Cost-Effective Production: Electronic Manufacturing Services strive to offer cost-effective solutions without compromising quality. Their efficient production processes and strategic sourcing of materials help keep costs manageable for clients.

PCB Prototype Dallas Texas is an essential step in the electronic product development process. PCB Prototype Dallas Texas offer fast, reliable, and high-quality PCB Prototype Dallas Texas, which can greatly benefit clients:

Rapid Prototyping: PCB Prototype Dallas Texas use advanced manufacturing techniques to produce prototypes quickly and efficiently. This rapid turnaround allows clients to test and iterate on their designs in a timely manner.

Design Verification: PCB Prototype Dallas Texas enable clients to verify the design and functionality of their boards before moving to full-scale production. This step helps identify and address any issues early on, reducing the risk of costly errors later.

Design for Manufacturability (DFM): PCB Prototype Dallas Texas work closely with clients to ensure the prototypes are designed for manufacturability. This approach helps streamline the production process and optimize cost-efficiency.

Local Support and Collaboration: Working with PCB Prototype Dallas Texas allows for close collaboration and communication throughout the development process. This proximity fosters stronger relationships and a better understanding of client needs.

Access to Expertise: PCB Prototype Dallas Texas often have extensive experience and knowledge in PCB Prototype Dallas Texas. Their expertise can provide valuable insights and guidance to clients during the prototype development stage.

Electronic Manufacturing Services and PCB Prototype Dallas Texas are essential components of the region's robust electronics industry. By partnering with Electronic Manufacturing Services and PCB Prototype Dallas Texas, businesses can benefit from comprehensive, high-quality services that cater to their unique needs. From design and prototyping to assembly and production, Electronic Manufacturing Services and PCB Prototype Dallas Texas offer the expertise and resources necessary to bring innovative electronic products to market successfully. Whether you're a startup or an established company, working with Electronic Manufacturing Services and PCB Prototype Dallas Texas can help you achieve your goals and drive success in the dynamic world of electronics.

0 notes

Text

The Future of Electronics Manufacturing: Trends and Innovations

The phenomenal creation of today's modernizing era is 'technology.' In just a century, we have come far ahead in terms of technical innovation, from micro-level devices like integrated circuits and semiconductors to the large, fully automated power generation unit, intelligent automation, and sensor technology. The evolution witnessed in the realm of electronics manufacturing services has transformed our lifestyles in many ways. This sector significantly impacts each segment of our lives and has drastically changed a person's approach to perceiving things.

As technology keeps evolving in today's fast-paced world, so does the demand for more efficient and smart devices for making our lives easier. Humanity has experienced colossal growth over the years which has resulted in enhancement of our lives through creation of wide-ranging electronic devices and innovations. To know more on how these advancements have revolutionized our world, let's explore more through this blog.

Microelectronics and miniaturization

The constant push for microelectronics and miniaturization so far has been one of the most noteworthy developments in this sphere, compelling manufacturers to develop more compact devices with enhanced functionality. This shift has resulted in significant challenges in controlling heat dissipation and ensuring signal integrity while opening possibilities to innovate and explore.

Cutting-Edge Manufacturing Technologies

Modern transformations in the manufacturing of technologies like robotics and automation have revolutionized the designing, production, and prototyping of electronic devices. This advancement has led to unprecedented flexibility, speed, and accuracy, hence providing a better quality product in a shorter time frame, which enhances productivity.

Organic and Sustainable Manufacturing

As awareness of sustainable development practices is rising, along with a huge number of global environmental concerns, people are switching to more organic and sustainable manufacturing of materials. Manufacturing is rapidly adopting energy-efficient production processes and green manufacturing techniques to cater to the demand for the public's sustainable products. The use of such organic materials has also opened up business opportunities in this sector to certain companies, providing them an edge over people still following conventional methods of manufacturing.

Smart Devices and the Internet of Things (IoT)

With the rapid rise of the emergence of IoT devices, there has been a huge requirement of smart products that can interact with each other seamlessly and save things autonomously while being connected digitally. It has pushed the world to re-evaluate ways of conventional manufacturing and switch to cutting-edge smart devices from network technology to efficient sensors for smooth functioning of IoT devices.

Printed Technology

Printed Technology or Additive Manufacturing has also altered the electronics manufacturing services industry significantly through the construction of layer-by-layer electronic components with specialized printers and materials. As it is a more economical method, manufacturers are often on the constant lookout for the progress of novel printing techniques. Unlike the conventional norms, 3D Printings are known to use flexible films and inks, reducing development time and charges. It also fosters the curation of complex geometric designs, which provides designers with more freedom to explore untapped avenues of the field and bring their visions to life.

Wrapping Up

To conclude, the future of the electronics industry showcases immense scope with the wide-ranging trends and innovations being followed. As the sphere is expanding with the emergence of smart technologies, we are heading towards the advanced stages of automation and enhanced connectivity. More innovations in IoT are leading us to a path towards advanced machines. This has created a rise in consumer demand for electronic devices and electronic manufacturing services that cater to their preferences.

As we are transitioning into the digital era, the commitment to sustainability will be a key factor in driving relentless growth and innovation in the electronics manufacturing sector while opening a gateway to possibilities. By embracing these trends and innovations, manufacturers can meet people's evolving needs while shifting to a more sustainable future. Hence, to make the most of these advancements and propel your business to a new level, partner with Aggressive's Electronics Manufacturing Services today.

Originally Published On: https://aggressivegroupco.blogspot.com/2024/04/the-future-of-electronics-manufacturing.html

0 notes

Text

led tv manufacturers in india

Radiant Appliances & Electronics Pvt Ltd. Operate in the domain of Electronics Manufacturing and aspire to be the Number 1 entity in India for ODM & OEM

Radiant Appliance and Electronics is a premier manufacturing company that caters to the consumer electronics and home appliances industry. In fact, it is the first company from Hyderabad to manufacture LED TVs for global market leaders and well-known MNCs from a state-of-the-art facility at E-City. We are one of the largest manufactures of televisions in India and manufacture TVs for OEMs that cater to more than 40% of the Indian television market.

#radiant appliances & electronics#home appliances manufacturers in india#led tv manufacturers in india#manufacturing#smart led televisions#tv manufacturing company#ems manufanufacturer#electronic manufacturing services#ems manufacturing company#ems manufacturing company in india

0 notes

Text

Enhancing Efficiency with Electronic Manufacturing Services

Introduction

In today's fast-paced and highly competitive electronics industry, efficiency is the name of the game. Manufacturers face the constant challenge of delivering high-quality electronic products to the market quickly while keeping production costs in check. This is where Electronic Manufacturing Services (EMS) come into play. EMS providers are essential partners for companies looking to enhance efficiency, streamline production processes, and stay ahead in the electronics manufacturing landscape. In this article, we will explore how EMS can enhance efficiency in electronic manufacturing.

Understanding Electronic Manufacturing Services (EMS)

Electronic Manufacturing Services (EMS) companies are specialized firms that offer a wide range of services related to electronics design, assembly, and testing. They work closely with original equipment manufacturers (OEMs) to take care of various aspects of the manufacturing process, from design and prototyping to production, testing, and even after-sales support. EMS providers offer expertise, infrastructure, and experience that can significantly contribute to improving efficiency throughout the manufacturing lifecycle.

Expertise in Design and Engineering

One of the key ways EMS enhances efficiency is through its expertise in design and engineering. EMS providers typically have experienced teams of engineers and designers who can assist OEMs in optimizing their product designs for manufacturability. This early involvement in the design phase can lead to significant cost savings and faster time-to-market.

EMS providers also have access to the latest technologies and tools for electronic design and simulation, helping to identify and rectify potential issues before they become costly problems during production. Efficient designs that minimize component count, reduce complexity, and improve manufacturability ultimately result in a smoother manufacturing process.

Scalable Production Facilities

Efficiency in manufacturing often comes down to the ability to scale production quickly and adapt to market demands. EMS providers typically maintain state-of-the-art production facilities equipped with the latest machinery and technology. This scalability allows them to handle both low-volume, high-mix production runs and large-scale manufacturing projects.

By leveraging EMS capabilities, OEMs can avoid the need for substantial capital investments in production equipment and facilities. This not only reduces upfront costs but also ensures that manufacturing resources can be efficiently allocated, allowing companies to focus on core competencies like product development and marketing.

Supply Chain Management

Efficient supply chain management is a critical aspect of electronic manufacturing. EMS providers have established relationships with suppliers, access to global supply networks, and the ability to procure components and materials at competitive prices. They can also manage inventory, reducing the risk of component shortages or excess stock.

Furthermore, EMS providers often implement just-in-time (JIT) inventory practices, which minimize holding costs and reduce the need for extensive warehouse space. This results in leaner and more cost-effective supply chain operations, improving efficiency across the board.

Quality Assurance and Testing

Efficiency in manufacturing is closely linked to product quality. EMS providers invest in rigorous quality control and testing processes to ensure that every electronic component and product leaving their facilities meets or exceeds industry standards. This commitment to quality not only reduces the likelihood of defects and product recalls but also enhances overall manufacturing efficiency.

Advanced testing methodologies, including automated optical inspection (AOI), in-circuit testing (ICT), and functional testing, help identify and address issues early in the production process. This proactive approach minimizes rework, reduces production downtime, and improves product reliability.

Rapid Prototyping and Time-to-Market

In today's fast-paced electronics industry, time-to-market is a critical factor for success. EMS providers offer rapid prototyping services, allowing OEMs to quickly develop and test product prototypes before full-scale production. This iterative process can help identify design flaws, optimize product performance, and accelerate the development cycle.

By leveraging EMS expertise and resources, OEMs can bring their products to market faster, gaining a competitive edge and maximizing revenue potential. Reduced development time also means that companies can respond more effectively to changing market dynamics and emerging opportunities.

Focus on Core Competencies

Perhaps one of the most significant advantages of partnering with EMS providers is that it allows OEMs to focus on their core competencies. By outsourcing manufacturing operations, companies can allocate resources and energy to product innovation, marketing, and customer support.

Efficiency is not just about optimizing production processes; it's also about allocating resources effectively. EMS providers take care of the complex manufacturing tasks, allowing OEMs to concentrate on strategic initiatives that drive growth and innovation.

Customized Solutions

EMS providers offer customized solutions tailored to the unique needs of each OEM. Whether it's a niche product with specialized requirements or a high-volume consumer electronics device, EMS providers can adapt their processes and services to meet specific demands. This flexibility ensures that OEMs receive the most efficient and cost-effective manufacturing solutions for their products.

Conclusion

In the fiercely competitive electronics manufacturing landscape, efficiency is the linchpin that separates successful companies from the rest. Electronic Manufacturing Services (EMS) providers play a pivotal role in enhancing efficiency by offering expertise in design and engineering, scalable production facilities, efficient supply chain management, quality assurance and testing, rapid prototyping, and a focus on core competencies. By partnering with EMS providers, original equipment manufacturers (OEMs) can streamline their manufacturing processes, reduce costs, accelerate time-to-market, and ultimately gain a competitive advantage in the global electronics market. In an industry where innovation and speed are paramount, EMS providers are the strategic partners that help companies thrive.

0 notes

Text

The Heart of Electronics Manufacturing: Exploring PCB Factories in China

In today's tech-driven world, printed circuit boards (PCBs) are the unsung heroes that power our devices, from smartphones to space shuttles. Behind the scenes, PCB factories in China play a pivotal role in the production of these intricate electronic components. In this blog post, we'll take a closer look at the fascinating world of PCB manufacturing and delve into why China has emerged as a global hub for this critical industry.

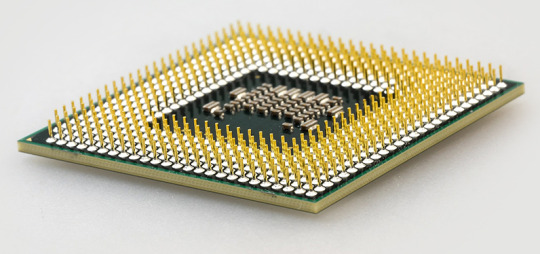

The PCB Manufacturing Process

Before we dive into the Chinese PCB factory, let's briefly understand the PCB manufacturing process. PCBs are the backbone of electronic devices, providing the connectivity and functionality required for seamless operation. The manufacturing process can be summarized in a few key steps:

Design: Engineers meticulously design the PCB layout, specifying the arrangement of components and electrical connections.

Prototyping: A prototype PCB is created to validate the design and functionality.

Production: Once the prototype is approved, production begins. This involves etching copper layers, drilling holes, and adding solder mask and silkscreen for component placement.

Assembly: Components such as microchips, resistors, and capacitors are soldered onto the PCB.

Quality Control: Rigorous testing ensures that each PCB meets industry standards and functions flawlessly.

Why China for PCB Manufacturing?

China has become synonymous with PCB China manufacturing for several compelling reasons:

Cost Efficiency: Chinese factories offer competitive pricing due to lower labor and material costs.

Advanced Technology: Many Chinese PCB factories are equipped with state-of-the-art machinery and automated production lines, ensuring precision and efficiency.

Vast Experience: China's PCB industry has decades of experience, making them experts in handling complex projects.

Global Reach: China's strategic location facilitates efficient global distribution, a critical factor for electronics manufacturers.

Environmental Concerns and Solutions

It's crucial to address environmental concerns associated with PCB manufacturing. While the industry has made significant strides in minimizing its environmental footprint, challenges remain. Chinese PCB factories are increasingly adopting eco-friendly practices, such as recycling and waste reduction, to mitigate these concerns.

Conclusion

In the world of electronics, PCBs are the unsung heroes that make our gadgets tick. Chinese PCB factories have played a pivotal role in the growth of this industry, thanks to their cost efficiency, technological prowess, and global reach.

FAQs on PCB Factories and Manufacturing in China

1.What is a PCB Factory?

A PCB factory produces printed circuit boards used in electronic devices.

2.Why choose a Chinese PCB Factory?

Chinese PCB manufacturers offer cost-effectiveness and advanced technology.

3.How can I find a reliable Chinese PCB Factory?

Research online, seek recommendations, check certifications, and visit the factory if possible.

4.What types of PCBs are available in China?

Chinese factories offer single, double, multi-layer, rigid, flexible, and rigid-flex PCBs with various materials and finishes.

5.Is sharing design files safe?

Sign NDAs and ensure security measures are in place.

6.How can I track my PCB order?

Use order tracking systems or communicate with customer support.

7.Are there import/export regulations or tariffs?

Consult with the factory and customs experts as needed.

8.What payment methods are accepted?

Common methods include bank transfers, PayPal, and credit cards. Clarify terms and currency beforehand.

#pcb china#pcb factory#china pcb manufacturer#pcb assembly china#electronic manufacturing services#pcb assembly near me#printed circuit board assembly

0 notes

Text

Disposable Vapes: What You Need to Know

Disposable Vape Manufacturer Malaysia are vaping devices that are designed for temporary use. They have an integrated battery and a pre-filled pod with an e-liquid and a coil. They do not need to be recharged, refilled, or cleaned. Once the battery is drained or the pod is empty, they can be discarded responsibly.

Disposable vapes are popular among smokers who want to try vaping without investing in a rechargeable device or dealing with maintenance. They are also convenient for vapers who want a backup device or a different flavor on the go. Disposable vapes come in various shapes, sizes, flavors, and nicotine strengths. Some of them even have adjustable airflow or LED lights.

Benefits of Disposable Vapes

Easy to use: Disposable vapes are ready to use out of the box. You just need to inhale to activate them and enjoy the vapor. There are no buttons, settings, or charging involved.

Affordable: Disposable vapes are cheaper than rechargeable devices and e-liquids. You can buy them individually or in bulk for a lower price per unit.

Portable: Disposable vapes are small and lightweight. You can carry them in your pocket, purse, or backpack without worrying about leakage or damage.

Variety: Disposable vapes offer a wide range of flavors and nicotine levels to suit different preferences and needs. You can choose from fruity, minty, tobacco, dessert, or even cocktail flavors. You can also find disposable vapes with nicotine salts, which deliver a smoother and more satisfying throat hit.

Drawbacks of Disposable Vapes

Wasteful: Disposable vapes generate a lot of Electronic Manufacturing Services that can harm the environment if not disposed of properly. You should always recycle your disposable vapes at a designated collection point or send them back to the manufacturer if they offer a recycling program.

Limited: Disposable vapes have a limited battery life and e-liquid capacity. Depending on how often you vape, they may last from a few hours to a few days. Once they run out of power or juice, you cannot use them anymore.

Inconsistent: Disposable vapes may have quality issues such as dry hits, burnt taste, leaking, or malfunctioning. They may also have variations in flavor and nicotine delivery due to different batches or storage conditions.

Best Disposable Vapes in 2023

If you are looking for some of the best disposable vapes in 2023, here are some recommendations based on online reviews:

IJOY LIO Boom Disposable Vape: This disposable vape can deliver over 3500 puffs with a powerful and efficient battery. It has 21 flavors available with two different nicotine levels. It also has an attractive design made of PCTG and aluminum alloy¹.

DotMod Dot Disposable: This disposable vape has a sleek and elegant design with a metallic finish. It can produce up to 2000 puffs with a smooth and flavorful vapor. It has 10 flavors available with 5% nicotine salt².

RELX Infinity Closed Pod Device: This disposable vape has a smart and ergonomic design with a dual-charging system. It can provide up to 500 puffs with a rich and satisfying vapor. It has 12 flavors available with 3% or 5% nicotine salt³.

Conclusion

Disposable vapes are a convenient and affordable way to enjoy vaping without any hassle. They are ideal for beginners, travelers, or occasional vapers who want a simple and satisfying experience. However, they also have some drawbacks such as environmental impact, limited lifespan, and quality issues. Therefore, you should always do your research before buying a disposable vape and dispose of it properly after use.

#Electronic Manufacturing Services#Electronics Manufacturing Services#Plastic Mold Supplier#Plastic Injection Molding Supplier

0 notes

Photo

SCSPCBA

#Smt Manufacturer#Prototype Pcb Assembly#Pcb Assembly Manufacturer#Electronic Manufacturing Services#Smt Soldering#Electronic Components

0 notes

Text

Electronic Manufacturing Services provider in Gujarat

Looking for a reliable Electronic Manufacturing Services provider in Gujarat? Discover our top-notch electronic manufacturing services, tailored to your specific needs.

#electronic Manufacturing Services provider in Gujarat#pcb assembly service provider#pcb assembly service provider in gujarat#pcb assembly service provider in india#ems solution provides#electronic manufacturing services provider in gujarat

5 notes

·

View notes

Text

For your supply chain & logistics with our hybrid model

Avalon has over two decades of experience in managing global, complex supply chains.

#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS#electronics#industry#manufacturing#quality

2 notes

·

View notes

Text

Power up your electronics with top-tier Electronic Manufacturing Services. From design to assembly, we ensure precision and quality, crafting solutions that fuel your innovation and elevate your projects to new heights.

0 notes

Text

Aggressive Group is an ISO certified company providing Electronic Design and Manufacturing Services. They offer a variety of services including Electronic Design Services, PCB Assemblies, and Box-Build Products. They work with both Indian and Global brands.

1 note

·

View note

Text

Diversity and Inclusion at Radiant

“Diversity, or the state of being different, isn't the same as inclusion. One is a description of what is, while the other describes a style of interaction essential to effective teams and organizations.” — Bill Crawford

Diversity and inclusion are two interconnected concepts- but they are far from interchangeable. Diversity is about the representation of an entity whereas inclusion is about how well the contributions, presence, and perspectives of different groups of people are values, appreciated, and integrated into an environment.

A diverse and inclusive workplace makes everyone, regardless of who or what they do, feel equally involved and supported in all areas of the workplace. The “All” areas are important.

Keeping the above things important and in perspective, we ensure that at Radiant, the work environment is always about feeling valued and appreciated irrespective of gender, race, region, religion, sexual orientation, and belonging to any certain group.

At Radiant, two kinds of workforce are employed, namely contractual workers and permanent employees. Each type of workforce brings its individual flavor of culture to the organization and along with it, its unique challenges. Below are some of the practices we follow to maintain a healthy, diverse and inclusive environment at the organization.

During recruitment both permanent and contractual, we make utmost efforts to maintain a balance of people from diverse backgrounds. We maintain one of the best gender ratios amongst our on roll and contractual workforce in an industry which is otherwise dominated by males. With respect to geographical diversity, we boast of great diversity in out talent base, both permanent and contractual. Our talent encompasses men and women from nineteen (19) states and UT's who work with passion and perseverance at our factory. This ensures that diversity is maintained at various levels of the organization among both internal and external stakeholders and leads to fair treatment for everybody irrespective of gender or region.

To encourage Inclusion, a “Connect with MD” session is conducted every month, wherein randomly selected contractual workers and staff get a chance to interact with the Managing Director and COO of the Radiant along with the HR head and voice out their opinions on their daily work life enabling the leadership team to understand the ground realities. This ensures that the work culture of the organization is inclusive and open-ended in nature.

In addition, we conduct Net Promoter Score (NPS) based employee engagement surveys that are conducted every month wherein all employees are free to voice in their opinions and provide constructive, actionable feedback which is implemented across the organization. All feedback on employee surveys are always kept confidential while the process is completely anonymous.

Striving to follow industry leading practices related to D & I, we at Radiant endeavor to provide the best possible work environment to our adaptive, agile and savvy workforce so that they put their hearts and minds in whatever they set to achieve at the factory.

#radiant appliances & electronics#led tv manufacturers in india#home appliances manufacturers in india#manufacturing#smart led televisions#ems manufanufacturer#tv manufacturing company#electronic manufacturing services#ems manufacturing company#ems manufacturing company in india

0 notes

Text

Avalon Sienna is your one-stop solution for all your manufacturing needs. Whether you need PCBAs, wire harnesses, magnetics, electro-mechanical components, sheet metal, machined parts, or injection molded plastics, we have the expertise and the infrastructure to deliver quality products on time and within budget. We also provide full system integration and product testing, ensuring that your products meet the highest standards of performance and reliability. Contact us today and let us help you achieve your manufacturing goals.

#Electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS#Avalon Sienna EMS

2 notes

·

View notes