#with or without the application of centrifugal force

Explore tagged Tumblr posts

Text

Torque and Zillion Zeutron (for day 6 two, electric boogaloo)

Third (and hopefully final) part of my explanation of Zillion Zeutron all brought on by @ilovefreedelahoya screaming about Centrifugal Force in the replies on a post.

As always, I don't have a degree, don't trust strangers on the internet, and do science by breaking stuff (but hopefully not without supervision)

TORQUE

It's great. It's forces for things moving in circles.

What does that actually mean though?

Well, when you apply a force to an object, it moves in the direction of the force, assuming there are no other forces on that object that might make it move in a different direction or not move at all!

Torque is, technically, a force applied to circling spinny things. It's given by the equation t = r x F x sin(theta), where theta is the angle between the applied force and the object, r is the distance from the application of the force to the rotation point, and F is just the force.

To get a real world example of this, go over to an old-fashioned door handle, the stick-looking kind and press it down at various different distances from the center:

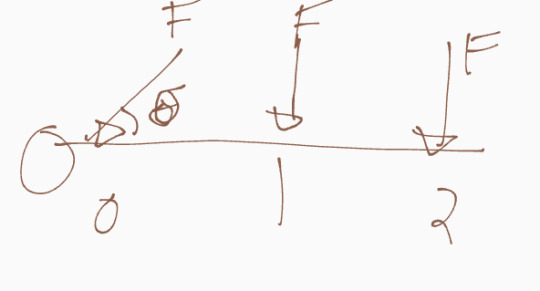

In this very well drawn diagram (a box can be any object in an FBD, people), an equal force is applied to a doorhandle at three different radii from the rotation point, applied at an angle of 30 degrees at point 0. (Let's just say R = .5 at 0 because I didn't think things through)

The torques would be as follows

t0 = F x .5 x sin(30) = .25F

t1 = F x 1 x sin(90) = F

t2 = F x 2 x sin(90) = 2F

As you can see, it gets harder and harder to push the doorhandles the closer you get to the knob, and the further away from pushing straight down!

What would happen if you applied the force pointed directly along the door handle, you asked? Well, theta would equal 0 and the sin(0) is 0, so you wouldn't apply any torque at all! That's why you can't spin a doorhandle by pressing directly along it's edge.

I know, yes, I'm supposedly talking about Beyblade.

So what does this have to do with Zeutron?

Another way of finding the torque is that t = I * a or torque is equal to the rotational inertia times the angular acceleration or alpha (sadly Tumblr does not seem to support Greek letters, torque is also usually given by tau, or a funky t)

Angular acceleration is analogous to normal, translational acceleration. And this means that Zeutron's increasing rotational inertia makes it theoretically harder to slow down.

First, let's talk about plain old acceleration.

Acceleration and velocity are both something called a vector - a number that has a magnitude (or how big it is) and a sign (is it going in the positive/negative direction? Usually, positive is up or right and negative down or left).

Acceleration is normally used to say something is speeding up. But, really, its a term for any change of the velocity. (That is a gross oversimplification but no-one wants a calculus 101 in addition to a physics 101.) Is your velocity changing direction? That's acceleration. Is your velocity slowing down? Also acceleration.

Now, if we rearrange our torque equation a little bit we get

t/I = a

Basically, the smaller your rotational inertia is compared to torque, the larger your angular acceleration is. Or, conversely, the larger your torque compared to rotational inertia, the larger your angular acceleration.

So what happens if you increase your rotational inertia like Zeutron manages to? Well fancy that, you've just decreased your angular acceleration.

In practice, this means that you need a much larger torque (usually a larger force applied, you know, circle-like) to change Zeutron's spin. It's going to be harder to slow down, and harder to stop, making it a true stamina type!

How does this affect the friction on the stadium? How does this affect a ring-out finish? How does this affect the magic feeling of connecting oneself with one's bey in an awesome and terrifying ritual known as Resonance?

All that's a bit above my pay-grade of zero dollars an hour. I have some ideas, but I don't want to be misleading or straight up wrong and I already did a fair bit of oversimplifying here.

But, yeah! There you have it, how Zeutron works. I'm just going to count this as my Mayblade for the day and just say I did prompt 6 twice. If you guys have any more questions (physics or beyblade or want me to explain another beyblade) I would be more than happy to. Its fun and good practice.

#mayblade 2025#Day 6 - science#beyblade#beyblade burst#science#science side of tumblr#scienceblr#long post#physics#I had fun with this

3 notes

·

View notes

Text

Leading Industrial Blower Manufacturer in Pune – Enhancing Industrial Airflow Solutions

Among these, centrifugal fan manufacturers in Pune have gained prominence for delivering powerful, reliable airflow systems across sectors such as manufacturing, automotive, pharmaceuticals, and more.

Understanding the Role of Industrial Blowers

An industrial blower manufacturer in Pune typically produces high-capacity devices designed to circulate air, control fumes, and manage ventilation in large-scale environments. These blowers are integral to maintaining temperature, ensuring air quality, and supporting operations in confined or high-temperature spaces.

One of the most effective technologies used in these systems is the centrifugal fan. A centrifugal fan manufacturer in Pune specializes in designing equipment that utilizes centrifugal force to generate a steady and powerful airflow. This makes them ideal for industries requiring high-pressure ventilation.

Key Factors Impacting Airflow Solutions

Choosing the right industrial blower manufacturer in Pune depends on several crucial factors:

Efficiency and Energy Consumption: Manufacturers must balance airflow power with energy efficiency. While high-powered systems can ensure effective ventilation, they may lead to increased energy costs. Many centrifugal fan manufacturers in Pune now offer energy-efficient models designed with advanced impeller designs and variable frequency drives (VFDs).

Durability and Build Quality: Given their continuous operation in harsh environments, industrial blowers must be corrosion-resistant and built with high-quality materials. The leading centrifugal fan manufacturers in Pune use powder-coated finishes and robust metal alloys to extend service life.

Customization and Application Suitability: Not all applications are the same. A top industrial blower manufacturer in Pune will offer custom solutions tailored to dust collection, HVAC, combustion air supply, or material handling. Tradeoffs often involve balancing cost, lead time, and application-specific requirements.

Noise and Vibration Control: Blowers with poor design can result in excessive noise and vibration, affecting workplace safety and comfort. Advanced centrifugal fan manufacturers in Pune prioritize aerodynamically balanced blades and noise-dampening enclosures.

Maintenance and After-Sales Support: Reliability is a key concern. Buyers often prefer industrial blower manufacturers in Pune that provide timely maintenance, spare parts availability, and technical support.

Challenges in Industrial Airflow System Design

Designing an effective airflow system isn’t without its challenges. Misjudging system resistance, choosing the wrong fan type, or failing to account for environmental variables can lead to inefficiencies or system failure. This makes working with experienced centrifugal fan manufacturers in Pune and industrial blower manufacturers in Pune essential.

Another challenge lies in regulatory compliance. Adhering to pollution control norms, ISO certifications, and safety guidelines requires a thorough understanding of industrial standards—something the best manufacturers in Pune integrate into their product design and documentation.

Why Pune is a Hub for Air Management Solutions

Pune has emerged as a center of excellence for mechanical and industrial engineering. With a strong talent pool, advanced manufacturing infrastructure, and an emphasis on sustainability, Pune hosts some of India’s most trusted industrial blower manufacturers and centrifugal fan manufacturers. These companies not only cater to domestic industries but are also gaining traction in global markets due to their innovation and commitment to quality.

Top 5 FAQs – Centrifugal Fan & Industrial Blower Manufacturers in Pune

Q1. What makes a centrifugal fan different from other types of industrial fans? Centrifugal fans use centrifugal force to move air radially outward, making them ideal for high-pressure applications. This sets them apart from axial fans that move air along a linear path.

Q2. How do I choose the right industrial blower manufacturer in Pune? Look for manufacturers with experience in your industry, customizable solutions, energy-efficient designs, and strong after-sales support.

Q3. Are centrifugal fan manufacturers in Pune ISO certified? Many top manufacturers in Pune are ISO certified, ensuring quality standards in manufacturing, testing, and delivery.

Q4. What industries commonly use industrial blowers and centrifugal fans? They are widely used in cement, pharma, automotive, textile, chemical processing, and food industries.

Q5. Can industrial blower systems be customized for specific airflow requirements? Yes, leading manufacturers in Pune offer tailored solutions to match precise airflow rates, pressure levels, and environmental conditions.

Conclusion

Choosing a leading industrial blower manufacturer in Pune or a trusted centrifugal fan manufacturer in Pune is vital to building efficient and reliable airflow systems. From improving air quality to boosting operational efficiency, these manufacturers play a crucial role in shaping India’s industrial future. Businesses must weigh efficiency, durability, and customization options to find the right solution that aligns with both performance and compliance.

0 notes

Text

Center Enamel: Pioneering Thermal Efficiency as China's Leading Heat Exchange Pressure Vessel Manufacturer

In the dynamic and energy-intensive landscape of modern industry, the efficient transfer of heat is not merely a desirable operational advantage; it is a fundamental pillar of process optimization, energy conservation, and sustainable production. From power generation and petrochemical refining to pharmaceutical manufacturing and food processing, heat exchange pressure vessels are indispensable components, orchestrating the precise thermal balance that drives industrial activity worldwide. Within this highly specialized and critical domain, one name consistently emerges as the benchmark of engineering excellence and manufacturing prowess from China: Shijiazhuang Zhengzhong Technology Co., Ltd., globally recognized as Center Enamel. We proudly assert our position not merely as a manufacturer, but as the indisputable leading force in China’s heat exchange pressure vessel industry, a testament to decades of specialized expertise, relentless innovation in thermal dynamics, and an unwavering commitment to delivering customized, high-performance solutions that precisely meet the exacting demands of global industries.

Our leadership in heat exchange pressure vessel manufacturing is not a mere claim; it is a distinction forged through an unparalleled understanding of thermodynamics and fluid mechanics, meticulous design for optimal heat transfer, precision manufacturing of intricate internal components, and rigorous adherence to the most stringent international safety and performance standards. Center Enamel embodies the pinnacle of Chinese specialized manufacturing capabilities, blending cutting-edge technology with profound process knowledge to empower global industrial development, ensuring thermal efficiency, operational safety, and environmental stewardship at every turn.

As a Global Leading Pressure Vessels Manufacturer, Shijiazhuang Zhengzhong Technology Co., Ltd(Center Enamel ) Powering Global Industries with Unrivaled Pressure Vessel Solutions, Your Trusted Global Partner for Mission-Critical Pressure Vessels. Center Enamel stands at the forefront of pressure vessel innovation and manufacturing, delivering pressure vessel solution to industries worldwide. With a legacy of excellence, Center Enamel has consistently set industry benchmarks, providing cutting-edge pressure vessel solutions for the most demanding applications globally.ProductsPressure VesselAtmospheric Pressure VesselsHorizontal Containers, Vertical Cylindrical Containers, Vertical Cylindrical Storage TanksSeparator Pressure VesselsGravity Separator, Cyclone Separator, Coalescing Separator, Centrifugal Separator, Steam-water Separator, Bearing Separator, Mechanical Filter, Ion exchange Filter, Air Filter, Fuel Filter, Adsorption Filter, BioFilter, Oil Filter, Hydraulic oil Filter, SeparatorHeat ExchangersShell and Tube Heat Exchangers, Plate Heat Exchangers, Spiral Heat Exchangers , Air Coolers, Liquid Coolers, Thermoelectric Coolers, Chill Water Main Unit, Evaporative Condensers, Air cooled Condensers, Electronic Gas CondensersReactor Pressure VesselsStirred Tank Reactors, Continuous Stirred-tank Reactors, Tubular Reactors, Tower Reactors, Fixed Bed Reactors, Fluidized Bed Reactors, Bioreactors

The Thermal Heartbeat of Industry: Understanding Heat Exchange Pressure Vessels

At its core, a heat exchange pressure vessel, commonly known as a heat exchanger, is an enclosed container designed to efficiently transfer thermal energy from one fluid to another without the fluids directly mixing. This critical function underpins countless industrial processes, enabling heating, cooling, condensation, evaporation, and heat recovery. These vessels are engineered to operate under a wide range of pressures and temperatures, making their design and fabrication inherently complex and critical to industrial safety and performance.

Common types of heat exchange pressure vessels include:

Shell-and-Tube Heat Exchangers: The most prevalent type, consisting of a shell with a bundle of tubes inside. One fluid flows through the tubes, and the other flows over the tubes (through the shell), transferring heat between them. They are highly versatile and can be designed for a wide range of pressures, temperatures, and fluid types.

Plate Heat Exchangers (Pressure Plate Heat Exchangers): Comprising a series of thin, corrugated metal plates that form channels for fluids. While some are gasketed, robust pressure-rated versions exist, offering high thermal efficiency and compact designs.

Air-Cooled Heat Exchangers (Fin-Fan Coolers): Used when cooling water is scarce or expensive. They use ambient air flowing over finned tubes to cool process fluids, often seen in petrochemical plants and power stations.

Hairpin Heat Exchangers: Featuring a U-shaped tube bundle inside a shell, offering true counter-current flow and high efficiency for specific applications.

Double Pipe Heat Exchangers: Simple and effective for smaller flow rates or applications requiring high individual pass heat transfer.

Condensers: Specialized heat exchangers designed to cool a hot vapor stream, causing it to condense into a liquid. Critical in power plants (steam condensers), chemical processing, and refrigeration.

Reboilers: Used in distillation columns to vaporize the liquid at the bottom of the column, providing the necessary heat for separation.

The critical importance of heat exchange pressure vessels stems from their multifaceted impact on industrial operations:

Energy Efficiency & Cost Savings: By recovering waste heat, preheating feed streams, or optimizing process temperatures, these vessels significantly reduce energy consumption and operational costs, contributing directly to economic sustainability.

Process Control & Optimization: Precise temperature control is essential for chemical reactions, phase changes, and maintaining product quality. Heat exchangers provide the accurate thermal management required for optimal process conditions.

Product Quality & Consistency: Maintaining consistent temperatures ensures uniform product properties, preventing degradation, undesirable side reactions, or inconsistent yields.

Environmental Compliance: Efficient heat recovery reduces the thermal load on cooling systems and minimizes energy wastage, leading to a smaller environmental footprint and lower greenhouse gas emissions.

Safety: Safely containing high-temperature, high-pressure, or hazardous fluids while facilitating heat transfer is paramount. Any failure in design or manufacturing can lead to catastrophic consequences.

Center Enamel’s Specialized Leadership in Heat Exchange Technology

Center Enamel’s distinguished position as China’s leading manufacturer of heat exchange pressure vessels is built upon a foundation of highly specialized expertise and an unwavering commitment to thermal performance in this critical domain:

1. Mastery in Design and Engineering for Optimal Heat Transfer:

Our engineering prowess in heat exchange vessels is rooted in a deep understanding of thermodynamics, fluid dynamics, and heat transfer principles. Our team of highly qualified engineers specializes in designing vessels that maximize thermal efficiency while minimizing pressure drop and fouling. We meticulously consider factors such as fluid properties (viscosity, specific heat, thermal conductivity), flow rates, desired temperature differentials, and operational pressures to select the optimal heat exchanger configuration, tube pattern, baffling arrangements, and surface areas.

Crucially, our expertise extends to the precise design and integration of all internal components that define heat exchange efficiency and reliability:

Tube Bundle Design: Optimizing tube layout, pitch, and material for efficient heat transfer and ease of cleaning/maintenance.

Baffling & Flow Distribution: Designing baffle arrangements (segmental, disc-and-doughnut, rod baffles) to induce turbulent flow, enhance heat transfer coefficients, and minimize bypass.

Fouling Mitigation: Incorporating design features that reduce fouling potential and facilitate mechanical or chemical cleaning, ensuring sustained performance.

Thermal Expansion Management: Designing expansion joints (e.g., bellows) or floating heads to accommodate differential thermal expansion between the shell and tubes, preventing stress and material failure.

Advanced Simulation & Optimization: We utilize state-of-the-art computational tools, including Computational Fluid Dynamics (CFD) simulations to model fluid flow, pressure drop, and heat distribution within the vessel. Thermal design software (e.g., HTRI, AspenTech EDR) is employed to accurately predict heat transfer performance, optimize surface areas, and ensure the most efficient and cost-effective design before fabrication. This sophisticated approach ensures that every Center Enamel heat exchanger is engineered for peak thermal performance and operational longevity.

2. Precision Manufacturing for Uncompromised Performance:

The effectiveness of a heat exchanger’s design is only as good as the precision of its manufacturing. At Center Enamel, we understand that tight tolerances, perfect alignment of tube bundles, and flawless welding are paramount to achieving designed thermal efficiencies and ensuring structural integrity under thermal cycling. Our state-of-the-art facilities employ advanced fabrication techniques that ensure:

Accurate Tube Bundle Fabrication: Meticulous control over tube bending, rolling, and welding into tube sheets ensures leak-tightness and optimal flow distribution.

Superior Welding & Joining: Automated welding systems (including tube-to-tubesheet welding machines) ensure high-integrity welds, critical for containing high-pressure and high-temperature fluids and preventing cross-contamination.

Dimensional Accuracy: Every component is manufactured to stringent dimensional tolerances, ensuring proper fit-up, minimized bypass, and optimal performance of the heat exchanger as an integrated system.

Specialized Forming: Expertise in forming complex components like dished heads, cones, and transition pieces, vital for robust pressure containment.

3. Tailored Material Selection for Diverse Media and Environments:

Heat exchangers often operate with fluids that are corrosive, erosive, or at extreme temperatures, demanding meticulous material selection. Center Enamel’s metallurgical experts possess extensive knowledge in specifying the optimal materials for various applications:

Carbon Steel: For general-purpose heat exchange, often with non-corrosive fluids.

Stainless Steels (304, 316, 316L): For resistance to a wide range of corrosive chemicals, hygienic applications, and moderate temperatures.

Duplex and Super Duplex Stainless Steels: For enhanced resistance to stress corrosion cracking, pitting, and crevice corrosion in highly aggressive environments (e.g., seawater, sour gas, high-chloride chemical processes).

High-Nickel Alloys (Inconel, Monel, Hastelloy): For exceptional resistance to extreme temperatures, highly corrosive acids, and other aggressive chemical media.

Clad Materials: Combining the cost-effectiveness of carbon steel with the corrosion resistance of an alloy layer, providing a robust and economical solution for specific process fluids.

Non-Ferrous Metals: Such as copper, brass, or titanium, selected for specific heat transfer properties or extreme corrosion resistance (e.g., titanium for seawater applications).

Our ability to select and expertly fabricate these materials ensures that our heat exchange vessels deliver exceptional longevity, even in the most challenging operational environments, including high-temperature processes, corrosive chemical streams, and extreme climatic conditions.

4. Rigorous Testing and Performance Validation:

Beyond standard ASME/PED compliance for pressure integrity, Center Enamel’s commitment to quality for heat exchange vessels extends to ensuring their thermal and mechanical performance. Our rigorous quality control processes include:

Comprehensive Nondestructive Testing (NDT): Ultrasonic Testing (UT), Radiographic Testing (RT), Magnetic Particle Testing (MPT), and Dye Penetrant Inspection (DPI) are performed on welds and critical areas to detect any subsurface or surface flaws.

Hydrostatic/Pneumatic Pressure Tests: Each vessel undergoes these tests to verify structural soundness, leak-tightness, and integrity under design pressures.

Thermal Design Validation: While actual thermal performance is validated during commissioning, our design process includes rigorous calculations and software simulations to guarantee the specified heat transfer rates.

Tube Leak Testing: Specific tests are conducted to ensure the integrity of individual tubes and tube-to-tubesheet joints, preventing cross-contamination between fluids.

Our meticulous documentation ensures full traceability of materials and processes, providing clients with complete transparency and compliance assurance.

5. Applications Across Key Industries Driven by Thermal Efficiency:

Center Enamel’s heat exchange pressure vessels are foundational to critical operations across a multitude of global industries:

Oil & Gas: Crucial for crude oil preheating, gas cooling and liquefaction (LNG), reboiling in distillation columns, cooling refinery products, and heat recovery in various process units.

Chemical & Petrochemical: Essential for temperature control in reactors, condensation of vapors, solvent recovery, and preheating/cooling of various chemical streams.

Power Generation: Main condensers in thermal power plants, feedwater heaters, auxiliary coolers, and heat recovery steam generators (HRSGs) in combined cycle plants.

HVAC & Refrigeration: Evaporators, condensers, and economizers in large-scale industrial refrigeration systems and district cooling.

Food & Beverage: Used for pasteurization, sterilization, chilling, and heating various food products, often requiring hygienic designs.

Pharmaceutical: Precise temperature control for reaction kinetics, sterilization of media, and solvent recovery, demanding high purity and compliance with strict regulations.

Metallurgy: Cooling of furnaces, quenching processes, and heat recovery in various metal processing stages.

6. Global Project Management and Seamless Logistics for Complex Equipment:

Our extensive experience in managing large-scale, complex international projects means we are adept at navigating the unique logistical challenges associated with transporting oversized and specialized heat exchange vessels globally. From meticulous planning and secure packaging to managing multi-modal transport (sea, road, rail) and complex customs procedures, Center Enamel ensures seamless, on-time delivery to even the most remote or challenging project sites worldwide.

7. Client Collaboration and Post-Installation Support:

Our customer-centric approach extends to close collaboration with clients' process engineers to ensure that the manufactured vessel precisely integrates with and fulfills the specified thermal requirements. Post-delivery, we provide comprehensive documentation, detailed installation guidance, and robust technical support for the operational and maintenance aspects of the heat exchange vessels, ensuring sustained optimal performance and energy efficiency.

Why Center Enamel Excels in Heat Exchange Pressure Vessels

Center Enamel’s leading position in the heat exchange pressure vessel market is defined by several key differentiating factors:

Proven Thermal Efficiency: Our meticulous design, advanced engineering tools, and precision manufacturing ensure that our heat exchangers consistently achieve the specified heat transfer rates, leading to significant energy savings and optimized process performance.

Enhanced Process Reliability & Uptime: By providing stable and precise temperature control, our vessels contribute significantly to increased plant uptime, reduced maintenance, and prevention of costly process upsets.

Optimized Footprint & Cost-Effectiveness: Our innovative designs often allow for optimized sizing, reducing overall footprint and material costs, while delivering superior thermal performance. Long-term durability provides excellent return on investment.

Absolute Safety & Compliance: Our adherence to the most stringent international codes and our focus on robust containment mitigate risks associated with high-temperature, high-pressure, or hazardous fluids, ensuring safety for personnel and compliance with environmental regulations.

Customization for Unique Thermal Challenges: We thrive on complex challenges, providing bespoke solutions for highly specific heat transfer needs, unusual fluid properties, extreme operating conditions, or unique space constraints.

Long-Term Durability & Reduced Maintenance: Crafted from meticulously selected materials and fabricated with precision, our heat exchange vessels are designed for an extended operational life, minimizing the need for frequent maintenance or costly replacements, even in demanding thermal cycling applications.

In a global industrial landscape where energy efficiency, precise thermal control, and uncompromising safety are paramount, the role of reliable and high-performance heat exchange pressure vessels cannot be overstated. Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel) stands as the definitive leader among China’s manufacturers in this specialized field. Our unwavering commitment to mastering complex thermal dynamics, coupled with our state-of-the-art manufacturing capabilities, rigorous quality control, and a profound understanding of diverse industry applications, collectively define our leadership. We are not just building vessels; we are engineering critical thermal solutions that optimize processes, conserve energy, safeguard operations, and drive sustainable growth across global industries. We invite industries worldwide to partner with Center Enamel, the trusted leader, to enhance your operational efficiency, ensure thermal mastery, and secure the foundational strength of your industrial processes, building a future of innovation and sustained success.

0 notes

Text

Replicating spider silk synthetically has been one of the most ambitious goals in biomaterials science due to its extraordinary combination of strength, elasticity, and lightness. Here’s how it’s done:

1. Recombinant DNA Technology

Scientists first isolate the gene that produces spidroin—the main protein in spider silk—and insert it into host organisms, such as:

E. coli bacteria

Yeast

Alfalfa plants

Goats (that produce silk proteins in their milk)

These hosts are then cultivated to produce large quantities of silk proteins in controlled bioreactors.

2. Protein Harvest & Purification

Once expressed, the spidroin proteins are:

Extracted from the host

Purified using centrifugation and chromatography

Concentrated into a viscous protein solution, called dope, which mimics the liquid form spiders use before spinning silk

3. Wet Spinning or Microfluidic Spinning

The protein solution is passed through a spinneret-like nozzle into a coagulation bath (like isopropanol or salt solution), creating solid silk fibers. This process mimics how spiders use water content and pH to trigger fiber formation.

Modern techniques include:

Wet Spinning: Continuous extrusion into an alcohol bath

Microfluidics: Precise pH, temperature, and shear-force control to align proteins into beta-sheet nanocrystals

Electrospinning: For nanofibers used in medical or filtration applications

4. Post-Processing for Enhanced Properties

Stretching or drawing the fiber increases alignment and strength

Crosslinking agents can enhance stability

Coating with graphene oxide or metal ions can improve conductivity or durability (as in the Iron Spider concept)

FeatureReal Spider SilkSynthetic VersionTensile Strength~1.1 GPaUp to ~0.9–1.0 GPa (improving)Elasticity30–40% elongation10–30% (depending on method)BiodegradabilityYesYesBiocompatibilityExcellentExcellent

Protein folding: Achieving proper beta-sheet alignment is complex

Yield efficiency: Producing enough silk protein at scale remains a bottleneck

Fiber uniformity: Variations during spinning can reduce strength

Biomedical sutures, nerve scaffolds, and tissue engineering

Wearable electronics (as bio-conductive threads)

Military gear and ultralight fabrics

Space and deep-sea materials (as proposed in your Iron Spider concept)

Would you like a side-by-side visual of this process or a Codex-style one-pager showing real vs. augmented silk synthesis?

Looking to explore deeper? Try SciSpace — the AI platform for academic research. It's your all-in-one workspace to discover, read, and analyze scientific literature.

Users also ask these questions:

What makes spider silk stronger than steel?

Can artificial spider silk be made at industrial scale?

What are the medical uses of synthetic spider silk?

You said:

What makes spider silk stronger than steel?

ChatGPT said:

Spider silk is often said to be stronger than steel — not because it can withstand higher forces overall, but because of its strength-to-weight ratio and unique mechanical properties. Here's why:

1. Molecular Structure: Beta-Sheet Nanocrystals

The main protein, spidroin, is composed of repeating blocks that self-assemble into beta-sheet nanocrystals.

These crystals act like hard domains, giving silk high tensile strength (resistance to being pulled apart).

Between these are amorphous, flexible regions that allow stretching and energy absorption, providing toughness.

2. Tensile Strength vs. Toughness

Tensile strength of spider silk: ~1.1–1.3 GPa (similar to high-grade steel)

But toughness (ability to absorb energy without breaking) is 10× greater than Kevlar

Silk can stretch up to 5× its original length without breaking, whereas steel is far more brittle.

3. Strength-to-Weight Ratio

Spider silk is lighter than cotton, yet can withstand similar or greater stress per unit weight than steel.

If scaled proportionally, a pencil-thick strand of dragline silk could stop a jetliner in flight — theoretically.

4. Biological Precision

Spiders spin silk with exquisite control of humidity, pH, ion gradients, and protein alignment—something humans struggle to replicate fully in synthetic materials.

Each silk type (dragline, flagelliform, aciniform, etc.) is tailored for specific purposes: strength, elasticity, stickiness.

PropertySpider SilkSteelTensile Strength~1.1 GPa~1.0–1.5 GPaDensity~1.3 g/cm³~7.8 g/cm³ElasticityVery HighLowToughnessExtremely HighModerateBiodegradableYesNo

Spider silk is inspiring bioengineered fibers for:

Body armor

Aerospace tethers

Artificial ligaments

Smart fabrics and soft robotics

0 notes

Text

Enduring Integrity Center Enamel's Welded Steel Tanks – Superior Corrosion Resistance for Aboveground Oil Storage

Enduring Integrity Center Enamel's Welded Steel Tanks – Superior Corrosion Resistance for Aboveground Oil Storage

In the dynamic world of petroleum infrastructure, the long-term integrity of aboveground oil storage tanks is continuously challenged by aggressive internal product chemistries and unforgiving external environmental conditions. Corrosion, left unchecked, can lead to costly leaks, environmental damage, and catastrophic failures. At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are committed to providing Aboveground Welded Steel Tanks for Oil Storage that are engineered with superior corrosion resistance as a foundational principle, ensuring unparalleled durability, safety, and reliability for critical petroleum assets worldwide.

While Center Enamel is a global leader and innovator in Glass-Fused-to-Steel (GFS) bolted tanks, renowned for their extreme corrosion resistance in liquid storage, our extensive expertise extends to the robust design and meticulous fabrication of welded steel tanks. These tanks are the cornerstone of large-scale crude oil terminals, refineries, and distribution hubs, where their inherent strength, vast capacity, and, crucially, their enhanced corrosion protection systems make them the preferred choice for enduring performance.

As a leading storage tank manufacturer worldwide. Center Enamel can provide Glass Lined Steel(GLS) tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized steel tanks and aluminum geodesic dome roofs, Wastewater and Biogas Project Equipments for global customers.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GLS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GLS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Bio

gas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

The Imperative of Corrosion Resistance in Aboveground Oil Tanks

Aboveground oil tanks face a dual threat from corrosion:

Internal Corrosion: Caused by the stored product itself. Crude oil can contain water, sulfur compounds (like H2S), organic acids, and salts, all of which become corrosive agents, especially at the oil-water interface or in the vapor space. Refined products can also be corrosive, particularly if they contain moisture or specific additives. Microbial Induced Corrosion (MIC) from bacteria in the tank bottom sludge is also a significant concern.

External (Atmospheric) Corrosion: The exterior of the tank is exposed to a range of environmental factors including UV radiation, rain, humidity, temperature fluctuations, industrial pollutants, and salt spray in coastal areas. These elements relentlessly attack the steel, leading to rust and degradation if not adequately protected.

Without superior corrosion resistance, these forces can compromise the tank's structural integrity, leading to leaks, costly repairs, and potential environmental and safety hazards.

Center Enamel's Multi-Layered Defense: Engineering for Superior Corrosion Resistance

Center Enamel's approach to aboveground welded steel tanks for oil storage is rooted in a comprehensive, multi-layered corrosion protection strategy. This goes beyond simple coatings to integrate material science, advanced design, and proactive protection systems:

Robust Material Selection and Design:

High-Grade Steel: We utilize meticulously selected high-grade carbon steel plates, specifically chosen for their strength, weldability, and inherent resistance to the stresses of long-term oil containment. For more aggressive products or environments, specialized alloys may be considered.

API Standards Compliance: Our tanks are rigorously designed and constructed in full compliance with API 650 (American Petroleum Institute Standard for Welded Tanks for Oil Storage). This standard includes provisions for corrosion allowances and material specifications that inherently contribute to long-term resistance. For larger or low-pressure tanks, API 620 is applied, similarly integrating robust material and design criteria.

Advanced Internal Lining Systems:

The interior of an oil tank is its first line of defense against product-induced corrosion. Center Enamel specifies and applies internal linings that are tailored to the specific type of crude or refined oil being stored:

Chemical-Resistant Epoxies & Novolac Epoxies: These high-performance coatings provide an inert barrier against organic acids, sulfur compounds, and water present in the crude oil. They are applied after meticulous surface preparation (e.g., abrasive blasting to NACE #1 / SSPC-SP 5 White Metal or SA 2.5), ensuring optimal adhesion and a seamless, pinhole-free protective layer.

Enhanced Bottom Plate Protection: Tank bottoms are particularly vulnerable to corrosion from accumulated water and sludge. Our designs can incorporate thicker bottom plates, specialty high-build linings, and sophisticated drainage systems to mitigate this risk.

Vapor Space Coatings: In fixed-roof tanks, the vapor space above the liquid can also be corrosive due to condensing vapors. Specialized coatings are applied here to provide comprehensive internal protection.

Durable External Coating Systems:

The exterior of the tank is continuously exposed to atmospheric elements. Center Enamel applies multi-layer external coating systems designed for maximum longevity and resistance:

Industrial-Grade Primers: Often zinc-rich primers, providing cathodic protection to the steel and excellent adhesion.

High-Build Intermediate Coats: Epoxy or similar high-solids coatings for thickness and barrier protection.

UV-Resistant Topcoats: Typically polyurethane or polysiloxane topcoats that offer excellent resistance to UV degradation, chalking, fading, and aggressive atmospheric conditions (e.g., salt spray, industrial pollutants). These systems often comply with ISO 12944 for corrosion protection of steel structures by protective paint systems, ensuring decades of performance.

Comprehensive Cathodic Protection Systems:

For the critical tank bottom (which is in contact with the ground or a foundation), Center Enamel implements state-of-the-art cathodic protection (CP) systems. These systems actively prevent external corrosion by introducing an electrical current that makes the tank bottom the cathode in an electrochemical cell, thereby protecting the steel.

Sacrificial Anode Systems: Using more active metals (e.g., magnesium, zinc) that corrode preferentially to the steel.

Impressed Current Systems: Using external power to drive a current through inert anodes, providing highly controlled and effective long-term protection.

CP systems are designed, installed, and monitored by certified professionals to ensure continuous and effective corrosion prevention for the tank bottom, which is often the most vulnerable area for leaks.

Advanced Tank Design Features for Corrosion Control:

Beyond coatings and CP, intrinsic design elements enhance corrosion resistance:

Floating Roofs: For volatile products, Internal Floating Roofs (IFR) or External Floating Roofs (EFR) reduce the vapor space, significantly minimizing oxygen ingress and volatile organic compound (VOC) emissions, thereby reducing internal corrosion from condensation and vapor-phase reactions.

Water Draw-off Systems: Efficient systems to regularly remove accumulated water from the tank bottom, preventing the formation of corrosive water-in-oil emulsions and highly corrosive water phases.

Sludge/Sediment Management: Designs that facilitate the removal of corrosive sludge and sediment from the tank bottom during cleaning and maintenance cycles.

Center Enamel's Commitment to Quality and Certification

Our dedication to superior corrosion resistance is underpinned by:

Certified Manufacturing: Our facilities operate under strict ISO 9001 quality management systems. Welding procedures are qualified, and welders are certified to relevant international codes, ensuring the integrity of every seam.

Rigorous Inspection and Testing: Every stage, from material procurement to final coating application and tank erection, undergoes stringent quality control. This includes non-destructive testing (NDT) of welds (radiography, ultrasonics, magnetic particle inspection), dry film thickness (DFT) measurements for coatings, and holiday testing for internal linings to detect any pinholes or discontinuities.

Global Compliance: Our tanks are engineered to comply not only with API standards but also with local environmental regulations (e.g., EPA, regional environmental agencies) for spill prevention and emission control, which are often tied to tank integrity.

The Long-Term Value Proposition

Investing in Center Enamel's Aboveground Welded Steel Tanks with superior corrosion resistance offers compelling long-term benefits:

Extended Service Life: Decades of reliable operation, minimizing the need for costly replacements.

Reduced Maintenance Costs: Less frequent need for major internal re-linings or external re-painting, significantly lowering operational expenditures.

Enhanced Safety & Environmental Protection: A robust, corrosion-resistant tank dramatically reduces the risk of leaks, spills, fires, and associated environmental damage, safeguarding both assets and reputation.

Optimized Operational Uptime: Fewer unscheduled outages due to corrosion-related failures, ensuring continuous product flow and revenue generation.

Preservation of Product Quality: Preventing contamination from internal corrosion products ensures the integrity of the stored refined oil.

Center Enamel: Your Trusted Partner for Enduring Oil Storage

In the demanding environment of aboveground oil storage, corrosion resistance is not an option; it's a fundamental necessity. Center Enamel's Welded Steel Tanks are engineered from the ground up to provide superior protection against the dual threats of internal and external corrosion, ensuring their structural integrity and operational reliability for decades.

As a global leader in storage solutions, Center Enamel combines unparalleled engineering expertise, advanced manufacturing capabilities, and a relentless commitment to quality and safety. We are dedicated to providing the robust and reliable infrastructure that supports the world's energy needs, ensuring that valuable petroleum assets are stored with enduring integrity and environmental responsibility.

Partner with Center Enamel to secure your vital oil assets. Contact us today to learn how our Aboveground Welded Steel Tanks, designed with superior corrosion resistance, can provide the long-term, safe, and reliable storage solution your operations demand.

0 notes

Text

Submersible Pumps: Overview, Working Principle, and Applications

A submersible pump is a type of pump that operates with the motor and the pump head submerged under the fluid it is pumping. It is designed to push fluid to the surface by converting rotational energy into kinetic energy, effectively pushing water (or other liquids) from one location to another.

Submersible pumps are widely used in applications ranging from dewatering and sewage systems to agricultural and industrial settings.

How Do Submersible Pumps Work?

Submersible pumps work by completely submerging the pump and motor in the fluid that needs to be pumped. Here’s how they work:

Fluid Intake:

The pump has an inlet (typically at the bottom) through which the fluid enters the pump.

Impeller Rotation:

Inside the pump, there is a rotating impeller that adds kinetic energy to the fluid, increasing its velocity.

Fluid Displacement:

As the fluid passes through the impeller, it is pushed outwards by centrifugal force, increasing its pressure and velocity.

Fluid Discharge:

The pressurized fluid exits through the pump's discharge port and is carried through the discharge pipe to the required location, whether it is above ground or to a separate system.

Motor Protection:

The motor, which is typically sealed, is designed to operate safely underwater. The fluid helps keep the motor cool, preventing overheating.

Key Components of a Submersible Pump

Motor: Powers the impeller to create the flow of water. It is sealed to prevent water from reaching the electrical components.

Impeller: The rotating blades that impart kinetic energy to the water, increasing its flow and pressure.

Pump Casing: Encloses the pump components and directs the water flow into the discharge.

Seal/Seal Housing: Protects the motor from water ingress and prevents leaks.

Suction and Discharge Ports: Inlet for the fluid and outlet for the pumped fluid.

Cable and Electrical Connections: Provide power to the motor and are built to withstand submersion.

Types of Submersible Pumps

Dewatering Pumps:

Use: Used to remove water from flooded areas, basements, construction sites, and mining operations.

Applications: Building sites, mining, emergency flood response.

Features: Typically lightweight and portable for easy transport and deployment.

Sewage and Effluent Pumps:

Use: Designed to handle wastewater containing solids, including sewage, sludge, and debris.

Applications: Sewage treatment plants, septic systems, and municipal wastewater systems.

Features: Equipped with impellers or grinders that can break down solid waste and handle large particles.

Submersible Well Pumps:

Use: Used for pumping water from wells, typically at greater depths, by moving water up from deep underground sources.

Applications: Residential water supply, agricultural irrigation, and deep well applications.

Features: High-pressure capability, durable design for deep applications.

Shallow Well Pumps:

Use: Suitable for pumping water from shallow wells (typically less than 25 feet).

Applications: Domestic water supply in rural or remote areas.

Features: Self-priming and easy to install.

Dirty Water Pumps:

Use: Designed to handle water with solid particles, sludge, or other contaminants.

Applications: Construction sites, drainage systems, and industrial applications where dirty water needs to be removed.

Features: Larger inlet for passing solid debris without clogging.

Solar Submersible Pumps:

Use: Powered by solar energy, these pumps are used in remote locations or off-grid systems.

Applications: Agricultural irrigation, water supply for remote areas.

Features: Typically energy-efficient and can operate without a traditional power supply.

Applications of Submersible Pumps

Dewatering:

Submersible pumps are commonly used to remove excess water in areas like construction sites, basements, and mining operations. They can quickly remove large volumes of water and prevent flooding.

Sewage and Wastewater Systems:

These pumps are ideal for sewage treatment plants and septic systems. They can handle not only water but also solids and sludge, making them essential for wastewater management in residential, commercial, and industrial environments.

Agriculture and Irrigation:

Submersible pumps are used to pump water from wells for irrigation purposes. They are particularly useful in rural areas or regions with a high reliance on groundwater.

Oil and Gas:

In the oil and gas industry, submersible pumps are used for transferring crude oil, water, or other fluids at offshore platforms, as they are designed to work submerged and handle heavy-duty tasks.

Industrial Processes:

Used to pump water, chemicals, and other fluids in various industrial applications. Submersible pumps can be used for cooling systems, heat exchange, or moving liquids in manufacturing processes.

Stormwater Drainage:

Submersible pumps are used to move stormwater or rainwater from low-lying areas or drainage basins, helping to prevent flooding during heavy rainfall.

Water Supply:

For residential or commercial water systems, submersible pumps are often used in wells to supply clean drinking water or for other uses such as industrial processing or irrigation.

Advantages of Submersible Pumps

Efficient for Deep Well Applications:

Submersible pumps are highly efficient at pumping water from deep sources, making them ideal for deep wells or underground tanks.

Compact and Portable:

These pumps are usually compact and portable, making them easy to transport and deploy in remote or temporary locations.

No Priming Required:

Submersible pumps are self-priming, meaning they do not require priming before operation. The motor is sealed, and the fluid helps prevent overheating.

Reduced Risk of Cavitation:

Because the pump is submerged, it reduces the risk of cavitation (the formation of vapor bubbles), which is common in non-submersible pumps when air enters the suction side.

Energy Efficient:

Submersible pumps can be more energy-efficient than other types of pumps, as the fluid helps cool the motor and eliminates the need for a priming system.

Lower Noise Levels:

Submersible pumps typically operate quieter than surface pumps since they are submerged underwater, which dampens the noise.

Disadvantages of Submersible Pumps

Higher Initial Cost:

Submersible pumps tend to be more expensive upfront due to their design, sealing, and motor protection systems.

Potential for Motor Damage:

If the pump becomes clogged or blocked, the motor could be at risk of overheating or damage, especially if the pump is not properly maintained.

Maintenance Challenges:

Maintenance and repairs can be more difficult because the pump is submerged and may require special tools or professional help for servicing.

Limited by Depth:

The pump's ability to operate effectively is limited by its design, and submersible pumps may not be suitable for extremely deep water sources or high-pressure applications.

Submersible pumps are essential tools in various industries, offering efficiency, reliability, and versatility in applications ranging from dewatering to sewage treatment and irrigation. By understanding how they work and where they can be used, you can choose the right submersible pump for your specific needs and ensure efficient fluid handling, even in challenging environments. For more info contact Water Pump Suppliers in UAE or call us at +971 4 2522966.

#Water Pumps#Water Pump Suppliers#Water Pump Suppliers in UAE#Water Pump Supplier#Water Pump Supplier in Dubai#Water Pump Dubai

0 notes

Text

Rotary Pumps Market Drivers Include Industrial Expansion and Demand for Fluid Efficiency

Introduction: Key Drivers Fueling Market Momentum

The Rotary Pumps Market is witnessing accelerated growth, largely propelled by two fundamental forces: industrial expansion and the increasing demand for fluid handling efficiency. As global economies invest in upgrading their manufacturing and processing infrastructures, the need for reliable and efficient pumping mechanisms is intensifying. Rotary pumps—known for their precision, low pulsation, and adaptability—are becoming essential in sectors where consistent fluid movement and energy savings are critical. Their application is now widespread across oil & gas, food processing, water treatment, and chemical industries, where demand is tied to scaling operations and energy-conscious machinery.

Industrial Expansion: A Robust Growth Engine

Industrialization, especially in emerging economies, has significantly amplified the demand for rotary pumps. Countries like India, China, Brazil, and several Southeast Asian nations are rapidly investing in industrial development projects. From petrochemical plants to large-scale food processing units, the scale and complexity of fluid transfer requirements are growing. Rotary pumps offer unmatched benefits in these settings due to their ability to handle high-viscosity fluids, abrasive liquids, and shear-sensitive materials with minimal degradation.

Moreover, infrastructure projects such as water and wastewater treatment facilities, mining operations, and energy plants further bolster the necessity of durable and efficient pumping systems. The ability of rotary pumps to maintain consistent flow rates and operate under varying pressure conditions gives them a strategic advantage in modern industrial setups.

Energy Efficiency: Rising Priority in Pump Selection

Another critical factor driving the rotary pumps market is the mounting emphasis on energy efficiency. With energy costs on the rise and regulatory agencies enforcing stringent efficiency standards, companies are turning toward pump solutions that help cut operating expenses without compromising performance. Rotary pumps are inherently energy-efficient, especially in comparison to centrifugal alternatives in low-flow, high-pressure applications.

The integration of variable frequency drives (VFDs), smart sensors, and automation technology has further enhanced the performance profiles of these pumps. These upgrades not only reduce energy usage but also contribute to real-time performance monitoring and predictive maintenance—two attributes essential for cost-conscious, environmentally responsible industries.

Supportive Policy and Technological Alignment

Government policies encouraging the use of energy-efficient machinery in industrial ecosystems also play a role in market expansion. Incentive programs, energy audits, and sustainability benchmarks set by authorities are nudging industries toward rotary pump adoption. At the same time, advancements in pump materials, seal technologies, and magnetic drive systems are aligning rotary pump offerings with next-gen industrial requirements.

Pump manufacturers are also capitalizing on the increased availability of digital platforms to monitor, analyze, and optimize pump performance remotely, providing an added layer of operational agility. This technological synergy between mechanical systems and smart industry platforms has made rotary pumps more attractive to both legacy operators and modern facilities.

Diverse Applications Across Industries

The versatility of rotary pumps has enabled their integration into a wide array of sectors. In the food and beverage industry, their gentle pumping mechanism ensures the integrity of viscous and shear-sensitive products. In chemical and oil processing plants, rotary pumps handle aggressive fluids and volatile compounds with precision and safety. In agriculture, they assist in irrigation systems and fluid fertilization, while in pharmaceuticals, they aid in sterile liquid transfer processes.

Each of these applications demands reliability, accuracy, and compliance with safety standards—qualities that rotary pumps are well-positioned to deliver consistently.

Competitive Landscape and Market Entry Potential

As demand continues to grow, numerous global and regional players are entering or expanding their footprint in the rotary pumps market. This increasing competition is leading to innovation in pump design, pricing strategies, and customer service models. Players offering energy-efficient models, strong aftermarket support, and modular product designs are carving out significant market share.

Additionally, strategic partnerships with OEMs and end-users help pump manufacturers better understand application-specific requirements, further refining their product offerings for competitive advantage.

Conclusion: From Industrial Growth to Sustainable Efficiency

The Rotary Pumps Market is firmly supported by two pivotal dynamics—industrial growth and the imperative for fluid efficiency. These forces not only boost current demand but also lay the groundwork for long-term relevance in evolving industries. As manufacturers seek smarter, greener, and more scalable pumping solutions, rotary pumps are poised to remain integral to fluid handling operations.

#RotaryPumpsMarket#IndustrialExpansion#EnergyEfficiency#FluidHandling#ManufacturingGrowth#SmartPumps#ProcessIndustry#RotaryTechnology#SustainablePumping#GlobalIndustryTrends

0 notes

Text

Centrifugal Pumps Design: What Changes Are Coming For 2025?

Centrifugal pumps are without a doubt one of the most common fluid handling devices in the world. This is not surprising given their straightforward design, numerous variations and efficient delivery of the job at hand. Centrifugal pumps are utilized in nearly every industry imaginable, including water treatment and manufacturing, agriculture and chemical processing.

Centrifugal Pumps Defined

A centrifugal pump is a machine that employs the principle of an impeller, a rotating disk with vanes, to add kinetic energy to a fluid. The spiraling or whirling motion produced will cause centrifugal force to aid in moving (the inertial force) the fluid from the center of rotation outward, thereby accelerating the fluid. The kinetic energy is then converted to pressure so that a pump can move fluids from a low position or low pressure to a higher position or pressure.

Key Features and Basic Operation

The impeller is the main body of the pump and is spinning at a high speed to create centrifugal force.

Continuous Flow of Fluid: Centrifugal pumps provides continuous & non-pulsating flow of fluid (when constant flow of fluid is required).

Priming Influenced By: Because pumps cannot prime themselves when dry, the pumps must be rinsed with liquiditania (primed) prior to use.

Applications of Centrifugal Pumps

Centrifugal pumps are extremely versatile and are utilized in a wide range of applications, including:

Water treatment and supply plants

Irrigation systems

Petrochemical and chemical processing

Food and beverage manufacturing

Fire protection systems

HVAC

Power production and boiler feed

Sewage and wastewater treatment

They are best equipped for the treatment of low-viscosity fluids such as water, solvents, oils, acids, and bases and are available in numerous forms suitable for specific applications, including multistage pumps for high-pressure applications, chopper pumps for fluid-solid suspensions, and magnetic drive pumps for dangerous chemicals.

Advantages of Centrifugal Pumps

High Efficiency: The hydraulic design of centrifugal pumps makes moving fluid with little energy loss which means less energy loss and lower maintenance.

Simple Construction: Having fewer moving parts means reduced maintenance and more reliability.

Multiple Capabilities: Large volumes of fluid can be transferred at different speeds and pressures.

Low Noise and Vibration: Centrifugal pumps run relatively quietly and smoothly naturally.

Safe for Hazardous Fluids: Sealless pumps do not allow any fluid to escape and make the handling of toxic fluids less threatenng to the user.

Limitations of Centrifugal Pumps

Not Applicable for High-Viscosity Fluids: Efficiency is significantly compromised with heavy or viscous fluid and hence positive displacement pumps would be better suited in such a case.

Priming Needed: Unable to prime itself in a dry state; must be filled with fluid before running.

Flow Rate Variation due to Changes in Pressure: Flow rate can vary with changes in system pressure, the variation is unacceptable for applications that require precise dosing or metering.

Shear Sensitivity: Shear sensitive fluids or other emulsions could be destroyed by the high-speed impeller.

To Conclude

Today, centrifugal pumps are one of the most common utilities in industry due to their efficiency, ease of use, and flexibility in variable applications. They do exceptionally well pumping large volumes of low viscosity fluids; they are often chosen due to being somewhat low cost to maintain and operate. In high viscosity or shear-sensitive fluid process applications, or any application, where control of flow is critical, other pump technologies such as sliding vane or gear pumps may work more efficient. Knowing the advantages and disadvantages of centrifugal pumps, a better decision can be made and optimized performance within any fluid system.

0 notes

Text

Selecting the Right Pump Type for Dewatering Applications

Selecting the right pump type for dewatering operations is essential for ensuring efficient and effective water removal. The type of pump chosen should be based on various factors, including the water source, flow rate, head requirements, and water quality (e.g., clean water, wastewater, or slurry). The wrong pump can lead to inefficiencies, unnecessary wear and tear, or even system failure.

Here’s a detailed guide to help you select the right pump type for your dewatering application based on common use cases and conditions.

1. Centrifugal Pumps

Overview:

Centrifugal pumps are the most commonly used pump type in dewatering applications. They use centrifugal force to move water, where water is drawn into the pump and accelerated by an impeller, creating pressure that moves the water through the discharge pipe.

Best For:

Flood Management: Ideal for handling large volumes of water in a short amount of time.

Construction Sites: Effective for pumping water from trenches, pits, and excavations.

General Dewatering: Commonly used for dewatering clean water or water with low sediment content.

Advantages:

High Flow Rates: Centrifugal pumps are capable of moving large amounts of water quickly, making them suitable for applications requiring high flow rates.

Simple Design: Easy to maintain and repair due to their simple and robust design.

Energy Efficient: When sized correctly, they offer good energy efficiency for large dewatering operations.

Low Maintenance: With fewer moving parts, centrifugal pumps generally require less maintenance than more complex pumps.

Limitations:

Not Ideal for Solids Handling: Not suitable for water with large solids or debris, as they can clog the impeller or damage the pump.

Require Priming: Many centrifugal pumps need to be primed before use, especially if air enters the suction line.

When to Use:

For clean water or water with minimal solids content.

In large-scale dewatering operations such as construction sites, mines, or flood zones.

When there is a need for high flow rate and medium head conditions.

2. Diaphragm Pumps

Overview:

Diaphragm pumps are positive displacement pumps, meaning they move a fixed amount of fluid per stroke. These pumps are self-priming and use a diaphragm that moves back and forth to draw water into the pump chamber and expel it.

Best For:

Slurry or Sludge Dewatering: Ideal for dewatering water mixed with heavy solids, sludge, or viscous fluids.

Construction Sites with High Solids: Useful in applications where water contains a high concentration of mud, silt, or other debris.

Mining Applications: Suitable for mining sites with water containing fine solids.

Advantages:

Self-Priming: Can operate in low water levels or fluctuating water conditions without needing an external priming mechanism.

Handles Solids Well: Can pump water with significant amounts of solids, slurry, or sludge without clogging.

Versatile: Can handle a variety of fluids, including those that are viscous or chemically contaminated.

Low Maintenance: Fewer moving parts compared to centrifugal pumps.

Limitations:

Lower Flow Rates: Generally have a lower flow rate compared to centrifugal pumps, making them more suitable for smaller-scale dewatering operations.

Higher Maintenance: The diaphragm may wear out over time and requires periodic maintenance or replacement.

Pulsating Flow: The pumping action is not as smooth as centrifugal pumps, which could affect applications requiring steady water flow.

When to Use:

When handling slurry, silt, or muddy water in construction, mining, or industrial sites.

In situations where low water levels are common and self-priming capabilities are needed.

For smaller-scale dewatering operations where high solids content is present.

3. Vortex Pumps

Overview:

Vortex pumps are a type of centrifugal pump, but they are specifically designed to handle water with high levels of debris, large solids, or sludge. They operate by creating a vortex that allows the water and solids to pass through the pump without clogging.

Best For:

Heavy Debris Handling: Ideal for dewatering operations where large debris or solids are present, such as construction sites with sand, gravel, or large particles.

Sewage or Wastewater: Useful in wastewater treatment, sewage handling, or floodwaters with substantial debris.

Advantages:

Handles Large Solids: Vortex pumps are designed to move large solids without clogging the pump, making them ideal for construction sites and sewage dewatering.

Reduced Maintenance: Since the design prevents solids from being trapped in the impeller, vortex pumps generally require less maintenance than centrifugal pumps.

Efficient for Water with Debris: Unlike centrifugal pumps, vortex pumps can efficiently pump water with suspended solids.

Limitations:

Lower Efficiency with Clean Water: Vortex pumps are less efficient when pumping clean water, as they are designed specifically to handle debris.

Lower Flow Rates: While efficient for handling solids, vortex pumps generally have lower flow rates compared to centrifugal pumps, making them less suitable for high-volume dewatering needs.

When to Use:

For dewatering sites with heavy debris or high solid content such as construction or demolition sites.

For sewage or wastewater applications where solids may be present.

In emergency flood control where water is mixed with sediment or large debris.

4. Submersible Pumps

Overview:

Submersible pumps are designed to be fully submerged in the water they pump. The motor is sealed in a casing to protect it from water, and the pump operates while completely submerged, making them ideal for dewatering in confined spaces.

Best For:

Flooded Areas: Used to pump water from basements, trenches, pits, or tanks where water has accumulated.

Sewage and Wastewater: Often used in wastewater treatment plants or for sewage dewatering, especially when pumping dirty water or wastewater with small solids.

Advantages:

Efficient for Deep Dewatering: Submersible pumps can operate efficiently in deep or confined areas where other pumps might struggle.

No Priming Needed: Submersible pumps are self-priming and can operate in situations where air may enter the suction line.

Quiet Operation: Typically, submersible pumps are quieter than external pumps, making them more suitable for residential or urban areas.

Limitations:

Requires Submersion: The pump must be submerged in the water to operate, making them unsuitable for dry applications.

Motor Maintenance: The motor is enclosed in a casing that must be maintained to ensure no water leakage occurs into the electrical components.

Limited Solid Handling: While some models can handle small solids, they are not ideal for large debris or highly contaminated water.

When to Use:

For flooded basements, trenches, or pits where the water is deep and confined.

For sewage and wastewater pumping, where the water contains small solids.

In residential or industrial dewatering in confined spaces where pump noise or vibration is a concern.

5. Peristaltic Pumps

Overview:

Peristaltic pumps are positive displacement pumps that use rollers or shoes to compress a flexible hose, pushing water through the hose in a continuous, pulsating manner. They are capable of handling slurries, sludge, and other viscous fluids.

Best For:

Slurry Dewatering: Effective in applications where water is mixed with large amounts of solids, chemicals, or slurry-like materials.

Chemical Handling: Often used in applications where precise dosing of chemicals is required alongside dewatering.

Advantages:

Handles Viscous Fluids: Excellent for moving highly viscous fluids or fluids with a high concentration of solids.

Self-Priming: Can operate in dry conditions and self-prime, eliminating the need for external priming equipment.

Minimal Wear: Since the pump mechanism doesn’t directly touch the fluid, it experiences less wear compared to other types of pumps.

Limitations:

Lower Flow Rates: Generally have lower flow rates compared to centrifugal or diaphragm pumps, making them suitable for smaller operations.

Pulsating Flow: The flow is not as smooth as other pumps, which may not be suitable for applications requiring continuous flow.

When to Use:

For slurry dewatering or handling viscous fluids.

In chemical dosing applications where precise flow is needed along with water removal.

Selecting the right pump type for your dewatering application depends on several factors, including water quality, flow rate, head requirements, and site conditions. Here's a quick recap on choosing the right pump:

Centrifugal Pumps: Best for large-volume, clean water dewatering applications.

Diaphragm Pumps: Ideal for slurry and high-solids content in water.

Vortex Pumps: Excellent for handling large debris and solids.

Submersible Pumps: Perfect for confined spaces or deep water removal.

Peristaltic Pumps: Best for dewatering viscous fluids or slurry-like materials.

By carefully assessing your water conditions, flow rate needs, and site-specific challenges, you can select the most efficient and effective pump for your dewatering operation. For more info contact Submersible Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

How Vibro Motors Improve Efficiency in Industrial Automation

How Vibro Motors Improve Efficiency in Industrial Automation

The manufacturing and industrial sectors are continuously evolving, driven by technological advancements that enhance productivity, reduce downtime, and optimize costs. One such innovation that has significantly contributed to industrial automation is the vibro motor. These powerful, precision-engineered motors play a crucial role in various industrial applications, offering efficiency, reliability, and cost-effectiveness.

In this comprehensive guide, we will explore how vibro motors work, their key applications, benefits, and why JK Industries, a leader among Vibro Motor Manufacturers in India, is at the forefront of this revolution.

Understanding Vibro Motors and Their Mechanism

A Vibro Motor, also known as a vibratory motor, is an electric motor designed to generate mechanical vibrations. It achieves this by rotating eccentric weights attached to both ends of the motor shaft, creating centrifugal force. This force induces vibrations, which can be harnessed for various industrial applications.

Key Features of Vibratory Motors:

Compact and robust design for heavy-duty applications

Low maintenance with high durability

Variable frequency and amplitude settings

Energy-efficient operation

Customizable options for specific industrial needs

Applications of Vibro Motors in Industrial Automation

The adaptability of vibratory motors makes them indispensable across numerous industries. Here are some of the primary applications:

1. Material Handling and Conveying

Industries such as mining, construction, and agriculture rely on Vibro motors to power vibratory feeders and screens. These motors facilitate the efficient movement of bulk materials, preventing blockages and enhancing throughput.

Mining Industry: Vibratory screens separate minerals based on size, improving sorting efficiency.

Construction: Vibrating conveyors transport cement, sand, and other materials efficiently.

Agriculture: Used in grain processing plants for sorting and grading.

2. Food Processing Industry

In food production, vibratory motors enable precise movement and handling of food products without causing damage.

Ensures uniform distribution of food particles in processing lines

Helps in quality control by removing unwanted elements

Used in vibrating sieves for separating contaminants from food products

3. Pharmaceutical & Chemical Industries

Precision and contamination-free processing are critical in the pharmaceutical and chemical sectors. Vibratory motors help maintain stringent quality control standards.

Used in tablet coating machines for uniform application

Facilitates precise powder mixing and sieving

Enhances drying processes by evenly distributing chemicals

4. Packaging Industry

In automated packaging systems, vibro motors help streamline the movement of goods on conveyor belts, ensuring accurate positioning, filling, and sorting.

Ensures even distribution of products in containers

Reduces spillage and packaging errors

Speeds up automated sorting and packing lines

5. Concrete Compaction

Construction sites extensively use vibratory motors in concrete compactors, which help remove air voids and improve the density of concrete structures.

Enhances the structural integrity of concrete

Reduces the likelihood of cracks and defects

Improves the longevity of buildings and infrastructure

Benefits of Incorporating Vibro Motors in Industrial Automation

1. Enhanced Operational Efficiency

By integrating vibratory motors into automation systems, industries can achieve faster and more precise operations. These motors facilitate consistent movement and sorting, significantly reducing manual intervention and labor costs.

2. Energy Efficiency and Cost Savings

Modern vibro motors consume less energy while delivering optimal performance. Their efficient design reduces power wastage, leading to lower operational costs and sustainable manufacturing.

3. Improved Precision and Quality Control

The ability to control vibration frequency and amplitude allows for precise handling of materials, ensuring uniform quality and reducing defects.

4. Reduced Downtime and Maintenance Costs

Designed for continuous operation under tough conditions, vibratory motors require minimal maintenance. Their durable construction ensures long service life, reducing unplanned downtime.

5. Versatility Across Industries

From mining to food processing and pharmaceuticals, vibratory motors can be adapted for a wide range of industrial applications, making them a valuable investment for businesses.

JK Industries: Leading the Vibro Motor Revolution in India

When it comes to sourcing high-quality vibratory motors, JK Industries is a trusted name among Vibrator Motor Manufacturers in India. With decades of experience, JK Industries has established itself as a leader in providing reliable and innovative vibration solutions.

Why Choose JK Industries?

Cutting-Edge Technology: Implements the latest advancements in vibration engineering to develop high-performance motors.

Custom Solutions: Offers tailored vibro motors to meet specific industrial requirements.

Superior Durability: Designs motors with high-grade materials for extended lifespan.

Energy-Efficient Designs: Focuses on reducing power consumption without compromising performance.

Exceptional Customer Support: Provides expert guidance for selecting the right motor for your application.

How to Select the Right Vibro Motor for Your Industrial Needs

Choosing the right vibratory motor depends on several factors, including:

1. Application Type

For bulk material handling: High-capacity vibratory motors with adjustable speed.

For food or pharmaceutical use: Hygienic, stainless steel motors with precise control.